Tally dascom 7106, 7206 User Manual

1

Read This First !

Congratulations…

On your choice of a Tally Dascom label printer.

Please take a moment to read this Quick Start Guide which will familiarise yourself with the

printer and its operation. The printer is a sophisticated but easy-to-use label printer featuring

simple media loading and quick connection.

We will guide you through unpacking the printer from its carton, connection to your

computer system and installation of the media including a quick self-test of the printer to

ensure it is working.

Safety

If you have not done so already, please carefully read the safety instructions included at the

beginning of this Quick Start Guide and in more detail on the user manual included on the

CD-ROM. Failure to observe the safety precautions could cause serious injury or damage to

both you and your property.

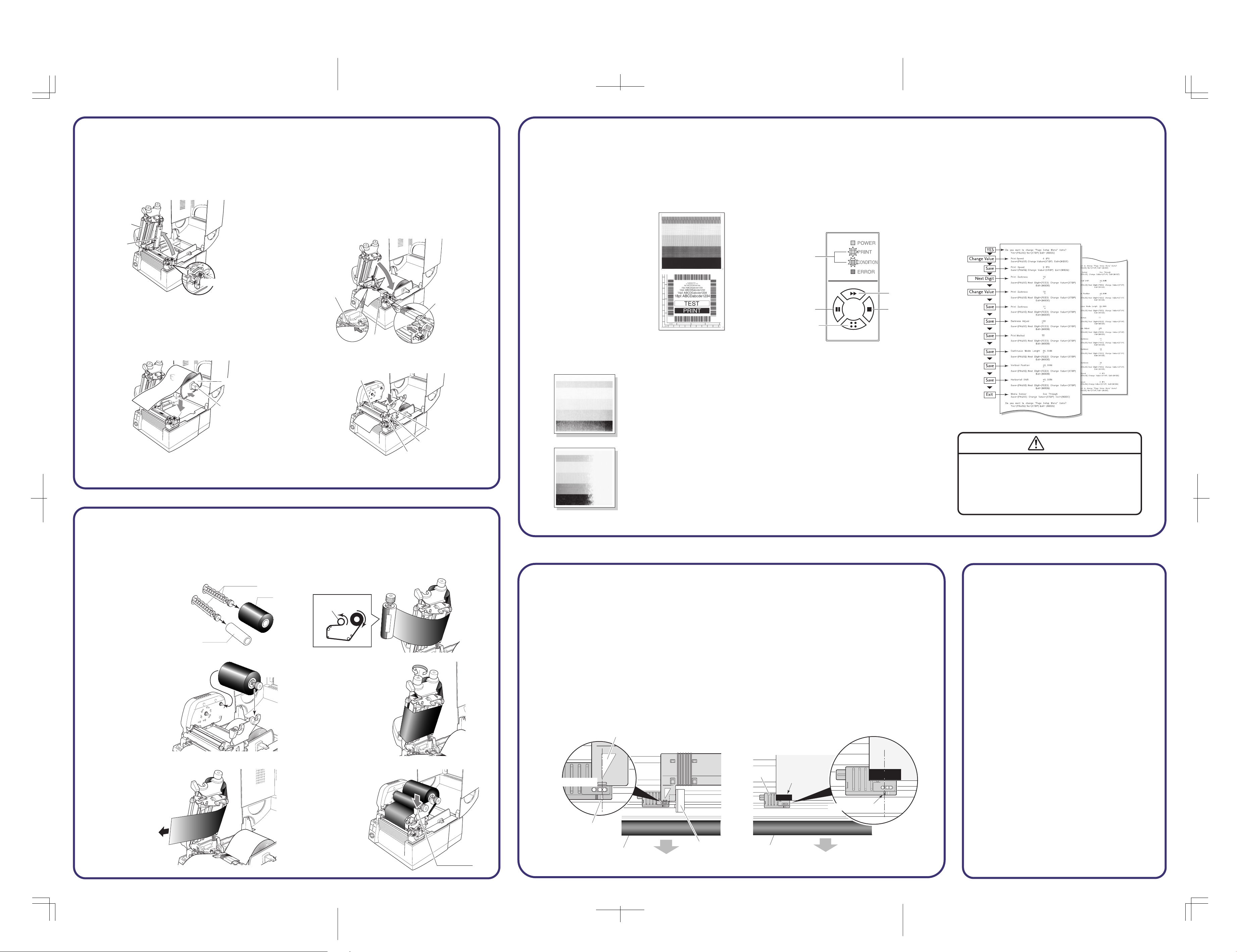

Unpacking Your Printer

a. Carefully unpack your new printer and ensure all the items shown on the adjacent picture

