TANKLESS

PRODUCT GUIDE

SAVE

ENERGY.

Energy-efficient, plentiful, and

endless supply of hot water.

Takagi has delivered innovative hot water solutions for

more than 70 years, and is sold exclusively by plumbing

wholesalers and contractors. Takagi’s selection of residential

and commercial tankless water heaters are unmatched for

SAVE

SPACE.

Compact size and wall-mounted to

free up valuable floor space.

SAVE

MONEY.

The smart choice that will save you a

substantial amount of energy.

1

quality and diversity. Anywhere hot water is needed, Takagi

provides an energy-efficient solution with long-lasting value

for years after installation. Takagi stands behind its products

and customeras with world-class service, combining cutting-

edge technology with committed people who take pride in

being the very best.

TANKLESS ADVANTAGE

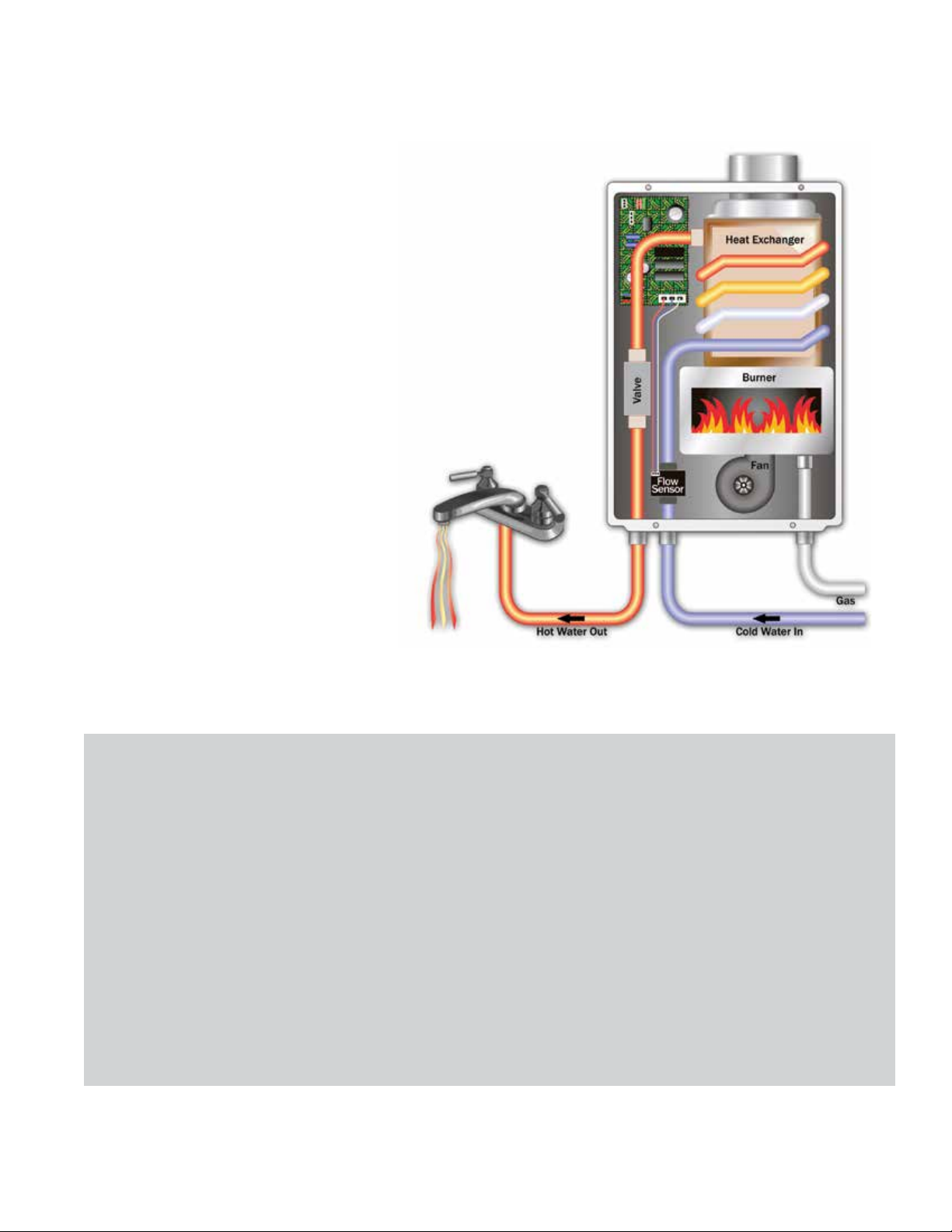

HOW IT WORKS – THE PROCESS:

• A hot water tap is opened.

• The opened tap allows water to flow

through the water heater. An internal

water flow sensor detects this flow.

• Upon flow detection, the flow sensor

sends the activation signal to the

computer board.

• The computer automatically ignites the

burner.

• As water flows through the heat

exchanger, it absorbs heat from the

burner.

• By the time the water exits the heater,

it has reached the designated set

temperature.

• When the hot water tap is closed, the

water heater automatically turns off.

ENDLESS

HOT WATER

Heating water only as it’s being used

means you will never run out of hot

water again. After the few seconds

it takes for the water to reach the

designated set temperature, our

water heaters will continually provide

a steady flow of hot water for as

long as your application needs it.

*Takagi tankless water heaters provide endless hot

water when sized appropriately for your home’s

needs.

ENERGY

CONSERVATION

Provides you with continuous hot water

in one of the most energy-efficient

ways possible. Conventional tank-type

water heaters will heat and store a set

volume of water, regardless of whether

someone is using that hot water or not.

Because our tankless water heaters

only activate when hot water is being

used, no standby energy losses are

incurred, providing efficient heating

while conserving energy.

COMPACT

SIZE

On top of all this, an Takagi tankless

water heater takes up much less space

than your conventional tank-type water

heater or boiler. Takagi’s wall-mount

design offers flexible installations

freeing up valuable storage space.

2

SAFETY

At Takagi, we place the safety and

reliability of our products above all else.

By incorporating technologically advanced

safety features into every model, we

provide the assurance and peace of mind

that can only come from an Takagi quality

product.

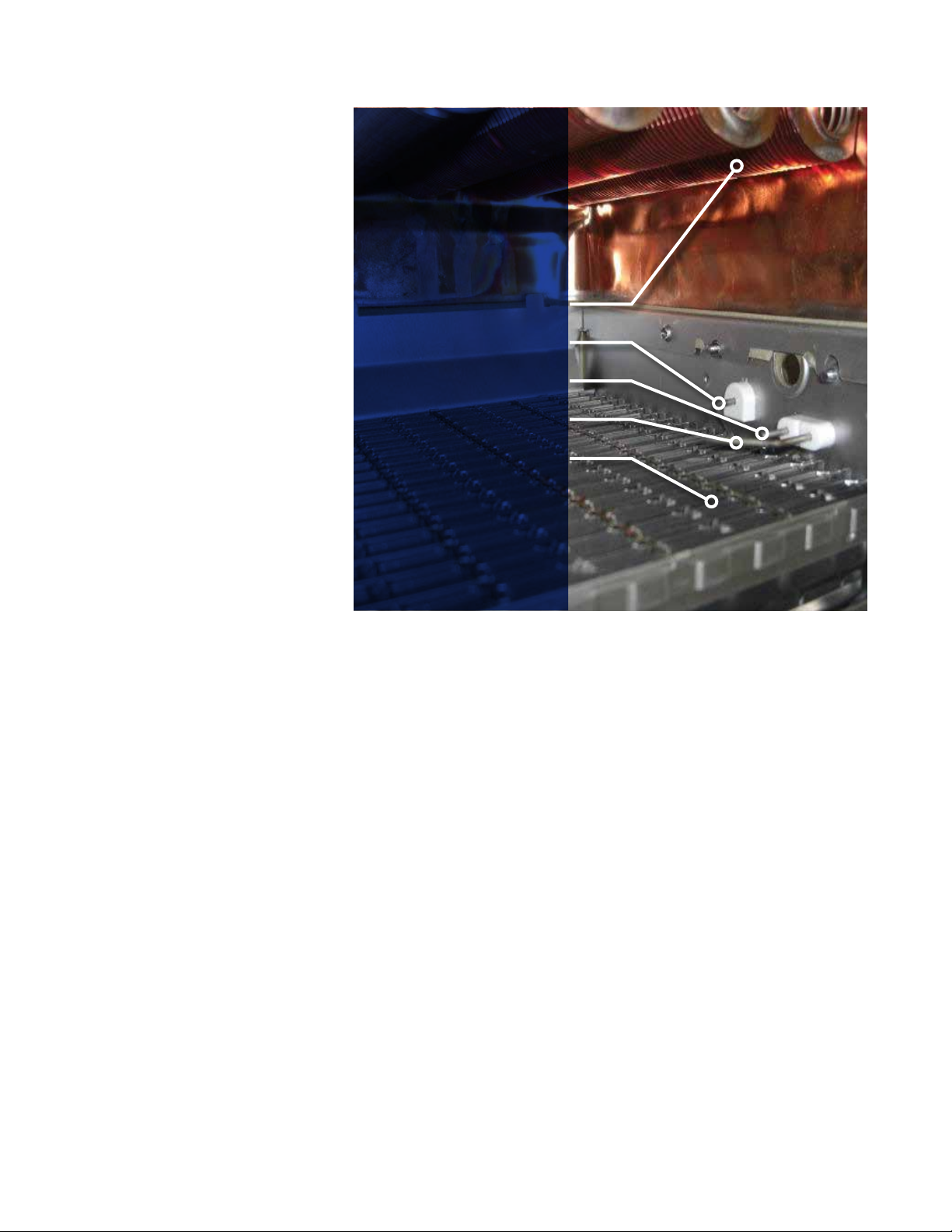

Air-Fuel Ratio (AFR)

Sensor

Takagi’s unique AFR sensor monitors and

maintains proper combustion at all times.

Together with the onboard computer, this

system will adjust the fan motor speed to

ensure that air and fuel have a proper

mixture ratio, minimizing emissions and

maximizing efficiency.

Additional Safety

Features

Freeze Protection:

Every heater in Takagi’s tankless lineup has

an internal freeze protection system, which

is rated to protect the heaters when installed

in sub-freezing conditions. This system

works to keep water temperatures within the

heat exchanger from falling below a certain

level, preventing freeze damage.

Hi-Limit Switch:

HEAT EXCHANGER

IGNITER

AFR

FLAME SENSOR

BURNER

Ensures that water temperatures do not exceed safe levels. Before the water temperature can even reach these unsafe levels,

the hi-limit switch activates by disengaging the gas valves, effectively shutting down the water heater.

PVC Venting:

Indoor condensing models have a thermistor and hi-limit switch that monitor the exhaust temperature. If the exhaust

temperature nears an unsafe limit, these features regulate combustion and can shut the heater down to protect the integrity of

the PVC vent material.

Overheat Cutoff Fuse:

Ensures that there are no breaches in the heat exchanger drum. In cases where enough physical damage might have been

done to the water heater to lead to a breach in the heat exchanger drum, the overheat cutoff fuse reacts by shutting down the

water heater if the surface of the heat exchanger retains too much heat.

3

0.016" (0.4mm)

0.020" (0.5mm)

water

water

drum coil

drum coil

drum

25% Thicker

DURABILITY

0.020" (0.5mm)

HEAT EXCHANGER WITH COMMERCIAL-GRADE COPPER

Only Takagi incorporates true commercial-grade heat exchangers in our tankless heaters (D2, 510U/C, or 510U, 510C,

H3, 540P, CT-199 and M50 non-ASME models). All aspects of the heat exchanger are designed to add the durability and

reliability that is vital to any successful commercial organization or business.

Commercial-Grade Copper Alloy

Our commercial-grade copper is a heat-resistant copper alloy, with additive elements that make it much stronger and harder

than the standard C1220 copper used in most other heat exchangers. Our commercial-grade copper has 8 times the tensile

strength of regular copper. Even at high temperatures, our commercial-grade copper maintains a fine grain and high strength.

Commercial-grade copper provides resistance to the damaging effects of erosion that can cause heat exchangers to leak.

Commercial-Grade Copper Tubing

Drum Thickness

During every ignition cycle, thermal expansion causes all heat exchangers to undergo heat stress. After the thousands of ON/

OFF cycles typically seen in a commercial application, this heat stress can prove damaging. This is why the heat exchangers

in our commercial and light commercial products utilize drums that are 25% thicker, ensuring the longevity of our products. A

thicker drum creates less strain on the heat exchanger.

A thinner drum strains more

under heat stress

drum

water

drum coil

water

drum coil

A thicker drum creates less

strain on the heat exchanger

water

drum coil

water

25% Thicker

drum coil

drum

4

WATER VALVES

Making true commercial-grade water heaters involves more than just redesigning our heat exchangers—every internal component

has to measure up to Takagi’s commercial standards. Just like our advanced heat exchangers, the longevity and functionality of

components such as our water valves and flow sensors are also of great importance.

