1

GENERAL SAFETY RULES

GB

WARNING! When using electric tools, basic safety precautions, including the following, should always be followed to

reduce the risk of fire, electric shock and personal injury.

Read all these instructions before operating this product and save these instructions.

MODEL NO. AC210516, AC210518

USER MANUAL

Electric Chain Saws

6096-210509

WARNING • PLEASE READ

Beware of kickback. Hold chain saw firmly with both hands when using. For your own

safety, please read and follow the safety precautions in this manual before attempting to

operate your chain saw. Improper use can cause serious injury.

DOUBLE INSULATED

1. Keep work area clean

Cluttered areas invite injuries. Do not start cutting

until you have a clear work area, secure footing, and

a planned retreat path from the falling tree.

2. Consider work area environment

Use extreme caution when cutting small sized brush

and sapling, as slender material may catch the saw

chain and be whipped toward you or pull you off balance. Do not operate a chain saw in a tree unless you

are specifically trained to do so. When cutting a limb

that is under tension, be alert for spring back so that

you will not be struck when the tension in the wood

fibers is released. Do not expose the chain saw to

rain. Do not use the chain saw in damp or wet locations. Do not use the chain saw in the presence of

flammable liquids or gases.

3. Store idle chain saw

When not in use, tools should be stored in a dry, high

or locked up place, out of reach of children.

4. Do not force the chain saw

The chain saw will do a better and safer job when

used at the rate for which it was intended.

5. Use the right tool

Cut wood only. Do not use the chain saw for purpos-

es for which it was not intended. For example, do not

use the chain saw for cutting plastic, masonry, or

non-building materials.

6. Dress properly

Do not wear loose clothing or jewelry, as they can get

caught in moving parts. Non-skid footwear is recommended when working outdoors. Wear protective hair

covering to contain long hair.

7. Use safety gear

Use safety glasses, safety footwear, snug fitting

clothing, protective gloves, and protective hearing

and head gear.

8. Carrying the saw

Carry the saw by the front handle with the saw

stopped. Keep your finger off the switch, and make

sure that the guide bar and saw chain are to the rear.

9. Do not abuse the cord

Never carry the tool by the cord or pull it to disconnect it from the socket. Keep the cord away from

heat, oil and sharp edges.

10. Secure work

Use clamps or a vice to hold the work.

11. Do not overreach

Keep proper footing and balance at all times.

12. Maintain the chain saw with care

Inspect the chain saw cords periodically and, if

damaged, have them repaired by an authorized

service facility. Keep the cord clear of the chain and

operator at all times. Never carry the saw by the cord

or pull it to disconnect from receptacle. Keep the cord

from oil and sharp edges. Inspect the extension cords

periodically and replace if damaged. Keep tools

sharp and clean for better and safer performance.

Follow instructions for lubricating and changing

accessories. Keep handles dry, clean and free from

oil and grease.

13. Disconnect the chain saw

Disconnect the chain saw when not in use, before

servicing, and when changing accessories and

attachments such as saw chain and guard.

14. Remove adjusting keys and wrenches

Form the habit of checking to see that keys and

adjusting wrenches are removed from the tool before

turning it on.

15. Avoid unintentional starting

Do not carry a plugged-in tool with a finger on the

switch. Ensure switch is off when plugging in.

16. Use outdoor extension leads

Use only extension cords that are intended for outdoor use and which are so marked.

17. Stay alert

Watch what you are doing. Use common sense. Do

not operate the chain saw when you are tired. Keep

all parts of your body away from the saw chain when

the motor is operating. Before you start the saw,

make sure the saw chain is not contacting anything.

18. Check damaged parts

Before further use of the tool, a guard or other part

that is damaged should be carefully checked to determine that it will operate properly and perform its

intended function. Check for alignment of moving

parts, free running of moving parts, breakage of

parts, mounting and any other conditions that may

affect its operation. A guard or other part that is dam

aged should be properly repaired or replaced by an

authorized service centre unless otherwise indicated

in this instruction manual. Have defective switches

replaced by an authorized service facility. Do not use

the tool if the switch does not turn it on and off.

Meaning of symbols marked on the product

Read the user manual before using the machine

Wear safety goggles to protect your eyes

Wear ear protector to protect against noise

Wear gloves to protect your hands

Wear safety boots to protect against electric shock

Do not expose to rain

Wear dust mask to protect against dust

Remove plug from the mains immediately if cable is damaged or cut

WARNING: Take care not to expose this tool

to rain and remove plug from mains immediately if the supply cable is damaged.

GB

3

GB

2

SPECIFICATIONS

MODEL NO. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .AC210516 . . . . . . . . . . . . . . . .AC210518

Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1800Watt . . . . . . . . . . . . . . . . . . . .1800Watt

No Load Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7,000/min. . . . . . . . . . . . . . . . .7,000/min.

