Page 1

2900

Operator Manual

Serial - Parallel - LAN

Operator Manual 1

Page 2

This Manual is published by TallyGenicom for use with the computer printer described herein. Translations,

reprinting or copying by any means of this manual, complete or in part, in any different form requires our

explicit approval. TallyGenicom reserves the right to revise this manual without notice, for any reason. This

includes, but is not limited to, utilization of advances in the state-of-the-art and changes in the equipment or

configuration thereof. Liability for difficulties arising from unknown or unforeseen technical limitations is

disclaimed.

FCC Statement

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to

Part 15, Subpart B of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial environment. This equipment generates,

uses, and can radiate radio frequency energy and, if not installed and used in accordance with the instruction

manual, may cause harmful interference to radio communications. Operation of this equipment in a residential

area is likely to cause harmful interference, in which case the user will be required to correct the interference

at his own expense.

WARNING

Only trained qualified personnel may open covers or remove parts that are not explicitly shown and described

in the Operator’s Manual as being accessible to the operator.

Please Note:

Printer drivers for various operating systems are available on the Internet at our Web Page

http://www.tallygenicom.com or http://www.tallygenicom.com/worldwide or at your

TallyGenicom distributor.

ACKNOWLEDGMENTS:

“IBM” and “Proprinter” are trademarks of International Business Machines Corporation.

“Epson” is a trademark of Seiko Epson Corp.

2900 Series Operator Manual

© October 2007

All rights reserved

TallyGenicom

6020 South 190th Street

Kent, Washington 98032

2 Operator Manual

Page 3

Contents

Preface ......................................................................................................... 3–9

Introduction ............................................................................................................................... 3–9

About This Manual ................................................................................................................... 3–10

Chapter 1 .................................................................................................... 3–11

Site Preparation ........................................................................................................................ 3–11

Figure 1 - 1. Shipping Screw Locations ............................................................................ 3–12

Unpacking your printer ........................................................................................................... 3–12

Repacking ................................................................................................................................. 3–12

Removing the Shipping Hardware.......................................................................................... 3–12

Figure 1 - 3. Rear view, showing Serial, Parallel and Power Plugs .................................. 3–13

Connecting the I/O ................................................................................................................. 3–13

Interface Connections and Powering Up ............................................................................... 3–13

................................................................................................................................................... 3–13

Interface Connectors ............................................................................................................... 3–13

Powering Up ............................................................................................................................. 3–14

Figure 1 - 4. Power plug and on/off switch ..................................................................... 3–14

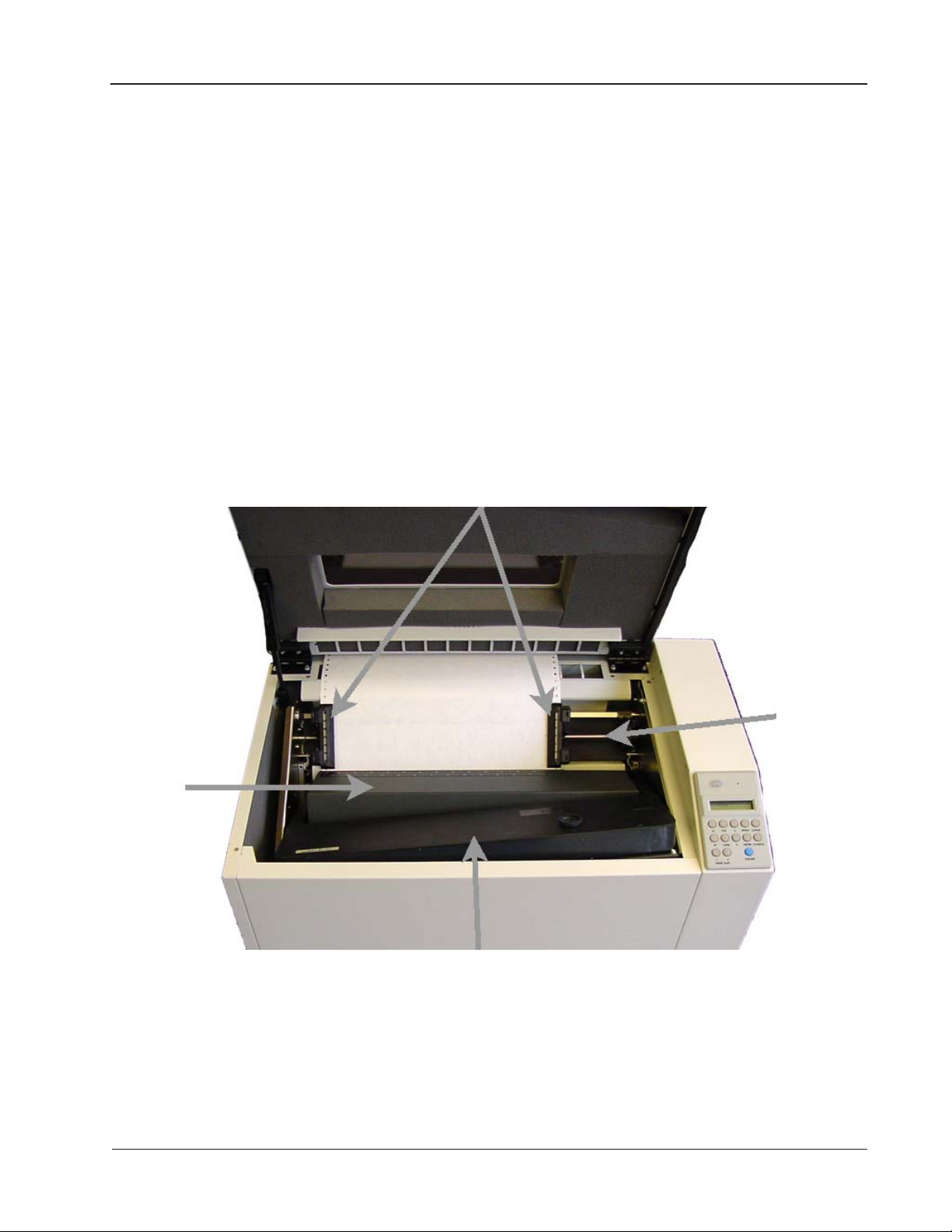

Figure 1 - 5. Inside the Lid ................................................................................................ 3–15

Paper System ............................................................................................................................. 3–15

Paper System Components ...................................................................................................... 3–15

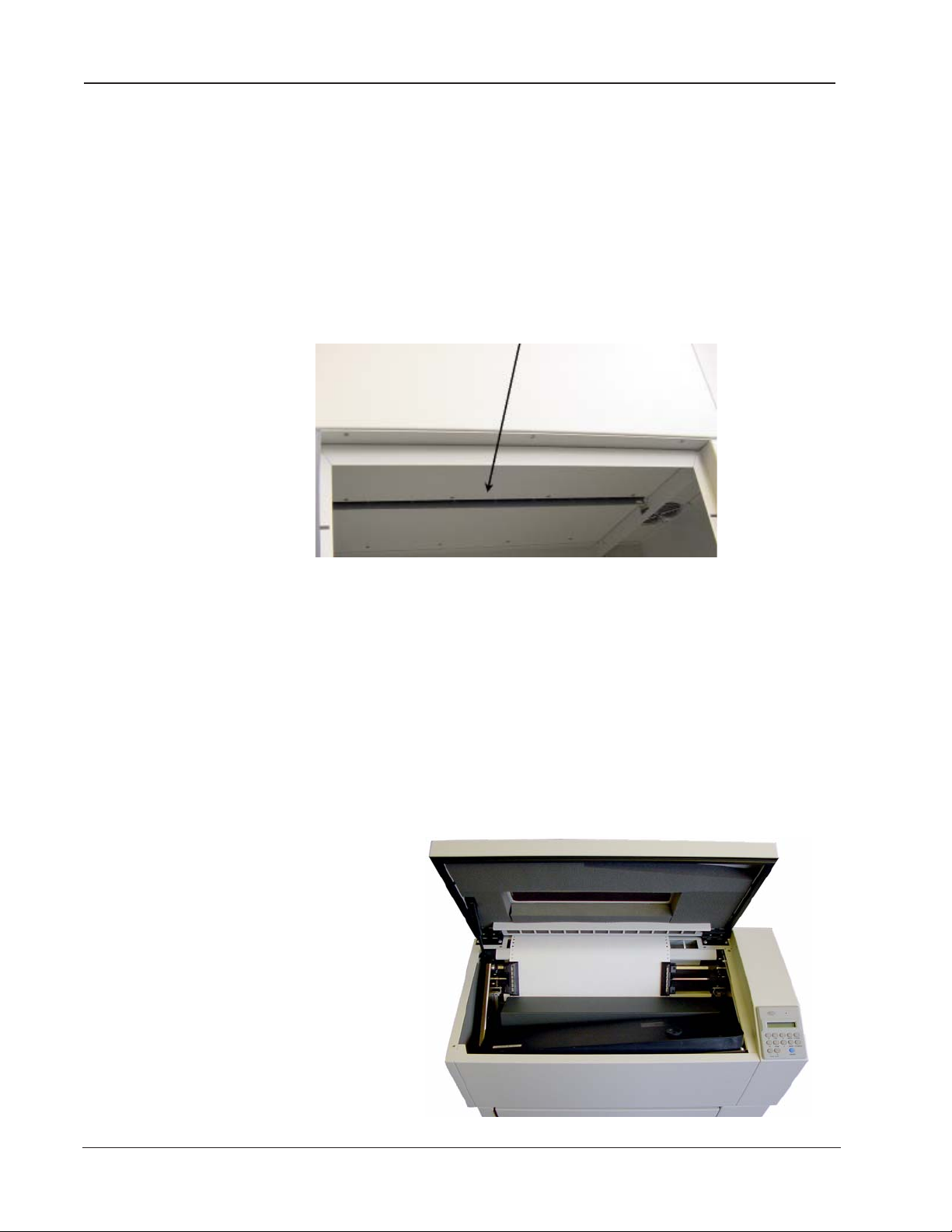

Print Gap ................................................................................................................................... 3–16