Our commercial-grade water heaters (D2, 510U/C, 510C, and T-H3), as well as our commercial water heaters (CT-199

and T-M50) feature a bypass and flow adjustment valve, which not only provide the optimal control and precision essential for

commercial usage, but also offer the durability needed to handle tough, high-volume conditions.

Stepper Motor Water Valves -

M50 Models

5

Bypass Valve - D2/510U/510C,

CT-199 and H3 Models

Flow Adjustment - D2/510U/510C

CT-199 and H3 Models

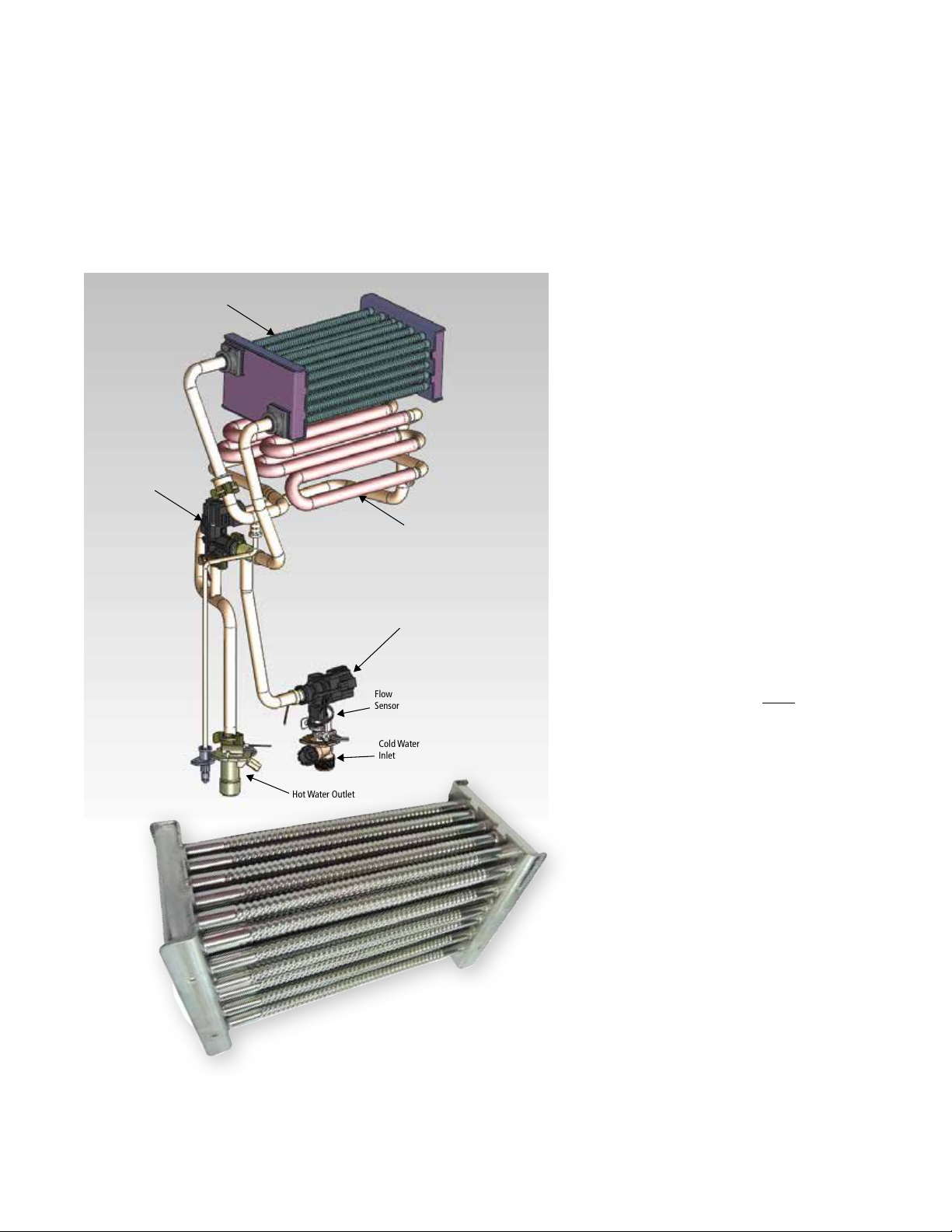

SECONDARY HEAT EXCHANGER 316L STAINLESS STEEL

(CONDENSING MODELS ONLY)

The secondary condensing heat exchanger is made of high-quality 316L stainless steel. This is where the rest of the heat

transfer occurs. Due to the lower temperature acidic condensation occurs, and stainless steel is required in order to avoid

corrosion.

For condensing heat exchangers, it is more suitable to use 316L stainless steel because of the extreme environment (heat,

acidic condensation, chloride) that the material is subjected to.

Secondary HX-Stainless Steel 316L

Bypass Valve

Hot Water Outlet

Flow

Sensor

Cold Water

Inlet

Primary HX

Commerical-Grade

Copper

Drum

Coil

Flow Adjustment

Valve

PRIMARY HEAT

EXCHANGER:

COPPER VS.

STAINLESS STEEL

• Heat transfers 25 times more readily

through copper than stainless steel.

Consequently, for the same amount

of heat transfer, stainless steel heat

exchangers need to be larger than

copper heat exchangers, leading to a

larger pressure loss.

• At higher temperatures, it is the nature

of stainless steel to become prone

to a number of problems not usually

experienced at room temperature. It is

vulnerable to pitting corrosion and stress

corrosion cracking (SCC).

• Stainless steel is NOT better for

durability because it is harder.

Hardness causes the material to

become brittle. Stainless steel will

crack after numerous cycles of

thermal expansion/contraction,

especially with chloride in the

water. Copper heat exchangers

are less brittle and better suited

for expansion/contraction without

cracking.

• In a

dual

heat exchanger design,

corrosion is not a big concern in

the non-condensing primary heat

exchanger because no condensation

forms on the exterior of the pipes.

Stainless steel is unnecessary for this

stage.

Note: H3M, H3J and H3S condensing line units use C1220

copper and do not have a bypass valve

* Diagram represents H3

6

WATER FLOW

Condensation can build up over time in any heat

exchanger, causing damage and premature leaks.

Takagi’s commercial models (M50 series) include

condensation reduction features that safeguard

against these types of damaging effects.

Better Water Pathway

Design

By redesigning and redirecting the flow of water,

the temperature of the heat exchanger drum and

finned coils stay elevated above dew point,

making it much more difficult for condensation to

build.

Fin Pitch

By widening the pitch of the heat exchanger fins,

not only do we improve durability by reducing

occurrences of blockage, we also maintain higher

temperatures on the upper finned coils. Keeping

these coils at elevated temperatures reduces the

likelihood of condensation buildup.

FIN

Finned Coil

90%-95% of total

heat absorbed)

Drum Coil

(5%-10%

of total heat

absorbed)

Hot Water Outlet

(100% heat absorbed)

No condensation

buildup on

drum coil

Burner

M

Bypass Valve

(M50)