Cutting Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12 m/sec . . . . . . . . . . . . . . . . .12 m/sec

Cutting Length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16” (40cm) . . . . . . . . . . . . . . . .18” (45cm)

Tension Ajustment

. . . . . . . . . . . . . . . . . . . . . . . . . . . .Chain-Rigid-Toolless . . . . . . . .Chain-Rigid-Toolless

Net Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4.3 Kg . . . . . . . . . . . . . . . . . . . .4.3 Kg

Oil Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .200ml . . . . . . . . . . . . . . . . . . . .200ml

Braking Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .200ml . . . . . . . . . . . . . . . . . . . .200ml

Vibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8.4m/s

2

. . . . . . . . . . . . . . . . . . .8.4m/s

2

Sound Power Level . . . . . . . . . . . . . . . . . . . . . . . . . . . .106.1 dB(A) . . . . . . . . . . . . . . .106.1 dB(A)

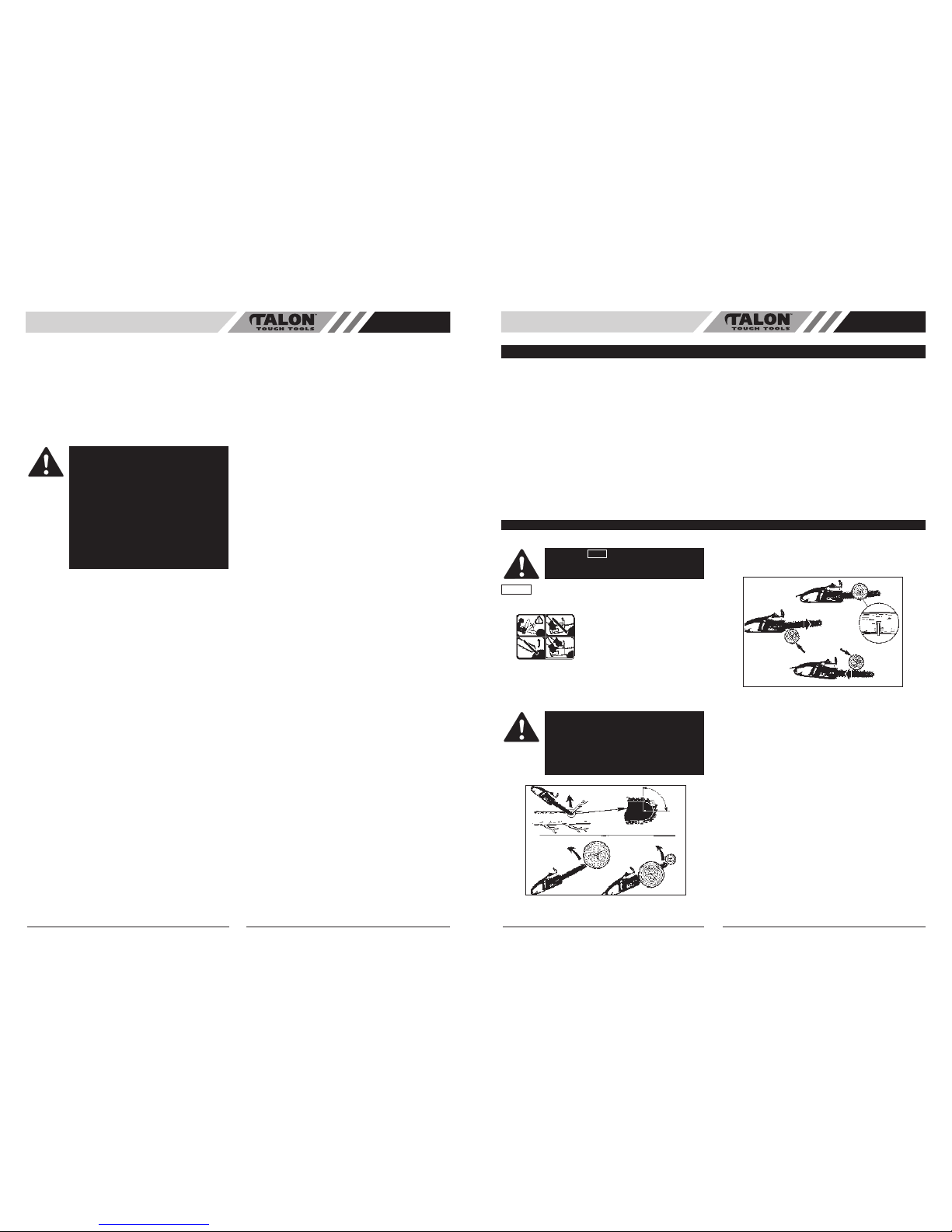

• HOW TO READ SYMBOLS AND COLORS (FIG. 1)

GREEN RECOMMENDED

Recommended cutting procedure.