Paper Tension ........................................................................................................................... 3–16

Tractors ..................................................................................................................................... 3–16

Figure 1 - 6. Left and Right Paper Tractors ..................................................................... 3–16

Installing the Ribbon Cartridge .............................................................................................. 3–17

Figure 1 - 8. Installing the Ribbon Cartridge................................................................... 3–17

Figure 1 - 7. Ribbon Cartridge .......................................................................................... 3–17

Figure 1 - 9. Ribbon Shield Panels.................................................................................... 3–18

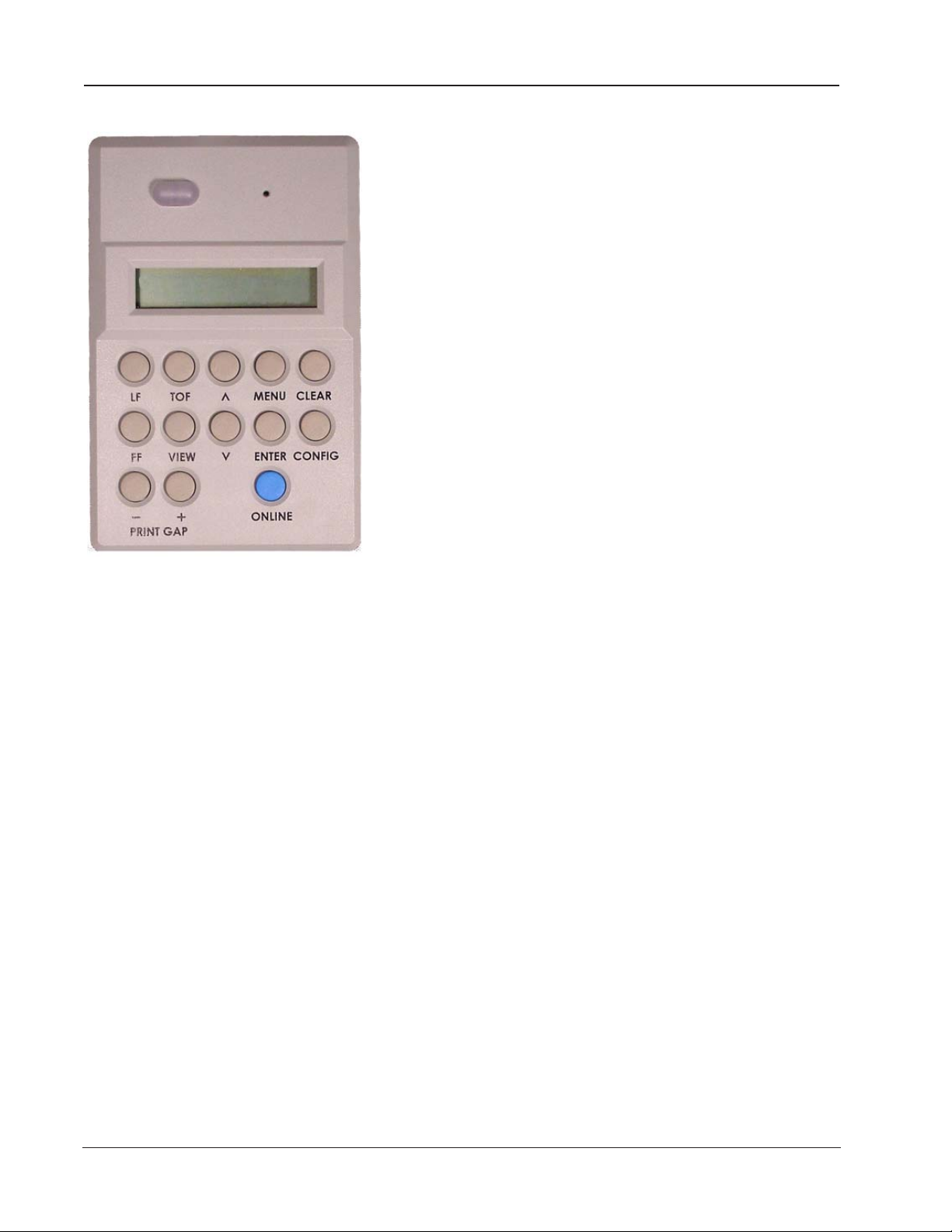

Figure 1 - 10. Control Panel .............................................................................................. 3–19

LED Indicators ......................................................................................................................... 3–19

LCD (Liquid Crystal Display) .................................................................................................. 3–19

Control Panel Components ..................................................................................................... 3–19

Operator Manual 3

Page 4

Chapter 2 .................................................................................................... 3–21

Introduction ............................................................................................................................. 3–21

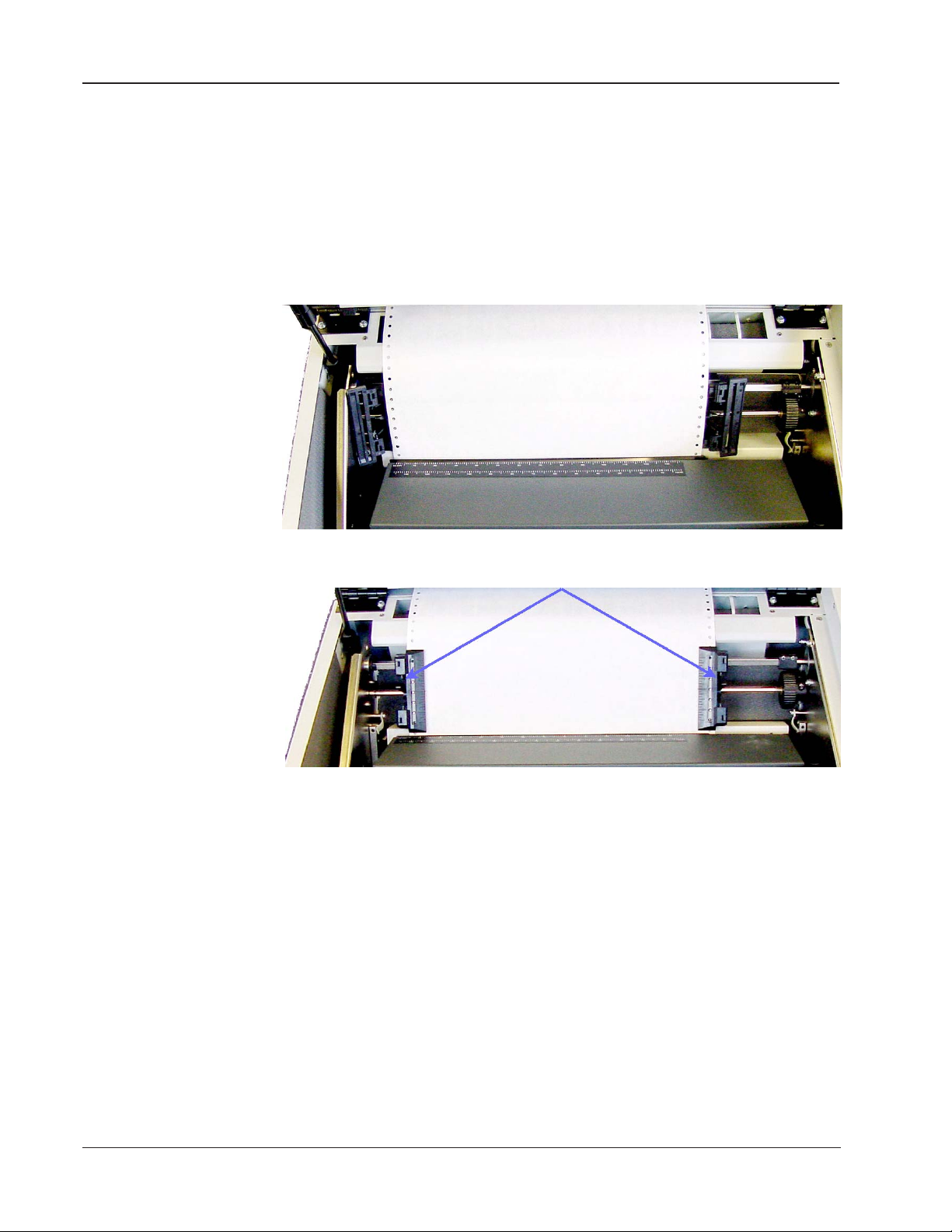

Loading Paper for Standard Printing Mode .......................................................................... 3–22

Figure 2 - 1. Inside Paper Inlet, visible when looking inside the printer cabinet. ........ 3–22

Figure 2 - 2. Paper path past the lid. ................................................................................. 3–22

