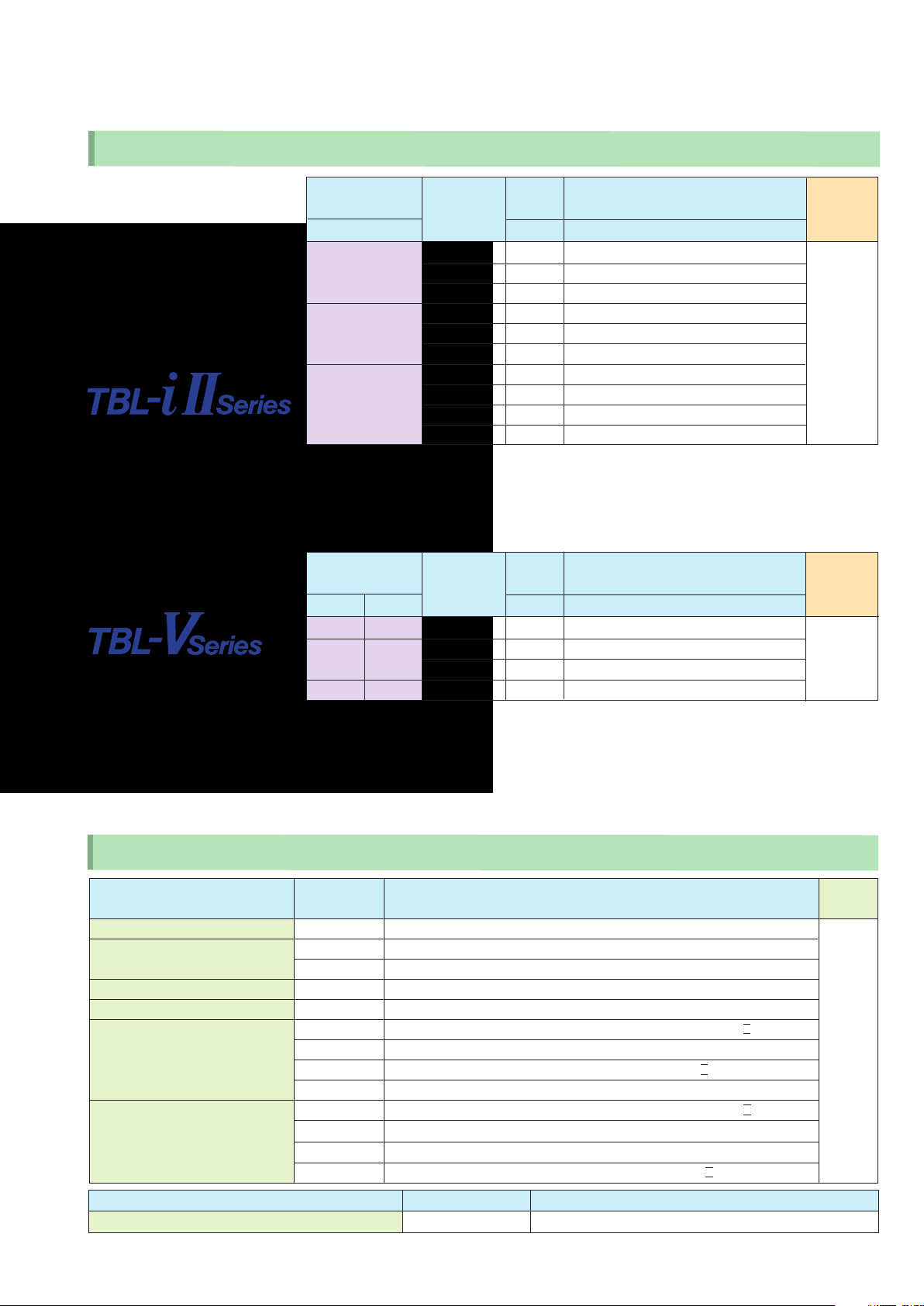

New Network Servo System

SV-NET

Network Servo System

Network Servo System

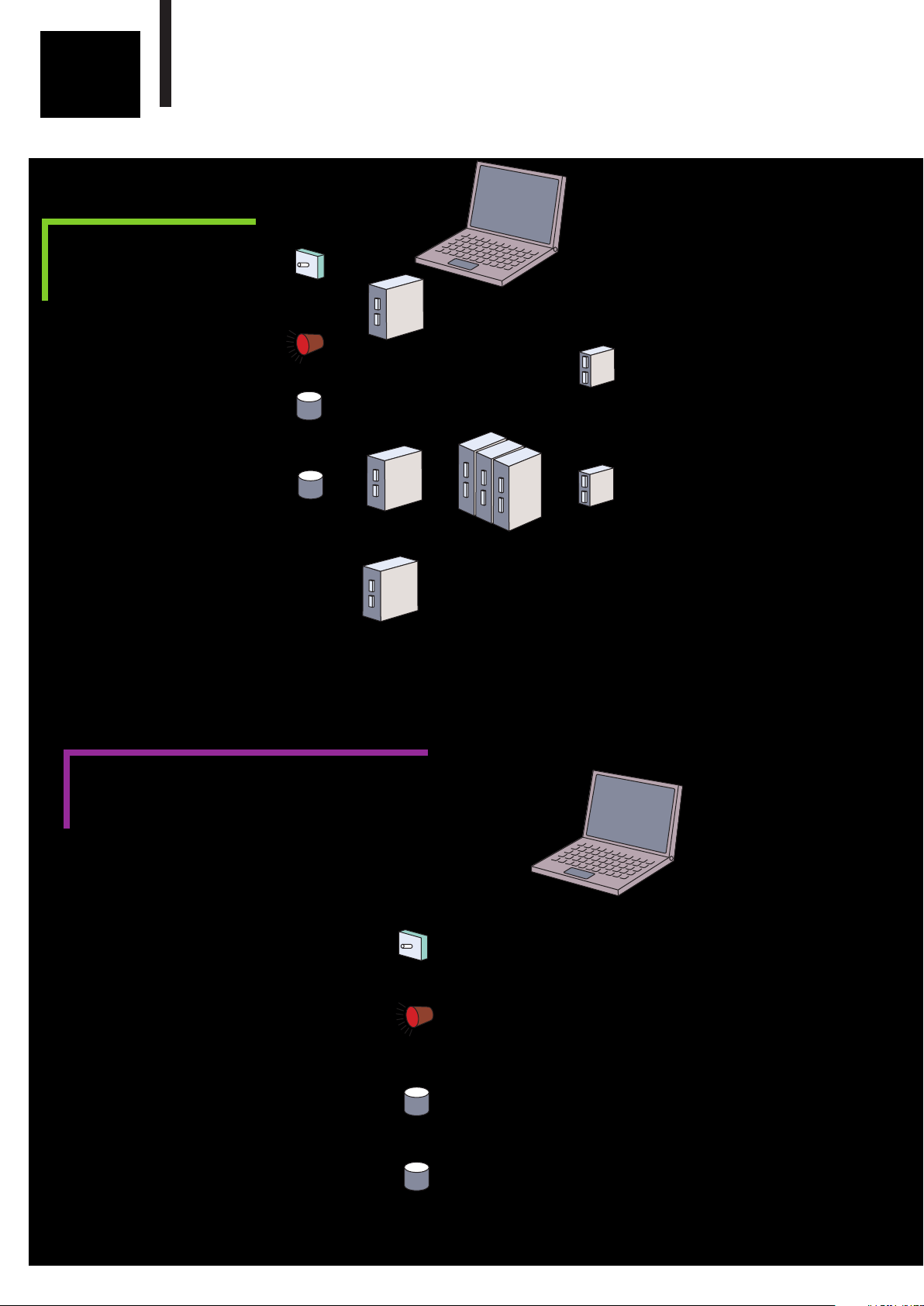

Making your small-scale system even more compact !

A debut of an agile network motion control providing up to 8-axis

simultaneous control

SV-NET, an original network system based on Controller Area Network

(CAN)(in-vehicle LAN type), realizes total compactness for your

small-scale systems.

With motors incorporating an almost trouble-free and capable

sensor you can set up a simple, compact and highly reliable

network servo system only Tamagawa can offer.

Compact

Controller

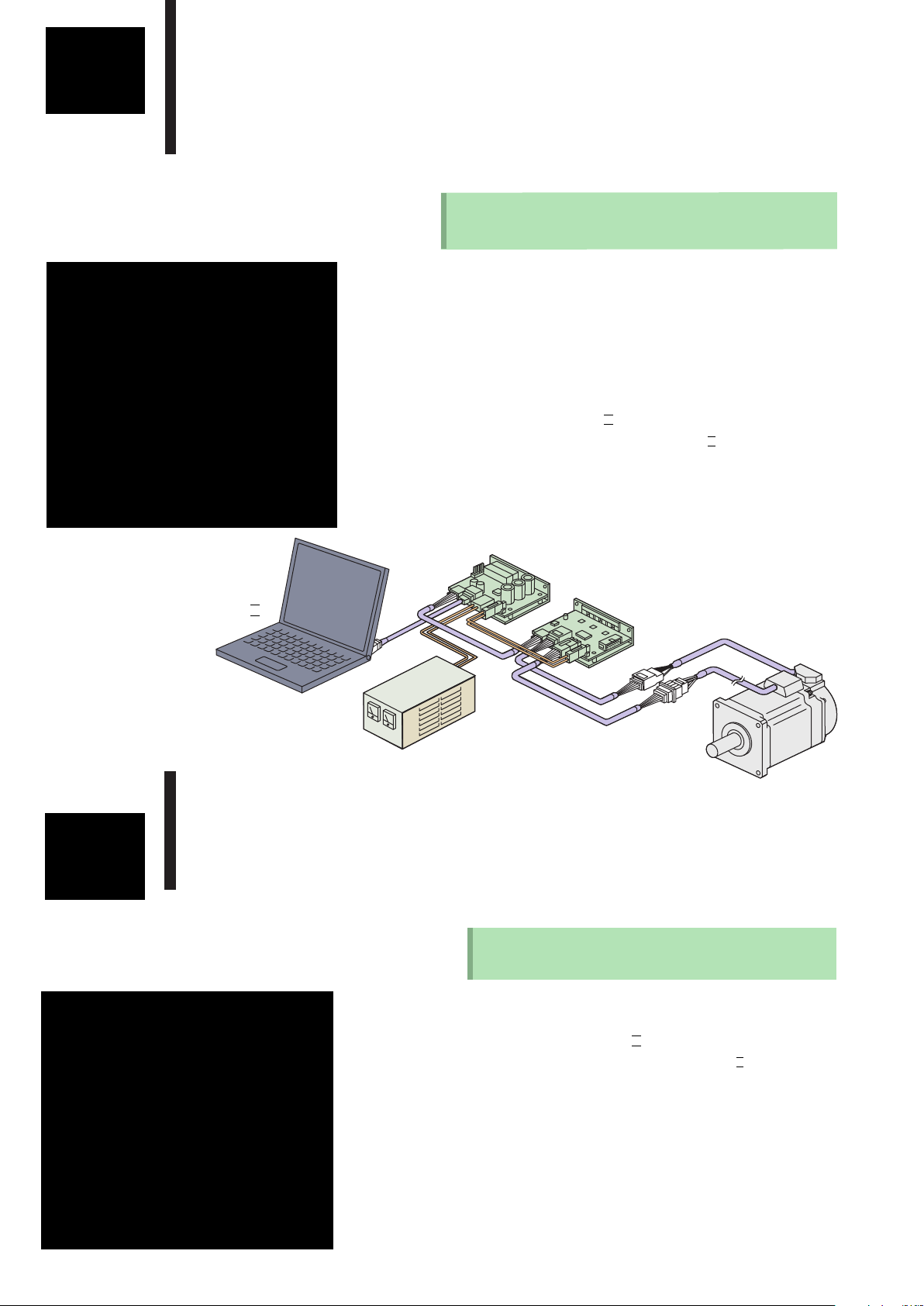

PC

USB connection

Reliability

Touch panel (to be developed)

[Recommended model : VT-2 (Keyence),

GOT-10 (Mitsubishi)]

Handy terminal (to be developed)

Driver

1 2

TBL-V Series motor

TBL-i ll Series motor

A novel proposition for compact network servos

Answers to your questions :

SV-NET motion controller network

Simple

Isn't your current system too large ?

・Compact system priced reasonably

・Compact size and volume

・Compact system of sequencer-less configuration

・Compact system offering a rich variety of commands

Isn't your motor prone to troubles ?

・A tough sensor nearly free from troubles

・Resolvers having proven its performance on vehicles, incorporated as the sensor

・Resolvers' MTBF being 1 million hours

Don't you want to reduce

the number of cables ?

