Page 1

OPERATION MANUAL

MST2000 SERIES

Loop Powered Multivariable SMARTFLOW® Trans mit ter

For Eng lish and Met ric Unit Ver sions

See Sec tion 15 for ap proval in for ma tion

www.thermobrandt.com

Let us point you in the right direction.

Eng lish Unit Soft ware Release H03

Met ric Unit Soft ware Re lease HM3

MA37-2000-00, November 2001

CSA Approvals

Page 2

MST2100, NEMA 1

Thermo Brandt In stru ments, Inc.

P.O. Box 1190, 3333 Airpark Road

Fuquay, North Carolina 27526 U.S.A.

Telephone: (919) 552-9011 Facsimile: (919) 552-9716

www.Thermo Brandtinstruments.com

All spec i fi ca tions sub ject to change with out no tice. HART® is a reg is tered trade mark of the HART Com mu ni ca tions Foun da tion. All other trade marks ac knowl edged.

Page 3

OPERATION MANUAL

This man ual is de signed to op ti mize the per for mance of the MST2000 Se ries Loop Powered

Multivariable SMARTFLOW® Trans mit ter. The end user should read and re view it care fully be fore in stall ing, us ing or main tain ing the trans mit ter. The in for ma tion con tained in this man ual cor re sponds

to the re vi sion level of the soft ware shipped with your MST2000. You can down load a copy of the lat est ver sion of this man ual along with other in for ma tion from our web site.

IMPORTANT: This man ual cov ers both the ENGLISH and METRIC Unit Ver sions of the MST2000 op er at ing soft ware. The ENGLISH or METRIC con fig u ra tion must be se lected at the time of or der and con fig ured at the fac tory. ENGLISH or METRIC UNIT CONFIGURATION IS NOT FIELD SELECTABLE.

It is the de sire of Thermo Brandt In stru ments that the MST2000 be setup and used as ef fec tively and ef fi ciently as pos si ble. If you have any ques tions or con cerns please con tact your

Thermo Brandt rep re sen ta tive or Thermo Brandt In stru ments at the fol low ing:

Tele phone: (919) 552-9011. Cus tomer Ser vice: Ex ten sion 28

Fac sim ile: (919) 552-9716

Web Ad dress: www.thermobrandt.com

E-mail: techsupp@brandtinstruments.com

TABLE OF CONTENTS Page

Model Num ber............................................2

Spec i fi ca tions ............................................3

MST2100 Di men sional Draw ing...................................4

MST2400 Di men sional Draw ing...................................4

Sec tion 1, Mount ing and Pro cess Con nec tions ...........................5

Sec tion 2, Con tin u ous Purge Op tion ................................5

Sec tion 3, In te gral “High Pres sure” Blowdown Sys tem Op tion ...................6

Sec tion 4, Elec tri cal Con nec tions ..................................7

Sec tion 5, LCD Dis play and In te gral Key Pad............................7

Sec tion 6, MST2000 Op er a tional Modes and Startup........................8

Sec tion 7, Pro gramming.......................................9

Sec tion 8, Pro gram Pa ram e ters...................................10

Sec tion 9, Alarm Pro gramming In for ma tion .............................16

Sec tion 10, For mulas & Con ver sion Factors ............................19

Sec tion 11, Test Jack ........................................20

Sec tion 12, Op tional Mod ule In stal la tion ..............................20

Sec tion 13, MST2000 HART® Com mu ni ca tions In for ma tion ....................23

Sec tion 14, Wiring Di a grams ....................................26

Sec tion 15, CSA Haz ard ous Area Ap provals ............................28

Sec tion 16, Cal i bra tion of the MST2000 ..............................30

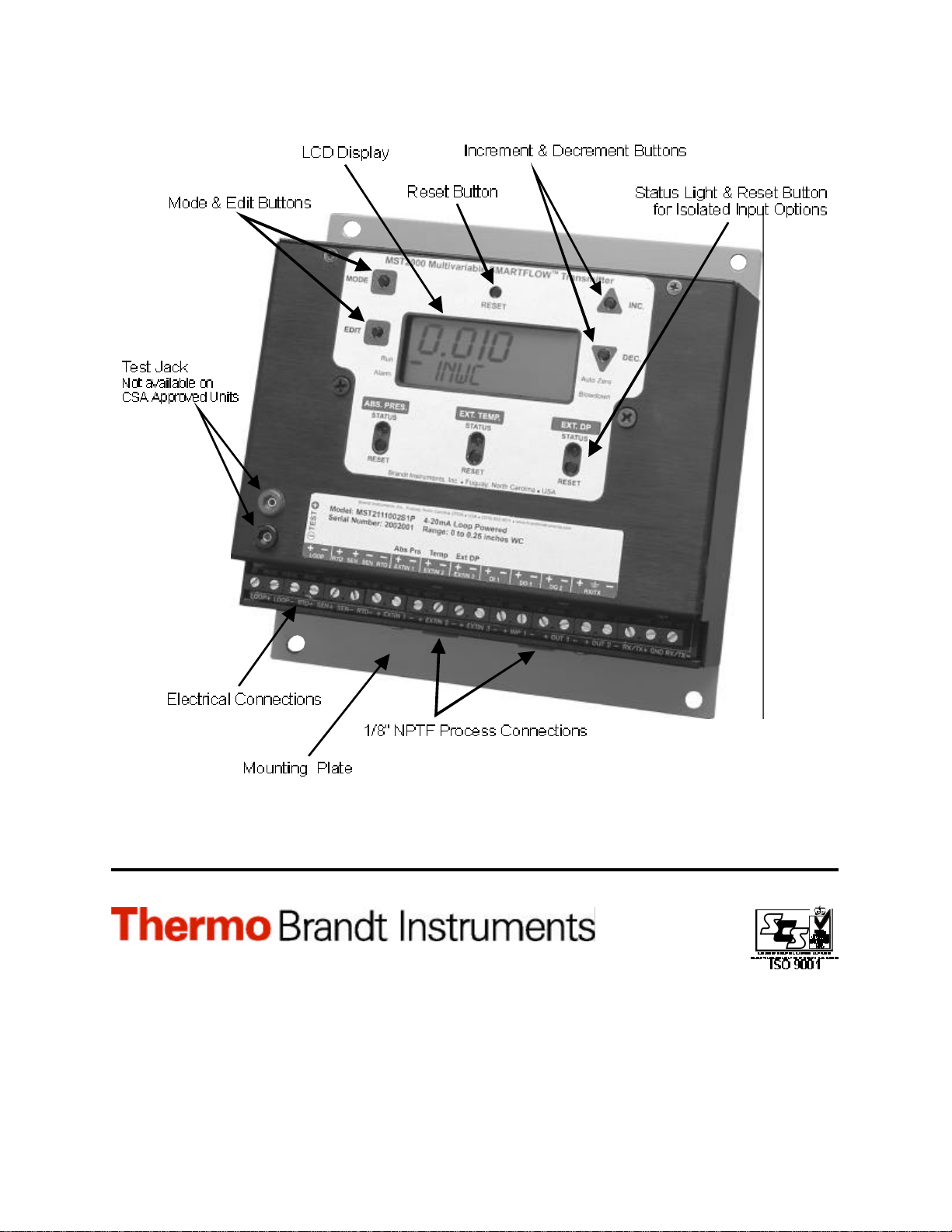

PRODUCT OVERVIEW

Thermo Brandt In stru ments’ MST2000 Se ries Loop Powered Multivariable SMARTFLOW® Trans -

mit ter pro vides the nec es sary ver sa til ity re quired to sat isfy to day’s de mand ing in dus trial pro cess ap -

pli ca tions. With pro gram ma ble con stants, in put/out put op tions and com mu ni ca tion fea tures the

MST2000 will con cur rently mea sure and/or ap ply the nu mer ous pro cess vari ables for a true mass flow

mea sure ment.

The MST2000’s con fig u ra tion is user friendly and is ac com plished through the in te gral key p ad (no ex ter nal soft ware or hard ware is re quired). The MST2000 is ca pa ble of pro duc ing and dis play ing sig nals

for Dif fer en tial Pres sure or for Flow . Op tional in put, dig i tal I/O and com mu ni ca tion mod ules can be in stalled at the fac tory or in the field as re quired.

Page 4 MST2000 Multivariable SMARTFLOW® Transmitter Brandt Instruments, Inc.

Page 4

OPERATION MANUAL

MODEL NUMBER

SERIES: LOOP POWERED MULTIVARIABLE SMARTFLOWTM TRANSMITTER

MST21 = MST2100, NEMA 1 Panel Mount En clo sure, Dif fer en tial Pres sure Con fig u ra tion & Non-isolated 4 Wire RTD In put Stan dard. u

MST24 = MST2400, NEMA 4X, Fi ber glass En clo sure, Dif fer en tial Pres sure Con fig u ra tion & Non-iso lated 4 Wire RTD In put Stan dard. u

ISOLATED INPUT MODULE: Ab so lute Pres sure Trans mit ter

0 = None

1 = Iso lated In put Mod ule: Ac cepts 4-20mA in put sig nal from an Ex ter nal Ab so lute Pres sure Trans mit ter. u

2 = Isolated Input Module with Integral Absolute Pressure Transmitter, 0-25 PSI (0-1.7 bar) range standard. Consult factory for

other ranges. MST2400 only. Requires Integral 24V Power Supply. See Output option 2 below.

ISOLATE

D INPUT

MODULE: Tem per a ture Trans mit ter

0 = None

CERTIFICATION

0 = None

1 = CSA Ap proved In trin sically Safe

COMMUNICATIONS

MODULE

DIGITAL I/O

MODULE

PRESSURE RANGES

1S = Stan dard Range 1Max. Span: 0-0.10” ( 0 to 2.54mm) W.C. Turn down to 0.010” (0.254mm)W.C. (10:1).

2S = Stan dard Range 2 Max. Span: 0-0.25” ( 0-6.35mm) W.C. Turn down to 0.025“ (0.635mm) W.C. (10:1).

3S = Stan dard Range 3 Max. Span: 0-1.00“ (0-25.4mm) W.C. Turn down to 0.10“ (2.54mm) W.C. (10:1).

4S = Stan dard Range 4 Max. Span: 0-4.00” (0-101.6mm) W.C. Turn down to 0.40” (10.16mm) W.C. (10:1).

5S = Stan dard Range 5 Max. Span: 0-16.0” (0-406.4mm) W.C. Turn down to 1.60” (40.64mm) W.C. (10:1).

6S = Stan dard Range 6 Max. Span: 0-50.0” (0-1270.0mm) W.C. Turn down to 5.00” 127.0mm) W.C. (10:1).

CR = Com pound RangeCon sult fac tory. Sup ply de sired Com pound Range.

All max i mum pres sure ranges have a turn down of 10:1.

Spec ify Pres sure Range # in model num ber (ex am ple 1S or CR).