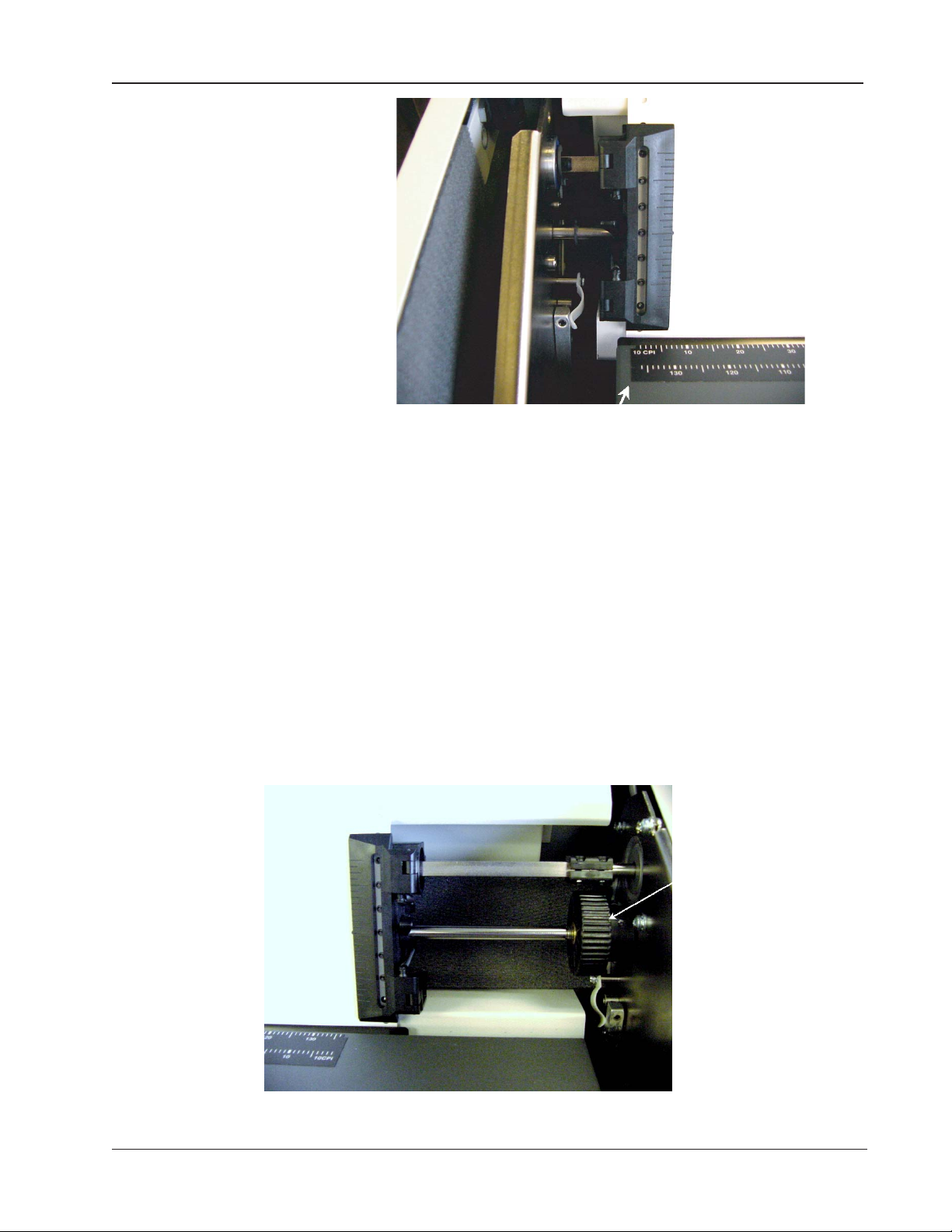

Figure 2 - 4. Column Alignment Scale ............................................................................. 3–23

Figure 2 - 5. Horizontal Vernier Wheel ............................................................................. 3–23

Figure 2 - 6. Top of Form Nubbin ..................................................................................... 3–24

Print Gap Adjustment .............................................................................................................. 3–25

Gap Zone .................................................................................................................................. 3–25

Print Gap Profile Mode ............................................................................................................ 3–25

Creating a Gap Zone Profile .................................................................................................... 3–25

Using a Saved Gap Zone Profile .............................................................................................. 3–26

Fine-tuning the Automatic Print Gap Setting ........................................................................ 3–26

Set Print Gap Detect Mode to Manual .................................................................................... 3–27

Figure 2 - 7. Typical Display when Print Gap Mode is set to “Auto” ............................... 3–27

Setting Up Configurations ....................................................................................................... 3–28

Figure 2 - 8. Typical display when adjusting Print Gap .................................................... 3–28

Chapter 3 .................................................................................................... 3–29

Introduction ............................................................................................................................. 3–29

Control Panel Display .............................................................................................................. 3–29

The Display During Normal Operation.................................................................................. 3–30

Figure 3 - 1. Control Panel Display for Normal Operation ............................................ 3–30

Current State ............................................................................................................................ 3–30

Current Configuration ............................................................................................................. 3–30

Paper Weight & Hammer Impact ........................................................................................... 3–30

The Display When In A Menu ................................................................................................. 3–31

Figure 3 - 2. Control Panel Display for Menus ................................................................. 3–31

Table 3 - 1 Paper Weight & Hammer Impact Indicator ................................................... 3–31

Control Panel Key Functions ................................................................................................... 3–32

Online Key ................................................................................................................................ 3–32

LF Key (Line Feed) .................................................................................................................. 3–32

FF Key (Form Feed) ................................................................................................................. 3–32

Figure 3 - 3. Control Panel ................................................................................................. 3–32

FF Key (Form Feed) continued ............................................................................................... 3–33

TOF Key (Top of Form)........................................................................................................... 3–33

View Key .................................................................................................................................... 3–33

PRINT GAP + and - Keys .......................................................................................................... 3–33

Up and Down Arrow Keys ........................................................................................................ 3–33

Menu Key .................................................................................................................................. 3–33

Enter Key................................................................................................................................... 3–34

Clear Key ................................................................................................................................... 3–34

Clear Key continued ................................................................................................................. 3–35

4 Operator Manual

Page 5

Config Key................................................................................................................................. 3–35

Control Panel Menus ............................................................................................................... 3–36

Categories, Parameters and Selections ................................................................................... 3–36

Using Menus ............................................................................................................................. 3–36

Example: Changing Form Length Using the Menu System ................................................ 3–38

How to Print a Control Panel Selected Options Report........................................................ 3–39

Operator Menu......................................................................................................................... 3–40

Font Category ........................................................................................................................... 3–40

Ser/Par Language .................................................................................................................... 3–40

Ser/Par Character Set .............................................................................................................. 3–41

Matrix ........................................................................................................................................ 3–41

OCRA Density ........................................................................................................................... 3–41

Ser/Par Style ............................................................................................................................. 3–42

CPI (Characters Per Inch) ....................................................................................................... 3–42

Panel Language ........................................................................................................................ 3–42

OCR Standards ......................................................................................................................... 3–42

Zero ........................................................................................................................................... 3–42

Compressed 8 ........................................................................................................................... 3–42

Forms Category ........................................................................................................................ 3–43

Length (lines) ........................................................................................................................... 3–43

Length (inches)........................................................................................................................ 3–43

LPI (Lines Per Inch) ................................................................................................................ 3–43

Top Margin ............................................................................................................................... 3–43

Bottom Margin ......................................................................................................................... 3–43

Left Margin ............................................................................................................................... 3–44

Right Margin ............................................................................................................................. 3–44

Horz Adjust ............................................................................................................................... 3–44

Vert Adjust................................................................................................................................. 3–44

Print to EOF (End Of Form) ................................................................................................... 3–44

Print to EOF (End Of Form) Continued ............................................................................... 3–45

Quick Access ............................................................................................................................. 3–45

Eject Distance ........................................................................................................................... 3–45

Eject Delay ................................................................................................................................ 3–46

Impact ....................................................................................................................................... 3–46

Paper Weight ............................................................................................................................ 3–46

Fast Slew .................................................................................................................................... 3–46

Double Strike ............................................................................................................................ 3–46

RibbonMonitor ......................................................................................................................... 3–46

RibnMon Thresh ...................................................................................................................... 3–47

Perf Skip .................................................................................................................................... 3–48

Print Gap Category ................................................................................................................... 3–48

Detect ........................................................................................................................................ 3–48

Adjust......................................................................................................................................... 3–48

Reset .......................................................................................................................................... 3–49

Mode ......................................................................................................................................... 3–49

Creating a Gap Zone Profile .................................................................................................... 3–50

Operator Manual 5

Page 6

Detect Distance ......................................................................................................................... 3–50

VFU Category (Vertical Format Units) ................................................................................... 3–51

VFU Enable ............................................................................................................................... 3–51

VT Channel (Vertical Tab Channel) ....................................................................................... 3–51

Skip When ................................................................................................................................. 3–51

Config Menu ............................................................................................................................. 3–52

Printer Category ....................................................................................................................... 3–52

Powerup .................................................................................................................................... 3–52

Ser/Par Emulation ................................................................................................................... 3–52

LAN Emulation (LAN Interface only) .................................................................................... 3–52

Dump Mode .............................................................................................................................. 3–52

IO Hold ..................................................................................................................................... 3–53

Report ....................................................................................................................................... 3–53

Beeper Mode ............................................................................................................................ 3–54

Beeper Volume ......................................................................................................................... 3–54

Codes Category ......................................................................................................................... 3–55

Auto LF (Line Feed) ................................................................................................................ 3–55

Auto CR (Carriage Return) ..................................................................................................... 3–55

Line Wrap ................................................................................................................................. 3–55

Wrap Line Feed ........................................................................................................................ 3–55