WARNING

1. Beware of kick back.

2. Do not attempt to hold saw

with one hand.

3. Avoid bar nose contact.

RECOMMENDED

4. Hold Saw properly with both

hands.

• DANGER! BEWARE OF KICKBACK!

BEWARE OF: ROTATIONAL KICKBACK

(Fig. 2A)

A = Kickback path

B = Kickback reaction zone

THE PUSH (PINCH KICKBACK) AND PULL REACTIONS (Fig. 2B)

A = Pull

B = Solid objects

C = Push

KICKBACK may occur when the NOSE or TIP of the

guide bar touches an object, or when wood closes in and

pinches the saw chain in the cut.

Tip contact in some cases may cause a lightning-fast

reverse reaction, kicking the guide bar up and back

toward the operator.

PINCHING the saw chain along the BOTTOM of the guide

bar may PULL the saw forward, away from the operator.

PINCHING the saw chain along the TOP of the guide bar

may PUSH the guide bar rapidly back toward the operator.

Any of these reactions may cause you to lose control of

the saw, which could result in serious personal injury.

IMPORTANT SAFETY

WARNING: RED Used to warn that an

unsafe procedure should not be performed.

1

3

2

4

WARNING: Kickback can lead to dangerous

loss of control of the chain saw and result in

serious or fatal injury to the saw operator or to

anyone standing close by. Always be alert

because rotational kickback and pinch kickback

are major chain saw operational dangers and

the leading cause of most accidents.

A

A

B

A

C

B

A

B

19. Warning!

The use of any accessory or attachment, other than

those recommended in this instruction manual, may

present a risk of personal injury.

20. Have your tool repaired by a qualified person

This electric tool is in accordance with the relevant

safety requirements. Repairs should only be carried

out by qualified persons using original spare parts,

otherwise this may result in considerable danger to

the user.

21. Guard against KICKBACK

A. GRIP SAW FIRMLY: Hold the chain saw firmly

with both hands when the motor is running.

Keep a good firm grip on the saw with both

hands, the right hand on the rear handle, and

the left hand on the front handle.

B. Do not over reach.

C. Keep proper footing and balance at all times.

D. Do not let the nose of the guide bar contact a

log, branch, ground or other obstruction.

E. Do not cut above shoulder height.

F. Use devices, such as low-kickback chain, guide

bar nose guards, chain brakes and special guide

bars, which reduce the risks associated with

kickback.

G. Use only replacement bars and chains

specified by the manufacturer or the equivalent.

22. Power supply

Connect the chain saw to correct voltage; be sure

that the voltage supplied is the same as that specified

on the nameplate of the tool.

23. DO NOT operate a chain saw that is damaged,

improperly adjusted, or not completely and securely

assembled. Be sure that the saw chain stops moving

when the trigger is released.

24. DO NOT attempt operations beyond your capacity or

experience.

25. DO NOT operate a chain saw with one hand! Serious

injury to the operator, helpers, or bystanders may

result from one-handed operation. A chain saw is

intended for two-handed use.

26. TO REDUCE potential for electric shock, do not operate the saw on wet or slippery surfaces, or during

snow storms, rain storms, and other adverse weather conditions.

27. Keep the handles dry, clean, and free of oil or grease.

28. DO NOT allow dirt, debris or sawdust to build up on

the motor or outside air vents.

29. Follow the manufacturer’s sharpening and maintenance instructions for the saw chain.

30. Cut at high motor speeds.

31. Operation of a chain saw should be restricted to

mature, properly instructed individuals.

32. Your chain saw is intended for occasional

homeowner use. It is not made for heavy continuous

use.

33. DO NOT FORCE a small saw to do a job requiring a

heavier duty unit.

34. Examine the electrical switches. Do not use the

chain saw if the switches do not properly turn on and

off. Do not attempt to make any repairs to the electric

switches. Take your saw to a Talon Authorized

Service Center.

35. Maintain extension cords Inspect the extension

cords periodically and replace if damaged. Only use

power cords that are suitably marked for outdoor use.

36. DO NOT operate your chain saw near or around

flammable liquids or gases, whether in or out of

doors. An explosion and/or fire may result.

37. All chain saw service, other than the items listed in

the user manual safety and maintenance

instructions, should be performed by competent

chain saw personnel. Do not attempt to repair it yourself; there are no user serviceable parts inside.

38. NEVER REMOVE, modify or make inoperative any

safety device furnished with your unit. The CHAIN

BRAKE

®

/Hand Guard is a major safety feature. The

saw will not run when the CHAIN BRAKE

®

is tripped.