・Network system designed to reduce amount of wiring

Compact

Reliability

Simple

Controller

Dedicated programming software

Offered free of charge : Free upgrading possible

"Control tower" for servo control

(Standard I/O 32/64)

RS-232C

Controller

PC

USB connection

Control power :

24VDC

Touch panel (to be developed)

[Recommended model :

VT-2 (Keyence),

GOT-10 (Mitsubishi)]

SV Programmer

Driver

Driver

Driver

Driver

Handy terminal

(to be developed)

motor

● 8-axis synchronous control

● S-curve / trapezoidal acceleration

and deceleration control

● Linear / circular interpolation

● Pass motions

● 8 user tasks

■ Applications

・Small to medium-size X-Y tables

・Belt conveyor units

・Handling units between equipments

・Automatic drilling and tapping machines

・Packing and packaging machines

・Food processing machines

・Automatic sorting machines

・Measuring and inspection systems

・Robots

・Textile and sewing machines

・AGV systems, automatic warehousing, etc.

Max. 8 axes connectable

3 4

Compact

Reliability

Simple

Motor

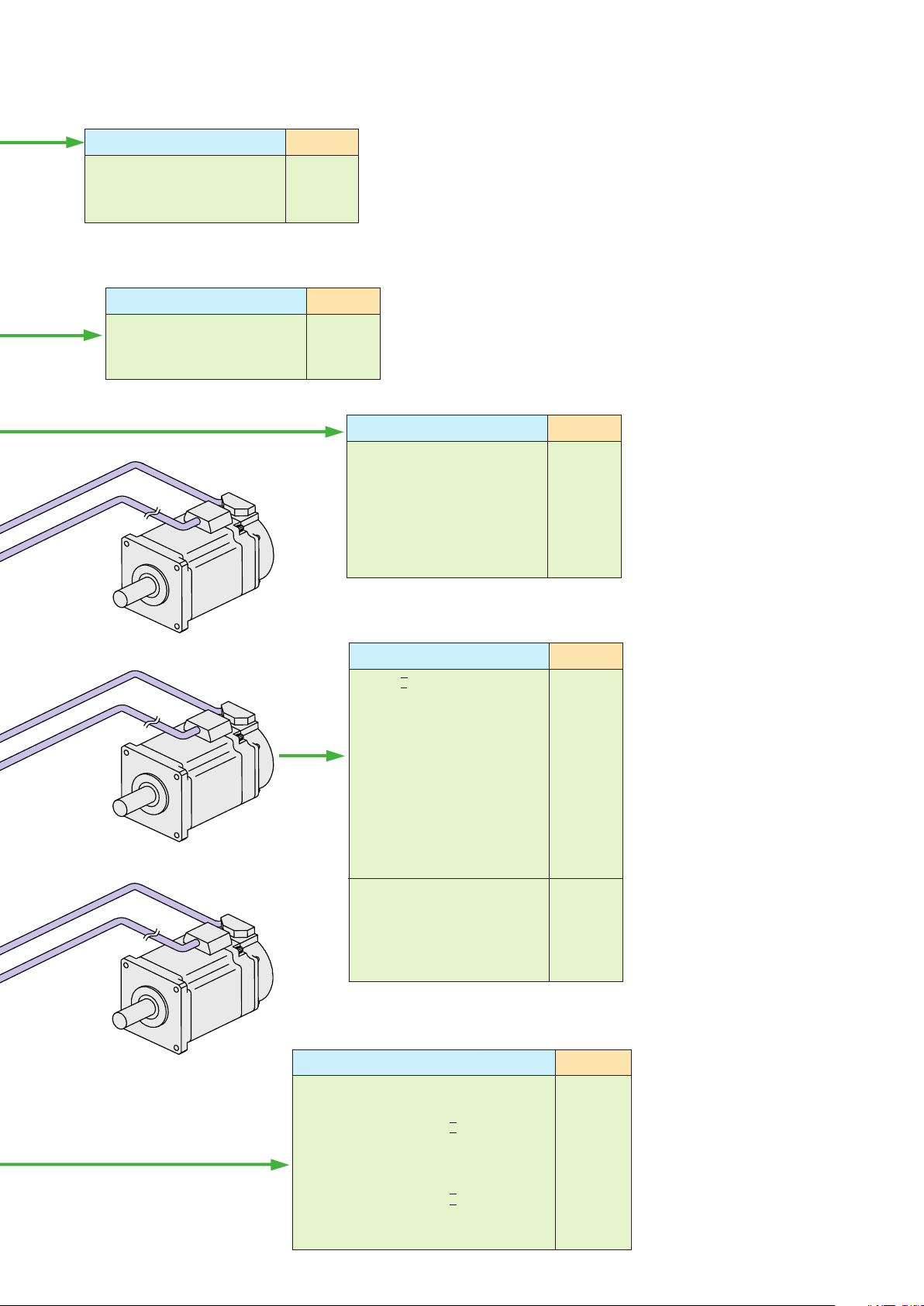

For the users who are planning "heavy-duty applications" for AC servo motors

● Heavy-load applications

● Z-axis applications

● IP 65 demanding applications

High-accuracy resolver mounted.

A rich lineup with options of speed reducer, brake, etc.

■ Applications

・Multiaxis robots

・Physical distribution machinery

・Food and packaging machinery

・Measuring equipment and the like

・Training equipment, medical and healthcare equipment

Optimal for speed control of equipment with simple positioning

and large load torque variation

For users who desire faster motion than with stepping motors

● Light-load applications

● Flanges of the same size as stepping motors

VR resolver mounted

■ Applications

・Weaving machines, embroidering machines

・Conveyance equipment, packaging equipment

・Uniaxial actuators

・Pumping equipment

・XY table / bench machine tools, etc.

Optimal for simple positioning and speed control applications

Compact

Reliability

Simple

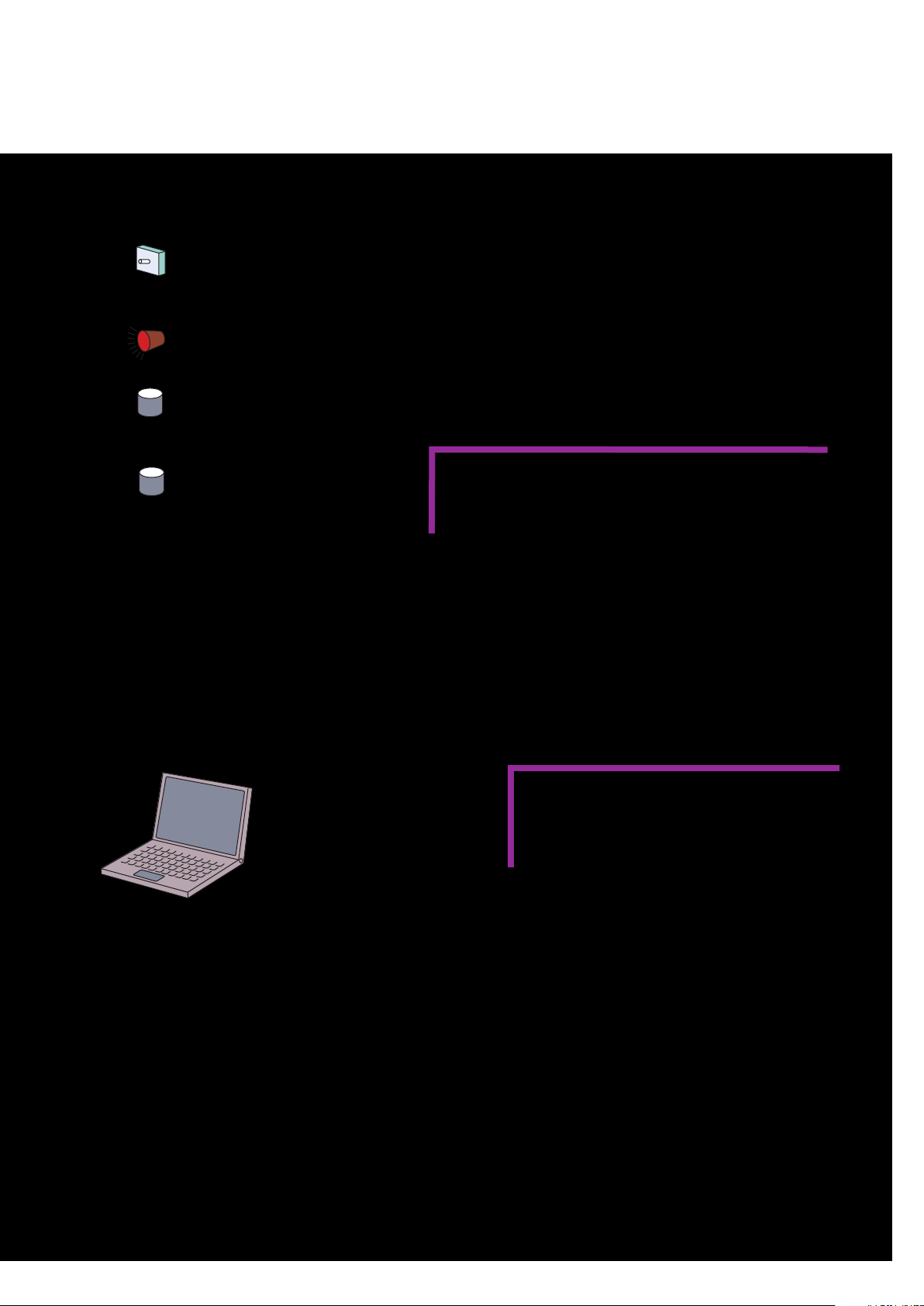

Servo System Configuration

Conventional

System

Conventional motion control

systems centered around PLC/

sequencers require a large

number of units.

Thus the users have to

take the trouble of learning about

their functions and operations.

Switch

Indicator lamp

Sensor

Sensor

Network Servo System

PC

■SV-NET is open for flexibility

I/O

I/O

Sequencer / PLC

Positioning unit

Positioning

unit

Driver

Driver

Motor

Motor

Communication

■SV-NET reduces components

SV-NET

Servo System Configuration

The SV-NET servo system employs a

controller with standard I/O interfaces and

network commands. With high-performance

drivers and rich motor variation, you can

structure a simple yet highly functional

motion control system. The SV-NET

not only provides optimal performance and

function to small to medium-size

systems but also helps reduce overall

cost reduction.

Indicator lamp

I/O

Switch

■SV-NET also works under RS-232C

PC

Driver

Motor

Driver

Sensor

Sensor

5 6

SV-NET controller

●SV-NET Servo System

Motor

User's Own Controller

Switch

Indicator lamp

Sensor

Sensor

● SV-NET Servo System

Driver

Driver

Motor

Motor

SV-NET is open to customized

system configuration

For users thinking of using his own host controller

SV-NET, using a CAN in the physical layer, provides a

network featuring excellent general-purpose properties.

Any customer who already has a host controller for

CAN or is now developing one can use this system quite easily.

Note : Communication specifications are disclosed under a separate agreement.

PC

Communication unit or

Regenerative communication unit

●SV-NET Servo System

Driver

Driver

Motor

Motor

Simple motion control by

RS232C communication

In applications where high speed and complex

motions are not primary requirements and

multiaxial synchronous control is not necessary,

SV-NET drivers can be controlled via RS232C

serial data communication.

PC application software "Master of SV-NET ll"

helps you to check and simulate simple motions,

and to manage system and motion parameters.

Note : Communication specifications are disclosed under a

separate agreement.

