Page 1

TECHNICAL MANUAL

OPERATOR'S, ORGANIZATIONAL, DIRECT

SUPPORT, AND GENERAL SUPPORT

BASE

NSN 4120-01-122-0629

MAINTENANCE

AIR CONDITIONER,

MOUNTED, AIR COOLED,

Hz,

MANUAL

HEADQUARTERS, DEPARTMENT OF THE ARMY

21 OCTOBER 1983

Page 2

Page 3

WARNINGS

TM5-4120-375-14

Disconnect main power

connector before attempting any electrical servicing of

air conditioner.

Dry cleaning solvent,

dangerous to personnel and property.

P-D-680 or P-S-661, used to clean parts is potentially

Avoid repeated and prolonged skin contact.

Do not use near open flame or excessive heat. Flash point of solvent is 100

degrees F (38 degrees C).

Avoid bodily contact with liquid refrigerant and avoid inhaling refrigerant gas.

Be especially careful that Refrigerant 22 does not come in contact with eyes.

In case of refrigerant leaks, ventilate area immediately.

Do not use compressed air for cleaning purposes except where reduced to less

than 30 psi and then only with effective chip guarding and personal protective

equipment.

Purge system with dry nitrogen prior to soldering.

Refrigerant heated to 1200

degrees F creates phosgene gas.

Be careful when working with high voltage. Failure

to comply can result in

serious injury or death.

The air conditioner must be grounded prior to operation. Connect one end of a

number 6AWG (American Wire Gage) copper wire ground lead to an underground

metallic water piping system or a driven metal ground rod or buried metal plate.

Connect the other end of the ground lead to the grounding bolt on the upper left

front corner of the unit.

Refrigerant-22 is contained in the refrigerant system under high pressure.

Extreme care must be exercised to prevent refrigerant from coming in contact

with exposed skin and eyes.

Provide adequate ventilation when discharging the

system in a confined area.

Polyurethane foam insulation breaks down to form toxic gases when heated to

brazing temperature.

All refrigerant gas must be discharged from system before

performing any removal procedures of refrigerant components.

Avoid contact with refrigerant acid.

Burns could result from contact with

refrigerant.

Acetone and methylethyl ketone are flammable and their vapors are explosive.

Prolonged or repeated inhalation of fumes on contact with the skin can be toxic.

Use in a well ventilated area, wear gloves and keep away from sparks or flame.

Scrape or pull off as much of the damaged insulation as possible. Soften the

remaining insulation and adhesive with acetone on MEK.

a

/(b blank)

Page 4

Page 5

TM 5-4120-375-14

C3

CHANGE

NO. 3

WASHINGTON, D.C., 28 February 1995

HEADQUARTERS

DEPARTMENT OF THE ARMY

Operator’s, Organizational, Direct Support, and

General Support Maintenance Manual

AIR CONDITIONER, BASE MOUNTED, AIR COOLED,

208 VAC, 3-PHASE, 60 HZ, SINGLE PACKAGE, 36,000 BTU/HR

PART NO. 97403-13219E0790

MODEL UAC40-5/6-08, NSN 4120-01-122-0629

MODEL 2463T100-1 , NSN 4120-01-218-6912

DISTRIBUTION STATEMENT A: Approved for public release; distribution is unlimited

TM 5-4120-375-14, 21 October, 1983, is changed as follows:

1. Remove and insert pages as indicated below. New or changed text material is indicated by a vertical bar

in the margin. An illustration change is indicated by a miniature pointing hand.

Remove pages Insert pages

E-3

and

E-4

2. Retain this sheet in front of manual for reference purpose.

By

Order of the Secretary of the Army:

E-3

and E-4

General, United States Army

Official:

MILTON H. HAMILTON

Administrative Assistant to the

Secretary of the Army

DISTRIBUTION:

To be distributed in accordance with DA

TM 5-4120-375-14.

08105

Form 12-25-E,

block no. 0028, requirements for

GORDON R. SULLIVAN

Chief of Staff

Page 6

Page 7

Page 8

Page 9

Page 10

Page 11

TM 5-4120-375-14

HEADQUARTERS

DEPARTMENT OF THE ARMY

WASHINGTON, D.C., 21 October 1983

OPERATOR’S, ORGANIZATIONAL, DIRECT SUPPORT,

AIR CONDITIONER, BASE MOUNTED, AIR COOLED,

208

VAC, 3-PHASE, 60 HZ,

SINGLE PACKAGE, 36,000 BTU/HR

PART NO. 97403-13219E0790

CHAPTER 1

Section I

Section II

Section III

MODEL

UAC40-5/6-08

2463T100-1

TABLE OF CONTENTS

NSN

4120-01-122-0629

4120-01-218-6912

1-1

1-3

1-6

CHAPTER 2

Section I

Section II

Section III

2-1

2-1

2-5

Change 1

i

Page 12

TM5-4120-375-14

TABLE OF CONTENTS (continued)

Page

Section

CHAPTER

Section

Section

CHAPTER

Section

Section

Section

Section

Section

Section

CHAPTER

IV.

3.

I.

II.

4.

I.

II.

III.

IV.

V.

VI.

5.

Operation Under

Unusual conditions ---------------

2-7

OPERATOR’S MAINTENANCE INSTRUCTIONS

Lubrication Instructions -------------------------

Troubleshooting ----------------------------------

3-1

3-1

ORGANIZATIONAL MAINTENANCE INSTRUCTIONS

Repair Parts, Special Tools, TMDE,

and Support Equipment ---------------------------Service upon Receipt of Equipment ----------------

Preventive Maintenance Checks and Services ------Troubleshooting ----------------------------------Maintenance Procedures --------------------------Preparation for Storage or Shipment --------------

4-1

4-2

4-7

4-12

4-20

4-134

DIRECT SUPPORT MAINTENANCE INSTRUCTIONS

Section

Section

Section

CHAPTER

Section

Section

APPENDIX

I.

II.

III.

6.

I.

II.

A.

B.

C.

D.

E.

F.

Repair parts, Special Tools TMDE,

and Support Equipment ---------------------------Troubleshooting ---------------------------------Maintenance Procedures ---------------------------

5-1

5-2

5-7

GENERAL SUPPORT MAINTENANCE INSTRUCTIONS

Troubleshooting

------------------------ -----------

Maintenance Procedures ----------------------------

References --------------------------------------Maintenance Allocation Chart ---------------------

Components of End Item List ----------------------

Expendable Supplies And Materials List ----------Wire List and Diagram

Glossary

------------------------ -----------------

------------------------ ----

6-1

6-2

A-1

B-1

C-1

D-1

E-1

F-1

ii

ALPHABETICAL INDEX

------------------------- ---------

INDEX- 1

Page 13

TM5-4120-375-14

CHAPTER 1

INTRODUCTION

CHAPTER OVERVIEW

The purpose of this chapter is twofold:

a. To provide you with the standard data required in all manuals

(i.e. forms and record data).

b.

To acquaint you with the air conditioner. This is done by

giving you a physical and functional description of those

major equipment parts that you are likely to come in contact

with.

INDEX

PAGE

I.

II.

III.

General Information.

Equipment Description.

Technical Principles of Operation.

SECTION I. GENERAL

1.

Fresh air dampers

2.

Air filter panel

Return air damper

3.

4.

Condenser coil guard

Main

5.

6.

7.

8.

9.

power connector

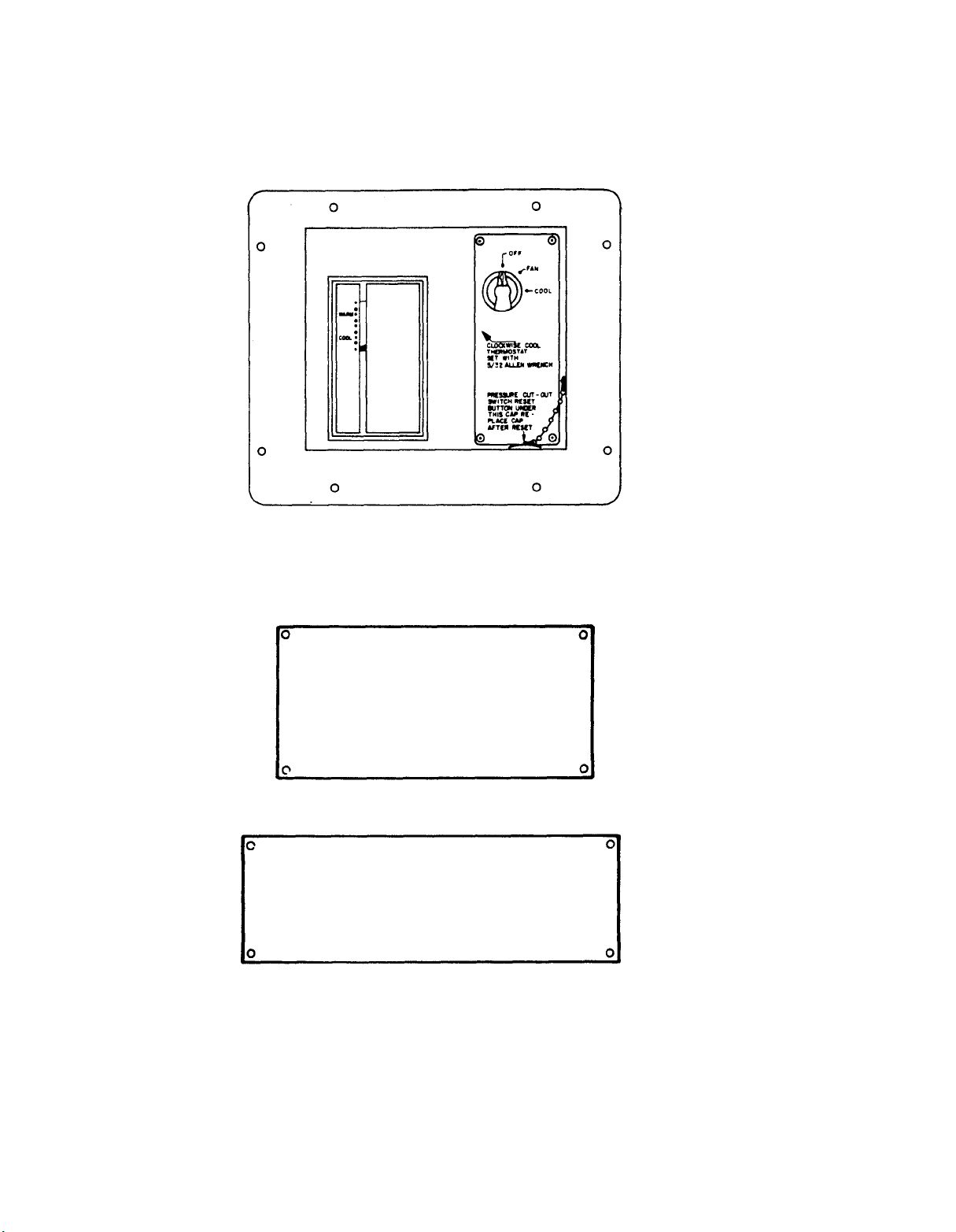

Rotary control switch

Thermostat

Evaporator fan outlets

Maintenance panel

1-1

1-3

1-6

INFORMATION

1-1

Page 14

TM5-4120-375-14

1-1.