Print on CR ............................................................................................................................... 3–56

Form Feed at TOF .................................................................................................................... 3–56

ESC ............................................................................................................................................ 3–56

Alt ESC (Alternate Escape)..................................................................................................... 3–56

Upper Only ............................................................................................................................... 3–56

Code 7F ..................................................................................................................................... 3–57

Print 80 - 9F Hex ...................................................................................................................... 3–57

Ignore Char .............................................................................................................................. 3–57

Sub Char From ......................................................................................................................... 3–57

Sub Char To .............................................................................................................................. 3–57

Configurations Category .......................................................................................................... 3–58

Save ............................................................................................................................................ 3–58

Load........................................................................................................................................... 3–58

Powerup Config ........................................................................................................................ 3–58

Config n Label - (where n = 1 to 10)....................................................................................... 3–58

Serial I/O Category .................................................................................................................. 3–60

Baud .......................................................................................................................................... 3–60

Data Bits .................................................................................................................................... 3–60

Stop Bits .................................................................................................................................... 3–60

Parity.......................................................................................................................................... 3–60

8th Bit ........................................................................................................................................ 3–60

Protocol ..................................................................................................................................... 3–60

Status Enquiry ........................................................................................................................... 3–61

DTR Function ........................................................................................................................... 3–61

DTR Function continued......................................................................................................... 3–62

DTR Polarity ............................................................................................................................. 3–62

6 Operator Manual

Page 7

Busy Polarity.............................................................................................................................. 3–62

RTS Function ............................................................................................................................ 3–62

Robust Xon ............................................................................................................................... 3–62

Parallel I/O Category............................................................................................................... 3–63

POPC (Print On Paper Command) ........................................................................................ 3–63

8th Bit ........................................................................................................................................ 3–63

Bi-Directional ............................................................................................................................ 3–63

Intellifilter Category ................................................................................................................. 3–64

Serial.......................................................................................................................................... 3–64

Parallel ...................................................................................................................................... 3–64

Twinax/Coax ............................................................................................................................ 3–64

LAN ........................................................................................................................................... 3–64

File Management ...................................................................................................................... 3–64

TCP/IP Menu (LAN Interface Only) ..................................................................................... 3–65

IP Addr Category ...................................................................................................................... 3–65

Gateway Category ..................................................................................................................... 3–65

Subnet Category ....................................................................................................................... 3–66

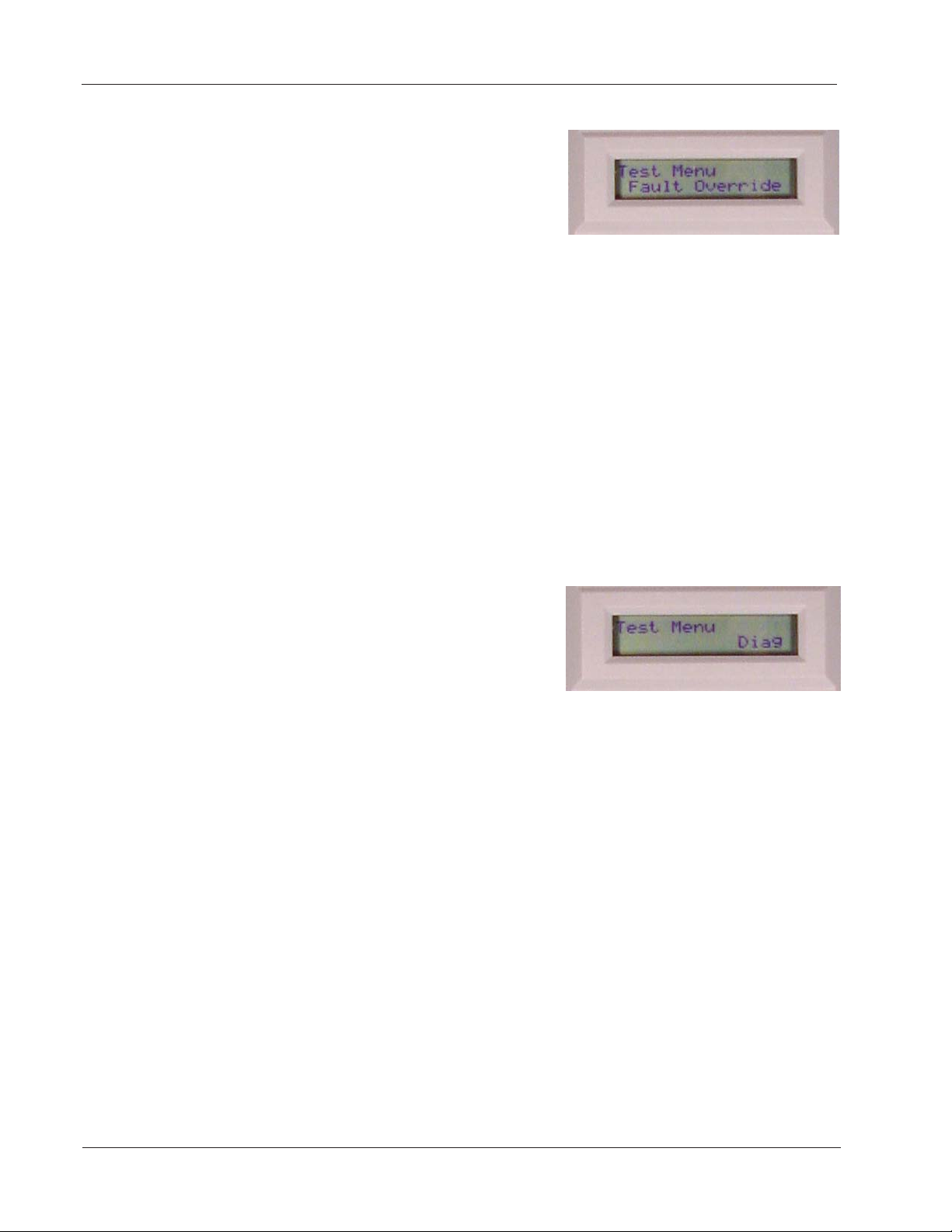

Test Menu.................................................................................................................................. 3–67

Pattern Category ....................................................................................................................... 3–67

Print ........................................................................................................................................... 3–67

Fault Override Category .......................................................................................................... 3–68

Paper Motion ............................................................................................................................ 3–68

Diag Category ........................................................................................................................... 3–68

Cal-Paper (Calibrate Paper Out)............................................................................................. 3–68

Help Menu ................................................................................................................................ 3–69

Figure 3 - 5. Control Panel Navigation............................................................................. 3–69

Appendix A: Troubleshooting ..................................................................... 3–71

Introduction ............................................................................................................................. 3–71

Messages .................................................................................................................................... 3–71

Faults ......................................................................................................................................... 3–71

Fault Correction Procedure..................................................................................................... 3–71

Table A - 1. Display Messages ............................................................................................ 3–72

Table A - 2. Paper/Printing Corrective Action ................................................................ 3–76

Operator Manual 7

Page 8

Appendix B: Specifications ......................................................................... 3–77

Industry and Agency Standards ............................................................................................... 3–77

Electro-Magnetic Emissions ..................................................................................................... 3–77

Electro-Magnetic Immunity ..................................................................................................... 3–77

Energy Conservation ................................................................................................................ 3–77

Safety ......................................................................................................................................... 3–77

Acoustic ..................................................................................................................................... 3–77

Marking ..................................................................................................................................... 3–77

Physical Configurations ........................................................................................................... 3–78

Weight ....................................................................................................................................... 3–78

Dimensions ............................................................................................................................... 3–78

Preventive Maintenance........................................................................................................... 3–78

Environment ............................................................................................................................. 3–78

Operating .................................................................................................................................. 3–78

Nonoperating ........................................................................................................................... 3–78

Safety ......................................................................................................................................... 3–78

Cooling System ......................................................................................................................... 3–79

Acoustics.................................................................................................................................... 3–79

Power Supply ............................................................................................................................ 3–79

Heat Load Contribution .......................................................................................................... 3–79

Emulations ................................................................................................................................ 3–80

Characters Per Inch.................................................................................................................. 3–80

Lines Per Inch........................................................................................................................... 3–80

Type Styles ................................................................................................................................. 3–80

Draft and Data Processing ....................................................................................................... 3–80

Gothic and Courier .................................................................................................................. 3–80

OCR–A and OCR–B ................................................................................................................. 3–80

Large Character Printing ......................................................................................................... 3–80

Standard Languages and Character Sets ................................................................................ 3–81

Nonvolatile Memory................................................................................................................. 3–82

Paper Description ..................................................................................................................... 3–82

Paper Movement Speed ........................................................................................................... 3–82

Throughput .............................................................................................................................. 3–82

8 Operator Manual

Page 9

Preface

Introduction

The 2900 Impact Printers are designed to handle heavy duty, high volume

workloads, with a straight paper path that provides unattended, jam-free printing of continuous forms, at high speeds. They have a wide range of printer

emulations, network printer management ability, popular graphics languages

and web administration utilities.

The 2900 Series offers the following I/O configurations (Modules):

• Standard Serial/Parallel

• LANPlex (Standard plus Ethernet 10/100 BASE-T)

In less than five minutes you can add other configurations by inserting a new

module. Installation instructions come with the module.

All interface configurations and printer

setups are performed through the control

panel on the top right of the unit. And

since the printer’s operational configuration is stored in nonvolatile memory;

you’ll never have to reconfigure your

printer because of a power loss.

