Tallygenicom 6300 Operator Manual

6300 Series

Operator Manual

Serial - Parallel - LAN - Twinax - Coax - IPDS

Operator Manual 1

This Manual is published by TallyGenicom for use with the computer printer described herein. Translations,

reprinting or copying by any means of this manual, complete or in part, in any different form requires our explicit

approval. TallyGenicom reserves the right to revise this manual without notice, for any reason. This includes, but

is not limited to, utilization of advances in the state-of-the-art and changes in the equipment or configuration

thereof. Liability for difficulties arising from unknown or unforeseen technical limitations is disclaimed.

FCC Statement

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part

15, Subpart B of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment. This equipment generates, uses,

and can radiate radio frequency energy and, if not installed and used in accordance with the instruction manual,

may cause harmful interference to radio communications. Operation of this equipment in a residential area is

likely to cause harmful interference, in which case the user will be required to correct the interference at his own

expense.

WARNING

Only trained qualified personnel may open covers or remove parts that are not explicitly shown and described in

the Operator’s Manual as being accessible to the operator.

Please Note:

Printer drivers for various operating systems are available on the Internet at our Web Page

http://www.tallygenicom.com or http://www.tallygenicom.com/worldwide or at your

TallyGenicom distributor.

ACKNOWLEDGMENTS:

“IBM” and “Proprinter” are trademarks of International Business Machines Corporation.

“DEC” is a trademark of Compaq Computer Corp.

“Printronix” and “PGL” are trademarks of Printronix, Inc.

“Epson” is a trademark of Seiko Epson Corp.

“QMS” and “Code V” are trademarks of Minolta-QMS Inc.

“HP” is a trademark of Hewlett-Packard Company.

“Genicom” is a trademark of Genicom L.L.C.

6300 Series Operator Manual

© February 2005

All rights reserved

TallyGenicom

6020 South 190th Street

Kent, Washington 98032

2 Operator Manual

Contents

Preface............................................................................................ Preface–11

Introduction.................................................................................................................... Preface–11

About This Manual......................................................................................................... Preface–12

Chapter 1 ................................................................................................... 1–13

In Chapter 1, you are instructed on how to set up your printer. You get a look at the

paper handling system, told how to install the ink ribbon, and are given a brief

introduction to the Control Panel.

Site Preparation ........................................................................................................................ 1–13

Figure 1 - 1. Shipping Screw Locations ............................................................................ 1–14

Unpacking your printer ........................................................................................................... 1–14

Repacking ................................................................................................................................. 1–14

Removing the Shipping Hardware ......................................................................................... 1–14

Rear Guide Assembly Instructions .......................................................................................... 1–15

Figure 1 - 2. Paper Stacking Chains.................................................................................. 1–15

Figure 1 - 3. Rear view, showing Serial, Parallel and Power Plugs .................................. 1–16

Connecting the I/O................................................................................................................. 1–16

Interface Connections and Powering Up ............................................................................... 1–16

Interface Connectors ............................................................................................................... 1–16

Powering Up ............................................................................................................................. 1–17

Figure 1 - 4. Power plug and on/off switch ...................................................................... 1–17

Figure 1 - 5. Inside the Lid ................................................................................................ 1–18

Paper System ............................................................................................................................. 1–18

Paper System Components ..................................................................................................... 1–18

Print Gap ................................................................................................................................... 1–19

Paper Tension ........................................................................................................................... 1–19

Tractors ..................................................................................................................................... 1–19

Figure 1 - 6. Left and Right Paper Tractors ..................................................................... 1–19

Installing the Ribbon Cartridge .............................................................................................. 1–20

Figure 1 - 7. Ribbon Cartridge .......................................................................................... 1–20

Figure 1 - 8. Installing the Ribbon Cartridge.................................................................. 1–20

Figure 1 - 9. Ribbon Shield Panels .................................................................................... 1–21

LED Indicators.......................................................................................................................... 1–22

LCD (Liquid Crystal Display)................................................................................................... 1–22

Figure 1 - 10. Control Panel .............................................................................................. 1–22

Control Panel Components .................................................................................................... 1–22

Operator Manual 3

Chapter 2 ................................................................................................... 2–25

Chapter 2 explains how to load the paper, set the print gap, and save configuration

settings.

Introduction.............................................................................................................................. 2–25

Figure 2 - 1. Inside Paper Inlet, visible when looking inside the printer cabinet. ......... 2–26

Loading Paper for Standard Printing Mode .......................................................................... 2–26

Figure 2 - 2. Paper path past the lid. .................................................................................. 2–27

Figure 2 - 3. Paper path into the wire rack. ....................................................................... 2–27

Figure 2 - 4. Column Alignment Scale............................................................................. 2–28

Figure 2 - 5. Horizontal Vernier Wheel ............................................................................. 2–28

Figure 2 - 6. Top of Form Nubbin ..................................................................................... 2–29

Print Gap Adjustment .............................................................................................................. 2–30

Gap Zone .................................................................................................................................. 2–30

Print Gap Profile Mode ............................................................................................................ 2–30

Creating a Gap Zone Profile.................................................................................................... 2–30

Using a Saved Gap Zone Profile .............................................................................................. 2–31

Fine-tuning the Automatic Print Gap Setting ........................................................................ 2–32

Figure 2 - 7. Typical Display when Print Gap Mode is set to “Auto” ................................ 2–32

Figure 2 - 8. Typical display when adjusting Print Gap .................................................... 2–33

Set Print Gap Detect Mode to Manual .................................................................................... 2–33

Setting Up Configurations ...................................................................................................... 2–34

Chapter 3 .................................................................................................. 3–35

Chapter 3 explains how to use the Control Panel, how to navigate the different menus

that are available on your printer, and all of the available parameters.

Introduction............................................................................................................................. 3–35

Control Panel Display.............................................................................................................. 3–35

The Display During Normal Operation ................................................................................. 3–36

Figure 3 - 1. Control Panel Display for Normal Operation............................................. 3–36

Current State ............................................................................................................................. 3–36

Current Configuration .............................................................................................................3–36

Paper Weight & Hammer Impact ........................................................................................... 3–36

The Display When In A Menu................................................................................................. 3–37

Figure 3 - 2. Control Panel Display for Menus.................................................................. 3–37

Table 3 - 1 Paper Weight & Hammer Impact Indicator ..................................................3–37

Control Panel Key Functions .................................................................................................. 3–38

Online Key ............................................................................................................................... 3–38

LF Key (Line Feed) ................................................................................................................. 3–38

FF Key (Form Feed)................................................................................................................ 3–38

Figure 3 - 3. Control Panel................................................................................................ 3–38

FF Key (Form Feed) continued .............................................................................................. 3–39

TOF Key (Top of Form) ..........................................................................................................3–39

View Key .................................................................................................................................... 3–39

4 Operator Manual

PRINT GAP + and - Keys.......................................................................................................... 3–39

Up and Down Arrow Keys ........................................................................................................3–39

Menu Key .................................................................................................................................. 3–39

Enter Key .................................................................................................................................. 3–40

Clear Key ................................................................................................................................... 3–40

Clear Key continued ................................................................................................................. 3–41

Config Key ................................................................................................................................ 3–41

Control Panel Menus ............................................................................................................... 3–42

Categories, Parameters and Selections ................................................................................... 3–42

Using Menus ............................................................................................................................. 3–42

Example: Changing Form Length Using the Menu System .............................................. 3–44

How to Print a Control Panel Selected Options Report ......................................................... 3–45

Operator Menu ......................................................................................................................... 3–46

Font Category ........................................................................................................................... 3–46

Ser/Par Language ................................................................................................................... 3–46

Tx/Cx Language (only on Twinax/Coax printers) .............................................................. 3–47

IPDS Language (only if IPDS is installed) ............................................................................. 3–47

Ser/Par Character Set .............................................................................................................. 3–47

Matrix ....................................................................................................................................... 3–48

OCRA Density ......................................................................................................................... 3–48

Ser/Par Style ............................................................................................................................. 3–49

Tx/Cx Style (only on Twinax/Coax printers) ........................................................................ 3–49

IPDS Style (only if IPDS is installed) ....................................................................................... 3–49

CPI (Characters Per Inch) ....................................................................................................... 3–49

