Page 1

HV Series

HV1000

One (1) HV1000 Whole House Ventilator

One (1) White Metal Grille w/(6) Screws

One (1) Package of Foam Gasket

One (1) Electrical Box Cover w/(2) Screws

One (1) Wall Switch (SPST)

Four (4) #8x3/4 Screws

One (1) Grounding Screw (green)

HV1600

One (1) HV1600 Whole House Ventilator

One (1) White Metal Grille w/(6) Screws

One (1) Package of Foam Gasket

Four (4) #8x3/4 Screws

One (1) Hand Held Remote Transmitter

Whole House Ventilators

Product Manual & Installation Guide

HVM.03

PLEASE LEAVE WITH HOMEOWNER

Read all instructions carefully before installing your HV

Serial Number _________ Date of Purchase __________Point of Purchase _________________

The serial number is located on the shipping carton and on a label affixed to the upper housing.

Unpacking your HV: When you have unpacked your HV carefully you will find the following:

The Best Location for your HV: The HV should be installed in your attic in a central location within your

home. Above a central hallway or at the top of a stairwell will provide the best airflow. The fan can be mounted vertically.

► Make sure that there aren’t any pipes, wires, rafters or air conditioning or heating ducts running through the space

where the HV will be installed and that the doors will open into an unoccupied area.

► Make sure that you have adequate exhaust area out of your attic. This can be accomplished with a combination of roof,

ridge, soffit or gable end vents or other attic exhaust points. The HV1000 requires a minimum of 2 square feet and the

HV1600 requires 3.5 square feet of clear exhaust area. Allow 50% loss of clear area for louvers and screens