Flow

Sensor

Cold Water Inlet

7

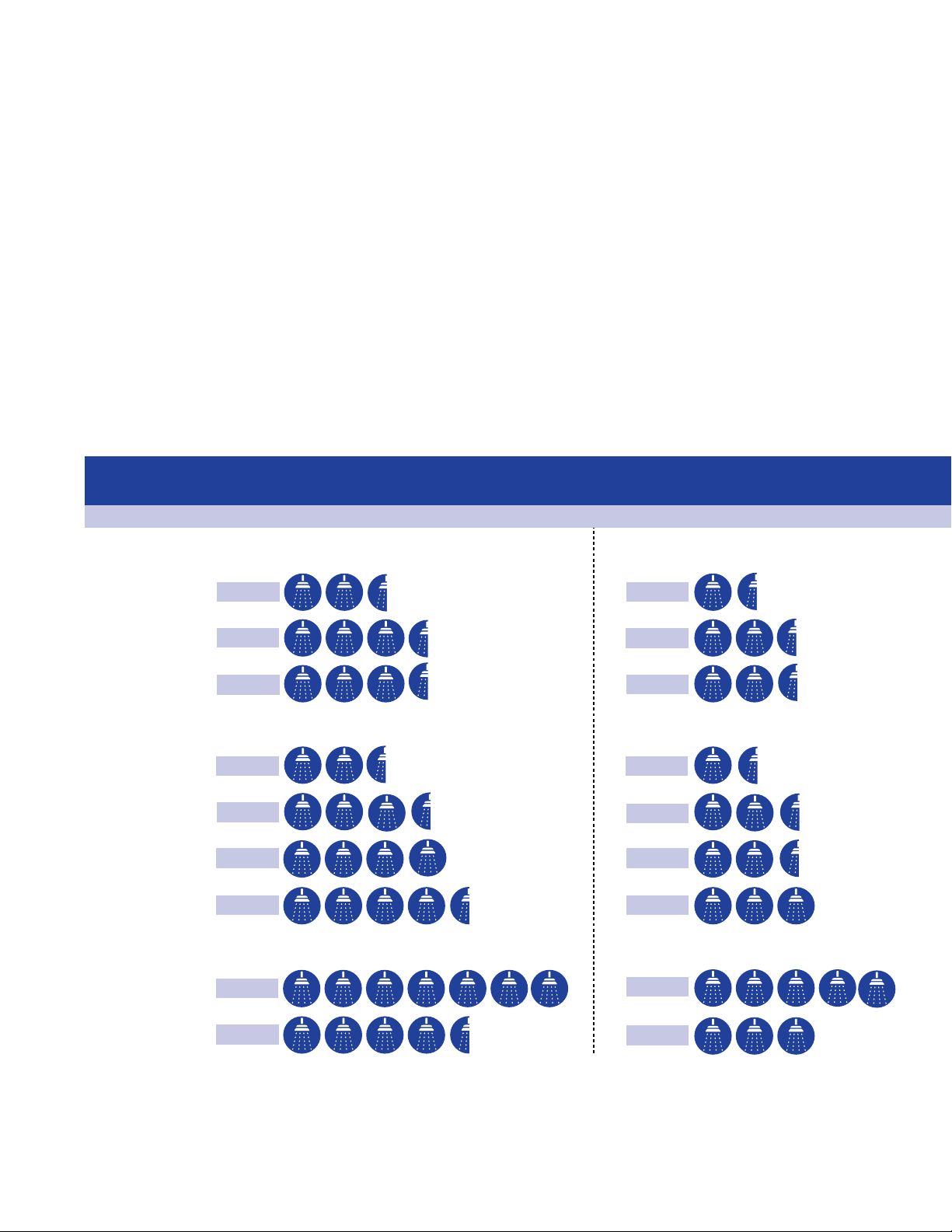

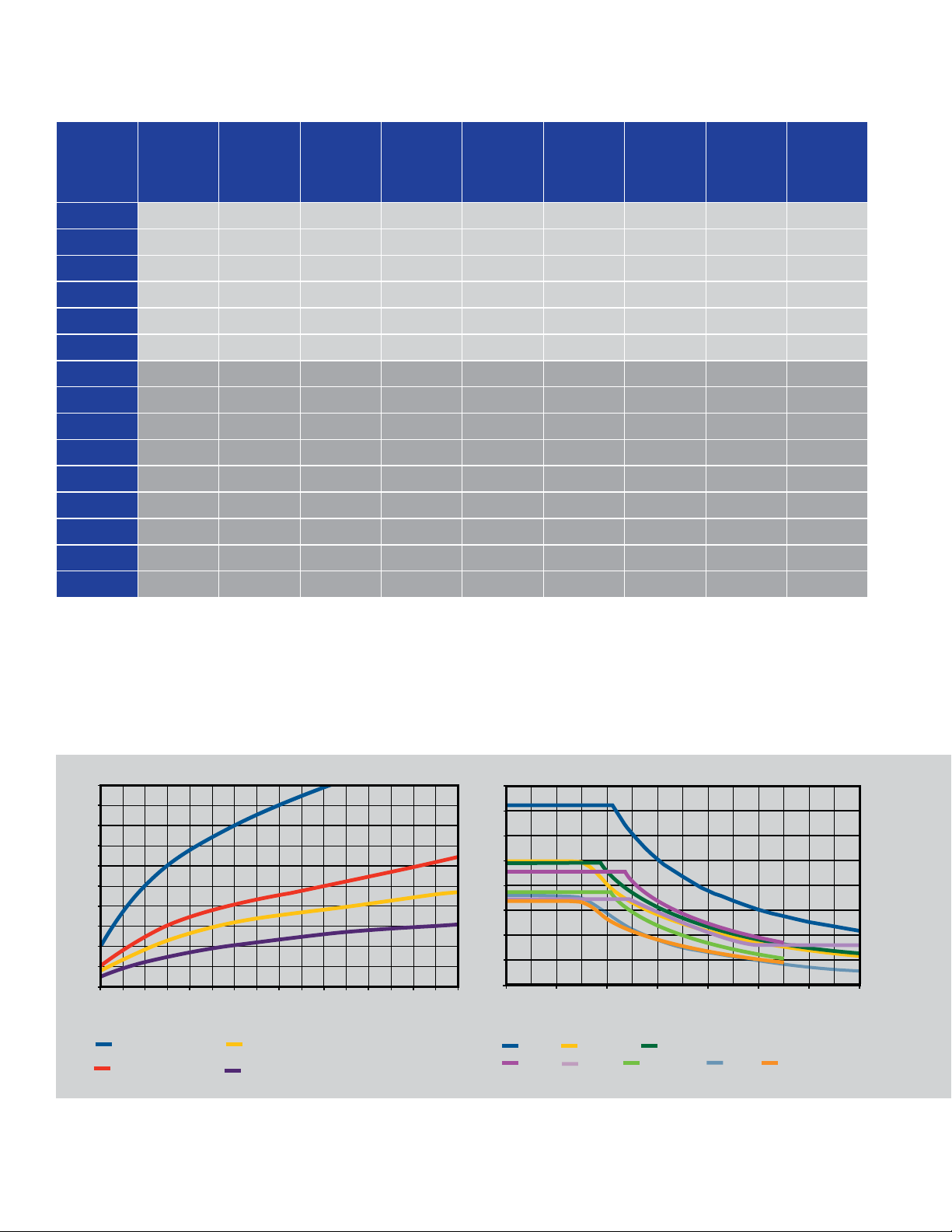

BASIC SIZING GUIDELINES

The flow rate capacity of tankless water heaters depends on

the temperature difference between the desired output and

incoming water temperature. The flow rate comparison chart

and table shown here summarize the flow rate charts found in

the specifications of each model.

Takagi water heaters are sized according to the peak flow

rate requirements, worst-case temperature-rise scenarios,

and types of applications. Once these factors have been

determined, refer to either the flow rate comparison here or

Application designers/engineers can decide whether

to size for full flow, expected flow, or utilize probability

models such as the modified “Hunter Curve.” For large

scale applications such as hotels, apartment complexes

and large restaurants, Hunter Curves are commonly used

to estimate the peak flow rate demand when given the

total amount of fixture units within an application. It is up

to the application designer/engineer to determine the

amount of fixture units within any given application.

the flow rate charts found in each model’s specifications.

Select the appropriate water heater as well as the amount of

water heaters required.

MATCH THE UNIT TO YOUR NEEDS

Warmer Climates

70°F Incoming Groundwater Temperature

Capacity - Number of Shower Heads

Non-Condensing Units

(Assuming the set point temperature is 120˚F )

Cooler Climates

50°F Incoming Groundwater Temperature

KJr2/110U/110C

K4/310U/310C

D2/510U/510C

Condensing Units

H3M

H3J

H3S

H3/540P

Commercial Units

M50

CT-199

2.5 Showers

3.5 Showers

3.5 Showers

2.5 Showers

3.5 Showers

4 Showers

4.5 Showers

7 Showers

4.5 Showers

1.5 Showers

2.5 Showers

2.5 Showers

1.5 Showers

2.5 Showers

2.5 Showers

3 Showers

5 Showers

3 Showers

8

FLOW RATE GUIDE

Temperature Rise vs. Gallons per Minute

Temp

Rise

30°

35°

40°

45°

50°

55°

60°

65°

70°

75°

80°

85°

90°

95°

100°

KJr2/

110U/

110C

K4/

310U/

310C

D2/

510U/

510C

H3M H3J H3S H3/540P CT-199 M50

6.6 8.0 10.0 6.6 6.6 8.0 10.0 10.0 14.5

6.6 8.0 9.3 6.4 6.6 8.0 10.0 10.0 14.5

5.7 7.8 8.1 5.6 6.6 8.0 9.5 9.5 14.5

5.1 6.9 7.2 5.0 6.6 7.6 8.4 8.4 13.5

4.6 6.2 6.5 4.5 6.1 6.8 7.6 7.6 12.2

4.2 5.7 5.9 4.1 5.5 6.2 6.9 6.9 11.1

3.8 5.2 5.4 3.7 5.1 5.7 6.3 6.3 10.1

3.5 4.8 5.0 3.4 4.7 5.3 5.8 5.8 9.4

3.3 4.4 4.7 3.2 4.3 4.9 5.4 5.4 8.7

3.1 4.1 4.3 3.0 4.1 4.6 5.0 5.0 8.1

2.9 3.9 4.1 2.8 3.8 4.3 4.7 4.7 7.6

2.7 3.7 3.8 2.6 3.6 4.0 4.4 4.4 7.2

2.5 3.5 3.6 2.5 3.4 3.8 4.2 4.2 6.8

2.4 3.3 3.4 2.3 3.2 3.6 4.0 4.0 6.4

2.3 3.1 3.3 2.2 3.0 3.4 3.8 3.8 6.1

Flow rate is determined by temperature rise. To determine your temperature rise, subtract the incoming water temperature from

the set output temperature. All units are factory set to 120°F or 122°F but can be changed.

Example of Hunter Curves for

Sizing Large Applications

100

90

80

70

60

50

40

30

Gallons Per Minute

20

10

0

0

Restaurants

Hospitals, Nursing Homes,

Dormitories, Hotels & Motels

75

25

50

125

150

175

225 325

200

Fixture Units

Apartments & Houses

Office Buildings & Schools

250

275

300

375

400

350100

Comparison of Flow Rates vs.

Temperature Rise

16

14

12

Flow Rate (gpm)

10

8

6

4

2

0

M50 D2/510U/510C H3/540P and CT-199

H3S K4/310U/310C

H3J

H3M

Temperature Rise (°F)

140120100806040200

KJr2/110U/110C

9

SIMPLE TANKLESS SIZING

TANKLESS MODELS

GROUND WATER TEMPERATURE

FACTO R

The temperature of incoming ground water

(cold water inlet temperature) varies greatly

throughout the U.S. and also fluctuates

with the changing of the seasons. The

temperature of water as it enters the

water heater will determine the amount of

“temperature rise” required to achieve the

desired hot water outlet temperature (120°F

is recommended).

The best way to measure incoming ground

water temperature is to use a thermometer

to measure cold water temperature during

the coldest season of the year. To simplify

the process, use this map to determine

whether your installation location is in the

Southern Zone, Central Zone or Northern

Zone.

PEAK HOT WATER DEMAND

The next step is to determine how many

gallons per minute of hot water will be

required during the busiest usage period

(peak demand). Consider all appliances

and fixtures that use hot water, including

lavatory faucets, kitchen faucets, washing

machines, dishwashers, showers and

bathtubs. Be sure to determine how many

appliances and fixtures will be used at the

same time (peak demand).

Average Ground Water Temperature

Average Ground Water

Temperature: 62°F to 77°F

Average Ground Water

Temperature: 52°F to 61°F

NORTHERN ZONESOUTHERN ZONE CENTRAL ZONE

Average Ground Water

Temperature: 37°F to 51°F

Remember, these are general recommendations. Your Takagi Water Heater Specialist can review your family’s

needs in even greater detail to make sure the model you choose will always provide enough hot water to meet

the demand.

10

KJR2 SERIES

The KJr2 Series is great for apartments, one bath homes in cold climates, condos and

summer cabins. A remote control is included as a standard feature.

T-KJR2-IN

Specifications

Gas Consumption Input Inlet Gas Pressure**

Model Number* Type

T-KJr2-IN-N Natural 19,500 140,000 4.0 10.5 0.79

Model Number*

T-KJr2-IN-N 6.6 3/4" NPT 3/4" NPT 12 12 3 4 38

*For propane models, change “N” to “P”

**For propane models, minimum inlet gas pressure is 8.0 in. W.C. and maximum inlet gas pressure is 14.0 in. W.C.

KJr2

Temperature

Settings

Electric 120 V

Maximum

GPM

Dipswitches 113°F 122°F (default) 131°F 140°F

With 100112183 remote (max. distance 150’ from heater, non-polarized 20 gauge wiring.)

99°F to 167°F (16 options), 122°F Default Factory Setting

Minimum

(BTU/H)

Hot/Cold

Connections

73 W / 0.61 A

(Operation)

Maximum

(BTU/H)

Gas

Connection

Minimum

(in. W.C.)

Clearances (in.)

Top Bottom Side Front

6 W / 0.05 A

(Standby)

111 W / 0.93 A

(Freeze-Protection)

Maximum

(in. W.C.)

Approx

Shipping

Weight (lbs)

UEF

11

ANSI Z21.10.3 • CSA 4.3

NON-CONDENSING

2-1/4" (56 mm) COLD

3-7/8" (98mm) GAS

4-7/8" (124mm) HOT

1" (26mm)

4" (102mm)

4-7/8" (123mm) 120V

7-3/4" (196mm)

2-1/4" (57mm)

Specifications

KJr2: Flow Rate vs. Temperature Rise

KJr2: Pressure Loss

Head (ft)

Indoor installation only

Power Vent or Power Direct Vent

Design

Low NOx Emissions

4” Category III Vent

Flow Rate up to 6.6 GPM

• Values based on factory testing. 0.4 GPM required

for continuous fire after initial ignition

Dimensions

13-3/4" (350mm)

10" (254mm)

4" (101 mm)

1-3/4" (45mm)1-3/4" (45mm)

2-1/4" (56mm)

Water Pressure: 15-150 psi

• Pressure Only Relief Valve Requires (Min 140,000 btu/h,

150 psi).

• 40 psi or above recommended for max. flow

Warranty

• 15-year limited warranty on heat exchanger in residential

applications.

• 5-year limited warranty on heat exchanger in commercial

applications.

• 5-year warranty on all parts.

• Refer to takagi.com for further warranty details

4" (102mm)

21-3/8" (544mm)

1-7/8" (47mm)

COLD 3-1/8" (79mm)

HOT 5-1/4" (133mm)

KJr2: Flow Rate vs. Temperature Rise

9.0

8.0

7.0

6.0

5.0

4.0

Flow rate (gpm)

3.0

2.0

1.0

0

Temperature rise (°F)

10 30

20-1/4" (520mm)

120V 1-3/8" (36mm)

GAS 4-7/8" (124mm)

50

70 90 110

100806040200.0

KJr2: Pressure Loss

50

45

40

35

30

25

20

Pressure Loss (psi)

15

10

5

0

Flow Rate (gpm)

2-1/4" (57mm)

1" (26mm)

2-1/4" (56 mm) COLD

3-7/8" (98mm) GAS

4-7/8" (123mm) 120V

4-7/8" (124mm) HOT

7-3/4" (196mm)

120

110

100

90

80

70

60

50

Head (ft)

40

30

20

10

0

8.06.0402.00.0

12

K4 SERIES

The K4 features a max flow rate of 8.0 gpm, providing enough hot water for a home with

up to three showers at the same time. A remote control is included as a standard feature.

T-K4-OS

T-K4-IN

Specifications

Gas Consumption Input Inlet Gas Pressure**

Model Number* Type

T-K4-IN-N Natural 11,000 190,000 4.0 10.5 0.80

T-K4-OS-N Natural 11,000 190,000 4.0 10.5 0.80

Model Number*

T-K4-IN-N 8 3/4" NPT 3/4” NPT 12 12 3 4 43

T-K4-OS-N 8 3/4" NPT 3/4” NPT 36 12 3 24 43

*For propane models, change “N” to “P”

**For propane models, minimum inlet gas pressure is 8.0 in. W.C. and maximum inlet gas pressure is 14.0 in. W.C.

K4

Temperature

Settings

Electric 120 V

Maximum

GPM

Dipswitches 113°F 122°F (default) 131°F 140°F

With 100112183 remote (max. distance 150’ from heater, non-polarized 20 gauge wiring.)

99°F to 167°F (16 options), 122°F Default Factory Setting

Minimum

(BTU/H)

Hot/Cold

Connections

88 W / 0.73 A

(Operation)

Maximum

(BTU/H)

Gas

Connection

6 W / 0.05 A

(Standby)

Minimum

(in. W.C.)

Clearances (in.)

Top Bottom Side Front

Maximum

(in. W.C.)

