INSTALLATION & OPERATING

INSTRUCTIONS

TUNING Models

Edition: 08/2012 Part No: EA 12.1

This harness restraint is manufactured in accordance to the European

Standard ECE-R 16.04 and/or FMVSS 209. It must only be installed in

cars on front outer seating positions and must only be used by adult

occupants [minimum age of 12] and a weight of at least 40 kg [88 lbs].

Please heed national laws and DOT requirements when installing this

product.

This harness restraint is not approved or intent to be used by children

less than 12 years of age or less than 40 kg [88 lbs] of weight.

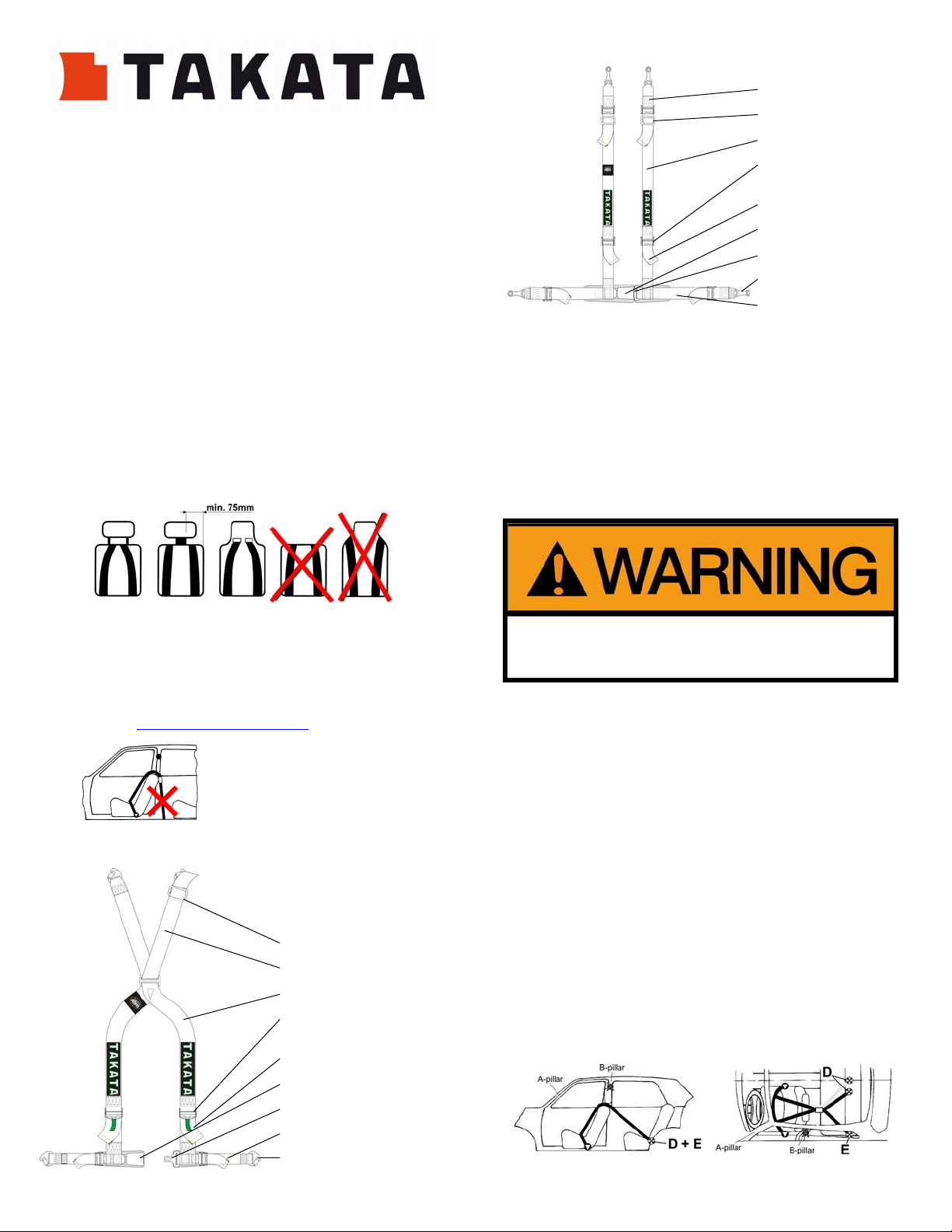

SEAT REQUIREMENTS

Harness belt systems must not be installed in vehicles equipped with

seats which do not have adjustable head restraints or seats with

backrests with integrated head restraints where there are no openings for

the shoulder belts. The seatbelts will not function properly in these type

of seats. Shoulder belts will tend to slip off the shoulders. Never create

a new opening in the seats installed in your car.