are present in your printer’s carton. In some cases, your supplier or Tally Dascom may have

added extra items required for your particular installation such as additional CD-ROM,

cable or manuals. Instructions for each of these items will be included within the

individual packages.

b. If you have any questions, or if you nd any of the items are missing, please initially refer back

to your supplier. Otherwise, contact details for Tally Dascom’s regional oces are shown on

the back page of this Quick Start Guide.

c. The printer is shipped with adhesive tape in place to hold the top cover closed. Simply

remove the two pieces of tape on either side of the top cover. Then simply open the cover by

lifting up and tipping it backwards.

d. There is another strip of adhesive tape that must be removed which holds the mechanism

closed for shipping. Remove the tape and attached paper by carefully peeling from the

plastic case..

Basic Carton Contents

The following items are only present in the 7206 and 7206-300 cartons:

The following items are present in all cartons:

Test label media Power cord

CD-ROM

Paper CoreSample RibbonRibbon Holder

Media holder barMedia holder guideHead cleaner

T

h

is

F

Q

o

r

u

s

d

u

i

c

e

pp

k

t

a

-S

li

i

le

e

t

a

d

d

r

t

C

o

G

p

D

er

u

R

id

a

O

t

e

i

M

c

n

g

o

.

v

in

e

s

r

tr

s

b

u

a

c

s

t

i

i

o

c

n

o

s,

p

e

p

r

le

a

t

a

io

s

e

n

.

s

ee

t

h

e

U

s

e

r's

M

a

n

u

a

l

o

n

th

e

Quick-start Guide

Printer

circuits diérents.

Brancher l'ordinateur dans une prise de courant diérente de fa?on à ce que l'ordinateur et le récepteur soient branchés sur des

Installer l'ordinateur autre part, par égard pour le récepteur.

Réorienter l'antenne de réception.

circuit de l'équipment; aussi, il est demandé a l'utilisateur d'essayer de corriger l'interférence par l'une ou plus des mesures suivantes:

Cependant, il n'y a pas de garantie contre les interférences avec les réceptions radio ou télévision, provoquées par la mise en et hors

Cet équipment est conçu pour fournir une protection satisfaisante contre de telles interférences dans une installation résidentielle.

classe A prescrites dans le Réglement sur le brouillage radioélectrique édicté par le ministère des Communications du Canada.

Le présent appareil numérique n'émet pas de bruite radio électriques dépassant les limites applicables aux appareils numériques de la

les instructions du fabricant, il risque de provoquer des intérferences avec la réception de la radio et de la télévision.

Cet équipment produit et utilise l'énergie à radiofréquences et s'iln'est pas installé et utilisé correctment, c'est à dire en accord strict avec

Etat de Conformite EMI à l'usage des Utilisateurs Canadiens

grantee of this device could void the user's authority to operate the equipment.

CAUTION: Use shielded cables to connect this device to computers. Any changes or modications not expressly approved by the

Consult the dealer or an experienced radio/TV technician for help.

Connect the equipment into an outlet on a circuit dierent from that to which the receiver is connected.

Increase the separation between the equipment and receiver.

Reorient or relocate the receiving antenna.

interference by one or more of the following measures:

radio or television reception, which can be determined by turning the equipment o and on, the user is encouraged to try to correct the

However, there is no guarantee that interference will not occur in a particular installation. If this equipment does cause inter ference to

Communications. This equipment is designed to provide reasonable protection against such interference in a residential installation.

limits for radio noise emissions from digital apparatus set out in the Radio Interference Regulations of the Canadian Department of

manufacturer's instructions, may cause interference to radio and television reception. This digital apparatus does not exceed the Class A

This equipment generates and uses radio frequency energy and if not installed and used properly, that is, in strict accordance with the

EMI Compliance Statement for Canadian Users

expense.

residential area is likely to cause harmful interference in which case the user will be required to correct the interference at his own

accordance with the instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a

commercial environment. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in

These limits are designed to provide reasonable protection against harmful inter ference when the equipment is operated in a

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15 of the FCC Rules.