Stan dard Ranges: MST2000 will be cal i brated at Max i mum Span. If an Ini tial Range Set ting is de sired, sup ply with

or der and unit will be shipped with this Ini tial Range pre set. (Ex am ple: 3S set to 0 to 0.5” W.C.).

Com pound Ranges: MST2000 will be cal i brated at de sired Com pound Range. Sup ply com pound range with or der

(ex am ple: -0.25 to +0.25” W.C.).

All spans will be cal i brated in Inches of W.C. Other Units of mea sure will be con verted to Inches of W. C.

OUTPUT & VERSION. See Note Be low.

1 = 4-20mA Out put. Eng lish Units Ver sion. u

2 = 4-20mA Out put with In te gral 120VAC to 24VDC Power Sup ply. 120VAC

3 = 4-20mA Out put. Met ric Units Ver sion. u

4 = 4-20mA out put with In te gral 120VAC to 24VDC Power Sup ply. 120VAC Source

2 = CSA Ap proved Di vi sion 2.

Review Sec tion 15 of this man ual for ap proval in for ma tion.

0 = None

H = HART® Com mu ni ca tions Mod ule. u

0 = None

D = Dig i tal I/O Mod ule with 1 In put, 1 Out puts. v

Source Re quired. MST2400 only. Eng lish Units Ver sion.

Re quired. MST2400 only. Met ric Units Ver sion.

OPTIONS

0 = None

B = In te gral High Pres sure Blowdown Sys tem. MST2400 Only. Re quires

Dig i tal I/O Mod ule. 120VAC source re quired. Reg u lated air sup plied to

100 PSIG. En clo sure size will change. Con sult Fac tory for spec i fi ca tions

and avail abil ity.

P = Con tin u ous Purge to Flowmeter. MST2400 Only. Spans of 0.25” W.C.

(6.35mmWC) or greater. A fil tered air sup ply source of 20 to 100 PSI

(1.4 to 6.9 bar) is re quired. u

ACCESSORIES

0 = None

P = Pipe Mount. MST2400 Only.

u De notes op tions & fea tures avail able with CSA In trin sically Safe

and Di vi sion 2 haz ard ous area ap prov als.

v De notes op tions & fea tures avail able with CSA Di vi sion 2 Ap -

provals Only.

Re view Sec tion 15, for CSA ap proval in for ma tion.

MST24 1 1 1 H D 2S 1 0 P

MST2000’s with Eng lish or Met ric Unit Ver sions are avail able but must be se lected at time of or der and con fig ured at

the fac tory. IT IS NOT A FIELD SELECTABLE OPTION.

Brandt Instruments, Inc. MST2000 Multivariable SMARTFLOW® Transmitter Page 5

Page 5

OPERATION MANUAL

SPECIFICATIONS

FUNCTIONAL SPECIFICATIONS

Ser vice: Clean, dry, non-corrosive Air or Gas. Other me dia may be pos si ble with the use of the Con -

Pres sure Ranges: Stan dard Pres sure Ranges:

Out put Sig nals: An a log: 4-20 mA sig nal (Max. Loop re sis tance = 615 Ohms @ 24 VDC) is user pro gram ma -

Com mu ni ca tions: Op tional: dig i tal HART® Com mu ni ca tions mod ule. See Sec tion 13, page 23 for HART® com -

Alarms: Pro gram ma ble hard ware alarms, underrange and overrange.

Dis play: High Con trast, 2 line, al pha nu meric LCD with -20 to 150o F (-28 to 66oC) op er at ing tem per -

Power Sup ply Re quired: 24 to 40 VDC loop power, min i mum 11 volts re quired at in puts.

Re verse Po lar ity Pro tec tion: Yes

Turn On Time: 4 sec onds (max i mum).

Tem per a ture Limits: Op er ating: -40 to 150oF (-40 to 66oC) Stor age: -40 to 180o F (-40 to 82oC)

Overpressure Limits: Proof Pres sure: 10 PSID (0.7 Bar) Burst Pres sure: 50 PSID (3.45 Bar)

Damping: Stan dard Time Con stant: 500 mSec. Ad di tional damp ing ad just able via in te gral key pad

Hu mid ity Limits: 100% Non-condensing, (MST2400 Only).

In puts: Stan dard: Non-isolated, 4 wire RTD in put con nec tion.

PERFORMANCE SPECIFICATIONS

Ac cu racy: For spans from 40% to 100% of max i mum range with TD of 1:1 to 2.5:1 then ac cu racy =

Sta bil ity: 0.1% of Max i mum Range / 12 Months

Am bi ent Tem per a ture: Zero: No Ef fect Span: Less than 0.001% of Re-ranged Span per Deg F. Cor rected by in -

Mount ing Po si tion Ef fect: Mi nor ef fect on Zero. Cor rected by setup pa ram e ters.

Vi bra tion Ef fect: Less than 0.2% of Max i mum Range / g, 10-130 Hz.

PHYSICAL SPECIFICATIONS:

En clo sure Types: MST2100: NEMA 1, An od ized Alu mi num. MST2400: NEMA 4X, Fi ber glass.

Pro cess Con nec tions: MST2100: 1/8” NPTF MST2400: 1/4” NPTF Stain less Steel

Elec tri cal Con nec tions: MST2100 & MST2400: Cage Clamp style ter mi nal block. 12-24 AWG wire size.

Weight: MST2100: 2.5 . (1.14 kg) MST2400: 8.0 lbs. (3.63 kg)

tin u ous Purge op tion. Con sult fac tory .

Range 1: 0 to 0.10” (0 TO 2.54mm) W.C. Range 4: 0 to 4.0” (0 to 101.6mm) W.C.

Range 2: 0 to 0.25” (0 to 6.35mm) W.C. Range 5: 0 to 16.0” (0 to 406.4mm) W.C.

Range 3: 0 to 1.0” (0 to 25.4mm) W.C. Range 6: 0 to 50.0” (0 to 1270.0mm) W.C.

ble to Dif fer en tial Pres sure or Flow Parameters. Ex ter nal in puts or pro grammed con stants

for tem per a ture and ab so lute pres sure along with con stants for Ef fec tive Area and Stan dard

Den sity, are nec es sary for a true flow mea sure ment.

Op tional Dig i tal: One (1) op tional dig i tal (open col lec tor) out put avail able. Ac ti va tion pro gram ma ble by end user.

mu ni ca tion in for ma tion.

a ture.

Max Line Pres sure: 50 PSIG (3.45 Bar).

from 0.5 to 5 Sec onds in 0.5 sec ond in cre ments.

Op tional 4-20mA Iso lated In puts: In put ranges are soft ware rangeable.

& Ex ter nal Tem per a ture: 4-20mA In put

& Ex ter nal Ab so lute Pres sure: 4-20 mA In put

Op tional Dig i tal In put: One op tional dig i tal (TTL level) in put is avail able.

0.15% of Re-ranged Span.

For spans from 20% to 39% of max i mum range with TD of 2.5:1 to 5:1 then ac cu racy =

(0.15 + 0.005 X TD)% of Re-ranged Span.

For spans from 10% to 19% of max i mum range with TD of 5:1 to 10:1 then ac cu racy =

(0.15 + 0.010 X TD)% of Re-ranged Span.

& TD = Max i mum Range / Re-ranged Span

ter nal tem per a ture sen sor.

MST2400: ½” Liq uid-Tight flex i ble con duit con nec tions.

Page 6 MST2000 Multivariable SMARTFLOW® Transmitter Brandt Instruments, Inc.

Page 6

OPERATION MANUAL

DIMENSIONS

Brandt Instruments, Inc. MST2000 Multivariable SMARTFLOW® Transmitter Page 7

Page 7

MOUNTING AND PROCESS CONNECTIONS OPERATION MANUAL

1. MOUNTING AND PROCESS CONNECTIONS

The MST2000 can be mounted in any di rec tion. There may be a mi nor ef fect on Zero

that can be cor rected by the setup pa ram e ters.

1.1 MST2100: NEMA 1 En clo sure

A. Re view the di men sional draw ing on page 5.

B. Pro cess con nec tions are via 1/8" NPT fe male ports lo cated on the bot tom of the hous ing. The high

pres sure port is la beled “HIGH”, the Low pres sure port is la beled “LOW” on the mount ing plate.

1.2 MST2400: NEMA 4X En clo sure

A. Re view the di men sional draw ing on page 5.

B. With out a con tin u ous purge op tion, pro cess air should be non-corrosive and dry. If a con tin u ous

purge op tion is in stalled please re view sec tion 2 on the con tin u ous purge. The con tin u ous purge

must be bal anced.

C. Pro cess con nec tions are via 1/4" NPT fe male ports lo cated on the bot tom of the en clo sure. The high

pres sure port is la beled “HIGH”, the Low pres sure port is la beled “LOW”.

1.3 Three Valve Man i fold

A. It is rec om mended that a three valve man i fold be in stalled in the pro cess, un less a con tin u ous

purge is in stalled . A three valve man i fold is avail able from the fac tory. It is in stalled in the pro cess

lines to iso late the pro cess sig nal dur ing in stal la tion and/or re moval of the MST2000 thus pre vent ing

pos si ble trans ducer over-pressurization and to zero trans mit ter.

þ Notes:

& Be fore con nec tions are made blow out pro cess lines throughly.

& It is rec om mended that pipe thread tapes not be used on pneu matic pip ing.

& Soap test all joints and fit tings for leaks.

& Pro cess lines should be the same di am e ter and ap prox i mately the same length.

þ Note: MST2000 DP sen -

sor max i mum op er at ing

static pres sure is 25

PSID.