Operator Manual Preface–9

Page 10

About This Manual

Conventions

We use the following conventions throughout this manual:

Text that is placed in italics draws your attention to additional helpful

information.

Sometimes your attention is more particularly drawn by the use of this

symbol.

CAREFUL!

This symbol marks information about actions

that may damage the equipment or injure the

user.

Preface–10 Operator Manual

Page 11

Chapter 1

Site Preparation

Choosing a site for your printer is important because the environment affects

your print quality. The best site for your printer is one that is protected from

dirt and heavy dust, and has a moderate temperature and humidity range. In

addition, the power source should be adequate for printer operation and

protected from power surges.

Keep the following factors in mind when choosing a printer location:

• Keep the operating environment temperature between 50°F and 104°F

• Do not locate your printer near air conditioners, open windows,

• The relative humidity should be between 10% and 90%

• The heat load contribution to the environment is 188 BTUs per hour

(10°C and 40°C).

heaters, nor in other areas where the temperature changes abruptly.

(noncondensing). Be sure to locate the printer away from any sources

of moisture, such as water faucets, refrigerators, and humidifiers.

at idle and can go as high as 2050 BTUs per hour under continuous

full-load printing conditions.

• Keep your printer away from dust, dirt, and open flames.

• Plug your printer into a grounded outlet.

• Minimum floor space recommended for your printer is 36" wide x 36"

deep (91.4 cm x 91.4 cm) to allow air movement around the printer.

Allow space to open printer doors as well. When the doors are fully

opened, the printer takes up 6.5 feet (2.0 m) of floor space.

Chapter 1: Setting Up Your Printer 1–11

Page 12

Unpacking the Printer

Unpacking your printer

Instructions for unpacking your printer are located on the outside of the

shipping container. After you have removed your printer from its container,

store the shipping materials for possible later use.

Repacking

Repacking your printer for storage or shipping is the reverse order of

unpacking. If shipping materials are needed, you can reorder them from your

dealer.

Removing the Shipping Hardware

The Shipping Hardware consists of 4 screws, identified by red tags, that secure

the printer base to the inside mechanism, and tie restraints that secure the

Paper Stacking Chains. The shipping screws fasten from underneath, 2 near the

front of the print cabinet and 2 near the rear of the cabinet.

CAREFUL!

DO NOT power up your printer before removing the shipping

hardware.

Arrows point to shipping

screw locations

1–12 Operator Manual

Figure 1 - 1. Shipping Screw Locations

Page 13

Interface Connections and Powering Up

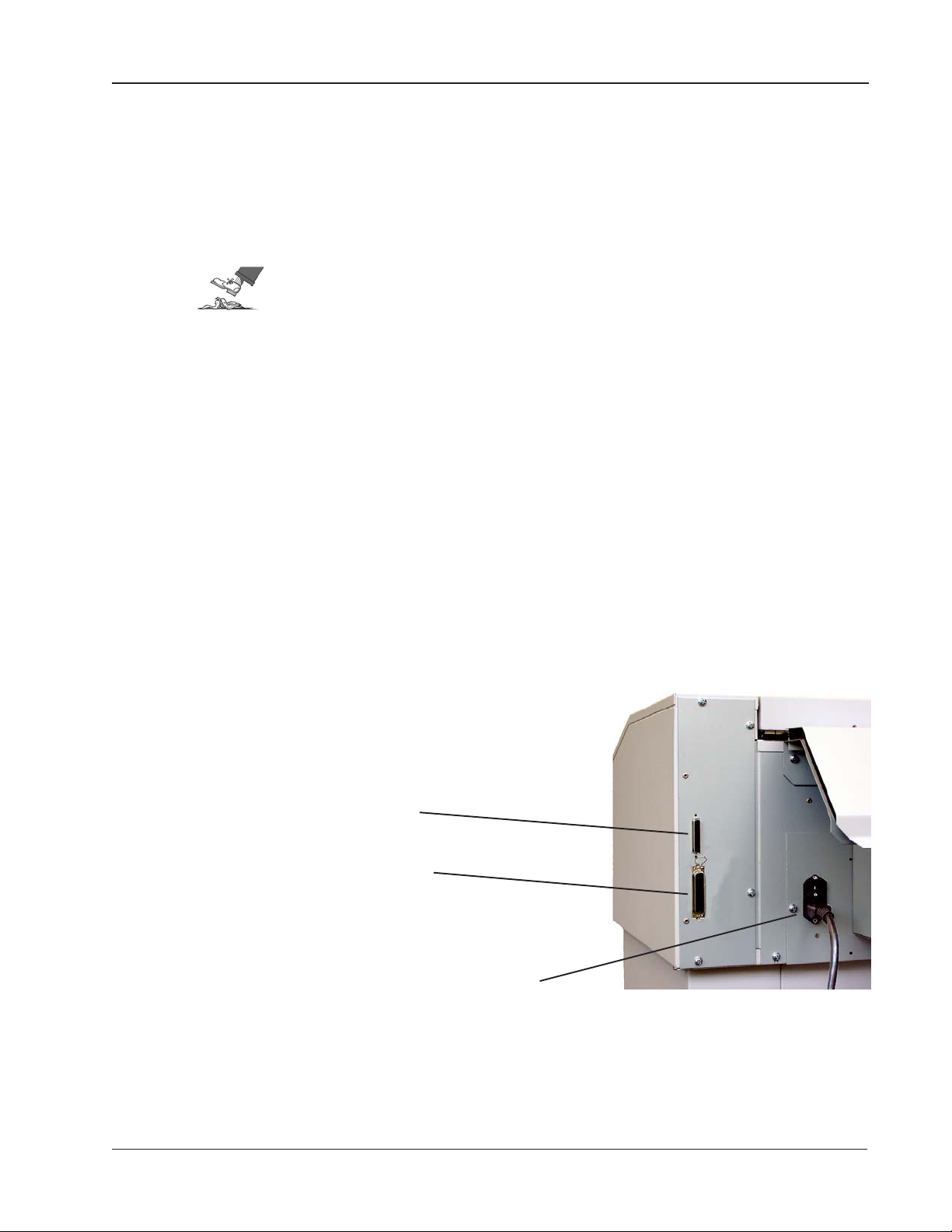

Interface Connectors

Properly secure the cable to the printer interface using the correct connectors.

Interface Connections

CAREFUL!

Connecting the I/O

Shielded I/O cables must be used on all installations to

comply with regulatory requirements.

After connecting each interface to your printer, run a print job from the Host

Computer to verify proper function of the printer.

Serial/Parallel Interfaces

To connect the Serial or Parallel I/O cable, plug in the cable to the proper

connector on the I/O panel.

The serial interface operates up to 38.4 kBaud and uses a standard DB 25 serial

cable connector and standard RS-232-C signals. Serial interface cables should

be no longer than 50 feet (15.2 meters).

The Centronics parallel port is IEEE-1284 compliant and uses a 36-pin 1284-B

type connector (AMP 555119-1 or equivalent). Parallel interface cables should

be no longer than 6 feet (2 meters)

Serial Interface Port

Parallel Interface Port

Figure 1 - 3. Rear view, showing Serial, Parallel and Power Plugs

Power Plug

Chapter 1: Setting Up Your Printer 1–13

Page 14

Powering Up

Powering Up

The power switch is located on the back of the printer, just above the 3-prong

power plug connector.

Figure 1 - 4. Power plug and on/off switch

Step 1.

Make sure the power is off by depressing the "0" side of the rocker power

switch. Connect the power cord. Plug the power cord into a proper power

outlet.

Step 2.

Turn the power on.

The printer runs a self-test each time it is powered up to check the main

processor and buffers for errors. Note that when you turn the printer on this

time, the Paper Out error displays. If any error message appears in the display,

check Appendix A for a description of the error and what actions are necessary

to clear the error.

1–14 Operator Manual

Page 15

Paper System

Paper System Components

The Tractors, Ribbon Cartridge, Platen and Paper Iron are all parts of the

paper system. The first two can be seen when the lid is raised. The Platen and

Paper Iron are hidden inside the housing.

Paper System Components

Tractors

Ribbon

support

platform

shaft for

tractors

Ribbon Cartridge

Figure 1 - 5. Inside the Lid

Chapter 1: Setting Up Your Printer 1–15

Page 16

Paper System Components

Tractors

The 2900 has two tractors to control paper movement, located on the left and

right.

A lever on each tractor keeps it locked in place on a horizontal shaft. To reposition a tractor, unlock the tractor and move it to the left or the right along the

shaft. Repositioning is generally needed only when inserting a new form or size

of paper.

Tractors

Open

Print Gap

locking

lever

Figure 1 - 6. Left and Right Paper Tractors

The 2900 printers offer Auto-Gap which simplifies operator set-up and printer

use by setting the optimum print gap based on the form thickness. The print

gap is automatically opened to its widest position when the printer is not

printing. To accommodate various thicknesses of paper, the print gap is

adjusted either automatically or manually. (See Chapter 2 pages 2-30 to 2-33

and Chapter 3 pages 3-56 to 3-58). If the Print Gap Detect Mode has been set to

"Auto," the auto gap sensing operation will take place the first time the power is

turned on, immediately after a "paper out" fault, when the TOF key is pressed,

and when printing is attempted without setting the Top Of Form. Dedicated

control panel keys also allow the print gap to be adjusted based on operator

preference.

Paper Tension

Vertical tension on the paper is pre-set. It is not controlled by the user.

1–16 Operator Manual

Page 17

Installing the Ribbon Cartridge

Step 1.

