tams elektronik

Manual

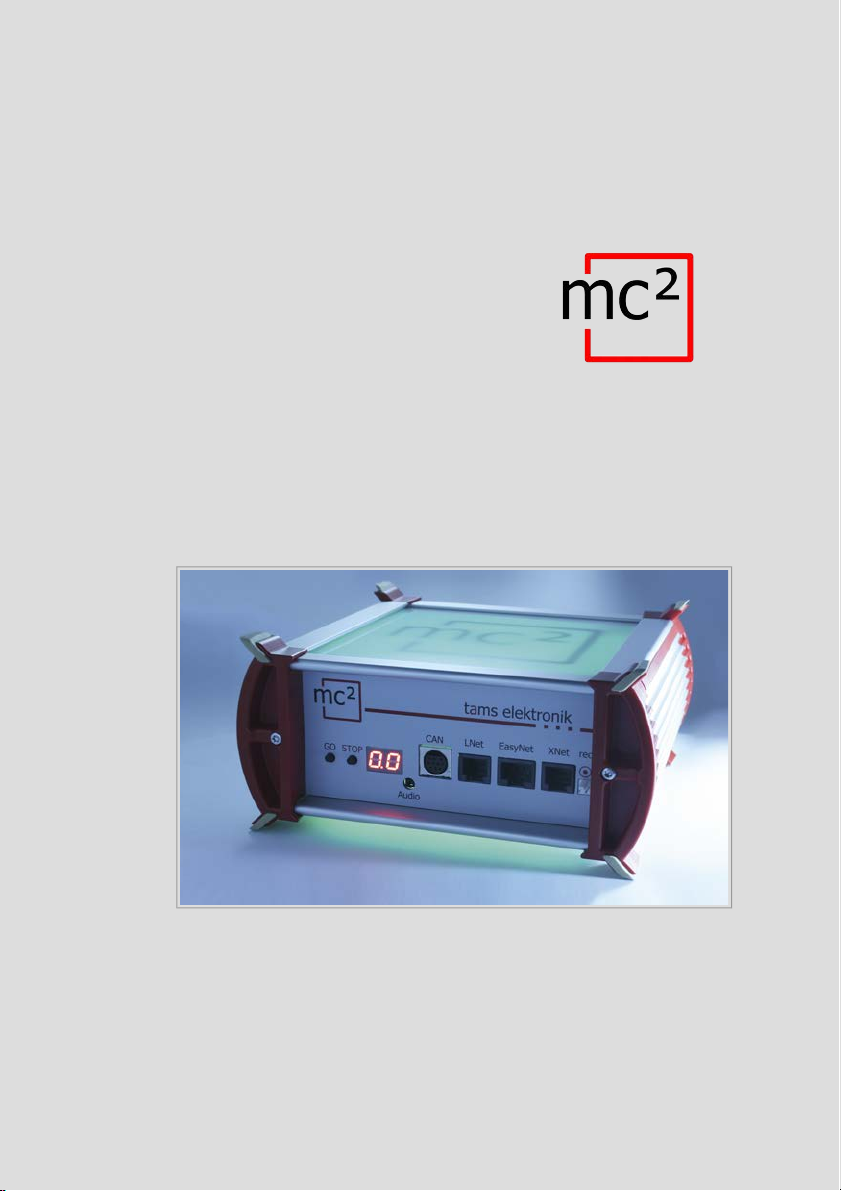

Digital Control Unit

for EasyControl Digital System

Item no. 40-03007

tams elektronik

n n n

Notes on this download version of the manual

This manual provides you with an overview of the features and functions of the digital central

unit mc². However, the manual is only one part of the instructions. Another essential part is

the direct help in the web interface of the central unit, the so-called mc²-Toolbox. You can

connect to a real mc² digital central unit via the Internet and test the web interface.

Link to the mc²-Toolbox

Notes for users of the digital central unit mc²

This download version of the manual may not correspond to the software and/or hardware

version of your mc². Please only use the version of the manual that is available for download

in the mc²-Toolbox.

Version 1.01 05/2021

This manual is part of the user software "mc²-Toolbox" and applies to:

Hardware of the mc²: Version 1.4

Firmware of the mc²: Version 1.03

Software for web interface mc²-Toolbox: Version 1.10

© Tams Elektronik GmbH

All rights reserved, in particular the right of reproduction, distribution and translation. Copies,

reproductions and alterations in any form require the written permission of Tams Elektronik

GmbH. We reserve the right to make technical changes.

Updates

Download the latest version of the manual after you have performed an update of the mc²Toolbox (the software for the web interface of the mc²). Appendix B contains an overview of

the changes and additions to the manual.

Printing the manual

The formatting is optimised for double-sided printing. The standard page size is DIN A5. If you

prefer a larger display, printing on DIN A4 is recommended.

0.2 | mc²

tams elektronik

Contents

1. Getting started........................................................................................................1.1

2. Commissioning........................................................................................................2.1

3. Your mc²................................................................................................................3.1

3.1. Display and operating elements.......................................................................3.3

3.2. Protocols........................................................................................................3.4

3.3. Virtual control devices.....................................................................................3.5

3.4. External digital input devices...........................................................................3.6

3.5. Boosters.........................................................................................................3.7

3.6. PC control.......................................................................................................3.8

4. Connections............................................................................................................4.1

4.1. Main and programming track...........................................................................4.2

4.2. Connection of external digital devices...............................................................4.3

4.2.1. Devices for the CAN bus.........................................................................4.3

4.2.2. Devices for the LocoNet.........................................................................4.4

4.2.3. Devices for the EasyNet.........................................................................4.5

4.2.4. Devices for the XpressNet......................................................................4.6

4.2.5. Digital central units for DCC and Motorola...............................................4.7

4.3. Connecting BiDiB devices.................................................................................4.8

4.4. Connection of s88 feedback modules................................................................4.9

4.5. Connection of external boosters.......................................................................4.10

4.6. Connection to the audio output........................................................................4.11

5. Configuring the system (Submenu "System")............................................................5.1

5.1. System Info....................................................................................................5.1

5.2. Vehicles..........................................................................................................5.3

5.3. Accessories.....................................................................................................5.4

5.4. Protocol..........................................................................................................5.5

5.5. Boosters.........................................................................................................5.6

6. Operation with the mc²...........................................................................................6.1

6.1. Operating and display elements.......................................................................6.1

6.1.1. STOP and GO buttons............................................................................6.1

6.1.2. Display and RGB-LEDs...........................................................................6.2

Contents| 0.3

tams elektronik

6.2. Submenu "Operation"......................................................................................6.4

6.2.1. Feedback..............................................................................................6.4

6.2.2. Programming........................................................................................6.5

6.2.3. Messages..............................................................................................6.7

6.2.4. BiDiB....................................................................................................6.7

6.2.5. Control..................................................................................................6.8

6.2.6. Model time............................................................................................6.8

6.3. Virtual control devices.....................................................................................6.9

6.3.1. HandControl.vi......................................................................................6.9

6.3.2. FunctionControl.vi..................................................................................6.11

6.3.3. DriveControl.vi.......................................................................................6.12

6.3.4. SwitchControl.vi.....................................................................................6.13

7. Updates..................................................................................................................7.1

8. Checklist for troubleshooting....................................................................................8.1

8.1. Heat generation..............................................................................................8.1

8.2. Automatic safety shutdown..............................................................................8.1

8.3. Problems with the power supply.......................................................................8.2

8.4. Problems with external input devices................................................................8.2

8.5. Problems when programming and controlling vehicles.......................................8.3

8.6. Problems when switching points and other accessories......................................8.4

8.7. Problems with s88 modules.............................................................................8.4

8.8. Problems with the software update..................................................................8.5

8.9. Technical hotline.............................................................................................8.5

8.10. Repairs...........................................................................................................8.5

9. Technical data.........................................................................................................9.1

9.1. Digital control unit mc²....................................................................................9.1

9.2. Power supply unit...........................................................................................9.4

10. Warranty, EC Conformity & WEEE............................................................................10.1

10.1. Warranty Statement........................................................................................10.1

10.2. EC Declaration of Conformity...........................................................................10.2

10.3. Declarations on the WEEE Directive..................................................................10.2

Appendix A: Organisations, Manufacturers, Products..............................................................

Appendix B: Changes and additions.......................................................................................

0.4 | Contents

tams elektronik

1. Getting started

The instructions for the digital central unit mc² consist of the following parts:

the guide, which is enclosed with the delivery in printed form and which contains all the

information you need for safe and proper commissioning of the mc². The contents of the

guide are also included in this manual. Nevertheless, keep the guide carefully in case you

want to commission the mc² again and do not have access to the manual. If you pass the

digital central unit on to another person, also give the guide with it.

this manual, which is available for download in the mc²-Toolbox (the web interface of the

central unit). In the manual you will find all the information you need for safe and proper

connection to your system and external devices, as well as an overview of the configuration

of your mc² and instructions for operation. Note: The manual applies to the software

version(s) of the mc² indicated on page 0.2 of this manual.

the direct help in the mc²-Toolbox

Contents of the package

After unpacking, check the delivery for completeness:

mc² digital control unit

power supply unit

mains cable (black) with Euro plug (CEE 7/16) and plug for mains cable socket (European

version / C7)

connection cable (grey) with RJ-45 connectors (at least Cat. 5e)

one 4-pole plug for connection to main and programming track and one 3-pole plug for

connection to external boosters

4 plastic brackets for mounting the mc²

this guide and sticker sheet for labelling the connection cables

Required additional equipment

It is not possible to use the mc² digital control unit without additional devices. You can use the

following devices for commissioning, configuration and operation of the model railway layout:

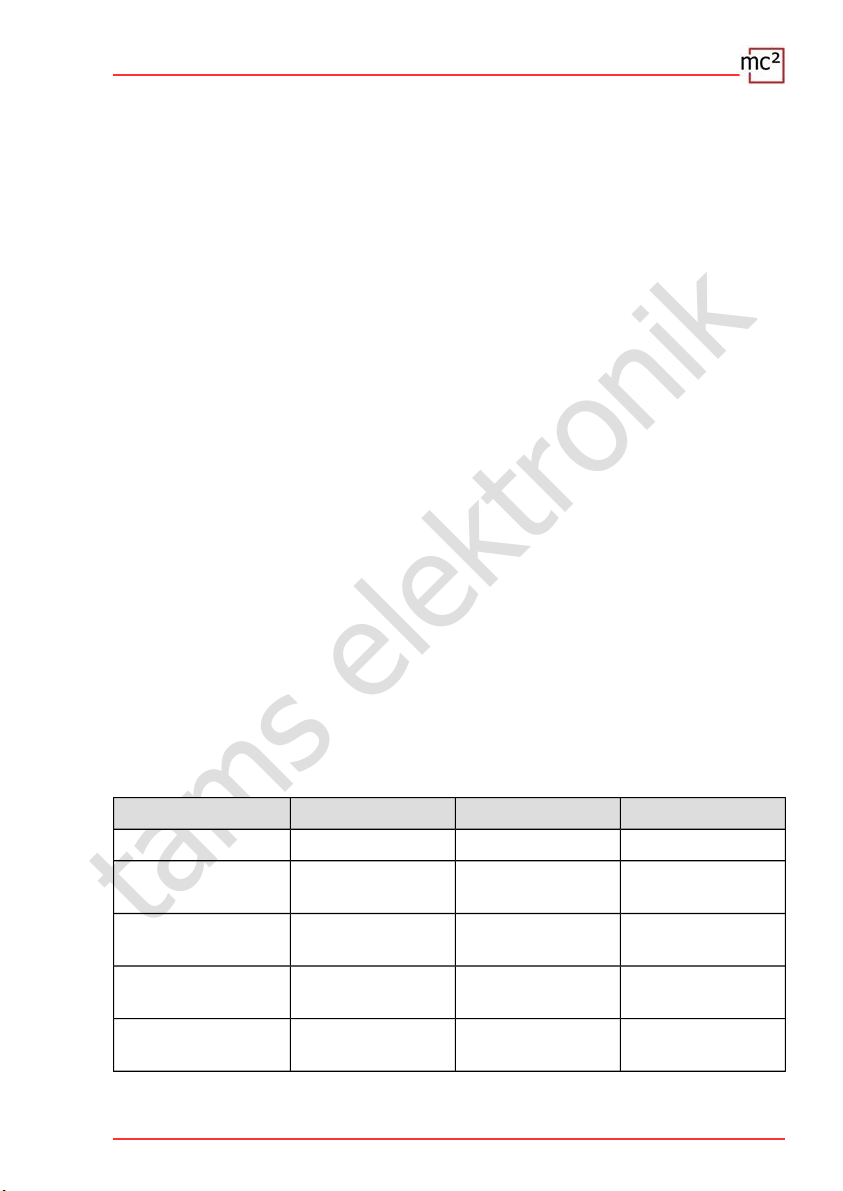

Commissioning Configuration Operation

PC X X X

Tablet

(and WLAN router)

Smartphone

(and WLAN router)

HandControl 2 ---

Other digital control

devices

X X X

X

--- --- X

X

(not recommended)

X

(restricted)

X

X

Getting started | 1.1

tams elektronik

Intended use

The digital control unit mc² is intended for controlling digital model railway layouts according

to the information in the instructions (consisting of guide, manual and direct aids). Only the

power supply unit included in the scope of delivery is permitted for the power supply. Any

other use is not in accordance with the intended use and will result in the loss of the warranty

claim. Intended use also includes reading, understanding and following all parts of the

instructions. The mc² is not intended to be used by children under the age of 14.

Safety instructions

Improper use and non-observance of the instructions can lead to incalculable hazards. Prevent

these dangers by carrying out the following measures:

Use the digital control unit and the power supply unit only in closed, clean and dry rooms.

Avoid humidity and splash water in the environment. After condensation has formed, wait

two hours for acclimatisation before use.

Disconnect the control unit from the power supply before carrying out wiring work.

Only plug the mains plug of the power supply unit into properly installed and fused earthed

sockets.

Heating of the control unit and the power supply unit during operation is normal and

harmless. Keep a distance of at least 20 cm between the sides, the top and the back to

surrounding surfaces to allow unhindered air exchange and to predect the units from

overheating.

Do not expose the units to high ambient temperatures or direct sunlight. Observe the

information on the maximum operating temperature in the technical data.

Regularly check the operational safety of the units, e.g. for damage to the connection

cables or damage to the housing.

If you notice damage or if malfunctions occur, switch off the supply voltage immediately.

Send in the control panel and/or the power supply unit for inspection.

Dangerous voltages occur inside the power supply unit. Therefore, never open the housing

of the power supply unit.

Care

Do not use any cleaning agents to clean the mc² and the power supply unit. Only wipe the

units dry. Disconnect the units from the power supply before cleaning.

1.2 | Getting started

tams elektronik

2. Commissioning

After commissioning, you must first configure your mc², i.e. adapt it to your ideas and adjust it

to the conditions of your model railway layout. It is therefore not recommended to start up the

mc² with a smartphone, as the display of the mc²-Toolbox (the web interface of your control

unit) is unclear due to the small screen size.

Direct connection to the PC

You can connect your mc² directly to your PC.

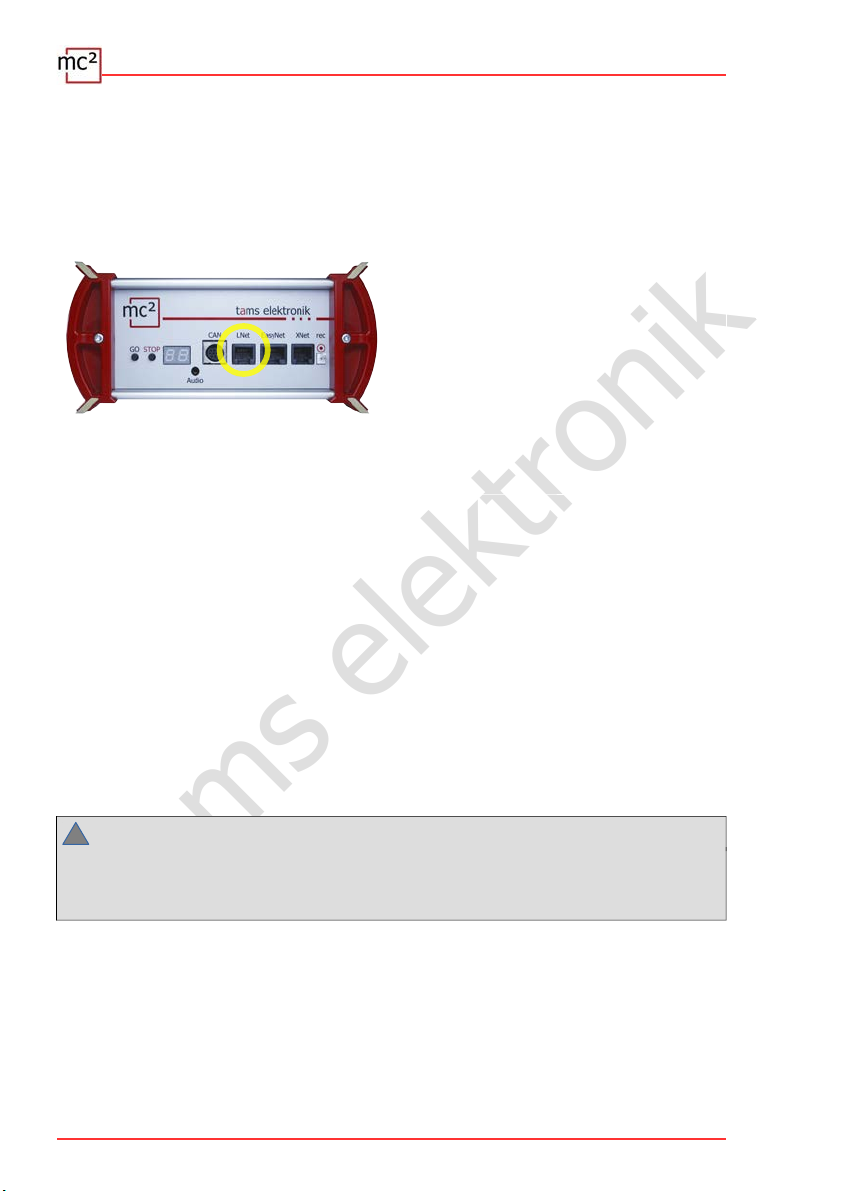

Plug the (grey) patch cable on one side

into the LAN interface of the mc² and on

the other side into the RJ45 socket of the

network interface of your computer.

Connecting to the Intranet / Internet

By connecting your mc² to your router, you can use devices such as a PC, tablet or

smartphone that also have a connection to the router to configure your mc² and control your

system. You can also use the router to connect to the Internet, which you need to check for

updates.

Plug the (grey) patch cable into the LAN

interface of the mc² on one side and into

a free RJ45 socket of the router on the

other side.

Commissioning | 2.1

tams elektronik

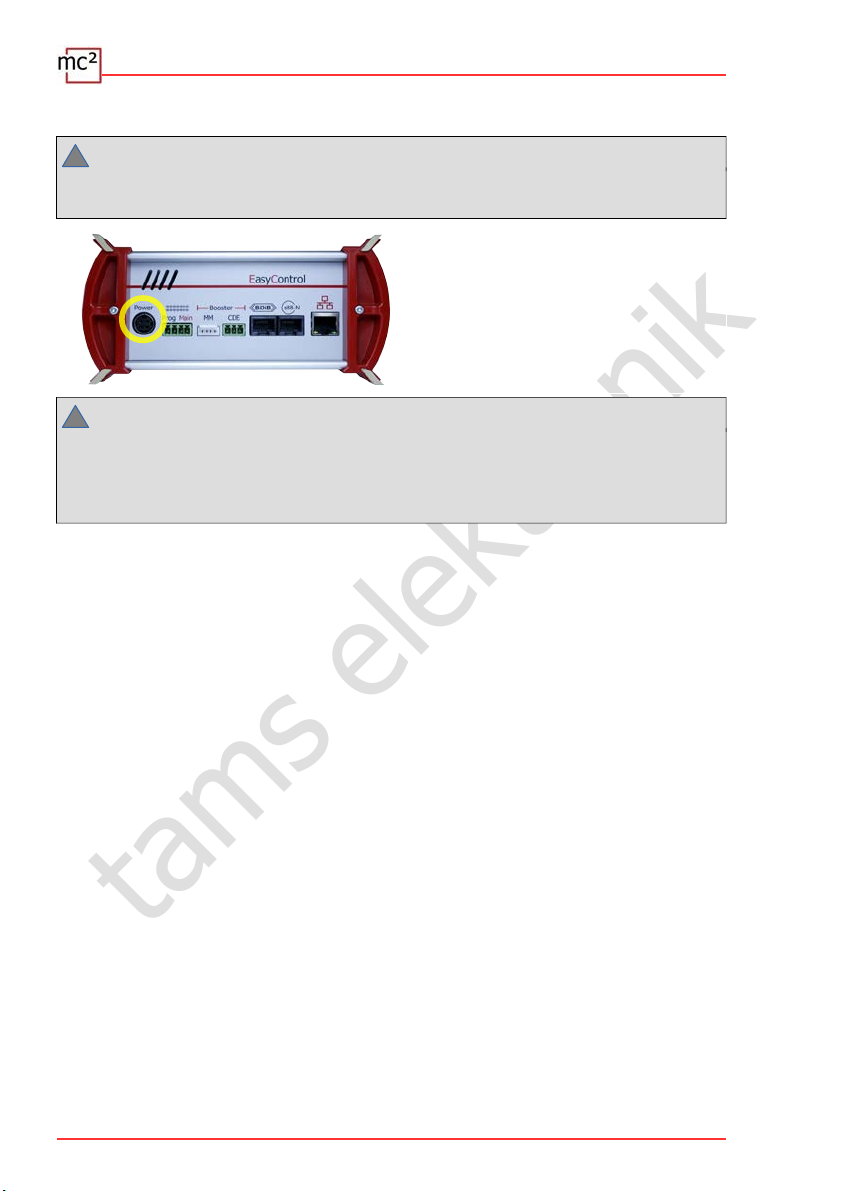

!