39. It is intended for infrequent use by homeowner’s, cottagers and campers, and for such general applications such as clearing, pruning, cutting firewood, etc.

It is not intended for prolonged use. If the intended

use involves prolonged periods of operation, this may

cause circulatory problems in the user’s hands due to

vibration. It may be appropriate to use a saw having

an anti-vibration feature.

40. Safety clothing required by government regulations,

or your employer should be used; otherwise, snug fitting clothing, safety footwear, and hand and ear protection should be worn.

WARNING: Kickback may occur when the

nose or tip of the guide bar touches an

object, or when the wood closes in and

pinches the saw chain in the cut. Tip contact

in some cases may cause a lightning-fast

reverse action, kicking the guide bar rapidly

back towards the operator. Pinching the saw

chain along the top of the guide bar may

push the guide bar rapidly back towards the

operator. Either of these reactions may

cause you to lose control of the saw, which

could result in serious injury to the user. The

following precautions should be followed to

minimize kickback.

4

GB

GENERAL INFORMATION

1

2

1. Rear Handle

2. Oil Tank Cap

3. Trigger Start

4. Sprocket cover

5. Chain Cover Control Knob

6. Chain Tension Ring

7. Electric Motor

8. Electric Cord

9. Chain Brake Lever / Hand

Guard

10. Lock / Button

11. Front Handle

12. Guide Bar

13. Saw Chain

14. Spiked Bumper

15. Rear hand Guard

16. Guide Bar Nose

17. Oil Tank Inspection Window

18. Cord Retainer

19. Chain Catcher

3

7

4

13

6

8

9

10

11

12

14

15

16

17

18

• SAFETY FEATURES

Numbers preceding the descriptions correspond with the numbers above to help you locate the safety feature.

3 TRIGGER START / STOP SWITCH stops saw motor when released.

9 CHAIN BRAKE LEVER / HAND GUARD activates the chain brake and protects the operator’s left hand in the

event it slips off the front handle while saw is running.

7 ELECTRIC MOTOR is double insulated for added safety.

10 LOCK / OFF BUTTON prevents accidental acceleration of the saw motor. The trigger cannot be squeezed unless

lock/off button is pushed forward to end.

13 LOW-KICKBACK CHAIN helps significantly reduce kickback, or the intensity of kickback, due to specially

designed depth gauges and Guard links.

19 CHAIN CATCHER reduces the danger of injury in the event saw chain breaks or derails during operation. The

catcher is designed to intercept a whipping chain.

5

19

5

GB

•

INTRODUCTION

This unit is designed for occasional homeowner use and

should not be used for commercial purposes or subjected

to heavy continuous use.

Your new chain saw can be used for a variety of projects

such as cutting firewood, making fence posts, felling small

trees, limbing, pruning at ground level, and light carpentry.

Cut only wood or wood products with your saw.

• ASSEMBLY REQUIREMENTS

Your new chain saw will require adjustment of chain and

filling the oil tank with lubricating oil before the unit is

ready for operation. Do not start the saw motor until the

unit is properly prepared. Read all instructions carefully.

Do not install any other size bar and chain than what is

recommended for your model.

• GUIDE BAR / SAW CHAIN INSTALLATION

TO INSTALL GUIDE BAR & SAW CHAIN:

1. Place power unit on flat surface.

2. To remove the side cover (A), turn the knob (B) counter-clockwise. (Fig. 3A)

3. Screw (C) the tension plate (D) on the bar. (Fig. 3B)

4. Spread the chain out with the cutting edges (E) of the

chain pointing in the DIRECTION OF ROTATION (Fig.

3C).

5. To fit the chain on the bar, turn the tension plate (D)

counter-clockwise to the end. Install the chain and bar

on the power unit, turn the tension plate (D) clockwise

and then put the side cover (A) on. (Fig. 3D)

6. Turn the knob clockwise, adjust the chain tension pin

and then fasten the knob.

7. After running the chain saw around 1 hour, adjust the

chain tension to 2mm.

• SAW CHAIN TENSION ADJUSTMENT

Proper tension of the saw chain is extremely important

and must be checked before starting, as well as during,

any cutting operation. Taking the time to make needed

adjustments to the saw chain will result in improved cutting performance and prolonged chain life.

NOTE: A new chain and bar will need readjustment after

as few as 5 cuts. This is normal during the break-in peri

od, and the interval between future adjustments will

lengthen quickly (Fig. 4).

TO ADJUST SAW CHAIN TENSION:

NOTE: Make sure the chain brake is disengaged.

Disengage the chain brake (A) by pulling it backward (Fig.

5A).