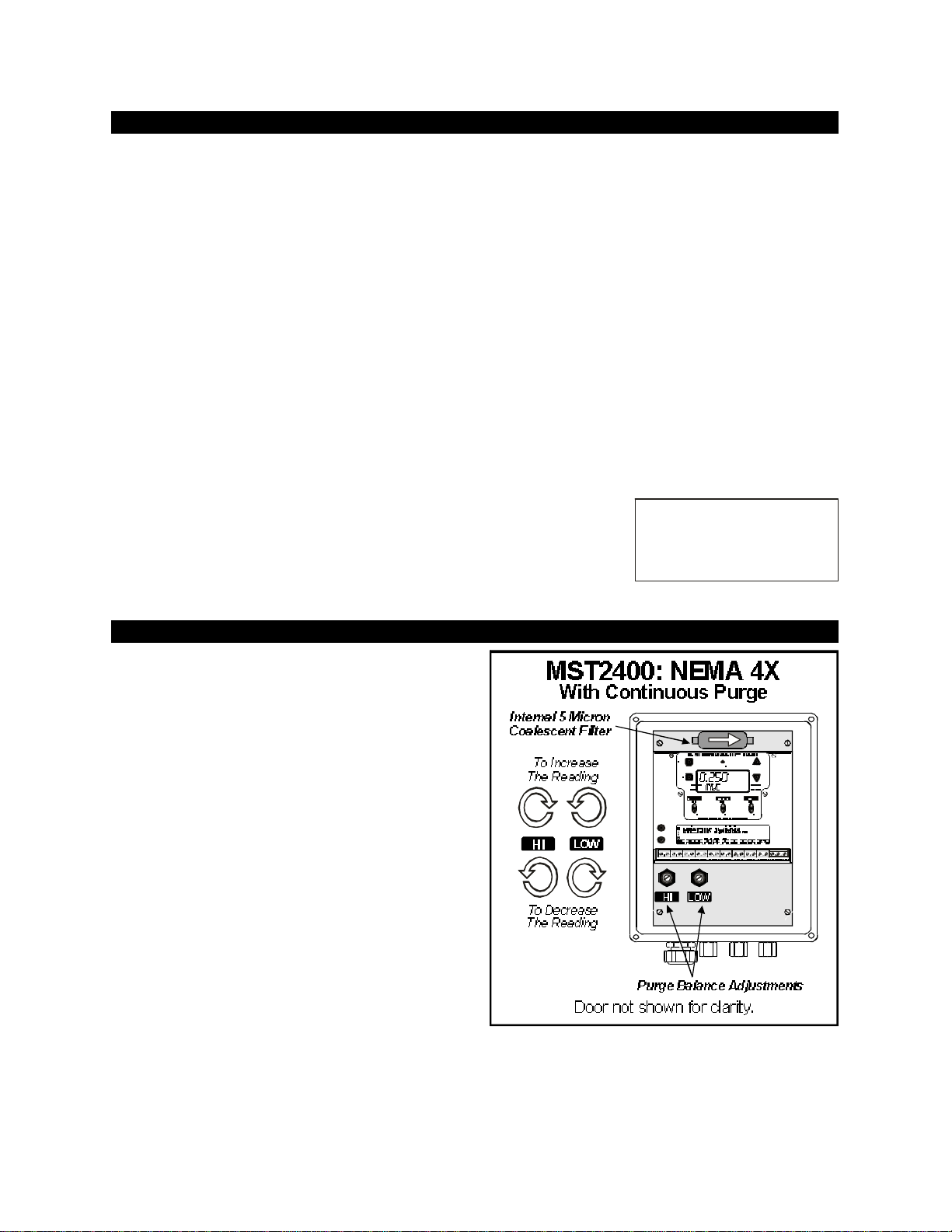

2. CONTINUOUS PURGE OPTION

The MST2400 can be or dered with a Con tin u ous

Purge Op tion. This op tion sup plies a con tin u ous

pneu matic purge to a Thermo Brandt pitot flow

sen sor to keep the sens ing ports free from plug ging dur ing op er a tion. There are Purge Bal ance

ad just ments lo cated on the front panel which

pro vide for the ze ro ing of pro cess air re sis tance.

If the Con tin u ous Purge Op tion has been or dered, please read the fol low ing setup in struc tions. The Con tin u ous Purge Op tion must be

bal anced once the pro cess is con nected to

the MST2400.

A 1/4" NPT fe male air sup ply port is pro vided on

the bot tom of the en clo sure for the Purge.

An in ter nal fil ter is sup plied with the unit, but air

sup ply should also be fil tered and reg u lated.

þ PROCESS LINE LENGTH & SIZE

& When a con tin u ous purge op tion is used, the pro cess

lines (Hi and Low lines) must be the same di am e ter

(pref er a bly 3/8" or larger) and the length of each line

should be the same within +/- 5%.

þ IMPORTANT:

& The Con tin u ous purge op tion air sup ply should be only clean, in stru ment qual ity air and should be greater than 20

psi (1.4 bar) and not ex ceed 100 psi (6.9 bar). A pre-filter should be in stalled in the sup ply line if the air qual ity is

sus pect. A 5 mi cron fil ter and a 0.3 mi cron co ales cent fil ter are rec om mended. Fail ure to pro vide clean, in stru ment

qual ity air through the Con tin u ous Purge can cause the MST2000 to give er ratic read ings. Fail ures at trib uted to a

con tam i nated air sup ply are not cov ered un der the war ranty.

Page 8 MST2000 Multivariable SMARTFLOW® Transmitter Brandt Instruments, Inc.

Page 8

OPERATION MANUAL In te gral “High Pres sure” Blowdown Sys tem

2.1 Bal ancing the Purge if the Pro cess is in Op er a tion

A. Re view the draw ing on page 5.

B. Pro cess must be in a steady state.

C. Dis con nect the HIGH and LOW lines from the trans mit ter. Mea sure the DP from the pro cess with a

pres sure cal i bra tor or other DP mea sur ing de vice..

D. Re cord the DP read ing. ______________________________

E. Re con nect the HIGH and LOW lines back to the trans mit ter. Make sure the Purge is op er at ing.

F. Ad just the “HIGH” and “LOW” Purge Bal ance ad just ments on the mount ing plate un til the dis play

read ing equals the read ing re corded in Step D. See the draw ing on page 5.

2.2 Bal ancing the Purge if the Pro cess is not in Op er a tion

A. Re view the draw ing on page 5.

B. En sure that there is no flow in the pro cess. If the flow can not be stopped com pletely fol low the in -

struc tions in Sec tion 2.1.

C. At tach the HIGH and LOW lines to flow me ter.

D. Ad just the “HIGH” and “LOW” Purge Bal ance ad just ments on the front panel till the dis play read ing

equals 0.0000 Inch W.C. See draw ing on page 5.

þ IMPORTANT: It is rec om mended that a Three Valve Man i fold not be used with an MST2400 which con -

tains the Con tin u ous Purge Op tion. Con sult fac tory.

2.3 In te gral 5 Mi cron Co ales cent Fil ter

A. The MST2400 with con tin u ous purge co mes with an in te gral 5 mi cron Co ales cent Fil ter. See the

Draw ing on page 5.

B. The fil ter is in tended as a sec ond ary de vice. The sup ply air should be reg u lated and fil tered be fore

en ter ing the en clo sure.

C. The in te gral fil ter will turn “RED” as it cleans the air. Re place the fil ter be fore the “RED” reaches the

right side, or out let end.

3. In te gral “High Pres sure” Blowdown Sys tem

The MST2400 can be or dered with an In te gral “High Pres sure” Blowdown Sys tem. This op tion is de signed to clean out Pitot Av er aging Flow sen sors us ing a blast of “High Pres sure” Air (up to 100 PSIG or

6.9 bar) while hold ing the last out put sig nal from the MST2400.

The MST2400 is ca pa ble of be ing pro grammed to per form a blowdown se quence any where from ev e ry

2 min utes up to once ev ery 24 hours (1440 min utes). The blowdown se quence can also be ac ti vated by

a re mote pulse from a DCS or other con trol ler.

A. Spec i fi ca tions:

a. Air Sup ply: Max i mum of 100 PSIG (6.9 bar) . If air sup ply is over 100 PSIG then a reg u la tor must be

in stalled.

b. Volt age: 120 VAC. Op tion con tains in te gral 24VDC power sup ply.

c. Se quence Du ra tion: Approximately 30 sec onds from time sig nal is held till sig nal is re stored.

d. Tem per a ture: Max i mum 150oF.

e. Pro gram ma ble intervals: 2 min utes to 1440 min utes (24 hours).

f. Pulse Sig nal from ex ter nal controller: Con tact clo sure for ½ sec ond (500 mil li sec onds).

B. Se quence of Op er a tion

a. The MST2400 be gins the Blowdown se quence by hold ing the last out put sig nal. “-HOLD-” will ap -

pear on the LCD. The Blowdown Status In di ca tor will also be lit. See the sec tion on the LCD Dis play.

b. Valves are ac ti vated to iso late and vent the trans mit ter from the pro cess to pre vent dam a ge.

c. The Hi & Low pro cess lines are al ter nately blown down for ap prox i mately 11 sec onds each.

d. Valves are au to mat i cally ac ti vated to re store sig nal from pro cess back to MST2400.

C. Ex ter nal Ac ti va tion Sig nal

The MST2400 In te gral Blowdown can be ac ti vated by a ½ sec ond ex ter nal contact closure pulse sig nal. The Blowdown can be con trolled by this sig nal only or in com bi na tion with the in te gral con trol of the

MST2400. The MST2000 must be pro grammed to ac cept this sig nal. Re fer to Pro gramming Pa ram e ters, Sec tion 8. See Wiring Di a grams in Sec tion 14.

þ Note: A 110VAC power source is re quired for the In te gral Blowdown Sys tem. An internal 24VDC

power sup ply is fur nished with the Blowdown. DO NOT USE THIS POWER SUPPLY TO POWER THE

LOOP SIGNAL.

Brandt Instruments, Inc. MST2000 Multivariable SMARTFLOW® Transmitter Page 9

Page 9

ELECTRICAL CONNECTIONS OPERATION MANUAL

4. ELECTRICAL CONNECTIONS

4.1 MST2100: NEMA 1 En clo sure

A. Re view the MST2100 and MST2400 di men sional

draw ings.

B. Re fer to the MST2000 Ter mi nal Block Draw ing.

C. MST2000 In stru ment Elec tri cal Con nec tions are

cage clamp style for 12-24 AWG. Wire should be

stripped back a min i mum of 3/16" inches (5mm).

D. The MST2000 Multivariable dif fer en tial pres sure

trans mit ter is a HART® com pat i ble loop-powered

4-20 milliamp trans mit ter. Power con nec tion is

made at the two left ter mi nal po si tions marked

LOOP+ and LOOP-. Nom i nal power sup ply volt age

is 24 volts DC which al lows up to 600 ohms se ries

re sis tance in the loop cir cuit.

þ For HART® ap pli ca tions, min i mum loop re sis tance is

250 ohms.

4.2 MST2400: NEMA 4X En clo sure

A. A ½" Liq uid Tite con duit con nec tion is lo cated on

the bot tom of the En clo sure.

B. Con duit should be in stalled to pre vent con den sa tion

from col lect ing in the in stru ment.

4.3 In te gral Power Sup ply Op tion.

A. The In te gral Power Sup ply Op tion re quires an ex ter nal 120 Volt Power Sup ply.

B. A six (6) po si tion screw type ter mi nal block and ½" Liq uid Tite Con duit con nec tion are sup plied with

the In te gral Power Sup ply Op tion.

4.4 Ca na dian Stan dards As so ci a tion Hazardous Area Ap provals

The MST2100 and MST2400 have been ap proved by CSA for haz ard ous area in stal la tions.

See Sec tion 15 for de tails or con tact the fac tory.

5. LCD DISPLAY and INTEGRAL KEY PAD

All con trols and in di ca tors are Lo cated on the front panel of the MST2000. Re fer to the LCD & Key Pad

Draw ing.

5.1 Key Pad

All pro gram ming and con trol op er a tions are per formed us ing four (4) pushbuttons on the key pad.

Fol low ing are sum ma ries of each key.

MODE: ! Tog gles the MST2000 be tween

RUN Mode and PROGRAM

Mode.

! Also used to change the edit cur -

sor when en ter ing a numeric

value.