FCC Compliance Statement for American Users

This device is not intended for use at a video workstation in compliance with Bildscharb V.

This product has been tested under EN ISO 7779 and has a acoustic level output no higher than 55db(A)

EMC Directive (2004/108/EC)/EN55022, EN55024, EN61000-3-2 & EN61000-3-3

Low Voltage Directive (2006/95/EC)/EN60950-1

CE marking shows conformity to the following criteria and provisions:

Compliance Statement for European Users

trademarks.

30. Trademarks or registered trademarks of other companies and products are included in this manual. Tally Dascom acknowledges all

29. If there are missing or incorrectly collated pages in this manual, contact us to obtain a new manual.

28. Please contact us if there are any mistakes or ambiguities within this manual.

prots caused by data loss due to failures, repairs, inspections, etc.

27. Data residing in the printer is temporary. Therefore, all data will be lost if power is lost. We are not liable for any damage or loss of

26. We are not liable for any damage caused by user's erroneous use of the printer and inadequate environment.

products contained herein.

25. We are not liable for any problems resulting from the use of optional products and consumable supplies other than the designated

misprints.

24. We are not liable for any damage resulting from the use of the information contained herein, regardless of errors, omissions, or

23. Reproduction, transfer, or transmission of the contents of this manual without prior consent is strictly prohibited.

22. The contents of this manual may be changed without prior notice.

21. If a problem occurs during printing, stop the printer immediately and unplug the power cord from the outlet.

tool as a ballpoint for operation.

20. Operate the control panel properly. A careless, rough handling may cause problems or malfunction. Do not use such sharp-edged

19. Do not open the printer during printing.

18. When the cover is open, be careful of the corners of cover. They could cause injury.

17. Make sure if you open the top cover, it is opened all the way. If only partially open, the cover could slam shut, possibly causing injury.

may cause suocation.

16. Discard or safely store the plastic packing bag. This bag should be kept away from children. If the bag is pulled over child's head, it

f. If the product exhibits a distinct change in performance, indicating a need for service.

e. If the product has been dropped or knocked or the cabinet has been damaged.

work by a qualied technician to restore the product to normal operation.

by the operating instructions since improper adjustment of other controls may result in damage and will often require extensive

d. If the product does not operate normally when the operating instructions are followed. Adjust only those controls that are covered

c. If the product has been exposed to rain or water or excessive humidity.

b. If liquid, aerosol chemicals or other chemicals have been spilled into the product.

a. When the power cord or plug is damaged or frayed.

15. Unplug this product from the wall outlet and refer servicing to qualied service personnel under the following conditions:

equipment and shall be easily accessible.

14. The mains plug on this equipment must be used to disconnect mains power. Please ensure that the socket outlet is installed near the

those compartments to service personnel.

those covers that are marked "Do Not Remove" may expose you to dangerous voltage points or other risks. Refer all servicing on

13. Except as explained elsewhere in this manual, don't attempt to service or disassemble this product yourself. Opening and removing

that could result in a risk of re or electric shock. Never spill liquid of any kind on the product.

12. Never push objects of any kind into this product through cabinet slots as they may touch dangerous voltage points or short out parts

outlet does not exceed 7.5 amperes for 220/240V outlet and 15 amperes for a 120V outlet.

extension cord do not exceed the extension cord ampere rating. Also, make sure that the total of all products plugged into the wall

11. If an extension cord is used with this product, make sure that the total of the ampere ratings on the products plugged into the

power cord or data cables or keep them under tension.

10. Do not allow anything to rest on the power cord. Do not locate this product where the cord will be walked on. Do not pull on the

obsolete outlet. Do not defeat the safety purpose of the grounding-type plug.

power outlet. This is a safety feature. If you are unable to insert the plug into the outlet, contact your electrician to replace your

9. This product is equipped with a three-pronged plug, a plug having a third grounding pin. This plug will only t into a grounding-type

power available, consult your dealer or local power company.