Panel Language ....................................................................................................................... 3–49

OCR Standards .........................................................................................................................3–50

Zero ........................................................................................................................................... 3–50

Compressed 8 ........................................................................................................................... 3–50

Forms Category ........................................................................................................................ 3–51

Length (lines) .......................................................................................................................... 3–51

Length (inches) ....................................................................................................................... 3–51

LPI (Lines Per Inch) ................................................................................................................3–51

Top Margin ............................................................................................................................... 3–51

Bottom Margin......................................................................................................................... 3–51

Left Margin ............................................................................................................................... 3–52

Right Margin ............................................................................................................................ 3–52

Horz Adjust ............................................................................................................................... 3–52

Vert Adjust .................................................................................................................................3–52

Print to EOF (End Of Form) ................................................................................................... 3–52

Print to EOF (End Of Form) Continued ............................................................................... 3–53

Quick Access ............................................................................................................................ 3–53

Eject Distance .......................................................................................................................... 3–53

Eject Delay................................................................................................................................. 3–54

Impact .......................................................................................................................................3–54

Paper Weight ............................................................................................................................ 3–54

Fast Slew .................................................................................................................................... 3–54

Operator Manual 5

Double Strike ............................................................................................................................ 3–54

RibbonMonitor ......................................................................................................................... 3–54

RibnMon Thresh ..................................................................................................................... 3–55

Perf Skip ................................................................................................................................... 3–55

Print Gap Category................................................................................................................... 3–56

Detect ........................................................................................................................................ 3–56

Adjust......................................................................................................................................... 3–56

Reset .......................................................................................................................................... 3–57

Mode ......................................................................................................................................... 3–57

Creating a Gap Zone Profile.................................................................................................... 3–57

Detect Distance ........................................................................................................................ 3–58

VFU Category (Vertical Format Units) .................................................................................. 3–58

VFU Enable .............................................................................................................................. 3–58

VT Channel (Vertical Tab Channel) ..................................................................................... 3–58

Skip When ................................................................................................................................ 3–58

Config Menu ............................................................................................................................3–59

Printer Category .......................................................................................................................3–59

Powerup ..................................................................................................................................... 3–59

Ser/Par Emulation ................................................................................................................... 3–59

LAN Emulation (LAN Interface only) ................................................................................... 3–60

Twinax Emul (Twinax/Coax only) ......................................................................................... 3–60

Dump Mode.............................................................................................................................. 3–60

I/O Hold Time ......................................................................................................................... 3–60

Report........................................................................................................................................ 3–61

Beeper Mode ............................................................................................................................ 3–61

Beeper Volume ......................................................................................................................... 3–61

Codes Category ........................................................................................................................ 3–62

Auto LF (Line Feed) ................................................................................................................ 3–62

Auto CR (Carriage Return) ..................................................................................................... 3–62

Line Wrap.................................................................................................................................. 3–62

Wrap Line Feed......................................................................................................................... 3–62

Print on CR ...............................................................................................................................3–63

Form Feed at TOF ................................................................................................................... 3–63

ESC ............................................................................................................................................ 3–63

Alt ESC (Alternate Escape) ..................................................................................................... 3–63

Upper Only ............................................................................................................................... 3–63

Code 7F ..................................................................................................................................... 3–64

Print 80 - 9F Hex....................................................................................................................... 3–64

Ignore Char .............................................................................................................................. 3–64

Sub Char From ......................................................................................................................... 3–64

Sub Char To .............................................................................................................................. 3–64

PTX SFCC (Only affects the Printronix P5000 emulation)................................................... 3–64

PTX ALS (Only affects the Printronix P5000 emulation) ..................................................... 3–64

TOF Control (Available when Genicom ANSI emulation is selected) ................................. 3–65

DC3 Operation (Available when Genicom ANSI emulation is selected)............................. 3–65

SISO OverszBar (Available when Genicom ANSI emulation is selected) ............................ 3–65

6 Operator Manual

Barcod Top Pos (Available when Genicom ANSI emulation is selected) ............................ 3–65

Oversz Top Pos (Available when Genicom ANSI emulation is selected) .............................3–65

Graphics Category .................................................................................................................... 3–66

Code V Cmd Char .................................................................................................................... 3–66

Smooth Size .............................................................................................................................. 3–66

PY Then..................................................................................................................................... 3–66

PN Then .................................................................................................................................... 3–66

Dark Bar .................................................................................................................................... 3–66

Table 3 - 2. Bar Code Dot Density .................................................................................... 3–67

Modplot ..................................................................................................................................... 3–67

Figure 3 - 4. Modplot Example ......................................................................................... 3–67

Version....................................................................................................................................... 3–67

Descender ................................................................................................................................. 3–67

Vertical Scale ............................................................................................................................ 3–68

Zero .......................................................................................................................................... 3–68

SFCC ......................................................................................................................................... 3–68

Code V Language ................................................................................................................... 3–68

PGL Language ........................................................................................................................ 3–68

Free Format ............................................................................................................................. 3–68

Automatic PY ........................................................................................................................... 3–68

MTPL Bar (only in MTPL emulation).................................................................................... 3–69

Secured (only in MTPL emulation) ........................................................................................ 3–69

IGP Terminator ........................................................................................................................ 3–69

BlkMaxH ................................................................................................................................... 3–69

BlkMaxV .................................................................................................................................... 3–69

BlkMinH .................................................................................................................................... 3–69

BlkMinV .................................................................................................................................... 3–69

Postnet Density ......................................................................................................................... 3–69

PGL Terminator ....................................................................................................................... 3–69

Ignore Term ............................................................................................................................. 3–70

Configurations Category ......................................................................................................... 3–71

Save ............................................................................................................................................ 3–71

Load .......................................................................................................................................... 3–71

Powerup Config ........................................................................................................................ 3–71

Config n Label - (where n = 1 to 10) ....................................................................................... 3–71

Serial I/O Category .................................................................................................................. 3–73

Baud .......................................................................................................................................... 3–73

Data Bits .................................................................................................................................... 3–73

Stop Bits .................................................................................................................................... 3–73

Parity .......................................................................................................................................... 3–73

8th Bit ....................................................................................................................................... 3–73

Protocol ..................................................................................................................................... 3–73

Status Enquiry ........................................................................................................................... 3–74

DTR Function ........................................................................................................................... 3–74

DTR Function continued... ...................................................................................................... 3–75

DTR Polarity ............................................................................................................................. 3–75

Operator Manual 7

Busy Polarity.............................................................................................................................. 3–75

RTS Function ............................................................................................................................ 3–75

Robust Xon ............................................................................................................................... 3–75

Parallel I/O Category............................................................................................................... 3–76

POPC (Print On Paper Command) ........................................................................................ 3–76

8th Bit ....................................................................................................................................... 3–76

Bi-Directional ............................................................................................................................ 3–76

Intellifilter Category ................................................................................................................. 3–77

Serial .......................................................................................................................................... 3–77

Parallel ....................................................................................................................................... 3–77

Twinax/Coax ............................................................................................................................ 3–77

LAN ........................................................................................................................................... 3–77

File Management ..................................................................................................................... 3–77

Twinax/Coax Category ........................................................................................................... 3–78

Send PA (Coax Only) .............................................................................................................. 3–78

Address (Twinax Only) ........................................................................................................... 3–78

SPD (Coax Only) ..................................................................................................................... 3–78

SCD (Twinax Only) ................................................................................................................. 3–78

SLD ........................................................................................................................................... 3–78

Host Font Style (Twinax Only) ................................................................................................ 3–79

Screen Size (Screen) (Coax Only) .......................................................................................... 3–79

Case (Coax Only) ..................................................................................................................... 3–79

Compatibility Switches (Coax Only) ....................................................................................... 3–79

IR Delay (Coax Only) ............................................................................................................. 3–80

Hex Passthrough ..................................................................................................................... 3–80

EPC ........................................................................................................................................... 3–81

GrAVM (Graphics AVM) ......................................................................................................... 3–81

IPDS Category (IPDS Only) ................................................................................................... 3–82

Address (Twinax Only) ........................................................................................................... 3–82

Density...................................................................................................................................... 3–82

Dark Bar ................................................................................................................................... 3–82

Smooth Size ............................................................................................................................. 3–82

Zero .......................................................................................................................................... 3–82

Host Override .......................................................................................................................... 3–82

TCP/IP Menu (LAN Interface Only) .................................................................................... 3–83

IP Addr Category ..................................................................................................................... 3–83

Gateway Category .................................................................................................................... 3–83

Subnet Category ...................................................................................................................... 3–84

Test Menu ................................................................................................................................. 3–85

Pattern Category ..................................................................................................................... 3–85

Print .......................................................................................................................................... 3–85

Fault Override Category.......................................................................................................... 3–86

Paper Motion ........................................................................................................................... 3–86

Diag Category ......................................................................................................................... 3–86

Cal-Paper (Calibrate Paper Out) ............................................................................................ 3–86

Help Menu ............................................................................................................................... 3–87

Figure 3 - 5. Control Panel Navigation ........................................................................... 3–87

8 Operator Manual

Appendix A: Troubleshooting.................................................................... A–89

Appendix A contains a listing of the error and fault messages that may appear on the

Control Panel Display and various troubleshooting procedures and problem fixes.