!

Connection to the power supply

Note:

Only use the power supply unit supplied as a power supply for your mc² and the

components of your system that are supplied by the integrated booster.

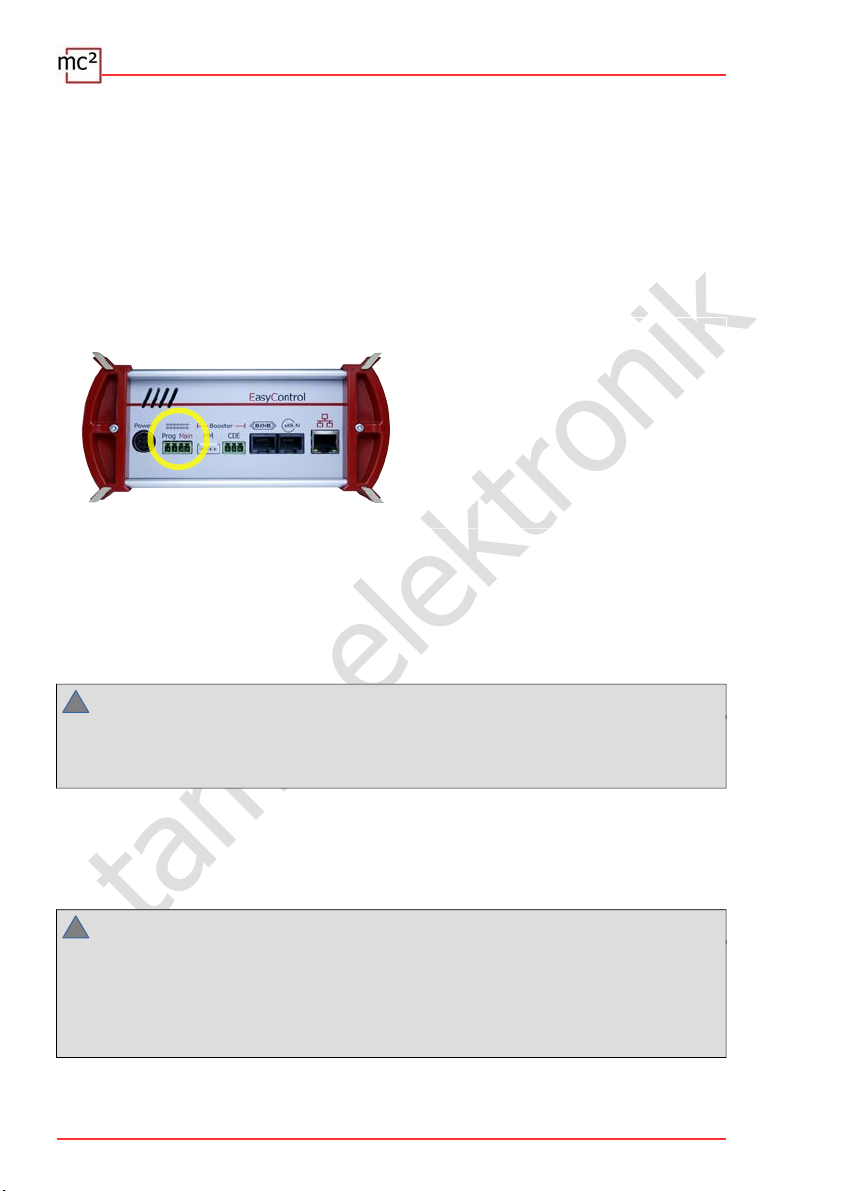

First, plug the 4-pin connector of the

power supply connection cable into the

"Power" socket on the back of the mc² so

that the flat part of the plug points

upwards.

Note:

There is a catch on the unit plug that prevents the power supply connection cable from

being pulled out accidentally. To be able to pull out the cable, you must pull the catch in the

direction of the cable. Never pull the cable out of the socket by force! Doing so may damage

connections in your mc².

Then plug the supplied (black) mains cable into the connection socket of the power supply

unit and into the socket.

Reading out the IP address of the mc²

Press and hold the "GO" button of the mc² until "IP" is shown in the display. If you continue

to press the "GO" key, the digits of the IP address appear one after the other. Tip: Write

down the digits including the dots.

Structure of the IP address: 123.456.789.123

Note: Leading zeros (after a dot) are not shown in the browser display.

Calling up the IP address in the browser

The mc²-Toolbox (i.e. the web interface of the mc²) has been tested with the browsers

Chrome, Firefox, Opera and Edge. The use of the browsers Internet Explorer and Safari is not

recommended, as they do not support all the required functions.

Enter the read IP address in the browser of the PC, tablet or smartphone. The start page

("Home") of the mc²-Toolbox will then open.

2.2 | Commissioning

tams elektronik

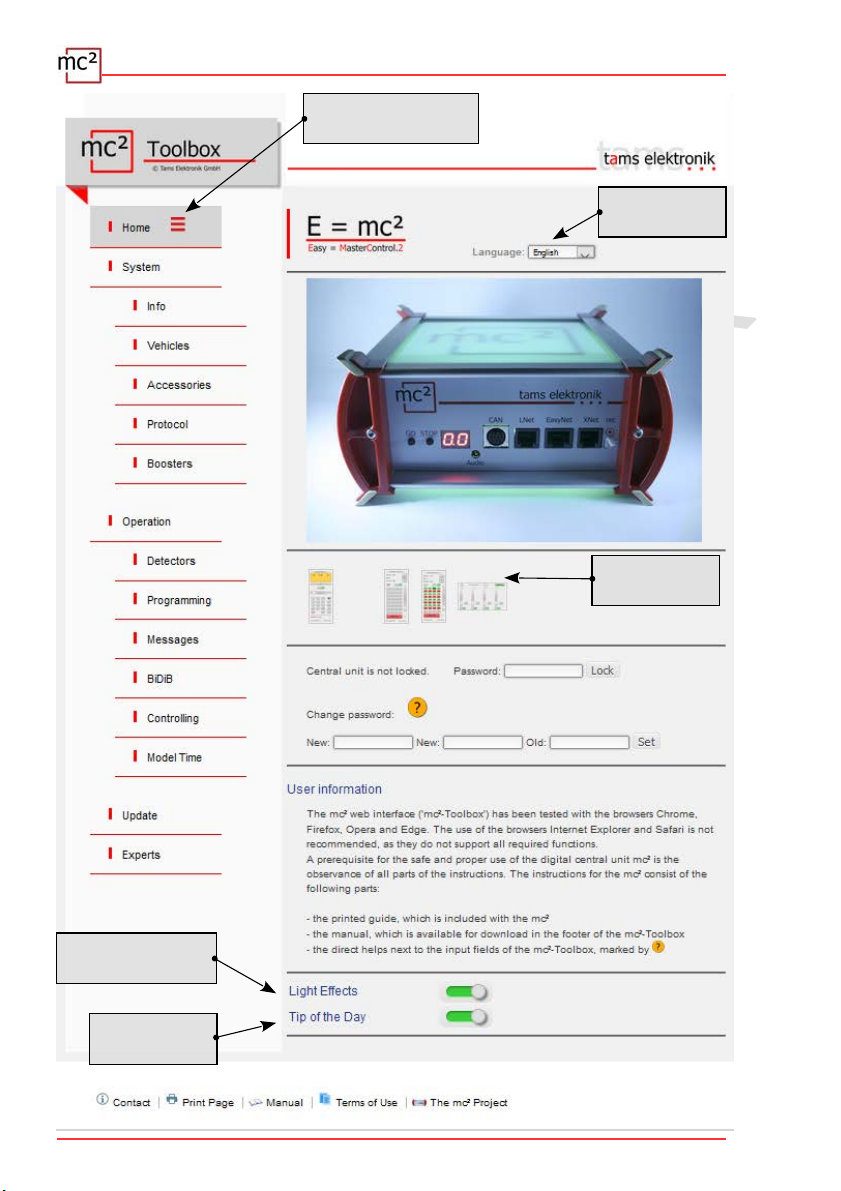

User settings in the mc²-Toolbox

Set the following on the start page of the web interface of your mc²:

longuage

Display of the submenu items: Change the display by clicking on the symbols.

Submenu items are always displayed

Submenu items are only displayed after clicking on the

higher-level main menu item.

Downloading the manual

Before connecting the mc² to your model railway layout, download the manual from the start

page of the mc²-Toolbox ("Home") and read it carefully. In the manual you will find all the

information you need to connect to your layout and external devices, as well as an overview of

the configuration of your mc² and notes on its operation.

In the manual you will also find the troubleshooting checklist, the technical data of the control

unit and the power supply unit and the warranty declaration.

Before the first test drive

For a first test run you can connect your mc² e.g. to a separate track oval, for which the

integrated booster is sufficient as a power supply, and familiarise yourself with the functions of

the control unit.

You have to do the following things before you can do a first round with a locomotive:

Connect the track output of the mc² to the rails (→ section 4.1 in the manual).

Configure the integrated booster, i.e. set the track voltage and the maximum current for

the nominal width of your layout (→ menu item "System / Boosters").

To control a locomotive, proceed as follows:

DCC decoder: Open the virtual HandControl on the start page ("Home") of the mc²-

Toolbox. Enter the DCC address and control the locomotive. For the functionality of the

HandControl.vi → section 6.3.1 in the manual.

MM decoder: Before you can control a locomotive with the HandControl.vi, you must create

the MM address in the locomotive list and assign an MM format to the locomotive (→ menu

item "System / Vehicles").

mfx decoder: First read out the UID and assign an address to the decoder (→ menu item

"Operation / Programming / m3"). You can then control the locomotive in m3 format with

HandControl.vi.

Commissioning | 2.3

tams elektronik

2.4 | Commissioning

Setting the display

of the submenu

Selecting

the language

Virtual

control units

(De)activating

"Boredom Mode"

(De)activating

Tip of the Day

tams elektronik

3. Your mc²

The main tasks of your mc² include,

to send the digital driving and switching commands to the vehicle and accessory decoders

to receive and forward the feedback signals from decoders and feedback units

to serve as a "medium" for programming the decoders.

Furthermore

a booster is integrated in your mc², which brings the digital signals to the track and

supplies the vehicles with power.

your mc² acts as an interface to various additional devices such as external input devices,

feedback devices, PC and mobile devices.

Browser-based

Your mc² uses the possibilities offered by PCs, mobile devices such as smartphones or tablets

and fast Internet in private households.