DRIFT II [bolt-on]

Definitions:

tail strap

basic 3-bar adjuster

shoulder belts

shoulder belt tilt lock

adjusters

adjustment strap ends

buckle

buckle tongue

bolt-on brackets

lap belt

INSTALLATION

ANCHOR POINTS, BOL TS AND THREADS:

These harness restraints are designed for installation to OEM stock

anchor points providing threads with the dimension of 7/16“ 20 UNF.

Bolts supplied match with this 7/16” 20 UNF thread size. Self-drilled

holes may be too weak or may be in an incorrect or dangerous

geometrical location. TAKATA does not take any responsibility for the

adequate performance of such anchor points. Always check for the

proper length of bolts used, the stock thread must be fully filled by the

bolt. Tighten 7/16” bolts with a torque of 40 Nm (30 ft-lb)

When shoulder belts are installed to rear seat lap belt anchorages, the

front seat backrest must be able to take load applied by the shoulder

belts during an accident. Tested and approved seats must be used for

such installation only. Horizontal installation of shoulder belts is preferred

(to a roll-cage or approved harness bar).

[A list of approved stock and special seats can be obtained from the

TAKATA website www.takataracing.com/seat-list

right right right wrong wrong

]

Never install shoulder belts

directly to the floor behind the

seat!

DRIFT III [snap-on]

Definitions:

basic 3-bar adjuster

tail strap

shoulder belts

shoulder belt tilt lock

adjusters

adjustment strap ends

buckle

buckle tongue

lap belt

snap-on brackets

Incorrect thread dimensions, using bolts that are too short

or not properly tightened bolts may result in belt failure

during an accident. Severe injuries or death may occur.

LAP BELT ANCHOR POINTS

1. Anchor points to the car centre/middle

They are either located to the centre tunnel or to the seat structure

close to the seat rail.

2. Outer/Outboard anchor points

They are either located to the door sill or to the seat structure close to

the seat rail. In case of a 2-door car with a lap belt slide-bar at the

door sill, use the front slide attachment point for harness restraint door

side lap belt installation.

SHOULD ER BELT ANCHORAGES

1. Shoulder belt anchor points for harness restraints with 2 tail

straps.

The rear seat lap belt anchor points [D & E] are available for

installation. Always install the shoulder belts [Drift II] crossing over to

prevent the shoulder belts from slipping off the shoulders during

normal wear as well as during an accident.