1. To adjust the chain tension release locking knob (B)

by turning counter clockwise. (Fig. 5B)

2. To tighten chain tension turn adjustment ring (A)

clockwise. (Fig. 5B)

3. Lock bar in place by tightening locking knob (B).

NOTE: If the chain is difficult to rotate or if it binds on the

guide bar, too much tension has been applied and must

be adjusted as follows:

4. Release locking knob (B).

5. Release chain tension by turning adjustment ring (A)

counter clockwise.

6. Tighten locking knob.

ASSEMBLY INSTRUCTIONS

CAUTION: Disconnect the chain saw from

mains before checking adjusting the chain

saw tension.

Fig. 3A

B

A

Fig. 3B

C

D

Fig. 3C

D

Fig. 3D

A

E

CAUTION: If a chain is TOO LOOSE or TOO

TIGHT, the bar chain and saw bearings will

wear more rapidly. Study Fig. 4 for information concerning correct cold tension (A), cor

-

rect warm tension (B), and as a guide for

when saw chain needs adjustment (C).

CAUTION: If the chain is too loose, more

than 3mm after applying down force with finger, as shown in Fig. 4. It needs to be adjusted, otherwise the stopping time might be

over the limit.

Fig.4

A

B

C

B

A

A

GB

7

GB

6

• FILLING OIL TANK

Using a funnel, fill oil tank with Talon Chain, Bar and

Sprocket oil. Wipe up any spills. Make sure no dirt gets

into the oil tank.

The saw chain requires lubrication while in use to minimize friction with the guide bar. The oil tank holds 200ml

of oil, enough to lubricate the chain for 15-20 minutes of

sawing.

We recommend using Talon Chain, Bar and Sprocket Oil,

which contains additives to reduce friction wear and

reduce resin residue formations.

NOTE: Your chain saw is equipped with an Automatic

Oiler system and is the ONLY source of lubrication for the

bar and chain (Fig. 6)

• TO START SAW

1. Make sure the chain brake IS DISENGAGED. The

motor will not start if the chain brake is in the

ENGAGED position. Disengage the chain brake by

pulling backward toward the motor (Fig. 7A).

2. An extension cord retainer is built into the switch handle that prevents the extension cord from pulling out of

the handle. To use this feature, simply double the

extension cord, about a foot from the end, and insert it

into the end of the handle. Hook the loop formed by

doubling the cord over the tab. Gently tug on the cord

to ensure that it is firmly retained in the saws handle.

Plug the receptacle end of the extension cord into the

tool;s power supply cord. (Fig. 7B)

3. Grip the saw with both hands, left hand holding the

front /handle (DO NOT HOLD CHAIN BRAKE ) and the

right hand holding the rear handle. Thumbs and fingers

should encircle both handles (Fig. 7C).

4. With your RIGHT THUMB, push the LOCK/OFF button

(C) forward at end the top of the rear handle, and at the

same time squeeze the trigger. To stop the saw,

release the trigger (Fig. 7D).

NOTE: It is not necessary to maintain pressure on the

LOCK/OFF button once the trigger is squeezed and the

motor is running. The LOCK/OFF button is a safety device

to avoid accidental starting.

• TO STOP MOTOR

The saw motor will automatically stop when the trigger is

released. The LOCK/OFF button will have to be

depressed and the trigger squeezed to restart the motor.

• CHAIN AND BAR LUBRICATION

Adequate lubrication of the saw

chain during cutting operations is

essential to minimize friction with

the guide bar.

Your chain saw is equipped with

an automatic oiler system. The

oiler automatically delivers the

proper amount of oil to the bar

and chain. There is no flow

adjustment.

The oil tank level can be checked in the inspection window (A) provided on the right side of the saw. Tank is full

when oil is at the top of the slot (Fig. 8).

NOTE: The saw chain stretches during use, particularly

when it is new, and occasional adjustment will be needed.

A new chain requires more frequent adjustment during the

break-in period. This is normal. See Section for Saw

Chain Tension Adjustment instructions.

•

CHAIN BRAKE / HAND GUARD

All Talon chain saws are equipped with a Chain brake

/Hand guard which stops a moving chain in milliseconds,

helping to reduce the hazard of kickback, a fast upward

motion of the guide bar which occurs when the saw chain

at the nose of the bar accidentally strikes an object or is

pinched in the cut.

The Hand Guard also protects your left hand in the event

it slips off the front handle.

CAUTION: The oil tank level should be frequently checked during operation to avoid

starving the bar and chain of lubrication.

Fig. 6

Oil Cap

OPERATING INSTRUCTIONS

WARNING: Ensure the extension cord is of

the proper size and type for your saw.