Make sure the printer is Offline or power is off. Open the printer lid and

remove the old ribbon by lifting it straight up off of the Ribbon Platform.

Figure 1 - 7. Ribbon Cartridge

Installing Ribbon Cartridge

Step 2.

Remove slack in the new ribbon by turning the knob on the ribbon cartridge as

indicated by the arrow printed next to the knob, then slip the ribbon, left side

first, over the two ribbon guides and between the front and rear panels of the

ribbon shield on the printer.

Step 3.

Press down lightly on the cartridge while turning the ribbon knob as before

until it seats on first the left, (as shown), and then the right cartridge drive

posts. Make sure that the ribbon does not twist or fold over.

Figure 1 - 8. Installing the Ribbon Cartridge

Chapter 1: Setting Up Your Printer 1–17

Page 18

Installing Ribbon Cartridge

The front and rear

panels of the ribbon

shield

Figure 1 - 9. Ribbon Shield Panels

1–18 Operator Manual

The ribbon has been carefully positioned

between the two panels of the ribbon shield.

Page 19

Control Panel Components

The Control Panel is located on the right front top of the printer housing. It is

used to program and direct most printer functions.

Red LED Indicator

Green LED Indica-

Control Panel Components

beeper

32-character

}

Figure 1 - 10. Control Panel

LED Indicators

The green ONLINE indicator illuminates whenever there is power to the

printer, and the printer is Online.

The red FAULT Indicator illuminates whenever an error or fault is detected. A

message also appears on the display to indicate what kind of fault is present (see

Appendix A for explanations of all error and fault messages).

LCD (Liquid Crystal Display)

The 32-character, 2-line Liquid Crystal Display shows printer status, menu

selections, normal, fault and error messages. It is divided into four main areas.

The displayed information will vary with menu selection and the configuration

of the printer.

Once the printer has been unpacked, the cables connected, the ribbon cartridge installed, and a box of paper (whether plain paper or pre-printed forms)

placed nearby, you are ready to load the paper and set the various parameters

via the Control Panel that will ensure that the 6300 Series printer performs

exactly as you need. This is covered in the next chapter.

Chapter 1: Setting Up Your Printer 1–19

Page 20

Blank

Page

1–20 Operator Manual

Page 21

Chapter 2

Introduction

This chapter covers how to load the paper and to set the print gap. It also covers

how to create saveable configuration settings for your own pre-printed forms.

Your printer is designed to use a continuous sheet, sprocket-fed paper. It can

handle:

• Six-part forms (1 original and 5 copies) with a maximum thickness of

• Page widths of 2.5" to 18" (6.4 cm to 45.7 cm).

Specific requirements for pre-printed forms are in Appendix C: Specifications.

.025" (0.6 mm).

Chapter 2: Loading Paper and Printing 2–21

Page 22

Standard Printing Mode

Loading Paper for Standard Printing Mode

Step 1.

Turn off the printer using the power switch on the back, or toggle the "Online"

button on the Control Panel until the LCD shows "Offline".

Step 2.

Raise the printer lid and open the doors on both tractors.

Figure 2 - 1. Inside Paper Inlet, visible when looking inside the printer cabinet.

Step 3.

Step 4.

Step 5.

Open the new box of paper. Remove the box top so that the paper can be

pulled out freely. Open the front of the printer cabinet and place the new box

of paper inside.

Feed the paper up through the paper inlet, as shown in figure 2-1, a little ways

past the tractors and through the gap between the top back of the printer and

the lid (Figure 2-2). It will flow out between the paper chains and fold into the

wire rack near the floor (Figure 2-3).

Place the left-side paper holes onto the left tractor pins and close the tractor

door.

Feed paper

between the

lid and the

top of the

printer.

2–22 Operator Manual

Figure 2 - 2. Paper path past the lid.

Page 23

Step 6.

Standard Printing Mode

Figure 2 - 4. Column Alignment Scale

The Column Alignment Scale is on the top of the ribbon support platform. It is

to be used for general guidance in horizontally aligning the form for each

print job. The leftmost mark on the scale indicates the location of the first, or

leftmost, printable character. Each successive tick mark indicates the location

of additional 10 CPI characters.

Unlock the right tractor and move it so that the paper's holes align directly

over the tractor pins, making sure that the paper is straight, then close the

tractor door. Gently push the tractor to the right until the paper is smooth.

Unlock the left tractor and, keeping the paper reasonably taut, holding onto

both tractors, move the paper to the left or the right until it is roughly aligned

with the desired mark on the Column Alignment Scale. Lock both tractors.

Horizontal Vernier Wheel

Figure 2 - 5. Horizontal Vernier Wheel

Chapter 2: Loading Paper and Printing 2–23

Page 24

Standard Printing Mode

Fine-tuning the Column Alignment can be done in two ways:

(1) Rotate the Horizontal Vernier Wheel, which is located on the right end of

the shaft on which the tractors ride. Depending upon the direction the paper

needs to move, you will rotate the wheel either upwards or downwards.

(2) Use the Control Panel. Go Offline, choose Menu, then use the arrow keys to

get to the Operator Menu. Press Enter. Use the arrow keys to get to Forms.

Press Enter. Use the arrow keys to get to Horz Adjust. Press Enter. Use the arrow

keys to increase or decrease the number that appears in the lower right of the

LCD. This will shift the position of Column 1.

Step 7.

Set the Top of the Form (TOF). This is done from the Control Panel. If the

printer is not on, turn it on now. If necessary, press the Online key until

“Offline” is displayed. Use the up or down arrow keys to move the perforation

line on the paper so that it is aligned with the nubbin on the tractor door. Once

the paper is positioned, press the TOF key. The paper will move downward to

the “ready to print” position and the correct print gap will be set based on the

form thickness.

2–24 Operator Manual

Nubbin

- - - - - - - - - - - - - - - - - - - - - - - - - - - - -

-

Figure 2 - 6. Top of Form Nubbin

Page 25

Print Gap Adjustment

The 2900 Auto-Gap feature automatically sets the correct print gap based on

form thickness. Dedicated control panel keys also allow the print gap to be

adjusted for darker or lighter print based on user preference. For ease of paper

loading, the print gap is set to its widest position while the printer is not

printing. The Auto-Gap feature is automatically initiated under the following

conditions:

1. The Print Gap Mode is Auto, the printer has been off but is now turned on,

and a TOF is set before any printing has begun.

2. The Print Gap Mode is Auto, the printer has been off but is now turned on,

and a print run is started before TOF is set.

3. The Print Gap Mode is Auto, a Paper Out Fault has been cleared, and either

the TOF is set or a print run is resumed.

4. The Print Gap Mode is Auto, the printer has been off but is now turned on,

and an adjustment is made using the “-” or “+” Print Gap keys on the Control

Panel.

Print Gap

Even though the print gap value has been automatically determined, there

might be times when it needs to be further fine-tuned using the Control Panel

as described below under Manually Adjust Print Gap on Control Panel.

Gap Zone

The Gap Zone feature is used to set up a variable print gap for forms that

contain areas of varying thickness. This is done by creating a Gap Zone Profile

for the form, saving it in one of the ten saved configurations, then loading that

configuration whenever the particular form is used.

Print Gap Profile Mode

As previously described, the Print Gap Mode is set up in the Print Gap Category

of the Operator Menu. There are three Print Gap Modes. In Manual Mode, the

print gap is set manually using the Print Gap keys on the control panel. In Auto

Mode (default), the print gap is automatically detected whenever a new form is

loaded, and when the printer is powered on. Profile Mode is the mode that

must be set when using the Gap Zone feature, as described below.

Creating a Gap Zone Profile

A Gap Zone Profile is created automatically in four simple steps:

Step 1 – Load the Form

Load the form for which the profile will be generated. Be sure to set the

Top of Form position, and be sure that the Form Length is set properly.

Step 2 – Set Profile Mode

The Print Gap Mode is set up in the Print Gap Category of the Operator Menu.

Set the Mode Parameter to Profile. Press Operator Menu => PrintGap =>

Mode => Profile => Enter.

Chapter 2: Loading Paper and Printing 2–25

Page 26

Print Gap

Step 3 – Create the Profile

Select the Detect Parameter in the Print Gap Category of the Operator Menu.

Press Menu => up arrow until Detect shows => Enter. This will cause the

printer to move down the form in 1/6 inch increments, performing a print

gap detection operation at each increment. Note that this operation will

take approximately five to six minutes for an 11 inch form. Also note that

the print gap detection operation will leave small dots imprinted on the

form, so the sample form will have to be discarded.

If the printer is placed Online while in Print Gap Profile Mode, and a

profile does not exist (i.e. the Detect function was not performed), then a

Profile Error message will be displayed on the control panel.

Step 4 – Save the Profile

Once the Gap Zone Profile is created, you will probably want to save it for

future use. By saving the Current Configuration into any of the ten saved

printer configurations, the Gap Zone Profile is automatically saved along

with the other configuration parameters. If the Current Configuration is

not saved, the Gap Zone Profile just created will be lost when the printer is

turned off. See page 3-71 for directions in how to save a configuration.

Using a Saved Gap Zone Profile

Whenever a configuration with the Print Gap Mode set to Profile is loaded, the

Gap Zone Profile is automatically used when printing forms.

The Gap Zone Profile can be inhibited by changing the Print Gap Mode from

Profile to either Manual or Auto.