Compact

Reliability

Simple

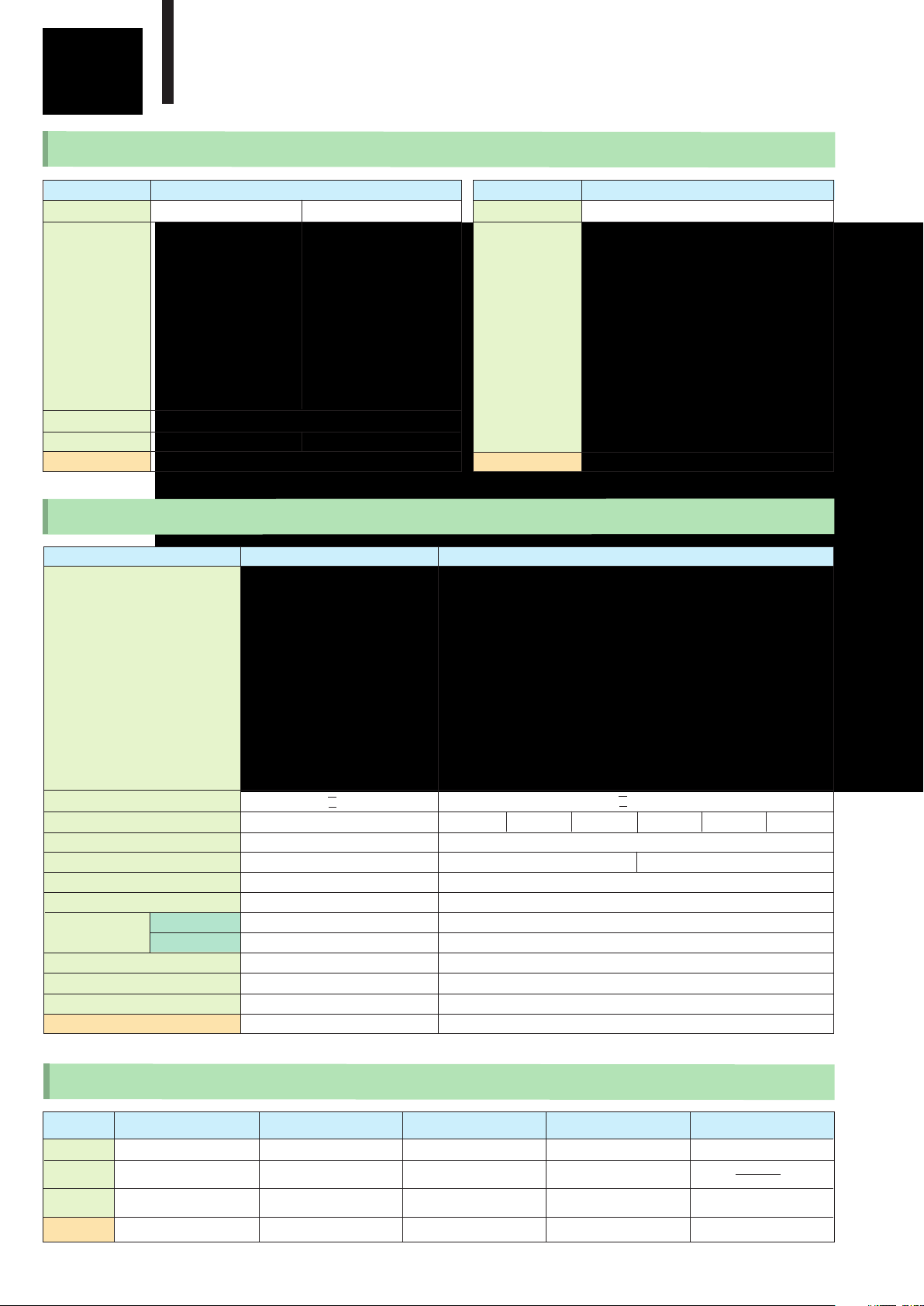

Product Lineup

SV-NET Controller

Model

Appearance

Supply voltage

I/O points

Page

SVCC- I SVCC-II

DC24V

32 64

SV-NET Driver

TA8440 series

11〜12

Model

Appearance

Page

SV Programmer

Programming software

Free of charge (Download from our website)

13〜14

Appearance

Combination motor series

Combination motor output

Control power source

Drive power source

Communication specifications

External connection I/O

Angle sensor

Regenerative capability

Dynamic brake

Mechanical brake output

Resolver

Encoder

Page

TA8410 series

TBL- i I I / TBL-V TBL- i lI / TBL-V

〜200W 〜100W 〜200W 〜400W 〜200W 〜400W 〜750W

DC24V DC24V

DC24V/48V AC100V AC200V

SV- N ET SV-N ET

○ ○

○ ○

○ ○

× ○

× ○

○ ○

15〜18

TA8411 series

19〜22

SV-NET Related Products

Regenerative

communication unit

Model

Related

equipment

Function

Page

7 8

TA8413

TA8410 series

Regen. com. function for

DC24V/DC48V units

25

Communication unit

TA8433

All SV-NET drivers

SV-NET com. Function

25

Master of SV-NET III

Software

All SV-NET drivers

Programming tool

26

Power supply unit

TA8 430

TA8420 series

DC288V 4-axis power +

Regen. Function

SV-NET training pack

TA8425

Controller + 3 sets of

motors & drivers

2623

AC Servo Motor

SV-NET Servo System

Mounting flange

[mm] [W] [V]

□40 TS4602 50

□60 TS4607 200

□80

Mounting flange

[inch] [mm] [W] [V]

#17 42 TS4742 50 DC24, DC48, AC100, AC200

TS4746 100 (DC24), DC48, AC100, AC200

#23 56.4

TS4747 200 (DC24), DC48, AC100, AC200

#34 86 TS4752 400 (AC100), AC200

Model

TS4601 30

TS4603 100

TS4606 100

TS4609 400

TS4611 200

TS4612 400

TS4613 600

TS4614 750

Model

Output

Output

Driver supply voltage

DC24, DC48, AC100, AC200

DC24, DC48, AC100, AC200

DC24, DC48, AC100, AC200

DC24, DC48, AC100, AC200

(DC24), DC48, AC100, AC200

AC100, AC200

AC100,AC200

AC200

AC200

AC200

Driver supply voltage

Page

27〜34

Page

35〜36

Cables & Accessories

Product type

Controller power cable

SV-NET cable

Driver power cable

Serial communication cable

Motor cable

Sensor cable

Product type

SV-NET terminating resistor unit

※Cable length can be specified by "N-number" in 10cm unit. (except for EU6517 : in 1m unit)

Model

EU9611

EU9610

EU9636

EU9613

EU6517

EU9614

EU9621

EU9635

EU9638

EU9615

EU9622

EU9645

EU9646

Related equipment

TA8440

TA8440 / TA8410 / TA8411 / TA8413 / TA8433

TA8420

TA8410 / TA8411 / TA8420 / TA8413

TA8440 (for upgrading firmware), TA8413 / TA8433

Combination of TA8410 / TA8420 and motor TBL-i ll series

Combination of TA8410 / TA8420 and motor TBL-i Vseries

Combination of TA8411and motor TBL-i ll series

Combination of TA8411and motor TBL-i V series

Combination of TA8410 / TA8411 and motor TBL-i ll series

Combination of TA8410 / TA8411 and motor TBL-i V series

Combination of TA8420 and motor TBL-i V series

Combination of TA8420 and motor TBL-i ll series

Model

EU9637

Page

37〜38

Related equipment

For TA8420

Compact

Reliability

Programming software

PC application software

"SV Programmer"

Simple

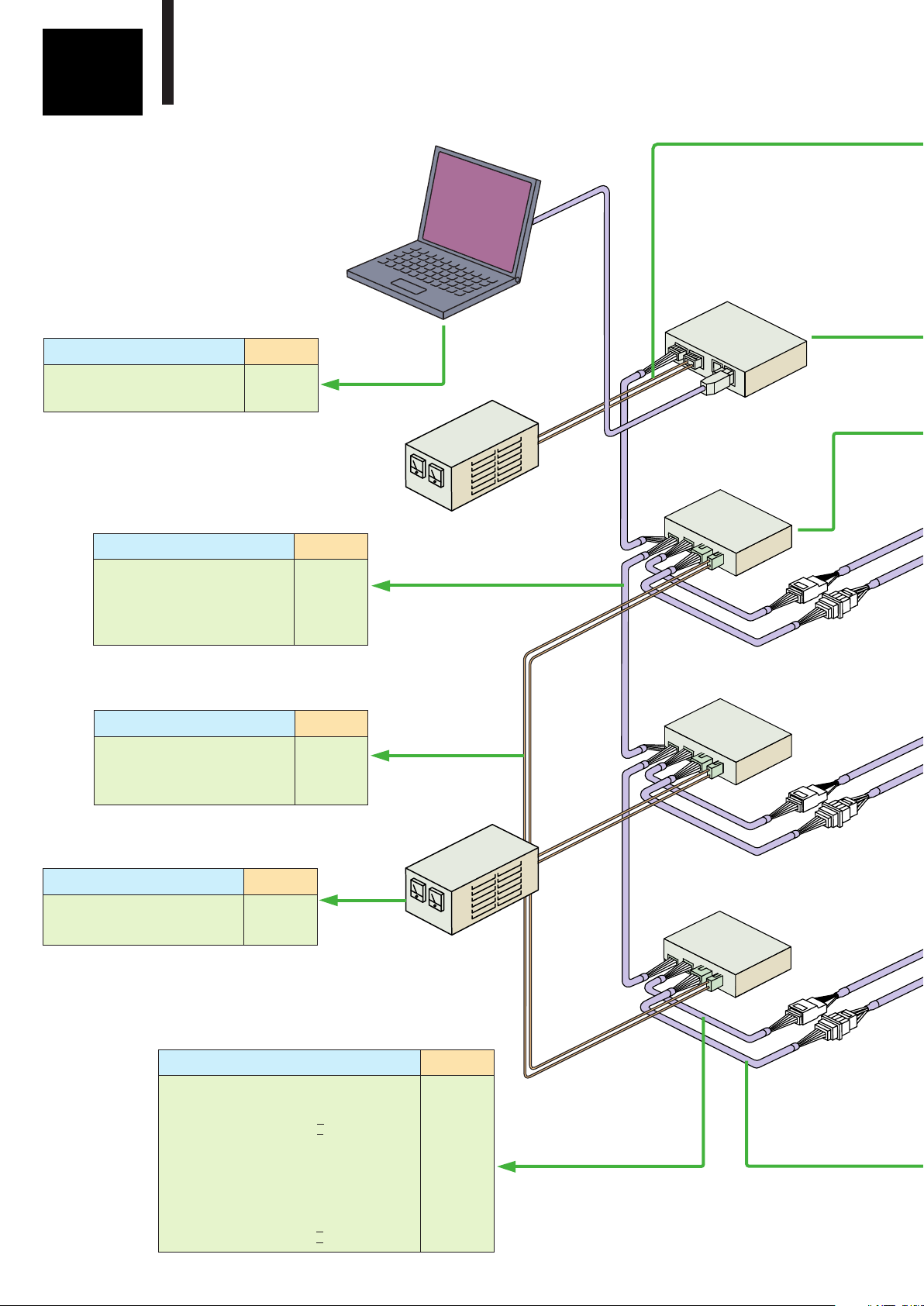

Product Categories

PC

Page

13〜14

Control power supply

Controller

Servo driver

Cable

SV-NET cable

TA8410/TA8 411/TA8413

/TA8433→EU 9610

TA8420→EU9636

Cable

Driver power cable

TA8410/TA8411/TA 8420

TA8413→EU9613

Power Supply

DC280V power supply

TA8430

Page

37

Servo driver

Page

37

Page

Servo driver

23

Drive power supply

Cable

Sensor Cable

TA8410/TA 8411

→EU9615 (for TBL- i I I connection)

TA8410/TA8411

→EU9622 (for TBL-V connection)

TA8420

→EU9645 (for TBL-V connection)

TA8420

→EU9646 (for TBL-iI I connection)

9

Page

38

SV-NET Servo System

Cable

Controller power cable

TA8440 series

→EU9611

Controller

SV-NET controller

TA8440 series

SVCC-I/SVCC-II

Page

37

Page

11〜12

Servo driver

SV-NET driver

DC24/48V 〜200W

TA 8 410 series

AC100/200V 〜750W

TA8411 series

DC280〜320V 750/400W

TA8420 series

Page

15〜24

Motor

Motor

Motor

Cable

AC servo motor

TBL-i II series

□40 30W TS4601

□40 50W TS4602

□40 100W TS4603

□60 100W TS4606

□60 200W TS4607

□60 400W TS4609

□80 200W TS4611

□80 400W TS4612

□80 600W TS4613

□80 750W TS4614

TBL-V series

#17 50W TS4742

#23 100W TS4746

#23 200W TS4747

#34 400W TS4752

Page

27〜34

35〜36

Page

Motor Cable

TA8410/TA8420

→EU9614 (for TBL-i II connection)

TA8410/TA8420

→EU9621 (for TBL-V connection)

TA8411

→EU9635 (for TBL-i II connection)

TA8411

→EU9638 (for TBL-V connection)