111 W / 0.93 A

(Freeze-Protection)

Approx

Shipping

Weight (lbs)

UEF

13

ANSI Z21.10.3 • CSA 4.3

NON-CONDENSING

Specifications

HOT

COLD 3-1/4" (84mm)

1-5/8" (43mm)

9-1/2" (241mm)

K4: Pressure Loss

Head (ft)

K4: Flow Rate vs. Temperature Rise

Indoor and Outdoor Installation Options

Power Vent or Power Direct Vent Design

Low NOx Emissions

4” Category III Vent

Flow Rate up to 8.0 GPM

• Values based on factory testing. 0.4 GPM required for

continuous fire after initial ignition

Water Pressure: 15-150 psi

• Pressure Only Relief Valve Requires (Min 190,000 btu/h,

150 psi).

• 40 psi or above recommended for max. flow

Dimensions

13-3/4" (350mm)

10" (254mm)

1-3/4" (45mm) 1-3/4" (45mm)

4" (101 mm)

1-3/8" (36mm)

Warranty

• 15-year limited warranty on heat exchanger in residential

applications.

• 5-year limited warranty on heat exchanger in commercial

applications.

• 5-year warranty on all parts.

• Refer to takagi.com for further warranty details

4-3/8" (113mm)

K4: Flow Rate vs. Temperature Rise

9.0

8.0

7.0

6.0

5.0

4.0

3.0

Flow rate (gpm)

2.0

1.0

0

10

Temperature rise (°F)

21-3/8" (544mm)

20-1/4" (520mm)

1-7/8" (47mm)

5-1/4" (133mm)

30

120V 1-3/8" (36mm)

GAS 4-7/8" (124mm)

50 70 90 110

100806040200.0

K4: Pressure Loss

50

45

40

35

30

25

20

Pressure Loss (psi)

15

10

5

0

1.0 3.0 5.0 7.0 9.0

Flow Rate (gpm)

1" (26mm)

COLD 2-7/8" (71mm)

120VAC 3-7/8" (99mm)

GAS 5-1/4" (135mm)

HOT 6-1/2" (164mm)

19-3/8" (493mm)

120

110

100

90

80

70

60

50

40

Head (ft)

30

20

10

8.06.0402.00.0

0

14

D2 SERIES

The D2 series is well suited for residential/commercial applications such as small restaurants

and beauty salons. Utilizing commercial grade copper alloy for the heat exchanger tubing, the

D2 series is also suitable for heavier residential usages such as combination space heating and

domestic recirculation systems. A remote control is included as a standard feature.

T-D2-INT-D2-OS

Specifications

Gas Consumption Input Inlet Gas Pressure**

Model Number* Type

T-D2-IN-N Natural 11,000 199,000 4.0 10.5 0.80

T-D2-OS-N Natural 11,000 199,000 4.0 10.5 0.80

Model Number*

T-D2-IN-N 10 3/4" NPT 3/4” NPT 12 12 3 4 45

T-D2-OS-N 10 3/4" NPT 3/4” NPT 36 12 3 24 45

*For propane models, change “N” to “P”

**For propane models, minimum inlet gas pressure is 8.0 in. W.C. and maximum inlet gas pressure is 14.0 in. W.C.

D2

Temperature

Settings

Electric 120 V 90 W / 0.75 A 6 W / 0.05 A

Maximum

GPM

Dipswitches 104°F 113°F 122°F (default) 140°F

With 100112155 remote (max. distance 400’ from heater, non-polarized 20 gauge wiring.)

100°F to 176°F (15 options), 122°F Default Factory Setting

Minimum

(BTU/H)

Hot/Cold

Connections

Maximum

(BTU/H)

Gas

Connection

Minimum

(in. W.C.)

Clearances (in.)

Top Bottom Side Front

Maximum

(in. W.C.)

111 W / 0.93 A

(Freeze-Protection)

Approx

Shipping

Weight (lbs)

UEF

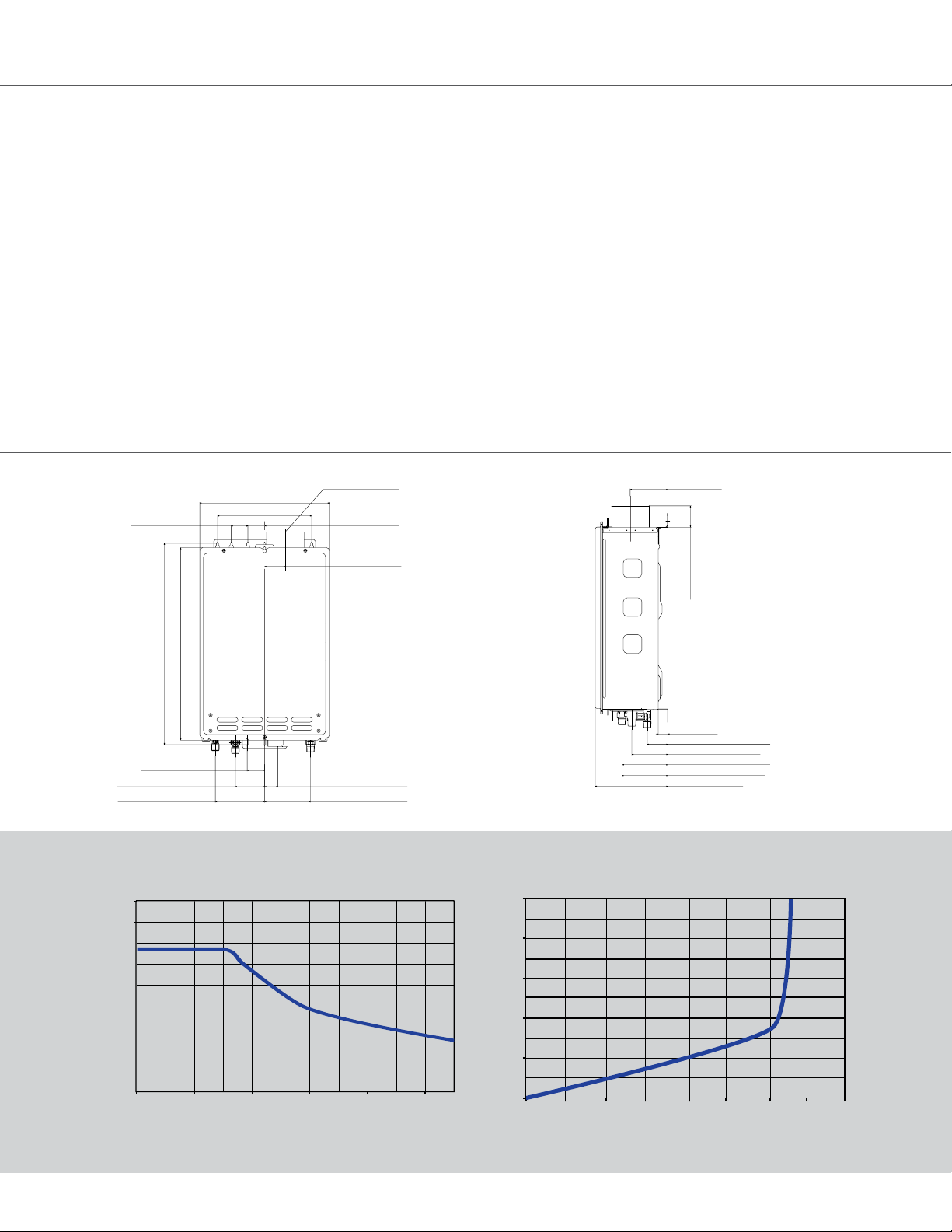

15

ANSI Z21.10.3 • CSA 4.3

NON-CONDENSING

Specifications

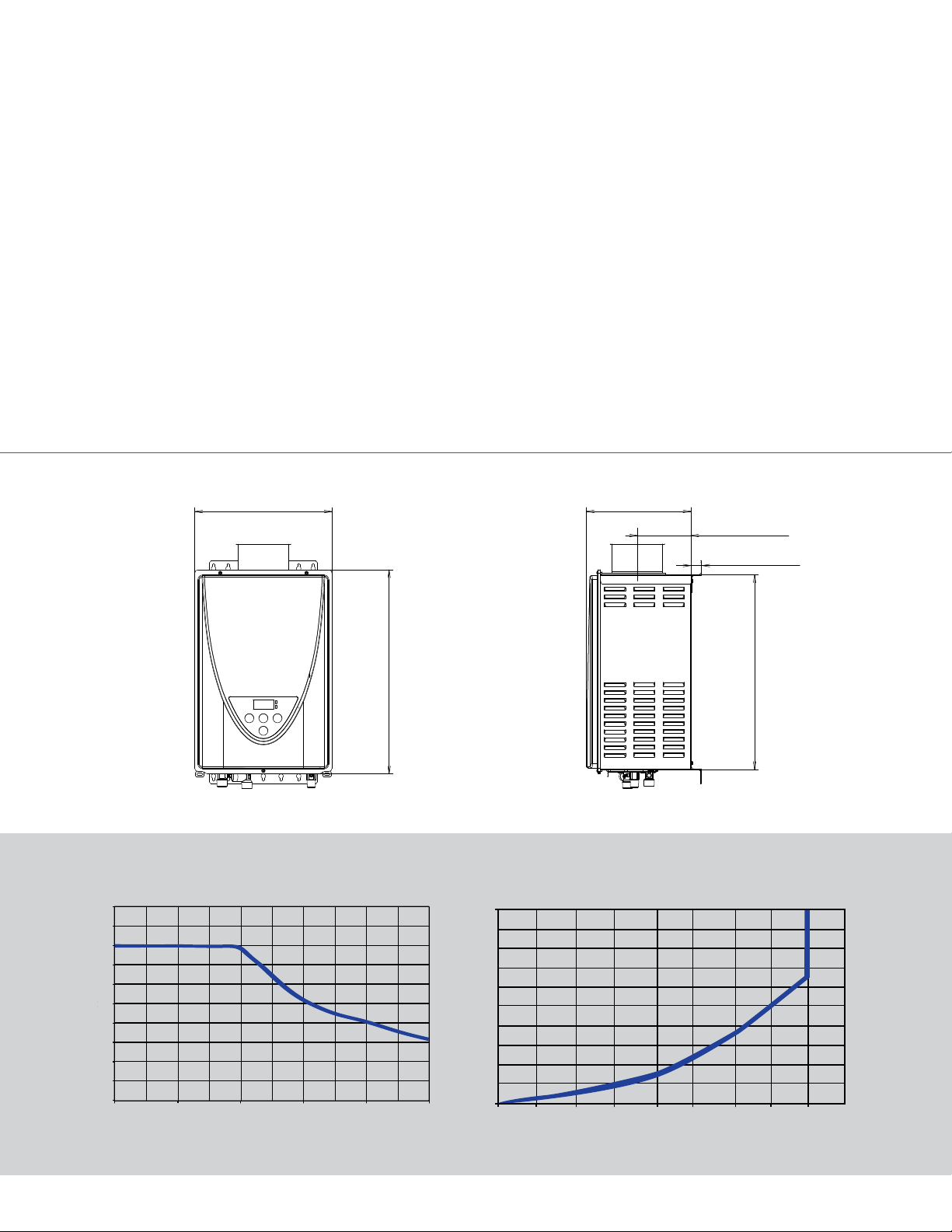

D2: Pressure Loss

Head (ft)

HOT

COLD 3-1/4" (84mm)

1-5/8" (43mm)

9-1/2" (241mm)

D2: Flow Rate vs. Temperature Rise

Indoor and Outdoor Installation Options

Power Vent or Power Direct Vent Design

Low NOx Emissions

4” Category III Vent

Flow Rate up to 10.0 GPM

• Values based on factory testing. 0.4 GPM required for

continuous fire after initial ignition

Water Pressure: 15-150 psi

• Pressure Only Relief Valve Requires (Min 199,000 btu/h,

150 psi).

• 40 psi or above recommended for max. flow

Dimensions

13-3/4" (350mm)

10" (254mm)

1-3/4" (45mm) 1-3/4" (45mm)

4" (101 mm)

1-3/8" (36mm)

Easy-Link up to 4 heaters

Warranty

• 15-year limited warranty on heat exchanger in residential

applications.

• 5-year limited warranty on heat exchanger in commercial

applications.

• 5-year warranty on all parts.

• Refer to takagi.com for further warranty details

4-3/8" (113mm)

D2: Flow Rate vs. Temperature Rise

12

10

8

6

Flow rate (gpm)

4

2

0

Temperature rise (°F)

21-3/8" (544mm)

20-1/4" (520mm)

1-7/8" (47mm)

5-1/4" (133mm)

120V 1-3/8" (36mm)

GAS 4-7/8" (124mm)

Set temperature: 122°F or lower

Set temperature: 131°F or higher

19-3/8" (493mm)

1" (26mm)

COLD 2-7/8" (71mm)

120VAC 3-7/8" (99mm)

GAS 5-1/4" (135mm)

HOT 6-1/2" (164mm)

D2: Pressure Loss

50

45

40

35

30

25

20

Pressure Loss (psi)

15

10

5

140120100806040200

0

Flow Rate (gpm)

8.0 10.06.0402.00.0

Set temperature: 122°F or lower

Set temperature: 131°F or higher

120

110

100

90

80

70

60

50

40

30

20

10

Head (ft)

0

16

110C SERIES

The 110C Simplicity Series is fuel convertible out of the box and easily installs using contractor

preferred concentric venting. Great for apartments, one bath homes in cold climates, condos

and summer cabins.