The web interface "mc²-Toolbox", i.e. the software with which you configure your digital

control and control your system, is called up via the browser of a PC, tablet or smartphone.

You then have access to all functions of the mc². The mc²-Toolbox is installed on your mc²

and you can perform updates for it in the same way as for the firmware of the central unit.

You do not need to install any software or app on your PC or mobile devices. The question of

whether the operating systems of the various devices are compatible with each other is

therefore irrelevant.

You can connect the mc² to your home network and the Internet via a router. Connection to a

Wlan router is a prerequisite for the use of mobile end devices. Alternatively, you can connect

a PC directly to your mc² (without a diversion via a router). An Internet connection is only

absolutely necessary if updates are to be requested.

The mc² Toolbox

With the Toolbox (the web interface of the mc²) you manage your digital control including all

connected input devices, feedback devices and boosters. You can

configure your mc², i.e. adapt it to your ideas and the conditions of your layout

programme your vehicle and accessory decoders

manage your feedback devices and query messages from the various data buses (BiDiB,

s88, Märklin-CAN, LocoNet)

display RailCom messages

carry out updates

Your mc² | 3.1

tams elektronik

Input and control devices

For the control of your layout you have various possibilities open to you, which you can also

combine with each other as you wish:

virtual control devices that you open on your smartphone, tablet or PC (→ section 3.3)

digital input devices from various manufacturers (→ section 3.4)

special PC control software (→ section 3.6)

3.2 | Your mc²

tams elektronik

3.1. Display and operating elements

STOP & GO

These two buttons of the mc² are used

to switch the track voltage on and off

to trigger a reset

as a trigger for displaying the IP address

to delete the internal configuration

Display

The 2-digit 7-segment display shows you essential information, e.g.

the current consumption in the booster circuit of the internal booster

the operating status (short circuit, stop, normal operation)

the IP address (due to the limitation to 2 display fields in several "sequences")

the progress of an update

RGB LEDs in the housing

The top and bottom of the mc² are made of translucent plastic. During operation, RGB LEDs

built into the housing visibly indicate the operating status of the mc² from a distance, e.g.

green for "normal operation" or red for "stop, track voltage is switched off".

Track voltage = off Track voltage = on

Your mc² | 3.3

tams elektronik

3.2. Protocols

Digital formats

The mc² sends digital driving and switching commands to the vehicle and accessory decoders

in the following formats:

DCC: 14, 28 or 128 speed steps

Motorola: I and II (14 or 28 speed steps)

m3: This format enables the control of vehicle decoders for the mfx protocol. Note:

Automatic registration of mfx decoders with the command station is not possible.

BiDiB

The mc² is simultaneously a BiDiB interface and BiDiB track output device in the sense of the

BiDiB specification.

Up to 31 nodes of one level can be connected to the BiDiB interface of the mc². With

appropriate PC control software, digital commands can be sent and messages received and

evaluated via the BiDi bus.

CAN, EasyNet and XpressNet

These protocols exclusively define the communication between input devices (e.g. hand

controllers) and the mc², but not the transmission of digital commands or feedback signals.

DCC-A

The RailCom-based extension of the DCC format enables the automatic registration of vehicle

decoders with the control centre. Currently (as of April 2021), a draft standard is available

from the RailCommunity, which is expected to be adopted in the course of 2021.

LocoNet

In a later software version it will be possible to send switching commands via LocoNet and to

evaluate feedback from LocoNet. The update will be available for download free of charge.

RailCom

A global RailCom detector is integrated in the mc², which receives the messages from the

RailCom decoders and forwards them to the PC. For forwarding the RailCom messages to the

PC control software, the mc² uses the BiDiB protocol.

s88

Up to 52 s88 or s88-compatible modules (= 832 contacts) can be connected to the s88

interface. Note: The s88-compatible modules also include, for example, feedback devices that

are connected via the CAN bus interface.

Data transmission to the PC

For information on the protocols used for data transmission between the mc² and the PC, see

section Fehler: Referenz nicht gefunden.

3.4 | Your mc²

tams elektronik

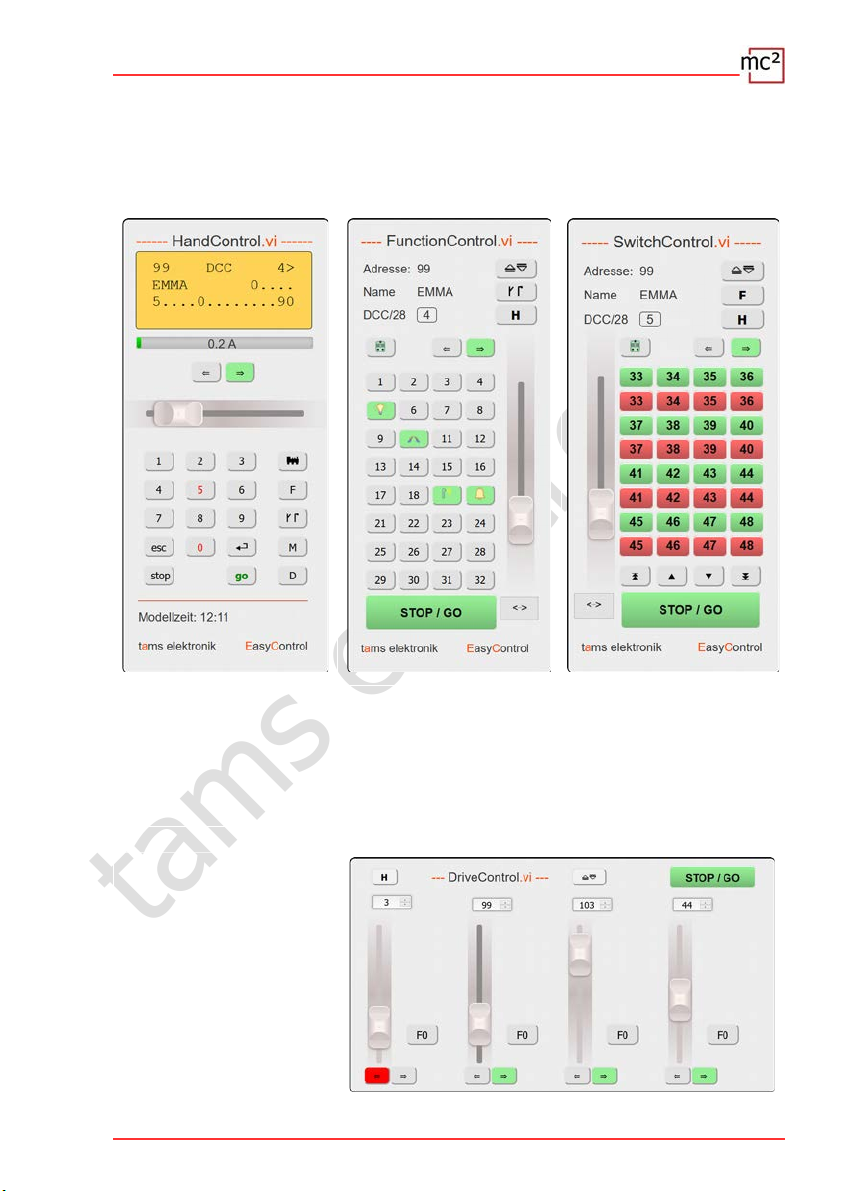

3.3. Virtual control devices

From the Toolbox, you have access to various virtual control devices to control your layout.

The virtual control devices are optimised for use with smartphones or tablets, but can just as

easily be used from the PC screen.

The HandControl.vi is similar

to the real HandControl.2

and can be used to call up

vehicles and switch functions

up to F9.

With DriveControl.vi,

4 locomotives can be

accessed simultaneously.

The speed level can be set,

the direction of travel can be

changed and the F0 function

can be switched on and off.

With the FunctionControl.vi

locomotives can be

controlled sensitively and

functions up to F32 can be

switched.

The SwitchControl.vi is

intended for switching

turnouts (or other stationary

components). The last

locomotive called up remains

under control.

Your mc² | 3.5

tams elektronik

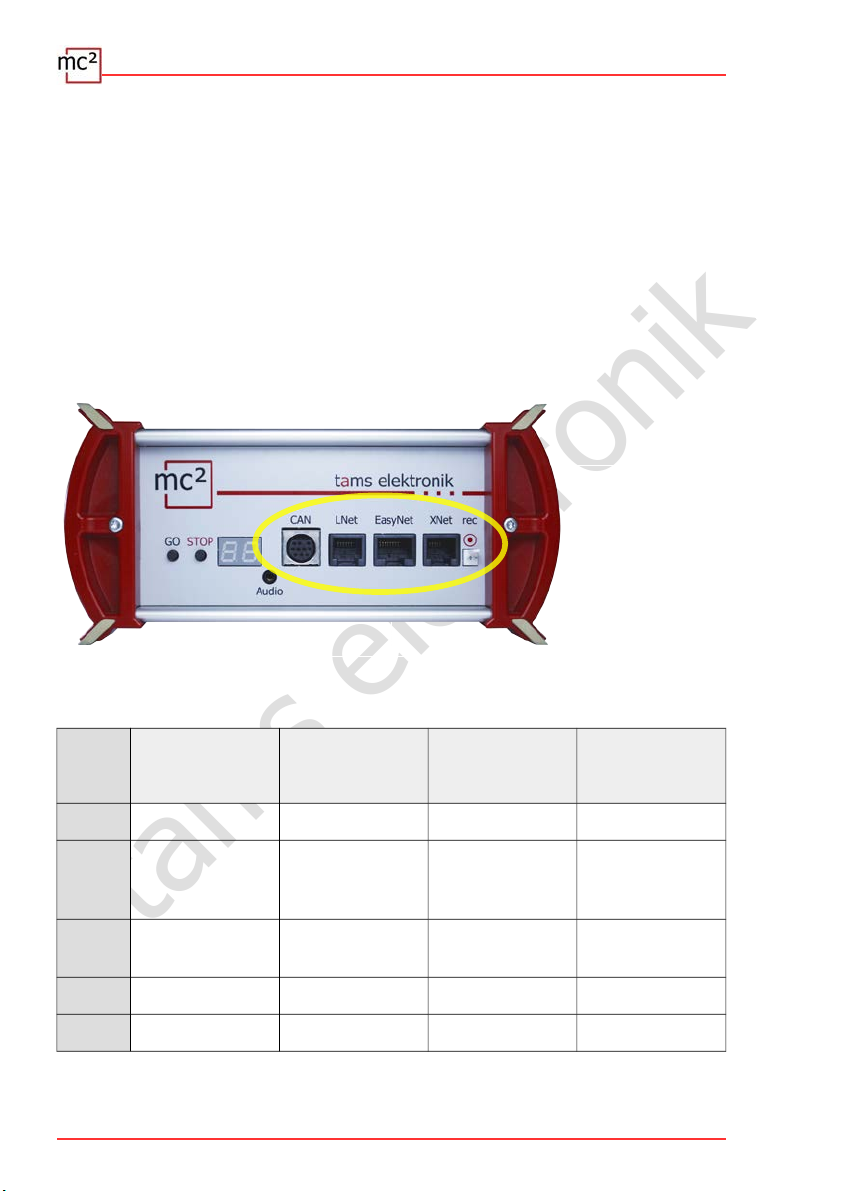

3.4. External digital input devices

The mc² has interfaces for various digital input devices from different manufacturers. You can

integrate manual control units and/or digital control centres for the following bus systems into

your digital control:

Märklin CAN-Bus

LocoNet

XpressNet

EasyNet

Via the universal interface "rec" you can also integrate all digital control units for the DCC or

Motorola format that have a track output into the EasyControl system and use them as

external control and switching devices.

