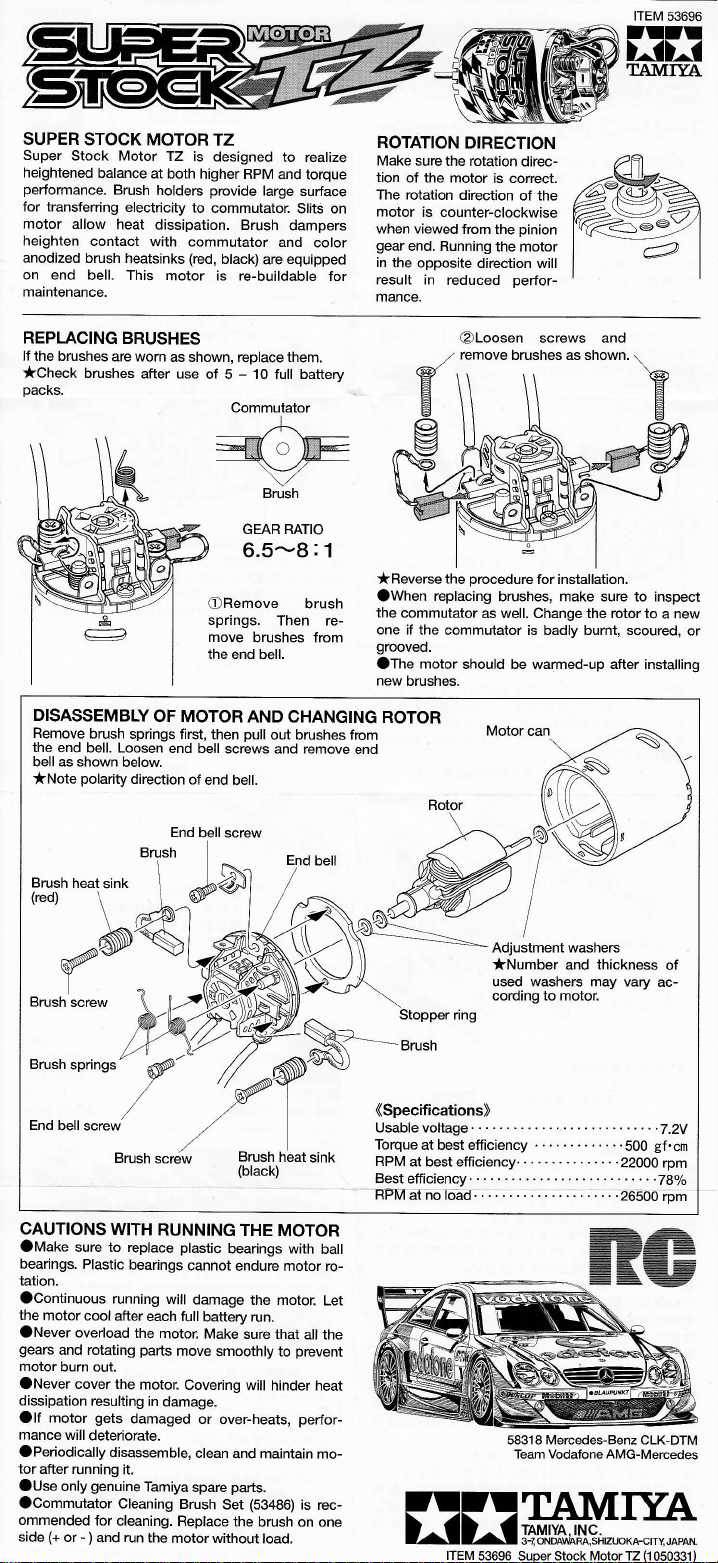

Page 1

ITEM

53696

'I'I

)^l)^l

TAMTYI\.

SUPER

Super

heightened

performance.

for transferring

STOCK MOTOR

Stock Motor

balance

Brush holders

motor allow

heighten

anodized brush

on end

maintenance.

contact

bell. This

REPI.ACING

lf

the brushes

*Check

packs.

are worn

brushes

DISASSEMBLY

Remove

brush

the

end bell. Loosen

bell as shown

polarity

*Note

TZ

TZ

is designed

at both

higher RPM and

electricity to

heat

provide

commutator.

dissipation. Brush

with commutator

heatsinks

BRUSHES

after use

black)

ted,

motor is re-buildable for

as shown, replace them.

of 5

Commutator

q"JE

(DRemove

springs.

move brushes from

the end bell.

OF MOTOR

springs first,

below.

direction

then

end bell

screws and remove

of

end bell.

to realize

torque

large

surface

Slits on

dampers

and

color

equipped

are

10 full battery

-

,\

\,/

Brush

GEAR RATIO

6.5-8: 1

brush

Then re-

AND CHANGING

pull

out brushes from

ROTATION

Make

tion

The rotation

motor

when viewed

gear

in

the opposite

result in

mance.

*Reverse

OWhen

the

commutator

one if the

grooved.

OThe

new brushes.

ROTOR

end

DIRECTION

sure the rotation

of the motor

direction

direc-

is correct.

of the

is counter-clockwise

pinion

from the

end. Running

replacing

motor

the motor

direction will

reduced

the

commutator is badly burnt, scoured,

perfor-

@Loosen

remove

procedure

should be warmed-up after installing

screws

brushes as shown.

for installation.

brushes, make sure to inspect

as well. Change the rotor to

and

y

a new

or

End bell screw

Brush

springs

End

bell scre#

Brush

scrJw

CAUTIONS

OMake sure to replace

bearings. Plastic

tation,

lDContinuous

the

motor

ONever

gears

motor

(DNever

dissipation resulting

motor

Olf

mance

aPeriodically disassemble,

tor after running

OUse only

OCommutator Cleaning

ommended

(+

side

WITH

running

cool after

overload

and rotating

burn

out.

cover the

gets

will

deteriorate,

genuine

for

cleaning. Replace

-

or

and

)

RUNNING

bearings

each full

the

motor. Make

parts

motor.

in

damage.

damaged

it.

Tamiya

run

the

will

ä)

THE

plastic

bearings with

cannot

endure motor ro-

damage

battery run.

move

Brush

motor without

sure that

smoothly to

Covering will

or over-heats,

clean

and maintain mo-

parts.

spare

Set

the

End

MOTOR

the motor^

all the

prevent

hinder heat

perfor-

(53486)

is rec-

brush on one

load.

bell

Stopper ring

-Brush

(Specifications)

Usablevoltage.

Torque

RPM

at bestefficiency....

Best

efficiency.

BPM at no löad

ball

Let

ftftffiffi,,"**

Adjustment washers

*Number

used washers may vary

cording to motor.

at best efficiency

.

. . .26500

'

5831 I Mercedes-Benz CLK-DTM

Team Vodafone AMc-Mercedes

ITEM

53696 Super Stock Motor TZ

thickness

and

...-......7.2V

. . ...500

...22000

....-.. . ..78o/o

:-

E--:

-:-EE==

::-.-

-=

-:

(1

of

ac-

gf.cm

rpm

rpm

=E

050331

)

Loading...

Loading...