Introduction............................................................................................................................. A–89

Messages .................................................................................................................................. A–89

Faults ........................................................................................................................................ A–89

Fault Correction Procedure .................................................................................................... A–89

Table A - 1. Display Messages ........................................................................................... A–90

Twinax Trouble Checklist ........................................................................................................ A–94

Table A - 2. Paper/Printing Corrective Action ............................................................... A–95

Appendix B: Optional Interfaces............................................................... B–97

Appendix B explains connecting and powering up with the Twinax and Coax

interfaces.

Figure B - 1. Rear view, showing Serial, Parallel, Optional LAN or Twinax/Coax Ports,

and Power Plug .................................................................................................................. B–97

Connecting the I/O................................................................................................................ B–97

Optional Interface Connections and Powering Up .............................................................. B–97

Interface Connectors .............................................................................................................. B–97

Figure B - 2. Twinax Smart “T” Adaptor ......................................................................... B–98

Figure B - 3. BNC Coax adapter ...................................................................................... B–98

Appendix C: Specifications ........................................................................ C–99

This section lists and explains technical aspects of printer performance and general

design specifications.

Industry and Agency Standards ............................................................................................. C–99

Electro-Magnetic Emissions ................................................................................................... C–99

Electro-Magnetic Immunity ................................................................................................... C–99

Energy Conservation .............................................................................................................. C–99

Safety ........................................................................................................................................ C–99

Acoustic .................................................................................................................................... C–99

Marking.................................................................................................................................... C–99

Physical Configurations .........................................................................................................C–100

Weight .....................................................................................................................................C–100

Dimensions ............................................................................................................................. C–100

Preventive Maintenance.........................................................................................................C–100

Environment .......................................................................................................................... C–100

Operating................................................................................................................................C–100

Nonoperating .........................................................................................................................C–101

Safety .......................................................................................................................................C–101

Cooling System....................................................................................................................... C–101

Operator Manual 9

Acoustics ..................................................................................................................................C–101

Power Supply ...........................................................................................................................C–102

Heat Load Contribution ........................................................................................................ C–102

Emulations ............................................................................................................................. C–103

Characters Per Inch............................................................................................................... C–103

Lines Per Inch ....................................................................................................................... C–103

Type Styles .............................................................................................................................. C–103

Draft and Data Processing .................................................................................................... C–103

Gothic and Courier.................................................................................................................C–104

OCR–A and OCR–B............................................................................................................... C–104

Large Character Printing ......................................................................................................C–104

Standard Languages and Character Sets .............................................................................C–104

Twinax / Coax / IPDS Character Sets.................................................................................. C–105

Nonvolatile Memory.............................................................................................................. C–105

Paper Description ...................................................................................................................C–106

Paper Movement Speed .........................................................................................................C–106

Throughput ............................................................................................................................ C–106

Preface–10 Operator Manual

Preface

Introduction

The 6300 Series Line Matrix Impact Printers are designed to handle heavy duty,

high volume workloads, with a straight paper path that provides unattended, jamfree printing of continuous forms, at high speeds. They have a wide range of

printer emulations, network printer management ability, popular graphics

languages and web administration utilities.

The 6300 Series offers the following I/O configurations (Modules):

• Standard Serial/Parallel

• FourPlex (Standard plus Twinax/Coax)

• FourPlex IPDS

• LANPlex (Standard plus Ethernet 10/100 BASE-T)

• LANPlex IPDS

In less than five minutes you can add other configurations by inserting a new

module. Installation instructions come with the module.

All interface configurations and printer setups

are performed through the control panel on the

top right of the unit. And since the printer’s

operational configuration is stored in nonvolatile

memory; you’ll never have to reconfigure your

printer because of a power loss.

Operator Manual Preface–11

About This Manual

Conventions

We use the following conventions throughout this manual:

Text that is placed in italics draws your attention to additional helpful

information.

Sometimes your attention is more particularly drawn by the use of this symbol.

CAREFUL!

This symbol marks information about actions

that may damage the equipment or injure the

user.

Preface–12 Operator Manual

Chapter 1

Site Preparation

Choosing a site for your printer is important because the environment affects

your print quality. The best site for your printer is one that is protected from

dirt and heavy dust, and has a moderate temperature and humidity range. In

addition, the power source should be adequate for printer operation and

protected from power surges.

Keep the following factors in mind when choosing a printer location:

• Keep the operating environment temperature between 50°F and 104°F

• Do not locate your printer near air conditioners, open windows, heaters,

• The relative humidity should be between 10% and 90%

• The heat load contribution to the environment is 188 BTUs per hour at

(10°C and 40°C).

nor in other areas where the temperature changes abruptly.

(noncondensing). Be sure to locate the printer away from any sources of

moisture, such as water faucets, refrigerators, and humidifiers.

idle and can go as high as 2050 BTUs per hour under continuous fullload printing conditions.

• Keep your printer away from dust, dirt, and open flames.

• Plug your printer into a grounded outlet.

• Minimum floor space recommended for your printer is 36" wide x 36"

deep (91.4 cm x 91.4 cm) to allow air movement around the printer.

Allow space to open printer doors as well. When the doors are fully

opened, the printer takes up 6.5 feet (2.0 m) of floor space.

Chapter 1: Setting Up Your Printer 1–13

Unpacking the Printer

Unpacking your printer

Instructions for unpacking your printer are located on the outside of the shipping

container. After you have removed your printer from its container, store the

shipping materials for possible later use.

Repacking

Repacking your printer for storage or shipping is the reverse order of unpacking.

If shipping materials are needed, you can reorder them from your dealer.

