Takata Racing RACE 4 User Manual

INSTALLATION & OPERATING

INSTRUCTIONS

RACING Models

Edition: 08/2012

Part No: EA 12.2

T

HIS M A N UAL C O NTAI N S IMPO R T ANT

INFO R M ATION S HOW N A S

SAFETY INSTRUCTIONS contain important hints to help you to install, use

and maintain the TAKATA Racing Harness properly and effectively.

This harness belt, when properly installed and used according to

applicable instructions can minimize injury. The ability of any

restraint system to minimize or prevent injuries is directly related

to the type and severity of accident. No restraint system can

prevent injury or death in every accident.

Racing harness belts are NOT designed to be installed into street

legal vehicles, and DO NOT meet federal and state vehicle safety

regulations. They are designed and tested to be used exclusively in

race cars and only in on-track events.

“This article is sold without warranty, express or implied, including

but not limited to the implied warranties of merchantability and

fitness for a particular purpose, all of which are specifically

disclaimed, and no warranty or representation is made as to this

product’s capability to protect the user from any injury or death.

Racing is dangerous! The user assumes the risk.

WARNINGS deal with important issues about installation, use,

misuse or modification of the racing harness.

Ignoring these WARNINGS will significantly reduce the

performance of the racing harness system. This can result in

serious personal injury or death during an accident.

Always read carefully and follow the information in

this manual, especially those highlighted as above.

A

B O U T T H E I M P O R T A N C E

O F T H I S M A N U A L

TAKATA Racing has attempted to make this racing harness manual extensive

and comprehensive. We have created it to help the reader understand racing

harness installation, use and maintenance, and how it relates to safety in

motorsports. Intensive research and experience in motorsports has led us to

prepare up-to-date instructions for optimized anchor point locations and racing

harness design features. What was considered acceptable in the early and mid1990s has changed and evolved as the result of currently available data.

Therefore, we ask the drivers, mechanics, teams and race car manufacturers to

read and heed the information in this manual carefully. Safe and effective use

of a Head And Neck Restraint also depends on specific restraint routing and

anchor point locations.

“The sanctioning body regulating the motorsport series in which you

are participating may have additional information specific to your

chassis. All information in this document is based upon the best

knowledge as of August 2012.”

!

1 2

1. DO Y

H

The installation procedures explained in this manual assume that you have the

knowledge, experience and tools required to install racing harnesses. If you do

not have the knowledge, experience and/or tools required or do not understand

the instructions, do not install the harness belt – have the harness belt system

installed by a professional who will be able to do the job correctly. Your safety

and the safety of others who will use the harness belt system are at stake!

Always heed all WARNING and SAFETY INSTRUCTION boxes. Always read

and heed all instructions in this manual carefully. Failure to follow WARNING,

SAFETY INSTRUCTIONS and all other instructions could result in severe

personal injuries and death.