TK-110C-NI

Specifications

Gas Consumption Input Inlet Gas Pressure**

Model Number* Type

TK-110C-NI Natural 15,000 140,000 4.0 10.5 0.81

Model Number*

TK-110C-NI 6.6 3/4" NPT 3/4” NPT 12 12 3 4 55

*Indoor models only. Units are field convertible from natural gas to propane with supplied conversion kit.

**For propane, minimum inlet gas pressure is 8.0 in. W.C. and maximum inlet gas pressure is 14.0 in. W.C.

110C

Temperature

Settings

Electric 120 V

Maximum

GPM

Dipswitches 120 °F (default) 140°F

With 100209924 remote (max. distance 400’ from heater, non-polarized 20 gauge wiring.)

100 °F to 140 °F (9 options), 120 °F Default Factory Setting

Minimum

(BTU/H)

Hot/Cold

Connections

53 W / 0.58 A

(Operation)

Maximum

(BTU/H)

Gas

Connection

Minimum (in.

W.C.)

Clearances (in.)

Top Bottom Side Front

2 W / 0.06 A

(Standby)

Maximum (in.

W.C.)

Approx

Shipping

Weight (lbs)

99 W / 0.83 A

(Freeze-Protection)

UEF

17

ANSI Z21.10.3 • CSA 4.3

NON-CONDENSING

Specifications

110C: Flow Rate vs. Temperature Rise

110C: Pressure Loss

Head (ft)

10-1/2” (266.5 mm)

5-7/16” (137.7 mm)

19-1/2” (495.7 mm)

1.0” (25.5 mm)

5-7/16” (137.7 mm)

Top view

Installations are simple and flexible with

contractor-preferred concentric venting

Long venting runs up to 43 feet and

operates in altitudes up to 10,100 feet

Gas convertible from natural gas to

propane using the included conversion kit

Flow Rate up to 6.6 GPM

• Values based on factory testing. 0.4 GPM required for

continuous fire after initial ignition

Meets Ultra-Low NOx requirements

Dimensions

13-3/4” (350 mm)

Water Pressure: 15-150 psi

• Pressure Only Relief Valve Requires (Min 140,000 btu/h,

150 psi)

• 40 psi or above recommended for max. flow

Warranty

• 15-year limited warranty on heat exchanger in residential

applications.

• 5-year limited warranty on heat exchanger in commercial

applications.

• 5-year warranty on all parts.

• Refer to takagi.com for further warranty details

10-1/2” (266.5 mm)

5-7/16” (137.7 mm)

1.0” (25.5 mm)

110C: Flow Rate vs. Temperature Rise

9.0

8.0

7.0

6.0

5.0

4.0

Flow rate (gpm)

3.0

2.0

1.0

0

10 30 50 70 90 110

Temperature rise (°F)

6040200.0

20-1/2” (520 mm)

80

100

110C: Pressure Loss

50

45

40

35

30

25

20

Pressure Loss (psi)

15

10

5

0

Flow Rate (gpm)

19-1/2” (495.7 mm)

8.06.0402.00.0

120

110

100

90

80

70

60

50

40

30

20

10

0

Head (ft)

18

310C SERIES

The 310C Simplicity Series is fuel convertible out of the box and easily installs using

contractor preferred concentric venting. It generates a max flow rate of 8.0 gpm, providing

enough hot water to run three showers at the same time.

TK-310C-NI

Specifications

Gas Consumption Input Inlet Gas Pressure**

Model Number* Type

TK-310C-NI Natural 15,000 190,000 4.0 10.5 0.82

Model Number*

TK-310C-NI 8 3/4" NPT 3/4” NPT 12 12 3 4 55

*Indoor models only. Units are field convertible from natural gas to propane with supplied conversion kit.

**For propane, minimum inlet gas pressure is 8.0 in. W.C. and maximum inlet gas pressure is 14.0 in. W.C.

310C

Temperature

Settings

Electric 120 V

Maximum

GPM

Dipswitches 120°F (default) 140°F

With 100209924 remote (max. distance 400’ from heater, non-polarized 20 gauge wiring.)

100 °F to 140 °F (9 options), 120°F Default Factory Setting

Minimum

(BTU/H)

Hot/Cold

Connections

71 W / 0.81 A

(Operation)

Maximum

(BTU/H)

Gas

Connection

2 W / 0.06 A

(Standby)

Minimum (in.

W.C.)

Clearances (in.)

Top Bottom Side Front

Maximum (in.

W.C.)

99 W / 0.83 A

(Freeze-Protection)

Approx

Shipping

Weight (lbs)

UEF

19

ANSI Z21.10.3 • CSA 4.3

NON-CONDENSING

Specifications

10-1/2” (266.5 mm)

5-7/16” (137.7 mm)

19-1/2” (495.7 mm)

1.0” (25.5 mm)

5-7/16” (137.7 mm)

Top view

310C: Pressure Loss

Head (ft)

310C: Flow Rate vs. Temperature Rise

10.0

Installations are simple and flexible with

contractor-preferred concentric venting

Long venting runs up to 43 feet and

operates in altitudes up to 10,100 feet

Gas convertible from natural gas to

propane using the included conversion kit

Flow Rate up to 8.0 GPM

• Values based on factory testing. 0.4 GPM required for

continuous fire after initial ignition.

Meets Ultra-Low NOx requirements

Dimensions

13-3/4” (350 mm)

Water Pressure: 15-150 psi

• Pressure Only Relief Valve Requires (Min 190,000 btu/h,

150 psi)

• 40 psi or above recommended for max. flow

Warranty

• 15-year limited warranty on heat exchanger in residential

applications.

• 5-year limited warranty on heat exchanger in commercial

applications.

• 5-year warranty on all parts.

• Refer to takagi.com for further warranty details

10-1/2” (266.5 mm)

5-7/16” (137.7 mm)

1.0” (25.5 mm)

310C: Flow Rate vs. Temperature Rise

9.0

8.0

7.0

6.0

5.0

4.0

Flow rate (gpm)

3.0

2.0

1.0

0

Temperature rise (°F)

20-1/2” (520 mm)

Pressure Loss (psi)

100806040200.0

310C: Pressure Loss

100

90

80

70

60

50

40

30

20

10

0

Flow Rate (gpm)

19-1/2” (495.7 mm)

8.06.0402.00.0

200

180

160

140

120

100

80

60

40

20

Head (ft)

0

20

510C SERIES

The 510C Simplicity Series is fuel convertible out of the box and easily installs using contractor

preferred concentric venting. It is well suited for residential/commercial applications such as

small restaurants and beauty salons. Utilizing commercial grade copper alloy for the heat

exchanger tubing, the 510C series is also suitable for heavier residential usages such as

combination space heating and domestic recirculation systems.

TK-510C-NI

Specifications

Gas Consumption Input Inlet Gas Pressure**

Model Number* Type

TK-510C-NI Natural 15,000 199,000 4.0 10.5 0.81

Model Number*

TK-510C-NI 10 3/4" NPT 3/4” NPT 12 12 3 4 55

*Indoor models only. Units are field convertible from natural gas to propane with supplied conversion kit.

**For propane, minimum inlet gas pressure is 8.0 in. W.C. and maximum inlet gas pressure is 14.0 in. W.C.

510C

Temperature

Settings

Electric 120 V

Maximum

GPM

Dipswitches 120°F (default) 140°F

With 100209924 remote (max. distance 400’ from heater, non-polarized 20 gauge wiring.)

100°F to 160°F (13 options), 120°F Default Factory Setting

Minimum

(BTU/H)

Hot/Cold

Connections

72 W / 0.85 A

(Operation)

Maximum

(BTU/H)

Gas

Connection

Minimum

(in. W.C.)

Clearances (in.)

Top Bottom Side Front

3 W / 0.07 A

(Standby)

100 W / 0.83 A

(Freeze-Protection)

Maximum

(in. W.C.)

Approx

Shipping

Weight (lbs)

UEF

21

ANSI Z21.10.3 • CSA 4.3

NON-CONDENSING

Specifications

510C: Flow Rate vs. Temperature Rise

10-1/2” (266.5 mm)

5-7/16” (137.7 mm)

19-1/2” (495.7 mm)

1.0” (25.5 mm)

5-7/16” (137.7 mm)

Top view

510C: Pressure Loss

Head (ft)

Installations are simple and flexible with

contractor-preferred concentric venting

Long venting runs up to 43 feet and

operates in altitudes up to 10,100 feet

Gas convertible from natural gas to

propane using the included conversion kit

Flow Rate up to 10 GPM

• Values based on factory testing. 0.4 GPM required for

continuous fire after initial ignition.

Meets Ultra-Low NOx requirements

Dimensions

13-3/4” (350 mm)

Water Pressure: 15-150 psi

• Pressure Only Relief Valve Requires (Min 199,000 btu/h,

150 psi)

• 40 psi or above recommended for max. flow

Easy-Link up to 4 heaters or connect up to

20 heaters with a Multi-Unit Controller

Warranty

• 15-year limited warranty on heat exchanger in residential

applications.

• 5-year limited warranty on heat exchanger in commercial

applications.

• 5-year warranty on all parts.

• Refer to takagi.com for further warranty details

10-1/2” (266.5 mm)

5-7/16” (137.7 mm)

1.0” (25.5 mm)

510C: Flow Rate vs. Temperature Rise

12

11

10

9

8

7

6

5

4

Flow rate (gpm)

3

2

1

0

Temperature rise (°F)

Set temperature: 125°F (52°C) or lower

Set temperature: 130°F (55°C) or higher

20-1/2” (520 mm)

140120100806040200

510C: Pressure Loss

100

90

80

70

60

50

40

Pressure Loss (psi)

30

20

10

0

Flow Rate (gpm)

19-1/2” (495.7 mm)

Set temperature: 125°F (52°C) or lower

Set temperature: 130°F (55°C) or higher

Set Temperature 125°F (52°C) or higher, maximum flow rate is limited to 8.0 gpm.

8.0 10.06.0402.00.0

220

200

180

160

140

120

100

80

60

40

20

0

Head (ft)

22

110U SERIES

The 110U Series is great for apartments, one bath homes in cold climates, condos and summer

cabins. Indoor models include an integrated temperature controller. A remote control is included

as a standard for outdoor models. Complies with SCAQMD Rule 1146.2 and other air quality

management districts with similar NOx Emission requirements of 14 ng/J or 20 PPM.

TK-110U-ETK-110U-I

Specifications

Gas Consumption Input Inlet Gas Pressure**

Model Number* Type

TK-110U-I Natural 15,000 140,000 4.0 10.5 0.81

TK-110U-E Natural 15,000 140,000 4.0 10.5 0.81

Model Number*

TK-110U-I 6.6 3/4" NPT 3/4” NPT 12 12 3 4 39

TK-110U-E 6.6 3/4" NPT 3/4” NPT 36 12 3 24 39

*Units are field convertible from natural gas to propane with supplied conversion kit.

**For propane, minimum inlet gas pressure is 8.0 in. W.C. and maximum inlet gas pressure is 14.0 in. W.C.

110U

Temperature

Settings

Electric 120 V

Maximum

GPM

Dipswitches 120°F (default) 140°F

With 100209924 remote (max. distance 400’ from heater, non-polarized 20 gauge wiring.)

100°F to 140°F (9 options), 120°F Default Factory Setting

Minimum

(BTU/H)

Hot/Cold

Connections

54 W / 0.64 A

(Operation)

Maximum

(BTU/H)

Gas

Connection

2 W / 0.06 A

(Standby)

Minimum

(in. W.C.)

Clearances (in.)

Top Bottom Side Front

Maximum

(in. W.C.)

96 W / 0.82 A

(Freeze-Protection)

Approx

Shipping

Weight (lbs)

UEF

NON-CONDENSING

23

ANSI Z21.10.3 • CSA 4.3

Specifications

110U: Flow Rate vs. Temperature Rise

100806040200.0

110U: Pressure Loss

Head (ft)

8.06.0402.00.0

120 VAC 1-5/8" (40 mm)

COLD 1-5/8" (41 mm)

GAS 5" (127 mm)

HOT 4-5/8" (116 mm)

20-1/2" (520 mm)

1" (26 mm)

13-3/4" (350 mm)

10" (254 mm)

1-3/4" (45 mm) 1-3/4" (45 mm)

21-1/2" (545 mm)

1-3/8" (36 mm)

4-3/8" (113mm)

19-3/8" (493 mm)

120 VAC 3" (75 mm)

GAS 5-1/4" (135 mm)

HOT 6" (153 mm)

COLD 6" (153 mm)

2-1/4" (58 mm)

3-5/8"(93 mm)

10" (256 mm)

1-7/8" (47 mm)

Indoor and Outdoor Installation Options

Power Vent or Power Direct Vent Design

Ultra-Low NOx Emissions

4” Category III Vent

Gas convertible from natural gas to

propane using

the included conversion kit

Flow Rate up to 6.6 GPM

• Values based on factory testing. 0.4 GPM required for

continuous fire after initial ignition

Dimensions

Water Pressure: 15-150 psi

• Pressure Only Relief Valve Requires (Min 140,000 btu/h,

150 psi).

