Commercial Gas

Tankless Water Heaters

Designed specifically for commercial applications. Fully

modulating, gas-fired, tankless, water heaters with sealed

combustion (optional) and power vented flue. Can be

installed indoors, outdoors, or direct vent. Capable of

supplying hot water for domestic hot water systems

(directly or indirectly) using water storage tanks,

recirculations systems, hydronic heating systems, radiant

floor heating systems, and/or combined domestic & heating

applications (local codes dictate proper compliance).

FEATURES

HEAT EXCHANGER IS

CONSTRUCTED OF HRS35

COMMERCIAL-GRADE COPPER*

■ Stronger than standard copper

and more resilient against erosion

CONTINUOUS MAXIMUM FLOW

RATES UP TO 14.5 GPM

EASY-LINK UP TO 4 UNITS

MULTI-LINK UP TO 10 UNITS

WITH TM-MC01

COMBINED INDOOR/

OUTDOOR MODELS

AVAILABLE IN NATURAL GAS OR

PROPANE

ASME MODELS AVAILABLE

LOW NOx EMISSIONS

COMPLIES WITH LEAD FREE

STANDARDS

SAFETY FEATURES:

■ Built in Freeze Protection

■ Manual Reset Hi-Limit

(Set at 194°F)

■ Overheat Cutoff Fuse

■ Inlet and Outlet Thermistors for

Constant Temperature Monitoring

■ Air-Fuel Ratio Rod

■ GFI, Fuse, and Surge Absorber

■ Flame Sensor

*only on non-asme products

Page 1 of 2 www.takagi.com TCGSS00413

VENTING AND COMBUSTION

■ 5” Category III Vent

■ Vertical or Horizontal Installation

■ 50’ Max Length, 5 Elbows max

(90° elbows = 5’ equivalent length)

■ Power Vent

■ Electronic Ignition - No Pilot Light

■ 5” Combustion Air Intake (with

optional kit)

OPTIONAL ACCESSORIES

■ Multi-Unit Controller, TM-MC01

(Part Number 9007675005) for

systems of 5-10 heaters

■ Remote Temperature Controller

(9007603005)