Possible applications for external digital input devices

Driving

(controlling vehicle

decoders)

Switching

(controlling accessory

decoders)

Programming

(programming

decoders)

Configuring

(setting up the digital

system control / mc²)

CAN X X --- ---

LNet X

not yet

implemented

(Status 04/2021)

--- ---

EasyNet X X X

possible

(with limitations)

XNet X X X (POM only) ---

rec X X --- ---

3.6 | Your mc²

tams elektronik

3.5. Boosters

Integrated booster

A booster is integrated in the mc², which can provide a maximum of 6.5 A current. This

current is usually sufficient for the operation of layouts of all nominal sizes. Depending on the

nominal size, the maximum output current must be limited.

Short-circuit sensitivity: 1 - 6.5 A. It can be adapted to the nominal size of the installation in

steps of 0.5 A.

Track voltage: 8 - 22 V. It can be adjusted in steps of 1 V.

Track signal: symmetrical

RailCom cutout: can be switched off.

The status messages of the integrated booster are reported to the control software via BiDiB.

They are then available as a basis for booster management.

External boosters

If one booster circuit is not sufficient for the operation of the layout, or if the signals for

vehicle and accessory decoders are to be output separately, additional external boosters can

be connected. Both Märklin-compatible boosters and DCC-compliant boosters can be used.

Boosters conforming to the BiDiB specification or boosters for use in LocoNet can be

connected directly to the corresponding interfaces. The use of different booster types for

separate parts of the layout or separately for the tasks "driving" and "switching" is basically

possible.

Output of the driving and switching commands

For the track output of the integrated booster and the interfaces for Märklin-compatible and

DCC-compliant boosters it is set separately whether

driving and switching commands or

only driving commands

are to be output. The setting for the integrated booster also applies to boosters on the BiDiB

and LocoNet interfaces.

Your mc² | 3.7

tams elektronik

3.6. PC control

Protocols: BiDiB or p50x

For the encryption of the data exchanged between the central unit and the PC control

software, the mc² uses the BiDiB protocol or - if this is not supported by the software - the

p50x protocol.

With software that supports BiDiB, all the possibilities offered by bidirectional communication

via the BiDiBus can be used. These include e.g.:

the direct sending of digital commands to the stationary BiDiB nodes via the BiDiBus cables

(e.g. to the accessory decoders)

receiving feedback from the stationary BiDiB nodes (e.g. from boosters and accessory

decoders).

the reception of messages from the global RailCom detector integrated in the mc².

If these possibilities are utilised, the safety and the transmission speed in PC-controlled

systems are significantly increased.

If the BiDiB protocol is not supported by the PC control software, the data transmission

between mc² and PC is automatically carried out via the p50x protocol. BiDiB nodes can then

not be used or only to a limited extent. BiDiB feedback modules are treated like s88

feedbacks, for example. The transmission of RailCom messages of the integrated global

RailCom detector to the PC control software is then not possible.

TCP to TCP

By default, the data is transmitted from the mc² to the PC or router via the LAN interface

using the network protocol TCP ("Transmission Control Protocol"). Whether the data is

encrypted in the BiDiB or p50x protocol is irrelevant. Many newer versions of model railway

control programs support TCP.

TCP to COM: Setting up a virtual COM port

With older model railway control programmes or older versions of the control programmes,

the data transfer between PC and digital control unit is usually based on the RS-232 standard

for serial interfaces. In most cases, these programmes use only the p50x protocol for

encoding the data.

The prerequisite for using these programmes is the setting up of a virtual serial interface (or

in other words: a virtual COM port). Various programmes are available on the internet for this

purpose, with the help of which a driver for a virtual COM port can be set up on the PC.

3.8 | Your mc²

tams elektronik

4. Connections

Danger of confusion!

!

Note that identical plug connections are used for different bus systems:

RJ12: LocoNet and XpressNet

RJ45: EasyNet, BiDiB, S88-N and LAN

Therefore, be very careful when plugging in the connection cables! Make sure that you do

not accidentally plug the cables into the wrong sockets! In the worst case, (even irreparable)

damage can occur to your mc² and/or the connected devices. This applies especially to

EasyNet devices, s88 modules and BiDiB components.

If you plug connection cables with RJ12 plugs into RJ45 sockets, the connection pins in the

socket will be bent. In this case, we recommend sending in the central unit for repair.

Avoid these risks by marking the connection cables (e.g. with the labels enclosed with the

delivery) and/or using different coloured cables for the different bus systems, e.g.

red for EasyNet

blue for the s88 bus

green for the BiDi bus

grey for the Ethernet (Lan)

Plug & Play

You can establish or interrupt connections to and from external devices to your mc² at any

time - even during operation (plug and play).

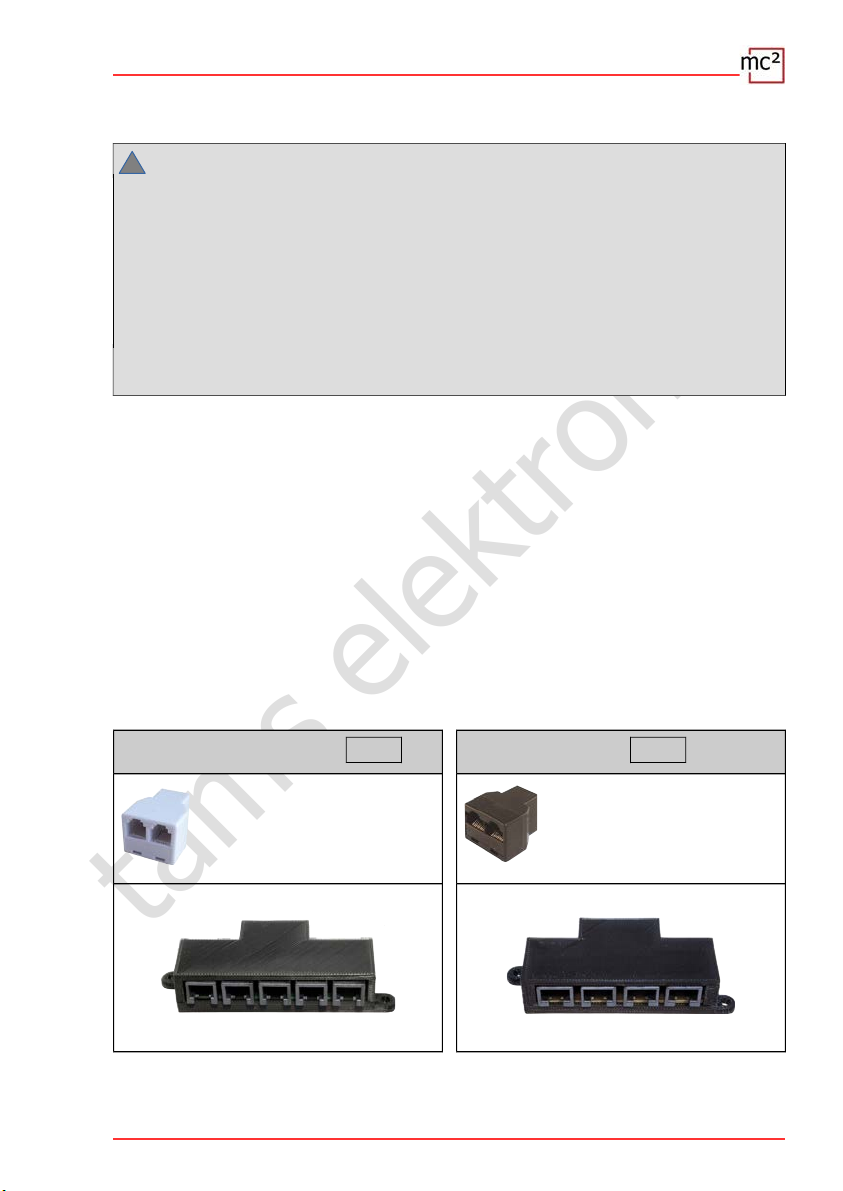

Distributors

To enable the use of several digital control units on one interface, you can use terminal blocks

or Y-distributors:

LocoNet and XpressNet RJ12 EasyNet RJ45

Y-distributor RJ12

(item no. 73-80493-01)

Input: 1 x RJ12

Output: 2 x RJ12

XL-Terminal block (item no. 73-80496-01)

Input: 1 x RJ12 | Output: 5 x RJ12

EasyNet-Termnal block (item no. 73-80195-01)

Input: 1 x RJ45 | Output: 4 x RJ45

Y-distributor RJ45

(item no. 73-80190-01)

Input: 1 x RJ45

Output: 2 x RJ45

Connections | 4.1

tams elektronik

!

!

4.1. Main and programming track

Connect the two track connections of the integrated booster

with the two rails (for 2-conductor systems) or

with one rail and the centre conductor (with 3-conductor systems).

The feeding of the booster current into the track should be done at a distance of approx. 2 to

3 m from a ring line, because the resistances at the transitions of the track sections are quite

high. If the distances are chosen too large, there may be problems with the short-circuit

feedback or with the power supply to the vehicles.

Use the 4-pin connector supplied to

connect the cables leading to the main

track ("Main") or to the programming track

("Prog").

Insert the connecting cables into the plug

part, screw them tight and then plug the

plug part onto the socket on the back of

the mc² in such a way that the screws

point upwards.

Recommended cable cross-sections

Programming track: 0.75 mm²

Main track: 0.75 to 1.5 mm² (depending on the current)

Booster configuration

Hint:

Before you start operation on your layout, you must configure the booster (→ section 5.5).

If the track voltage and/or the max. current are set too high, damage to the tracks and/or

vehicles can occur during operation.

Programming track

You can use a separate piece of track as a programming track or a section of track on your

layout (e.g. a siding) that you can electrically separate from the rest of the layout during

programming.

Hint:

If you integrate the programming track into your model railway layout, you must ensure that

both tracks are electrically separated from the rest of the layout during programming.

Otherwise the programming track connection of the mc² can be damaged! In

addition, you will otherwise program all decoders on the layout that react to the set data

format.

