Page 1

6300 Series

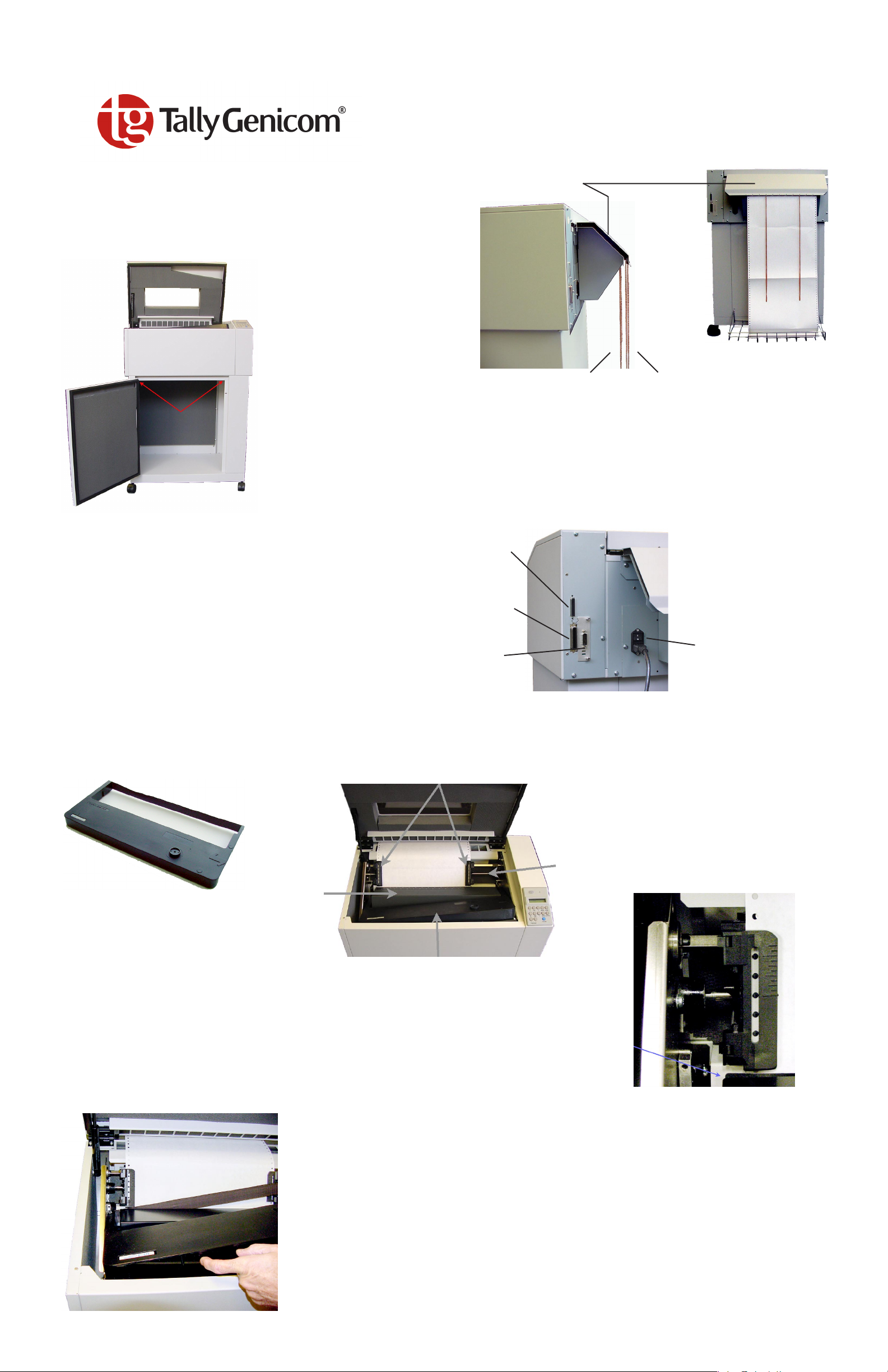

2. Assemble Rear Paper Guide

Use the two screws already installed in the back of the printer to secure

the Rear Guide Assembly (packed seperately). Cut the plastic ties and

remove the plastic bag holding the paper chains. Paper exits the printer

through these passive paper stacking chains that help fold and stack

printed forms uniformly. Make sure the chains are not tangled.