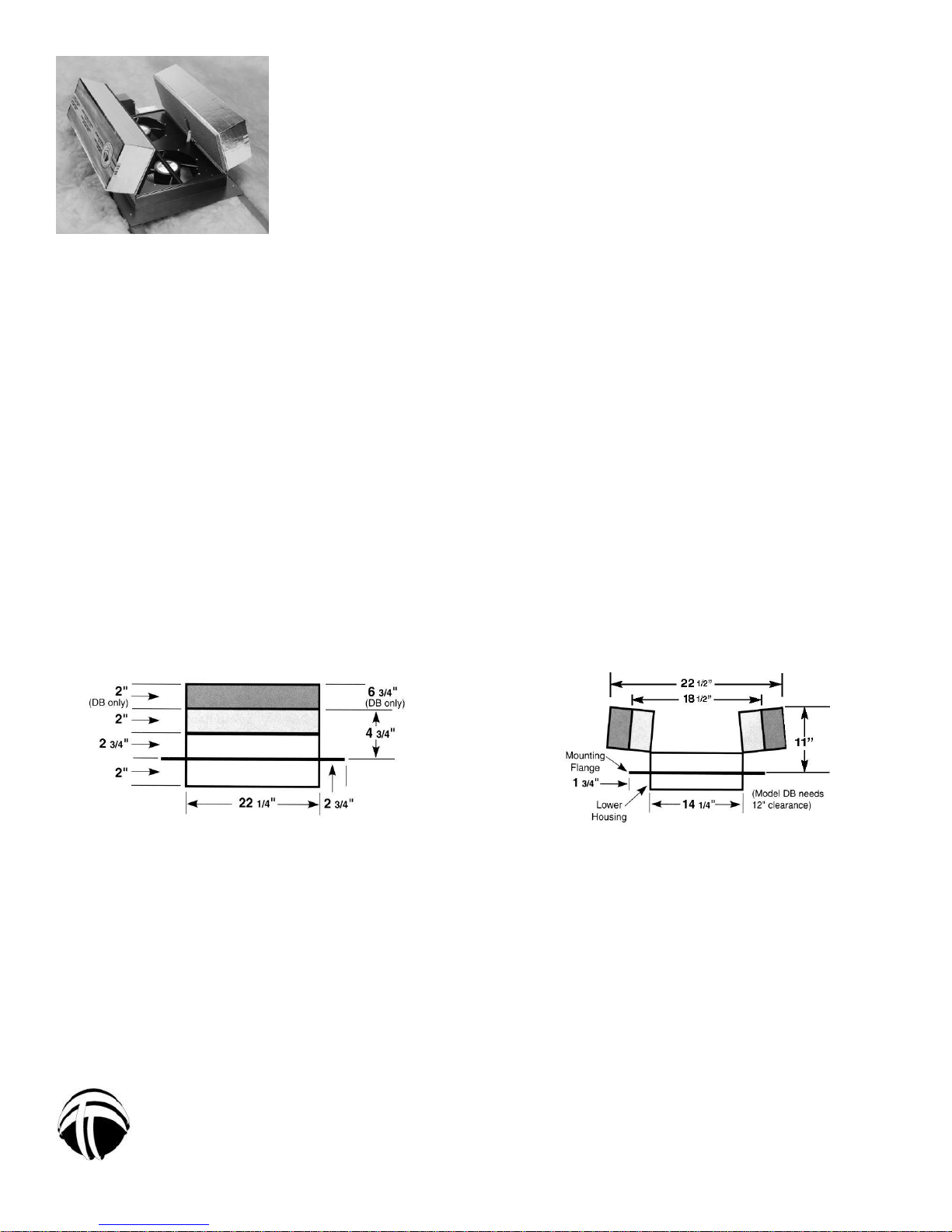

► Make sure that there is enough clearance above the fan for the doors to open. The minimum requirement for the HV

with R22 insulating doors is 11” and 12” is required for models with R38 insulating doors.

WARNING To reduce the risk of Fire, Electric Shock, or Injury to persons, observe the following:

Use this unit in the manner intended by the manufacturer. If you have any questions, contact the manufacturer.

Installation work and electrical wiring must be done by a qualified person(s) in accordance with all applicable codes and

standards, including fire rated construction.

Before servicing or cleaning unit, switch power off at service panel and lock service panel to prevent power from being

switched on accidentally. When the service disconnecting can not be locked, securely fasten a prominent warning device,

such as a tag, to the service panel.

When cutting or drilling into wall or ceiling, do not damage electrical wiring or other hidden utilities.

Never place a switch where it can be reached from a tub or shower.

Do not use this fan over cooking appliances.

Do not use this fan over a tub or shower.

Do not use this fan with any solid state speed control device.

CAUTION: For general ventilation use only. Do not use to exhaust hazardous or explosive materials and vapors.

Tamarack Technologies, Inc.• 320 Main Street • Buzzards Bay, MA 02532

508-759-4660 • 800-222-5932 • Fax 508-759-6001 www.tamtech.com

Page 2

Installation

Tools and supplies needed

You will need two pieces of 2x stock to match your existing framing, a saw to cut the hole in the

ceiling, a hammer or screw gun to attach the blocking to the existing joists and a Phillips head

screw driver to attach the grille.