SCOPE .

a.

Type of Manual: Operator’s, Organizational, Direct

Support, and

General Support Maintenance.

b.

Model Number and Equipment Name: Unifab Industries

Inc. model number

UAC 40-5/6-08, Talley Corporation model number 2463T100-1, Air

conditioner 36,000 BTU/HR, Base Mounted, 208 volt, 3 Phase, 50/60

Cycle, AC, Single Package.

c.

Purpose of Equipment:

Provide filtered, cooled air to a desired

predetermined range and circulating the air to provide cooling of

equipment or personnel within the air conditioned area.

1-2.

MAINTENANCE FORMS AND RECORDS.

Department of the Army forms and procedures used for equipment maintenance will

be those prescribed by DA PAM 378-750, the Army Maintenance Management Systems

(TAMMS).

1-3.

DESTRUCTION OF ARMY MATERIAL TO PREVENT ENEMY USE.

Refer to TM 750-244-3, Procedures for Destruction of Equipment to Prevent Enemy

use, for information about destruction.

1-4.

PREPARATION FOR STORAGE OR SHIPMENT.

Instructions for preparation for storage and shipment are in Chapter 4.

1-5.

If your air conditioner needs Improvement, let us know. Send us an EIR. Y

the user,

equipment.

is hard to perform.

REPORTING EQUIPMENT IMPROVEMENT RECOMMENDATIONS (EIRs).

OU

,

are the only one who can tell us what you do or do not like about your

Let us know why you do not like the design.

Put it on an SF 368 Quality Deficiency Report.

Tell us why a procedure

Mail it

directly to Commander, U.S. Army Troop Support Command, ATTN: AMSTR-QX, 4300

Goodfellow Boulevard, St. Louis; MO 63120-1798.

1-2

Change 1

Page 15

SECTION II. EQUIPMENT DESCRIPTION

TM5-4120-375-14

1-6.

PURPOSE OF AIR CONDITIONER.

The air conditioner is used primarily in van type enclosures. The units provide

filtered, cooled air, as required,

to maintain the service conditions necessary

for the efficient operation of electronic equipment in the vans. The air

conditioner also provide for the comfort of operating personnel housed within

the vans.

1-7.

CAPABILITIES AND FEATURES.

a. Base mounted and air cooled.

b.

Electric motor driven and designed for continuous operation under

varying loads.

c.

Furnishes air circulation.

d.

Furnishes 36,000 BTU/HR for cooling.

e. Furnishes fresh air.

1-3

Page 16

TM5-4120-375-14

1-8.

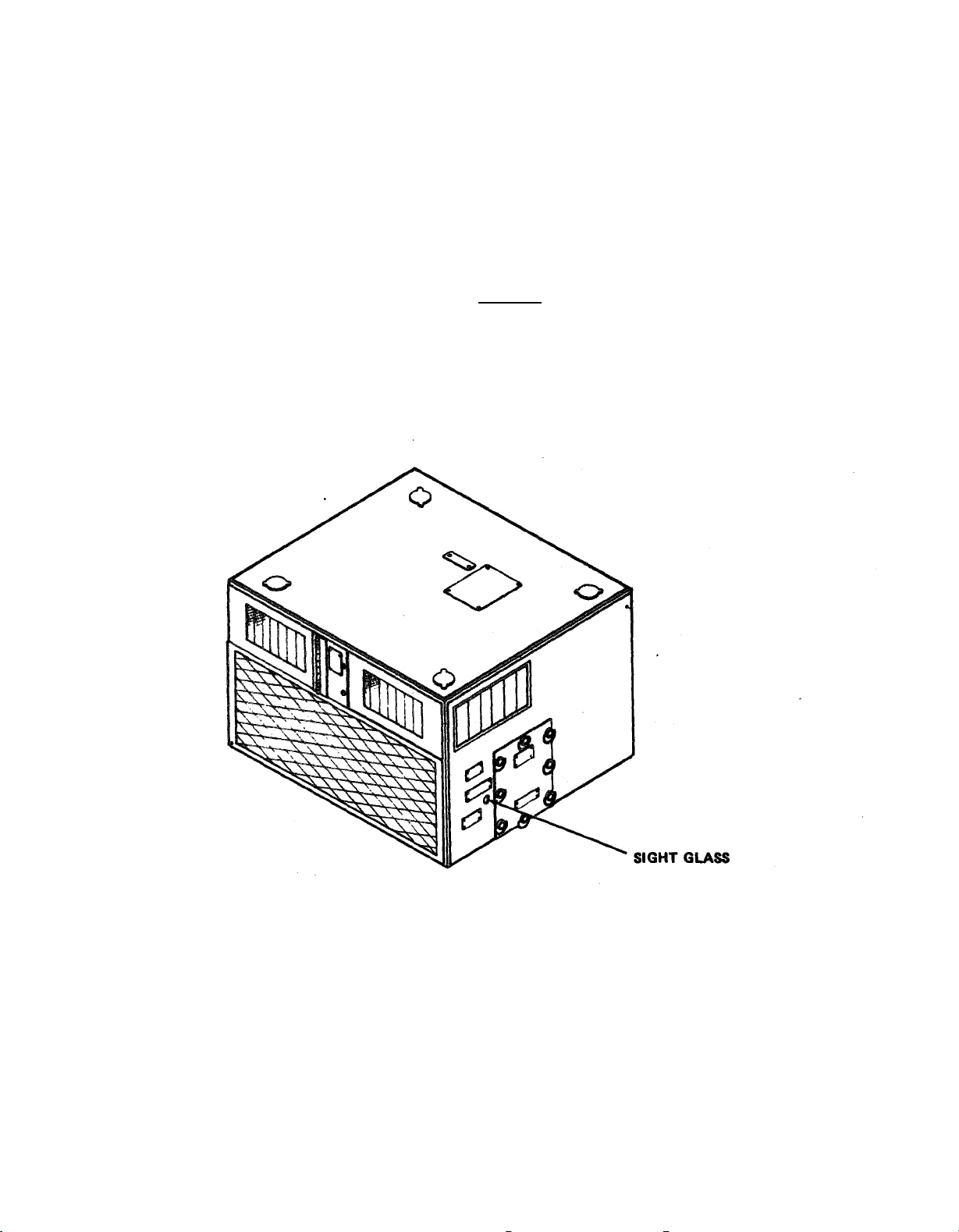

LOCATION AND DESCRIPTION OF MAJOR COMPONENTS.

Compressor

1.

Evaporator coil

2.

Evaporator fan motor

3.

4.

Expansion valve

Condenser coil

5.

6.

Junction box

Dual pressure switch

7.

Solenoid valve

8.

Condenser fan motor

9.

Dryer

10.

11.

Condensate drain exit

Sight glass

12.

1-4

Page 17

TM5-4120-375-14

1-9. IDENTIFICATION.

The air conditioner has one identification plate, it is located on the front

panel.

It provides the Air Conditioner nomenclature, national stock number,

part number, contract number, serial number, and weight.

1-10.

Air Conditioner, Base Mounting

Unifab Industries, Inc.

UAC 40-5/6-08

4120-01-122-0629

The Talley Corporation

2463T100-1

4120-01-218-6912

97403-13219E0790

36.92 IN. ( .93 m)

42.34 IN. (1.07 m)

27.85 IN. ( .70 m)

475 lbs. (215 kg)

8.5 kw

36,000 BTU/HR

208

60

3

Change 1

1-5

Page 18

TM5-4120-375-14

1-11.

SECTION III.

GENERAL.

TECHNICAL PRINCIPLES OF OPERATION

The air conditioner is a base mounted, self-contained, electric motor driven

unit that provides

36,000 BTU/HR for cooling.

Once started, it operates

automatically due to the relationship of the components, controls and

instruments.

1-12.

VENTILATION.

Placing the selector switch in the FAN position energizes the fan motor which

forces air out of the evaporator

ventilation is determined by the

fan guard. The amount of outdoor air used for

position of the damper control knobs.

1-6

Page 19

TM5-4120-375-14

1-13.

COOLING.

With the selector switch in the COOL position the fan motors and the compressor

are energized.

The fan motors and compressor run continuously. The thermostat

controls the amount of cooling.

1-7/(1-8 blank)

Page 20

Page 21

TM5-4120-375-14

CHAPTER 2

OPERATING INSTRUCTIONS

CHAPTER OVERVIEW

This chapter contains a functional description of’ the major components of the

air conditioner.

It explains how to operate the Air Conditioner.

For your

convenience, below is an index of’ this chapter.

INDEX

SECTION

I.

II.

III.

IV.

2-1.

GENERAL.

TITLE PAGE

Instructions

Under Usual Conditions

Under Unusual Conditions

Preventive Maintenance Checks and Services

SECTION I.

2-1

2-5

2-7

2-2

2-1

Page 22

TM5-4120-375-14

SECTION II. PREVENTATIVE MAINTENANCE CHECKS AND SERVICES

2-2.