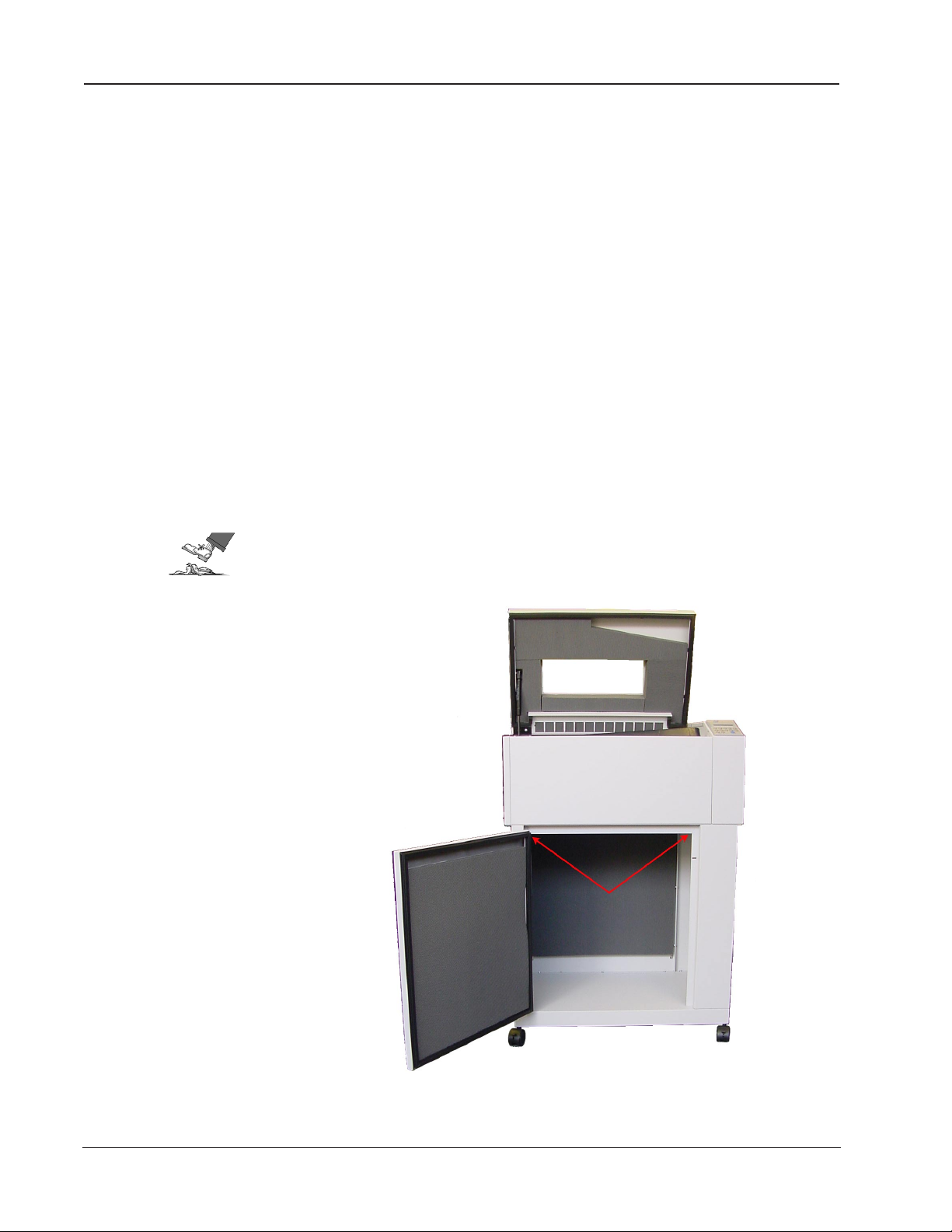

Removing the Shipping Hardware

The Shipping Hardware consists of 4 screws, identified by red tags, that secure the

printer base to the inside mechanism, and tie restraints that secure the Paper

Stacking Chains. The shipping screws fasten from underneath, 2 near the front of

the print cabinet and 2 near the rear of the cabinet.

CAREFUL!

DO NOT power up your printer before removing the shipping

hardware.