38

10

Compact

Reliability

Simple

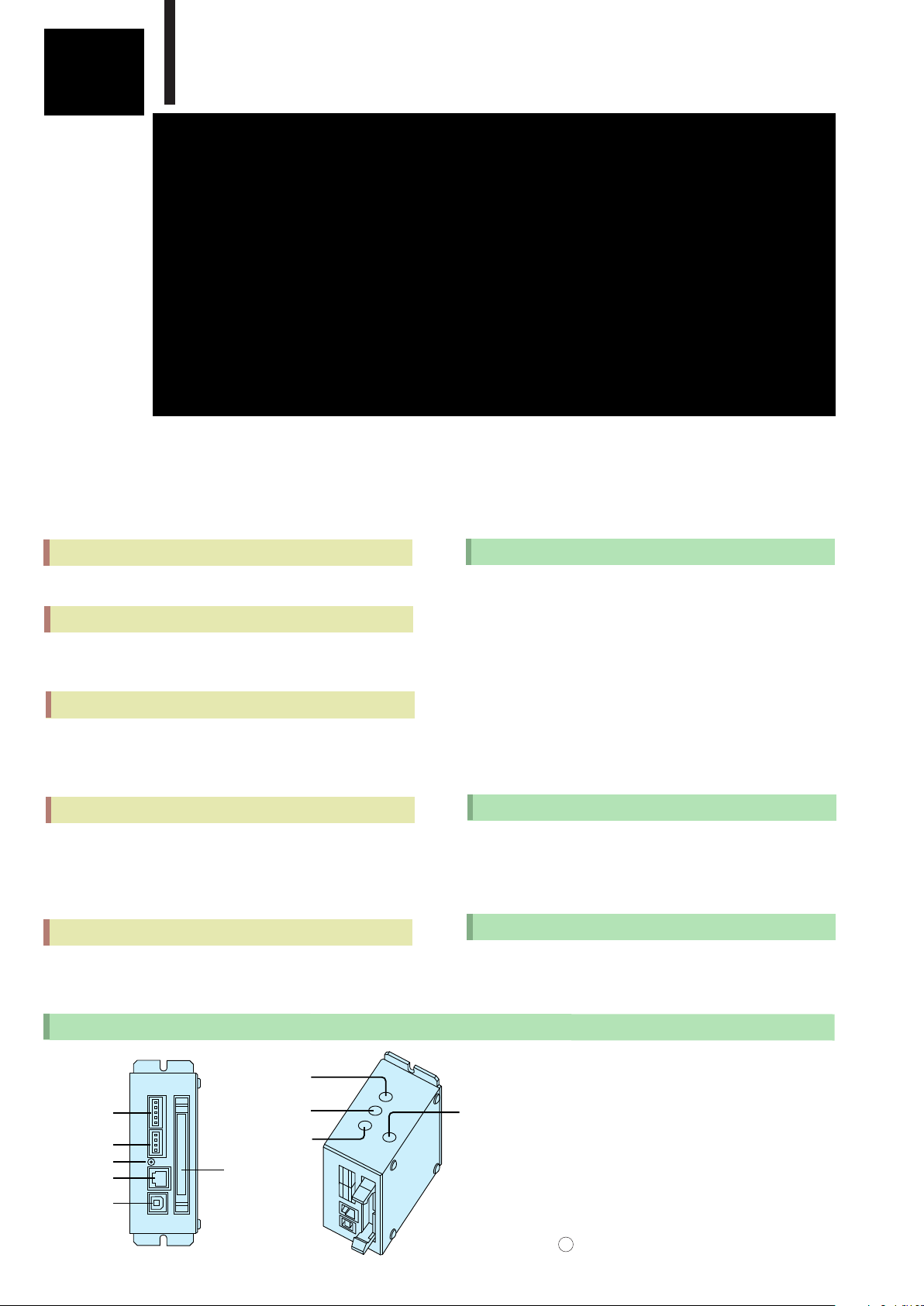

SV-NET Controller TA8440

SV-NET Controller "TA8440" and PC Software

"SV Programmer" being the

Mainstay of your Motion Control System

USB

Easy USB connection to PC.

Control power (DC24V)

Control power is supplied from the controller to all

the drivers via SV-NET cables.

Max. 8-axis control

Up to 8 axes controllable. Also synchronous operation

for 8 axes. Linear interpolation (8 axes),

circular interpolation (2 axes)

Stand-alone operation

The system can operate on a prepared program

without connecting PC.

Flexible system structuring possible by various I/O

combinations.

I/O interfaces up to 64 points

16 input points/16 output points : Total 32 points (SVCC-I)

32 input points/32 output points : Total 64 points (SVCC-II)

Main functions of TA8440

■ SV-NET port ×1

■ USB port ×1

■ Power supply DC24V

■ I/O 32 or 64 points

■ Stand-alone operation

■ Max. connectable axes : 8

■ 8-axis synchronous operation

■ Program memory capacity 640 KB

■ Interpolation cycle 4 ms

■ Transmission cycle 2 ms

PC application

■ SV Programmer (programming software)

You can download the programming software from the following

website free of charge :

http : //sv-net.tamagawa-seiki.com

Accessories

■ USB cable (for PC connection)

Names of TA8440 parts

1

SV-N ET : CAN Connector

○

7

SW-I D

○

8

HW-I D

○

○

9

BOOT

○

6

I/O

SV-N ET

1

○

2

Power

○

3

Status

○

4

RS232C

○

USB

5

○

11 12

10

○

PF No.

2

Power : Power input connector

○

3

Status : LED

○

4

RS232C : For upgrading firmware

○

5

USB : For PC connection

○

6

I/O : Connector

○

7

SW-ID : Set at factory

○

8

HW-ID : Set at factory

○

BOOT : Used for upgrading firmware

9

○

10

PF No. : Set at factory

SV-NET Servo System

TA8440 Model Designation

T A 8 4 4 0 N □ □ □ □ E □ □ □

Product type Cover color

10:SVCC-I

20:SVCC-II

0:Black (standard)

1:Black (standard)

2:Red

3:Silver

4:Green

5:Blue

6:White

Other option

0:Standard

TA8440 Basic Specifications

Unit specifications

■ Power input

DC24V±10%

Current consumption 0.3A Max.

■ SV-NET

Number of ports ×1

Communication protocol SV- NET

Physical layer:CAN

Control power output DC24V

■ USB

Number of ports ×1 for PC connection

■ I/O

1 port 32 points (16 input points, 16 output points)

SVCC - I ×1 port

SVCC- I I ×2 ports

■ Program memory capacity 640 KB

Motion control specifications

■ Number of control axes : 8

■ Transmission cycle : 4ms

Software

■ PC application

SV Programmer

Environmental specifications

■ Operation environment 0〜40℃ 90%RH Max.

No condensation

■ Storage temperature −10〜85℃

■ Applicable standard RoHS Directive

Accessories

■ USB cable (for PC connection)

■ SV Programmer

Installation CD for a charge is available.

Free download is available from web site.

http : //sv-net.tamagawa-seiki.com

Software specification

100:Standard

42

TA MAGAWA

SV-NET

POWER

116

108

100

RS232C

USB

STATU S

SVCC- I

PF-1

4.2

55

TA MAGAWA

SV-NET

POWER

116

108

100

RS232C

USB

STATU S

SVCC- II

PF-1

PF-2

4.2

SVCC - II

External Connection Diagram

USB

PC

SV-NET

Driver

Power

supply

SV-N ET

Power

1

GND

2

CAN_L

3

SHIELD

4

CAN_H

5

+24V

GND

1

NC

2

NC

3

+24V

4

Current

capacity

100 mA Max.

Current

capacity

100 mA Max.

Current

capacity

100 mA Max.

Current

capacity

100 mA Max.

×4

×4

×4

×4

×4

×4

×4

×4

SVCC - I

I/O -1 & I/O-2

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

73

73

Input power 24V IN 0-3

Input power 24V IN 4-7

IN 0

IN 1

IN 2

IN 3

IN 4

IN 5

IN 6

IN 7

Input power 24V IN 8-11

Input power 24V IN 12-15

IN 8

IN 9

IN 10

IN 11

IN 12

IN 13

IN 14

IN 15

Output power ground OUT 0-3

Output power ground OUT 4-7

OUT 0

OUT 1

OUT 2

OUT 3

OUT 4

OUT 5

OUT 6

OUT 7

Output power ground OUT 8-11

Output power ground OUT 12-15

OUT 8

OUT 9

OUT 10

OUT 11

OUT 12

OUT 13

OUT 14

OUT 15

2

2

Compact

Reliability

Simple

SV Programmer

Programming Servo monitor

Jog operation

Parameter

management

Up-to-date programming with a

rich supply of commands realizing

a speedy and flexible system development for you !

Programming tool "Program Grid"

Programming is done in Tamagawa's original

language.

That is, you select a command from the pull-down

menu in each step and enter an argument in

correspondence to the command.

The up-to-date programming is quite easy.

"Servo Monitor" for graphical view

of operation

Positions, speeds, and currents are logged and

displayed in graphs.

Axes of the graphs are scalable as you like.

"Jog Operation" for trial run

Constant speed operation or step operation can be

performed for each individual axis.

In JOG operation, you can operate the motor without

programming, just by selecting menu.

Main Functions of SV Programmer

■ Program Grid

Tamagawa's original language

Max. 5000 steps

Program memory capacity 640 KB

Variables capacity 32KB

■ Jog operation

Constant speed operation and step operation possible

Override function usable

■ Servo monitor function

Monitored items : Position, speed, and feedback current

Time axis and measurement axis scale changeable

■ Device setup

Device (driver) parameter management

Display in list or in category

Changing and saving parameters

Upload/Download, storage, printing, etc.

of parameter data

■ Controller setup

Parameter information management for SV-NET controller

Display in list or in category

Changing and saving parameters

Upload/Download, storage, printing, etc. of parameter data

13

"Device Setup" for collective parameter management

The parameters for the connected devices (drivers)

can be managed collectively.

The parameter settings can be loaded, stored, and

printed. The category display facilitates adjustments

with its easy-to-understand display of parameters

such as control modes, servo commands, and servo

gains.

Unique programming commands

■The user can customize the acceleration

/deceleration pattern, using composite commands.

In addition to movement patterns, such as

trapezoidal and S-curve patterns, you can create

your own acceleration / deceleration patterns

optimum for the system.

■Monitor commands for checking status of the

controller or drivers

set specified data in variables.

You can use these variables in the program to make

the motion so flexible.

■Use of indirect reference to variables enhances the

efficiency of programming.

You can accomplish a speedy system development.

SV-NET Servo System

Basic Specifications

■ PC environment

Applicable model PC/AT compatible machine

Applicable OS Windows 2000, XP, Vista

Necessary memory 256 MB Min.

Hard disk 500MB Min.

■ USB

USB 2.0 Full Speed

■ Programming specifications

Language Tamagawa's original language

Program capacity 640 KB

Program steps Max. 5000 steps

User tasks Max. 8 tasks

Variables capacity 32KB

Variables type 32-Bit signed integer

(−2147483648〜2147483647)

Arithmetic operation Substitution, unary, addition,

subtraction, multiplication,

division, remainder

Logical operation Logical inversion, logical

multiplication (AND), logical

addition (OR), exclusive OR,

logical shift

Jump instructions Unconditional jump, unary,

AND, equality sign,

inequality sign, less or equal,

more or equal, small, large

Subroutines Call instruction available

■ Motion control specifications

Number of control axes Max. 8

Transmission cycle 2ms

Interpolation cycle 4 ms

Interpolation function Linear interpolation ( 8axes)/

Circular interpolation (2axes)

Control system Position control, speed control,

current control

Compensation function Electronic gear

Command units mm /deg (in position control)

Acceleration/deceleration

S-curve and trapezoidal control

Home position return function

Jog operation

Override function

SV- N ET 1 system

14

Compact

Reliability

Simple

SV-NET Driver TA8410 Series

AC Servo Drivers running on 24V/48VDC and max. 200W

Powerful functions within a compact body !

SV-NET in daisy chain

Daisy chain connection minimizes wiring

requirement.

Powerful functions

The functions packed into the small framework

facilitate not only network connection, but also

easy external signal inputs such as pulse commands

or analog commands through the use of an I/O

connector.

The extension board built-in type SVD-DW has

add-on functions, which can interface with

A/B/Z outputs and encoder as well.

Resolver

The standard brushless resolver is employed as a

high-reliability angle sensor.

Compatible with a variety of encoders

The drivers interface not only with the

resolver but also with various encoders.

(SVD-DW with built-in extension board only)

Drive power DC24/48V

Main Functions of TA8410

■ Control commands

Position command input SV-NET/pulse command

Speed command input SV-NET/analog command

Current command input SV-NET/analog command

■ Parameter setting functions

Control mode, Position loop gain, Speed loop gain,

Speed integration gain,

Feed forward, Resonance control filter, Analog

command scale setting, Electronic gear setting,

Smoothing, Acceleration limit, etc.

■ Protective functions

Sensor error, Drive power error,

Over-heat, Over-speed, Overload,

Excessive deviation, etc.

■ Applicable sensors

Brushless resolver (Smartsyn/Singlsyn)

Encoder 17BIT- INC /ABS (SVD-DW only)

Encoder Minimal wiring incremental

(SVD - DW only)

■ Input and output signals

Servo ON input, Alarm reset input, Alarm output,

In-the-position output, A/B/Z output

(SVD-DW with built-in extension board only), etc.

Product & Accessories

■TA8 410 unit only

15 16

SV-NET Servo System

TA8410 Model Designation

TA8410 N □○○○ E □

Software specifications

100〜:See list of motor-driver combinations.

Sensor specifications

N1 * * * E5 * * : 2048 C/T

Minimal wiring incremental (*1)

N3 * * * E6 * * :17 B I T-A BS (*1)

N3 * * * E7 * * :17 B I T- I N C (*1)

N7 * * * E1 * * / E2 * * :Brushless resolver

I/O specifications, etc.

0:I/O I/F absent (standard, network connection only)

1:I/O I/F present (right angle type/with lock)

2:I/O I/F present (straight type/with lock) (*2)

3:I/O I/F present (right angle type/without lock)

4:Extension board (open collector output)+I/O I/F absent (*3)

5:Extension board (open collector output)

+ I/O I/F present (right angle/with lock) (*3)

6:Extension board (open collector output)

+ I/O I/F present (right angle/without lock) (*3)

7:Extension board (line driver output)+I/O I/F absent (*3)

8:Extension board (line driver output)

+ I/O I/F present (right angle/with lock) (*3)

9:Extension board (line driver output)

+ I/O I/F present (right angle/without lock) (*3)

(*2) Setting possible for open frame type only

(*3) SVD-DW type

Casing specifications, etc.