GENERAL.

Preventative Maintenance Checks and Services (PMCS, Table 2-1.)

are to be completed to ensure the air conditioner is ready to use at

all times.

defects before the air

2-3.

PMCS PROCEDURES.

a.

These checks and services help you find and repair

conditioner is damaged or fails.

Item numbers

in the first column of Table 2-1 are the order in

which inspections are to be done. Column two “Interval” lists when

to do them.

b.

If minor defects are found when the air conditioner is running

take notes on what they are and notify organizational maintenance.

CAUTION

While the air conditioner is running, if any defect develops

that you think will damage the air condiitioner, stop it at once.

2-2

Page 23

TM5-4120-375-14

Table 2-1.

Operator/Crew

If the equipment must be kept in continuous operation, check

and service only those items that can be checked and serviced

without disturbing operation. Hake the complete checks and

services when

the equipment can be shut down.

B-Before Operation

ITEM INTERVAL ITEM TO BE

NO.

1

BDA

*

INSPECTED

Inspect controls and fittings

for defective or loose parts.

2

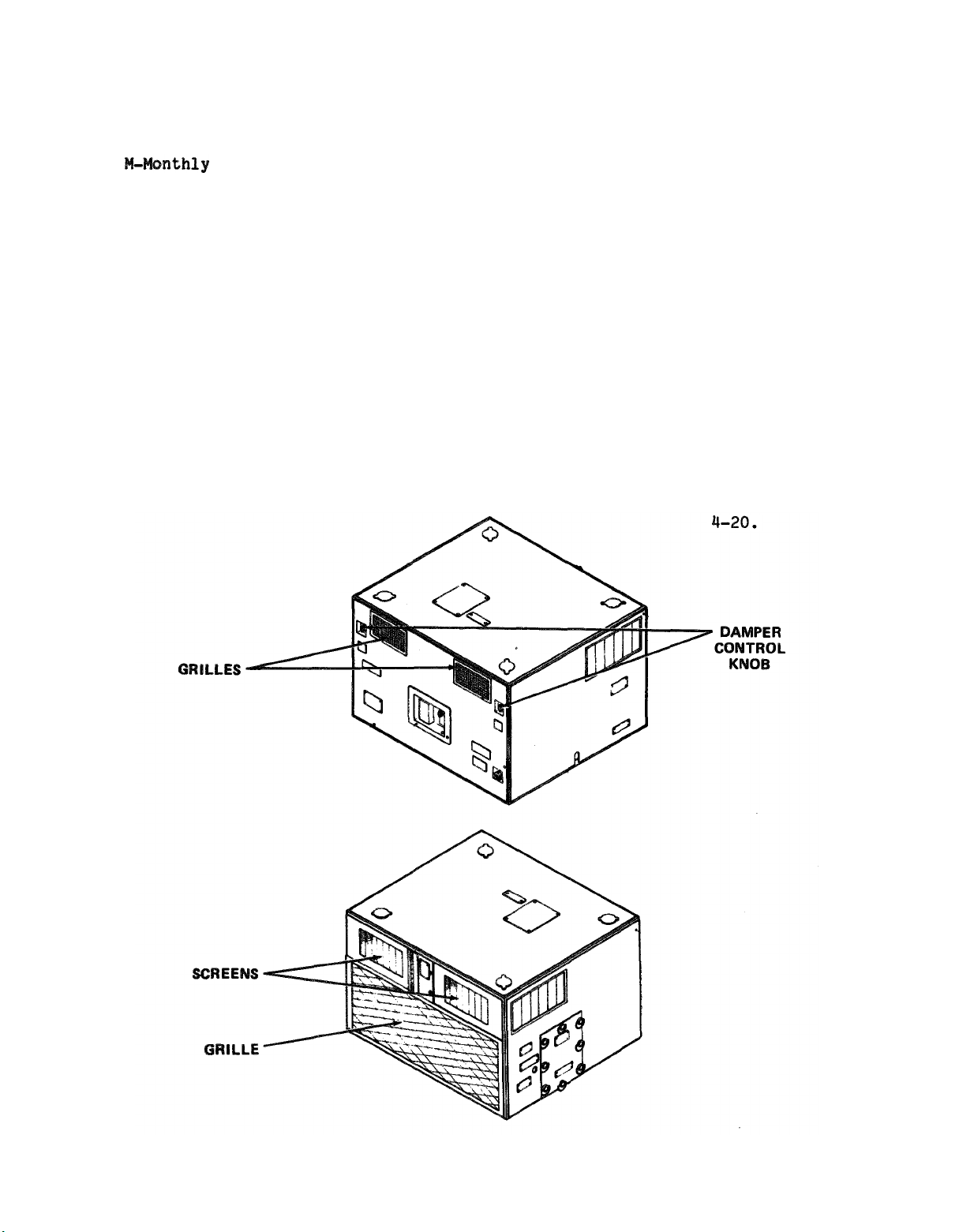

*

Screens and Grilles (Cheek for dirt and obstructions).

Preventive Maintenance Checks

NOTE

D-During Operation

PROCEDURE

and Services

A-After Operation

EQUIPMENT

IS NOT READY/

AVAILABLE IF:

2-3

Page 24

TM5-4120-375-14

TABLE 2-1.

B-Before Operation

OPERATOR/CREW PREVENTIVE MAINTENANCE CHECKS AND SERVICE

D-During Operation

A-After Operation

-------------------- ------------------------- ------------------------ ----ITEM INTERVAL

NO.

BDA

ITEM TO BE

INSPECTED

PROCEDURE

EQUIPMENT

IS NOT READY/

AVAILABLE IF:

3

4

5

6*

*

*

*

Be careful when working with high voltage.

Sight Glass (Check for cloudy or bubbles).

Damper Control (Check for Freedom of movement).

Noise or Vibration (Listen for any unusual noise or vibration).

Panels (Check for damage).

Failure to comply can result

in serious injury or death.

7*

Main Power Connector (Inspect for loose connection).

2-4

Page 25

TM5-4120-375-14

2-4.

2-5.

SECTION III.

OPERATION UNDER USUAL CONDITIONS

PREPARATION FOR USE.

a. Inspect the entire unit for external damage. Report any

deficiencies to the proper maintenance level.

Be careful

in serious

b.

Connect power.

when working with

injury or death.

high voltage.

Failure to comply can result

c. Perform preventive maintenance checks and services.

STARTING THE EQUIPMENT.

Before you operate: Always keep in mind the CAUTIONS AND WARNINGS.

a. Ventilation mode.

(1).

(2).

Turn rotary control switch to FAN position.

Adjust damper to admit fresh air as desired.

2-5

2-5

Page 26

TM5-4120-375-14

2-5.

STARTING THE EQUIPMENT (cont.).

CAUTION

Assure that crankcase heater is on six hours prior to operating.

NOTE

For maximum cooling capacity when outside temperature is

high, set damper controls at full MIN position.

b.

Cooling mode.

(1).

(2).

(3)0

Set thermostat for desired

Turn rotary control switch

Turn damper control knobs to desired position from MIN

room temperature.

to

COOL.

(100% RETURN-AIR) to MAX (100% FRESH-AIR).

2-6

Page 27

TM5-4120-375-14

2-6.

Allow 15 minutes operation to ensure unit has stabilized, then check

sight glass for cloudiness.

OPERATION.

If unit does not operate, refer to

troubleshooting procedures in Chapter 3 of this manual.

CAUTION

Check sight glass for bubbles or yellow color.

If sight glass is bubbly yellow color, notify Direct Support

Maintenance.

If the glass is free of bubbles and the dot is

green, the system is properly charged.

Change 1

2-7

Page 28

TM5-4120-375-14

2-7.

2-8.

STOPPING.

Turn rotary control switch to OFF position.

OPERATIONAL INSTRUCTION WARNING PLATES.

DISCONNECT

MAIN POWER PLUG

BEFORE SERVICING ELECTRICAL

SYSTEM

OPERATE

ONLY WITH PANEL

INSTALLED

2-8

Page 29

SECTION IV OPERATION UNDER UNUSUAL CONDITIONS

TM5-4120-375-14

2-9.

OPERATION IN EXTREME COLD.

a. Keep entire unit free of snow and ice.

Cover unit when not in use.

b.

2-10.

b. Cut amount of fresh air used.

2-11. OPERATION IN DUSTY OR SANDY AREAS.

2-12. OPERATION UNDER RAINY OR HUMID CONDITIONS.

a. Keep unit clean and dry.

b. Cover unit when not in use.

c. Remove cover during dry periods and allow unit to

dry.

2-13. OPERATION IN SALT WATER AREAS.

a. Rinse with clean water and dry as much of unit as possible to

prevent corrosion.

b.

Cover

unit when not in use.

2-14. OPERATION IN HIGH ALTITUDES.

a. The operating efficiency of the unit will be reduced at higher

altitudes.

2-9/(2-10 blank)

Page 30

Page 31

TM5-4120-375-14

CHAPTER

3

OPERATOR'S MAINTENANCE INSTRUCTIONS

CHAPTER OVERVIEW

This chapter contains all the necessary maintenance instructions to keep your

air conditioner in good repair.

INDEX

SECTION

I.

II.

III.

TITLE

Lubrication Instructions.

Operator Troubleshooting.

Operator Troubleshooting Table.

PAGE

3-1

3-1

3-2

SECTION I.LUBRICATION INSTRUCTIONS

3-1.

There is no lubrication required for this air conditioner.

SECTION II.

TROUBLESHOOTING

3-2.

GENERAL.

a. Table

3-1

provides information useful in diagnosing and

correcting malfunctions which you may find during the operation

of

or maintenance

the unit or its components.

Perform the

tests/inspections and corrective actions in the order listed.

b.

This manual cannot list all malfunctions that may occur, nor

all tests or inspections and corrective actions.

If a

malfunction is not listed or is not corrected by listed

corrective actions, notify your supervisor.

3-1

Page 32

TM5-4120-375-14

SECTION III. OPERATOR TROUBLESHOOTING TABLE

TABLE

3-1

OPERATOR TROUBLE SHOOTING TABLE

MALFUNCTION

TEST OF INSPECTION

VENTILATION MODE (ONLY)

1.