Fig. 7C

C

Fig. 7D

Fig. 7A

A

Fig. 7B

Fig. 8

A

CAUTION: Never starve the bar and chain of

lubrication oil. Running the saw DRY or with

TOO LITTLE OIL will decrease cutting efficiency, shorten chain saw life, and cause

rapid dulling of the chain and excessive wear

of the bar from overheating. Too little is evidenced by smoke or bar discoloration.

CAUTION: A loose chain can jump off the

bar while you are cutting, as well as wear the

bar and chain. A chain that is too tight can

damage the saw. Either situation, chain too

loose or too tight, could cause serious personal injury.

The chain brake is a safety feature which is activated if

pressure is applied against the guard or when, in the

event of kickback, the operator’s hand strikes the lever.

When the chain brake is activated, chain movement

abruptly stops and the power supply to the motor is imme

-

diately cut off.

The purpose of the chain brake is to reduce the possibili-

ty of injury due to kickback. The chain brake cannot,

however, provide the measure of intended protection if the

saw is carelessly operated.

The chain brake is disengaged (chain can move) when

the brake is pulled back and locked. This is the normal

running position (Fig. 9A).

The chain brake is engaged (chain cannot move) when

the brake is in forward position (Fig. 9B).

NOTE: The motor will not start if the chain brake is in the

engaged position.

CHAIN BRAKE TEST

Before cutting with your saw, the chain brake should be

tested as follows:

A. Make sure the chain brake is disengaged (Fig. 9A).

B. Place the saw on a firm, flat, dry surface that is clear

of any debris. Do not let the saw come in contact

with any objects.

C. Plug the unit into the power source.

D. Grasp the front handle (not the Chain Brake / Hand

Guard Lever) with your left hand. Thumb and fingers

should encircle the handle.

E. Grasp the rear handle with your right hand. Thumb

and fingers should encircle the handle.

F. Depress the LOCK/OFF button with your right thumb.

Squeeze the trigger with your index finger. (Fig. 7D.)

G. While the motor is running, activate the chain brake

by rolling your left hand forward against the lever.

H. Chain and motor should stop abruptly.

• FELLING

Felling is the term for cutting down a tree. Small trees up

to 15-18cm in diameter are usually cut in a single cut.

Larger trees require notch cuts. Notch cuts determine the

direction the tree will fall.

FELLING A TREE:

NOTE: Direction of fall (B) is

controlled by the notching cut.

Before any cuts are made,

consider the location of larger

branches and natural lean of

the tree to determine the way

the tree will fall.

• GENERAL GUIDELINES FOR FELLING TREES:

Normally felling consists of 2 main cutting operations,

notching (C) and making the felling cut (D).

Start making the upper notch cut (C) on the side of the

tree facing the felling direction (E). Be sure you don’t

make the lower cut too deep into the trunk.

The notch (C) should be deep enough to create a hinge

(F) of sufficient width and strength. The notch should be

wide enough to direct the fall of the tree for as long as

possible.

Never saw completely through the trunk. Always leave a

hinge. The hinge guides the tree. If the trunk is completely cut through, control over the felling direction is lost.

Insert a wedge or felling lever in the cut well before the

tree becomes unstable and starts to move. This will prevent the guide bar from binding in the felling cut if you

have misjudged the falling direction. Make sure no

bystanders have entered the range of the falling tree

before you push it over.

Fig. 9A

CAUTION: The chain brake should not be

used for starting and stopping the saw during

normal operation.

Fig. 9B

WARNING: If the chain and motor fail to

stop when the chain brake is engaged, take

the saw to the nearest professional Service

Center. Do not use the saw if the chain

brake is not in proper working order.

GENERAL CUTTING INSTRUCTIONS

WARNING: A retreat path (A) should be

planned and cleared as necessary before cuts

are started. The retreat path should extend

back and diagonally to the rear of the expected line of fall, as illustrated in Fig. 10.

CAUTION

: If felling a tree on sloping ground,

the chain saw operator should keep on the

uphill side of the terrain, as the tree is likely

to roll or slide downhill after it is felled.

Fig. 10A

A

B

WARNING: Do not cut down a tree during

high or changing winds or if there is a danger

to properly. Consult a tree professional. Do

not cut down a tree if there is a danger of

striking utility wires; notify the utility company

before making any cuts.

F

C

3/4

D

3.5cm

E

Fig. 10B

WARNING:

Never walk in front of a tree that

has been notched. Make the felling cut (D)

from the other side of the tree and 3-5cm

above the edge of the notch (C) (Fig. 10B).

9

GB

8

GB

FELLING CUT:

1. Use wooden or plastic wedges (G) to prevent binding

the bar or chain (H) in the cut. Wedges also control

felling (Fig. 10C).

2. When diameter of wood being cut is greater than the

bar length, make 2 cuts as shown (Fig. 10D).