1:Covered type (BLACK:standard)

2: 〃 (RED)

3: 〃 (SILVER)

4: 〃 (GREEN)

5: 〃 (BLUE)

6: 〃 (WHITE)

※…… 0 as per separate product specifications

0:Open frame

Continuous rating output current specifications

3:4 Arms (12 Arms Max.)

5:8 Arms (24 Arms Max.)

Basic model

TA8410 (low-voltage drive) series

□

□

(Singlsyn/Smartsyn)

(*1) SVD-DW type

Basic Specifications

ltem TA 8 410 series

Control power voltage ※1

Drive power voltage ※1

Control power current

Drive power capacity

Communication specifications

Sensor

Driver internal resolution

Brushless resolver

(Singlsyn/Smartsyn)

2048 (1/rev) 2 (1/rev) 2048 (1/rev)

Combination motors

Combination motor output [W]

Operating temperature range

Storage temperature range

Operating humidity

Definition of rotating direction

CW rotation as viewed from motor shaft end : Forward rotation ※2

Recommended load inertia

Mass

Directive

※1…Do not use the same power supply for the control power and the drive power

(when the drive power is DC24V). Otherwise, troubles may occur. When

the use of the same power supply is inevitable, take precautions, such as

inser ting a diode, so that the voltage variation on the drive power side may

not adversely affect the control power side.

※2…Definition of rotating direction can be changed by parameter.

DC24V ±10%

DC24〜48V ±10%

0.1 A

As per motor combination

Communication protocol:SV-NET

Physical layer:CAN

17BIT-ABS/

17BIT- INC

17

TBL-V series / TBL- i I I series

〜200W

0〜+40℃

−10〜+85℃

90%RH Max. (no condensation)

30 times the motor inertia Max.

Approx. 0.3kg

Complying with RoHS Directive

Min.wiring

incremental encoder

Control Specifications

Control specifications As per separate communication specifications

Baud 1 Mbps

rate

MAC I D 31

(factory set value : changeable by parameter)

(factory set value : changeable by rotary SW or by parameter)

External View & Dimensions

SVD-DL

(2)

4

±0.5

108

30

15

±0.2

4.5

TA MAGAWA

STATUS

CN2

SV-NET

CN5

SENSOR

CN3

MOTOR

CN1

POWER

SVD-DL

4.5

±0.5

116

±0.2

Resolver type

(8)

(CONTROL/CAN)

100

(8)

CN2

CN5

(SENSOR)

CN3

(MOTOR)

CN1

(POWER)

(15)

LED

(STATUS)

MAC ID

SVD-DW

17.5

CN9

BAT

CN10

MON

M4 setscrew hole

(2)

4

CN9

(BATTERY)

±0.5

±0.5

108

116

CN10

(MONITOR)

(8)

LED

(STATUS)

CN2

(CONTROL/SV-NET)

CN5

(SENSOR)

100

CN3

(MOTOR)

CN1

(POWER)

CN8

(I/O 2)

CN7

(I/O 1)

(15)

CN8

(I/O 2)

CN7

(I/O 1)

75

(3)

MAC ID

75

(3)

35

±0.2

4.5

TA MAGAWA

STATUS

CN2

SV-NET

CN5

SENSOR

CN3

MOTOR

CN1

POWER

SVD-DW

Built-in extension board type

Resolver type

Encoder 17Bit ABS/INC

Encoder 2048C/T INC

Compact

Reliability

Simple

Connection

CN1 (main power)

Connector for supplying main power (drive power).

●Header:5569-02A1 (MOLEX)

PIN No. FUNCTION

1 GND(main)

2 DC24V/DC48V(main)

Mating connector (not supplied as accessory)

・Receptacle housing:5557-02R (MOLEX)

・Terminal :5556-TL (MOLEX)

CN3 (motor connection)

Connector for connecting motor cable

●Header:5569-06A1 (MOLEX)

PIN No.

1

2

3

4

5

6

Mating connector (not supplied as accessory)

・Receptacle housing:5557-06R (MOLEX)

・Terminal :5556-TL (MOLEX)

(BK)……motors with brake only

(BK)……motors with brake only

FUNCTION

Standard

U

V

W

F・G

CN7 (I/O connection)

Connectors for connecting I/O input/output signals.

Connector types vary depending on "N-number."

●N***1 header:HIF3BA-16PA-2.54DS (HIROSE)…right angle, with lock

●N***2 header:HIF3BA-16PA-2.54DSA (HIROSE)…straight, with lock

●N***3 header:HIF3F-16PA-2.54DS (HIROSE)…right angle, without lock

PIN No.

※「A-I n」:Analog signal input,「D-I n」:Signal input,「D-O ut」:Digital signal output

1

○

MCP604 equivalent TLP112A equivalent

10kΩ

※Mating connector (to be prepared by users)

・Socket:HIF3BA-16D-2.54R (HIROSE)

I/O FUNCTION

GND

1

A-In AIN (Analog command input) See Fig. 1

2

D-In Reverse-PLS+ (Reverse command pulse input+)

3

D-In Reverse-PLSー (Reverse command pulse input−)

4

D-In Forward-PLS+ (Forward command pulse input+)

5

D-In Forward-PLSー (Forward command pulse input−)

6

GND

7

D-In AUX (Auxiliary)

8

D-In C-RST (Counter reset input)

9

D-In RST (Reset input) See Fig. 3

10

D-In Reverse-LMT (Reverse drive disable input)

11

D-In Forward-LMT (Forward drive disable input)

12

D-In SVON (Servo ON input)

13

D-In INP (In-the-position signal output)

14

D-Out ALM (Alarm signal output)

15

+24V

16

Analog signal input

1.65kΩ

Vref(+1.65V)

Digital signal input

2

○

150Ω

I/O internal circuit

Digital signal input

3

○

1SS388 equivalent

+5V

470Ω

74VHC04

ON:1V Max.

OFF:open or 3.5V Min.

(Reverse voltage of diode : 40V)

4

○

SSM5N15FE equivalent

15

16

CN7 Pin number

17 18

2

1

CN1 Pin number

5

6

4

3

2

1

CN3 Pin number

See Fig. 2

See Fig. 4

Digital signal output

DG

3

1

4

2

CN2 (control signal)

Connector for connecting control power (DC24V) and communication

(CAN). Even when communication (CAN) is not used, be sure to input

control power (DC24V) between PIN 1 and PIN 5 of the CN2.

●Header:734-165 (WAGO)

PIN No. FUNCTION

1 GND (control)

2 CAN L (ー)

3 GND (SHIELD)

4 CAN H (+)

5 DC24V (control)

Mating connector (not supplied as accessory)

・Connector plug:734-105 (WAGO)

CN5 (sensor connection)

Connector for connecting sensor cable

●Tab header:1376020-1 (Tyco Electronics AMP)

PIN No.

A1

B1

A2

B2

A3

B3

A4

B4

A5

B5

A6

B6

Mating connector (not supplied as accessory)

・Receptacle housing:1-1318118-6 (Tyco Electronics AMP)

・Terminal :1318108-1 (Tyco Electronics AMP)

Min. wiring 17BIT-ABS/INC Resolver

A − S2 (output)

A/ − S4 (output)

B − S1 (output)

B/ − S3 (output)

Z SD R1 (excitation)

Z/ SD/ R2 (excitation)

− VB −

− GND-VB −

VCC VCC −

GND GND ー

− − ー

GND (SHIELD) GND (SHIELD) GND (SHIELD)

FUNCTION

CN8 (I/O connection) SVD-DW only

●Header:HIF3BAF-14PA-2.54DS (HIROSE)

PIN No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

※「D-Out」:Digital signal output,

CN9 (

※Used with 17B-ABS encoder only

●Connector:IL-2P-S3FP2-1 (JAE)

Battery:ER17500VC (Toshiba Battery)

I/O

D-Out

D-Out NC LEAD ー

D-Out LAG LAG +

D-Out NC LAG ー

D-Out Z Z+

D-Out NC Zー

GND

GND

A-Out Monitor output1

(factory setting:motor current)

A-Out Monitor output2

(factory setting:speed feedback)

Open cnnector Line driver

LEAD LEAD +

「A-Out」:Analog signal output

FUNCTION

GND

GND

NC

NC

backup battery connection connector) SVD-DW only

PIN No. FUNCTION

1 GND (ー)

2 VB (+)

1

5

CN2 Pin number

1

CN9 Pin number

2

List of Motor / Driver Combinations

SV-NET Servo System

●TBL-V Series (E1 )

□

□

DC24V system / DC48V system

Motor model

Driver model to be combined

TS4742 (50W/50W-□42) TA8410N*5**E111

TS4746 (98W/100W-□56.4) TA8410N*5**E112

TS4747 (92W/200W-□56.4) TA8410N*5**E113

Note) TBL- V series employs the resolver (Singlsyn) only.

Compact

Reliability

Simple

System Configuration

DC24/48 Type

TBL-V/TBL-i II MOTOR

TBL-V/TBL-i II MOTOR

TBL-V/TBL-i II MOTOR

TA8410 TBL-DRIVER

SENSOR

MOTOR

TA8410 TBL-DRIVER

SENSOR

MOTOR

TA8410 TBL- DRIVER

SENSOR

MOTOR

CN4

CN3

CN4

CN3

CN6

CN2

CN2

CN1

CN2

CN1

CN2

CN1

CAN+

4

CANー

2

GND

3

GND

1

DC24V

5

GND

1

DC24/48V

2

CAN+

4

CANー

2

GND

3

GND

1

DC24V

5

GND

1

DC24/48V

2

CAN+

4

CANー

2

GND

3

GND

1

DC24V

5

GND

1

DC24/48V

2

Twist Pair /

Each Pair Shielded +

All Shielded Cable

Twist Pair /

Each Pair Shielded +

All Shielded Cable

Twist Pair /

Each Pair Shielded +

All Shielded Cable

●TBL- i II Series (E2 )

DC24V system

Motor model

□

□

Driver model to be combined

DC48V system

Motor model

Driver model to be combined

TS4601 (30W-□40) TA8410N*3**E241 TS4601 (30W-□40) TA8410N*3**E281

TS4602 (50W-□40) TA8410N*3**E242 TS4602 (50W-□40) TA8410N*3**E282

TS4603 (100W-□40) TA8410N*5**E243 TS4603 (100W-□40) TA8410N*3**E283

TS4606 (100W-□60) TA8410N*5**E256 TS4606 (100W-□60) TA8410N*3**E296

TS4607 (100W-□60) TA8410N*5**E257 TS4607 (200W-□60) TA8410N*5**E297

SV-N ET Motion Controller

(Termination resistor)

(120Ω)

PC

CAN+

4

CANー

2

3

GND

1

GND

(Built-in

5

DC24V

termination

1

4

resistor)

GND

(120Ω)

USB

DC24V

Control Power Supply:DC24V

GND

DC24V

Drive power:DC24〜48V

0V

DC24〜48V

PC

SV-N E T Controller

Terminating resistor 120Ω to be connected

Control Power

DC24V

Drive Power Supply

DC24/48V

SV-N ET Driver TA 8410

Motor

SV-N E T Driver TA 8410

Motor

SV-N ET Driver TA8 410

Motor

Compact

Reliability

Simple

SV-NET Driver TA8411 Series

AC Servo Drivers running on

100V/200VAC outputs up to

750W within a compact body.

SV-NET in daisy chain

The daisy chain connection minimizes wiring

requirement.

TA8411 Model Designation

TA8411 N □○○○ E □

Software specifications

100〜:Standard specifications

Sensor specifications

N1 * * * E5 * * :2048 C/T

Minimal wiring incremental

N3 * * * E6 * * :17 BIT-ABS

N3 * * * E7 * * :17 BIT- INC

N7 * * * E1 * * / E2 * * :Brushless resolver

Mechanical specifications, etc.

1:Extension board (open collector output)

2:Extension board (I ine driver output)

Casing specifications, etc.

1:Covered type (BLACK:standard)

2: 〃 (RED)

3: 〃 (SILVER)

4: 〃 (GREEN)

5: 〃 (BLUE)

6: 〃 (WHITE)

Input voltage / output current specifications

2:AC100V / 2 Arms (6 Arms Max.)

3:AC100V / 4 Arms (8 Arms Max.)

4:AC100V / 6 Arms (12 Arms Max.)

6:AC200V / 2 Arms (6 Arms Max.)

7:AC200V / 4 Arms (8 Arms Max.)

8:AC200V / 6 Arms (12 Arms Max.)

Basic model

TA8411 (high-voltage drive) series

□

□

(Singlsyn/Smartsyn)

Powerful functions

The functions packed into the small framework

facilitate not only network connection, but also

easy external signal inputs such as pulse commands

or analog commands through the use of an I/O

connector. It outputs A/B/Z signals and interfaces

with encoders as well.

Resolver

Brushless resolver is used as the standard

high-reliability angle sensor.

Compatible with a variety of encoders

The drivers are compatible not only with the

resolver but also with various encoders.