EDIT: ! Se lects the pa ram e ter to edit

when in Pro gramming Mode.

! Also saves the ed ited pa ram e ter

data to memory.

INCREMENT: ! In cre ments (steps for ward) through pa ram e ters and/or nu meric val ues.

DECREMENT: ! Dec re ments (steps back wards) through pa ram e ters and/or nu meric val ues.

RESET: ! Re sets the CPU. Re starts pro gram and loads in pro grammed vari ables stored in

the E-Prom

Page 10 MST2000 Multivariable SMARTFLOW® Transmitter Brandt Instruments, Inc.

Page 10

OPERATION MANUAL MST2000 OPERATIONAL MODES and START UP

5.2 LCD Dis play

The MST2000 High Con trast LCD dis play will

dis play two (2) lines si mul ta neously. The dis play

is used to setup and cal i brate the MST2000 and

dis play and mon i tor in put and out put sig nals and

other vari ables.

The lines of dis play are:

Nu meric: ! Where the val ues for DP or

Flow are dis played.

! The vari ables for pa ram e ters

are ed ited and dis played.

Al pha nu meric: ! Where units of mea sure and

pa ram e ter names are dis played.

Sta tus

In di ca tors:

! Used to dis play the op er a tional sta tus of the MST2000. The Sta tus in di ca tor will

in di cate when the MST2000 is in “RUN Mode”, if there is an Alarm and whether

an AutoZero or Blowdown se quence is in pro cess.

6. MST2000 OPERATIONAL MODES and START UP

The MST2000 has two ba sic op er a tional Modes. They are:

RUN MODE ! In this mode the MST2000 is op er at ing and dis play ing the mea sure ments.

PROGRAM

MODE

! In this mode the MST2000 is ready for pro gram ming. Note: The PROGRAM Mode

can be pass word pro tected.

Startup

When power is first ap plied, the MST2000 Liq uid Crys tal Dis play (LCD) will first dis play RESET fol lowed

by READEE and then dis play the se lected runtime pa ram e ter. The avail able runtime pa ram e ters are

listed be low.

ENGLISH UNITS VERSION METRIC UNITS VERSION

INWC

SCFM

ACFM

LBHR

TEMP

ABS_PR

ALARMS

DP in Inches of Wa ter Col umn

Gas Flow in Stan dard Cu bic Feet per Min ute

Gas Flow in Ac tual Cu bic Feet per Min ute

Mass Flow in Pounds per Hour

Process Tem per a ture in De grees Fahr en heit

Process Ab so lute Pres sure in PSI

MST2000 Alarm Sta tus

MMWC

NM3-HR

M3-HR

KG-HR

TEMP

ABS_PR

ALARMS

DP in mil li me ters of Wa ter Col umn

Gas Flow in Nor mal Cu bic Me ters per Hour

Gas Flow in Cu bic Me ters per Hour

Mass Flow in Ki lo grams per Hour

Process Tem per a ture in De grees Cel sius

Process Ab so lute Pres sure in Bar

MST2000 Alarm Sta tus

• The de fault dis play mode is ini tially set at the fac tory for inches of wa ter col umn (INWC) or mil li me ters of wa ter col umn (MMWC). The user may se lect other runtime flow vari ables by press ing

the INC (in cre ment) or the DEC (dec re ment) keys. Note: Eng lish or Met ric Unit Con fig u ra -

tions are not field selectable. They must be set at the fac tory.

• The MODE key is used to tog gle be tween RUN mode and PRO GRAM mode.

• The EDIT key is used to clear ‘latched’ alarms in runtime (RUN) mode.

Brandt Instruments, Inc. MST2000 Multivariable SMARTFLOW® Transmitter Page 11

Page 11

PROGRAMMING OPERATION MANUAL

7. PROGRAMMING

The MST2000 PROGRAM mode is ac cessed by press ing the MODE key. When the MODE key is

pressed one of the fol low ing will oc cur.

þ NOTE:

& The MST2000 can be Pass word pro tected to pre vent un au tho rized ac cess to pro gram ming pa ram e ters. The

MST2000 is shipped from the fac tory with the Pass word dis abled.

7.1 If the Pass word Pa ram e ter is En abled (else go to Sec tion 7.2)

A. The MST2000 will then dis play ENT_PW prompt ing the user to en ter the re quired pass word.

þ NOTE:

& The user must press the EDIT key within 4 sec onds to be gin en ter ing the cur rent pass word or the MST2000 will re -

turn to RUN mode. The pass word is a unique num ber be tween 1 and 9999 and is en tered as de scribed in Sec tion

7.5.

& Dur ing pass word en try, if no keys are pressed for more than 4 sec onds, the MST2000 will re turn to RUN mode.

7.2 If the Pass word Pa ram e ter is Dis abled or af ter the Pass word is suc cess fully en tered.

Af ter the pass word has been prop erly en tered, Brandt and verXXX will be mo men tarily dis played

and then fol lowed by the first avail able PROGRAM pa ram e ter.

þ NOTE: ver XXX indicates the installed soft ware re vi sion level.

7.3 Se lect the Pa ram e ter to Edit

A. Once the Pa ram e ters are dis played use the INC and DEC keys to scroll up and down through the

avail able pa ram e ters. See pa ram e ters, Sec tion 8.0.

B. To edit a se lected pa ram e ter, press the EDIT key and the ed it ing menus will be come ac tive.

C. Pa ram e ters are ei ther a nu meric value (ex am ple: Ef fec tive Area) or con trol a hard ware/op er at ing

mode.

7.4 Editing of a Hard ware/Op er ating Mode Pa ram e ter.

A. If a pa ram e ter con trols a hard ware or op er at ing mode fea ture, use the INC and DEC keys to scroll

through the avail able set tings.

B. Af ter the de sired set ting is se lected, press the EDIT key again to save the se lected set ting to mem -

ory.

C. The LCD will dis play SAVED for ap prox i mately 1 sec ond and then redisplay the new set ting.

7.5 Editing a Nu meric Value Pa ram e ter.

A. If the se lected pa ram e ter to edit is a nu meric value,

the ed it ing menus will dis play the cur rent value and

the cur rent cur sor po si tion for the dec i mal po si tion.

B. Use the INC and DEC keys to in cre ment or dec re -

ment the nu meric value at the cur rent cur sor po si -

tion.

C. To change the cur sor po si tion press the MODE

key. The LCD will dis play ‘x 1’ if the ones col umn is

to be changed, ‘x 10’ for the tens col umn, ‘x D1’ for

the tenths col umn, ‘x D01’ for the hun dredths col -

umn, etc. The num ber will not in cre ment or dec re -

ment if the pa ram e ter limit is reached. See the

Chart Be low and the ex am ples to the right.

Page 12 MST2000 Multivariable SMARTFLOW® Transmitter Brandt Instruments, Inc.

Page 12

OPERATION MANUAL PROGRAM PARAMETERS

LEFT OF

DECIMAL

X1 X X D1 X

X10 X X D01 X

X100 X X D001 X

X1K X X D0001 X

X10K X

X100K X

X1M X

1000000. 100000. 10000. 1000. 100. 10. 1.

RIGHT OF

DECIMAL

.1 .01 .001 .0001

D. Af ter the num ber is changed to the de sired value, press the EDIT key again to save the new value to

mem ory.

E. The LCD will dis play saved for ap prox i mately 1 sec ond and then redisplay the new set ting.

8. PROGRAM PARAMETERS

The Avail able PROGRAM pa ram e ters are shown be low along with a de scrip tion of how each pa ram e ter is ap plied. They are listed in the or der they ap pear in the PROGRAM menus.

Pa ram e ter De scrip tion Fac tory De fault

LCDCON LCD Con trast ad just ment. Avail able range is from 0 to 10. Use lower

set tings for best con trast in colder en vi ron ments and higher set tings for

best con trast in hot ter en vi ron ments.

5

420OUT 4-20 milliamp Out put as sign ment. Avail able as sign ments are: 0 = INWC or MMWC

Eng lish Units Ver sion: 0 = INWC (pri mary vari able), 1 = SCFM,

2 = ACFM, 3 = LBHR.

Met ric Units Ver sion: 0 = MMWC (pri mary vari able), 1 = NM3-HR,

2 = M3-HR, 3 = KG-HR

420_ZE 4 Milliamp Zero set ting. The 4 milliamp zero set ting ad justs the

milliamp lower range of the pri mary vari able (INWC or MMWC). The

avail able range is the nat u ral span of the dif fer en tial pres sure sen sor.

420_SP 20 Milliamp Span set ting. The 20 milliamp span set ting ad justs the

milliamp span value of the pri mary vari able (INWC or MMWC). The

avail able range is the nat u ral span of the dif fer en tial pres sure sen sor.

þ NOTE: The 420_SP value (span) must al ways be greater than the 420_ZE

value (zero) for proper op er a tion.

F_SPAN Flow Span set ting. The flow span set ting con trols the up per 4-20

milliamp value as sign ment (turn down) when the 4-20 out put is as signed to the runtime cal cu lated flow vari ables (SCFM, ACFM, LBHR

or NM3-HR, M3-HR, KG-HR). The lower 4-20 milliamp value as sign ment is al ways ref er enced to zero (0). The avail able range is:

Eng lish Unit Ver sion: 0 to 10,000,000 (no units).

Met ric Unit Ver sion: 0 to 50,000,000 (no units).

Set equal to the low

range of the natural

span.

Set equal to the

upper range of the

natural span.

20000

Brandt Instruments, Inc. MST2000 Multivariable SMARTFLOW® Transmitter Page 13

Page 13

PROGRAM PARAMETERS OPERATION MANUAL

Pa ram e ter De scrip tion Fac tory De fault

E_AREA Ef fec tive Area of flow me ter de vice. The ef fec tive area is re quired for

flow cal cu la tions and is en tered to be the same as shown on the Thermo

Brandt flow me ter la bel. The avail able range is:

Eng lish Unit Ver sion: 0.0000 to 500.0000 square feet.

Met ric Unit Ver sion: 0.0000 to 100.0000 square meters.

þ NOTE: Some flow me ter de vices use ‘K fac tors’ in stead of ef fec tive ar eas to

de fine mass flow re la tion ships. Ef fec tive ar eas can be cal cu lated from given

K fac tors. See For mulas, Sec tion 10.

þ NOTE: Thermo Brandt flow me ter de vices are spec i fied in square feet. To

con vert to square me ters, mul ti ply the square feet value by 0.0929.

STDDEN Standard Density. The standard density is required for mass flow

calculations and is entered for the specific gas being measured. The

standard density is entered at the standard reference temperature of 68

degrees F or 20 de grees C. The avail able range is:

Eng lish Unit Ver sion: 0.0000 to 2.0000 pounds per cu bic foot.

Met ric Unit Ver sion: 0.0000 to 40.0000 Ki lo grams per cu bic me ter.

TMPSRC Temperature source. Available assignments are 0 = CONstant,

1 = EXTernal and 2 = RTD.