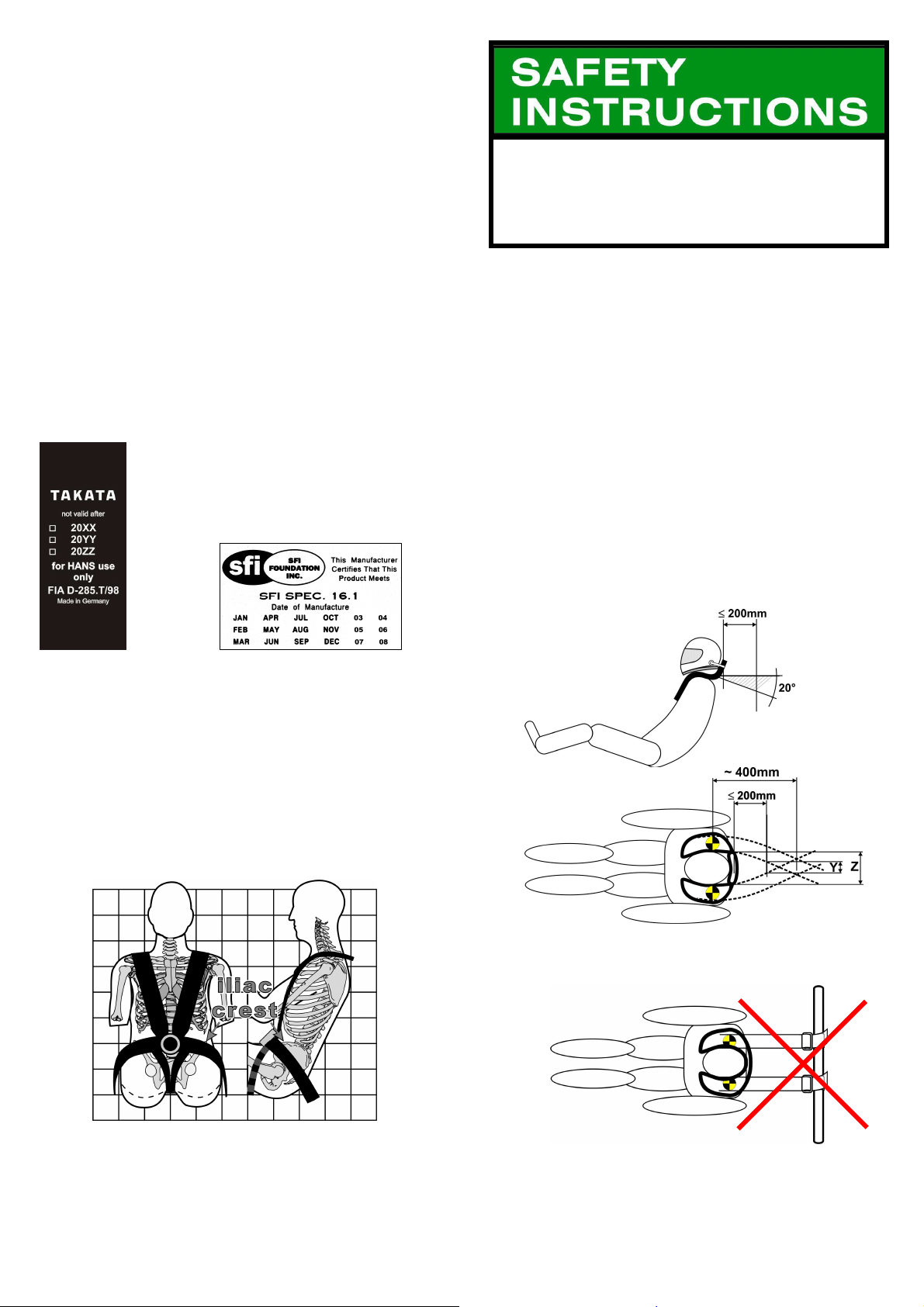

Approvals for racing harnesses are granted by sanctioning bodies like FIA and

SFI. Some TAKATA racing harness models are approved by multiple sanctioning

bodies and therefore may carry multiple labels. One of these labels should apply

to the motor sport in which you are participating.

FIA

Racing harnesses manufactured for motor sport in countries, or for racing series

that fall under the FIA regulation, must carry the appropriate FIA labels.

FIA-labelled belts are valid for five [5] years from last day of the year of

manufacture unless regulated differently by the sanctioning body of the motor

sport in which you are participating. The last year of FIA validity is indicated on

the label. Each separate strap assembly is labelled.

SFI A

Racing harnesses specifically manufactured for motor sport requiring SFI 16.1 or

OU HAVE EXPERIENCE INSTALLING RACING

ARNESSES

HOMOLOGATED RACING HARNESSES

?

PPROVED RACING HARNESSES

SFI 16.5 approval are tested and labelled accordingly.

These racing harnesses MUST be replaced two [2] years

after the month and year of manufacture. The date of

manufacture is indicated on all three SFI labels – [1] at the

lap belt, [2] at the shoulder harness and [3] at the anti-sub

strap.

Example of a FIA label Example of a SFI Label

Label will be marked with Label will be marked with

valid year valid month and year

A

NCHORAGE LOCATIONS AND GEOMETRIES

B

ELT ROUTING

An occupant can be effectively restrained ONLY by load transfer through the

hard points of the occupant’s body. The only accessible hard points are the

following:

• pelvic

• thorax [chest] to a limited level only

• clavicle [shoulders]

Therefore, it is essential that strap routing be optimised as described in the

following graphs.