AIR CONDITIONER FAILS TO OPERATE.

Be careful when working with high voltage.

in serious injury or death.

Step 1.

Check to see if main power cord is plugged in.

Connect power cable to air conditioner.

Step 2.

Check to see that power supply circuit breaker is in the

ON position.

CORRECTIVE ACTION

WARNING

Failure to comply can result

Step 3.

Place circuit breaker to the ON position.

Check to see if selector switch is in fan position.

Place selector switch in fan position.

3-2

Page 33

TM5-4120-375-14

TABLE 3-1

OPERATOR TROUBLESHOOTING TABLE (cont.)

------------------------------------------------------------------------------MALFUNCTION

TEST OF INSPECTION

CORRECTIVE ACTION

-----------------------------------------------------------------------------

COOLING MODE

2.

INSUFFICIENT

Step 1.

COOLING.

Check to see if selector switch is in COOL position.

Place selector switch in COOL position.

Step 2.

Check

to see

if THERMOSTAT is in COOLER position.

Notify Organizational Maintenance.

Step 3. Inspect air filter and return air grilles for

obstructions.

Notify Organizational Maintenance.

Step 4. Inspect sight glass for bubbles.

Notify Organizational Maintenance.

3-3

/(3-4 blank)

Page 34

Page 35

CHAPTER 4

TM5-4120-375-14

ORGANIZATION MAINTENANCE

This chapter contains the following frequently

INSTRUCTIONS

used maintenance information.

The symptom index on page 4-12 is a guide to the troubleshooting information.

There is also an index to the maintenance procedures on page 4-21.

INDEX

SECTION

TITLE

I . Repair Parts, Special Tools, TMDE, and Support Equipment

II. Service Upon Receipt

III. Preventive Maintenance Checks and Services

IV.

V.

VI.

Troubleshooting

Maintenance Procedures

Preparation for Shipment or Storage

Page

4-1

4-2

4-7

4-12

4-20

4-134

For authorized common tools and equipment, refer to the

TabIe of Organizational and Equipment (MTOE) applicable

4-2.

N

SPECIAL TOOLS, TMDE, AND SUPPORT EQUIPMENT.

O special tools, TMDE, or support equipment are required for this

Modified

to your unit.

air conditioner.

4-3.

REPAIR PARTS.

Repair parts are listd and illustrated in TM 5-4120-375-24P.

Page 36

TM5-4120-375-14

SERVICE UPON RECEIPT

4-4.

SECTION II.

UNLOADING THE EQUIPMENT.

The crated air conditioner may be unloaded and moved by any means, provided

the unit weight is supported by the base platform.

4-5.

UNPACKING THE EQUIPMENT.

CAUTION

So that the unit is protected,

it should be left crated until moved

to the location where it is to be installed.

a.

General.

To uncrate the unit,

and lift off the top.

remove the bands from the top panel

Remove sides in a similar manner.

The unit is then ready for inspection.

b.

Depreservation. Prepare the air conditioner for

operation as outlined on DA Form

inspection and

2258

(depreservation Guide for Vehicles and Equipment.

4-6.

INSPECTING AND SERVICING EQUIPMENT.

a.

Inspect the entire air conditioning unit, including motors, fans,

controls, etc.,

to be certain that all parts have been received and

without damage. Report any deficiencies to the proper maintenance

level.

CAUTION

Do not remove tags from equipment until the instructions have been

followed. Failure to follow these instructions can result in serious

damage to the equipment.

b.

Test the joints in the refrigerant circuit for leaks in accordance

with paragraph

5-17.

4-2

Page 37

TM5-4120-375-14

4-7.

1.

SERVICE UPON RECEIPT CHECKLIST.

Exterior

Panels and Grilles

a.

b.

2.

Front

Control Box

a.

b.

Front Panel Main Power Connector a.

3.

b.

Inspect for signs of rough

handling and damage.

Service or reject any component

if damage prevents the air

conditioner from working.

Check for broken or damaged knob.

Insure that switches move freely

from position to position.

Repair any component that is found

to be malfunctioning.

Inspect main power connector

for damage.

Repair of replace main

power connector.

properly.

4-3

Page 38

TM5-4120-375-14

4-7.

SERVICE UPON RECEIPT CHECKLIST. (cont.)

LOCATION

Side

5.

ITEM

Return Air Damper

ACTION

b.

Remove air filters and inspect

the filter for accumulation of

dirt.

c.

Clean filter.

a.

Check to see that the FRESH AIR

control moves freely between the

the MIN and MAX position and that

the return air damper opens and

closes properly.

b.

Adjust or repair FRESH AIR controls.

4-4

Page 39

TM5-4120-375-14

4-8.

INSTALLATION INSTRUCTIONS.

a.

The unit may be supported by, or suspended from, any convenient

part of the van or trailer capable of withstanding a concentrated

load of approximately 550 pounds (292 kg.).

b.

If the unit is to be mounted

near a wall or partition, allow

clearance to permit removal of panels.

c.

Follow the base plan in figures below in selecting a suitable location

or in constructing an installation base. Lift unit by lifting rings

only.

4-5

Page 40

TM5-4120-375-14

4-8.

INSTALLATION INSTRUCTIONS.

d.

Connect a 1/2 inch threaded pipe to the drain connections on

(cont.)

the bottom right side of the unit to remove condensate water.

Extend piping or hose to deposit water in a suitable location or

container. Drain system must have

"U" trap on exterior drain

line.

e.

Be sure the main rotary switch on the control box is in the OFF

position, and connect a 208 volt, 60 cycle, 3 phase power source

to the main power connector at the lower right front corner of

the unit.

WARNING

The air conditioner must be grounded prior to

operation. Connect one end of a

number 6AWG (American Wire Gage) copper wire ground lead to an underground

metallic water piping system or a driven metal ground rod or buried metal

plate. Connect the other end of the ground lead to the grounding bolt on the

upper left front corner of the unit.

f.

The new unit should not require servicing, as it is shipped

completely assembled and ready to operate when power is

applied.

However, if any defects have been found during the

inspection of the equipment they should be corrected as necessary

before the unit is placed into operation.

4-6

Page 41

TM5-4120-375-14

SECTION III.

4-9.

GENERAL.

To insure that the air conditioner is ready for

be inspected systematically so that the defects

before the result is serious damage or failure.

operation of the unit shall be noted for future

as an operation has ceased.

if operation were to continue.

ORGANIZATIONAL

operation at all times, it must

may be discovered and oorrected

Defects discovered during

corrections to be made as soon

Stop operation which would damage the equipment

All deficiencies and shortcomings shall be

recorded together with the corrective action taken on DA Fom 2404 "Equipment

Inspection and Maintenance Worksheet",

equipment fails to operate, troubleshoot with proper equipment.

at the earliest opportunity. If your

Report any

deficiencies using proper forms, (See DA PAM 738-750).

4-10. PREVENTIVE MAINTENANCE CHECKS AND SERVICES (PMCS).

Dry cleaning solvent, P-D-680, or P-S-661, used to clean

parts is potentially dangerous to personnel and property.

Avoid repeated and prolonged skin contact. Do not use

near open flame or excessive heat.

is 100 degrees F

(38 degrees C).

Flash point of solvent

Do not use compressed air for cleaning purposes except where

reduced to less than 30 psi (2.11 km/ cm 2) and then only with

effective chip guarding and personal protective equipment.

Change 1

4-7

Page 42

TM5-4120-375-14

Table 4-1.

ORGANIZATIONAL PREVENTIVE MAINTENANCE CHECKS AND SERVICES.

M-Monthly Q-Quarterly

ITEM INTERVAL

NO.

1.

2.

3.

MQS

*

*

*

ITEM TO BE

INSPECTED

Controls and

fittings

Refrigeration

components

Fresh air filters

PROCEDURE EQUIPMENT

Check for defective

or loose parts. or replace

Check for visable

and audible leaks.

Check for dirt or

damage.

S-Semiannually

IS NOT READY/

AVAILABLE IF:

If damaged repair

controls in

accordance with

paragraph 4-16.

If leak exist

notify Direct

Support Maintenance.

Replace fresh

air filters in

accordance with

paragraph 4-19.

4-8

Page 43

TM5-4120-375-14

Table 4-1. ORGANIZATIONAL

---------------------------------------------------------------------------

ITEM

NO.

INTERVAL

MQS

ITEM TO BE PROCEDURE EQUIPMENT

INSPECTED IS NOT READY;

PREVENTIVE MAINTENANCE CHECKS

Q-Quarterly

AND SERVICES.

S-Semiannually

(cont.)

AVAILABLE IF’:

----------------------------------------------------------------------------

4.

5.

*

Screens and Grilles

*

Damper control

Check for dirt or

damage.

Check for freedom

of movement.

If damaged

repair or replace

screens and

grilles in

accordance with

paragraph 4-17

and 4-18.

Adjust or replace

damper control

in accordance

with paragraph

paragraph 4-20.

4-9

Page 44

TM5-4120-375-14

Table 4-1.

M-Monthly

ORGANIZATIONAL PREVENTIVE MAINTENANCE CHECKS AND SERVICES. (cont.)

Q-Quarterly

S-Semiannually

—---- ------------------------- --------------------- -------------------- ------

ITEM INTERVAL

NO.

MQS

ITEM TO BE

INSPECTED

PROCEDURE

EQUIPMENT

IS NOT READY/

AVAILABLE IF:

6.

*

Fans

Check for security

of attachment, bent

or broken blades.

If damaged repair

or replace fans

in accordance with

paragraphs

4-25

and 4-26.

7.

4-10

*

Thermostat

Check for proper

operation.

Inspect

for security of

If damaged repair

or replace

thermostat in

accordance with

paragraph 4-16.

Page 45

TM5-4120-375-14

Table 4-1.

ORGANIZATIONAL PREVENTIVE MAINTENANCE CHECKS AND SERVICES. (cont.)

M-Monthly

ITEM INTERVAL

No.

8.

9.