• LIMBING

Limbing a tree is the process of removing the branches

from a fallen tree. Do not remove supporting limbs (A)

until after the log is bucked (cut) into lengths (Fig. 11).

Branches under tension should be cut from the bottom up

to avoid binding the chain saw.

• BUCKING

Bucking is cutting a fallen log into lengths. Make sure you

have a good footing and stand uphill of the log when cutting on sloping ground. If possible, the log should be supported so that the end to be cut off is not resting on the

ground. If the log is supported at both ends and you must

cut in the middle, make a downward cut halfway through

the log and then make the undercut. This will prevent the

log from pinching the bar and chain. Be careful that the

chain does not cut into the ground when bucking as this

causes rapid dulling of the chain.

When bucking on a slope, always stand on the uphill side.

1. Log supported along entire length: Cut from top

(overbuck), being careful to avoid cutting into the

ground (Fig. 12A).

2. Log supported on 1 end: First, cut from bottom

(underbuck) 1/3 diameter of log to avoid splintering.

Second, cut from above (overbuck) to meet first cut

and avoid pinching (Fig. 12B).

3. Log supported on both ends: First, overbuck 1/3

diameter of log to avoid splintering. Second, underbuck to meet first cut and avoid pinching (Fig.

12C).

NOTE: The best way to hold a log while bucking is to use

a sawhorse. When this is not possible, the log should be

raised and supported by the limb stumps or by using sup

porting logs. Be sure the log being cut is securely supported.

•

BUCKING USING A SAWHORSE

For personal safety and ease

of cutting, the correct position

for vertical bucking is essential (Fig. 13).

VERTICAL CUTTING:

A. Hold the saw firmly with

both hands and keep the

saw to the right of your

body while cutting.

B Keep the left arm as

straight as possible.

C. Keep weight on both feet.

• GUIDE BAR MAINTENANCE

Proper maintenance of the guide bar, as explained in

this section, is essential to keep your saw in good

working order.

SPROCKET TIP LUBRICATION:

(For units supplied with sprocket tip guide bars only.)

Lubrication of the sprocket tip is recommended after each

saw use. Always thoroughly clean the guide bar sprocket

tip before lubrication.

Tool for lubrication: Talon Lube Gun (disposable)

This grease gun is designed to fit the small lubrication

point on the guide bar.

The disposable Lube Gun is packed with grease.

WARNING:

As the felling cut gets close to

the hinge, the tree should begin to fall. When

tree begins to fall, remove saw from cut,

unplug, put chain saw down, and leave area

along retreat path (Fig. 10A).

Fig. 10C

Fig. 10D

G

H

WARNING:

Never cut tree limbs while stand-

ing on tree trunk.

Fig. 11 Fig. 12A

Fig. 12B

A

2

12

1

Fig. 13

A

B

C

CAUTION: While the saw is cutting, be sure

the chain and bar are being properly lubricated.

BAR / CHAIN MAINTENANCE

WARNING:

Ensure that the power cord is

disconnected before performing any maintenance on your saw.

CAUTION: Failure to lubricate the guide bar

sprocket tip as explained below will result in

poor performance and seizure, voiding the

manufacturer’s warranty.

WARNING:

Wear heavy duty work gloves

when performing this application to reduce

risk of personal injury.

To Lubricate Sprocket Tip:

1. Unplug the chain saw from the power source.

NOTE: It is not necessary to remove the saw chain to

lubricate the guide bar sprocket tip. Lubrication can be

done on the job.

2.

Clean the guide bar sprocket tip.

3. Using disposable Lube gun, insert needle nose into

the lubrication hole and inject grease until it appears

at the outside edge of the sprocket tip (Fig.14).

4. Make sure that the chain brake is deactivated. Rotate

the saw chain by hand. Repeat the lubrication procedure until the entire sprocket tip has been greased.

To Clean Guide Bar Rails:

1. Remove sprocket cover, bar and chain.

2. Using a screwdriver, putty knife, wire brush or other

similar instrument, clear residue from the rails on the

guide bar. This will keep the oil passages open to provide proper lubrication to the bar and chain. (Fig. 15)

3. Reinstall the bar, chain, sprocket cover and bar bolt

retaining nuts. (See Section GUIDE BAR / SAW

CHAIN INSTALLATION).

• GUIDE BAR MAINTENANCE

Most guide bar problems can be prevented merely by

keeping the chain saw well maintained.

Incorrect filing and non-uniform cutter and depth gauge

settings cause most guide bar problems, primarily resulting in uneven bar wear. As the bar wears unevenly, the

rails widen, which may cause chain clatter and difficulty in making straight cuts.

Insufficient guide bar lubrication and operating the saw

with a chain that is TOO TIGHT will contribute to rapid bar

wear (see Section CHAIN MAINTENANCE INSTRUCTIONS).