Optimal performance of your racing harness requires proper installation and

proper use. Heed and obey the following instructions with respect to racing

harness geometry and routing.

• Bracket installation and operation.

• Wearing the racing harness.

• Adjusting the racing harness.

L

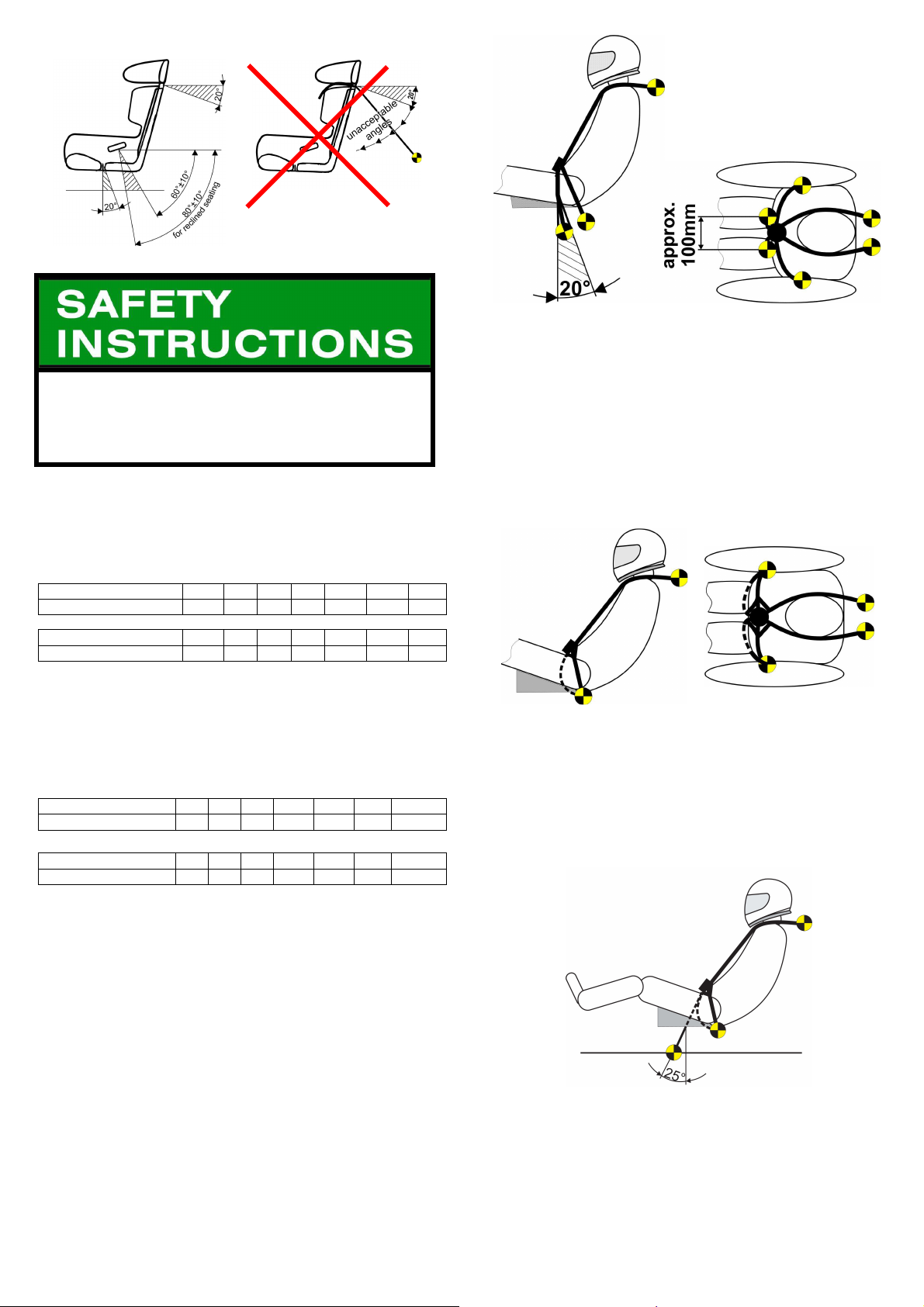

AP BELT ROUTING

Lap belt straps must be routed over the pelvic bone to stay firmly and tightly in

the crest between the pelvic bone and the upper thigh.