TMPCON Temperature Constant. The temperature con stant can be used for

mass flow calculations when no external temperature inputs are

available and is entered as the average gas temperature. The avail able

range is:

Eng lish Unit Ver sion: -50.0000 to 900.0000 de grees F.

Met ric Unit Ver sion: -50.0000 to 900.0000 de grees C.

1.0000 for English.

0.0929 for Metric.

0.07517 for English.

1.20367 for Metric.

0 = CONstant

68.0000 for English.

20.0000 for Metric

RTDCAL RTD Calibration offset. The RTD calibration offset constant allows the

user to offset the actual measured value from the direct RTD input. The

value may be positive or negative and is entered in degrees F. The

available range is :

Eng lish Unit Ver sion: -10.0000 to 10.0000 de grees F.

Met ric Unit Ver sion: -10.0000 to 10.0000 de grees C.

EX_TPZ External Temperature Zero. The External Temperature Zero is the

lower range (4 milliamp zero) setting for the external 4-20 milliamp

‘temperature’ input channel. The available range is:

Eng lish Unit Ver sion: -50.0000 to 100.0000 de grees F.

Met ric Unit Ver sion: -50.0000 to 100.0000 de grees C.

TPZCAL Temperature Zero Calibration. The Temperature Zero Calibration

value is the 4 milliamp (zero) count value from the external 4-20 milliamp

‘temperature’ input channel. This parameter is used to calibrate the zero

point of the incoming 4-20 signal from the external 4-20 temperature

device. To calibrate the zero point of the incoming 4-20 signal, press the

EDIT key. The screen will display IN4MA. Set the incoming signal for 4

milliamps (or connect an external 4-20 calibrator set for 4 milliamps) and

press the EDIT key. The MST2000 will measure the external temperature

input channel and save the new 4 milliamp reference to memory.

0.0000

0.0000

4175

If an external

temperature option

is pre-installed and

calibrated at the

factory this will be

custom set for that

unit.

Page 14 MST2000 Multivariable SMARTFLOW® Transmitter Brandt Instruments, Inc.

Page 14

OPERATION MANUAL PROGRAM PARAMETERS

Pa ram e ter De scrip tion Fac tory De fault

EX_TPS External Temperature Span. The External Temperature Span is the

upper range setting for the external 4-20 milliamp ‘temperature’ input

channel. The avail able range is:

Eng lish Unit Ver sion: 0.000 to 990.0000 de grees F.

Met ric Unit Ver sion: 0.000 to 990.0000 de grees C.

TPSCAL Temperature Span Calibration. The Temperature Span Calibration

Value is the 20 milliamp (span) count value from the external 4-20

milliamp ‘temperature’ input channel. This parameter is used to

calibrate the span point of the incoming 4-20 signal from the external

temperature device. To calibrate the span of the incoming 4-20 signal,

press the EDIT key. The screen will display IN20MA. Set the incoming

signal for 20 milliamps (or connect an external 4-20 calibrator set for 20

milliamps) and press the EDIT key. The MST2000 will measure the

external temperature input channel and save the new 20 milliamp

reference to memory.

APRSRC Absolute Pressure Source. Available assignments are 0 = CONstant

and 1 = EXTernal.

þ Note: MST2000 DP sen sor max i mum op er at ing static pres sure is 25 PSID.

APRCON Absolute Pressure Constant. The absolute pressure constant can

be used for mass flow calculations when no external absolute pressure

input is available and is entered as the average absolute pressure

inside the duct. The avail able range is:

Eng lish Unit Ver sion: 0.000 to 100.0000 PSIA.

Met ric Unit Ver sion: 0.000 to 100.0000 Bar.

200.0000

21000

If an external

temperature op tion

is pre-installed and

calibrated at the

factory this will be

custom set for that

unit.

0 = CONstant

14.6960 for English.

1.01325 for Metric.

EX_APZ External Absolute Pressure Zero. The External Absolute Pressure

Zero is the lower range (4 milliamp zero) setting for the external 4-20

milliamp ‘absolute pressure’ input channel. The avail able range is:

Eng lish Unit Ver sion: 0.000 to 100.0000 PSIA.

Met ric Unit Ver sion: 0.000 to 100.0000 Bar.

þ Note: MST2000 DP sen sor max i mum

op er at ing static pres sure is 25 PSID.

APZCAL Absolute Pressure Zero Calibration The Absolute Pressure Zero

Calibration value is the 4 milliamp (zero) count value from the external

4-20 milliamp ‘absolute pressure’ input channel. This parameter is

used to calibrate the zero point of the incoming 4-20 signal from the

external 4-20 absolute pressure device. To calibrate the zero point of

the incoming 4-20 signal, press the EDIT key. The screen will display

IN4MA. Set the incoming signal for 4 milliamps (or connect an external

4-20 calibrator set for 4 milliamps) and press the EDIT key. The

MST2000 will measure the external absolute pressure channel and

save the new 4 milliamp reference to memory.

EX_APS External Absolute Pressure Span. The External Absolute Pressure

Span is the upper range setting for the external 4-20 milliamp ‘absolute

pressure’ input channel. The available range is:

Eng lish Unit Ver sion: 0.000 to 100.0000 PSIA.

Met ric Unit Ver sion: 0.000 to 100.0000 Bar.

þ Note: MST2000 DP sen sor max i mum

op er at ing static pres sure is 25 PSID.

0.000

4175

If an external

absolute pressure

option is

pre-installed and

calibrated at the

factory this will be

custom set for that

unit.

25.0000 for English.

1.7237 for Metric

Brandt Instruments, Inc. MST2000 Multivariable SMARTFLOW® Transmitter Page 15

Page 15

PROGRAM PARAMETERS OPERATION MANUAL

Pa ram e ter De scrip tion Fac tory De fault

APSCAL Absolute Pressure Span Calibration. The Absolute Pressure Span

Calibration value is the 20 milliamp (span) count value from the external

4-20 milliamp ‘absolute pressure’ input channel. This parameter is used

to calibrate the span point of the incoming 4-20 signal from the external

absolute pressure device. To calibrate the span point of the incoming

4-20 signal, press the EDIT key. The screen will display IN20MA. Set the

incoming signal for 20 milliamps (or connect an external 4-20 calibrator

set for 20 milliamps) and press the EDIT key. The MST2000 will measure

the external absolute pressure channel and save the new 20 milliamp

reference to memory.

INPUTO Input Offset. The Input Offset parameter allows the user to adjust

(calibrate) the actual pressure (zero) value to the MST2000 displayed

value. The input offset parameter is displayed and stored in memory as

counts. After the EDIT key is pressed, the edit menu displays the real

time pressure input. The user then uses the INC and DEC keys to adjust

the desired offset. The pressure input must be connected to a pressure

source and be at minimum range value (zero reference) during this

adjustment. Use the MODE key to adjust the cursor position (i.e.. x D1, x

D10, x D100, etc.) to change the offset count by different increments. The

available range is –50,000 to 50,000 counts (approximately +/- 20%

adjustment of full scale). The factory default is as set by the factory during

initial system calibration.

INPUTG Input Gain. The Input Gain parameter allows the user to adjust the gain

of the actual pressure (full scale) value to the MST2000 displayed value.

The input gain parameter is displayed and stored in memory as a gain

multiplier. After the EDIT key is pressed, the edit menu displays the real

time pressure input. The user then uses the INC and DEC keys to adjust

the desired gain. The pressure input must be connected to a pressure

source and at maximum range value during this adjustment. Use the

MODE key to adjust the cursor position (i.e.., x D1, x D01, x D001 etc.) to

change the gain multiplier by different increments. The available range is

0.8000 to 1.2000 (approximately +/- 20 % adjustment of full scale). The

factory default is as set by the factory during initial system calibration.

21000

If an external

absolute pressure

option is

pre-installed and

calibrated at the

factory this will be

custom set for that

unit.

This is a factory

default setting

determined during

calibration. It should

be recorded by the

user in the event it

will be necessary to

restore the Input

Offset to the original

value. This setting

is also recorded on a

label located under

the cover of the

MST2000.

This is a factory

default setting

determined during

calibration. It should

be recorded by the

user in the event it

will be necessary to

restore the Input

Gain to the original

value. This setting

is also recorded on a

label located under

the cover of the

MST2000.

OUTPTO Output Offset. The Output Offset parameter allows the user to adjust the

actual 4 milliamp (zero) output value as referenced to the MST2000

displayed zero value. The output offset parameter is displayed and

stored in memory as counts. After the EDIT key is pressed, the edit menu

displays the actual count offset and the microprocessor sets the output to

the 4.000 milliamp value. The user then presses the INC and DEC keys

to adjust the desired milliamp offset. Use the MODE key to adjust the

cursor position (i.e. x D1, x D10, x D100, etc.) to change the offset count

by different increments. The available range is –1,000 to 10,000 counts

(approximately 3.9 to 6.5 milliamp adjustment range). The factory default

is as set by the factory during initial system calibration.

Page 16 MST2000 Multivariable SMARTFLOW® Transmitter Brandt Instruments, Inc.

This is a factory

default setting

determined during

calibration. It should

be recorded by the

user in the event it

will be necessary to

restore the Output

Offset to the original

value. This setting is

also recorded on a

label located under

the cover of the

MST2000.

Page 16

OPERATION MANUAL PROGRAM PARAMETERS

Pa ram e ter De scrip tion Fac tory De fault

OUTPTG Output Gain. The Output Gain parameter allows the user to adjust the

actual 20 milliamp (span) output value as referenced to the MST2000

displayed full scale value. The output gain parameter is displayed and

stored in memory as a gain multiplier. After the EDIT key is pressed, the

edit menu displays the actual multiplier value and the microprocessor

sets the output to the 20.000 milliamp value. The user then uses the

INC and DEC keys to adjust the desired full scale milliamps. Use the

MODE key to adjust the cursor position (i.e., x D1, x D01, x D001 etc.)

to change the gain multiplier in different increments. The available

range is 0.8000 to 1.1000. (Approximately 16.5 to 20.5 milliamp

adjustment range). The factory default is as set by the factory during

initial system calibration.

þ NOTE: The minimum and maximum output current range is 3.9 milliamps

and 20.5 milliamps (3.8 milliamps is reserved for fault ‘low’ current and

21.0 milliamps is reserved for fault ‘high’ current).

þ Note: If HART

ited to 4.0 milliamps.

®

com mu ni ca tions are en abled, the min i mum cur rent is lim -

AVGFAC Averaging Factor. The Averaging Factor controls the digital filtering

level (damping) of the displayed pressure value (and the 4-20 milliamp

output). The average factor parameter controls the size (depth) of the

digital FILO (first in – last out) filter algorithm. Available range is 1 to 10.

The average factor does not affect the inherent update rate of the LCD

or 4-20 milliamp output (approximately two times per second) except

during power up initialization when the FILO registers are first being

loaded.