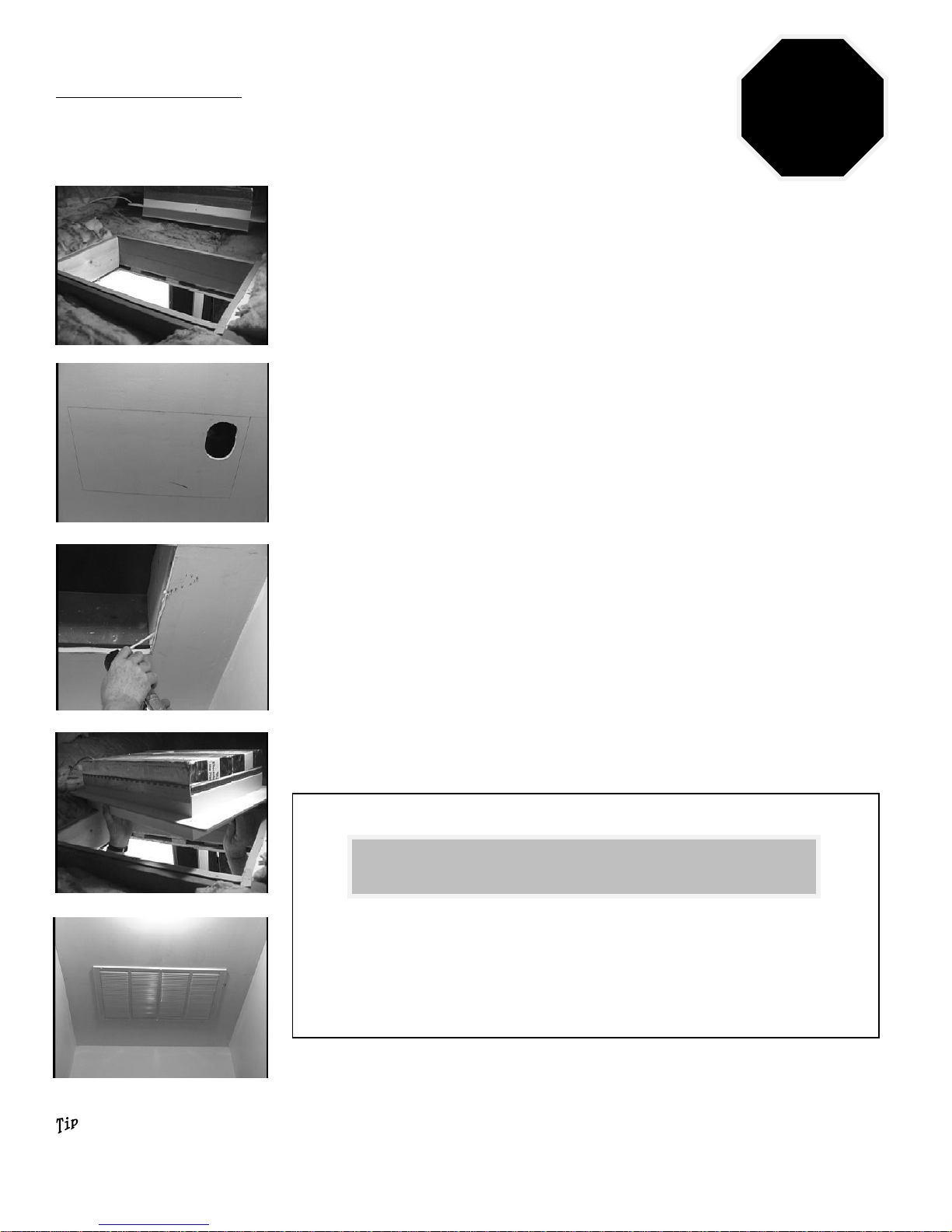

Figure 1

Figure 2

Figure 3

Figure 4

Figure 5

1. The fan housing will fit either 16” or 24” on center framing. Cut two pieces of 2x stock

(2 x 6 or 2 x 8 etc.) of the same dimension as the existing joists. Add these pieces of

framing to form a box between the joists. (Figure 1).

2. Cut a hole in the ceiling under where the HV will be installed. The hole should be no

larger than 14 1/2" x 22 1/2". This will allow for the grille to cover the exposed edges.

The suggested method for making the proper sized hole in the ceiling is; cut a pilot hole

under where the fan will be installed. (Figure 2) From above, using a saw, cut along the

inside edge of the framework removing the ceiling panel and any strapping within the

frame. Do not damage electrical wiring or other hidden utilities.

3. Install the foam gasket (supplied) on the top of the joists and added framing. Check

the joint between the ceiling and the 2x stock. Some types of ceilings are spaced away

from the joists. Any gap between the 2x’s and the ceiling should be sealed prior to final

installation. (Figure 3) Use a low expansion spray foam sealant (not supplied).

4. Set the HV on the gasket with the doors facing to open into the attic. The lower

housing will fit into the box with the mounting flanges overlapping the joists. (Figure 4)

The HV should not be forced into this opening. Forcing it into place may cause the

doors to bind and not function properly.