If the Form Length is changed to a value other than the one used to create the

Gap Zone Profile, the profile will be automatically disabled. If the printer is

then placed Online while still in Print Gap Profile Mode, a Profile Error message will be displayed on the control panel.

Fine-tuning the Automatic Print Gap Setting

When in Auto Gap mode, even though the print gap is automatically determined, you may need to further fine-tune it using the Control Panel. If your

print is not crisp and dark, you can adjust the print gap until all dots in the

printed characters are uniformly dark; be careful not to adjust the gap too tight,

to prevent paper jams.

The “-” and “+” Print Gap keys are normally locked to prevent accidental print

gap changes. These keys can be unlocked by holding down both keys simultaneously for approximately 3 seconds until the print gap adjustment display

appears. These keys will remain unlocked for approximately 1 minute after the

last key is pressed, after which they will once again be locked.

2–26 Operator Manual

Page 27

Print Gap

After unlocking the Print Gap keys:

Press one of the Print Gap keys on the Control Panel. This activates the Print

Gap adjustment display. Look at the Control Panel. The upper right region of

the LCD shows a number

by the detection process. The lower right region displays a “fine tuning” offset

which is added to the detected print gap to set the actual gap number. Initially

the “fine tuning” offset is 0, but it can be made negative or positive to adjust the

print gap smaller or larger, respectively, by pressing the

corresponding “-” or “+” Print Gap key on the control panel. The

offset range is limited by the printer. The lower left region of the

LCD provides a graphical indication of the adjustment being

made. There is a 5 second time-out: if no keys are pressed the

control panel display will revert to the prior menu and display.

Fine-tuning the print gap in this way may be done while printing

is in progress, allowing the operator to modify the gap and

immediately observe the effect it has upon print appearance.

See Chapter 3 for the specifics of the Print Gap menu.

1

corresponding to the optimal print gap determined

1. This number is for general reference. The precise relationship between the

displayed number and physical distance is complex and beyond the scope of this

manual.

Figure 2 - 7. Typical Display when Print Gap Mode is set to “Auto”

If you prefer to manually set the Print Gap for the forms you will be using:

Set Print Gap Detect Mode to Manual

Use the Arrow and Enter keys to select Menu => Operator Menu => Print Gap

=> Mode => Manual.

Step 1. Manually Adjust Print Gap on Control Panel

Press one of the Print Gap keys on the Control Panel. This activates the Print

Gap adjustment display. The lower right region of the LCD shows a number

corresponding to the current gap separating the hammer impactors from the

platen. Press the "+" or "-" Print Gap key to roughly match the setting to the

kind of paper that is loaded. This number will get larger or smaller respectively.

The range of allowed change is unrestricted over the complete gap range.

Typical values range from 54 to 110 for single-part through six-part forms.

1

2

1. This number is for general reference. The precise relationship between the

displayed number and physical distance is complex and beyond the scope of this

manual.

2. The control software will prevent selection of a print gap so small that it would

pinch the paper so tightly that it will bind within the mechanism.

Chapter 2: Loading Paper and Printing 2–27

Page 28

Manually Setting Print Gap

The lower left region of the LCD provides a graphical indication of the adjustment being made.

There is a 5 second time-out: if no keys are pressed

the control panel display will revert to the prior

menu and display. The Print Gap keys may be

pressed while printing is in progress, allowing the

operator to modify the print gap and immediately

observe the effect it has upon print appearance.

Figure 2 - 8. Typical display when adjusting Print Gap

Step 2. Run a Print Test

Press Clear. Make sure you're offline. Use the Arrow and Enter keys to select

Menu => Test Menu => Pattern => Print => Upper. Press Enter. This last action

begins running a print test. After a short while, press Enter to halt the test.

Examine what has been printed.

The print should be crisp and dark, with no smearing. The paper should move

smoothly through the print mechanism:

• If the print gap is open too far, the print may start fading out, especially

on the last sheet of a multi-part form.

• If the print gap is too narrow, the ribbon will start smearing ink on the

page, especially when the ribbon is moving and the paper is not. In

extreme cases, the shuttle may stop, and the paper may jam.

Repeat Step 1 and Step 2 until the print gap is set just right. This print gap

configuration can be saved and may be retrieved every time this particular

paper is loaded. What you have just set, though, will not change until someone

goes through Steps 1 & 2 again, or until a saved configuration with a different

print gap is loaded.

Setting Up Configurations

The 2900 printer can save up to ten personalized configurations, so you don't

have to recreate configurations you use frequently. Each configuration can be

given a label of up to 15 characters. When you first receive your printer, each

label is a generic "CONFIG" followed by a number 1 through 10. See page 3-71

for instructions on how to save configurations.

2–28 Operator Manual

Page 29

Chapter 3

Introduction

In this chapter you will learn how to use the Control Panel, how to navigate the

menus, and how to select and store parameter values as part of a configuration.

You will also learn how to obtain printouts that show all available parameters,

current configuration settings, and technical information like accumulated

running time and operating thresholds.

Let's begin with looking at the control panel display, and at each of the keys.

Control Panel Display

The information presented on the control panel display primarily depends

upon whether the printer is in normal operation, or in one of the menus.

Chapter 3: Printer Menus and the Control Panel 3–29

Page 30

Control Panel Display

The Display During Normal Operation

During normal operation, the top line of the display indicates the current state

of the printer, such as Online, Offline, or a fault message.

The second line of the display will indicate which of 10 saved configurations is

currently loaded. Each of the configurations can be assigned a unique name

and any of the configurations can be designated as the power up configuration.

By default, this line will display Config 1.

Green light is on

Current State

Paper Weight &

Hammer Impact

Current Configuration

Current State

The printer is “online” and the green light is on.

Current Configuration

This is the set of parameters, as detailed in the rest of this chapter, that have

been saved in Configuration 1. The asterisk indicates that Configuration 1 is

selected.

Figure 3 - 1. Control Panel Display for Normal Operation

Paper Weight & Hammer Impact

The lack of a symbol here means the hammer impact is set to “Normal” and the

paper weight is set to “Light”. See Table 3-1.

3–30 Operator Manual

Page 31

Control Panel Display

Indicator Paper Weight and Hammer Impact

(blank)

H

–

H

Table 3 - 1 Paper Weight & Hammer Impact Indicator

hammer impact setting is “Normal”

paper weight setting is “Light”

hammer impact setting is “Normal”

paper weight setting is “Heavy”

hammer impact setting is “High”

paper weight setting is “Light”

hammer impact setting is “High”

paper weight setting is “Heavy”

The Display When In A Menu

When a menu is selected, the top line of the display shows which menu, category, or parameter one is in.

The second line of the menu will display the next lowest level of the menu

hierarchy. If the top line displays a menu, the second line will display a category; and if the top line displays a category, the second line will display a

parameter; if the top line displays a parameter, the second line will display a

selection for that parameter. An asterisk is displayed in the far right column of

the second line when a parameter is selected.

No light is on

Menu, Category, or Parameter

Category, Parameter, or Selection

Figure 3 - 2. Control Panel Display for Menus

Chapter 3: Printer Menus and the Control Panel 3–31

Page 32

Control Panel Key Functions

Control Panel Key Functions

Online Key

This key toggles the printer between Online and Offline

states, or exits from the menu directly to an Online state.

When the printer is Online, the indicator will light. In the

Offline state, you may change parameter selections, load

paper, and so on.

LF Key (Line Feed)

This key advances the paper one line. It performs the same

function whether the printer is Online or Offline. You may

auto-repeat this command by holding down the key.

While Offline With Data Buffered

Any buffered data falling in the next line (as defined by the

current LPI setting), prints. This repeats upon subsequent LF

keystrokes as long as there is data in the buffers. If pressed

while printing is in progress, the printer ignores the key

Figure 3 - 3. Control Panel

command and maintains the Top of Form position.

While Offline With No Data Buffered

Paper advances one line. While printing is in progress, the printer ignores the

command and maintains the Top of Form position.

While In A Fault Condition

Paper advances one line. No data is printed and the Top of Form position

moves down one line. This allows the use of the LF Key to advance paper while

in a Paper Out condition without printing any buffered data.

FF Key (Form Feed)

This key performs the same function whether the printer is Online or Offline.

While Offline With Data Buffered

Any buffered data falling between the current form position and the top of the

next form (as defined by the current Form Length setting), prints. This function repeats upon subsequent FF keystrokes as long as there is data in the

buffers. The printer ignores the command while printing is in progress and

maintains the Top of Form position.

While Offline With No Data Buffered

Paper advances to the top of the next form. The printer ignores this command

while printing is in progress and maintains the Top of Form position.

3–32 Operator Manual

Page 33

FF Key (Form Feed) continued

When In a Fault Condition

Pressing the FF Key while in a Fault Condition advances the paper one form.

No data prints, and the Top of Form position is maintained. This allows the use

of the FF Key to advance paper while in a Paper Out condition, without printing any buffered data.

TOF Key (Top of Form)

When you load paper, you line up the top of your form (usually the perforation) with the indicated position on the tractor (see Figure 2-6). Once the

paper is loaded, pressing this key moves the paper so that printing commences

at the proper position on the form.

View Key

Holding down this key moves the paper up so that you can see the last line that

was printed. If you press it while a job is printing, it will suspend the print job

until you release the key.

PRINT GAP + and - Keys

Pressing one or the other of these keys initiates a manual adjustment to the

current print gap. Pressing these keys can be used as a “shortcut” to get to the

Adjust display otherwise found by using the arrow and enter keys to select

Menu => Operator Menu => Print Gap => Adjust.