• 40 psi or above recommended for max. flow

Warranty

• 15-year limited warranty on heat exchanger in residential

applications.

• 5-year limited warranty on heat exchanger in commercial

applications.

• 5-year warranty on all parts.

• Refer to takagi.com for further warranty details

4-3/8" (113mm)

110U: Flow Rate vs. Temperature Rise

9.0

8.0

7.0

6.0

5.0

4.0

3.0

Flow rate (gpm)

2.0

1.0

0

Temperature rise (°F)

2-1/4" (58 mm)

19-3/8" (493 mm)

1" (26 mm)

120 VAC 3" (75 mm)

GAS 5-1/4" (135 mm)

COLD 6" (153 mm)

HOT 6" (153 mm)

10" (256 mm)

110U: Pressure Loss

100

90

80

70

60

50

40

Pressure Loss (psi)

30

20

10

0

Flow Rate (gpm)

220

200

180

160

140

120

100

80

60

40

20

0

Head (ft)

24

310U SERIES

The 310U features a max flow rate of 8.0 gpm providing enough hot water to run three

showers at the same time. Indoor models include an integrated temperature controller. A remote

control is included as a standard for outdoor models. Complies with SCAQMD Rule 1146.2

and other air quality management districts with similar NOx Emission requirements of 14 ng/J

or 20 PPM.

TK-310U-ETK-310U-I

Specifications

Gas Consumption Input Inlet Gas Pressure**

Model Number* Type

TK-310U-I Natural 15,000 190,000 4.0 10.5 0.82

TK-310U-E Natural 15,000 190,000 4.0 10.5 0.82

Model Number*

TK-310U-I 8 3/4" NPT 3/4” NPT 12 12 3 4 39

TK-310U-E 8 3/4" NPT 3/4” NPT 36 12 3 24 39

*Units are field convertible from natural gas to propane with supplied conversion kit.

**For propane, minimum inlet gas pressure is 8.0 in. W.C. and maximum inlet gas pressure is 14.0 in. W.C.

310U

Temperature

Settings

Electric 120 V

Maximum

GPM

Dipswitches 120°F (default) 140°F

With 100209924 remote (max. distance 400’ from heater, non-polarized 20 gauge wiring.)

100°F to 140°F (9 options), 120°F Default Factory Setting

Minimum

(BTU/H)

Hot/Cold

Connections

79 W / 0.99 A

(Operation)

Maximum

(BTU/H)

Gas

Connection

2 W / 0.06 A

(Standby)

Minimum

(in. W.C.)

Clearances (in.)

Top Bottom Side Front

Maximum

(in. W.C.)

96 W / 0.82 A

(Freeze-Protection)

Approx

Shipping

Weight (lbs)

UEF

25

ANSI Z21.10.3 • CSA 4.3

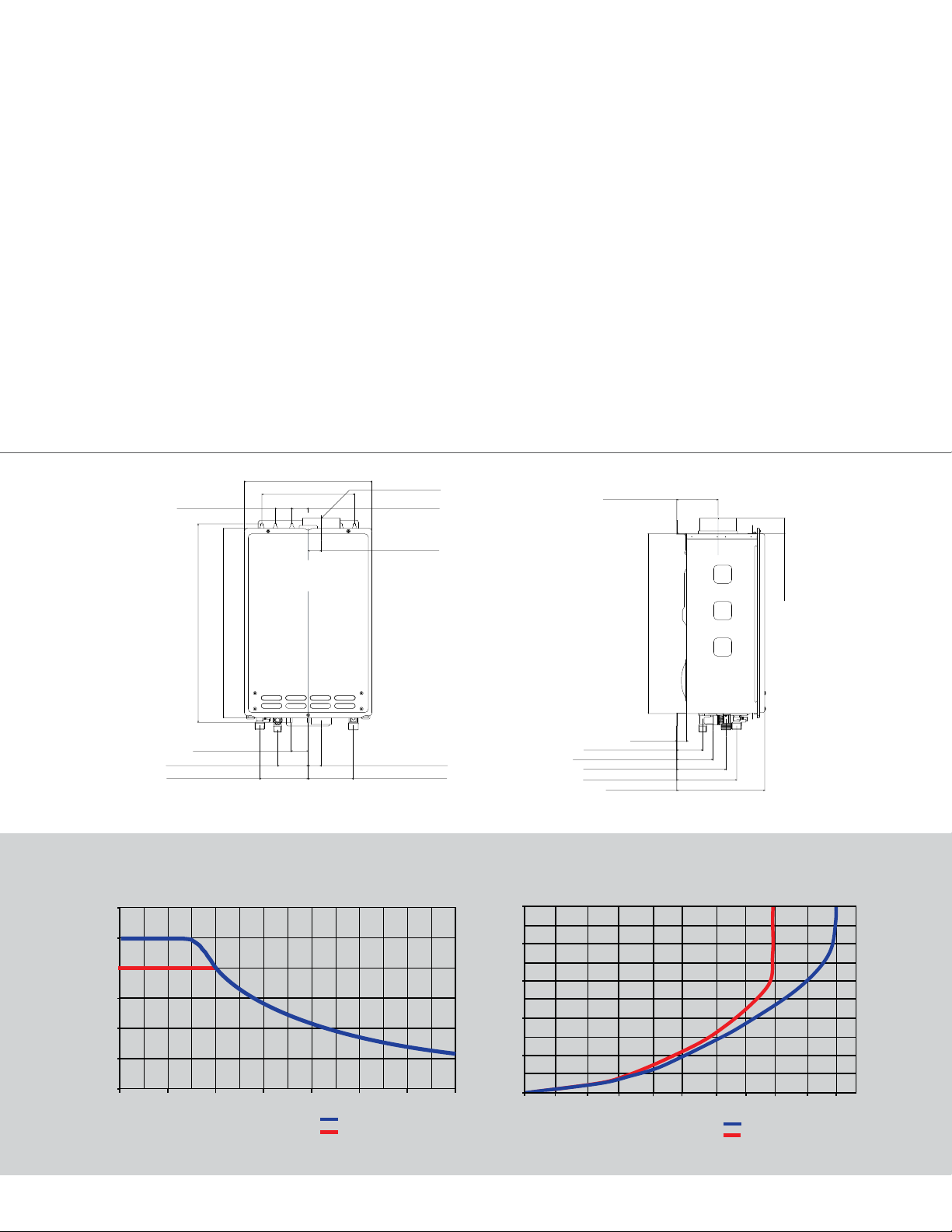

NON-CONDENSING

Specifications

120 VAC 1-5/8" (40 mm)

COLD 1-5/8" (41 mm)

GAS 5" (127 mm)

HOT 4-5/8" (116 mm)

20-1/2" (520 mm)

1" (26 mm)

13-3/4" (350 mm)

10" (254 mm)

1-3/4" (45 mm) 1-3/4" (45 mm)

21-1/2" (545 mm)

1-3/8" (36 mm)

4-3/8" (113mm)

19-3/8" (493 mm)

120 VAC 3" (75 mm)

GAS 5-1/4" (135 mm)

HOT 6" (153 mm)

COLD 6" (153 mm)

2-1/4" (58 mm)

3-5/8"(93 mm)

10" (256 mm)

1-7/8" (47 mm)

310U: Flow Rate vs. Temperature Rise

310U: Pressure Loss

8.0 10.06.0402.00.0

Head (ft)

Indoor and Outdoor Installation Options

Power Vent or Power Direct Vent Design

Ultra-Low NOx Emissions

4” Category III Vent

Gas convertible from natural gas to

propane using

the included conversion kit

Flow Rate up to 8 GPM

• Values based on factory testing. 0.4 GPM required for

continuous fire after initial ignition

Dimensions

Water Pressure: 15-150 psi

• Pressure Only Relief Valve Requires (Min 190,000 btu/h,

150 psi).

• 40 psi or above recommended for max. flow

Warranty

• 15-year limited warranty on heat exchanger in residential

applications.

• 5-year limited warranty on heat exchanger in commercial

applications.

• 5-year warranty on all parts.

• Refer to takagi.com for further warranty details

4-3/8" (113mm)

310U: Flow Rate vs. Temperature Rise

9.0

8.0

7.0

6.0

5.0

4.0

3.0

Flow rate (gpm)

2.0

1.0

0

Temperature rise (°F)

100806040200.0

100

90

80

70

60

50

40

Pressure Loss (psi)

30

20

10

0

2-1/4" (58 mm)

310U: Pressure Loss

Flow Rate (gpm)

19-3/8" (493 mm)

1" (26 mm)

120 VAC 3" (75 mm)

GAS 5-1/4" (135 mm)

COLD 6" (153 mm)

HOT 6" (153 mm)

10" (256 mm)

220

200

180

160

140

120

100

80

60

40

20

0

Head (ft)

26

510U SERIES

The 510U series is well suited for residential/commercial applications such as small restaurants

and beauty salons. Indoor models include an integrated temperature controller. A remote control

is included as a standard feature for outdoor models. Utilizing commercial-grade copper alloy

for the heat exchanger tubing, the D3U series is also suitable for heavier-residential usages such

as combination space heating and domestic recirculation systems.

TK-510U-ETK-510U-I

Specifications

Gas Consumption Input Inlet Gas Pressure**

Model Number* Type

TK-510U-I Natural 15,000 199,000 4.0 10.5 0.82

TK-510U-E Natural 15,000 199,000 4.0 10.5 0.81

Model Number*

TK-510U-I 10 3/4" NPT 3/4” NPT 12 12 3 4 40

TK-510U-E 10 3/4" NPT 3/4” NPT 36 12 3 24 40

*Units are field convertible from natural gas to propane with supplied conversion kit.

**For propane, minimum inlet gas pressure is 8.0 in. W.C. and maximum inlet gas pressure is 14.0 in. W.C.

510U

Temperature

Settings

Electric 120 V

Maximum

GPM

Dipswitches 120°F (default) 140°F

With100209924 remote (max. distance 400’ from heater, non-polarized 120 gauge wiring.)

100°F to 160°F (13 options), 120°F Default Factory Setting

Minimum

(BTU/H)

Hot/Cold

Connections

82 W / 1.02 A

(Operation)

Maximum

(BTU/H)

Gas

Connection

3 W / 0.07 A

(Standby)

Minimum

(in. W.C.)

Clearances (in.)

Top Bottom Side Front

Maximum

(in. W.C.)

97 W / 0.82 A

(Freeze-Protection)

Approx

Shipping

Weight (lbs)

UEF

27

ANSI Z21.10.3 • CSA 4.3

NON-CONDENSING

Specifications

510U: Flow Rate vs. Temperature Rise

510U: Pressure Loss

Head (ft)

120 VAC 1-5/8" (40 mm)

COLD 1-5/8" (41 mm)

GAS 5" (127 mm)

HOT 4-5/8" (116 mm)

20-1/2" (520 mm)

1" (26 mm)

13-3/4" (350 mm)

10" (254 mm)

1-3/4" (45 mm) 1-3/4" (45 mm)

21-1/2" (545 mm)

1-3/8" (36 mm)

4-3/8" (113mm)

19-3/8" (493 mm)

120 VAC 3" (75 mm)

GAS 5-1/4" (135 mm)

HOT 6" (153 mm)

COLD 6" (153 mm)

2-1/4" (58 mm)

3-5/8"(93 mm)

10" (256 mm)

1-7/8" (47 mm)

Indoor and Outdoor Installation Options

Power Vent or Power Direct Vent Design

Ultra-Low NOx Emissions

4” Category III Vent

Gas convertible from natural gas to

propane using

the included conversion kit

Flow Rate up to 10 GPM

• Values based on factory testing. 0.4 GPM required for

continuous fire after initial ignition

Easy-Link up to 4 heaters or connect up to

20 heaters with a Multi-Unit Controller

Dimensions

Water Pressure: 15-150 psi

• Pressure Only Relief Valve Requires (Min 199,000 btu/h,

150 psi).

• 40 psi or above recommended for max. flow

Warranty

• 15-year limited warranty on heat exchanger in residential

applications.

• 5-year limited warranty on heat exchanger in commercial

applications.

• 5-year warranty on all parts.