4.2 | Connections

tams elektronik

4.2. Connection of external digital devices

4.2.1. Devices for the CAN bus

Info

The CAN bus is actually a data bus developed for the (car) industry and is used by various

model railway manufacturers for communication between digital devices. Note: The

manufacturers use different data protocols, therefore the devices of different manufacturers

cannot communicate with each other. The protocol of the CAN interface of the mc² is that of

the Märklin CAN bus.

Connection: 10-pole

For the connection of

Mobile Station 2 and 3 (not MS 1)

Central Station 2 and 3 (configured as

"Slave")

Feedback units for the Märklin CAN bus

Note: The feedback units send their data via the CAN bus,

the data protocol corresponds to the s88 bus.

Possible applications of the CAN input devices

You can use the input devices that you integrate into the digital control system via the

interface for the CAN bus for

to control vehicle decoders for Motorola, DCC and mfx (the latter in m3 format) or

to switch accessory decoders for Motorola and DCC

However, it is not possible to program decoders or configure the digital system using CAN

input devices.

Power supply of the devices at the CAN interface

Devices such as the hand control units Mobile Station 2 and 3 are supplied with power via the

bus line. The Central Station 2 and 3 control units and feedback devices for the CAN bus have

their own power supplies.

Notice:

!

The total current of all external digital devices that are connected to the various interfaces of

the mc² and do not have their own power supply must not exceed 1.2 A. Otherwise, the mc²

automatically switches off the power supply for the external devices.

Connections | 4.3

tams elektronik

!

4.2.2. Devices for the LocoNet

Info

The LNet connector allows the connection of digital devices whose data transmission is done

via the LocoNet developed by Digitrax.

Connection: RJ12

For the connection of

FRED hand controller from Uhlenbrock

DAISY 2 hand controller from Uhlenbrock

SmartControl light from Piko

LocoNet booster

LocoNet accessory decoder

LocoNet feedback

Note: The control of boosters and accessory decoders for

LocoNet as well as the forwarding of feedback signals from

LocoNet are not yet supported. (Status: 04/2021).

Possible applications of the LocoNet input devices

You can use the input devices that you integrate into the digital control system via the

LocoNet interface

to control vehicle decoders for Motorola, DCC and mfx (the latter in m3 format) or

to switch accessory decoders for Motorola and DCC

However, it is not possible to program decoders or configure the digital system using LocoNet

input devices.

Power supply of the devices at the LocoNet interface

LocoNet handheld control devices are usually powered via the bus line. Other LocoNet digital

devices such as command stations, boosters or accessory decoders have their own power

supplies.

Notice:

The total current of all external digital devices that are connected to the various interfaces of

the mc² and do not have their own power supply must not exceed 1.2 A. Otherwise, the

mc² automatically switches off the power supply for the external devices.

4.4 | Connections

tams elektronik

4.2.3. Devices for the EasyNet

Info

The EasyNet is the data bus for the EasyControl digital system. Devices and adapters that have

been specially developed for this system communicate via this bus.

Connection: RJ45

For the connection of

HandControl and HandControl 2

LokControl

MasterControl (with configuration as

"slave")

mControl

Note: The connection of the adapters XNControl, SniffControl or wControl does not make

sense, as corresponding interfaces are integrated in the mc².

Possible applications of the EasyNet input devices

You can use the input devices that you integrate into the digital system via the EasyNet

interface

to control vehicle decoders for Motorola, DCC and mfx (the latter in m3 format)

to switch accessory decoders for Motorola and DCC

to program vehicle decoders and accessory decoders

to configure essential properties of the mc² / the digital system

Note: It is not possible to program decoders or to configure the mc² and the digital system

with input devices that are integrated into the EasyNet via the mControl (Keyboard 6040,

Memory 6043, driving consoles Control 80 or 80F and Infra Control 80F from Märklin).

Power supply of the units at the EasyNet interface

The EasyNet control units HandControl and HandControl.2, LokControl and MasterControl with

configuration as slave are supplied via the bus line. A separate power supply is required for

the mControl adapter and the connected digital devices.

Notice:

!

The total current of all external digital devices that are connected to the various interfaces of

the mc² and do not have their own power supply must not exceed 1.2 A. Otherwise, the mc²

automatically switches off the power supply for the external devices.

Connections | 4.5

tams elektronik

!

4.2.4. Devices for the XpressNet

Info

The Xnet interface enables the connection of input devices that establish the connection to

the digital control centre via the XpressNet developed by Lenz Elektronik.

Connection: RJ12

For the connection of

Lenz hand controllers (e.g. LH100 and

LH101)*

Locomouse from Roco (from version 2)

Multimouse from Roco

* For the connection of Lenz hand controllers, an additional

adapter may be required.

Possible applications of the XpressNet input devices

You can use the input devices that you integrate into the digital system via the XpressNet

interface

to control vehicle decoders for Motorola, DCC and mfx (the latter in m3 format),

to switch accessory decoders for Motorola and DCC,

to program decoders using main track programming (POM).

However, it is not possible to use XpressNet input devices to program decoders on the

programming track or to configure the digital system.

Power supply to the devices on the XpressNet interface

Input devices for the XpressNet are supplied via the bus line.

Notice:

The total current of all external digital devices that are connected to the various interfaces of

the mc² and do not have their own power supply must not exceed 1.2 A. Otherwise, the

mc² automatically switches off the power supply for the external devices.

4.6 | Connections

tams elektronik

4.2.5. Digital central units for DCC and Motorola

Info

The interface "rec" receives track signals in DCC and Motorola format. It is therefore the

universal interface for connecting all DCC and MM digital central units with a track output (a

so-called "sniffer"). It is used to integrate disused digital central units as control and switching

devices into the EasyControl system.

Connection: 2-pole, grid dimension 2.54 mm. Tip: For the connection use e.g. the DCC

programming cable item no. 40-01009-01. This cable has a 2-pole socket which you can plug

directly onto the connection.

For the connection of e.g.

Märklin Control Unit 6020 and 6021

Märklin Central Station (from version 1)

Uhlenbrock Intellibox

Possible applications of DCC and Motorola digital command stations

You can use the central units, which you integrate into the digital system via the interface

"rec" (the sniffer),

to control vehicle decoders for Motorola, DCC and mfx (the latter in m3 format),

to switch accessory decoders for Motorola and DCC.

However, it is not possible to programme decoders or configure the digital system using the

digital central units.

Connections | 4.7

tams elektronik

!

4.3. Connecting BiDiB devices

Info

BiDiB is a universal data bus that enables bidirectional communication between all stationary

components of a digital control system.

Connection: RJ45

Connection options

At the BiDiB interface of the mc², digital commands and track signals are output and the

feedback signals from the BiDi bus are received.

For the connection of max. 31 BiDiB nodes of

one level, e.g.

BiDiB accessory decoders

BiDiB feedback modules

BiDiB boosters

A supply voltage of 12 V is applied to the BiDiB interface. BiDiB nodes can be supplied with a

current of 500 mA in total, which do not require any additional current for their basic functions

(e.g. feedback unit). If the current requirement of the connected BiDiB nodes is greater, an

additional power supply is required (e.g. BiDi-Power, art. no. 46-09116 or 46-09017).

The mc² automatically detects the connected BiDiB nodes. You can display technical information

about the nodes and the structure of the BiDi bus on your system in the menu item "Operation /

BiDiB" of the mc²-Toolbox.

Notice:

The total current of all external digital devices that are connected to the various interfaces of

the mc² and do not have their own power supply must not exceed 1.2 A. Otherwise, the

mc² automatically switches off the power supply for the external devices.

4.8 | Connections

tams elektronik

4.4. Connection of s88 feedback modules

Info

The mc² regularly initiates read-in cycles in which the levels of all registers in the clock are

"passed through" from one register to the next to the central unit according to the bucket

brigade memory principle. Like most modern central units, the mc² compares the read-in data

with those of the previous read-in cycle and evaluates only the changed data or passes only

the changes on to the control software.

Connection: RJ45 (according to s88-N)

Connection options

You can connect a total of up to 52 s88 feedbacks or s88-compatible modules (with max. 832

contacts).

for direct connection of all s88 feedback

modules with connections according to

s88-N

Connection of (older) s88 feedback modules

with 6-pole pin headers via adapter S88-ABR (item no. 44-09110) or S88-A-SR (item

no. 44-09210)

Note:

!

There are s88 feedback modules available with RJ45 connections where the contact

assignments do not correspond to the s88-N standard. These are not suitable for connection

to the mc². Damage to the mc² and/or the connected modules may occur during

commissioning!

Configuration

Before starting operation, you must enter the number of connected s88 feedback modules.

→ Section 6.2.1 in the manual

→ Menu item "Operation / Detectors"

Connections | 4.9

tams elektronik

4.5. Connection of external boosters

If one booster is not sufficient to supply the layout or if the commands for vehicle and

accessory decoders are to be output separately ("driving and switching separately"), you can

connect additional external boosters.

MM: Märklin-compatible boosters

Connection: 5-pole, grid dimension 2.54 mm

CDE: DCC-compatible boosters

Connection: 3-pole, grid dimension 5.08 mm

(Connector plug included in delivery)

BiDiB: Boosters according to BiDiB

specification

Connection: RJ45

LocoNet-Boosters

Connection: RJ12

Note: The control of boosters and accessory decoders for

LocoNet as well as the forwarding of feedback signals from

LocoNet are not yet supported. (Status: 04/2021).

Simultaneous use of different booster interfaces

If you want to supply separate layouts (parts) or use separate boosters e.g. for driving and

switching, you can use all booster interfaces at the same time. However, you cannot supply

several booster sections of a layout mixed with different booster types (DCC-compliant,

Motorola-compatible, BiDiB, LocoNet).

Supply of several booster sections of a layout

Basically, if possible, identical boosters should be used to supply several booster sections of a

layout.

In combination with the integrated booster of the mc² you can use:

Booster B-4 (item no. 40-19407 or 40-19417): Connection to the DCC-compliant booster

output ("CDE") of the mc² or

BiDi-Booster (item no. 40-19407): Connection to the BiDiB interface of the mc². The

operating values of the BiDi booster are then reported back and can be used as a basis for

the booster management of a control software.

4.10 | Connections

tams elektronik

Note:

!

If you use other boosters than those previously mentioned to supply your system, you

should not use the integrated booster of the mc² to supply a booster section. Otherwise,

short-circuits and disturbances in data transmission may occur when crossing the separation

points between the sections.

Configuration

Before you start system operation, you must configure the boosters, i.e. set them to match

the nominal size of your system.

→ Section 5.5 in the manual

→ Menu item "System / Boosters"

4.6. Connection to the audio output

Info

The audio output of the mc² is technically correctly designated as a "line-out output". The lineout signal at the output has a high sound quality.

At present (as of 04/2021), the output is not yet supported by the software of the control unit.

With a later software version, it will be possible to store and retrieve background sounds in the

mc². It is also planned to call up situation-specific sounds together with the switching of

functions.