Lap belt downward angle should be approximately 60° measured from the

horizontal, passing through the occupant’s hip joint. This is the suggested

angle for upright seating [15-20° backrest declinat ion]. A higher backrest

declination, e.g. 30° – 40°, as is common in open w heel race cars, requires a

belt angle of 70° – 80°.

Make sure there are no sharp edges [seat structure, seat mounts, chassis]

that may tear or cut the lap belt webbing.

S

HOULDER BELT ROUTING

Shoulder belts must run from the shoulders horizontally or down, at no more

than a 20° angle.

For the best restraint of the occupant’s upper torso, anchor points should not

be further back than 200 mm [8”] from back of user’s seat.

In the event that the anchor points are further towards the rear of the vehicle

[e.g. using a roll cage bar for wrap around attachment] the distance between

the strap anchorages will narrow or even cross over as described in following

graphs.

It is especially crucial to follow this strap routing when a Head And Neck

Support is in use.

3 4

Shoulder belt mountings, located more than 200 mm [8”] from the back of the

user’s seat or angled upwards, are not good practice and are most strongly

discouraged. If shoulder belt anchor points are further back in the vehicle, the

belts should be closer together at their mounting points, even crossing

depending on the distance of the anchor points, but both belt and Head And

Neck Support performance are severely compromised. See Table Below

Shoulder belts shall cross over when the anchor points are located more

than approx. 500 mm [20”] behind the seat backrest.

For 75 mm [3”] webbing wrap around installation the following approx. anchor

point distances are suitable:

Reduce numbers by 25mm [1”] if a Head And Neck Support specific harness is

to be installed.

In metric measure

Distance from seat in mm

Anchor point distance in mm

In imperial measure

Distance from seat in inch

Anchor point distance in inch

side

200 300 400 500 600 700 800

150 100 75 75 -75 -100 -150

8 12 16 20 24 28 32

6 4 3 3 -3 -4 -5

by side

side by

side

crossed

over

crossed

over

crossed

over

F

OR

75

MM

[3”]

WEBBING BOLT ON INSTALLATION

Reduce numbers by 25mm [1”] if a Head And Neck Support specific harness is

to be installed.

In metric measure

Distance from seat in mm

Anchor point distance in mm

In imperial measure

Distance from seat in inch

Anchor point distance in inch

200 300 400 500 600 700 800

150 100 50 0 -50 -100 -150

8 12 16 20 24 28 32

6 4 2 0 -2 -4 -6

Single

crossed

point

over

crossed

over

crossed

over

F

ORMULA MODELS

This anti-sub strap design requires sitting on the straps or having a thin seat

panel allowing the straps running rearwards right underneath the driver’s buttock

and attaching in the region near or on the lap belt anchorages.

The anti-submarining strap routing over the upper thighs and attachment to the

shoulder belt latches with the buckle in between, does not provide a direct load

path from the shoulder belts down to the anti-submarining strap anchor points.

The indirect routing requires a type of preloading of the anti-submarining straps

during a frontal impact. This is achieved by sitting on the anti-submarining straps,

routing them rearwards and attaching them in the region near or on the lap belt

anchorages.

Important: This anti-sub strap design requires sitting on the straps or having a

thin seat panel allowing the straps running rearwards right underneath the

driver’s buttock.

N

EGATIVE G BELT

(7

TH

POINT

)

Used in conjunction with a 6-point formula crotch belt system as an additional

point to maintain the position of the lap belt in “Negative G” i.e. rollovers

A

NTI-SUB STRA P ROUTING

6-

POINT MODELS WHERE ANTI-SUB STRAPS ARE CONNECTED TO THE

BUCKLE

Anti-submarining strap routing shall be vertical down from the groin, and

preferably approximately 20° back,

Anchor points shall be approximately 100 mm [4”] lateral apart from each other.

In case of a low seating position (e.g. in open wheel race cars), this separation

may be reduced since the anchor points are closer to the thighs.

5 6

Loading...

Loading...