• Refer to takagi.com for further warranty details

4-3/8" (113mm)

510U: Flow Rate vs. Temperature Rise

12

11

10

9

8

7

6

5

4

Flow rate (gpm)

3

2

1

0

Temperature rise (°F)

Set Temperature 130°F (55°C) or higher, maximum flow rate is limited to 8.0 gpm.

Set temperature: 125°F (52°C) or lower

Set temperature: 130°F (55°C) or higher

140120100806040200

510U: Pressure Loss

100

90

80

70

60

50

40

Pressure Loss (psi)

30

20

10

0

Flow Rate (gpm)

2-1/4" (58 mm)

19-3/8" (493 mm)

1" (26 mm)

120 VAC 3" (75 mm)

GAS 5-1/4" (135 mm)

COLD 6" (153 mm)

HOT 6" (153 mm)

10" (256 mm)

8.0 10.06.0402.00.0

Set temperature: 125°F (52°C) or lower

Set temperature: 130°F (55°C) or higher

Set Temperature 125°F (52°C) or higher, maximum flow rate is limited to 8.0 gpm.

220

200

180

160

140

120

100

80

60

40

20

0

Head (ft)

28

H3M SERIES

The H3M Series is a high efficiency, ultra-low NOx condensing model with up to 0.91 Uniform

Energy Factor, allowing for the use of 3”or 4” PVC venting or Category IV stainless steel. Indoor

models have an integrated temperature controller and outdoor models include a remote control

as a standard feature.

T-H3M-DV

T-H3M-OS

Specifications

Gas Consumption Input Inlet Gas Pressure**

Model Number* Type

T-H3M-DV-N Natural 15,000 120,000 4.0 10.5 0.90

T-H3M-OS-N Natural 15,000 120,000 4.0 10.5 0.91

Model Number*

T-H3M-DV-N 6.6 3/4" NPT 1/2" NPT 12 12 3 4 54

T-H3M-OS-N 6.6 3/4" NPT 1/2" NPT 36 12 3 24 52

*For propane models, change “N” to “P”

**For propane models, minimum fire is 13,000 BTU/H, minimum inlet gas pressure is 8.0 in. W.C. and maximum inlet gas pressure is

14.0 in. W.C.

H3M

Temperature

Settings

Electric 120 V

Maximum

GPM

Dipswitches 120°F (default) 140°F

With 100209924 remote (max. distance 400’ from heater, non-polarized 120 gauge wiring.)

100°F to 140°F with 5°F intervals (9 options), 120°F Default Factory Setting

Minimum

(BTU/H)

Hot/Cold

Connections

54 W / 0.7 A

(Operation)

Maximum

(BTU/H)

Gas

Connection

3 W / 0.05 A

(Standby)

Minimum

(in. W.C.)

Clearances (in.)

Top Bottom Side Front

Maximum

(in. W.C.)

224 W / 2 A (Freeze-Protection)

UEF

Approx

Shipping

Weight (lbs)

29

ANSI Z21.10.3 • CSA 4.3

CONDENSING

Specifications

H3M: Flow Rate vs. Temperature Rise

H3M: Pressure Loss

Side viewFront view

10-5/16" (262.2mm)

10-13/16" (274.6mm)

6" (152.1mm)

2-9/16" (64.8mm)

2-3/4" (70.2mm)

Condensate drain port 3-1/4" (82.1mm)

Gas 4-1/8" (105.4mm)

Hot 6-1/2" (164.6mm)

Cold 7" (178.5mm)

120VAC 7-3/4" (196.5mm)

1" (25.5mm)

INDOOR MODEL

Side viewFront view

Indoor and Outdoor Installation Options

Power Vent or Power Direct Vent Design

Ultra-Low NOx Emissions

Flow Rate up to 6.6 GPM

• Values based on factory testing. 0.4 GPM required for

continuous fire after initial ignition

Water Pressure: 15-150 psi

• Pressure Only Relief Valve Requires (Min 120,000 btu/h,

150 psi).

• 40 psi or above recommended for max. flow

Dimensions

13-7/8" (352mm)

10" (254mm)

6-1/4" (158.5mm)

4" (102mm)4" (102mm)

58.4

Warranty

• 15-year limited warranty on heat exchanger in residential

applications.

• 5-year limited warranty on heat exchanger in commercial

applications.

• 5-year warranty on all parts.

• Refer to takagi.com for further warranty details

10-13/16" (274.6mm)

10-5/16" (262.2mm)

6" (152.1mm)

2-3/4" (70.2mm)

2-9/16" (64.8mm)

5-1/16" (129.1mm)

H3M: Flow Rate vs. Temperature Rise

10

9

8

7

6

5

4

Flow rate (gpm)

3

2

1

0

0 20

Temperature rise (°F)

Hot 4-3/4" (121.1mm)

Condensate drain port

24" (609.4mm)

22-7/8 (580mm)

Cold 1/2" (13.3mm)

5-3/8" (137mm)

7-1/16" (180mm)

120VAC 3-1/16" (77mm)

Gas 4/1/2" (113.7mm)

40 60 80 100

110

H3M: Pressure Loss

60

55

50

45

40

35

30

25

20

Pressure Loss (psi)

15

10

5

0

0.0 1.0

Flow Rate (gpm)

2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 10.0

1" (25.5mm)

Condensate drain port 3-1/4" (82.1mm)

Gas 4-1/8" (105.4mm)

Hot 6-1/2" (164.6mm)

Cold 7" (178.5mm)

120VAC 7-3/4" (196.5mm)

140

120

100

80

60

Head (ft)

40

20

0

30

H3J SERIES

The H3J series offers high efficiency Ultra-Low NOx condensing technology allowing for the use

of 3” PVC venting and has 0” clearance to combustibles. Indoor models have an integrated

temperature controller and outdoor models include a remote control as a standard feature.

T-H3J-OST-H3J-DV

Specifications

Gas Consumption Input Inlet Gas Pressure**

Model Number* Type

T-H3J-DV-N Natural 15,000 160,000 4.0 10.5 0.94

T-H3J-OS-N Natural 15,000 160,000 4.0 10.5 0.95

Model Number*

T-H3J-DV-N 6.6 3/4" NPT 3/4" NPT 12 12 3 4 71

T-H3J-OS-N 6.6 3/4" NPT 3/4" NPT 36 12 3 24 69

*For propane models, change “N” to “P”

**For propane models, minimum fire rate is 13,000 BTU/H, minimum inlet gas pressure is 8.0 in. W.C. and maximum inlet gas pressure is 14.0 in. W.C.

H3J

Temperature

Settings

Electric 120 V

Maximum

GPM

Built In / without remote 120°F (default) 140°F

With 100209924 remote (max. distance 400’ from heater, non-polarized 20 gauge wiring.)

100°F to 140°F with 5°F intervals (9 options), 120°F Default Factory Setting

Minimum

(BTU/H)

Hot/Cold

Connections

73 W / 0.61 A

(Operation)

Maximum

(BTU/H)

Gas

Connection

Minimum

(in. W.C.)

Clearances (in.)

Top Bottom Side Front

3 W / 0.03 A

(Standby)

174 W / 1.5 A

(Freeze-Protection)

Maximum

(in. W.C.)

UEF

Approx

Shipping

Weight (lbs)

31

ANSI Z21.10.3 • CSA 4.3

CONDENSING

Specifications

22-1/22" (570 mm)

10-3/4" (272mm)

22-1/22" (570 mm)

2-5/8" (68 mm)

Exhaust

Intake

2-5/8" (65 mm)

5-3/4" (147 mm)

11-1/4" (285 mm)

1/2 (13 mm)

GAS 5-1/8" (131 mm)

HOT 5-1/2" (140 mm)

COLD 6-3/4" (172 mm)

Drain port 6" (152 mm)

120 VAC 6-7/8" (174 mm)

H3J: Flow Rate vs. Temperature Rise

120

H3J: Pressure Loss

Indoor and Outdoor Installation Options

Power Vent or Power Direct Vent Design

Ultra-Low NOx Emissions

Flow Rate up to 6.6 GPM

• Values based on factory testing. 0.4 GPM required for

continuous fire after initial ignition

Water Pressure: 15-150 psi

• Pressure Only Relief Valve Requires (Min 160,000 btu/h,

150 psi).

• 40 psi or above recommended for max. flow

Dimensions

17-3/4" (450 mm)

4" (102 mm)

∅

Female

7" (180 mm)

6-1/4" (159mm)

4" (101 mm)

4" (102 mm)

∅

Female

Warranty

• 15-year limited warranty on heat exchanger in residential

applications.

• 5-year limited warranty on heat exchanger in commercial

applications.

• 5-year warranty on all parts.

• Refer to takagi.com for further warranty details

11-1/4" (285 mm)

5-3/4" (147 mm)

HOT 4-3/4" (120 mm)

H3J: Flow Rate vs. Temperature Rise

10

9

8

7

6

5

4

Flow rate (gpm)

3

2

1

0

0 20

Temperature rise (°F)

24-7/8" (631 mm)

23-5/8" (600 mm)

Drain port

6-3/4" (170 mm)

COLD 5/8" (17 mm)

120 VAC 3" (77 mm)

GAS 5-3/4" (147 mm)

Condensate drain port

7-1/2" (189 mm)

40 60 80 100 120

H3J: Pressure Loss

50

45

40

35

30

25

20

Pressure Loss (psi)

15

10

5

0

0.0 1.0

Flow Rate (gpm)

2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 10.0

Intake

2-5/8" (68 mm)

2-5/8" (65 mm)

Exhaust

10-3/4" (272mm)

1/2 (13 mm)

GAS 5-1/8" (131 mm)

HOT 5-1/2" (140 mm)

Drain port 6" (152 mm)

COLD 6-3/4" (172 mm)

120 VAC 6-7/8" (174 mm)

Condensate drain port

7-7/8" (199 mm)

100

80

60

40

20

0

Head (ft)

32

H3S SERIES

The H3S series offers high efficiency Ultra-Low NOx condensing technology allowing for the

use of 3” PVC venting and has 0” clearance to combustibles. Indoor models are certified up

to 10,100 ft. altitude. Indoor models have an integrated temperature controller and outdoor

models include a remote control as a standard feature.

T-H3S-DV T-H3S-OS

Specifications

Gas Consumption Input Inlet Gas Pressure**

Model Number* Type

T-H3S-DV-N Natural 15,000 180,000 4.0 10.5 0.95

T-H3S-OS-N Natural 15,000 180,000 4.0 10.5 0.94

Model Number*

T-H3S-DV-N 8 3/4" NPT 3/4" NPT 12 12 3 4 71

T-H3S-OS-N 8 3/4" NPT 3/4" NPT 36 12 3 24 69

*For propane models, change “N” to “P”

**For propane models, minimum fire rate is 13,000 BTU/H, minimum inlet gas pressure is 8.0 in. W.C. and maximum inlet gas pressure is 14.0 in. W.C.

H3S

Temperature

Settings

Electric 120 V

Maximum

GPM

Built In / without remote 120°F (default) 140°F

With 100209924 remote (max. distance 400’ from heater, non-polarized 20 gauge wiring.)

100°F to 140°F with 5°F intervals (9 options), 120°F Default Factory Setting

Minimum

(BTU/H)

Hot/Cold

Connections

78 W / 0.65 A

(Operation)

Maximum

(BTU/H)

Gas

Connection

Minimum

(in. W.C.)

Clearances (in.)

Top Bottom Side Front

3 W / 0.03 A

(Standby)

174 W / 1.5 A

(Freeze-Protection)

Maximum

(in. W.C.)

UEF

Approx

Shipping

Weight (lbs)

33

ANSI Z21.10.3 • CSA 4.3

CONDENSING

Specifications

10-3/4" (272mm)

22-1/22" (570 mm)

2-5/8" (68 mm)

Exhaust

Intake

2-5/8" (65 mm)

5-3/4" (147 mm)

11-1/4" (285 mm)

1/2 (13 mm)

GAS 5-1/8" (131 mm)

HOT 5-1/2" (140 mm)

COLD 6-3/4" (172 mm)

Condensate drain port

Drain port 6" (152 mm)

120 VAC 6-7/8" (174 mm)

H3S: Flow Rate vs. Temperature Rise

H3S: Pressure Loss

Indoor and Outdoor Installation Options

Power Vent or Power Direct Vent Design

Ultra-Low NOx Emissions

Flow Rate up to 8 GPM

• Values based on factory testing. 0.4 GPM required for

continuous fire after initial ignition

Water Pressure: 15-150 psi

• Pressure Only Relief Valve Requires (Min 180,000 btu/h,

150 psi).

• 40 psi or above recommended for max. flow

Dimensions

17-3/4" (450 mm)

4" (102 mm)

∅

Female

7" (180 mm)

6-1/4" (159mm)

4" (101 mm)

4" (102 mm)

∅

Female

Warranty

• 15-year limited warranty on heat exchanger in residential

applications.