This is a factory

default setting

determined during

calibration. It should

be recorded by the

user in the event it

will be necessary to

restore the Output

Gain to the original

value. This setting

is also recorded on a

label located under

the cover of the

MST2000.

1= No Filtering

DEFDSP Default Display. The Default Display parameter assignment selects

the LCD display mode after power up and initialization. Available

assignments are:

Eng lish Unit Ver sion: 0 = INWC (pri mary vari able), 1 = SCFM, 2 = ACFM,

3 = LBHR or 4 = SCAN. Se lecting SCAN will cause the dis play to se quence

through the cal cu lated vari ables at 4 sec ond in ter vals.

Met ric Unit Ver sion: 0 = MMWC (pri mary vari able), 1 = NM3-HR, 2 =

M3-HR, 3 = KG-HR or 4 = SCAN. Se lecting SCAN will cause the dis play to

se quence through the cal cu lated vari ables at 4 sec ond in ter vals.

DSPRES Display Resolution. The Display Resolution parameter assignment

controls the number of digits that are displayed to the right of the

decimal. The display resolution can be set as fol lows:

Eng lish Unit Ver sion: From 1 to 4 Digits to the right of the dec i mal. Met ric

Unit Ver sion: From 1 to 3 Digits to the right of the dec i mal.

aLARMS The MST2000 has multiple alarm features. Alarms are available for

4-20 milliamp limit checks (under-range and over-range), RTD faults,

external 4-20 milliamp PCB communication failures and internal

hardware circuit faults. Alarms are enabled and disabled by setting the

individual binary bits in the ALARM WORD register to a ‘1’ or ‘0’

respectively. Since the individual binary bits cannot be displayed on the

LCD, the user must input the decimal word equivalent representing the

enabled and disabled bits. The individual alarm bit assignments and

the associated binary values are shown in Sec tion 9.

0 = INWC for

English.

0 = MMWC for

Metric.

3 = X.XXX

0 = Alarms Disabled

Brandt Instruments, Inc. MST2000 Multivariable SMARTFLOW® Transmitter Page 17

Page 17

PROGRAM PARAMETERS OPERATION MANUAL

Pa ram e ter De scrip tion Fac tory De fault

P_WORD Password. The password is used to prevent unauthorized access to the

programming parameters. The password may be any value between 0

and 9999. A password value of 0 disables the password feature.

BD_ENB Blow Down Enable. The Blow Down Enable parameter allows the user

to enable or disable the integrated blow down sys tem.

• A value of ‘0’ dis ables the Blowdown Sequence.

• A value of ‘1’ en ables the blowdown func tion with ex ter nal trig ger

only. An external trig ger must be ap plied to the ‘IN1’ ter mi nal to

ini ti ate the Blowdown se quence.

• A value be tween 2 and 1440 en ables the MST2000 to con trol the

Blowdown se quence on timed in ter vals (in min utes). The time in ter val be gins as soon as the MST2000 is put back in ‘RUN’

mode. For val ues be tween 2 and 1440 min utes, an ex ter nal trig ger may also be ap plied to com mand ad di tional blowdown se quences. The ex ter nal trig ger event does not re set the MST2000

blowdown in ter nal timer.

þ Note: The min i mum ex ter nal trig ger pulse width is 500 mil li sec onds.

HT_ENB HART En able. The HART

or dis able the HART® Com mu ni ca tion op tion. Avail able as sign ments are

0 = Dis abled and 1 = En abled.

þ Note: IF the HART

milliamp ‘un der range’ cur rent val ues are not al lowed on the 4-20mA out put

ter mi nals dur ing RUN Mode.

®

En able pa ram e ter al lows the user to en able

®

op tion is en abled, 3.8 milliamp ‘fault cur rent’ and 3.9

0 = Password

Disabled

0 = Blowdown

Disabled.

0 = Default if no

HART® option

installed.

1 = Enabled if

HART® option

installed.

Page 18 MST2000 Multivariable SMARTFLOW® Transmitter Brandt Instruments, Inc.

Page 18

OPERATION MANUAL ALARM PROGRAMMING INFORMATION

9. ALARM PROGRAMMING INFORMATION

9.1 Alarm ‘ENABLE’ Word Def i ni tion

The ALARM ‘ENABLE’ WORD (16 bit word) is divided into two 8 bit bytes. The lower order byte (bits 1 –

8) is used to enable and disable the alarm functions. The higher order byte (bits 9 – 16) is used to control

how the alarm is displayed and/or output to the user interface. Some bits are currently undefined and

reserved for future use.

BIT16BIT15BIT14BIT13BIT12BIT11BIT10BIT9BIT8BIT7BIT6BIT5BIT4BIT3BIT2BIT

32768 16384 8192 4096 2048 1024 512 256 128 64 32 16 8 4 2 1

9.2 Low Byte ‘BIT’ Def i ni tions

A. Under-range: En abling the un der-range alarm bit will cause the un der-range alarm to be come ac -

tive when the 4-20 milliamp out put cur rent reaches 3.9 milliamps.

B. Over-range: Enabling the over-range alarm bit will cause the over-range alarm to become active

when the 4-20 milliamp output current reaches 20.5 milliamps.

C. RTD Fault: Enabling the RTD fault alarm bit will cause the RTD fault alarm to become active if an

open circuit or short circuit is sensed in the 4-wire RTD loop connection. See Sec tion 9.3 G

D. ISO Comm er ror: En abling the ISO Comm er ror alarm bit will cause the ISO Comm er ror alarm(s)

to be come ac tive if any com mu ni ca tion er rors or hard ware faults are de tected from any of the ex ter nal 4-20 milliamp in put boards. (ISO = Iso lated Out put Mod ule). See Sec tion 9.3 G.

E. Hardware Fault: Enabling the Hardware Fault error alarm bit will cause the Hardware Fault error

alarm to become active if any internal hardware circuit faults (including microprocessor watchdog

timer faults) are detected from the MST2000 internal circuitry.

1

þ Note: For each alarm fault bit above, in di vid ual alarm sta tus bit(s) are pro vided in the ALARM STATUS word to

iden tify which alarm is ac tive. Each alarm sta tus bit and the as so ci ated bi nary val ues are de scribed later in this

sec tion.

9.3 High Byte ‘BIT’ Def i ni tions

A. Fail-low: Enabling the Fail-low bit will cause the 4-20 milliamp output to change to the fault current

value of 3.8 milliamps if any alarm is active.

B. Fail-high: Enabling the Fail-high bit will cause the 4-20 milliamp output to change to the fault current

value of 21.0 milliamps if any alarm is active.

C. Last-val: Enabling the Last-val bit will cause the 4-20 milliamp output to hold at the last value if any

alarm is active.

þ Note:

& The user must insure that only one of the 3 fault current control bits is set for proper operation.

& When entering PROGRAM mode, the 4-20 milliamp output current will change to the fault current as set by the fault

current control bits.

D. LCD Icon: Enabling the LCD Icon bit will cause the LCD ‘Alarm’ icon to be turned on if any alarm is

active.

Brandt Instruments, Inc. MST2000 Multivariable SMARTFLOW® Transmitter Page 19

Page 19

ALARM PROGRAMMING INFORMATION OPERATION MANUAL

E. Latched Output: Enabling the Latched Output bit will cause any active alarm to become latched

and held active even if the alarm condition clears. Any ‘latched’ alarms can be cleared during RUN

mode by pressing the EDIT key (if the active alarm(s) are no longer active). After pressing the EDIT

key, any latched alarms that are no longer active will be cleared and any alarms that are still active

will remain latched.

F. Digital Out1: Enabling the Digital Out1 bit will cause the digital output channel (OUT1) to change to

the LOW state if any alarm is active.

þ Note: The OUT1 (and OUT2) channels are ‘open collector’ style outputs. The user must externally

connect an active pull-up voltage to the output pins for proper operation. The maximum external pull-up

voltage that can be applied to the output pins is 24 volts DC.

G. Ex ter nal Con stants: En abling the Ex ter nal Con stants bit will cause the pro grammed con stants for

tem per a ture or pres sure to be used in the mass flow cal cu la tions if ei ther the ex ter nal tem per a ture

or pres sure in puts are se lected and in fault con di tions.

9.4 Alarm ‘STATUS’ Word Def i ni tion

The ALARM STATUS word indicates which alarms are active during RUN mode. Since the

individual binary bits cannot be displayed on the LCD, the decimal word equivalent representing the

active alarm status bits is displayed. The individual alarm status bit assignments and the associated

binary values are shown below.

þ Note: If alarms are ac tive, the alarm ICON on the LCD will be lit and the ALARM sta tus value will be dis -

played ev ery 10 sec onds. The user may also use the INC/DEC keys to ac cess the alarm sta tus value on

the LCD.

BIT16BIT15BIT14BIT13BIT12BIT11BIT10BIT9BIT8BIT7BIT6BIT5BIT4BIT3BIT2BIT

32768 16384 8192 4096 2048 1024 512 256 128 64 32 16 8 4 2 1

9.5 Alarm Sta tus ‘BIT’ Def i ni tions

A. Under-range: Indicates Under-range alarm is active.

• Bi nary value = 1.

B. Over-range: Indicates Over-range alarm is active.

• Bi nary value = 2.

C. RTD Fault: Indicates RTD fault (open circuit or short circuit) alarm is active.

• Bi nary value = 4.

D. ISO Comm1 error: Indicates communication or hardware fault error alarm from external 4-20 PCB

channel 1 is active.

• Bi nary value = 8.

E. ISO Comm2 error: Indicates communication or hardware fault error alarm from external 4-20 PCB

channel 2 is active.

• Bi nary value = 16.

F. ISO Comm3 error: Indicates communication or hardware fault error alarm from external 4-20 PCB

channel 3 is active.

• Bi nary value = 32.

1

Page 20 MST2000 Multivariable SMARTFLOW® Transmitter Thermo Brandt In stru ments

Page 20

OPERATION MANUAL ALARM PROGRAMMING INFORMATION

G. Hardware Fault: Indicates hardware fault error from MST2000 internal circuitry is active.

• Bi nary value = 64.

H. Watchdog Timer Fault: Indicates watchdog timer fault error from internal microprocessor is active.

• Bi nary value = 128.

9.6 Alarm ‘ENABLE’ Word Dec i mal Cal cu la tion Ex am ples

To calculate the decimal word equivalent for the ALARM ‘ENABLE’ WORD the user must determine

which alarms and alarm control bits are to be enabled and then sum the binary values of each enabled

bit. The decimal word equivalent is then programmed into the ALARM ‘ENABLE’ WORD using the

programming menus.

A. EXAMPLE 1

The user desires to enable the following alarm/alarm control enable bits:

LCD Icon, Fail-low, RTD Fault and Under-range.

a. LCD Icon bi nary value = 2048

b. Fail-low bi nary value = 256

c. RTD Fault bi nary value = 4

d. Un der-range bi nary value = 1

• Dec i mal equiv a lent sum = 2309 (dec i mal value to pro gram into ALARM ‘EN ABLE’ WORD).