Later software versions will be available for free download from the Tams Elektronik website at

www.tams-online.de.

For the connection of

Active speakers (e.g. typical PC speakers)

Amplifiers in combination with passive loudspeakers

The connection is made via 2.5 mm stereo jack plugs.

Connections | 4.11

tams elektronik

4.12 | Connections

tams elektronik

5. Configuring the system (Submenu "System")

In the submenu "System" you make all the settings that are necessary to adjust your mc² for

operation with your layout. The explanations for the input fields open when you click on the

symbol .

5.1. System Info

In this menu item you can get an overview of the essential data of your digital central unit:

Hardware and software status of your mc²

Serial number, IP address and MAC address of your mc²

Flash and RAM allocation

Supply voltage

Temperature of the mc²

Track voltage: This value is set in the menu item "System / Boosters" according to the

nominal size of the layout.

Current / maximum current: The maximum current is set in the menu item "System /

Boosters". If the maximum current is exceeded, the integrated booster of the mc² is

automatically switched off.

Connected input devices: All input devices connected to the interfaces for EasyNet,

XpressNet, LocoNet or the CAN bus are displayed. Information on feedback devices

connected to the mc² can be queried in the menu items "Operation / Detectors" and

"Operation / BiDiB".

Info: Flash and RAM

"Flash" refers to the internal permanent memory of the mc², in which all data is stored that is

retained after switching off, e.g. the configuration, the locomotive database or audio files. An

occupancy of up to 90 % is not critical. It can be exceeded, for example, if a large number of

audio files are stored.

"RAM" refers to the internal working memory of the mc², in which all data generated during

operation are stored. An occupancy of up to 90 % is not critical. If this value is permanently

exceeded, there may be a defect in your mc². In this case, please contact the Technical

Hotline.

Info: Supply voltage

The supply voltage is 24 V in normal operation. If it is below 22 V, the power supply unit is

overloaded. This case occurs, for example, when the output current of the integrated booster

reaches the maximum of 6.5 A and at the same time many additional devices are connected to

the mc² which are supplied via the bus lines. In this case, you must reduce the current in the

booster circuit and/or the number of additional devices connected. In case of a permanent

overload, the power supply unit switches off automatically and switches on again after the

overload has been eliminated (hiccup mode).

Configuring the system (Submenu "System") | 5.1

tams elektronik

!

!

Info: Temperature

Heating of the central unit during operation is normal and harmless. Under permanent full

load, i.e. if the integrated booster supplies more than 6 A of current for a longer period of

time, the temperature can reach up to 75 °C.

Notice:

To prevent the mc² from overheating, you must ensure that a distance of at least 20 cm to

surrounding surfaces is maintained on the side surfaces and the top and rear of the mc².

If a high temperature is reached at low load, the mc² probably has a defect.

Notice:

If you notice overheating and suspect a defect in the mc² as the cause, disconnect the

central unit from the supply voltage immediately. Fire hazard! Send the mc² in for testing.

Saving and loading system settings

The configurations for the boosters, the protocols, the accessory decoders and the feedback

modules are saved in the file with the system settings. For the vehicle decoders, only the

standard format and purging are saved.

You can save and load the vehicle database ("locomotive list") separately in the menu item

"System / Vehicles".

Tip: When you have finished configuring your mc², you should save the system settings. You

can then load the settings again if the internal fixed memory of the mc² (the so-called "flash")

is damaged, e.g. in the event of a power failure.

5.2 | Configuring the system (Submenu "System")

tams elektronik

5.2. Vehicles

Management of the vehicles

Standard format

At delivery, the DCC format with 28 speed steps is set as standard, i.e. this protocol is applied

to the track by default. Vehicle decoders with the standard format can therefore be controlled

directly, vehicle decoders with different formats only if they have been created in the

locomotive list beforehand. The setting of the standard format is taken over as the default

setting in the locomotive list.

Standard

format

MM1/14

MM2/14

MM2/27A

MM2/27B

DCC/14

DCC/28

DCC/126

DCC/SDF

m3/126 mfx decoders that have been assigned an

Locomotive list

The database with your vehicles (in short "locomotive list") is a central part of your digital

control. Assigning names to your vehicles is not mandatory, but can be very helpful if the

decoder address has been forgotten or accidentally changed.

Function icons

Various icons are stored, which illustrate the numerous possible functions of vehicle decoders

(lights, couplers, smoke generators, sounds). Each icon is displayed in two versions, showing

the function in switched on or switched off state. You can replace the standard icons with your

own.

Vehicle decoders,

which can be controlled directly

all MM-decoders and mfx-decoders

If addresses >255 are selected, the mc²

automatically switches to DCC format, for

addresses >10,239 to m3 format.

all DCC decoders and mfx decoders that

support DCC

If addresses > 10,239 are selected, the

mc² automatically switches to the m3

format.

m3 address

Notes

As soon as the m3 signal is

present on the track (e.g. after

accidentally entering a locomotive

address >10,239), mfx vehicle

decoders react exclusively to m3

commands and no longer to MM

and/or DCC commands.

Assignment of the m3 address:

→ System / Vehicles / m3

→ Operation / Programming / m3

Configuring the system (Submenu "System") | 5.3

tams elektronik

Tractions

The control of locomotives in tractions is only possible if the same number of speed steps is

assigned to the decoders. Tractions with vehicle decoders with different data formats are

possible. Possible combinations:

DCC and Motorola decoders with 14 speed steps

DCC decoders with 28 speed steps and Motorola decoders with 27 speed steps

DCC decoders with 128 speed steps and mfx decoders with 126 speed steps

If you form tractions of locomotives with different driving directions, you can invert the driving

direction for one locomotive. In operation, this locomotive will then travel backwards (or vice

versa) when travelling forwards.

Tractions react together under all decoder addresses of the traction to driving commands and

the command to change direction. To switch the functions, the locomotive must be called up

under its respective address.

Further settings in the "Vehicles" menu item

Purging: You can specify that decoders that have not received any new driving or switching

commands within the set time (1 to 20 minutes) are removed from the refresh.

Lnet Dispatch: LocoNet hand controllers are used to control one specific vehicle. If you

have connected such a hand controller to the LNet interface of your mc², assign it "its"

decoder address here.

5.3. Accessories

Management of the accessory decoders

In this menu item you set how your accessory decoders are to be controlled by default:

Standard format

Minimum and maximum switching time

Number of repetitions of accessory decoder commands

You can also specify for which decoders exceptions to the standard format should apply.

Tip: The input field "Remarks" is intended for your notes on the accessory decoders. You can

enter free texts and save them in external files or load texts from external files.

5.4 | Configuring the system (Submenu "System")

tams elektronik

5.4. Protocol

Optimisation of the data transmission

With the default setting "normal", a safe and sufficiently fast transmission of digital data

between the mc², the decoders and the feedbacks is guaranteed for many installations.

In the help that opens after clicking on the symbol , you will find detailed explanations of

what is hidden behind the various terms. Basically, you should always set the default values if

you are not sure what deviating settings will do. In the following cases you should check the

settings and adjust them if necessary:

Use of Motorola decoders

Change the MM signal pause setting if

locomotives with Motorola I decoders do not react to driving and switching commands or

show a bad driving behaviour during driving operation

if function decoders for the Motorola format (e.g. in function models) do not react to digital

commands.

No use of RailCom

In this case, switch off RailCom and NOP. This switches off the RailCom gap and suppresses

the sending of NOP commands, thus increasing the speed of data transmission to the

decoders.

Control of mfx decoders

You must activate m3 (and assign an m3 address to the mfx decoders) to be able to control

them with the m3 format. Note: As soon as the m3 signal is present on the track (e.g. after

accidentally entering a locomotive address > 10,239), mfx vehicle decoders react exclusively

to m3 commands and no longer to MM and/or DCC commands.

If you prefer to control mfx decoders in DCC or MM format, you must deactivate m3.

Configuring the system (Submenu "System") | 5.5

tams elektronik

!

5.5. Boosters

Settings for the integrated and external boosters

With the setting of the nominal size, standard values for track voltage, maximum current,

short-circuit sensitivity and inrush time are preset, with which a safe operation on your layout

is guaranteed.

In the help that opens after clicking on the symbol , you will find explanations of what is

hidden behind the various terms. Basically, you should set the default values if you are not

sure what deviating settings will cause.

Setting options for the integrated booster

track voltage at the output

maximum current (cut-off current)

short-circuit sensitivity

inrush time

signal routing

The settings for the integrated booster also apply to boosters connected to the BiDiB and

LocoNet interfaces.

Notice:

Too high a track voltage and/or too high a cut-off current can cause damage to vehicles or

tracks. You are on the "safe side" if you set the nominal size of your layout in the menu item

"System / Boosters" and thus preset the usual values.

Setting options for the external boosters

Short-circuit sensitivity

Signal routing

The settings are made separately for DCC-compliant and Märklin-compatible boosters.

Info: Signal routing

By default, the commands for controlling the vehicle decoders are sent continuously via the

booster outputs of a digital central unit, the commands for the accessory decoders only when

required. For this purpose, the transmission of the vehicle decoder commands is briefly

interrupted, the accessory decoder commands are transmitted in the resulting gap.

In PC-controlled (larger) layouts, this type of data transmission can lead to problems, e.g. if

vehicle decoders receive stop commands too late and the locomotives overrun signals as a

result. To avoid this, in (larger) PC-controlled layouts the output of commands for vehicle and

accessory decoders is separated ("separate driving and switching").

With your mc² you can switch off the output of the accessory decoder commands separately

for the internal booster, the DCC-compliant and the Märklin-compatible booster output. The

setting for the internal booster also applies to boosters on the BiDiB and LocoNet interface. At

the booster output where the output of accessory decoder commands is switched off, only

vehicle decoder commands are then transmitted. For the output of the accessory decoder

commands then use another booster output.

5.6 | Configuring the system (Submenu "System")

tams elektronik

6. Operation with the mc²

6.1. Operating and display elements

The mc² has a STOP and GO button with which you can trigger essential functions directly on

the unit. To switch the track voltage on and off, you can alternatively click on the photo of the

mc² on the start page ("HOME") of the mc²-Toolbox.

The display on the front provides you with essential information about the operating status of

your mc². In addition, the RGB LEDs built into the housing change colour and thus visibly

indicate the operating status from afar.

6.1.1. STOP and GO buttons

Button Duration Function

GO short Switching on track voltage

STOP short Switching off track voltage St.

GO

GO,

GO,

GO, ...

STOP long

GO +

STOP

off*

GO

+ on*

off*

GO+STOP

+ on*

long

short,

short,

short, ...

long Reset ausführen rE

when

switching

on

when

switching

on

Reading out the IP address

The individual digits of the IP

address are retrieved by pressing

the "GO" key several times.

→ Section 2

Sending BiDiB-Identify for

the mc² (→ registration of

the mc² with the PC

control software)

Configuration incl. deleting

the locomotive list and

resetting to factory settings

Starting recovery software

→ section 7

Shown

in the display

0.0 or current power

consumption

IP|

12|3.4|56.|78|9.1|23

St.