Drive power AC100/200V

Single-phase, AC90~115V/AC180~253V, 50Hz/60Hz

Dynamic brake and regenerative circuit

are built

Product & Accessories

■TA8411 unit only

Main Functions of TA8411

■ Control commands

Position command input SV-NET/pulse command

Speed command input SV-NET/analog command

Current command input SV-NET/analog command

■ Parameter setting functions

Control mode, Position loop gain, Speed loop gain,

Speed integration gain,

Feed forward, Resonance control filter, Analog

command scale setting, Electronic gear setting,

Encoder output resolution setting, Acceleration limit, etc.

■ Regenerative function Built-in circuit

■ Dynamic brake function Built-in circuit

■ Mechanical brake drive output DC24V-0.4A Max.

■ Protective functions

Sensor error, Drive power error,

Over-heat, EEPROM error, Over-speed

Overload, Excessive deviation, etc.

■ Applicable sensors

Brushless resolver (Smartsyn/Singlsyn)

Encoder 17BIT- INC /ABS

Encoder Minimal wiring incremental

■ Input and output signals

Servo ON input, Alarm reset input, Alarm output,

In-the-position output, A/B/Z output

(built-in extension board type only), etc.

19 20

Basic Specifications

ltem TA 8 411 series

Control power voltage

Drive power voltage

Control power current

Single-phase, AC90〜115V / AC180〜253V 50/60 Hz

0.1 A (fan type:+0.1A / brake type:+0.4A)

Drive power capacity

Communication specifications

Sensor

Driver internal resolution

Brushless resolver

(Singlsyn/Smartsyn)

2048 (1/rev) 2 (1/rev) 2048 (1/rev)

Combination motor

Combination motor output [W]

Operating temperature range

Storage temperature range

Operating humidity

Definition of rotating direction

CW rotation as viewed from motor shaft end : Forward rotation

Recommended load inertia

Mass

Directive

DC24V ±10%

As per motor combination

Communication protocol:SV-NET

Physical layer:CAN

17BIT-ABS/

17BIT-INC

17

Min. wiring

incremental encoder

TBL-V series / TBL- i I I series

〜400W (drive power AC100V)

〜750W (drive power AC200V)

0〜+40℃

ー10〜+85℃

90%RH Max. (no condensation)

30 times the motor inertia Max.

Approx. 0.6kg

Complying with RoHS Directive

Control Specifications

Control specifications As per separate communication specifications

Baud rate 1 M bps

MAC I D 31

(factory set value : changeable by parameter)

(factory set value : changeable by rotary SW or by parameter)

SV-NET Servo System

External View & Dimensions

SVD-ALW

15

φ5

TA MAGAWA

CN7

I/O 1

CN2

SV−

NET

POWER

37

5

*

STATUS

SVD-ALM

±1

STATUS

(LED)

CN2

(CONTROL/

SV-NET)

POWER

(LED)

FG

(M 4 screw)

TA8411 N 2 / N 6

CN9

BAT

CN8

I/O 2

CN10

MON

CN5

SENSOR

CN3

MOTOR

CN1

POWER

15

*

CN9

(BATTERY)

CN10

(MO NITO R)

CN1

(AC I N)

R2.5

*

* *

160

10

±0.5

*

170

5

±1

180

CN6

(DB/RB)

CN6

DB/RB

(Mounting surface)

±1

130

(3)

External View & Dimensions

SVD-AMW

15

φ5

TA MAGAWA

CN7

I/O 1

CN2

SV−

NET

POWER

37

SVD-AMW

5

±1

*

STATUS

STATUS

(LED)

CN2

(CONTROL/SV-NET)

POWER

(LED)

FG

(M 4 screw)

TA8411 N 3 / N 7

*

CN9

BAT

CN8

I/O 2

CN10

MON

CN5

SENSOR

CN3

MOTOR

CN1

POWER

15

*

CN9

(BATTERY)

CN10

M ON ITO R

CN1

(AC I N)

R2.5

(3)

* *

160

10

*

±0.5

170

5

±1

180

CN6

(DB/RB)

CN6

DB/RB

130

(Mounting surface)

±1

(3)

SVD-AHW

φ5

25

TA MAGAWA

CN7

I/O 1

CN2

SV−

NET

POWER

5

47

STATUS

SVD-AHW

±1

*

CN9

BAT

CN8

I/O 2

CN10

MON

CN5

SENSOR

CN3

MOTOR

CN1

POWER

25

*

* *

(BATTERY)

M ON ITO R

STATUS

(LED)

CN2

(CONTROL/SV-NET)

POWER

(LED)

CN1

(AC I N)

FG

(M 4 screw)

TA8411 N 3 / N 7

CN9

CN10

R2.5

(3)

(Mounting surface)

±1

±0.5

160

180

170

±1

CN6

(DB/RB)

CN6

DB/RB

130

5

10

*

*

(3)

Compact

Reliability

Simple

Connection

CN1 (main power)

Connector for supplying main power (drive power).

●Header:5569-02A1 (MOLEX)

PIN No. FUNCTION

1

2

Mating connector (not supplied as accessory)

・Receptacle housing:5557-02R (MOLEX)

・Terminal :5556-TL (MOLEX)

Single-phase AC100V / AC200〜220V (main)

CN3 (motor connection)

Connector for connecting motor cable

●Header:1-178139-2 (Tyco Electronics AMP)

PIN No.

A1

A2

A3

B1

B2

B3

Mating connector (not supplied as accessory)

・Receptacle housing :1-178129-6

・Receptacle contact :175218-2

(BK)……Motors with brake only

(BK)……Motors with brake only

(Tyco Electronics AMP)

(Tyco Electronics AMP)

FUNCTION

Standard

U

V

W

F・G

CN6 (External resistance)

Connectors for connecting external resistance.

●Header:5569-04A1 (MOLEX)

PIN No. FUNCTION

1

2

3

4

Mating connector (not supplied as accessory)

・Receptacle housing:5557-04R (MOLEX)

・Terminal :5556TL (MOLEX)

RG1 (regenerative resistance connection)

DB1 (dynamic brake resistance connection)

RG2 (regenerative resistance connection)

DB2 (dynamic brake resistance connection)

CN7 (I/O connection)

Connectors for connecting I/O input/output signals.

●Header:HIF3BAF-16PA-2.54DS (HIROSE)

PIN No.

※「A-In」:Analog signal,「D-In」:Signal input,「D-Out」:Digital signal output

I/O FUNCTION

GND

1

A-In AIN (Anglog command input) See Fig. 1

2

D-In Reverse-PLS+

3

D-In Reverse-PLSー

4

D-In Forward-PLS+

5

D-In Forward-PLSー

6

GND

7

D-In AUX (Auxiliary input)

8

D-In C-RST (Counter reset input)

9

D-In RST (Reset input) See Fig. 3

10

D-In Reverse-LMT (Reverse drive disable input)

11

D-In Forward-LMT (Forward drive disable input)

12

D-In SVON (Servo ON input)

13

D-In INP (In-the-position signal output)

14

D-Out ALM (Alarm signal output)

15

+24V

16

(Reverse command pulse input+)

(Reverse command pulse input−)

(Forward command pulse input+)

(Forward command pulse input−)

CN1 Pin number

A1

CN3 Pin number

CN6 Pin number

See Fig. 2

See Fig. 4

2

1

B1

B2

B3

A2

A3

4

3

2

1

CN2 (control signal)

Connector for connecting control power (DC24V) and communication

(CAN). Even when communication (CAN) is not used, be sure to input

control power (DC24V) between PIN 1 and PIN 5 of the CN2.

●Header:734-165 (WAGO)

PIN No. FUNCTION

1 GND (control)

2 CAN L (ー)

3 GND (SHIELD)

4 CAN H (+)

5 DC24V (control)

Mating connector (not supplied as accessory)

・Connector plug:734-105 (WAGO)

CN5 (sensor connection)

Connector for connecting sensor cable

●Tab header:1376020-1 (Tyco Electronics AMP)

PIN No.

A1

B1

A2

B2

A3

B3

A4

B4

A5

B5

A6

B6

Mating connector (not supplied as accessory)

・Receptacle housing:1-1318118-6 (Tyco Electronics AMP)

・Terminal :1318108-1 (Tyco Electronics AMP)

Analog signal input

1

○

MCP604 equivalent

1.65kΩ

10kΩ

Vref (+1.65V)

※Mating connector (not supplied as accessory)

・Socket:HIF3BA-16D-2.54R (HIROSE)

Min. wiring 17BIT-ABS/INC Resolver

A − S2 (output)

A/ − S4 (output)

B − S1 (output)

B/ − S3 (output)

Z SD R1 (excitation)

Z/ SD/ R2 (excitation)

− VB −

− GND-VB −

VCC VCC −

GND GND ー

− − ー

GND (SHIELD) GND (SHIELD) GND (SHIELD)

Digital signal input

2

○

TLP112A equivalent

150Ω

I/O Internal Circuit

FUNCTION

Digital signal input Digital signal output

3

○

1SS388 equivalent

+5V

470Ω

74VHC04

ON:1V Max.

OFF:open or 3.5V Min.

(Reverse voltage of diode : 40V)

4

○

SSM5N15FE equivalent

15

16

(PCB facing side)

CN1 Pin number

1

5

CN2 Pin number

B1

A1

CN5 Pin number

DG

3

1

4

2

B6

A6

21 22

Connection

CN8 (I/O connection)

●Header:HIF3BAF-14PA-2.54DS (HIROSE)

PIN No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

※「D-Out」:Digital signal output,「A-Out」:Analog signal output

I/O

Open connector Line driver

D-Out

D-Out NC LEAD ー

D-Out LAG LAG +

D-Out NC LAG ー

D-Out Z Z+

D-Out NC Zー

GND

GND

A-Out Monitor output1

(factory setting:motor current)

A-Out Monitor output2

(factory setting:speed feedback)

LEAD LEAD +

FUNCTION

GND

GND

NC

NC

See Figs. 1

and 2

SV-NET Servo System

7407 equivalent

1

(open collector) (line driver)

※Mating connector (not supplied as accessory)

・Socket:HIF3BA-14D-2.54R (HIROSE)

CN9 (

backup battery connection connector)

※Used with 17B-ABS only

●Connector:IL-2P-S3FP2-1 (JAE)

PIN No. FUNCTION

1 GND

2 VB (+)

Battery:ER17500VC (Toshiba Battery)

2

I/O Internal Circuit

AM26C31 equivalent

1

CN9 Pin number

2

List of Motor / Driver Combinations

●TBL-V Series (E1 )

AC100V system / AC200V system

Motor model Driver model to be combined

TS4742 (50W/50W- □42) TA8411N*3**E111/TA8411N*7**E111

TS4746 (100W/100W- □56.4) TA8411N*3**E112/TA8411N*7**E112

TS4747 (200W/200- □56.4) TA8411N*3**E113/TA8411N*7**E113

TS4752 (320W/400W- □86) TA8411N*3**E114/TA8411N*7**E114

Note) TBL- V series employs the resolver (Singlsyn) only.

□

□

System Configuration

AC100V/200V Type

PC

Control power supply

DC24V

Drive power supply

Single-phase

AC100V/AC200V

SV-N E T Controller

SV-N ET Driver TA 8411

SV-N E T Driver TA 8411

SV-N ET Driver TA8 411

●TBL- i ll Series (E2 )

AC100V system

Motor model E number

TS4601 (30W- □40) TA8411N*2**E241 TS4601 (30W- □40) TA8411N*6**E281

TS4602 (50W- □40) TA8411N*2**E242 TS4602 (50W- □40) TA8411N*6**E282

TS4603(100W- □40) TA8411N*2**E243 TS4603 (100W- □40) TA8411N*6**E283

TS4606 (100W- □60) TA8411N*2**E256 TS4606 (100W- □60) TA8411N*6**E296

TS4607 (200W- □60) TA8411N*3**E257 TS4607 (200W- □60) TA8411N*6**E297

TS4609 (400W- □60) TA8411N*4**E259 TS4609 (400W- □60) TA8411N*7**E299

TS4611 (200W- □80) TA8411N*3**E271 TS4611 (200W- □80) TA8411N*6**E201

TS4612 (400W- □80) TA8411N*7**E202

TS4613 (600W- □80) TA8411N*8**E203

TS4614 (750W- □80) TA8411N*8**E204

Motor

Terminating resistor 120Ω to be connected

Motor

□

□

AC200V system

Motor model E number

Motor

Compact

Reliability

Simple

SV-NET Driver TA8420 Series

DC280V to 325V, 400W/750W AC Servo Drivers

Small Size and Large Capacity

SV-NET Network Driver

Daisy chain connection minimizes wiring

requirement.

Drive power : DC280V to 325V

Built-in dynamic brake control

Resolver

The angle sensor employed is a resolver featuring

high environmental resistance.

Compact

Reliability

Simple

Power Source Unit TA8430

※These driver models are not equipped with a heat

radiator. Please consult us about the details of

your application.

Main Functions of TA8430 Power Source Unit

■ AC-DC conversion

Input rating AC200V/220V 3φ

Output rating About DC280/308V

■ Number of connections

4systems

■ Power capacity

Max. 8 A per system (TOTAL:18A Max.)