MQS

*

*

ITEM TO BE

INSPECTED

Evaporator coil

Condenser coil

Q-Quarterly

PROCEDURE

Check evaporator

coil for cleanliness.

Check for visible

and

audible leaks.

Check condenser

coil for cleanliness.

Check for visible

and audible leaks.

S-Semiannually

EQUIPMENT

IS NOT READY/

AVAILABLE IF:

If leaks exist

notify Direct

Support Maintenance.

If leaks exist

notify Direct

Support Maintenance.

Page 46

TM5-4120-375-14

4-11. TROUBLESHOOTING.

a.

Table 4-2 contains troubleshooting information for locating and cor-

recting most of the operating troubles which are the responsibility

of organizational maintenance. Each malfunction for an individual

component, unit, or system is followed by a list of tests or

inspections which will help you to determine probable causes and

corrective actions to take. Perform the tests/inspections and

corrective actions in the order listed.

b.

This manual cannot list all malfunctions that may occur, nor all

tests or inspections and corrective actions.

not listed or is not corrected by listed corrective actions, notify

your supervisor.

c.

Onlv those functions within the scope of organizational maintenance are listed.

of operator/crew maintenance, refer to Table 3-1

SECTION IV. TROUBLESHOOTING

If a malfunction is

For troubleshooting procedures within the scope

.

4-12. SYMPTOM INDEX.

Locate the malfunction which is the same, or most nearly the same,

as the trouble you are having with the air conditioner.

The Symptom

Index lists the first page of troubleshooting information for that

malfunction. Follow the steps one by one, and perform the corrective

actions listed.

Malfunction

Number Description

1.

2.

3.

4.

5.

Air conditioner fails to operate.

Compressor fails to start.

Insufficient cooling.

Evaporator fan fails to operate

Condenser fan fails to operate

Page

4-13

4-14

4-15

4-15

4-16

4-12

Page 47

TM5-4120-375-14

Table 4-2. TROUBLESHOOTING

--------------------------------------------------------------------------TEST OR INSPECTION

CORRECTIVE ACTION

----------------------------------------------------------------------

VENTILATION MODE ONLY

1.

AIR CONDITIONER FAILS TO OPERATE.

Be careful when working with high voltage. Failure to comply can result in

serious injury or death.

Step 1.

Step 2.

Step 3.

Step 4.

Step 5.

Check to see if main

Connect power

208VAC, three

Check to see if main

power is plugged in.

cable to a source suppling

phase, 60 Hz. power.

power connector is defective in

accordance with paragraph 4-23.

Replace defective main power connector in

accordance with paragraph 4-23.

Check for loose electrical connections.

Tighten electrical connections.

Check for defective wiring in accordance

with paragraph

4-24.

Replace defective wiring. Use identical

wire consult Appendix F-and solder (Item 12,

table D-1) all terminals connectors in

accordance with paragraph 4-24.

Check

to see that selector switch is in FAN position.

Place selector switch in FAN position. If

the air conditioner will NOT operate check

for a defective switch in accordance with

paragraph 4-16.

Replace defective switch

in accordance with paragraph 4-16.

4-13

Page 48

TM5-4120-375-14

Table 4-2.

MALFUNCTION

COMPRESSOR FAILS TO START.

2.

Step 1.

Step 2.

TROUBLESHOOTING (cont.)

TEST OR INSPECTION

CORRECTIVE ACTION

COOLING MODE

Loosen eight turnlock fasteners on maintenance panel.

Remove maintenance panel.

Place circuit breaker in the ON position. If

the air conditioner will not operate in the

COOL position, check for a defective circuit

breaker in accordance with paragraph 4-22.

Replace defective circuit breaker in

accordance with paragraph 4-22.

Check

to see if dual pressure switch contacts are

open.

Push reset button at the dual pressure switch.

If compressor does not start, stop air

conditioner. Notify Direct Support Maintenance.

WARNING

Be careful when working with high voltage.

Failure to comply can

result in serious injury or death.

Step 3.

Check to see that selector switch is in COOL

position.

Place selector switch in COOL position.

air conditioner will NOT operate check for a

defective switch in accordance with paragraph

4-16.

Replace defective switch in accordance with

paragraph 4-16.

If the

4-14

Page 49

TM5-4120-375-14

Table 4-2.

MALFUCTION

INSUFFICIENT COOLING.

3.

Step 1.

TROUBLESHOOTING (cont.)

TEST OR INSPECTION

CORRECTIVE ACTION

Check to see that thermostat (temperature control)

is set correctly.

Place thermostat in cooler position.

Replace defective thermostat in accordance

with paragraph 4-16.

Step 2.

Check for correct operation of evaporator fan

assembly.

Replace or repair damaged evaporator fan

assembly in accordance with paragraph 4-25.

4-15

Page 50

TM5-4120-375-14

MALFUNCTION

Step 3.

Step 4.

Table 4-2.

TROUBLESHOOTING (cont.)

TEST OR INSPECTION

CORRECTIVE ACTION

Check for correct operation of condenser fan assembly.

Replace or repair damaged condenser fan

assembly in accordance with paragraph

4-26.

Check

fresh air dampers.

Remove eight screws and eight rubber washers

securing lifting ring covers to top panel and

frame.

Remove lifting ring covers.

Remove twenty-three screws and eight screws

securing top panel to frame.

Remove top panel.

Inspect for freedom of movement, lubricate if

required (Item 17, table D-1).

Tighten loose mountings.

Replace or repair fresh air dampers, in

accordance with paragraph 4-20.

4-16

Page 51

TM5-4120-375-14

Table 4-2.

MALFUNCTION

TROUBLESHOOTING (cont.)

TEST OR INSPECTION

Step 5.

Check evaporator fresh air filter.

Loosen two turnlock fasteners on air filter

panel door.

Open door.

Slide air filters out of unit and inspect

filters.

Spray filters with a water hose in opposite

direction of air flow (see arrow on filter

frame) .

Shake water from filter and allow to dry

before installing.

CORRECTIVE ACTION

Inspect air filter for damage.

Replace air filter if damaged in accordance

with paragraph 4-19.

CAUTION

Do not use oil on filters.

4-17

Page 52

TM5-4120-375-14

Table 4-2.

Step 6.

TROUBLESHOOTING (cont.)

Check evaporator fan outlets for obstruction.

Remove obstruction.

4-18

Page 53

TM5-4120-375-14

Table 4-2.

MALFUNCTION

TROUBLESHOOTING (cont.)

TEST OR INSPECTION

CORRECTIVE ACTION

--------------------------------------------------------------Step 7.

Check for correct system pressures in accordance

with Table 5-2.

Notify direct support maintenance.

Step 8.

Check for moisture in system.

Notify Direct Support Maintenance.

CAUTION

Check sight

If sight glass is a

glass for green color indicating unit is charged properly.

yellow color, notify Direct support maintenance.

Step 9.

Check for correct discharge pressure in accordance

with Table 5-2.

Notify direct support maintenance.

4-19

Page 54

TM5-4120-375-14

ORGANIZATIONAL MAINTENANCE PROCEDURES

4-13.

SECTION V.

GENERAL INSTRUCTIONS.

Most maintenance instructions in this section will list

resources required, personnel required and equipment for

the start of the procedure.

NOTE

Resources required are not listed unless they apply to the

procedure.

Personnel required are listed only if the task requires more

than one.

If PERSONNEL is not listed,

it means one person can

do the task.

The normal standard equipment condition to start a maintenance

task is air conditioner stopped and control switch OFF.

EQUIPMENT CONDITION is not listed unless some other condition

is required besides the power being

OFF.

4-20

Page 55

TM5-4120-375-14

ORGANIZATIONAL MAINTENANCE PROCEDURES INDEX

Paragraph Page

Air Filters

Condensate Main and Fittings

Condenser Fan Motor and Housing

Condenser Coil Guard

Control Box

a. Rotary Control Switch

b. Thermostat

Dampers and Controls

Evaporator Fan Motor and Housing

Evaporator Fan Guard

Junction Box

a. Circuit Breaker

b. Relays

c. Electrical Connectors

Lifting Ring Covers

Panels

Power Wiring Harness

Wiring Harness

4-19

4-21

4-26

4-18

4-16

4-16

4-16

4-20

4-25

4-17

4-22

4-22

4-22

4-22

4-14

4-15

4-24

4-23

4-47

4-68

4-114

4-45

4-34

4-35

4-36

4-49

4-105

4-43

4-76

4-78

4-79

4-80

4-22

4-24

4-97

4-88

4-21

Page 56

TM5-4120-375-14

4-14.

LIFTING RING COVER

This task cover:

a. Removal

b.

Inspection

c.

Installation

-------------------------------------------------------------------------------INITIAL SETUP

Test Equipment

None

Tool

S

TOOL KIT (SC 5180-90-C-N18)

References

None

Troubleshooting References

None

Special Environmental Conditions

None

General Safety Instructions

Turn air conditioner OFF before performing maintenance.

LOCATION/ITEM

ACTION

REMARKS

REMOVAL

Lifting Ring Cover

1.

a.b.Remove two screws (1), and two rubber washers (2)

securing lifting ring cover (3) to frame and top

panel.

Remove lifting ring cover.

4-22

Page 57

LIFTING RING COVER (CONT. )

TM5-4120-375-14

LOCATION/ITEM

Lifting Ring Cover

2.

Rubber washers are to be placed between lifting ring cover and top panel.

Lifting Ring Cover

3.

ACTION

Inspect for damage.

a.

Repair or replace if damaged.

b.

NOTE

Align holes in

a.

lifting ring cover (3) with frame

and top panel.

Secure lifting

b.

sorews (1) and

ring cover with two

two rubber washers (2) to

frame and-top panel.

REMARKS

4-23

Page 58

TM5-4120-375-14

4-15.

PANELS

------------------------ ------------------------ -------------------- -----------This tasks covers:

Removal

a.

b.

Inspection,

c.

Installation

service and repair

------------------------ ------------------------ ------------------------ -------INITIAL SETUP

Test Equipment

None

Tools

TOOL KIT (SC 5180-90-C-N18)

References

None

Troubleshooting References

None

Special Environmental Conditions

None

General Safety Instructions

Turn air conditioner OFF before performing maintenance.