1 2

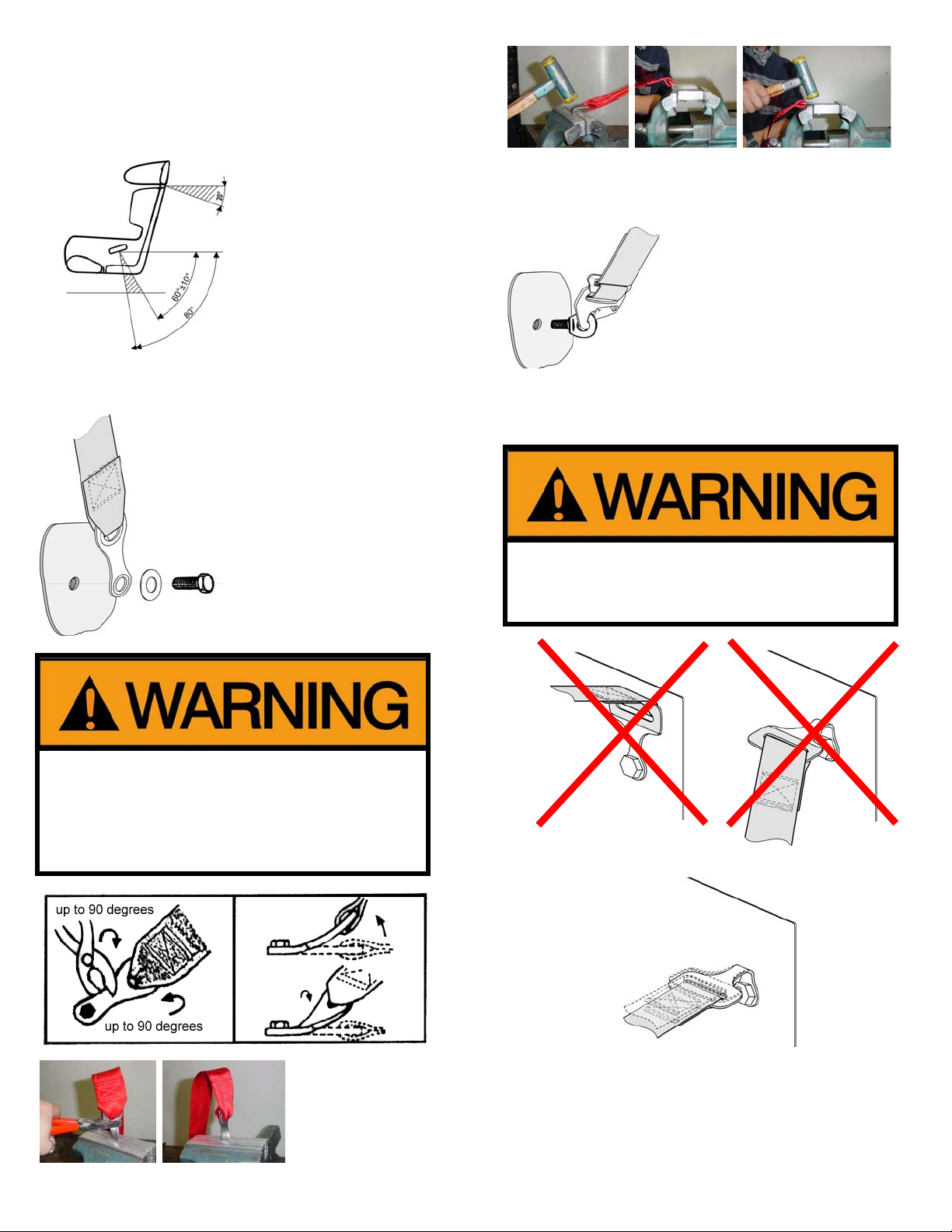

2. Other anchor points

Self-drilled anchor points or anchor points to a roll cage or harness bar

must meet the following requirements to provide adequate

performance:

a) Strength: > 14.7 kN [3200 lbs] each

b) Geometry:

Lap belt shall route between 60°

and 80° down

Shoulder belts routing shall be

horizontal and not more than –

20° down.

Route shoulder belts symmetrically to seat centre line

backwards.

INSTALLATION OF BRAC KETS

1. Stainless Steel Bolt-on Bracket Installation

washer

bolt

The brackets are made from

special stainless steel so they

can be pre-bent at installation

to the direction of pull of the

webbing where it is attached to

the bracket as the belt flows

over the body.

Proper alignment of the

webbing pull through the

bracket reduces the bending

stress [risk of fatigue cracks] to

anchor points during driving

and during an accident.

2. Snap-on bracket with eye bolt Installation

The eye bolt must be positioned so the

snap-on bracket can hook into the eye

with enough freedom for the bracket to

move into the direction of pull. The

snap-on bracket must be allowed to

fully align with the webbing routing

when loaded.

3. Bending Procedure

Brackets which are restricted in alignment to the direction

of pull may be damaged or cut during an accident causing

complete or partial belt failure during an accident.

Severe injuries or death may occur.

Do not bend bracket back and forth several times. Multiple

bends in opposite directions will weaken the material and

the bracket may fail during an accident.

Make sure the webbing is not damaged during bracket

bending or the webbing may fail during an accident.

Severe injuries or death may occur.

3 4

WRONG WRONG

CORRECT

Loading...

Loading...