5. If desired, secure the HV to the top of the joists using the #8x3/4 screws provided.

When fastening the mounting flange to the joists care should be taken that all screws

are tightened evenly to avoid the door hinges binding.

6. Wire the HV as shown in the Wiring section of this manual. It is recommended that

the wiring of the HV be done by a licensed electrician.

7. Check the HV for proper operation. Turn the unit on and allow 30 seconds for the

doors to fully cycle open and the fans to start. DO NOT FORCE THE DOORS OPEN.

8. Install the grille (6 screws included) on the ceiling below the fan. (Figure 5)

DO NOT

PULL ON,

CARRY BY

OR STRESS

THE DOORS

Operating your HV

HV1000 - The HV1000 is operated by the wall switch installed per the wiring

instructions. An optional remote control kit is available (Part# TTi-HVRC).

HV1600 - The HV1600 is controlled by the hand held remote transmitter.

Additional controls, when used, may override the remote control. See the Wiring

section of this manual for further details.

IMPORTANT

Be sure at least one window is open when the fan is operating

Some owners find the installation has a more finished look when the inside of the blocking has been painted before

the unit is installed and the grille is put in place.

Page 3

Wiring

Be sure to turn off power before wiring the HV Whole House Fan

HV1000

HV1600 (Optional Wiring)

Hardwiring the unit to wall switches using the BLUE and

YELLOW wires will provide additional, manual control.

Using these switches will override the remote control

function.

Specifications

Voltage …………………………….

Power

HV1000…………………..….......

HV1600…………………..….......

Airflow @ .03” (System)

HV1000 …………..............…….

HV1600 High……………...…….

HV1600 Low ……………………

115VAC 60 Hz

147 Watts

227 Watts

1000 CFM

1600 CFM

900 CFM

R-Value

HV1000 & HV1600-GR …………

HV1000-DB & HV1600-GDR…..

Weight

HV1000………………………..….

HV1600……………………………

Rough Opening……………………

Grille Dimensions………………….

Grille Color ………………………...

R-22

R-38

17 Lbs.

21 Lbs.

14 ½” x 22 ½”

15 ¾” x 25 ¾”

White

Important - Wiring the HV is different than a normal ON/OFF fan. Because the doors are motorized, they need power to

open and power to close. The HV requires a constant source of power. The fan operation is controlled internally.

Please follow the instructions carefully. It is recommended that the wiring of the HV be done by a licensed electrician.

The HV whole house cooling fans are not for use with solid state speed controls

Care

All the motors in the HV are permanently sealed and do not require oiling. To keep dirt, dust and debris from the fans we

recommend that you periodically remove the grille from within the living space and dust the fan blades. Please remember

to make sure that the fan is OFF before dusting the fan blades.

Page 4

Troubleshooting

Switch

Doors

Fans

Possible Cause

Try

On

Do Not Open

Do Not Run

No Power

Check connections and circuit breakers

On

(audible “click”)

Do Not Open

Do Not Run

No constant power on RED

Check wiring connections. There must be

constant power on the red wire.

Off

Do Not Close

Stop

RED and BLACK are connected

together

Check wiring connections. Connections at the

fan must be made individually.

On

Both Open

One Fan Runs

Something blocking fan rotation

Turn the power off and check for foreign

matter blocking blade rotation.

On

Both Open- One

closes then

opens ...

One Fan Runs

Door motor gears or switch may

have been stressed during

installation. Framing opening may

be too small.

Remove fan from between joists and test

operation while fan is sitting on top of joists. If

the fan operates, enlarge the opening and

return the fan to installed position.

Off

Both ClosedOne opens then

closes…

Stop

Door motor gears or switch may

have been stressed during

installation. Framing opening may

be too small.

Remove fan from between joists and test

operation while fan is sitting on top of joists. If

the fan operates, enlarge the opening and

return the fan to installed position.