Quick Start Guide

1. Remove the Shipping Hardware

There are 4 screws,

identified by red

tags, that secure the

printer base to the

inside mechanism,

and tie restraints

that secure the

Paper Stacking

Chains. The 4

shipping screws

fasten from

underneath. Remove

all of these

restraints.

Rear Paper Guide

Paper comes out between these two

sets of chains.

3. Connect the I/O and Power Up

Secure the cable to the printer interface using the correct connectors.

Shielded I/O cables must be used on all installations

to comply with regulatory requirements.

Serial Interface Port

Parallel Interface Port

On/Off Switch

Optional LAN or

Twinax / Coax

Interface

& Power Plug

4. Install the Ribbon Cartridge

Step A. Open the printer lid. Remove slack in the new ribbon by turning the knob on the ribbon cartridge as indicated by the arrow printed

next to the knob.

Tractors

Shaft for

Tractors

Ribbon Cartridge

Ribbon

Support

Platform

Ribbon Cartridge

Step B. Carefully position the ribbon between the two panels of the ribbon shield.

Step C. Press down lightly on the cartridge while turning the ribbon knob as before until it seats on

first the left, (as shown), and then the right cartridge drive posts. Make sure that the ribbon does

not twist or fold over.

Page 2

5. Loading Paper for Standard Printing Mode

Step A. Raise the printer lid and open the doors on both tractors.

Step B. Place the stack of paper inside the cabinet on the floor and

feed the paper up through the paper slot, a little ways past the

tractors and through the gap between the top back of the printer

and the lid. It will flow out between the paper chains and fold into

the wire rack near the floor.

Feed paper

between the lid

and the top of

the printer.

Paper Slot

The paper falls

into the wire

rack.

Tractors

Open

Step C. Place the left-side paper holes onto the left tractor pins and close

the tractor door.

Locking

Lever

Step D. The Column Alignment Scale is on the top of the ribbon support

platform. It is to be used for general guidance in horizontally aligning the

form for each print job. The left-most mark on the scale indicates the

location of the first, or left-most, printable character. Each successive tick

mark indicates the location of additional 10 CPI characters.

Column Alignment Scale

Step E. Unlock the right tractor and move it so that the paper's holes align directly over the tractor pins, making sure that the paper is straight,

then close the tractor door. Gently push the tractor to the right until the paper is smooth. Unlock the left tractor and, keeping the paper

reasonably taut, holding onto both tractors, move the paper to the left or the right until it is roughly aligned with the desired mark on the

Column Alignment Scale. Lock both tractors.

Fine tune the Column Alignment: Rotate the

Horizontal Vernier Wheel, which is located on

Horizontal Vernier Wheel

the right end of the shaft on which the tractors

ride. Depending upon the direction the paper

needs to move, you will rotate the wheel either

upwards or downwards. Use this wheel to get

the paper perfectly positioned horizontally.

Step F. Set the Top of the Form (TOF). This is done from the Control

Panel. If the printer is not on, turn it on now. If necessary, press the

Online key until “Offline” is displayed. Use the up or down arrow keys to

move the perforation line on the paper so that it is aligned with the

nubbin on the tractor door. Once the paper is positioned, press the TOF

key. The paper will move downward to the “ready to print” position and

the correct print gap will be set based on the form thickness.

Nubbin for

Top of Form

Alignment

- - - - - - - - - - - - - - - -

Step G. Adjusting the Print Gap. The “+” or “-” Print Gap keys allow the

print gap to be fine tuned based on operator preference. The “+” key

increases the print gap and the “-” key decreases the gap. These keys may

be pressed while printing, giving instant feedback of the effect of the

modified print gap (see Chapter 2 of the Operator Manual). Faded print

indicates too wide a gap and smeared ink indicates too narrow a gap. The

print gap should be adjusted such that the print is crisp and dark, with no

smearing.