■ Built-in regenerative function

Regenerative resistance to be connected externally

(Option:EU6656N2)

■ Compatible driver

TA8420 series

23 24

Compact

Reliability

Simple

System Configuration

DC280V Type

System configuration using a power source unit

TA8420 System Configuration Diagram

Host Controller or

Communication Unit

(TA8433) or the like

SV- NET

Cable

Backup battery

ER175000VC (TOSHIBA)

(for 17 Bit ABS only )

Power Input

R S T

When TA8430 power source unit used

Rating :

AC200/220V

No Fuse Breaker (NFB)

Power line protection

(Overcurrent)

Noise Filter

Reduction of noise from power line

Magnetic Contactor (MC)

ON/OFF of servo driver power

Power Factor

Improving Reactor

(to improve efficiency of power supply)

Y ZX

Ext. Regenerative Resistor (Option)

EU6656N2

TA8430 Power Source Unit

1

AC INPUT

R

T

2

S

CN3 CN4

CN1

CN2

RB[+V] R B[ーV]

CN4 FOR SENSOR

Tab Header:1376020-1(AMP)

TA8420 (Front)

Sensor Cable

Motor Cable

CN4

CN3

CN2A

PWR

CN3 FOR MOTOR

Header:5569-06A1 (MOLEX)

CN2-A FOR CONTROL

Header:S10B-J21DK-GGYR(JST)

CN5 ONLY 17B-ABS

Connector:IL-2P-S3FP2-I(JST)

CN5

CN1 FOR POWER

Header:5569-02A1 (MOLEX)

CN1

POWER LED

TA8420 (Back)

CN2-B

3

Surge Protector

Protection of electronic circuitry

from lightning surge or the like

Grounding

Daisy chain connection

SV-NET Cable

SV-NET connectors CN2A amd CN2B

are connected inside TA8420, so they

can be used for daisy chain connection.

Output voltage

DC280V/308V

DC Output Connectors (C N1〜C N4)

4 systems connectable

Header:

1-178136-2

(Tyco Electronics AMP)

Applicable connector

Receptacle housing:

1-178128-3

(Tyco Electronics AMP)

Receptacle contact:

1-175218-2

(Tyco Electronics AMP)

Power source : DC280V

(DC235〜370V)

CN3 FOR MOTOR

Header:5569-06A1 (MOLEX)

CN2-B FOR CONTROL

Header:S10B-J2 DK-GGYR (JST)

CN4 FOR SENSOR

Tab Header:1376020-1(AMP)

CN4

CN3

CN2A

CN5

CN1

PWR

CN2-A FOR CONTROL

Header:S10B-J21DK-GGYR(JST)

CN5 ONLY 17B-ABS

Connector:IL-2P-S3FP2-I(JST)

CN1 FOR POWER

Header:5569-02A1 (MOLEX)

POWER LED

Compact

Reliability

Simple

SV-NET Regeneration &

Communication Unit TA8413

Driver and motor protected

against regenerative action

Main Functions of TA8413 Regeneration &

Communication Unit

■ Regenerative protection function

Drivers and motors are protected by controlling the

rise of drive voltage due to regenerative action.

A lineup of DC24/48V specifications with built-in

regenerative resistor.

■ SV-NET conversion function

Conversion from RS232C to SV- N ET

■ Master of SV-NET II

PC application "Master of SV-NET II" helps to

enable parameter management of drivers and simple

control from the personal computer.

■ Compatible driver

TA8 410 series

PC「Master of SV- N ET I I」

Reliability

Compact

Simple

SV-NET

Communication Unit TA8433

Control of SV-NET drivers via

RS232C/ RS422 /RS485

Regenerative unit

Driver (Example :TA 8410)

Stabilized power supply

Motor

Main Functions of TA8433

Communication Unit

■ SV-N E T conversion function

Conversion from RS232C/RS422/RS485 to SV-NET

■ Master of SV-N ET II

PC application "Master of SV-NET lI " helps to

enable parameter management of drivers and

simple control from the personal computer.

■ Applicable drivers

All SV-NET drivers

25 26

Compact

Reliability

Simple

Master of SV-NET II

Main Functions of Master of SV- NET II

■ Control mode

Position control, Speed control, Current control

■ Parameter management

Reading and writing to / from parameter list

■ Simple programming

Programming in 20 steps Max. possible.

■ Applicable drivers

All SV-NET drivers

Compact

Reliability

Simple

SV-NET Training Pack TA8425

With the 100VAC / 200VAC power outlet and a PC connected,

this training pack creates an environment for operating three

axes of motors.

Configuration

■ SV- N ET controller

TA8 440 × 1

■ Driver

TA8410 × 3

■ Motor

TBL-i I I 100W TS4603 × 2

TBL-V 50W TS4742 × 1

■ Power source

AC100V/200V input

DC24V output 2.5A

■ Accessories

Power cable × 1

USB cable × 1

CD-ROM × 1

Compact

Reliability

Simple

Servo Motor

AC Servo Motor

Optimal for industrial robots, press machines,

machine tools, weaving machines

Small size and high reliability

Rigidly built and highly reliable, incorporating

thorough quality control.

A rich lineup of models

The angle sensor is a brushless resolver as standard.

Options include encoder 17BIT INC/ABS and

incremental 2048 C/T (min. wiring) types.

Brake is also available.

Brushless Resolver

The brushless resolver can withstand harsh

environmental conditions

(high temperature, low temperature, vibration, shock).

Basic Specifications

Output

Mounting flange

[mm] [V][W]

□40

□60

□80

Model

TS4601 30

TS4602 50

TS4603 100

TS4606 100

TS4607 200

TS4609 400

TS4611 200

TS4612 400

TS4613 600

TS4614 750

Driver power voltage

DC24・DC48

AC100・AC200

AC100・AC200

AC100・AC200

AC100・AC200

100

200

AC100・AC200

AC100・AC200

AC100・AC200

DC24

DC48

DC24

DC48

DC24

DC48

DC24

DC48

AC200

AC200

AC200

Rated torque

[N・m]

0.095

0.095

0.159

0.159

0.159

0.318

0.318

0.318

0.318

0.318

0.318

0.64

0.64

0.64

1.27

0.64

1.27

1.91

2.39

Max. torque

[N・m]

0.29

0.29

0.48

0.48

0.48

0.95

0.95

0.95

0.95

0.95

0.95

1.91

1.91

1.91

3.82

1.91

3.82

5.73

7.16

Rated rotation

speed

−1

[min ]

3,000

3,000

3,000

3,000

3,000

3,000

3,000

3,000

3,000

3,000

3,000

1,500

3,000

3,000

3,000

3,000

3,000

3,000

3,000

Max. rotation speed

−1

[min ]

5,000

5,000

4,600

4,700

5,000

3,600

4,600

5,000

3,600

4,600

5,000

1,900

3,900

5,000

5,000

5,000

5,000

5,000

5,000

27

Motor Characteristics (without brake and oilseal)

SV-NET Servo System

Power supply voltage

Motor flange size

Motor model

Rated output

Rated torque

Stall torque

Momentary max. torque

Rated rotation speed

Max. rotation speed

Rotor inertia

Rated power rate

Mechanical time constant

Shaft friction torque

Axial play

PR

TR

TS

TP

NR

N MAX

J M

QR

τm

Tf

N・m MAX

mm MAX

Allowable radial load

Allowable axial load

W

N・m

N・m

N・m

ー1

min

ー1

min

kg・m

kW/s

ms

N

N

TS4601

2

0.013×10

0.095

0.095

0.29

3,000

5,000

Power supply voltage

Motor flange size

Motor model

N MAX

t

τ

W

P

R

N・m

T

R

N・m

T

S

N・m

T

P

ー1

min

N

R

ー1

min

2

kg・m

J

M

kW/s

Q

R

ms

m

N・m

MAX

T

f

mm

MAX

N

N

Rated output

Rated torque

Stall torque

Momentary max. torque

Rated rotation speed

Max. rotation speed

Rotor inertia

Rated power rate

Mechanical time constan

Shaft friction torque

Axial play

Allowable radial load

Allowable axial load

※The characteristic value is that with no brake or no oil seal.

TS4602

TS4601

30

0.095

0.095

0.29

ー4

0.019×10

0.013×10

7.2

1.5

□40

50

0.159

0.159

0.48

ー4

12.9

0.9

0.02

78.4

39.2

TS4603

0.035×10

TS4602

30

0.159

0.159

0.48

3,000

4,600

ー4

0.019×10

7.2

12.9

1.4

AC100V (E100) AC200V (E200)

TS4606

100

100

0.318

0.318

0.318

0.318

0.95

0.95

3,000

5,000

ー4

0.085×10

28.7

11.9

0.7

1.2

0.2

Low-voltage type

DC24V (E520) DC48V (E620)

□40 □60 □40 □60

50

0.9

TS4603

ー4

0.035×10

0.02

100

0.318

0.318

0.95

3,000

3,600

28.7

0.7

TS4606

ー4

0.085×10

100

0.318

0.318

0.95

3,000

3,600

11.9

1.4

TS4607

ー4

0.018×10

100

0.64

0.64

1.91

1,500

1,900

22.6

1

0.04

TS4601

0.095

0.095

3,000

5,000

ー4

0.013×10

30

0.29

7.2

1.4

TS4602

50

0.159

0.159

0.48

3,000

4,700

ー4 ー4

0.019×10

12.9

0.9

TS4603

0.035×10

0.02

100

0.318

0.318

0.95

3,000

4,600

28.7

0.7

TS4606

0.318

0.318

3,000

4,600

ー4

0.085×10

0.95

11.9

100

1.2

TS4607

ー4

0.18×10

200

0.64

0.64

1.91

3,000

3,900

22.6

1.0

0.04

0.2

□80

TS4613

600

1.91

1.91

5.73

196

68.6

TS4614

750

2.39

2.39

※※※

7.16

78.4

39.2

□60

TS4607

TS4609

200

0.64

0.64

※

※

1.91

400

1.27

1,27

3.82

High-voltage type

高電圧タイプ

□80

TS4601

TS4611

30

200

0.095

0.64

0.095

0.64

※

0.29

1.91

196

68.6

□40

□60

TS4602

TS4603

50

0.159

0.159

0.48

100

0.318

0.318

0.95

TS4607

TS4606

100

0.318

0.318

0.95

□60

200

0.64

0.64

1.91

78.4

39.2

TS4611

TS4609

400

1.27

1,27

※

3.82

200

0.64

0.64

1.91

TS4612

400

1.27

1.27

3.82

3,000

5,000

ー4

0.18×10

22.6

0.9

ー4

0.34×10

0.04

47.9

0.6

ー4

0.28×10

14.3

1.0

0.06

ー4

0.013×10

7.2

1.5

ー4

0.019×10

12.9

0.9

ー4

0.035×10

0.02

28.7

0.7

ー4

0.085×10

11.9

1.2

ー4

0.18×10

22.6

0.9

ー4

0.34×10

0.04

47.9

0.6

ー4

0.028×10

14.3

1.0

ー4

0.55×10

0.06

29.7

0.6

ー4

0.86×10

42.2

0.6

ー4

1.06

0.08

×10

53.6

0.6

0.2

196

68.6

※When combined with TA8411 driver, the momentary max. torque is reduced to two times the rated torque.

78.4

39.2

196

68.6

343

98

ー4

ー4

Model designation

TS □□□□ N □□□□ E □□□

Shaft end specifications

00:No oil seal Round shaft (standard)

01:No oil seal Double-milled

Basic type

10:17 bit INC-SE, No brake

15:2,048C/T (min. wiring) INC-SE, No brake

20:17/33 bit (17B) ABS-SE, No brake

30:1X Resolver, No brake (motor flange size □40)

33:1X Resolver, No brake (motor flange size □60, □80)

60:17 bit INC-SE, Brake

65:2,048C/T (min. wiring) INC-SE, Brake

70:17/33 bit (17B) ABS-SE, Brake

80:1X Resolver, Brake (motor flange size □40)

83:1X Resolver, Brake (motor flange size □60, □80)

02:No oil seal Keyway

05:Oil seal Round shaft

06:Oil seal Double-milled

07:Oil seal Keyway

Power source specifications

520:DC24V

620:DC48V

100:AC100V

200:AC200V

28

Compact

Reliability

Simple

Specifications

Common Specifications

Insulation classification

Withstand voltage

Insulation resistance

Protection

Direction of rotation

F class

AC1500V, 1 minute

DC500V, 100 MΩ or above

Fully-closed, self-cooling, IP65

(excl. connectors and shaft opening)

CCW as viewed from shaft end when

energized in sequence of U→V→W

Operating temperature range

Storage temperature range

Humidity

Coating color

(□40〜□80)

0〜+40(℃)

ー10〜+85(℃)

85% RH Max.

(No condensation)

Shaft Loading Conditions

Motor model

Allowable radial load

[N (kgf)]

TS4601

TS4602

TS4603

78.4(8)

TS4606

TS4607

TS4609

TS4611

196(20)

TS4612

TS4613

TS4614

Be sure to use your motors within the ranges specified in the above table. Please consult us about any of your applications outside the specified ranges.