■ Direct Vent Conversion Kit

■ Pipe Cover

■ Vent Cap

■ Backflow Preventor

■ Concentric Termination Kits

WARRANTY

■ 15-year limited warranty on heat

exchanger in residential

applications

■ 10-year limited warranty on heat

exchanger in commercial

applications

■ 5-year limited warranty on all parts

T-M50

ANSI Z21.10.3

CSA 4.3

Commercial Gas

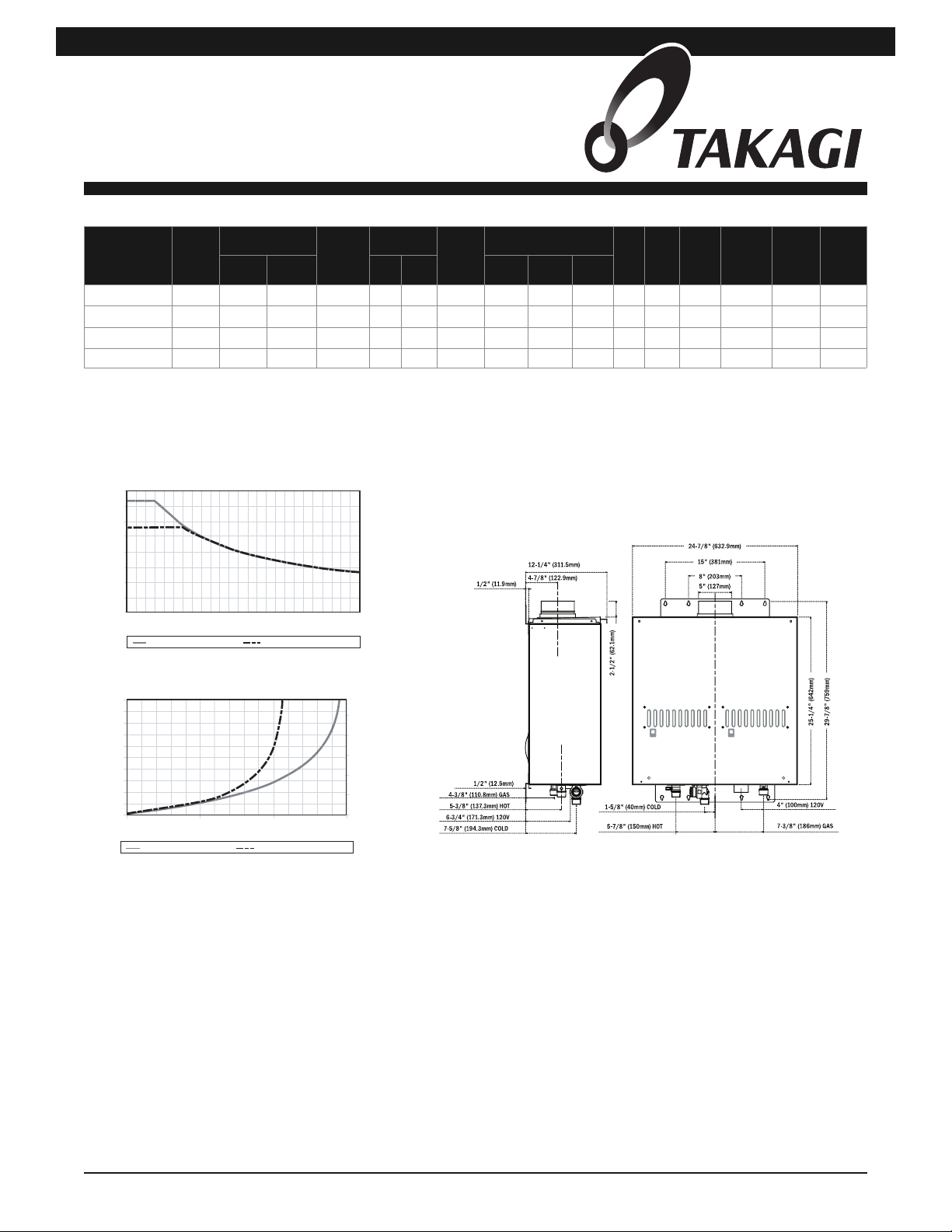

Flow Rate Vs. Temperature Rise

Flow Rate (gpm)

Temperature Rise (°F)

Flow Rate (gpm)

Pressure Loss (psi)

Above shown rate is based on single unit only

Pressure Loss

Set temperature of 145° or lower Set temperature of 150° or higher

0

25 456585 105 125145

2

4

6

8

10

12

14

16

10.0

5.0

0.0

0

20

40

15

25

0

10

10

20

30

50

5

15.0

Set temperature of 145° or lower Set temperature of 150° or higher

Tankless Water Heaters

MODEL

NUMBER

FUEL

TYPE

GAS CONSUMPTION

INPUT

MIN.

BTU/H

MAX.

BTU/H

THERMAL

EFFICIENCY

INLET GAS

PRESSURE

MIN.

in. w.c.

MAX.

in. w.c.

DIMENSIONS IN INCHES

MAX

HEIGHT WIDTH DEPTH

GPM*

VOLT AMP FLUE**

INTAKE

(OPTIONAL)

HOT/COLD

GAS

CONN.

SHIPPING

T-M50-N Natural 15,000 380,000 80% 5.0 10.5 0.5-14.5 24-7/8 25-1/4 12-1/4 120 1.48 5” O.D. 5” O.D. 1” NPT 113

T-M50-P Propane 15,000 380,000

T-M50-N ASME Natural 15,000 380,000

T-M50-P ASME Propane 15,000 380,000

All dimension in inches.

15-150 psi water pressure. 40 psi or above recommended for maximum flow.

*Current numbers based on factory testing, 0.5 GPM required for activation, 0.4 GPM required for continuous fire after initial ignition.