B. EXAMPLE 2

The user desires to enable the following alarm/alarm control enable bits:

Digital Out1, Latched Output, Fail-high, ISO Comm error, Over-range and Under-range.

a. Dig i tal Out1 bi nary value = 8192

b. Latched Out put bi nary value = 4096

c. Fail-high bi nary value = 512

d. ISO Comm er ror bi nary value = 8

e. Over-range bi nary value = 2

f. Un der-range bi nary value = 1

• Dec i mal equiv a lent sum = 12811 (dec i mal value to pro gram into ALARM ‘EN ABLE’ WORD).

9.7 Alarm ‘STATUS’ Word Dec i mal De code Ex am ples

To determine which individual alarm status bits are active, the user must take the decimal equivalent

value from the ALARM ‘STATUS’ WORD register and decode it into the associated binary bit values.

This is accomplished using binary division of the decimal word. The examples below show manual

division. The user may also use a decimal to binary calculator to simplify this procedure.

A. Example 1

• ALARM ‘STATUS’ WORD = 37

• Using bi nary di vi sion, di vide the dec i mal word by each bi nary bit value start ing with the most sig -

nif i cant bit value (bit 8 = 128) and then each suc ces sive lower bit.

a.

37 B 128 = 0 with a re main der of 37.......bit 8 (Watch dog timer fault) = 0

b.

37 B 64 = 0 with a re main der of 37........bit 7 (Hard ware fault) = 0

c.

37 B 32 = 1 with a re main der of 5.........bit 6 (ISO comm3 er ror) = 1

d.

5 B 16 = 0 with a re main der of 5 .........bit 5 (ISO comm2 er ror) = 0

e. 5 B 8 = 0 with a re main der of 5...........bit 4 (ISO comm1 er ror) = 0

f.

5 B 4 = 1 with a re main der of 1...........bit 3 (RTD fault) = 1

g. 1 B 2 = 0 with a re main der of 1 ..........bit 2 (Over-range) = 0

h.

1 B 1 = 1 with a re main der of 0...........bit 1 (Un der-range) = 1

• The dec i mal ALARM ‘STATUS’ WORD of 37 in di cates the fol low ing ac tive alarms:

ISO Comm3 error, RTD fault and Under-range.

B. Example 2

Brandt Instruments, Inc. MST2000 Multivariable SMARTFLOW® Transmitter Page 21

Page 21

FORMULAS & CONVERSION FACTORS OPERATION MANUAL

• ALARM ‘STATUS’ WORD = 206

• Using bi nary di vi sion, di vide the dec i mal word by each bi nary bit value start ing with the most sig -

nif i cant bit value (bit 8 = 128) and then each suc ces sive lower bit.

a.

206 B 128 = 1 with a re main der of 78 ......bit 8 (Watchdog timer fault) = 1

b.

78 B 64 = 1 with a re main der of 14........bit 7 (Hard ware fault) = 1

c. 14 B 32 = 0 with a re main der of 14 ........bit 6 (ISO comm3 er ror) = 0

d.

14 B 16 = 0 with a re main der of 14 ........bit 5 (ISO comm2 er ror) = 0

e. 14 B 8 = 1 with a re main der of 6 ..........bit 4 (ISO comm1 er ror) = 1

f.

6 B 4 = 1 with a re main der of 2 ...........bit 3 (RTD fault) = 1

g.

2 B 2 = 1 with a re main der of 0 ...........bit 2 (Over-range) = 1

h.

0 B 1 = 0 with a re main der of 0 ...........bit 1 (Un der-range) = 0

• The dec i mal ALARM ‘STATUS’ WORD of 206 in di cates the fol low ing ac tive alarms:

Watchdog timer fault, Hardware fault, ISO Comm1 error, RTD fault and Over-range.

10. FORMULAS & CONVERSION FACTORS

The following formulas are used in the MST2000 software calculations:

• Velocity = × ÷1096845. DP Density

•

ACFM= × × × ÷Ae 667.657 DP T P

•

SCFM = × × × ÷Ae DP P T23972 677..

• LB/ HR = SCFM Standard × ×Density (@ F)

( )

( )

o

68 60

• Ae or Effective Area (sq.ft)= ×Kfactor Nominal Area (sq.ft). Thermo Brandt supplies the

Effective Area (Ae) specification with each of its flowmeters.

• Where:

6 Ve loc ity is in Feet per Min ute

6 DP (Dif fer en tial Pres sure) is in Inches of Wa ter Col umn

6 T (Tem per a ture) is in de grees Ran kine (de grees Ran kine = de grees Fahr en heit + 459.67)

6 P (Ab so lute pres sure) is in pounds per square inch (PSI)

6 Den sity is in pounds per cu bic foot (Lb/FT3)

6 Ae (Ef fec tive Area) is in Square Feet.

Met ric Con ver sion Fac tors

• Me ters per sec ond x 196.850 = Feet per min ute

• Bar x 14.5038 = PSIA

• Square me ters x 10.7643 = Square feet

• Mil li me ters of wa ter col umn B 25.4 = Inches of Wa ter Col umn

• Ki lo grams per hour x 2.205 = Pounds per hour

• Ki lo grams per cu bic me ter B 16.0136 = Pounds per cu bic foot.

• Cu bic meters per hour x 0.5885 = Cu bic feet per min ute

• (De grees C + 273.15) x 1.8 = de grees Ran kine

• Ae or Ef fec tive area (in square feet) = Kfactor x Nom i nal Area (square me ters) x 0.0929.

Thermo Brandt sup plies the Ef fec tive Area (Ae) spec i fi ca tion with each of its flowmeters. The

user must con vert to square me ters be fore en ter ing the ef fec tive are pa ram e ter in the ‘E_AREA’

pro gram ming menu.

11.

Page 22 MST2000 Multivariable SMARTFLOW® Transmitter Brandt Instruments, Inc.

Page 22

OPERATION MANUAL TEST JACK

TEST JACK

A Test Jack is stan dard on the Non I.S. Ap proved MST2000’ s. It al lows the user to mon i tor the mA out put of the unit with out dis con nect ing the loop. Re view di men sional draw ings on page 4. The Test Jack

is re moved for all I.S. and Di vi sion 2 ap proved MST2000’s.

To monitor the mA output of the MST2000 you will need a precision milliammeter. Push the positive lead

from the meter into the positive jack (RED) and the negative lead from the meter into the negative jack

(BLACK).

12. OPTIONAL MODULE INSTALLATION

The MST2000 Loop Powered Multivariable SMARTFLOW® Trans mit ter’s de sign is such that op tional in put, dig i tal I/O and HART® com mu ni ca tion mod ules can be in stalled in the field. This al lows the

user the ver sa til ity to change and adapt to dif fer ent ap pli ca tion needs. This sec tion con tains guide lines

for in stall ing the op tional mod ules and up dat ing the MST2000’s pro gram ming if nec es sary. Please re view this sec tion be fore at tempt ing to make any up grades. If there are any ques tions or prob lems

please call the fac tory for as sis tance.

þ NOTE:

& Any upgrades should be made in a clean and dust free environment.

& Anti-static discharge precautions should be adhered to.

12.1 Iso lated 4-20mA In put Mod ules (ISO Mod ule)

A. Thermo Brandt Part Number FP37-OPTN-ISO

a. The Iso lated 4-20mA In put Mod ule (ISO) al lows the MST2000 to ac cept an iso lated 4-20mA sig nal

from ei ther an Ab so lute Pres sure Trans mit ter or Ex ter nal Tem per a ture Trans mit ter. The 2nd D.P.

Trans mit ter Op tion is un avail able at the time this man ual was printed.

b. All iso lated 4-20mA In put Mod ules are iden ti cal, but they must be mounted in the cor rect lo c a tion on

the Main Board. See pho to graph and draw ings in this sec tion.

c. The Mod ule will be shipped in a sealed bag along with stand offs (2) and in struc tion sheet.

B. Installing the ISO Module Option.

a. Dis con nect all power from the MST2000.

b. De cide which slot the ISO Mod ule will fill. Re move the Op tion Cover La bel cov er ing that slot.

c. Take off the MST2000 Cover by re mov ing the 4 flat head screws. It is not nec es sary to re move the

Main Board from the hous ing.

d. Lo cate the slot, con nec tor and two mount ing holes for the ISO Mod ule on the Main Board.

e. Re move the ISO Mod ule and two (2) stand offs from the bag.

f. Snap the Stand offs into the two holes lo cated on the Main Board as shown in the draw ing. Note the

ori en ta tion of the stand off.

g.

Brandt Instruments, Inc. MST2000 Multivariable SMARTFLOW® Transmitter Page 23

Page 23

OPTIONAL MODULE INSTALLATION OPERATION MANUAL

Align the ISO Mod ule such that the re set but ton and LED are to ward the LCD and fac ing up. The

con nec tor will be on the bot tom of the board. Snap the ISO Mod ule into the stand offs while mak ing

sure the con nec tor and header are prop erly aligned.

h. Re place the cover.

i. Hook up the MST2000 as per the ter mi nal block wir ing di a gram on page 7.

j. Ap ply Power to the MST2000.

C. Programming the MST2000 to recognize the ISO Module(s)

a.

Re view Sec tion 7 on Pro gramming and Sec tion 8 on Pa ram e ters.

b. De pending on which slot the ISO Mod ule was in stalled, se lect one of the fol low ing pa ram e ters to edit:

c.

TMPSRC: Tem per a ture Source.

d.

APRSRC: Ab so lute Pres sure Source.

e.

Use the INC or DEC but tons to scroll to ‘1=EXT’ (1 = EX Ter nal)

f. Press the EDIT key to save this change to memory.

D. Calibrating the ISO Module

a. Ex ter nal Ab so lute Pres sure Trans mit ter ISO Mod ule . Re view the Pro gram Pa ram e ters in sec tion 8.

i. Con nect a 4-20 mA source to the Ab so lute Pres sure Trans mit ter ISO Mod ule in put ter mi nals

(marked EXTIN 1). See ter mi nal block draw ing on page 7.

ii.

Make sure pa ram e ter aprSRC (Ab so lute Pres sure Zero Source) is set to 1 (1 = EX Ter nal).

iii.

Set the EX_APZ (Ab so lute Pres sure Zero) pa ram e ter.

iv.

Set the APZCAL (Ab so lute Pres sure Zero Cal i bra tion) pa ram e ter:

.

. ! Ap ply 4.0 milliamps. Press the Edit Key to read and store the 4 milliamp cal i bra tion value.

.

. ! Ap ply 20.0 milliamps. Press the Edit Key to read and store the 20 milliamp cal i bra tion value.

! Press the Edit key. Dis play will change to read IN4mA.

v.

Set the EX_ABS (Ab so lute Pres sure Span) pa ram e ter.

vi.

Set the APSCAL (Ab so lute Pres sure Span Cal i bra tion) pa ram e ter.

! Press the Edit key. Dis play will change to read IN20mA.