343(35)

Allowable axial load

[N (kgf)]

39.2(4)

68.6(7)

98(10)

Loading point

20(mm) from flange face

Not painted

Wire Connection Table

Applicable motor model

Motor power line side

Tab housing (Tyco Electronics AMP)

B1 B2 B3

A1

A2

A3

Sensor

B1 B2 B3

B4 B5 B6

A1

A4

A2

A3

A5

(1) 17 bit Incremental type

ENCODER CONNECTION

PIN No. FUNUCTION COLOR

A1

A2

A3

A4

A5

A6

B1

B2

B3

B4

B5

B6

SD

Vcc

SD

GND

SHIELD

:178964−3

Tab contact

:175289−2

:175288ー2(PIN No. B2, B3)

Tab housing

:1ー1318115−6

Tab contact

A6

:1318112−1

BLU

RED

BLU/BLK

BLK

SHIELD

TS4601〜TS4614

(Tyco Electronics AMP)

(2) 17 bit ABS type

ENCODER CONNECTION

PIN No. FUNUCTION COLOR

A1

A2

A3

A4

A5

A6

B1

B2

B3

B4

B5

B6

SD

VB

Vcc

SD

GND

GND

SHIELD

BLU/BLK

BRW/BLK

SHIELD

MOTOR & BRAKE CONNECTION

PIN No. FUNUCTION COLOR

A1

A2

A3

B1

B2

B3

U

V

W

C.G

(BRAKE)

(BRAKE)

(3) Min. wiring incremental

ENCODER CONNECTION

PIN No. FUNUCTION COLOR

A1

BLU

BRW

RED

BLK

A2

A3

A4

A5

A6

B1

B2

B3

B4

B5

B6

ー

UE,A

ー

VE,B

ー

WE,Z

SHIELD

UE,A

VE,B

WE,Z

Vcc

ー

ー

ー

GND

RED

WHT

BLK

GRN/YEL

(YEL)

(BLU)

BLU/BLK

GRN/BLK

YEL/BLK

SHIELD

BLU

GRN

YEL

RED

BLK

(4) Resolver

RESOLVER CONNECTION

PIN No. FUNUCTION COLOR

A1

A2

A3

A4

A5

A6

B1

B2

B3

B4

B5

B6

S2

S1

R1

S4

S3

R2

SHIELD

BLU

BRW

RED

BLU/BLK

BRW/BLK

BLK

SHIELD

29

Shaft Specifications

For motors with shaft keyway

R

SV-NET Servo System

(Keyway width)

S

Motor model

Q (keyway length)

TS4601

TS4602

16

TS4603

TS4606

TS4607

TS4609

TS4611

20

TS4612

TS4613

25

TS4614

For motors with double milled shaft

S

S

6.2(0,ー0.2)

11(0,ー0.2)

15.5(0,ー0.2)

Q

(Keyway length)

Dimensions : mm

R (keyway)

3P9(ー0.006,ー0.031)

Supplied key size

3×3×16 (half circle)

(JIS B 1301)

5P9(ー0.012,ー0.042)

6P9(ー0.012,ー0.042)

5×5×20 (half circle)

(JIS B 1301)

6×6×25 (half circle)

(JIS B 1301)

For motors with oil seal

When oil seal is provided, be sure to use under the following

conditions :

・Keep the level of oil below the lip of the oil seal.

・Use the oil seal in a way that it is exposed

to the spray of oil.

S

Motor model

TS4601

TS4602

TS4603

TS4606

TS4607

TS4609

TS4611

TS4612

TS4613

TS4614

Q (milling width)

16

20

25

Q

S (milling width)

7.5 (±0.2)

13 (±0.2)

17.5 (±0.2)

Oil seal

30

Compact

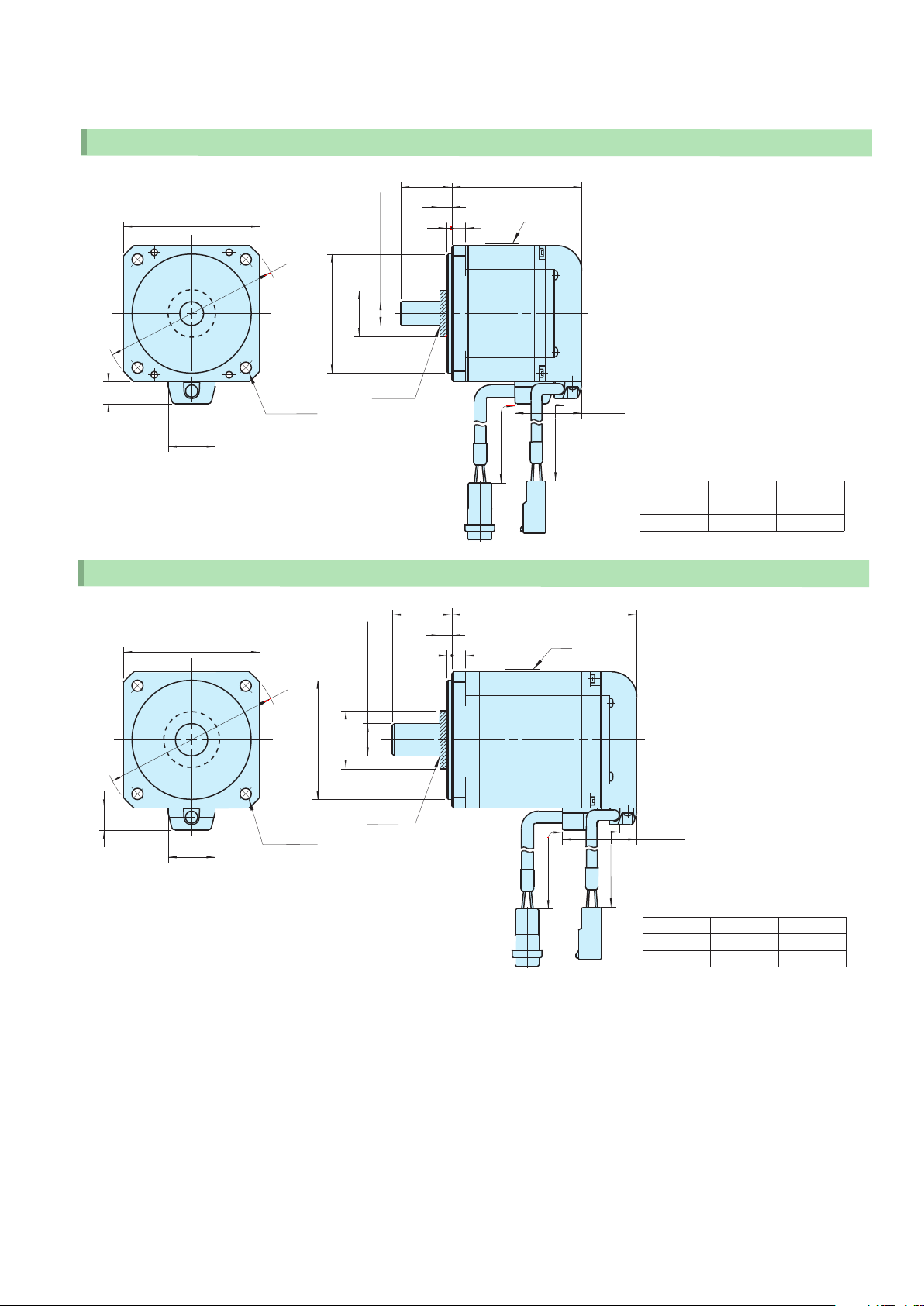

Dimensional Outline

Reliability

Simple

(Standard Type)

●□40 (30W,50W,100W)

□40

φ

55

)

(11.1

(21

2-φ4.5

PCD 46

)

●□60 (100W)

□60

0

−0.021

30h7

φ

equal division

φ80

0

−0.025

±1

25

)

(7

※

0

−0.009

2.5

8h 6

φ

)

20

(φ

※

(Oil seal)

0

−0.009

8h6

φ

)(φ

21

50h7

※

φ

5

±1

25

)(7

※

3

L

±50

300

Name plate

6

±1

Name plate

±50

300

±1

L

)(

39

L dimension

Rated output

Model

L(mm)

※Without oil seal, the shaded part is absent.

30W 50W

TS4601 TS4602

(Unit:mm)

100W

TS4603

73.559.553.5

)(13

4-φ5.5

PCD 70

)(27.6

●□60 (200W,400W)

□60

□

φ

)

13

(

)

(

27.6

4-φ5.5

PCD 70

PCD 70

equal division

80

0

−0.025

50h7

φ

equal division4-φ5.5

(Oil seal)

0

)

27

(φ

※

−0.011

14h6

φ

(Oil seal)

)(40.2

±50

300

±1

30

※

)(

7

3

6

±50

300

L

Name plate

±50

300

L dimension

Rated output

Model

L(mm)

±1

)(42.8

±50

300

L dimension

Rated output

Model

L(mm)

200W

TS4607

76.1

100W

TS4606

59.8

400W

TS4609

98.1

31 32

●□80 (200W,400W)

□80

φ

105

0

−0.030

70h 7

φ

SV-NET Servo System

(Unit:mm)

0

−0.011

14 h6

φ

±1

30

)(

※

7

3

8

±1

L

Name plate

※Without oil seal, the shaded part is absent.

)

(φ27

※

)(13

4-φ6.6

PCD 90

)(27.6

●□80 (600W,750W)

□80

φ

)(

13

)(27.6

4-φ6.6

PCD 90

equal division

105

0

−0.030

70 h7

φ

equal division

)

34

(φ

※

(Oil seal)

0

−0.013

19 h6

φ

(Oil seal)

35

)(

39.2

±50

300

±1

)(

※

7

8

3

±50

300

±1

L

Name plate

±50

300

±50

300

L dimension

Rated output

Model

L(mm)

(

)

43.8

200W

TS4611

64.3

400W

TS4612

76.3

L dimension

Rated output

Model

L(mm)

600W

TS4613

99.7

750W

TS4614

108.7

Compact

Dimensional Outline

Reliability

Simple

(Brake Type)

●□40 (30W,50W,100W)

□40

φ

55

)

(11.1

(21

2-φ4.5

PCD 46

)

●□60 (100W)

□60

0

−0.021

30h7

φ

equal division

φ80

±1

25

)

(7

※

0

−0.009

8h 6

φ

)

20

(φ

※

(Oil seal)

0

−0.009

8h6

φ

2.5

5

±50

±1

25

)(7

※

6

3

Name plate

300

L

Name plate

±1

L

±1

※Without oil seal, the shaded part is absent.

74.7()

±50

300

L dimension

Rated output

Model

L(mm)

89.1 95.1

50W30W

TS4602TS4601

(Unit:mm)

100W

TS4603

109.1

)(13

4-φ5.5

PCD 70

)(27.6

●□60 (200W,400W)

□60

φ80

0

−0.025

50h7

※

φ

equal division

0

−0.025

50h7

※

φ

)

21

(φ

(Oil seal)

0

27(φ )

−0.011

14 h6

φ

64.2()

±50

300

±1

30

※

7( )

3

6

±50

300

±1

L

Name plate

L dimension

Rated output

Model

L(mm)

100W

TS4606

83.8

)(13

equal division

4-φ5.5

PCD 70

)(27.6

(Oil seal)

±50

300

±50

300

( )

77.4

L dimension

Rated output

Model

L(mm)

200W

TS4607

110.7

400W

TS4609

132.7

33 34

●□80 (200W,400W)

□80

SV-NET Servo System

±1

30

※

0

−0.011

14 h 6

φ

105

0

−0.030

70 h7

φ

φ

)

27(φ

※

7( )

8

3

±1

L

Name plate

※Without oil seal, the shaded part is absent.

(Unit:mm)

)(13

)(27.6

●□80 (600W,750W)

□80

φ

)(

13

)(27.6

4-φ6.6

PCD 90

4-φ6.6

PCD 90

105

0

−0.030

70 h7

φ

equal division

(Oil seal)

equal division

0

−0.013

19 h6

φ

34(φ )

※

(Oil seal)

70.2()

±50

300

±1

35

7( )

※

3

8

Name plate

±50

300

L dimension

Rated output

Model

L(mm)

±1

L

200W

TS4611

95.3

400W

TS4612

107.3

80.4( )

±50

300

±50

300

L dimension

Rated output

Model

L(mm)

600W

TS4613

136.3

750W

TS4614

145.3

Compact

Reliability

Simple

AC Servo Motor

AC Servo Motor

Optimal replacement for

step motors

Servo motors mechanically compatible with step motors

The TBL-V series AC servo motors have the same flange size as

that of step motors. Hence, they can be installed in replacement of

such step motors.

(Note : The installation dimensions of step motors may vary by makers. Check the drawing for details.)

VR resolver

The VR resolver is of a simple structure with fewer parts than the

brushless resolver. lt features lower cost and even higher reliability.

Motor Characteristics

Power supply voltage

Motor flange size

Motor model

Rated output