HV1000: The most common problem with the HV1000 is caused by incorrect wiring. Before you check anything else make sure:

WHITE wire in HV1000 is connected to 115 VAC Line Neutral; RED wire in HV1000 is connected to 115 VAC Line Hot (Constant Hot

Feed); BLACK wire in HV1000 is connected to a switch that will make it hot when the switch is closed.

HV1600: If the wireless remote fails to activate the fan, the battery may need replacing. The transmitter uses a type A23/12V battery.

Remove the back plate from the transmitter and remove the battery. Following the markings, replace the battery. Secure the back plate

to the transmitter.

Our unique energy saving system, the R-Gardian, is designed for homes with blown in insulation and will protect

your insulation when using an HV Whole House Ventilator (R22 model only). The R-Gardian may be purchased separately.

LIMITED WARRANTY

If, within the period of three years from the date of purchase, the HV 1000 or HV 1600 (the Product) is defective or

malfunctions in normal home use, Tamarack Technologies, Inc. will repair or replace the Product, at its discretion.

Customer is responsible for shipping charges. NOTE: Some states codes require fans to be hardwired. Hardwiring of the

HV1600 will not void warranty provided the wiring is performed by a licensed electrician.

Conditions, Exclusions, and Limitations-This Warranty is subject to the following conditions, exclusions and limitations:

THIS WARRANTY DOES NOT COVER PROBLEMS RESULTING FROM INSTALLATION, OPERATION OR MAINTENANCE THAT HAS BEEN

UNDERTAKEN OTHER THAN IN ACCORDANCE WITH THE INSTRUCTIONS. THIS WARRANTY DOES NOT COVER PROBLEMS RESULTING

FROM DEFECTS IN OR CAUSED BY ASSOCIATED EQUIPMENT (FURNACES, SOLARIA, ETC.); FROM REPAIRS OR MODIFICATIONS

ATTEMPTED BY PERSONS OTHER THAN TAMARACK TECHNOLOGIES, INC.; FROM ABUSE, ACCIDENTAL OR SHIPPING DAMAGE OR ACTS

OF GOD. THIS WARRANTY DOES NOT APPLY TO THE PRODUCT USED OUTSIDE THE UNITED STATES, ITS TERRITORIAL POSSESSIONS,

AND CANADA. EXCEPT AS SET FORTH ABOVE, NO EXPRESS OR IMPLIED WARRANTY IS GIVEN OR AUTHORIZED BY TAMARACK

TECHNOLOGIES, INC. AND ALL OTHER SUCH WARRANTIES ARE EXPRESSLY DISCLAIMED. ANY WARRANTY OR MERCHANTABILITY OF

FITNESS FOR ANY PARTICULAR PURPOSE SHALL BE LIMITED TO THE WARRANTY HEREUNDER. MOREOVER, ANY LIABILITY OF

TAMARACK TECHNOLOGIES, INC. FOR THE PRODUCT SHALL BE LIMITED TO THE REPLACEMENT VALUE OF THE PRODUCT. IN NO EVENT

SHALL TAMARACK TECHNOLOGIES, INC. BE LIABLE FOR ANY INCIDENTAL DAMAGES OR FOR ANY CONSEQUENTIAL PROPERTY OR

COMMERCIAL DAMAGES, IRRESPECTIVE OF THE CAUSE THEREOF, OCCURRING EITHER DURING OR AFTER THE WARRANTY PERIOD,

INCLUDING WITHOUT LIMITATION ANY DAMAGES TO ANY PART OF A BUILDING OR ITS CONTENTS.

NOTE: SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES AND SOME

STATES DO NOT ALLOW LIMITATIONS ON HOW LONG AN IMPLIED WARRANTY LAS TS, SO THE ABOVE LIMITATIONS OR EXCLUSIONS MAY

NOT APPLY TO YOU. THIS WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS AND YOU MAY ALSO HAVE OTHER RIGHTS THAT VARY FROM

STATE TO STATE.

Tamarack Technologies, Inc.• 320 Main Street • Buzzards Bay, MA 02532

508-759-4660 • 800-222-5932 • Fax 508-759-6001 www.tamtech.com

Loading...

Loading...