Fr red

Dots flash alternately

Colour of the

RGB LEDs

green

red

red

blue

circulating

blue

flashing

+ white

swelling

violet

* off: Switching off the power supply

* on: Switching on the power supply while holding down the button(s)

Operation with the mc² | 6.1

tams elektronik

6.1.2. Display and RGB-LEDs

Shown

in the display

Colour of the

RGB LEDs

Meaning

0.0 to 6.5 green

current current consumption [A]

The track voltage is switched on.

St. red

Stop. The track voltage is switched off.

td

green

"Test Drive". In test mode you can control and

test vehicle and accessory decoders on the

programming track with the virtual control units

HandControl.prog. and FunctionControl.prog.

SH

red-violet

flashing

"Short Circuit" / short circuit during operation.

Troubleshooting → section 8.2

ot

yellow

"Overtemperature" / Overheating

Troubleshooting → Section 8.2

rE

blue

flashing

+ white

swelling

A reset is performed.

St.

blue

circulating

Stop / The track voltage is switched off.

If the STOP button was previously held longer, the command

for the BiDiB Identify for the mc² is sent.

PA

no colour

change

Pairing. Control software is loaded for the first

time on a connected PC or mobile terminal

IP|12|3.4|56.|78|9.1|23

no colour

change

IP address

The individual digits of the IP address are retrieved by pressing

the "GO" key several times. → Section 2

Pf

red

"Power failure". The input voltage is below 22

V. Disconnect the control unit from the supply

voltage immediately!

Troubleshooting → section 8.3

LP

red

"Low Power". The input voltage after switching

on is below 22 V. Disconnect the control unit

from the supply voltage immediately!

Troubleshooting → section 8.3

6.2 | Operation with the mc²

tams elektronik

Shown

in the display

Colour of the

RGB LEDs

Meaning

Fr

1...99 or ---

[ ]

E + digit

Dots flash

alternately

red

violet

circulating

blue

flashing

+ white

swelling

no colour

change

violet

The configuration is deleted and the mc² is

reset to the factory settings.

An update is being carried out. The digits

indicate the progress in %. During writing, the

progress display is interrupted.

The update is being processed and completed.

An internal error has occurred. Please make a

note of the digit(s) and contact the hotline.

The recovery software has been started.

→ Section 7

Operation with the mc² | 6.3

tams elektronik

6.2. Submenu "Operation"

In this submenu you can do all the things that occur during operation of you layout:

Controlling vehicle and accessory decoders

Reading out and programme decoders

Checking feedback modules

Reading out and displaying system messages

Setting the model time

The explanations of the input fields are opened when you click on the symbol .

6.2.1. Feedback

Overview of all connected feedback devices (s88, CAN, BiDiB and LocoNet)

Management and test of s88- and CAN- feedback modules

s88- (and CAN-) feedback modules

In this menu item you have to set how many s88 modules you have connected. Otherwise,

the feedback modules will not be taken into account when evaluating the s88 messages. A

module with 16 inputs is considered to be one. Modules with fewer inputs (e.g. 8) are

evaluated proportionally (e.g. as ½ module).

Note: CAN feedback modules are connected to the CAN interface, but their feedback signals

are forwarded via the s88 bus. They are therefore managed together with the s88 feedback

modules (→ menu item "Operation / Detectors").

You can also check the occupancy messages of the connected s88 and CAN feedback modules

and thus detect faulty messages. Differences between the display and the actual state of an

input indicate problems with the s88 bus, faults on the s88 module or on system parts

connected to the s88 module.

You can set the type of display

static or dynamic

for one or more modules

BiDiB feedback modules

The list is limited to the display of BiDiB nodes that meet the occupancy class requirements

defined in the BiDiB specification.

The display of all BiDiB nodes including the representation of their assignment to the levels as

well as the listing of their properties can be found in the menu item "Operation / BiDiB". There

you also have the option to trigger an Identify command and to perform a reset. → Section

6.2.4

LNet

The display of LocoNet detectors is not yet implemented. It will be implemented with one of

the next updates, which you can then download free of charge.

6.4 | Operation with the mc²

tams elektronik

6.2.2. Programming

Programming and reading vehicle and accessory decoders

Testing vehicle and accessory decoders

In this menu item you have access to all common programming types for vehicle and

accessory decoders:

Programming on the main track or programming track

Data formats: DCC, m3 and Motorola

With the virtual HandControl.prog on the side you can directly check the settings of decoders

on / at the programming track.

Note that main track programming (POM) and programming on the programming track

(PROG) and reading out the configuration variables (CVs) is not possible for all decoder types

and data formats.

Vehicle

decoders

DCC read out POM + PROG POM + PROG POM + PROG

program POM + PROG POM + PROG POM + PROG

MM read out PROG:

determine address

program PROG --- ---

m3 read out PROG:

determine UID

program

* Background info on programming accessory decoders

According to RailCommunity standard RCN-214, there are two ways of programming DCC

accessory decoders:

PROG:

assign addres

Accessory

decoders

Basic*

assign addres* ---

--- ---

--- ---

Accessory

decoder

Extended*

Basic is the most common type of programming. Unless otherwise stated in the accessory

decoder instructions, assume that "Basic" is the type of programming used for this decoder.

Extended is mainly used for programming signal decoders. Please check in the manual if

the decoder supports this type of programming.

With many Motorola accessory decoders it is possible to assign them their address by entering

a turnout address from a block of 4. To do this, they must be put into programming mode,

e.g. by attaching a jumper or pressing a button. With the mc² you can directly assign an

address to these Motorola accessory decoders when you connect them to the programming

track.

Operation with the mc² | 6.5

tams elektronik

HandControl.prog

The HandControl.prog and the FunctionControl.prog have almost the same functionality as the

standard versions of the virtual controllers and are especially used for testing decoder

settings. However, in test mode (display "td" in the display of the mc²) you can only control

vehicle and accessory decoders on / at the programming track.

HandControl.vi → section 6.3.1

FunctionControl.vi → section 6.3.2

The following functions differ from the standard version of the virtual HandControl:

Change to FunctionControl.prog

Change of the interface for switching accessory decoders at the programming track

Change to HandControl.vi (the standard version of the virtual HandControl)

Testing accessory decoders

To select the turnout

address, enter the

address via the

number fields.

Afterwards you can

switch between the

two turnout positions

with the buttons

and

6.6 | Operation with the mc²

Turnout

"straight ahed"

Turnout

adress

Turnout

position

Turnout

"branch"

tams elektronik

6.2.3. Messages

Read out and display system messages

The messages help to check the function of the connected components and to find the causes

of malfunctions.

RailCom messages

You can display all messages or limit the type of messages to be displayed by:

Decoder address

Decoder type

Type of message

Messages from the BiDi bus

The display of BiDiB messages is currently not yet implemented (as of April 2021).

System messages

These help to find causes of malfunctions of your digital system. Tip: Before contacting the

Technical Hotline about problems with your digital control, connect your mc² to a PC or tablet.

The hotline staff may ask you to read out certain types of messages.

6.2.4. BiDiB

Display of all connected BiDiB nodes, their assignment to the levels and their properties

Identify and Reset

The list shows all connected BiDiB nodes and their assignment to the levels. According to the

BiDiB specification, the mc² is a node and fulfils the tasks of a BiDiB interface and a track

output device. The integrated booster also reports its data via the BiDi bus. The mc² is

therefore displayed as a BiDiB node in the top level - regardless of whether other BiDiB

components are present.

The properties of the BiDiB nodes are listed in the info field:

the address

the manufacturer

the type designation

the name and

the features

After right-clicking on the name of a node, a window opens and you can send an Identify

command or reset the node.

Operation with the mc² | 6.7

tams elektronik

6.2.5. Control

Calling the virtual HandControl.vi

The HandControl.vi is similar to the "real" HandControl.2. You can select and control vehicle

decoders directly with it. From the HandControl.vi you can also reach the other virtual control

units

FunctionControl.vi for controlling a vehicle decoder

DriveControl.vi to control up to four vehicle decoders simultaneously

SwitchControl.vi for switching accessory decoders

For the functionality and operation of the virtual control units → section 6.3

6.2.6. Model time

Controlling the layout according to timetable

For the control of your layout according to a timetable this menu item allows you

to start and stop the model time

to define the start time

to define teh time factor: Depending on the setting, the model time runs up to 60 times

faster than the real time.

to select the design

Alternatively, you can set the model time in your PC control software.

Tip: Use a smartphone or tablet that you position in a place visible from all areas of your

layout to display the model time. You can choose between four different designs for the

display of the model time.

6.8 | Operation with the mc²

tams elektronik

6.3. Virtual control devices

The virtual control devices enable e.g. the use of tablet(s) or smartphone(s) as external

control units or tests during configuration or programming on the PC screen. Depending on

the operating situation, you can choose between four different user interfaces and switch back

and forth:

HandControl.vi with a user interface based on the HandControl.2

FunctionControl.vi for controlling one vehicle decoder

DriveControl.vi for simultaneous control of up to four vehicle decoders

SwitchControl.vi for switching accessory decoders

6.3.1. HandControl.vi

Calling up the vehicle address

Proceed as follows to select a locomotive or function decoder for driving and/or switching:

Click on the locomotive symbol .

Enter the decoder address by clicking on the number fields.

Confirm the entry with .

The "Display" shows the address, the data format, the vehicle name, the current speed step

and driving direction as well as the switched-on functions.

To delete an incorrect entry, click on . .

Driving a locomotive

For the locomotive shown in the "display", you can

change the speed level with the slider and

change the direction of travel by clicking on the direction switch.

The current power consumption is shown in the bar below the display.

Switching functions

For the selected vehicle, you can switch the functions F0 to F9 on and off directly by clicking

on the number fields. To switch functions up to F32, you must switch to FunctionControl.vi by

clicking on . All switched-on functions up to F20 are shown in the "Display".

Switching to other virtual control units or to the menu

You can switch directly to the other virtual control units or back to the menu.

FunctionControl.vi to control the selected vehicle

SwitchControl.vi to switch accessory decoders

DriveControl.vi to control up to four vehicles

Menu of the mc²-Toolbox

Operation with the mc² | 6.9

tams elektronik

6.10 | Operation with the mc²

Current direction

> forwards

< backwards

Current

speed level

Digital

format

Vehicle

name

Delete

entry

Change to

FunctionControl.vi

Speed

controller

Change to

SwitchControl.vi

Actual current

Back to menu

Decoder

address

Confirm

infput

Function keys

(F)1, 2, 3…9, 0

Direction

change-over

switch

Switched on

functions

0, 5, 10, 19, 20

Select locomotive

Change to

DriveControl.vi

tams elektronik

6.3.2. FunctionControl.vi

With the FunctionControl.vi you can control the vehicle decoder that you have previously