LOCATIONS/ITEM

ACTION

REMARKS

REMOVAL

Evaporator Fan Guard

1.

Control Box

2.

a.

Remove four screws (1) securing evaporator

fan guard (2) to front panel and frame.

b.

Remove evaporator fan guard.

a.

Remove four screws (3) and four screws (4)

securing control box (5) to frame and front panel.

b.

Disconnect electrical connector plug (P-6).

4-24

Page 59

PANELS (CONT. )

TM5-4120-375-14

LOCATIONS/ITEM

REMOVAL

Front Panel

3.

4.

Right Side

Top Panel

5.

Panel

a.

Remove

ACTION

thirty-four screws (6) and two

REMARKS

screws (7) securing front panel (8) to frame .

Remove front panel.

b.

Remove thirty-one screws (9) securing right

a.

side panel (10).

b.

Remove right side panel.

a.

Remove eight screws (11), eight rubber

washers (12) securing lifting ring covers (13)

to frame and top panel (14).

Remove four lifting ring covers.

b.

c.

Remove

eight screws (15) and twenty-three

screws (16) securing top panel to frame.

d.

Remove top panel.

4-25

Page 60

TM5-4120-375-14

PANELS (CONT.)

LOCATIONS/ITEM

REMOVAL

Air Filter Panel

6.

Maintenance Panel

7.

Left Side Panel

8.

ACTION

a.

Remove two screws

lock fasteners

(17) and loosen two turn

(18)

securing air filter panel (19)

REMARKS

to frame.

Remove air filter panel.

b.

a.

Loosen eight turnlock fasteners (20) securing

maintenance panel

(21) to

left side panel (22)

and frame.

Remove maintenance panel.

b.

a.

Remove twenty-seven screws (23) securing left side

panel (22) to frame.

Remove left side panel.

b.

4-26

Page 61

table D-1

table D-1

TM5-4120-375-14

table D-1

table D-1

4-27

Page 62

TM5-4120-375-14

PANELS (CONT.)

LOCATION/ITEM

INSPECTION, SERVICE AND REPAIR

11. Air Filter Panel

a.

Inspect for loose or damaged insulation.

b.

Replace damaged insulation material and

secure insulation with adhesive in accordance with

item 2, table D-1.

c.

Inspect hinge for damage and freedom of

movement.

d.

Lubricate hinge as required.

Inspect information plates for damage.

e.

f.

If damaged notify Direct Support Maintenance.

Inspect turnlock fasteners for damage.

g.

h.

Replace damaged turnlock fasteners.

i.

Inspect panel for damage.

ACTION

REMARKS

Repair or replace if damaged.

j.

4-28

Page 63

TM5-4120-375-14

PANELS (CONT. )

------------------------------------------------------------------------LOCATION/ITEM

ACTION

REMARKS

INSPECTION, SERVICE AND REPAIR

—

12. Maintenance Panel

a.

Inspect

b.

Replace

gaskets

item 2,

c.

Inspect

Replace

d.

secure insulation with adhesive in accordance with

item 2, table D-1.

e.

Inspect information plates for damage.

f.

If damaged notify Direct Support Maintenance.

Inspect turnlock fastener for damage.

g.

h.

Replace damaged turnlock fastener.

i.

Inspect panel for damage.

for loose or damaged gaskets.

damaged gasket material and secure

with adhesive in accordance with

table D-1.

for loose or damaged insulation.

damaged insulation material and

Repair or replace if damaged.

j.

4-29

Page 64

TM5-4120-375-14

PANELS (CONT.)

LOCATION/ITEM

-------------------------------------------------------------------------------

ACTION

REMARKS

INSTALLATION

13. Left Side Panel

a.

Align holes in left side panel (22) with holes in

frame.

b.

Secure left side panel with twenty-seven

screws (23).

14. Maintenance Panel

a.

Align holes in maintenance panel

(21) with holes in

left side panel and frame.

b.

Secure maintenance panel with eight turnlock

fasteners (20).

4-30

Page 65

PANELS (CONT.)

TM-4120-375-14

LOCATION/ITEM

INSTALLATION

15. Air Filter Panel

a. Align holes in air filter panel (19) with holes in

b.

16. Top Panel

a. Align holes in top panel with holes in frame.

b.

c. Align four lifting ring covers (13) with top

Rubber washers are to be placed between lifting ring cover and top panel.

ACTION

REMARKS

frame.

Secure air filter panel with two screws (17)

and two turnlock fasteners (18).

Secure top panel (14) with twenty-three screws (16)

and eight screws (15).

panel and frame.

NOTE

4-31

Page 66

TM5-4120-375-14

PANELS (CONT.)

LOCATION/ITEM

INSTALLATION

ACTION

REMARKS

17. Right Side Panel

18. Front Panel

Align holes in right side panel (10) with holes in

a.

frame.

Secure right side panel with thirty-one

b.

screws (9).

holes

Align holes in front panel (8) with

a.

b.

Secure front panel with thirty-four

in frame.

screws (6)

and two screws (7).

4-32

Page 67

PANELS (CONT.)

TM5-4120-375-14

LOCATION/ITEM

19. Control Box

Connect electrical connector (P-6) to control box.

a.

b.

Align holes in control box

panel and frame.

c.

Secure control box with four screws (4) and

four screws

20. Evaporator Fan Guard

Align holes in evaporator fan guards (2) with holes

a.

in front panel

b.

Secure evaporator fan guards with eight

screws (1).

ACTION

(3).

(8)

REMARKS

(5) with holes in front

and frame.

4-33

Page 68

TM5-4120-375-14

4-16.

CONTROL BOX

------------------------ --------------------- --------- --------------------------

This task covers:

a.

Removal

b.

Test/Inspection

c.

Installation

-------------------- ------------------------ ------------------------ -----------INITIAL SETUP

Test Equipment

None

Tools

TOOL KIT (SC 5180-90-C-N18)

References

None

Troubleshooting References

None

Special Environmental Conditions

None

General Safety Instructions

Turn air conditioner OFF before performing maintenance.

LOCATION/ITEM

ACTION

REMARKS

----------------- ------------------------------ --------------------------------REMOVAL

Control Box

1.

a.

Remove four screws (1) and four screws (2)

securing control box (3) to frame and front panel.

Disconnect electrical connector

b.

(P-6).

c.

4-34

Page 69

TM5-4120-375-14

CONTROL BOX (CONT.)

---------------------------------------------------------------------------LOCATION/ITEM

ACTION

REMARKS

REMOVAL

Rotary Switch

2.

Remove eight screws (4) securing control box

a.

back panel (5) to control box.

b.

Loosen two set screws (6) securing rotary switch

knob (7) to rotary switch (10).

c.

Remove knob (7).

d.

Remove nut (8) and washer (9) securing rotary switch

to control box.

e.

Tag and remove wires from rotary switch terminal

numbers 11, 12, and 13.

f.

Remove rotary switch (10) from control box.

Control Box

3.

Wiring Harness

Remove four screws (11) and four lock nuts (12)

a.

securing control box wiring harness (13) to

control box back panel (5).

Remove control box wiring harness.

b.

4-35

Page 70

TM5-4120-375-14

LOCATION/ITEM

REMOVAL

4.

Thermostat

ACTION

REMARKS

a. Tag and remove wires from thermostat.

b. Remove three flat nuts (14) and three star

(16)

washers (15) securing thermostat

to control

box .

c. Remove thermostat.

4-36

Page 71

CONTROL BOX (CONT.)

TM5-4120-375-14

LOCATION/ITEM

TESTING/INSPECTION

Rotary Switch

5.

ACTION

REMARKS

a. Place knob in the OFF position.

b. Check for the lack of continuity between terminals

11 and 12, 11 and 13, and 12 and 13.

c. Place knob in the FAN position.

d. Check for continuity between terminals 11 and 12.

Check for lack of continuity between terminals

11 and 13 and 12 and 13.

e. Place knob in the COOL position.

f.

Check for continuity between terminals 11 and 12

and 11 and 13.

Replace defective rotary switch.

g.

4-37

Page 72

TM5-4120-375-14

CONTROL BOX (CONT.)

LOCATION/ITEM

TESTING/INSPECTION

Thermostat

6.

ACTION

a.

Place thermostat in ambient temperature of 80 -90 F

REMARKS

(28-32 C).

b.

Place temperature control on thermostat in

WARM position.

c.

Check for continuity between terminals COM and NC.

d.

If lack of continuity is found replace defective

thermostat.

e.

Place temperature control on thermostat in the COOL

position.

f.

Check for continuity between terminals COM and NO.

If lack of continuity is found replace defective

g.

thermostat.

h.

Place thermostat in ambient temperature of 40 -50 F

(4-10 c).

i.

Place temperature control on thermostat in the WARM

position.

Check continuity between terminals COM and NC.

j.

k.

If lack of continuity is found replace defective

thermostat.

1.

Place temperature control on thermostat in the COOL

position.

m.

Check continuity between terminals COM and NO.

n.

If lack of continuity is found replace defective

thermostat.

4-38

Page 73

CONTROL BOX (CONT.)

TM5-4120-375-14

LOCATION/ITEM

TESTING/INSPECTION

Control Box

7.

a. Inspect

Replace

b.

gaskets

item 2,

c. Inspect

Replace

d.

ACTION

for loose or damaged gaskets.

damaged gasket material and secure

with adhesive in accordance with

table D-1.

for loose or damaged insulation.

damaged insulation

❑ aterial and

REMARKS

secure insulation with adhesive in accordance with

item 2, table D-1.

e. Inspect information plates for damage.

f.

If damaged notify Direct support maintenance.

Inspect panel for damage.

g.

h. Repair or replace damaged panel.

i. Inspect chain assembly for damage.

Replace if damaged.

j.

4-39

Page 74

TM5-4120-375-14

CONTROL BOX (CONT.)

LOCATION/ITEM

INSTALLATION

Thermostat

8.

ACTION

a Align thermostat (16) with holes in control box (3).

b Attach two wires to proper terminals on thermostat

and one wire to thermostat mounting stud.

c. Secure thermostat and wires with three flat

nuts (14) and three star washers (15).