8. This product should be operated from the type of power source indicated on the marking label. If you are not sure of the type of

provided.

near or over a radiator or heat source. This product should not be placed in a built-in installation unless proper ventilation is

should never be blocked by placing the product on a bed, sofa, rug or other similar surface. This product should never be placed

7. To ensure reliable operation of the product and to protect it from overheating, do not block or cover these openings. The openings

6. Slots and openings on the cabinet and the back or bottom are provided for ventilation.

people around it.

5. Do not place this product on an unstable cart, stand or table. The product may fall, causing serious damage to the product and

salt or iron particles.

4. Do not use this product near water or where a chemical reaction can occur such as in a laboratory or where there is a lot of oil, dust,

ketone or similar chemicals. Instead use a damp cloth for cleaning, when the printer is disconnected from the mains supply.

3. Unplug this product from the wall outlet before cleaning. Do not use liquid or aerosol cleaners, thinner, trichloroethylene, benzine,

2. Follow all warnings and instructions marked on the product.

1. Read all of these instructions and save them for later reference.

these precautions can result in personal injury or property damage or, in extreme situation, serious injury or death.

For the safe operation of your printer, please read the following important operation and safety instructions carefully. Failure to observe

Safety Instructions - which must be strictly observed

!

Connection to Power

2

a. Check that the power switch to the printer is turned OFF.

b. Connect the power cord to the printers power socket.

c. Insert the mains plug in to the AC outlet.

Power Switch

Power Cord Inlet

Use an AC outlet that accepts a three-pronged plug.

Caution

Otherwise, static electricity may be generated and there

will be danger of electric shock.

AC Outlet

Connection to a Computer

This product has two interfaces that can be used to receive printing data: a serial port

(RS232C) and a USB port (USB1.1). An optional internal Ethernet, an IEEE1284 Parallel or

Wireless LAN interface can be added by your dealer. If an optional network interface is

used, contact your Tally Dascom Systems dealer.

With the exception of a wireless LAN connection, an interface cable is necessary to connect

the printer to a computer. To connect the cable, proceed as follows:

a. Turn OFF the power switches of both the printer and the computer.

b. Connect one end of the interface cable to the interface connector on the back of the

printer and secure it with locks or locking screws, where available.

c. Connect the other end of the interface cable to the interface connector on the computer

and secure it with locks or locking screws, where available.

Serial Interface Cable

USB Interface Cable

For Further Information . . .

For further information and more detailed instructions on the use of your new

printer, please refer to the complete user manual included on the CD-ROM

accompanying your printer. Alternatively, you can download the user manual and

additional data from Tally Dascom's websites shown below.

DAS COM R EPR ESE NTATIVE S

GERMANY

DASCOM Eu ro pe Gm bH

Heuweg 3

D-89079 U lm

Deutschla nd

Tel.: +4 9 (0) 731 2075 0

Fax: +49 (0) 7 31 2075 100

www.dascom.com

UNITED KI NGDOM

DASCOM GB Ltd

ViewPoint, Basin g View,

Basingsto ke, H ampshire

RG21 4RG, Engl and

Phone: +4 4 (0) 1256 481481

Fax: +44 (0) 1 256 481400

www.dascom.com

SINGAPORE

DASCOM AP Pte Ltd

63 Hillvi ew Aven ue

#08-22, L am So on Industrial Building

Singapore 6 69569

Phone: +6 5 676 0 8833

Fax: +65 6760 1066

www.dascom.com

AMERICAS

DASCOM Am erica s Corporation

421 W. Main Street

Waynesboro, VA 22980

USA

Phone: +1 (877 ) 434 13 77

www.dascom.com

All rights reserved

© August 2010 DASCOM Europe GmbH

Printed in China

FRANCE

DASCOM Eu ro pe Gm bH

117 Avenue Vi ctor Hugo

92100 Bou logne -Billancourt

France

Phone: +3 3 (1) 73 02 51 98

www.dascom.com

RUSSIA an d CIS

DASCOM Eu ro pe Gm bH

Representat ion M oscow

Leninsky Prospek t 95a, Office 322

119313 Mo scow, Russi an Fe deration

Phone: +7 (495 ) 984 70 65

Fax: +7 ( 495) 984 56 42

www.dascom.com

CEE

DASCOM Eu ro pe Gm bH

Europaring F15 3 01

2345 Brun n a. G.

Austria

Phone: +4 3 (1) 236 01 70 10

www.dascom.com

379854a-EN

JM74992-00F

Quick Start Guide

7106 7206 Thermal Printers

This Quick-Start Guide covers basic operation.