Arrows point to 4

shipping screw locations

1–14 Operator Manual

Figure 1 - 1. Shipping Screw Locations

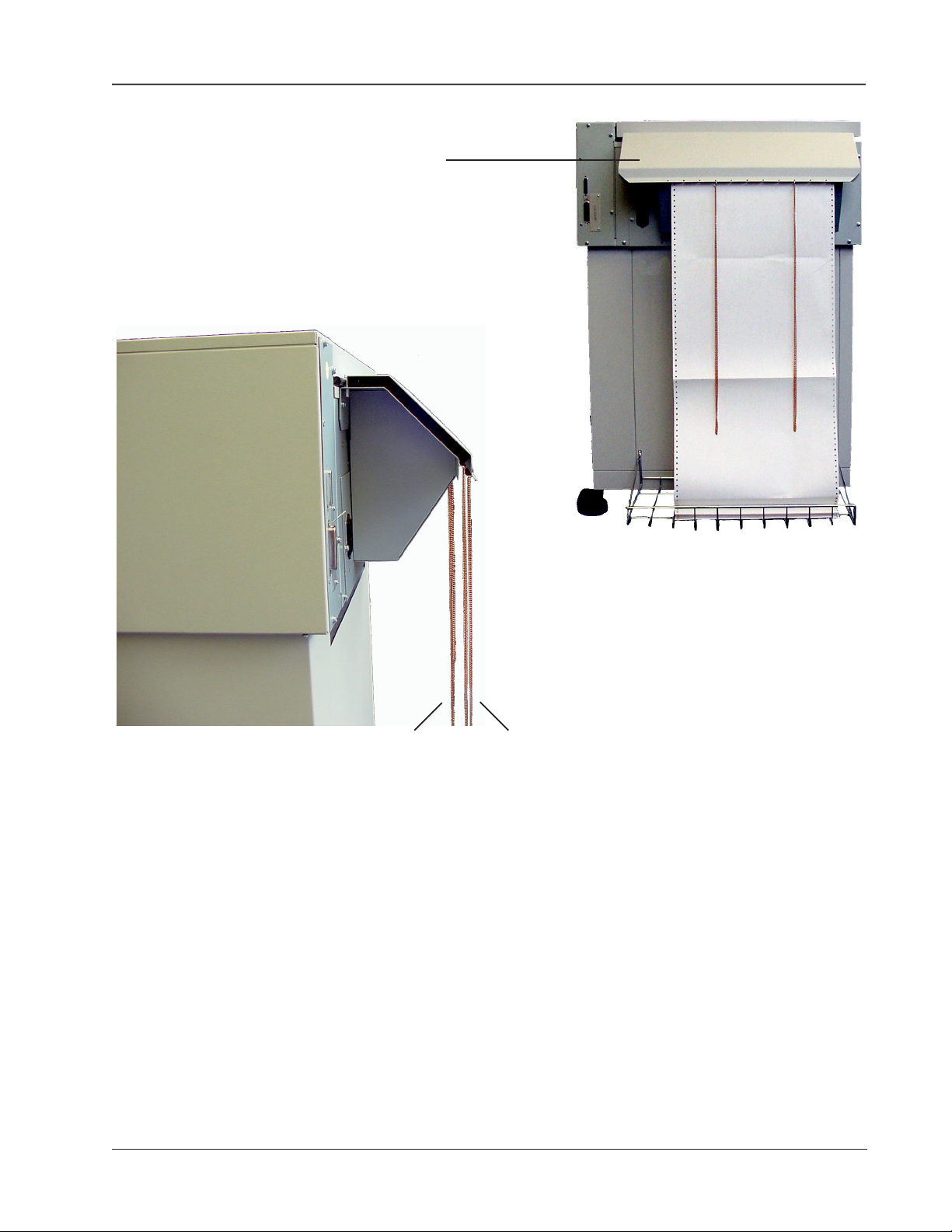

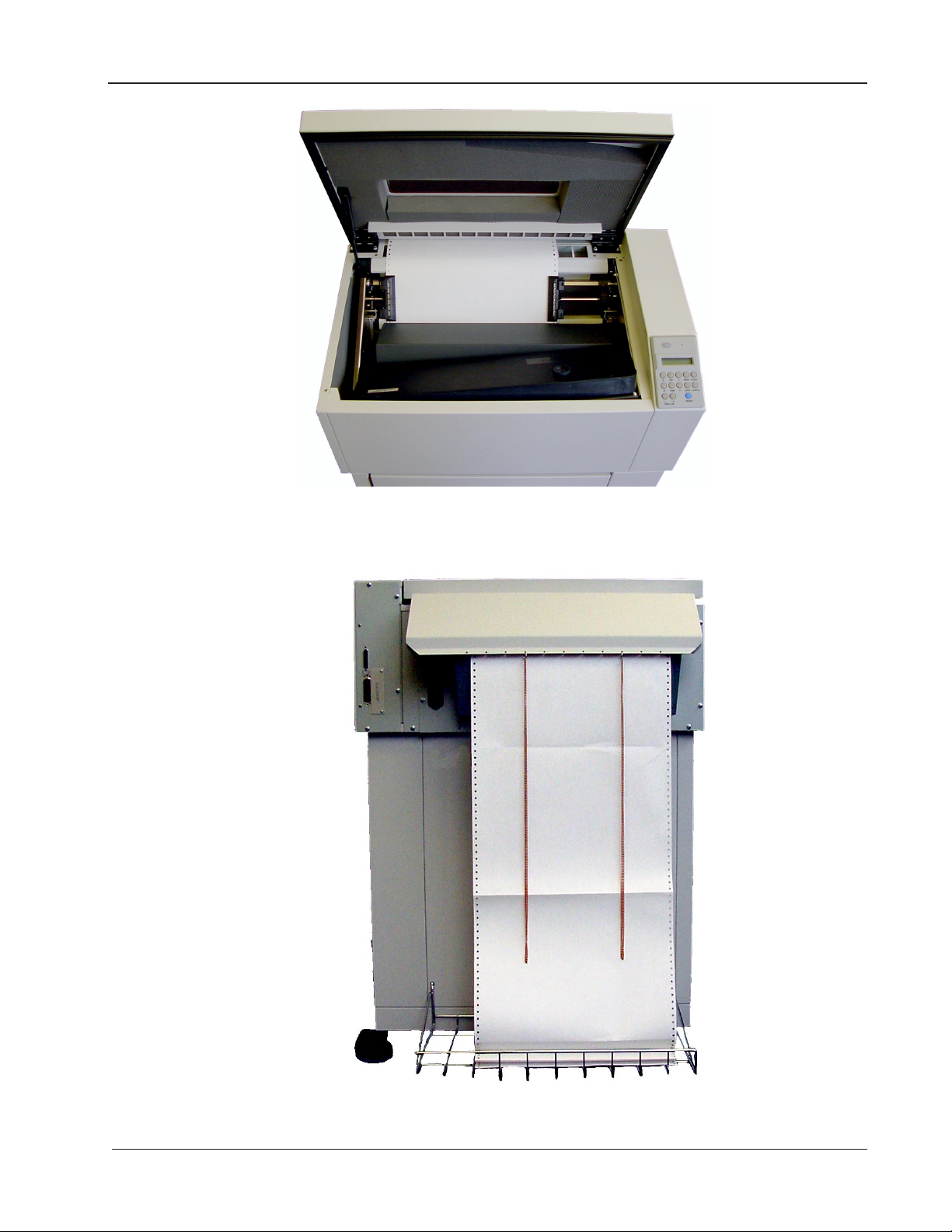

Rear Paper Guide

Paper Stacking Chains

Paper comes out between these

two sets of chains.

Figure 1 - 2. Paper Stacking Chains

Rear Guide Assembly Instructions

Use the two screws already installed in the back of the printer to secure the Rear

Guide Assembly (packed separately). Cut the plastic ties and remove the plastic

bag holding the paper chains. Paper exits the printer through these passive paper

stacking chains that help fold and stack printed forms uniformly. Make sure the

chains are not tangled.

Chapter 1: Setting Up Your Printer 1–15

Interface Connections

Interface Connections and Powering Up

Interface Connectors

Properly secure the cable to the printer interface using the correct connectors.

CAREFUL!

Connecting the I/O

Shielded I/O cables must be used on all installations to

comply with regulatory requirements.

After connecting each interface to your printer, run a print job from the Host

Computer to verify proper function of the printer.

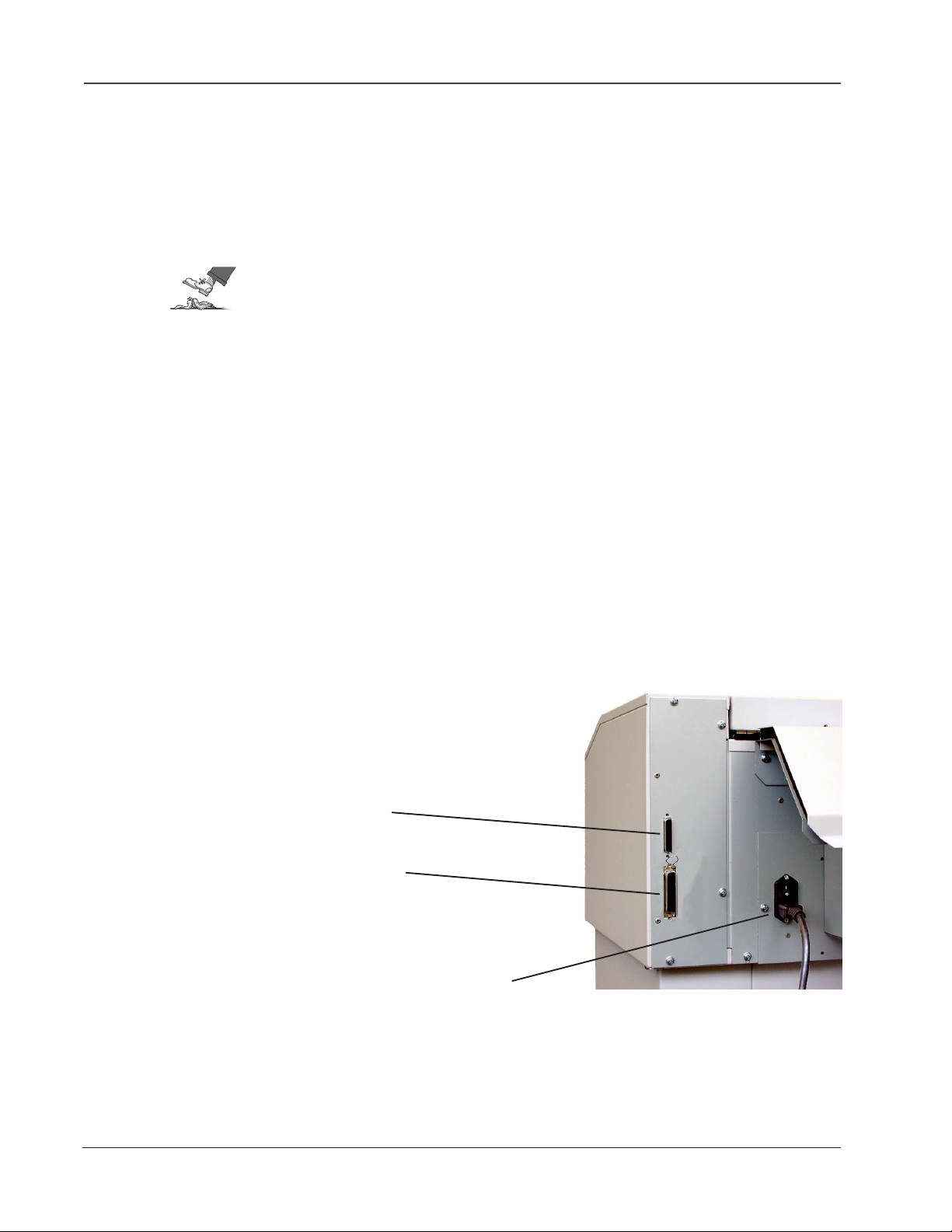

Serial/Parallel Interfaces

To connect the Serial or Parallel I/O cable, plug in the cable to the proper

connector on the I/O panel.

The serial interface operates up to 38.4 kBaud and uses a standard DB 25 serial

cable connector and standard RS-232-C signals. Serial interface cables should be

no longer than 50 feet (15.2 meters).

The Centronics parallel port is IEEE-1284 compliant and uses a 36-pin 1284-B

type connector (AMP 555119-1 or equivalent). Parallel interface cables should be

no longer than 6 feet (2 meters)

Serial Interface Port

Parallel Interface Port

The optional Twinax and Coax interface modules are installed between the

Serial/Parallel connectors and the power plug. Appendix B: Optional Interfaces

describes these.

1–16 Operator Manual

Power Plug

Figure 1 - 3. Rear view, showing Serial, Parallel and Power Plugs

Powering Up

The power switch is located on the back of the printer, just above the 3-prong

power plug connector.

Powering Up

Figure 1 - 4. Power plug and on/off switch

Step 1.

Make sure the power is off by depressing the "0" side of the rocker power switch.

Connect the power cord. Plug the power cord into a proper power outlet.

Step 2.

Turn the power on.

The printer runs a self-test each time it is powered up to check the main

processor and buffers for errors. Note that when you turn the printer on this

time, the Paper Out error displays. If any error message appears in the display,

check Appendix A for a description of the error and what actions are necessary to

clear the error.

When connecting the Twinax interface at this time, other messages that may

appear are Setup Address and Lost Sync (28). These messages appear because

the printer/host interface has not been properly set up. If you cannot connect

the interface at this time, you can still test certain aspects of printer performance

by placing the printer Offline (depress the Online/Offline key), then entering the

Menu Mode. While in Menu Mode you may select print and operation

parameters or test certain printer systems.