6300 Series Quick Start Guide

Page 3

2. Bringen Sie die Papierstaplerketten an

Das Papier verlässt den Druckbereich durch eine Reihe passiver

Papierstaplerketten, die dazu beitragen, dass die gedruckten Formulare gefaltet und

gleichmäßig gestapelt werden. Befestigen Sie zwei Ketten an der Drahtführung

und zwei an der hinteren Papierführung, so dass das Papier dazwischen laufen

kann. Die Ketten dürfen nicht verwickelt sein.

6300 Serie

Kurzanleitung zur

Inbetriebnahme

1. Entfernen Sie die

Transportsicherungen

Die Transportsicherungen bestehen aus 4 rot

markierten Schrauben sowie aus Sicherungsbändern

für die

Papierstaplerketten.

Die

Transportschrauben

sind von unten

aus

eingeschraubt;

sie befinden

sich beim

vorderen

Bereich des

Papierfaches.

Entfernen Sie

alle

Transportsicherungen.

Hintere Papierführung

Das Papier läuft zwischen diesen beiden Kettenreihen.

3. Verbinden Sie das Schnittstellenkabel und

schalten Sie den Drucker ein

Befestigen Sie das Kabel an der Druckerschnittstelle. Vergewissern Sie sich

dabei, dass Sie die korrekten Steckertypen verwenden.

Verwenden Sie bei allen Installationen nur geschirmte

Schnittstellenkabel gemäß den behördlichen

Bestimmungen.

Serieller Schnittstellen-anschluss

Paralleler Schnittstellen-anschluss

Optionale LAN- Schnittstelle bzw.

optionale Twinax-/Coax -Schnittstelle

Ein-/AusSchalter &

Netzstecker

4. Setzen Sie die Farbbandkassette ein

Schritt A. Öffnen Sie den Gehäusedeckel. Spannen Sie das Farbband, indem Sie den Knopf auf der Farbbandkassette in die durch den Pfeil neben

dem Knopf angegebene Richtung drehen.

Traktoren

Welle für

Traktoren

Farbbandkassette

Hammerbankgehäuse

Farbbandkassette

Schritt B. Schieben Sie das Farbband vorsichtig zwischen die beiden Leisten des Farbbandschildes.

Schritt C. Setzen Sie die Kassette mit leichtem Druck ein, während Sie wie zuvor den Farbbandknopf

drehen, bis die Kassette zuerst auf der linken (wie abgebildet) und dann auf der rechten

Antriebsachse sitzt. Versichern Sie sich, dass das Farbband sich nicht verdreht oder faltet.

Page 4

5. Papier für Standard-Druckmodus einlegen

Schritt A. Heben Sie den Gehäusedeckel an und öffnen Sie die

Klappen der beiden Traktoren.

Schritt B. Stellen Sie den Papierstapel auf den Boden des Papierfaches

und führen Sie das Papier nach oben durch den Papierschlitz, ein

Stück an den Traktoren vorbei und durch den Spalt zwischen dem

hinteren, oberen Bereich des Druckers und dem Gehäusedeckel. Das

Papier tritt dann zwischen den Papierketten heraus und wird in die

unten am Druckergehäuse angebrachte Drahtablage gefaltet.

Führen Sie das

Papier durch

den Spalt

zwischen

Gehäusedeckel

und oberen

Bereich des

Druckers.

Papierschlitz

Das Papier fällt

in die

Drahtablage.

Schritt C. Legen Sie die linke Transportlochung des Papiers über die Stifte

Traktoren

geöffnet

des linken Traktors und schließen Sie die Traktorklappe.

Verriegelungs-

hebel

Schritt D. Die Spaltenskala befindet sich oben auf dem Hammerbank-Gehäuse.

Spalte 1 vorgedruckter Formulare bzw. die Perforierung links von

unbedrucktem Papier sollte mit der vom Formularautor festgelegten

Markierung auf der Skala übereinstimmen. Die Skala stellt eine

Orientierungshilfe dar. Der Benutzer entscheidet, welche Skalamarkierung

sich am besten für die verwendeten Formulare eignet.