For detailed operating instructions, please see the User's Manual on the

supplied CD-ROM.

72067106

3

Media Installation

5

Self Tests and Printer Configuration

a. Push the large blue head open lever to release the head unit and then

raise it to the position shown below. On the 7206, you will also need to

raise the sensor arm by simply lifting it, the 7106 does this automatically.

Head unit

Sensor arm

Large blue-head open lever

b. Firstly, slide the two black plastic parts of the media holder assembly

together. Ensure correct alignment of the guide with the bar as it can

only be installed in one direction.

c. Slide the roll of media over the media bar. The media guide must be on

the right side of the roll of media (as viewed from the front of the

printer) with the ribbed surface of the media guide touching the media

roll as shown in the illustration.

Media holder guide

Media holder bar

d. Set the media roll and media holder in to the printer as shown above. It

is advisable to pull a length of media forwards and through the

mechanism ready for later positioning.

e. Move the media roll so it is touching the left side of the housing. Then

slide the black media guide so it is touching the media on the right

side. Do not try to hold the media too tightly with these guides as it will

cause the printer to jam during printing.

f. You may need to adjust the media sensors as described in section 6.

This will depend on the media types you are using.

g. Align the media with the left xed media guide, align the right movable

media guide with the media width, and lower the sensor arm.

Fixed media guide

Sensor arm

h. Lower and lock the head unit. Align it with the width of the media that

has been set, then set the media width and media thickness adjustment

dials. See section 5 for more info.

Head unit

Media width adjustment

i. With the power switched on, push the FEED key to feed the media. It will

halt at the next print start position.

Movable media

guide

Head close knob

Media thickness adjustment

Self Test Print

Performing a self test print is an easy way to check on the state of printer

settings and print quality. Install the media as explained in sections 3 & 4

and then operate the printer as follows.

For label media

Turn on printer power while pushing

the FEED key. When the PRINT LED has

begun to ash slowly , release the FEED

key.

For continuous media

Turn on printer power while pushing

the FEED key. When the PRINT LED has

stopped ashing slowly and has begun

to ash rapidly, release the FEED key.

The printer will produce the self test

shown, then it will stop. To repeat, press

the FEED key again. To exit, switch of

the printer.

Media Adjustments

Using the Self Test Print shown above, you

can make adjustments to the printer settings

such as media width and media thickness

(printhead pressure). The location of these

two adjustments is explained in section 3.h

and also shown on the labels on the printer's

mechanism.

The rst sample, left, shows an incorrectly

set “media th ickness adjustment”. For

standard label media, it is recommended you

set the blue dial to the “0” position.

The second sample, left, shows an incorrectly

set “media width adjustment”. For 4-inch or

100mm wide media, the adjuster should be

set to the “9” position on the blue dial.

The settings shown above are for general label

media and may not apply to specialist media.

Printer Conguration Menu

If the printer power is turn on while the MODE/REPEAT key is pressed, the

printer enters menu setup mode. In this mode, the printer’s conguration

can be changed using the menu system. During menu setting mode,

the CONDITION LED is on. Media must be installed in the printer to use

the Menu System.

Light up

FEED key (CURSOR)

PAUSE key (YES)

MODE/REPEAT key (EXIT)

Functions of the keys

After each menu item is printed, the printer will also print the function of

each of the buttons at that time. They vary slightly depending on the menu

selected but generally t the following guidelines:

PAUSE key (YES): : It is pushed to either select the current menu

option or to save the new setting after which

it advances to the next menu.

STOP key (CHANGE/NO): : Whilst changing a menu value (such as head

temperature), pressing this key displays the

next menu value available but does not save

the setting.

In the “main menu”, pressing this key moves

to the next menu available.