Chapter 1: Setting Up Your Printer 1–17

Paper System Components

Paper System

Paper System Components

The Tractors, Ribbon Cartridge, Platen and Paper Iron are all parts of the paper

system. The first two can be seen when the lid is raised. The Platen and Paper

Iron are hidden inside the housing.

Tractors

Ribbon

support

platform

shaft for

tractors

Ribbon Cartridge

Figure 1 - 5. Inside the Lid

1–18 Operator Manual

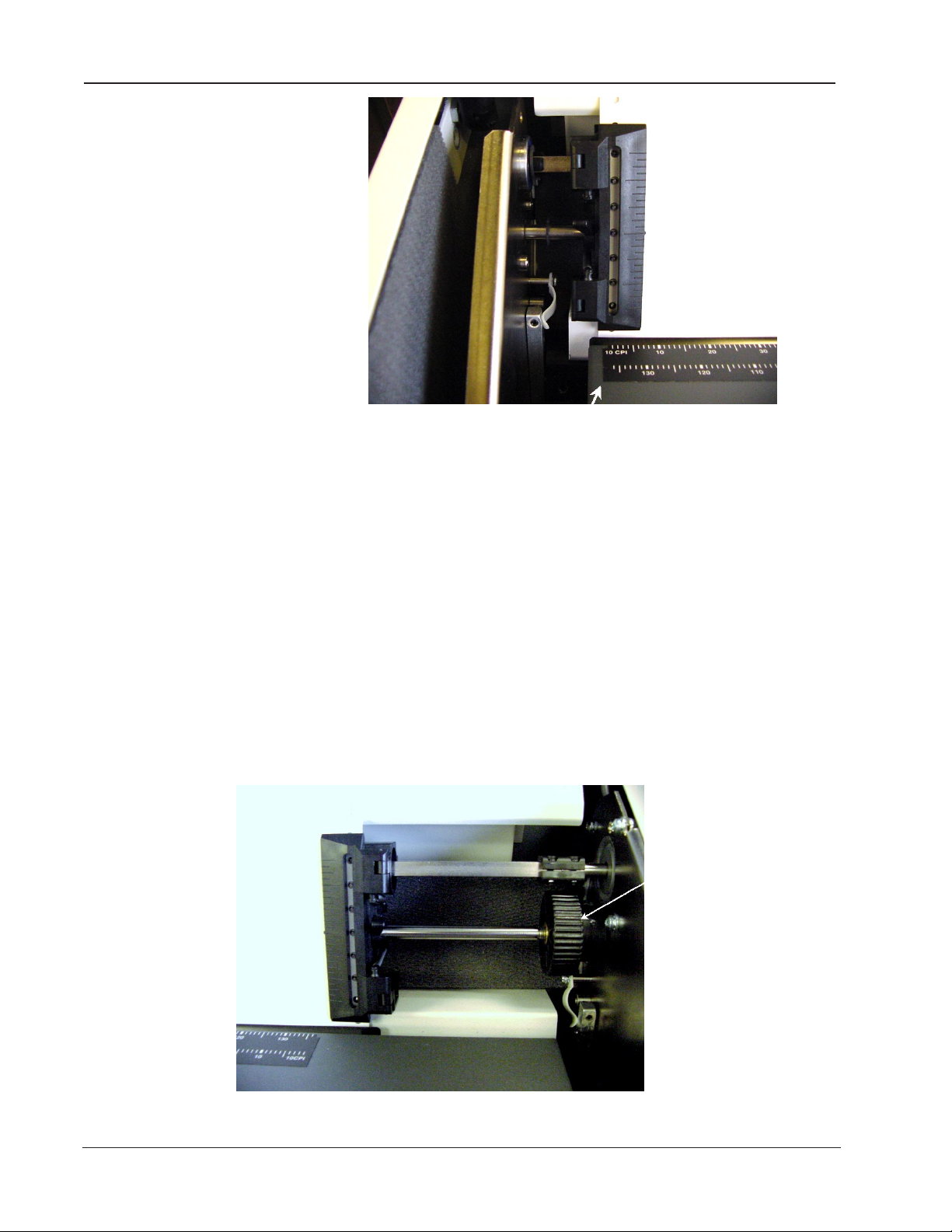

Tractors

Tractors

Open

Paper System Components

The 6300 Series has two tractors to control paper movement, located on the left

and right.

A lever on each tractor keeps it locked in place on a horizontal shaft. To reposition a tractor, unlock the tractor and move it to the left or the right along the

shaft. Repositioning is generally needed only when inserting a new form or size of

paper.

Print Gap

locking

lever

Figure 1 - 6. Left and Right Paper Tractors

The 6300 Series line printers offer Auto-Gap which simplifies operator set-up and

printer use by setting the optimum print gap based on the form thickness. The

print gap is automatically opened to its widest position when the printer is not

printing. To accommodate various thicknesses of paper, the print gap is adjusted

either automatically or manually. (See Chapter 2 pages 2-30 to 2-33 and Chapter 3

pages 3-56 to 3-58). If the Print Gap Detect Mode has been set to "Auto," the auto

gap sensing operation will take place the first time the power is turned on,

immediately after a "paper out" fault, when the TOF key is pressed, and when

printing is attempted without setting the Top Of Form. Dedicated control panel

keys also allow the print gap to be adjusted based on operator preference.

Paper Tension

Vertical tension on the paper is pre-set. It is not controlled by the user.

Chapter 1: Setting Up Your Printer 1–19

Installing Ribbon Cartridge

Installing the Ribbon Cartridge

Step 1.

Make sure the printer is Offline or power is off. Open the printer lid and remove

the old ribbon by lifting it straight up off of the Ribbon Platform.

Figure 1 - 7. Ribbon Cartridge

Step 2.

Remove slack in the new ribbon by turning the knob on the ribbon cartridge as

indicated by the arrow printed next to the knob, then slip the ribbon, left side

first, over the two ribbon guides and between the front and rear panels of the

ribbon shield on the printer.

Step 3.

Press down lightly on the cartridge while turning the ribbon knob as before until

it seats on first the left, (as shown), and then the right cartridge drive posts. Make

sure that the ribbon does not twist or fold over.

1–20 Operator Manual

Figure 1 - 8. Installing the Ribbon Cartridge

The front and rear

panels of the ribbon

shield

Installing Ribbon Cartridge

Figure 1 - 9. Ribbon Shield Panels

The ribbon has been carefully positioned

between the two panels of the ribbon shield.