REMARKS

4-40

Page 75

CONTROL BOX (CONT.)

TM5-4120-375-14

LOCATION/ITEM

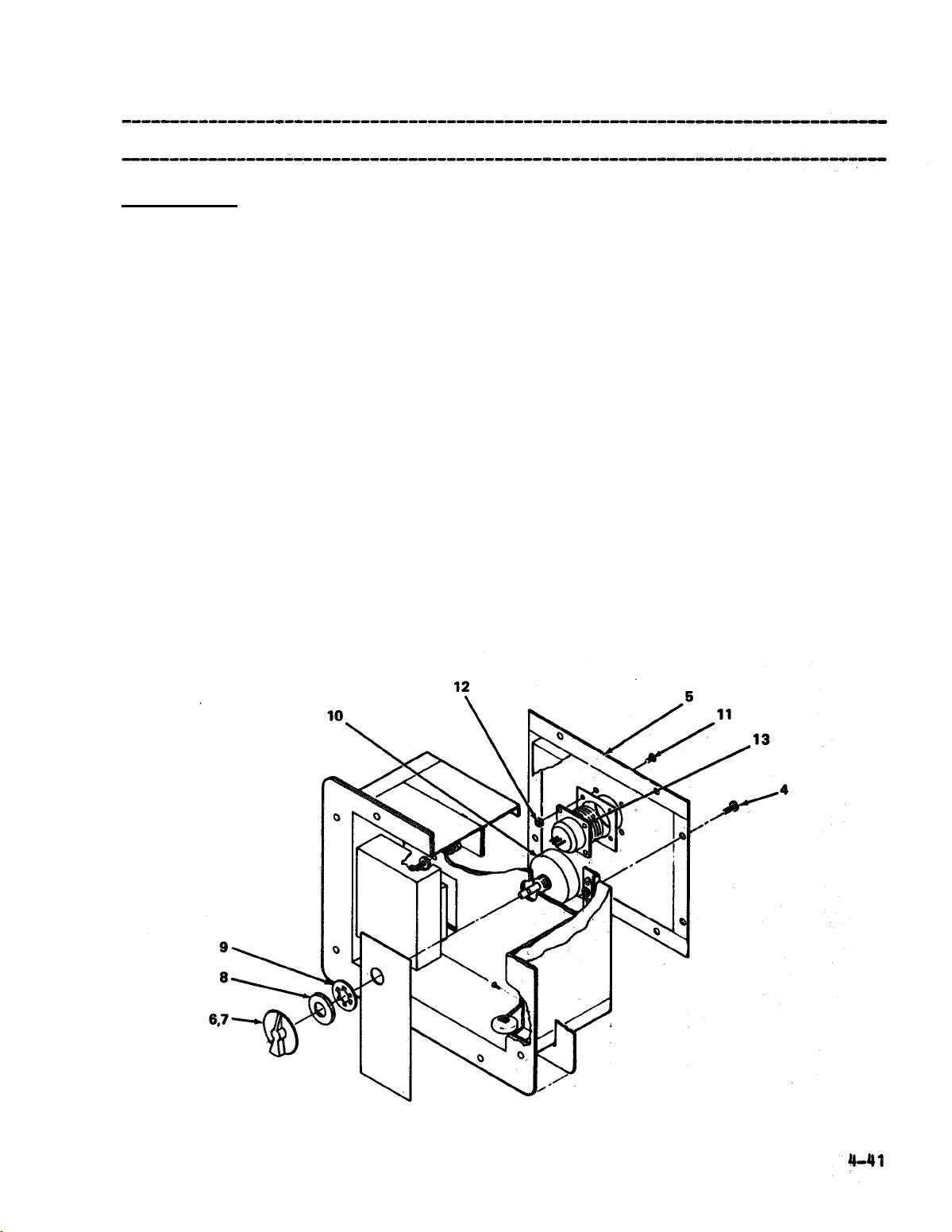

INSTALLATION

Rotary Switch

9.

10. Control Box

Wiring Harness

ACTION

Attach wires to terminal numbers 11,12 and 13.

a.

Align rotary switch (10) with hole in control box.

b.

Secure rotary switch to control box with

c.

REMARKS

star washer (9) and retaining nut (8).

Attach rotary switch knob to rotary switch.

d.

Secure rotary switch knob (7) to

e.

tightening two set screws (6) on

rotary switch by

rotary switch

knob .

Align control box wiring harness

a.

(13) with control

box back panel (5).

b.

Secure control box wiring harness to control box

back panel with four screws (11) and four

screws (12).

4-41

Page 76

TM5-4120-375-14

CONTROL BOX (CONT.)

LOCATION/ITEM

ACTION

REMARKS

--------------------------------------------------------------------------------

INSTALLATION

110 Control Box

a. Align control box (3) with holes in frame.

b. Secure control box with four screws (2)

and four screws (l).

4-42

Page 77

4-17.

TM5-4120-375-14

4-43

Page 78

TM5-4120-375-14

EVAPORATOR FAN GUARD (CONT.)

LOCATION/ITEM

INSPECTION

Evaporator Fan Guard

2.

INSTALLATION

Evaporator Fan Guard

3.

ACTION

REMARKS

a. Inspect for damage.

b. Repair or replace if damaged.

a. Align evaporator fan guard (2) with holes in

front panel (3) and frame.

b. Secure evaporator fan guard with four

screws (l).

4-44

Page 79

4-18.

TM5-4120-375-14

4-45

Page 80

TM5-4120-375-14

CONDENSER COIL GUARD (CONT.)

------------------------- ------------------------ -------------------------- ----LOCATION/ITEM

ACTION REMARKS

-------------------- -------------------- ------------------------- ---------------

INSPECTION

Condenser Coil Guard

2.

a. Inspect for damage.

b. Repair or replace if damaged.

INSTALLATION

Condenser Coil Guard

3.

a. Align condenser coil guard (3) with

holes in frame.

b. Secure condenser coil guard

with sixteen screws (1)

and two screws (2).

4-46

Page 81

4-19.

TM5-4120-375-14

4-47

Page 82

TM5-4120-375-14

AIR FILTERS (CONT.)

LOCATION/ITEM

INSPECTION AND SERVICE

Air Filters

2.

a. Spray filters with a water hose in opposite

b. Shake water from filter and allow to dry before

c. Inspect for

d. Replace if damaged.

Do not use oil on filters.

ACTION

REMARKS

direction of air flow (See arrow on filter frame)

installing.

damage.

CAUTION

NOTE

Note position arrow on filter frame when installing air filters.

Arrow must point toward evaporator coil.

4-48

Page 83

4-20 DAMPERS AND CONTROLS

THIS TASKS COVERS:

a. Removal

b. Inspection and repair

c. Installation

INITIAL SETUP

Test Equipment

None

Tools

TOOL KIT (SC 5180-90-C-N18)

References

None

Troubleshooting References

None

Special Environmental Conditions

None

General Safety Instructions

Turn air conditioner OFF before performing maintenance.

TM5-4120-375-14

LOCATION/ITEM

REMOVAL

Right Side Panel

1.

ACTION

a. Remove thirty-one screws (1) securing

right side panel (2) to frame.

REMARKS

4-49

Page 84

TM5-4120-375-14

DAMPERS AND CONTROLS (CONT.)

-------------------- ------------------------ ------------------------- ----------LOCATION/ITEM

ACTION

REMARKS

-------------------------------------------- ------------------------ -----------REMOVAL

Lifting Ring

2.

Covers

a.

Remove eight screws

(3)

and eight rubber washers (4)

securing lifting ring cover (5) to top panel (6)

and frame.

Remove lifting ring cover.

b.

Top Panel

39

a.

Remove twenty-three screws (7) and eight

screws (8) securing top panel (6) to frame.

b.

Remove top panel.

4.

Left Side Panel

a.

Loosen bottom center turnlock fastener (9)

in maintenance panel (10).

Remove twenty-seven screws (11) securing left

b.

side panel (12) to frame.

c.

Remove left side panel.

4-50

Page 85

DAMPERS AND CONTROL (CONT.)

TM5-4120-375-14

LOCATION/ITEM

REMOVAL

Left Return Air Damper

5.

ACTION

Loosen two screws (13) on mechanical post (14)

a.

REMARKS

securing control cable (15) to left return air

damper (16) and fresh air damper.

Remove two screws (17) securing left

b.

return air damper to frame.

Loosen screw (18) securing control cable housing (19)

c..

to control mechanism (20).

Pull control cable through control cable housing

d.

until it clears mechanical post on left return air

damper.

Remove left return air damper.

e.

Page 86

TM5-4120-375-14

DAMPERS AND CONTROLS (CONT.)

--------------------------------------------- ---------------------------- ------LOCATION/ITEM

ACTION

REMARKS

-------- --------------------------------- ----------------------------- ---------REMOVAL

Left Fresh Air Damper

6.

and Screen

a.

Loosen screws (21) on mechanical post (22) securing

control cable (23) to left return air damper and

fresh air damper (24).

b.

Pull control cable through control cable housing

until it clears mechanical post on left return air

damper.

c.

Remove four screws (25) and four nuts (26)

securing left fresh air damper (24) and

screen to frame.

Remove fresh air damper and screen.

d.

4-52

Page 87

DAMPERS AND CONTROLS (CONT.)

TM5-4120-375-14

LOCATION/ITEM

REMOVAL

ACTION

a.

Loosen screws (27) on mechanical post (28) securing

REMARKS

control cable (29) to left return air damper (30) and

fresh air damper (31).

b.

Loosen set screw (33) on control cable knob (34).

C..

Remove control cable knob.

d.

Remove retaining nut (35) and

control cable (37) to damper

e.

Remove one screw (39) and one look nut (40)

star washer (36) securing

control box (38).

scouring clamp (41) to frame,

f.

Remove clamp (42) from control cable housing

(43).

Slide control cable and housing out of unit.

Change 1

4-53

Page 88

TM5-4120-375-14

DAMPERS AND CONTROLS (CONT.)

LOCATION/ITEM

REMOVAL

8.