þ NOTE: For those MST2400 with the Integral Absolute Pressure Transmitter option installed , the ISO

Module has been calibrated at the factory.

Page 24 MST2000 Multivariable SMARTFLOW® Transmitter Brandt Instruments, Inc.

Page 24

OPERATION MANUAL OPTIONAL MODULE INSTALLATION

b. Ex ter nal Tem per a ture Trans mit ter ISO Mod ule . Re view the Pro gram Pa ram e ters in sec tion 8.

i. Con nect a 4-20 mA source to the Ex ter nal Tem per a ture Trans mit ter ISO Mod ule in put ter mi nals

(marked EXTIN 2). See ter mi nal block draw ing on page 7.

ii.

Make sure pa ram e ter TMPSRC (Tem per a ture Source) is set to 1 (1 = EX Ter nal).

iii.

Set the EX_TPZ (Tem per a ture Zero) pa ram e ter.

iv.

Set the TPZCAL (Tem per a ture Zero Cal i bra tion) pa ram e ter.

.

. ! Ap ply 4.0 milliamps. Press the Edit Key to read and store the 4 milliamp cal i bra tion value.

.

. ! Ap ply 20.0 milliamps. Press the Edit Key to read and store the 20 milliamp cal i bra tion value.

! Press the Edit key. Dis play will change to read IN4mA.

v.

Set the EX_TPS (Tem per a ture Span) pa ram e ter.

vi.

Set the TPSCAL (Tem per a ture Span Cal i bra tion) pa ram e ter.

! Press the Edit key. Dis play will change to read IN20mA.

12.2 Dig i tal In put / Out put Mod ule In stal la tion

A. Thermo Brandt Part Number FP37-OPTN-DIO

a. The Dig i tal I/O mod ule al lows the MST2000 to ac cept one (1) dig i tal in put and out put (1) dig i tal out -

puts.

b. The Dig i tal I/O mod ule must be in stalled on the right most con nec tor. See pho to graph and draw ings

in this sec tion.

c. The Dig i tal I/O module will be shipped in a sealed bag along with stand offs (2) and in struc ti on sheet.

B. Installing the Digital I/O Module Option.

a. Dis con nect all power from the MST2000.

b. Take off the MST2000 Cover by re mov ing the 4 flat head screws. It is not nec es sary to re move the

Main Board from the hous ing.

c. Lo cate the slot, con nec tor and two mount ing holes for the Dig i tal I/O module on the Main Board.

d. Re move the Dig i tal I/O module and two (2) stand offs from the bag.

e. Snap the standoffs into the two holes lo cated on the Main Board as shown in the draw ing. Note the

ori en ta tion of the stand offs.

f. Align the Dig i tal I/O mod ule such that con nec tor will be on the bot tom of the board. Snap the module

into the stand offs while mak ing sure the con nec tor and header are prop erly aligned.

g. Re place the cover.

h. Hook up the MST2000 as per the ter mi nal block wir ing di a gram on page 7.

i. Ap ply Power to the MST2000.

C. For Dig i tal I/O wiring con fig u ra tions see sec tion 14.

12.3 HART® Com mu ni ca tions Mod ule

A. Thermo Brandt Part Number FP37-OPTN-HART

a. The HART® Com mu ni ca tion mod ule al lows the MST2000 to com mu ni cate with stan dard HART® In -

ter faces.

b. The HART® Com mu ni ca tion mod ule must be in stalled on the up per left most con nec tor. See pho to -

graph and draw ings in this sec tion.

c. The HART® Com mu ni ca tion mod ule will be shipped in a sealed bag along with stand offs (2) and in -

struc tion sheet.

B. In stalling the HART® Com mu ni ca tion Mod ule Op tion.

a. Dis con nect all power from the MST2000.

b. Take off the MST2000 Cover by re mov ing the 4 flat head screws. It is not nec es sary to re move the

Main Board from the hous ing.

c. Lo cate the slot, con nec tor and two mount ing holes for the HART® mod ule on the Main Board.

d. Re move the HART® mod ule and two (2) stand offs from the bag.

e. Snap the Stand offs into the two holes lo cated on the Main Board as shown in the draw ing. Note the

ori en ta tion of the stand off.

f.

Brandt Instruments, Inc. MST2000 Multivariable SMARTFLOW® Transmitter Page 25

Page 25

MST2000 HART® Communications Information OPERATION MANUAL

Align the HART® mod ule such that con nec tor will be on the bot tom of the board. Snap the mod ule

into the stand offs while mak ing sure the con nec tor and header are prop erly aligned.

g. Re place the cover.

h. Hook up the MST2000 as per the ter mi nal block wir ing di a gram on page 7.

i. Ap ply Power to the MST2000.

13. MST2000 HART® Communications Information

13.1 Power and Loop Con di tions

The MST2000 Multivariable differential pressure transmitter is a HART® conforming loop-powered

4-20 milliamp transmitter. Power connection is made at the two left terminal positions marked LOOP+

and LOOP-. Nominal power supply voltage is 24 volts DC which allows up to 600 ohms series

resistance in the loop circuit. Higher loop resistance can be used with higher power supply voltages as

required. See the loop resistance-voltage graph below in determining the minimum loop voltage

required.

Note: For HART® communication applications, minimum loop resistance is 250 ohms.

13.2 HART® Con nec tions

Maximum resistance

versus DC loop voltage

All electrical connections are per standard HART® connections. Refer to HART® Communication

Foundation Document HCF_SPEC-54 (HART® FSK Physical Layer Specification, Revision 8.0) for

additional information. The current sense resistor may be connected in either the high or low side of the

field loop wiring. HART® communication devices must be connected in accordance with

HCF_SPEC-54 for proper operation. Typical connection methods are shown in the following diagrams.

13.3 Ca bling Re quire ments

The field wiring of a HART® based system should use shielded twisted pair cable. When using cable

with multiple twisted pairs, it is important not to use the other pairs for signals that might interfere with

the HART® communication signals.

Typical multi-drop

connection with digital

communications.

Page 26 MST2000 Multivariable SMARTFLOW® Transmitter Brandt Instruments, Inc.

Page 26

OPERATION MANUAL MST2000 HART® Communications Information

Typical Point to Point

Connection with

analog signaling.

If the ca ble is lon ger than sev eral me ters, it’s re sis tance and ca pac i tance may be come sig nif i cant in the

HART® RC time-constant lim i ta tion ® x C [ 65 mi cro sec onds). When us ing a sin gle field de vice and a

host with a 250 ohm load and no other sig nif i cant re sis tance, the 65 mi cro sec ond lim i ta t ion would al low

0.26 uF of ca pac i tance for the sys tem. Al lowing 0.01 uF (10,000 pF) for the host and field de vice (each

hav ing a CN=1), the to tal ca ble ca pac i tance could be up to 0.25 uF. How ever, if the ca ble re sis tance

was 110 ohms, the sys tem re sis tance be comes 360 ohms, which then al lows for a to tal per mit t ed ca ble

ca pac i tance of 0.18 uF. This cor re sponds to a nom i nal ca ble length of 900 me ters for a ca ble with a rat ing of 200 pF/me ter. If the ca ble needs to be ex tended up ward to wards the max i mum HART® ca ble

length of 1500 me ters, a ca ble with a lower ca pac i tance rat ing must be se lected.

• In a multi-dropped sys tem, the ad di tional ca pac i tance from each net worked trans mit ter must

also be con sid ered. Each trans mit ter has an es tab lished CN value. A CN value of 1 in di cates

that the trans mit ter rep re sents 5000 pF of load ca pac i tance.

• The MST2000 trans mit ter has a CN Value of 1 ( 5000pF).

• The in ter nal re sis tance of the MST2000 trans mit ter is in ex cess of 100,000 ohms and can be ig -

nored in the ca ble length cal cu la tions.

13.4 HART® Com mu ni ca tion Dis tance

Up to 1.5 km (1 mile) when using multiple twisted pair cables. Communication distance varies

depending on type of cable used.

Use the following formula to determine cable length for specific applications:

6

C

+

10000

×

65 10

L

=

R C

×

( )

Where:

L = Length in Meters or Feet

R = Resistance in Ohms (Ω ) including barrier resistance.

C = Cable capacitance in pF/m or pF/ft

Cf = Maximum shunt capacitance of receiving devices in pF/m or pF/ft.

13.5 Power Sup ply Re quire ments

To minimize signal degradation of the HART® communication signals, the following power supply

specifications are required.

• Volt age: .......................24 V DC (typ i cal)

• Max i mum rip ple (47 to 125 Hz): ..........0.2 V (peak to peak)

• Max i mum noise (500 Hz to 10 kHz): ........1.2 mV

• Max i mum se ries im ped ance (500 Hz to 10 kHz):..10 ohms

( )

f

−

C

Brandt Instruments, Inc. MST2000 Multivariable SMARTFLOW® Transmitter Page 27

Page 27

MST2000 HART® Communications Information OPERATION MANUAL

13.6 In trin sic Safety Con sid er ations

Intrinsic safety approvals for the MST2000 are pending. Contact the factory for additional information

involving hazardous applications with the use of safety barriers.

13.7 HART® Com mand In for ma tion

The MST2000 transmitter is compliant with HART® Command Revision 5.1. The following commands

are supported. Reference HART® Document HCF_LIT-20 (HART® Technical Overview) for additional

information.

COMMAND HART® Command Set Description

0 Universal Read Unique Identifier

1 Universal Read Primary Variable (pv)

2 Universal Read (pv) current and percent of range

3 Universal Read (pv) current and four predefined variables

6 Universal Write Polling Address

11 Universal Read Unique Identifier associated with Tag

12 Universal Read Message

13 Universal Read Tag, Descriptor, Date

14 Universal Read sensor information

15 Universal Read output information

16 Universal Read final assembly number

17 Universal Write message

18 Universal Write tag, descriptor, date

19 Universal Write final assembly number

35 Common Practice Write (pv) range values

50 Common Practice Read dynamic variable assignments

51 Common Practice Write dynamic variable assignments

59 Common Practice Write number of response preambles

pv = primary vari able

13.8 Thermo Brandt In stru ments HART® Man u fac turer Iden ti fi ca tion Code = 96 Hex, 150 Dec i mal

13.9 MST2000 HART® Trans mit ter Vari able Code As sign ments.

Vari able Code ENGLISH UNIT VERSION METRIC UNIT VERSION

0 or 1 DP in Inches of W.C. D.P. In Mil li me ters of W.C.

2 Stan dard Cu bic Feet Per Min ute (SCFM) Nor mal Cu bic Me ters Per Hour (NM3-HR)

3 Ac tual Cu bic Feet per Min ute (ACFM) Cu bic Me ters per Hour (M3-HR)

4 Mass in Pounds per Hour (LB/HR) Mass in Ki lo grams per Hour (KG-HR)

5 Ex ter nal Tem per a ture in Degree Fahr en heit Ex ter nal Tem per a ture in De gree Cel sius