Schritt E. Entriegeln Sie den rechten Traktor und bewegen Sie ihn so, dass die Papierlochung genau über

die Traktorstifte passt. Stellen Sie dabei sicher, dass das Papier gerade ist. Schließen Sie dann die

Traktorklappe. Schieben Sie den Traktor vorsichtig nach rechts, bis das Papier glatt ist. Entriegeln Sie den

linken Traktor und, während Sie das Papier einigermaßen straff halten, wobei Sie beide Traktoren

festhalten, bewegen Sie das Papier nach links oder rechts, bis es ungefähr mit der gewünschten Markierung

auf der Spaltenskala übereinstimmt. Verriegeln Sie beide Traktoren.

Spaltenskala

Exakte Einstellung der Spaltenausrichtung: Drehen Sie das horizontale

Feineinstellungsrad, das rechts außen an der Welle angebracht ist, auf der sich die

Traktoren befinden. Je nachdem, in welche Richtung das Papier verschoben

werden soll, drehen Sie das Rad entweder nach oben oder nach unten. Verwenden

Sie dieses Rad, um das Papier horizontal exakt zu positionieren.

Schritt F. Stellen Sie die Oberkante des Blattes

(Top of Form, TOF) ein. Dies wird vom Bedienfeld aus gemacht.

Falls der Drucker ausgeschaltet ist, schalten Sie ihn jetzt ein. Drücken Sie

die Online-Taste, bis “Offline” angezeigt wird. Verwenden Sie die Nachoben- bzw. Nach-unten-Pfeiltaste, um die Perforationslinie des Papiers so zu

verschieben, dass sie sich mit der Noppe an der Traktorklappe auf einer

Linie befindet. Wenn das Papier ausgerichtet ist, drücken Sie die TOFTaste.

Schritt G. Stellen Sie den Druckkopfabstand (Print Gap) ein. Wenn der

Druckkopfabstand-Erkennungsmodus auf “auto” steht, wird der

Druckkopfabstand beim Drücken der TOF-Taste automatisch auf die Stärke

des eingelegten Papiers eingestellt. Sie können mit der "+"- bzw. "-"-Taste

eine exakte Einstellung vornehmen (siehe Kapitel 2 der

Bedienungsanleitung). Drücken Sie Clear. Verwenden Sie die Pfeiltasten

und die Eingabetaste (Enter), um folgende Auswahl zu treffen: Menu =>

Testmenue => Muster => Druck => Gross. Drücken Sie Enter, um einen

Testdrucklauf zu beginnen. Drücken Sie Enter, um den Druckvorgang

anzuhalten. Sehen Sie sich den Testausdruck an. Ein verblasstes Druckbild

deutet darauf hin, dass der Druckkopfabstand zu groß ist. Bei

verschmiertem Druckbild ist der Druckkopfabstand zu klein. Wiederholen

Sie Schritt G so oft, bis der Druck scharf und dunkel ist und keine

Schmierspuren aufweist.

Horizontales

Feineinstellungsrad

Noppe zur

Ausrichtung

der Blattoberkante

-.........................

086184 - Kurzanleitung zur Inbetriebnahme für 6300 Serie

Page 5

6300 Serie

Guide d’installation rapide

1. Retrait des attaches d’expédition

Les attaches d’expédition consistent en 4 vis,

identifiées par des étiquettes rouges, qui fixent le

socle de l’imprimante au mécanisme interne et des

fixations attachent les chaînes d’empilage du papier.

Les quatre vis d’expédition sont fixées sous la partie

inférieure avant du châssis de l’imprimante. Retirez

toutes ces attaches.

2. Installation des chaînes d’empilage du papier

Le papier sort de la zone d’impression grâce à un jeu de chaînes

d’empilage passives qui permettent de plier et d’empiler uniformément les

pages imprimées. Fixez deux chaînes au guide métallique et deux autres

au guide de papier arrière pour que le papier puisse être correctement

alimenté entre elles. Assurez-vous que les chaînes ne sont pas emmêlées.

Guide de papier arrière

Le papier passe entre les deux groupes de chaînes.

3. Connexion d’interface et mise sous tension

Fixez solidement le câble à l’interface de l’imprimante à l’aide des

connecteurs corrects.

Utilisez des câbles d’interface blindés sur toutes

les installations pour respecter les réglementations

en vigueur.