FEED key (CURSOR): : With some menu options such as head

temperature, there is more than one “digit”

than can be changed. This key moves the

cursor to the next digit.

MODE/REPEAT key (EXIT): : Exits the current menu or the menu system.

STOP key (CHANGE/NO)

Shown below is a sample menu output from the menu system.

This particular example is changing the print speed and print darkness

then continues through the remainder of the “Print Setup” menu.

The actual output from the printer is “vertically reversed” due to the way

the printer outputs the menu options. Please look at the example below to

see how the output changes.

Caution

When you are changing a menu value, pressing the "PAUSE" key (YES)

causes the printer to save the currently selected parameter.

The CONDITION LED ashes briey. Do not turn o the power to

the printer at this time as this may cause a malfunction.

If the power is accidentally turned o, rst reset the printer to factory

defaults.

4

a. Check the kind of ribbon used and set the ribbon winding direction using

menu setup mode or operation panel. This is the method for installing an

outside wound ribbon (also known as “ink out”).

b. Place the new, unused ribbon and the

paper core (tube) on to a ribbon

holder each.

Insert the ribbon holders all the way

in to the ribbon and paper core.

c. Install the unused ribbon and holder

in to the rear ribbon drive unit.

The splines on the ribbon drive gear

mechanism engage with the end of

the ribbon holder.

d. Push the head open lever to release

the head unit. Pull out the ribbon

from the bottom of the head unit to

the ribbon winding side.

Thermal Transfer Ribbon Installation (7206 only)

Ribbon holders

Ribbon

Paper core

1

2

e. Using the adhesive leader of the ribbon or some adhesive tape, x the

end of the ribbon to the empty cardboard ribbon holder and wind on

some ribbon.

Winding side

ribbon holder

Winding side

ribbon holder

f. Put the ribbon holder which holds

the cardboard tube in the ribbon

drive unit, then rotate it in the

direction shown by the arrow

to remove slack and wrinkles from

the ribbon.

g. Push the head close knob to lower

and lock the head unit. Be sure to

always push the head close knob

to lock the head unit

h. If the ribbon is wrinkled, push the

FEED key until the wrinkles

disappear. If the wrinkles

do not disappear or if it slips,

perform ribbon balance

adjustment and ribbon

tension adjustment as

described in Chapter 3 of

the full user’s manual

on the CD supplied.

Head close knob

6

Unusually Shaped Media Adjustment

For non-standard media sizes and shapes, you may need to adjust the media sensors from their usual positions

To detect gaps between labels and for media with notches or holes, use

the transparent or see-through sensor:

a. First, move the lower sensor to the center of the media installed or

in line with the hole or notch in the media.

b. Then align the upper sensor marker with the lower sensor marker as

shown in the diagram below.

c. For easy and quick alignment (and to reset to factory positions)

slide both the upper and lower sensors to the right-most position of

travel. They will now be perfectly aligned over the centre of the

mechanism.

Upper sensor marker

Upper sensor

Aligned with the marker

Bottom sensor

Transparent

sensor marker

Platen

Front

Movable

media guide

To detect media with black ‘registration’ marks on the back of the media,

use the reective sensor:

a. In reective sensor mode, only the lower sensor is used.

b. Adjust the position of the lower reective sensor so that the marker

is at the center of the black mark on the media as shown below.

c. The upper sensor arm is still closed over the media to help guide it

through the printer, even though the upper sensor arm is no longer

used.

Media

Bottom sensor

Platen

Black mark

Reective sensor marker

Front

Black mark

7

Windows® Drivers

Printer Driver Installation

If the drivers are not included with the printer, you can download the

latest version free-of-charge from our web site, details of which are on

the back of this Quick Start Guide.

Under the latest versions of Windows®, the computer will often

automatically detect the presence of the printer. Therefore it is

advisable to download the drivers from our web site before installing

the printer so the les are ready for installation:

www.dascom.com

During installation of the printer driver, the computer may ask you to

select the printer required.

You will need to click on the "Have Disk..." box then tell the computer

the location of the driver les on your CD ROM.

Your supplier will assist you with the correct drivers and software

which are compatible with your particular computer system if you are

not using Windows®.

Windows® is a trademark of Microsoft® Corporation.

Loading...

Loading...