**Category III required

Pressure only relief valve required (Min. 380,000 BTUs. 150 PSI).

82% 8.0 14.0 0.5-14.5 24-7/8 25-1/4 12-1/4 120 1.48 5” O.D. 5” O.D. 1” NPT 113

80% 5.0 10.5 0.5-14.5 24-7/8 25-1/4 12-1/4 120 1.48 5” O.D. 5” O.D. 1” NPT 113

82% 8.0 14.0 0.5-14.5 24-7/8 25-1/4 12-1/4 120 1.48 5” O.D. 5” O.D. 1” NPT 113

CLEARANCES:

INDOOR: Top 12”, Bottom 12”, Front 24”, Back 0.5”, Sides 2”

OUTDOOR: Top 36”, Bottom 12”, Front 24”, Back 0.5”, Sides 2”

APPROX.

WEIGHT

(LBS)

The fully modulating, on-demand, gas fired tankless water heater(s) shall be Takagi Tankless Water Heater model T-M50 or T-M50-ASME, having a maximum input rating of 380,000 Btu/h

and available in NG or LP. The heater shall have 1 in. male NPT water and gas connections. The inlet gas supply pressures shall be 5.0 in. WC (min.) up to 10.5 in. WC (max.) for NG and

8.0 in. WC (min.) up to 14 in. WC (max.) for LP. The heater(s) can use an accessory temperature remote, TM-RE30/9007603005, that can be installed up to 400 ft. from the heater using 18

gauge (minimum) control wire. The temperature remote shall provide diagnostic information, fault history, and heater set temperature. The heater(s) shall operate using 120 V / 60 Hz

power source.

The heater(s) shall be vented with 5” diameter Category III vent pipe with a length not to exceed 50 ft. (equivalent), terminating horizontally or vertically. The heater(s) can be direct

vented with optional direct vent conversion kit, TM-DV50/9007669005, using 5” diameter pipe. The intake pipe may use material such as PVC, ABS, aluminum, or Category III pipe

and cannot exceed 50 ft. (equivalent) length. The outdoor installation shall use a vent cap, TM-VC50/9007677005.

The water heater(s) shall contain two separate combustion sections for built-in redundancy, each section containing a copper, fin tube heat exchanger with quick release brass or bronze

waterways. The heater(s) shall be controlled by onboard solid-state printed circuit boards which use the following factory installed components: thermistors to monitor water

temperature; flow sensors to measure flow rate; flame sensors to monitor combustion; Air-Fuel Ratio Rod to measure and adjust air input in order to maintain optimal combustion

efficiency. The heater also consists of inline fusing and surge absorbers for electrical surge protection, electronic spark igniters, aluminized stainless steel burners, hi-limit temperature

switches, modulating gas valves, dual freeze protection that will automatically fire the heater (indoor direct vent model only) and use heating blocks to protect the heat exchanger,

and overheat cutoff fuses.

The heater(s) can manifold to Easy-Link up to 4 heaters to provide additional capacity. The Easy-Link controls shall be built onto the onboard solid-state printed circuit board and does

not require external controls. The linking control wire shall be supplied with the heater. The heater(s) can use a Multi-Unit controller, TM-MC01/9007675005, to manifold 5-10 heaters.

The Easy-Link and Multi-Unit Controller shall modulate the system for the most efficient performance. The Easy-Link and Multi-Unit Controller shall rotate the priority heater every

12 hours of operation time or 100 starts for balanced duty/cycle operation.

The heater(s) shall be CSA approved for sale in the United States and Canada, have a minimum thermal efficiency of 80%, meets ASHRAE 90.1-2007, complies with Low NOx emissions

of 40 ng/J or 55 ppm, and shall be certified to NSF 5 Standards. The T-M50 ASME shall be certified by ASME with the HLW stamp.

Page 2 of 2 www.takagi.com TCGSS00413

Head (ft)

Specification

Loading...

Loading...