Port d’interface série

Port d’interface parallèle

Bouton de mise

sous/hors

tension et prise

Interfaces réseau local ou

Twinax/ coaxiale optionnelles

d’alimentation

électrique

4. Installation de la cartouche à ruban

Étape A. Ouvrez le capot de l’imprimante. Supprimez le jeu du nouveau ruban en tournant le bouton de la cartouche comme indiqué par la flèche

en regard du bouton.

Guides

d’entraînement

Cartouche à ruban

Logement de la

rangée de

marteaux

Étape B. Placez avec précaution le ruban entre les deux

panneaux de protection du ruban.

Arbre des

guides

d’entraînement

Cartouche à ruban

Étape C. Appuyez légèrement sur la cartouche tout en tournant le bouton de la cartouche jusqu’à ce

qu’elle s’enclenche d’abord à gauche (comme illustré) puis à droite. Assurez-vous que le ruban n’est

pas retourné ou plié.

Page 6

5. Chargement du papier en mode d’impression normal

Étape A. Soulevez le capot de l’imprimante et ouvrez les portes des

deux guides d’entraînement.

Étape B. Placez une pile de papier à l’intérieur sur le sol de l’armoire

et faites passer le papier par la fente d’alimentation, juste après les

guides d’entraînement et l’écart entre la partie supérieure arrière de

l’imprimante et le capot. Il passera entre les chaînes du papier et

s’empilera dans le réceptacle métallique près du sol.

Faites passer le

papier entre la

partie supérieure

arrière de

l’imprimante et

le capot.

Logement du papier

Le papier

s’empile dans le

réceptacle

métallique près

du sol.

Guides

d’entraînement

Ouvrez

Étape C. Placez les perforations gauches du papier dans les picots du guide

d’entraînement gauche et refermez la porte du guide d’entraînement.

Levier de

verrouillage

Étape D. La règle d’alignement de colonnes se trouve sur la partie supérieure

de l’emplacement de la rangée de marteaux. La première colonne de

formulaires préimprimés ou la perforation gauche du papier ordinaire doit

s’aligner sur le repère de la règle que le créateur de formulaires a créée. La

règle sert de référence générale. L’opérateur détermine le repère qui

convient le mieux pour ses formulaires.

Étape E. Débloquez le guide d’entraînement droit et déplacez-le de telle manière que les perforations du

papier s’alignent directement sur les picots d’entraînement. Assurez-vous que le papier est droit. Refermez

ensuite la porte du guide d’entraînement. Poussez légèrement le guide d’entraînement vers la droite

jusqu’à ce que le papier repose correctement. Débloquez le guide d’entraînement gauche, tout en exerçant

Règle d’alignement de colonnes

une tension suffisante sur le papier entre les deux guides d’entraînement. Déplacez le papier vers la gauche

ou la droite jusqu’à ce qu’il s’aligne le mieux possible sur le repère voulu de la règle d’alignement de

colonnes. Verrouillez les deux guides d’entraînement.

Meilleur réglage de l’alignement de colonnes : faites pivoter la roulette vernier horizontale qui

se trouve à l’extrémité droite de l’arbre sur lequel se déplace les guides d’entraînement.

Suivant la direction vers laquelle se déplace le papier, faites pivoter la roulette vers le haut ou

le bas. Utilisez cette molette pour obtenir une position horizontale parfaite du papier.

Étape F. Réglez le haut de page (TOF). Ce réglage s’effectue sur le panneau de commandes. Si

l’imprimante est hors tension, allumez-la. Appuyez sur la touche Online jusqu’à ce que le

message Offline (en ligne) s’affiche. Avec les touches fléchées Haut et Bas, alignez la ligne de

perforations du papier sur l’aspérité de la porte du guide d’entraînement. Une fois le papier

positionné, appuyez sur la touche TOF.

Étape G. Réglez l’écart d’impression. Si le mode de détection de l’écart

d’impression est sur “auto”, l’écart d’impression initial correct pour

l’épaisseur du papier chargé est automatiquement calculé lorsque vous

appuyez sur la touche TOF. Vous pouvez appuyer sur la touche Print Gap

“+” ou “-” pour ajuster ce réglage (voir le chapitre 2 du Manuel de

l’opérateur). Appuyez sur Clear. Utilisez les touches fléchées ou Enter pour

sélectionner Menu => Menu de test => Modèle => Impr => Majusc. Appuyez

sur Enter pour lancer un test d’impression. Appuyez sur Entrée pour

arrêter le test. Examinez l’imprimé. Une impression faible indique un

écart trop important et des traînées d’encre indiquent un écart trop faible.