Damper Box

ACTION

a.

Remove four screws (47) and four screws (48)

securing control box

b.

Disconnect electrical connector (P-6) from back of

(49) to

frame and front panel.

REMARKS

control box.

c.

Remove control box.

d.

Remove thirty-four screws (50) and two screws

(51)

securing front panel

e.

Remove front panel.

(52)

to frame.

4-54

f. Remove two screws (54) securing damper box (55)

to frame.

g. Remove

Page 89

a.

b.

c.

d.

TM5-4120-375-14

e.

4-55

Page 90

TM5-4120-375-14

DAMPERS AND CONTROLS (CONT)

____________________________________________ _________________________

LOCATION/ITEM

ACTION REMARKS

_______________________________________________________________________________

REMOVAL

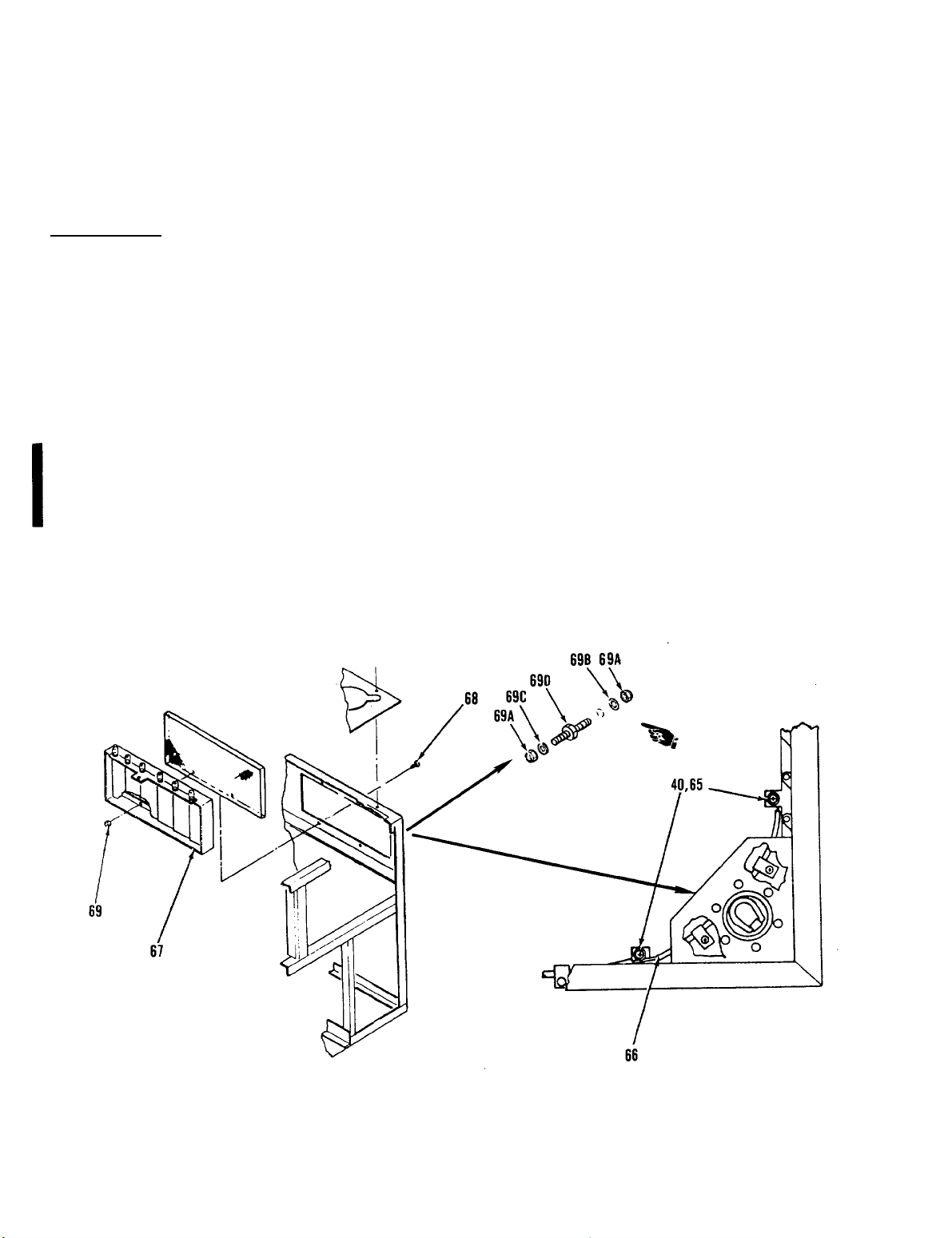

10. Right Fresh Air

Damper and Screen a.

Loosen screws (40) on mechanical post (65) securing

control cable (66) to right return air damper and

fresh air damper (67).

b.

Pull control cable through control cable housing

until it clears mechanical post on right return air

damper.

c.

Remove four screws (68) and four nuts (69)

securing right fresh air damper and

screen to frame.

Remove two lock nuts (69A), lock washer (69B),

d.

flat washer (69C), and grounding stud (69D).

Remove fresh air damper and screen.

e.

4-56

Change 1

Page 91

TM5-4120-375-14

Change 14-57

Page 92

TM5-4120-375-14

DAMPERS AND CONTROLS (CONT.)

LOCATION/ITEM

INSPECTION AND REPAIR

12. Damper Control and Cable

a. Inspect for freedom, of movement, lubricate if

b. Tighten loose mountings.

c. Replace defective controls.

13. Damper

a. Inspect for freedom of movement.

b. Inspect for damage.

c. Straighten bent louver blades.

d. Inspect for damaged gaskets.

e. Replace damaged gasket material and secure

ACTION

REMARKS

required (Table D-1, Item 17).

gasket with adhesive (Table D-1, Item 2).

f. Replace damaged damper.

4-58

Page 93

TM5-4120-375-14

DAMPERS AND

LOCATION/ITEM

CONTROLS (CONT.)

ACTION

NOTE

c.

Secure control cable housing (88) to frame with

one screw (80) and one locknut (81) and one clamp

(82).

REMARKS

d.

Align control cable (73) with damper box.

damper

control box

and star washer (77).

f.

Attach control cable knob to

Tighten set screw on control

g.

h.

Tighten screws (71).

control cable (73).

cable knob.

Change 1

4-59

Page 94

TM5-4120-375-14

Change 1

DAMPERS AND CONTROLS (CONT.)

--------------------------------------------------------------------------LOCATION/ITEM

ACTION REMARKS

------------------------------------------------------------------------------------------

INSTALLATION

15. Right Fresh

and Screen

Air Damper

a. Align right fresh air damper (67) and

b.

c.

d.

screen to frame.

Secure right fresh air damper and

screen to frame with four screws (68)

and four locknuts (69).

Install grounding stud (69D), flat washer (69C),

lock washer (69B), and two lock nuts (69A).

Secure control cable (66) to right fresh air

damper with mechanical post (65) and

tighten screw (40).

4-60

Page 95

DAMPERS AND CONTROLS (CONT.)

TM5-4120-375-14

LOCATION/ITEM

INSTALLATION

16. Right Return Air Damper

a. Align right return air damper (59) to frame.

b. Secure right return air damper to frame

c. Slide control cable (58) into unit insuring that

d.

ACTION

REMARKS

with two screws (60).

cable passes through mechanical post (57) on

right return air damper.

Secure control cable to right return air damper

with mechanical post and tighten screw (40).

4-61

Page 96

TM5-4120-375-14

DAMPERS AND CONTROLS (CONT.)

LOCATION/ITEM

INSTALLATION

17.

Damper Box

ACTION

a.

Align damper box (55) with holes in frame.

b.

Secure damper box to frame with two screws (54).

c.

Align front panel (53) with holes in frame.

Secure front panel to frame with thirty–four

d.

REMARKS

screws (50) and two screws (51).

e.

Connect electrical connector (P-6).

f.

Align control box (49) with holes in front panel

and frame.

Secure control box to front panel and frame with

g.

4-62

Page 97

TM5-4120-375-14

LOCATION/ITEM

INSTALLATION

ACTION

NOTE

b.

c.

d.

Align control cable with damper box (38).

REMARKS

32

Secure control cable (29) to damper control box

e.

with retaining nut (35) and star

f.

Attach control cable knob (34) to control cable

washer

(36).

(29) .

Tighten set screw (33) on control cable knob.

Tighten screws (27).

Change 1

4-63

Page 98

TM5-4120-375-14

DAMPERS AND CONTROLS (CONT.)

-------------------------------------------------------------------------------LOCATION/ITEM

ACTION

REMARKS

—----- --------------------------------------------------------------------------

INSTALLATION

19.

Left Fresh Air Damper

and Screen

a. Align left fresh air damper (24) and

screen to frame.

b.

Secure left fresh air damper and

screen to frame with four screws (25)

and four locknuts (26).

c. Secure control cable (23) to left fresh air

damper with mechanical post

screw

(21)

on mechanical post.

(22) and tighten

4-64

Page 99

DAMPERS AND CONTROL (CONT.)

TM5-4120-375-14

LOCATION/ITEM ACTION

20. Left Return Air Damper

a.

Align left return air damper (16) to frame.

b.

Secure left side return air damper to frame

with two screws (17).

Slide control cable

cable passes through ❑ echanical post (14) on

left return air damper and fresh air damper.

Secure control cable to left return air damper

d.

with mechanical post and tighten screw

mechanical post (14).

e.

Align control cable housing (19) with control

mechanism (20).

f.

Secure control cable housing to control mechanism

with one screw (18).

REMARKS

(15)

into unit insuring that

(13) on

4-65

Page 100

TM5-4120-375-14

DAMPERS AND CONTROLS (CONT.)

LOCATION/ITEM

ACTION

REMARKS

------------------------ --------------------- --------------------------- -------INSTALLATION

21. Left Side Panel

Align holes in left side panel

a.

(12) and maintenance

panel (10) with holes in frame.

Secure left side panel with twenty-seven

b.

screws (11).

Tighten bottom center turnlock fastener

c.

(9)

on maintenance panel.

4-66

Loading...

Loading...