Chapter 1: Setting Up Your Printer 1–21

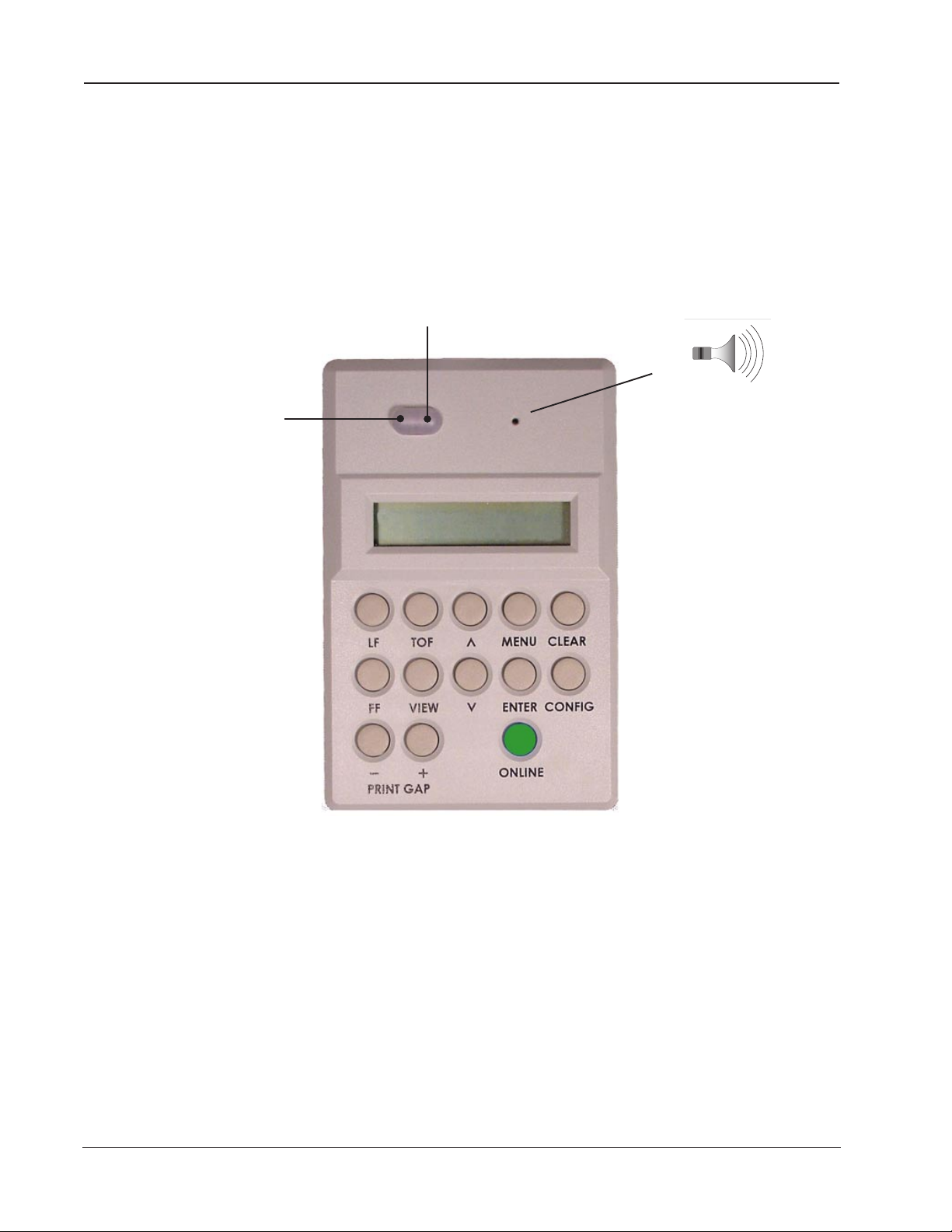

Control Panel Components

Control Panel Components

The Control Panel is located on the right front top of the printer housing. It is

used to program and direct most printer functions.

Red LED Indicator

Green LED Indicator

beeper

32-character

2-line LCD

}

display

LED Indicators

The green ONLINE indicator illuminates whenever there is power to the printer,

and the printer is Online.

The red FAULT Indicator illuminates whenever an error or fault is detected. A

message also appears on the display to indicate what kind of fault is present (see

Appendix A for explanations of all error and fault messages).

LCD (Liquid Crystal Display)

The 32-character, 2-line Liquid Crystal Display shows printer status, menu selections, normal, fault and error messages. It is divided into four main areas. The

displayed information will vary with menu selection and the configuration of the

printer.

1–22 Operator Manual

Figure 1 - 10. Control Panel

Once the printer has been unpacked, the cables connected, the ribbon cartridge

installed, and a box of paper (whether plain paper or pre-printed forms) placed

nearby, you are ready to load the paper and set the various parameters via the

Control Panel that will ensure that the 6300 Series printer performs exactly as you

need. This is covered in the next chapter.

Chapter 1: Setting Up Your Printer 1–23

Blank

Page

1–24 Operator Manual

Chapter 2

Introduction

This chapter covers how to load the paper and to set the print gap. It also covers

how to create saveable configuration settings for your own pre-printed forms.

Your printer is designed to use a continuous sheet, sprocket-fed paper. It can

handle:

• Six-part forms (1 original and 5 copies) with a maximum thickness of

• Page widths of 2.5" to 18" (6.4 cm to 45.7 cm).

Specific requirements for pre-printed forms are in Appendix C: Specifications.

.025" (0.6 mm).

Chapter 2: Loading Paper and Printing 2–25

Standard Printing Mode

Loading Paper for Standard Printing Mode

Step 1.

Turn off the printer using the power switch on the back, or toggle the "Online"

button on the Control Panel until the LCD shows "Offline".

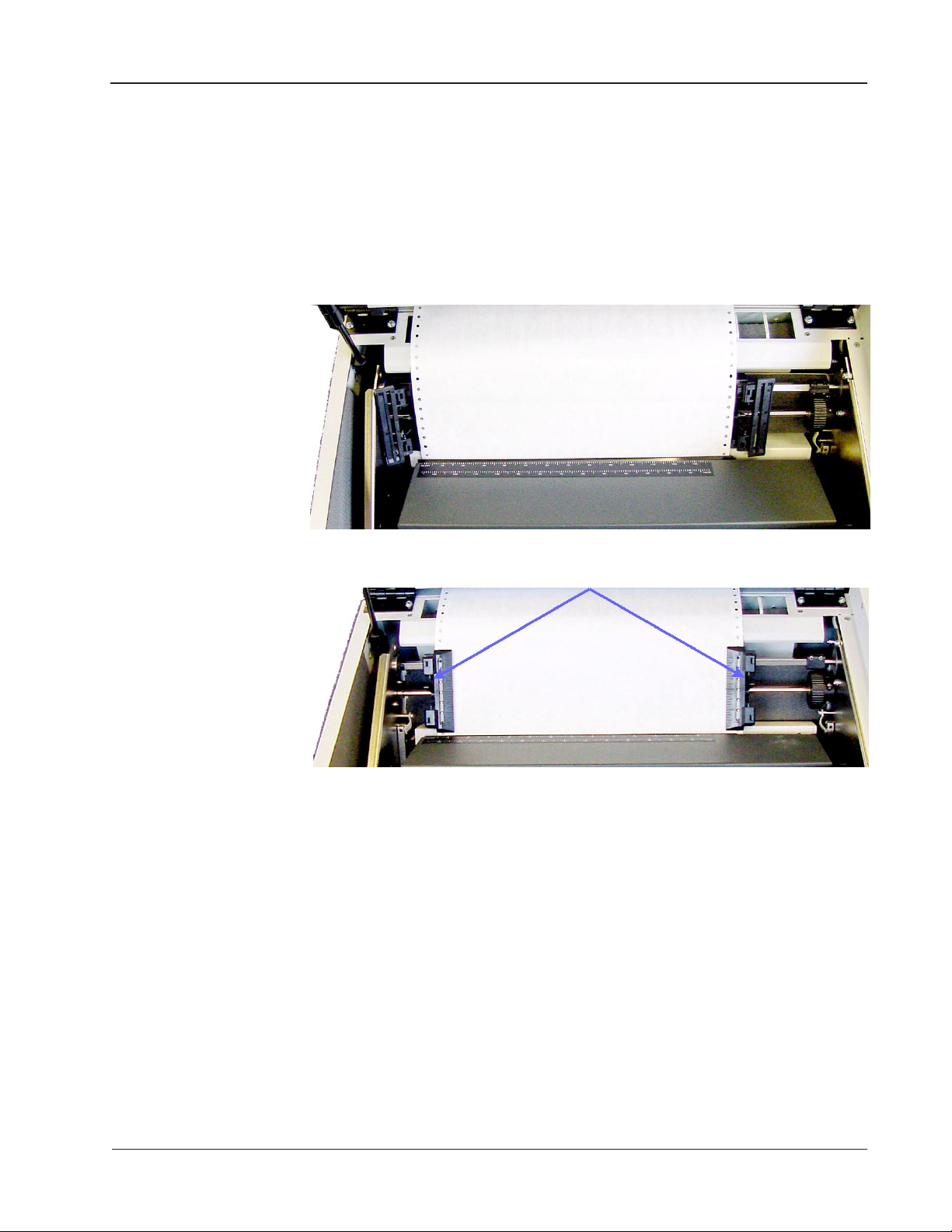

Step 2.

Raise the printer lid and open the doors on both tractors.

Figure 2 - 1. Inside Paper Inlet, visible when looking inside the printer cabinet.

Step 3.

Open the new box of paper. Remove the box top so that the paper can be

pulled out freely. Open the front of the printer cabinet and place the new box of

paper inside.

Step 4.

Feed the paper up through the paper inlet, as shown in figure 2-1, a little ways

past the tractors and through the gap between the top back of the printer and

the lid (Figure 2-2). It will flow out between the paper chains and fold into the

wire rack near the floor (Figure 2-3).

Step 5.

Place the left-side paper holes onto the left tractor pins and close the tractor

door.