Recommencez l’Étape G jusqu’à ce que l’impression soit nette et noire sans

traînée.

Roulette vernier

horizontale

Repère pour

l’alignement du

haut de page

- - - - - - - - - - - - - - - -

086184 – Guide d’installation rapide 6300 Serie

Page 7

6300 Serie

2. Installazione delle catene di

accatastamento carta

La carta esce dall’area di stampa mediante un set di catene passive di

accatastamento carta che aiutano a piegare e ad accatastare i moduli

stampati in maniera uniforme. Fissare due catene alla guida del filo e due

alla guida posteriore della carta in modo da poter alimentare la carta fra

di loro. Accertarsi che le catene non siano aggrovigliate.

Guida di riferimento rapido

1. Rimozione della bulloneria di

spedizione

La bulloneria di spedizione consiste di 4 viti, identificate

da linguette rosse, che fissano la base della stampante al

meccanismo interno, e di dispositivi di sicurezza che

fissano le

catene di

accatastamento

carta. Le viti di

spedizione

inferiori

compiono il

fissaggio da

sotto, vicino

alla parte

anteriore

dell’armadietto

della

stampante.

Rimuovere

tutti questi

dispositivi di

sicurezza,

comprese le

staffe sotto le

viti ad aletta.

Guida posteriore della carta

La carta fuoriesce fra questi due set di catene.

3. Collegamento I/O e accensione

Fissare il cavo all’interfaccia della stampante utilizzando i connettori

corretti.

Per conformità con i requisiti normativi, è necessario

usare cavi I/O schermati per tutte le installazioni.

Porta di interfaccia seriale

Porta di interfaccia

parallela

Interfaccia LAN opzionale o

Interfaccia Twinax/coassiale opzionale

Interruttore di

accensione e

spina di

corrente

4. Installazione della cartuccia a nastro

Passo A. Aprire il coperchio della stampante. Eliminare il gioco del nuovo nastro girando la manopola sulla cartuccia a nastro, come indicato dalla

freccia stampata accanto alla manopola.

Dispositivi di trazione

Asta per i

dispositivi

di trazione

Cartuccia a nastro

Alloggiamento

del gruppo

martelli

Cartuccia a nastro

Passo B. Sistemare con cautela il nastro fra i due pannelli sullo schermo del nastro.

Passo C. Premere leggermente la cartuccia verso il basso mentre si gira la manopola del nastro come

fatto in precedenza, fino a che non si installa prima sul morsetto della guida sinistra (come illustrato)

e poi su quello della guida destra della cartuccia. Accertarsi che il nastro non si attorcigli o non si

pieghi.

Page 8

5. Caricamento della carta per la modalità di stampa normale

Passo A. Sollevare il coperchio della stampante e aprire gli sportelli su

entrambi i dispositivi di trazione.

Passo B. Sistemare la risma di carta sul fondo dell’armadietto e alimentarla

nella apposita apertura, superando di poco i dispositivi di trazione e passandola

attraverso la fessura fra la parte superiore del retro della stampante e il

coperchio. La carta scorre fra le catene e si piega nel cestello in rete metallica

vicino al pavimento.

Alimentare la

carta fra il

coperchio e la

parte superiore

della stampante.

Fessura per la carta

La carta cade nel

cestello in rete

metallica.

Dispositivi di trazione

aperti

dispositivo di trazione sinistro e chiudere lo sportello del dispositivo di

trazione.

Leva di

blocco

Passo D. La scala di allineamento delle colonne si trova in cima all’alloggiamento del gruppo martelli. La

prima colonna dei moduli pre-stampati o la perforazione sinistra della carta comune devono essere allineate

con l’indicatore sulla scala designata dalla persona che ha creato il modulo. La scala serve come guida

generale. Ogni operatore determina l’indicatore di scala che meglio si adatta ai rispettivi moduli.