Control Panel Key Functions

Up and Down Arrow Keys

When Online

These keys make fine adjustments to the Top of Form position.

^

^

When Offline

These keys position the paper in preparation for setting the Top of Form

position. (In this mode, these keys will auto-repeat if you hold them down).

They are also for scrolling through Menu items (see Menu key, next).

After making adjustments, it's not necessary to reset the Top of Form (unless a

different top margin is required for a new form).

In Operator, Config, or Test menus

The Up and Down Arrow keys scan lists of categories, parameters, and selections.

Menu Key

Pressing this key allows you to access menu selections, which you can scroll

through using the Up and Down Arrow keys. To go back one level in the

hierarchy, press the Menu key, i.e., pressing the Menu key returns you to a

previous selection. This key command is only available when the printer is in

an Offline mode.

Chapter 3: Printer Menus and the Control Panel 3–33

Page 34

Control Panel Key Functions

Enter Key

In any of the menus, this key allows you to enter a lower level, to assign a selection to a parameter, or to perform a menu function.

When the printer is in a Paper Out Fault condition, and the PrntEOF parameter is set

to Off, pressing the Enter Key allows printing to the end of the current form. When

PrntEOF is set to On, the printer automatically prints to the end of the current form.

Clear Key

In Operator, Config, Test, or Help Menus

Pressing this key returns the printer to Offline status.

When Online

Pressing the Clear key clears the panel of any errors that do not cause the

printer to go Offline, such as "Parity Error."

When Offline

If the printer is in a clearable fault condition, the fault clears upon pressing the

Clear key. If it's not in a clearable fault condition, pressing the Clear key brings

up the Clear menu.

The Clear Menu

Clear Buffers

Clears all buffers. It also resets the application task to its initial state.

Clear Ribbon Count

When using the Ribbon Monitor feature, this selection must be used to clear

the ribbon count when changing ribbons. See the RibbonMonitor and

RibnMon Thresh setting in the Forms category of the Operator menu later in

the chapter.

Clear All Configs

Copies the Default Configuration settings into all saved configurations. Any

parameters not listed on the Configuration Report, such as special characters

downloaded from the host computer, are unaffected.

Clear Current Config

Copies the Default Configuration settings into the current configuration. Any

parameters not listed on the Configuration Report, such as special characters

downloaded from the host computer, are unaffected.

Clear Reset

The printer controller performs a hardware reset. You may use this in lieu of

cycling power to the printer. As with cycling power, the Powerup Configuration

is loaded as the Current Configuration (see later in chapter).

3–34 Operator Manual

Page 35

Clear Key continued

Config Key

Offline

This is a “shortcut” to the Load Configurations menu item (see later in chapter), allowing you to enter a menu where any of ten saved configurations can be

loaded into the Current Configuration.

Use the Up and Down Arrow keys to scroll through the configurations. Pressing the Enter key loads the one you choose.

Control Panel Key Functions

Chapter 3: Printer Menus and the Control Panel 3–35

Page 36

Using Menus

Control Panel Menus

This section discusses the menus and how to access and select values from them

for formatting documents, controlling print operations, or testing the printer.

The four main menus are Operator, Config, Test, and Help.

Categories, Parameters and Selections

Within the Operator, Config, and Test menus, there are a number of categories.

Within some categories there are sub-categories. Within each of these categories or sub-categories is a list of parameters. In some cases, a parameter can

execute a function upon pressing Enter, or in other cases, it displays a list of

options for that parameter.

The Help menu has no categories or parameters. You'll use this menu to print

out a list of all menus, categories, parameters and options.

Using Menus

Before going through these four main menus, let's learn how to access them.

Here are some things to remember:

• You must first be in Offline state to access menus, except for Print Gap.

• The Online key takes the printer Online and Offline.

• All scrolling is performed using the Up and Down Arrow keys.

• The Enter key selects parameter values or initiates a desired procedure.

• Selected options are marked with an asterisk (*).

• To exit Menu mode without making changes, depress the Clear key or

the Online key.

When the printer is Online, the green light is on and the Liquid Crystal Display

reads “Online”:

3–36 Operator Manual

Page 37

Using Menus

The name of the configuration displays on the lower line.

In this state, the only keys that respond are:

• Up and Down Arrows

•LF

•FF

• Clear

• View

• Online

• Print Gap (+ & - )

When the printer is Offline, no light is on and the display reads:

In the Offline state, pressing the Menu key gives you access to the first level of

the menu system. Upon doing this, the display reads:

Now, in the Offline state, you may access one of four available menus (Operator, Config, Test, and Help) by pressing the Up and Down Arrow keys, followed

by Enter.

As you scroll through using the Up Arrow key (with Operator Menu displaying

first) the display reads in order:

Config Menu

TCP/IP

Test Menu

Help Menu

(if LAN is installed)

Each of these menus except for Help has multiple levels of categories, selections and parameters. You access them by scrolling through the lists with the

Up and Down arrows, and by pressing Enter when you see the category, parameter, or selection you want.

Chapter 3: Printer Menus and the Control Panel 3–37

Page 38

Changing Form Length

Example: Changing Form Length Using the Menu System

If you wanted to change the Form Length from the default of 66 lines to 65

lines, this is how you do it:

1. Make sure your printer is in an Offline state. If it's not, toggle the

Online key.

2. Press the Menu key. The display reads:

3. Press Enter to select the Operator menu and press the down arrow key

until you see Forms. The display reads:

4. Press the Enter key to select Forms. Press the down arrow key until the

display reads Length (lines):

5. Forms Length (lines) is the selection you want, so press the Enter key.

The display reads:

(The asterisk means that 66 is the current selection, see page 3-42.)

6. You want to change this to 65. Press the Down arrow once and the

display reads:

3–38 Operator Manual

Page 39

Print Selections Report

7. Press the Enter key. The Form Length is set to 65, and an asterisk

appears beside the number. Exit the menu mode by pressing the Clear

key.

It's helpful to remember that at any time, you may leave a menu in one of two

ways.

• Press the Clear key to leave Menu Mode and remain Offline.

• Toggle the Online key to leave Menu Mode and return the printer to

Online.

How to Print a Control Panel Selected Options Report

The organization of the multilevel menus is shown on the Control Panel

Selected Options Printout. All of the current selections are marked with an

asterisk.

1. Toggle the Online key once or twice to clear the display and put the

printer Offline. Offline should be displayed and the green light should

be off.

2. Press the Menu key.

3. Use the Up or Down arrow keys until you see Help Menu on the display.

4. Press Enter.

The Control Panel Selected Options Report begins printing. When it's finished, press the FF key, tear off the sheet and use it to become familiar with all

of the menu items.

Chapter 3: Printer Menus and the Control Panel 3–39

Page 40

Operator Menu

⇒

Operator Menu

Font

1. Toggle the Online key once or twice to clear the display and put the

printer Offline. Offline should be displayed and the green light should

be off.

2. Press the Menu key.

3. Use the Up or Down arrow keys until you see Operator Menu on the

display.

4. Press Enter.

5. Use one of the arrow keys until the desired category appears; press the

Menu key if you need to back up a level.

Font Category

This category contains parameters that

control how print looks on a page and

the display language. Use the Arrow and

Enter keys to select Menu => Operator

Menu => Font to get here. They are as

follows:

Ser/Par Language

This parameter allows you to select the language used by emulations attached to

the Parallel, Serial, and LAN ports. The language selection defines the character substitutions in Hex locations 23, 24, 40, 5B, 5C, 5D, 5E, 60, 7B, 7C, 7D, and

7E. The default is US.

The details of the character substitutions can be found in the Line Printer

Applications Manual. The possible options are:

US German Norwegian/Dan

French UK Spanish

Swedish/Finish Italian Japanese

Portuguese Canadian Hungarian

Chinese French T6 Swedish T6

Italian T6 Canadian Alt Swedish Basic

French Withdrawn Nor/Dan T6 UK LG

Dutch LG Finnish LG Swiss LG

JIS Roman LG Nor/Dan LG Swedish LG

ISO Nor/Dan LG Portuguese LG VT 100

Turkish LG Cro-ASCII Nor/Dan Epson

French Epson UK Epson Spanish Epson

Italian Epson Norwegian Epson Danish Epson

Spanish 2 Epson Lat Amer Epson IRV

3–40 Operator Manual

Page 41

Ser/Par Character Set

This parameter allows you to select a character set that occupies locations Hex

80 through FF used by emulations attached to the Parallel, Serial, and LAN

ports. The default is Code Page 437:

The details of the character sets can be found in the Line Printer Applications

Manual. The possible options are:

Latin 1 8859-1 Latin 2 8859-2 Latin 9 8859-15

Cyrillic 8859-5 Greek 8859-7 Turkish 8859-9

Code Page 437 Code Page 850 Code Page 851

Code Page 852 Code Page 855 Code Page 857

Code Page 863 Code Page 866 Code Page 869

Code Page 928 Code Page 437G Code Page 866B

Code Page 1250 Code Page 1251 Code Page 1252

Code Page 1253 Code Page 1254 DEC MultiNational

DEC Turkish Siemens Turkish DEC Technical

DEC Supplemental Greek Supplemental Turkish Supplemental

Mazovia Kamenicky Roman-8

Katakana ISO 13 Line Draw Italic

Operator Menu ⇒ Font

Matrix

There are two font modes available on your printer. One mode is called Enhanced and the other is called CDF (for Constant Density Font). Enhanced

fonts include Draft and Data Processing, Near Letter Quality (Gothic and