To help minimize bar wear, the following guide bar maintenance is recommended.

BAR WEAR - Turn guide bar frequently at regular intervals (for example, after 5 hours of use), to ensure even

wear on top and bottom of bar.

BAR GROOVES - Bar grooves (or rails which support and

carry the chain) should be cleaned if the saw has been

heavily used or if the saw chain appears dirty. Rails

should always be cleaned every time the saw chain is

removed.

OIL PASSAGES - Oil passages at bar pad should be

cleaned to ensure proper lubrication of the bar and chain

during operation. This can be done using a soft wire small

enough to insert into the oil discharge hole.

NOTE: The condition of the oil passages can be easily

checked. If the passages are clear, the chain will automatically give off a spray of oil within seconds of starting

the saw. Your saw is equipped with an automatic oiler

system.

• CHAIN MAINTENANCE INSTRUCTIONS

WARNING:

Unless you have experience and specialized training for

dealing with kickback (see Safety Precautions), always

use a low-kickback saw chain, which significantly reduces

the danger of kickback. Low-kickback saw chain does not

completely eliminate kickback. A low-kickback or “safety

chain”, should never be regarded as total protection

against injury.

A low-kickback saw chain should always be used in conjunction with other kickback protection devices such as

the chain brake / Hand Guard furnished with your unit.

Always use a replacement saw chain designed as “lowkickback” or a saw chain which meets the low-kickback

performance.

A standard saw chain (a chain which does not have the

kickback reducing guard links) should only be used by an

experienced professional chain saw operator.

• What is a Low-Kickback Saw Chain?

A low-kickback saw chain is a chain which has met the

kickback performance requirements of ISO 9518.

By keeping the chain brake and saw chain in good working condition and correctly serviced as recommended in

this manual, you will be able to maintain the safety system

of your chain saw over the life of the product.

• CHAIN TENSION:

Check the chain tension frequently and adjust as often as

necessary to keep the chain snug on the bar, but loose

enough to be pulled around by hand. (See Section SAW

CHAIN TENSION ADJUSTMENT).

• BREAKING IN A NEW SAW CHAIN

A new chain and bar will need readjustment after as few

as 5 cuts. This is normal during the break-in period, and

the interval between future adjustments will begin to

lengthen quickly.

Over a period of time, however, the moving parts of the

saw chain will become worn, resulting in what is called

CHAIN STRETCH. This is normal. When it is no longer

possible to obtain correct chain tension adjustment, a link

will have to be removed to shorten the chain. See your

Talon Authorized Service Center to have this repair performed.

Fig. 14 Fig. 15

WARNING:

Never remove, modify or make

inoperative any safety device furnished with

your unit. The Chain Brake/Hand Guard and

low-kickback saw chain are major safety

features provided for your protection.

WARNING:

Always wear heavy duty

protection work gloves and disconnect the

extension cord when working on the saw

chain.

WARNING:

Never have more than 3 links

removed from a loop of chain this could

cause damage to the sprocket.

• CHAIN LUBRICATION:

Always make sure the automatic oiler system is working

properly. Keep the oil tank filled with Talon Chain, Bar and

Sprocket Oil.

Adequate lubrication of the bar and chain during cutting

operations is essential to minimize friction with the guide

bar.

Never starve the bar and chain of lubricating oil. Running

the saw dry or with too little oil will decrease rapid cutting

efficiency, shorten saw chain life, cause rapid dulling of

the chain, and lead to excessive wear of the bar from

overheating. Too little oil is evidenced by smoke or bar

discoloration.

• PREVENTATIVE MAINTENANCE

SERVICING A DOUBLE INSULATED APPLIANCE

In this double-insulated appliance, two systems of insulation are provided instead of grounding. No grounding

means is provided on a double-insulated appliance, nor

should a means for grounding be added to the appliance.

There are no owner serviceable parts inside. A doubleinsulated appliance is marked with the words, “DOUBLE

INSULATION” or “DOUBLE INSULATED”. The symbol

(square within a square) may also be marked on the appliance.

Any service must only be carried out by a qualified technician at an authorized service centre.

1. Place switch in “OFF” position and unplug the power

supply before the appliance is serviced, cleaned or

maintenance is performed.

2. Keep air intake clean and air vents free of debris to

avoid overheating the motor.

3. Clean with a damp sponge and mild soap. Do not

squirt with water, hose with water or other liquids.

4. No lubrication is necessary as the motor is equipped

with lifetime lubricated bearings.

5. If the saw does not operate, turn switch to “OFF”

position and disconnect extension from power supply

first, then from blower. Check power supply for blown

fuses or tripped circuit breakers. Do not attempt to

repair it yourself. There are no serviceable parts

inside.

10

GB

Loading...

Loading...