Passo E. Sbloccare il dispositivo di trazione destro e spostarlo in modo che i fori della carta si allineino

direttamente sui dentini del dispositivo di trazione; accertarsi che la carta sia diritta, e quindi chiudere lo

sportello del dispositivo di trazione. Spingere delicatamente il dispositivo di trazione verso destra fino a

che la carta non presenta grinze. Sbloccare il dispositivo di trazione sinistro e, mantenendo la carta tesa il

più possibile aiutandosi con i due dispositivi di trazione, spostare la carta verso sinistra o verso destra fino

a che non è più o meno allineata con l’indicatore desiderato sulla scala di allineamento delle colonne.

Bloccare entrambi i dispositivi di trazione.

Passo C. Sistemare i fori del lato sinistro della carta sui dentini del

Scala di allineamento colonne

Regolare l’allineamento della colonna: ruotare la ruota verniera orizzontale situata all’estremità destra

dell’asta su cui operano i dispositivi di trazione. A seconda della direzione di spostamento della carta, la

ruota viene girata verso l’alto o verso il basso. Usare questa ruota per ottenere una precisa posizione

orizzontale della carta.

Passo F. Impostare la parte superiore del modulo (top of form, TOF) tramite il pannello di

controllo. Se la stampante non è accesa, accenderla adesso. Premere il tasto Online fino a che

non viene visualizzato “Offline”. Usare le frecce rivolte verso l’alto e verso il basso per spostare

la linea perforata della carta in modo da allinearla con la piccola sporgenza sullo sportello del

dispositivo di trazione. Quando la carta è in posizione, premere il tasto TOF.

Passo G. Impostare la distanza di stampa. Se la modalità di rilevamento per la

distanza di stampa è impostata su “auto”, dopo la pressione del tasto TOF viene

automaticamente determinata un’impostazione per la distanza di stampa adatta

allo spessore della carta. Premere il tasto "+" o "-" per Print Gap per regolare

ulteriorimente questa impostazione (fare riferimento al capitolo 2 del Manuale

per l’operatore). Premere Clear. Usare i tasti direzionali a freccia e Enter per

selezionare Menu => Menu Test => Campione => Stampa => Maiusc. Premere

Enter per avviare una prova di stampa. Premere Enter per interrompere questa

prova. Esaminare lo stampato. Una stampa sbiadita indica che la distanza è

troppo ampia, mentre macchie d’inchiostro indicano una distanza troppo ridotta.

Ripetere il Passo G fino a che lo stampato non risulta nitido e scuro, senza

macchie.

Ruota verniera

orizzontale

Sporgenza per

l’allineamento

della parte

superiore del

- - - - - - - - - - - - - - - -

modulo

086184 - 6300 Serie - Guida di riferimento rapido

Page 9

Serie 6300

2. Preparación de las cadenas de apilamiento

del papel

El papel sale del área de impresión a través de un conjunto de cadenas de

apilamiento del papel que ayudan a doblar y apilar las hojas impresas

uniformemente. Fije dos de las cadenas al alambre guía y dos a la guía de

papel posterior para que el papel pase entre ellas. Verifique que no estén

enredadas las cadenas.

Guía de consulta rápida

1. Retire los herrajes de embalaje

Hay 4 tornillos, identificados por etiquetas rojas, que

fijan la base de la impresora al mecanismo interno y

amarras que aseguran las cadenas para apilar el papel.

Los tornillos

de embalaje

inferiores se

atornillan

por debajo,

cerca de la

parte

delantera

del gabinete

de la

impresora.

Retire todos

esos

sujetadores.

Guía de papel posterior

El papel sale entre estos dos juegos de cadenas.

3. Conecte el cable de E/S y encienda la

impresora

Enchufe el cable en la impresora usando los conectores correspondientes.

Se deben usar cables de E/S blindados en todas las

instalaciones a fin de cumplir con los reglamentos.

Puerto de la interfaz en serie

Puerto de la interfaz paralela

Interfaz LAN optativa o

Interfaz Twinax/coax optativa

4. Instale el cartucho de la cinta

Paso A. Abra la tapa de la impresora. Gire la perilla del cartucho de la cinta como lo indica la flecha impresa junto a la

misma a fin de estirar la cinta.