2–26 Operator Manual

Feed paper

between the

lid and the

top of the

printer.

Standard Printing Mode

Figure 2 - 2. Paper path past the lid.

Figure 2 - 3. Paper path into the wire rack.

Chapter 2: Loading Paper and Printing 2–27

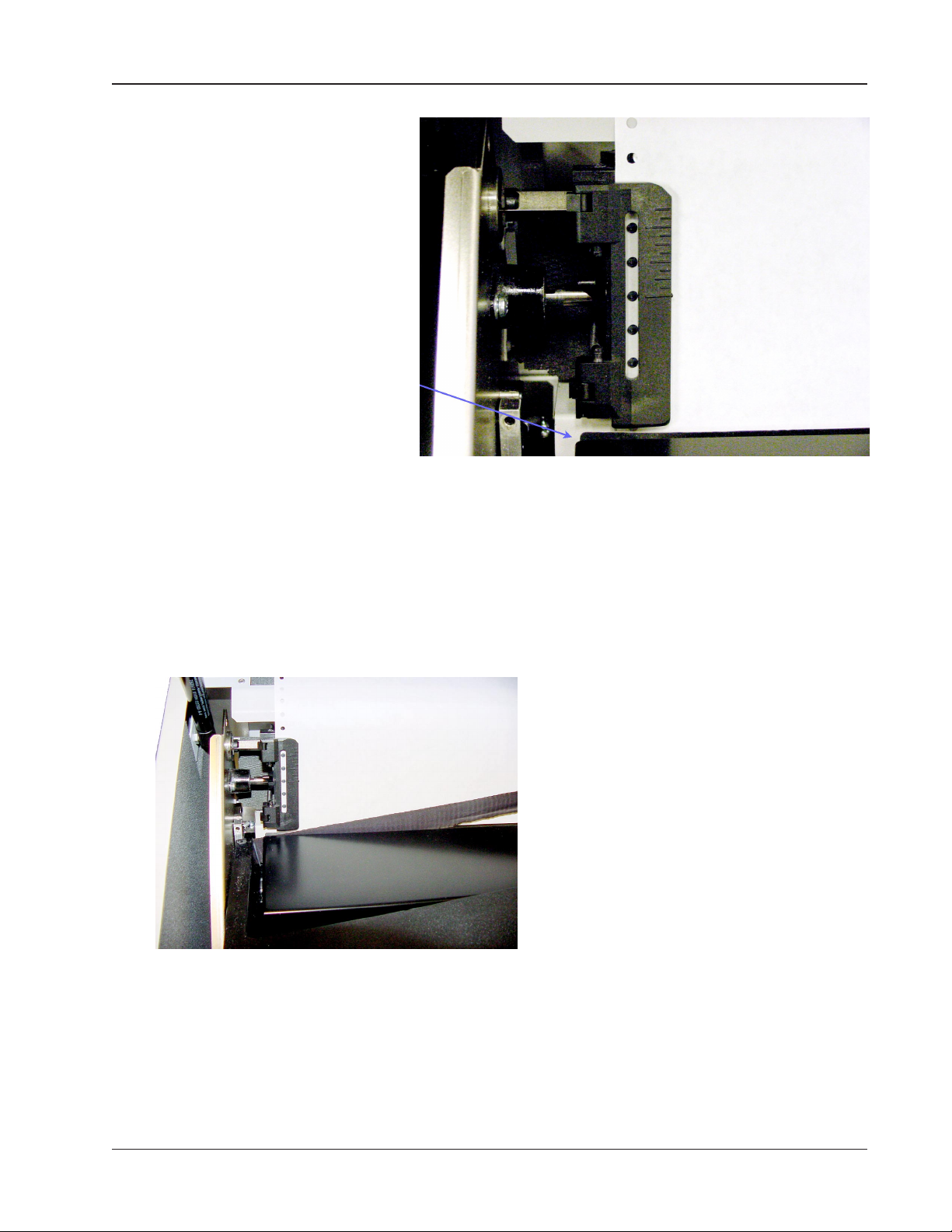

Standard Printing Mode

Step 6.

The Column Alignment Scale is on the top of the ribbon support platform. It is

to be used for general guidance in horizontally aligning the form for each print

job. The leftmost mark on the scale indicates the location of the first, or leftmost,

printable character. Each successive tick mark indicates the location of additional

10 CPI characters.

Figure 2 - 4. Column Alignment Scale

Unlock the right tractor and move it so that the paper's holes align directly over

the tractor pins, making sure that the paper is straight, then close the tractor

door. Gently push the tractor to the right until the paper is smooth. Unlock the

left tractor and, keeping the paper reasonably taut, holding onto both tractors,

move the paper to the left or the right until it is roughly aligned with the desired

mark on the Column Alignment Scale. Lock both tractors.

Horizontal Vernier Wheel

2–28 Operator Manual

Figure 2 - 5. Horizontal Vernier Wheel

Step 7.

Standard Printing Mode

Fine-tuning the Column Alignment can be done in two ways:

(1) Rotate the Horizontal Vernier Wheel, which is located on the right end of the

shaft on which the tractors ride. Depending upon the direction the paper needs to

move, you will rotate the wheel either upwards or downwards.

(2) Use the Control Panel. Go Offline, choose Menu, then use the arrow keys to

get to the Operator Menu. Press Enter. Use the arrow keys to get to Forms. Press

Enter. Use the arrow keys to get to Horz Adjust. Press Enter. Use the arrow keys

to increase or decrease the number that appears in the lower right of the LCD.

This will shift the position of Column 1.

Set the Top of the Form (TOF). This is done from the Control Panel. If the

printer is not on, turn it on now. If necessary, press the Online key until “Offline”

is displayed. Use the up or down arrow keys to move the perforation line on the

paper so that it is aligned with the nubbin on the tractor door. Once the paper is

positioned, press the TOF key. The paper will move downward to the “ready to

print” position and the correct print gap will be set based on the form thickness.

Nubbin

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Figure 2 - 6. Top of Form Nubbin

Chapter 2: Loading Paper and Printing 2–29

Print Gap

Print Gap Adjustment

The 6300 Series Auto-Gap feature automatically sets the correct print gap based

on form thickness. Dedicated control panel keys also allow the print gap to be

adjusted for darker or lighter print based on user preference. For ease of paper

loading, the print gap is set to its widest position while the printer is not printing.

The Auto-Gap feature is automatically initiated under the following conditions:

1. The Print Gap Mode is Auto, the printer has been off but is now turned on,

and a TOF is set before any printing has begun.

2. The Print Gap Mode is Auto, the printer has been off but is now turned on,

and a print run is started before TOF is set.

3. The Print Gap Mode is Auto, a Paper Out Fault has been cleared, and either

the TOF is set or a print run is resumed.

4. The Print Gap Mode is Auto, the printer has been off but is now turned on,

and an adjustment is made using the “-” or “+” Print Gap keys on the Control

Panel.

Even though the print gap value has been automatically determined, there might

be times when it needs to be further fine-tuned using the Control Panel as described below under Manually Adjust Print Gap on Control Panel.

Gap Zone

The Gap Zone feature is used to set up a variable print gap for forms that contain

areas of varying thickness. This is done by creating a Gap Zone Profile for the

form, saving it in one of the ten saved configurations, then loading that configuration whenever the particular form is used.

Print Gap Profile Mode

As previously described, the Print Gap Mode is set up in the Print Gap Category of

the Operator Menu. There are three Print Gap Modes. In Manual Mode, the print

gap is set manually using the Print Gap keys on the control panel. In Auto Mode

(default), the print gap is automatically detected whenever a new form is loaded,

and when the printer is powered on. Profile Mode is the mode that must be set

when using the Gap Zone feature, as described below.

Creating a Gap Zone Profile

A Gap Zone Profile is created automatically in four simple steps:

Step 1 – Load the Form

Load the form for which the profile will be generated. Be sure to set the Top

of Form position, and be sure that the Form Length is set properly.

Step 2 – Set Profile Mode

The Print Gap Mode is set up in the Print Gap Category of the Operator Menu. Set

the Mode Parameter to Profile. Press Operator Menu => PrintGap => Mode =>

Profile => Enter.

2–30 Operator Manual

Loading...

Loading...