Tractores

Eje de los

tractores

Cartucho de cinta

Alojamiento

del

conjunto del

martillo

Interruptor de

encendido/

apagado y

enchufe

eléctrico

Cartucho de cinta

Paso B. Coloque la cinta cuidadosamente entre los dos paneles del protector de la cinta.

Paso C. Empuje el cartucho ligeramente a la vez que gira la perilla del cartucho como lo hizo antes

hasta que asiente sobre los postes giratorios primero del lado izquierdo (como se muestra) y luego

del lado derecho. Verifique que la cinta no esté doblada ni torcida.

Page 10

5. Instalación del papel para la modalidad de

impresión estándar

Paso A. Levante la tapa de la impresora y abra las puertas de ambos tractores.

Paso B. Coloque la pila de papel dentro del gabinete en el piso y alimente el papel

a través de la ranura, un poco más allá de los tractores y a través de la abertura

entre la parte superior trasera de la impresora y la tapa. El papel saldrá entre las

cadenas y se doblará en la repisa de metal cerca del piso.

Alimente el

papel entre la

tapa y la parte

superior de la

impresora.

Ranura para el papel

El papel cae

sobre la bandeja

de metal.

Tractores

Abierto

Paso C. Coloque los orificios del papel del lado izquierdo sobre los dientes

del tractor izquierdo y cierre la tapa del tractor.

Palanca de

bloqueo

Paso D. La escala de alineación de columnas se encuentra en la parte superior del alojamiento del

conjunto del martillo. La columna 1 para formularios impresos (o la perforación izquierda en caso de

papel en blanco) debe quedar alineada con la marca de la escala designada por el creador del

formulario. La escala es tan sólo una guía general. El operador determinará cuál marca de la escala

funciona mejor con los formularios.

Paso E. Abra la tapa del tractor derecho y muévalo de manera que los orificios del papel queden

alineados directamente sobre los dientes, asegurando que el papel esté recto y luego cierre la tapa del

tractor. Empuje el tractor suavemente hacia la derecha hasta que el papel esté sin arrugas. Quítele el

seguro al tractor izquierdo, mantenga el papel más o menos estirado, sujetando ambos tractores, y

mueva el papel hacia la izquierda o derecha hasta que quede alineado con la marca deseada de la escala

para alineación de columnas. Asegure ambos tractores.

Escala de alineación de columnas

Perfeccione la alineación de las columnas: Gire la rueda horizontal de Vernier,

situada en el extremo derecho del eje sobre el cual se mueven los tractores.

Dependiendo de la dirección hacia la que se tenga que mover el papel, gire la rueda

hacia arriba o hacia abajo. Use la rueda para dejar el papel perfectamente alineado

sobre plano horizontal.

Paso F. Ajuste el inicio del formulario (TOF). Esto se hace a través del panel de

control. Si la impresora no está encendida, enciéndala. Oprima el botón Online

hasta que se muestre “Offline”. Use las flechas arriba o abajo para mover la línea de

perforación del papel hasta que quede alineada con la orilla saliente de la tapa de

los tractores. Una vez situado el papel, oprima el botón TOF.

Paso G. Ajuste la distancia del cabezal. Si está en “auto” la modalidad de

detección de la distancia del cabezal, en el momento de pulsar el botón TOF

se habrá determinado una distancia apropiada para el grueso del papel

cargado. Puede oprimir el botón “+” o “-” Print Gap para ajustar con

precisión (consulte el capítulo 2 del Manual del operador). Oprima Clear.

Use los botones de flecha y Enter para seleccionar Menú => Prueba =>

Diseño => Imprimir => Mayúsculas. Oprima Enter para comenzar una

prueba de impresión. Oprima Enter para detener la prueba. Examine lo

que se imprimió. Si el color de la impresión está apagado, significa que la

abertura está muy grande y si la tinta está manchada que está demasiado

pequeña. Repita el paso G hasta que la impresión salga nítida y oscura, sin

manchas.

Rueda horizontal de Vernier

Orilla para la

alineación del

inicio del

formulario

- - - - - - - - - - - - - - - -

086184 - Guía de consulta rápida para la serie 6300

Loading...

Loading...