• 5-year limited warranty on heat exchanger in commercial

applications.

• 5-year warranty on all parts.

• Refer to takagi.com for further warranty details

11-1/4" (285 mm)

5-3/4" (147 mm)

10.0

9.0

8.0

7.0

6.0

5.0

4.0

Flow rate (gpm)

3.0

2.0

1.0

0.0

0 20

24-7/8" (631 mm)

23-5/8" (600 mm)

HOT 4-3/4" (120 mm)

Drain port

6-3/4" (170 mm)

COLD 5/8" (17 mm)

120 VAC 3" (77 mm)

GAS 5-3/4" (147 mm)

Condensate drain port

7-1/2" (189 mm)

H3S: Flow Rate vs. Temperature Rise

40 60 80 100 120

Temperature rise (°F)

22-1/22" (570 mm)

H3S: Pressure Loss

50

45

40

35

30

25

20

Pressure Loss (psi)

15

10

5

0

0.0 1.0

2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 10.0

Flow Rate (gpm)

Intake

2-5/8" (68 mm)

2-5/8" (65 mm)

Exhaust

10-3/4" (272mm)

1/2 (13 mm)

GAS 5-1/8" (131 mm)

HOT 5-1/2" (140 mm)

Drain port 6" (152 mm)

COLD 6-3/4" (172 mm)

120 VAC 6-7/8" (174 mm)

Condensate drain port

7-7/8" (199 mm)

120

100

80

60

40

20

0

Head (ft)

34

H3 SERIES

Utilizing commercial-grade copper alloy for the heat exchanger tubing, the H3 is suitable

for heavier residential usages such as combination space heating and domestic recirculation

systems. Indoor models have an integrated temperature controller and outdoor models include

a remote control as a standard feature. Indoor models are certified up to 10,100 ft. altitude.

Complies with Ultra-Low NOx regulations.

T-H3-DV T-H3-OS

Specifications

Gas Consumption Input Inlet Gas Pressure**

Model Number* Type

T-H3-DV-N Natural 15,000 199,000 4.0 10.5 0.93

T-H3-OS-N Natural 15,000 199,000 4.0 10.5 0.95

Model Number*

T-H3-DV-N 10 3/4" NPT 3/4" NPT 12 12 3 4 71

T-H3-OS-N 10 3/4" NPT 3/4" NPT 36 12 3 24 69

*For propane models, change “N” to “P”

**For propane models, minimum fire rate is 13,000 BTU/H, minimum inlet gas pressure is 8.0 in. W.C. and maximum inlet gas pressure is 14.0 in. W.C.

H3

Temperature

Settings

Electric 120 V

Maximum

GPM

Built In / without remote 120°F (default) 140°F

With 100209924 remote (max. distance 400’ from heater, non-polarized 20 gauge wiring.)

100°F to 160 °F with 5°F intervals (13 options), 120°F Default Factory Setting

Minimum

(BTU/H)

Hot/Cold

Connections

89 W / 0.74 A

(Operation)

Maximum

(BTU/H)

Gas

Connection

Minimum

(in. W.C.)

Clearances (in.)

Top Bottom Side Front

4 W / 0.04 A

(Standby)

175 W / 1.5 A

(Freeze-Protection)

Maximum

(in. W.C.)

UEF

Approx

Shipping

Weight (lbs)

35

ANSI Z21.10.3 • CSA 4.3

CONDENSING

Specifications

10-3/4" (272mm)

22-1/22" (570 mm)

2-5/8" (68 mm)

Exhaust

Intake

2-5/8" (65 mm)

5-3/4" (147 mm)

11-1/4" (285 mm)

1/2 (13 mm)

GAS 5-1/8" (131 mm)

HOT 5-1/2" (140 mm)

COLD 6-3/4" (172 mm)

Condensate drain port

Drain port 6" (152 mm)

120 VAC 6-7/8" (174 mm)

H3: Flow Rate vs. Temperature Rise

H3: Pressure Loss

Indoor and Outdoor Installation Options

Power Vent or Power Direct Vent Design

Ultra-Low NOx Emissions

Flow Rate up to 10 GPM

• Values based on factory testing. 0.4 GPM required for

continuous fire after initial ignition

Water Pressure: 15-150 psi

• Pressure Only Relief Valve Requires (Min 199,000 btu/h,

150 psi).

• 40 psi or above recommended for max. flow

Dimensions

17-3/4" (450 mm)

4" (102 mm)

∅

Female

7" (180 mm)

6-1/4" (159mm)

4" (101 mm)

4" (102 mm)

∅

Female

Easy-Link up to 4 heaters or connect

up to 20 heaters with a Multi-Unit

Controller

Warranty

• 15-year limited warranty on heat exchanger in

residential applications.

• 5-year limited warranty on heat exchanger in

commercial applications.

• 5-year warranty on all parts.

• Refer to takagi.com for further warranty details

11-1/4" (285 mm)

5-3/4" (147 mm)

HOT 4-3/4" (120 mm)

H3: Flow Rate vs. Temperature Rise

11

10

9

8

7

6

5

Flow rate (gpm)

4

3

2

1

0

20 40

Temperature rise (°F)

24-7/8" (631 mm)

23-5/8" (600 mm)

Drain port

6-3/4" (170 mm)

COLD 5/8" (17 mm)

120 VAC 3" (77 mm)

GAS 5-3/4" (147 mm)

Condensate drain port

7-1/2" (189 mm)

60 80 100 120 140

Set temperature: 125°F or lower

Set temperature: 130°F or higher

Pressure Loss (psi)

Intake

2-5/8" (68 mm)

2-5/8" (65 mm)

Exhaust

22-1/22" (570 mm)

10-3/4" (272mm)

1/2 (13 mm)

GAS 5-1/8" (131 mm)

HOT 5-1/2" (140 mm)

Drain port 6" (152 mm)

COLD 6-3/4" (172 mm)

120 VAC 6-7/8" (174 mm)

Condensate drain port

7-7/8" (199 mm)

H3: Pressure Loss

50

45

40

35

30

25

20

15

10

5

0

0.0 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 10.0

Flow Rate (gpm)

Set temperature: 125°F or lower

Set temperature: 130°F or higher

100

80

60

40

Head (ft)

20

0

36

540P SERIES

The 540P Series integrates a recirculation pump to provide instant hot water in residential

applications with dedicated recirculation lines. The pump is easily controlled with a simple user

interface and multiple pump settings allow you to customize pump operation to meet your needs

while maximizing heater efficiency. Indoor models have an integrated temperature and pump

controller and outdoor models include a remote control as a standard feature.

TK-540P-NIH TK-540P-NEH

Specifications

Gas Consumption Input Inlet Gas Pressure**

Model Number* Type

TK-540P-NIH Natural 15,000 199,000 4.0 10.5 0.93

TK-540P-NEH Natural 15,000 199,000 4.0 10.5 0.95

Model Number*

TK-540P-NIH 10 3/4" NPT 3/4" NPT 12 12 3 4 71

TK-540P-NEH 10 3/4" NPT 3/4" NPT 36 12 3 24 70

*For propane models, change “N” to “P”

**For propane models, minimum fire is 13,000 BTU/H, minimum inlet gas pressure is 8.0 in. W.C. and maximum inlet gas pressure is

14.0 in. W.C.

540P

Temperature

Settings

Electric 120 V

Maximum

GPM

Built In / without remote 120°F (default) 140°F

With 100276687 remote (max. distance 400’ from heater, non-polarized 20 gauge wiring.)

100°F to 140°F with 5°F intervals (9 options), 120°F Default Factory Setting

Minimum

(BTU/H)

Hot/Cold

Connections

1.09 W / 1.34 A

(Operation)

Connection

Maximum

(BTU/H)

Gas

5 W / 0.1 A

(Standby)

Minimum

(in. W.C.)

Clearances (in.)

Top Bottom Side Front

Maximum

(in. W.C.)

192 W / 1.6 A

(Freeze-Protection)

UEF

Approx

Shipping

Weight (lbs)

37

ANSI Z21.10.3 • CSA 4.3

CONDENSING

Specifications

540P: Flow Rate vs. Temperature Rise

540P: Pressure Loss

Set temperature: 130°F or higher

Drain port 4-7/8" (124 mm)

HOT 6-3/4" (171 mm)

RETURN 3-1/8" (79 mm)

11-1/4" (285 mm)

5-3/4" (147 mm)

Exhaust 2-5/8" (65 mm)

Intake 2-5/8" (68 mm)

RETURN 4-5/8" (117 mm)

GAS 5-1/8" (131 mm)

HOT 6-1/2" (164 mm)

COLD 6-3/4" (172 mm)

1/2 (13 mm)

Drain port 6-1/4" (159 mm)

120 VAC 3-7/8" (174 mm)

540P Indoor (AT-H3P-DV)

Indoor and Outdoor Installation Options

Power Vent or Power Direct Vent Design

Ultra-Low NOx Emissions

Integrated recirculation pump

Flow Rate up to 10 GPM

• Values based on factory testing. 0.4 GPM required for

continuous fire after initial ignition

Water Pressure: 15-150 psi

• Pressure Only Relief Valve Requires (Min 199,000 btu/h,

150 psi).

• 40 psi or above recommended for max. flow

Dimensions

17-3/4" (450 mm)

15" (381 mm)

Φ 4" (102 mm)

7" (180 mm)

6-1/4" (159 mm)

Φ 4" (102 mm)

FemaleFemale

Easy-Link with up to 3 other T-H3 heaters

Warranty

• 15-year limited warranty on heat exchanger in residential

applications.

• 5-year limited warranty on heat exchanger in commercial

applications.

• 5-year warranty on all parts.

• Refer to takagi.com for further warranty details

11-1/4" (285 mm)

5-3/4" (147 mm)

540P: Flow Rate vs. Temperature Rise

11

10

9

8

7

6

5

Flow rate (gpm)

4

3

2

1

0

0

Temperature rise (°F)

24-7/8" (631 mm)

23-5/8" (600 mm)

20 40

COLD 5/8" (17 mm)

120 VAC 3" (77 mm)

GAS 5-3/4" (147 mm)

Condensate drain port

7-1/2" (189 mm)

60 80 100

Set temperature: 125°F or lower

Set temperature: 130°F or higher

110

Intake 2-5/8" (68 mm)

Exhaust 2-5/8" (65 mm)

1/2 (13 mm)

RETURN 4-5/8" (117 mm)

GAS 5-1/8" (131 mm)

Drain port 6-1/4" (159 mm)

HOT 6-1/2" (164 mm)

COLD 6-3/4" (172 mm)

120 VAC 3-7/8" (174 mm)

Condensate drain port

7-7/8" (199 mm)

540P: Pressure Loss

50

45

40

35

30

25

20

Pressure Loss (psi)

15

10

5

0

0.0 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 10.0

Flow Rate (gpm)

Set temperature: 125°F or lower

100

80

60

40

Head (ft)

20

0

38

M50 SERIES

The M50 Series, specifically designed for heavy-duty applications, is the largest

Takagi tankless heater yet and the most powerful (14.5 GPM max) in the tankless industry.

The M50 Series is suitable for commercial applications (hotels, restaurants, government,

convalescent homes, etc.) that require high demand and the most durable of heaters. Along

with commercial-grade copper alloy, the M50 Series is the only commercial unit in the industry

that offers a “dual-combustion system,” providing redundancy for added reliability.

T-M50-N

Specifications

Model

Number*

T-M50-N Natural 15,000 380,000 4.0 10.5 80%

Model

Number*

T-M50-N 1" NPT 1" NPT 12*** 12 2 4*** 113

†For ASME version, use model number T-M50-ASME-N

*For propane models, change N to P

**For propane models, minimum inlet gas pressure is 8.0 in. W.C. and maximum inlet gas pressure is 14.0 in. W.C.

***If installed outdoors, top clearance is 36” and front clearance is 24”

M50

Temperature

Settings

Electric

Type

Connections Clearances (in.)

Water Gas Top Bottom Side Front

Built In / without remote 110°F, 115°F, 120°F (default), 135°F, 145°F, 155°F, 165°F, 185°F

With 100112155 remote (max. distance 400’ from heater, non-polarized 20 gauge wiring.)

100°F to 175°F with 5°F intervals (16 options), 120°F Default Factory Setting

120

VAC

Gas Consumption Input Inlet Gas Pressure**

Minimum

(BTU/H)

175 W / 1.48 A

(Operation)

Maximum

(BTU/H)

16 W / 0.13 A

(Standby)

Minimum

(in. W.C.)

271 W / 2.26 A

(Freeze-Protection)

Maximum

(in. W.C.)

Thermal

Efficiency

Approx

Shipping

Weight (lbs)

39

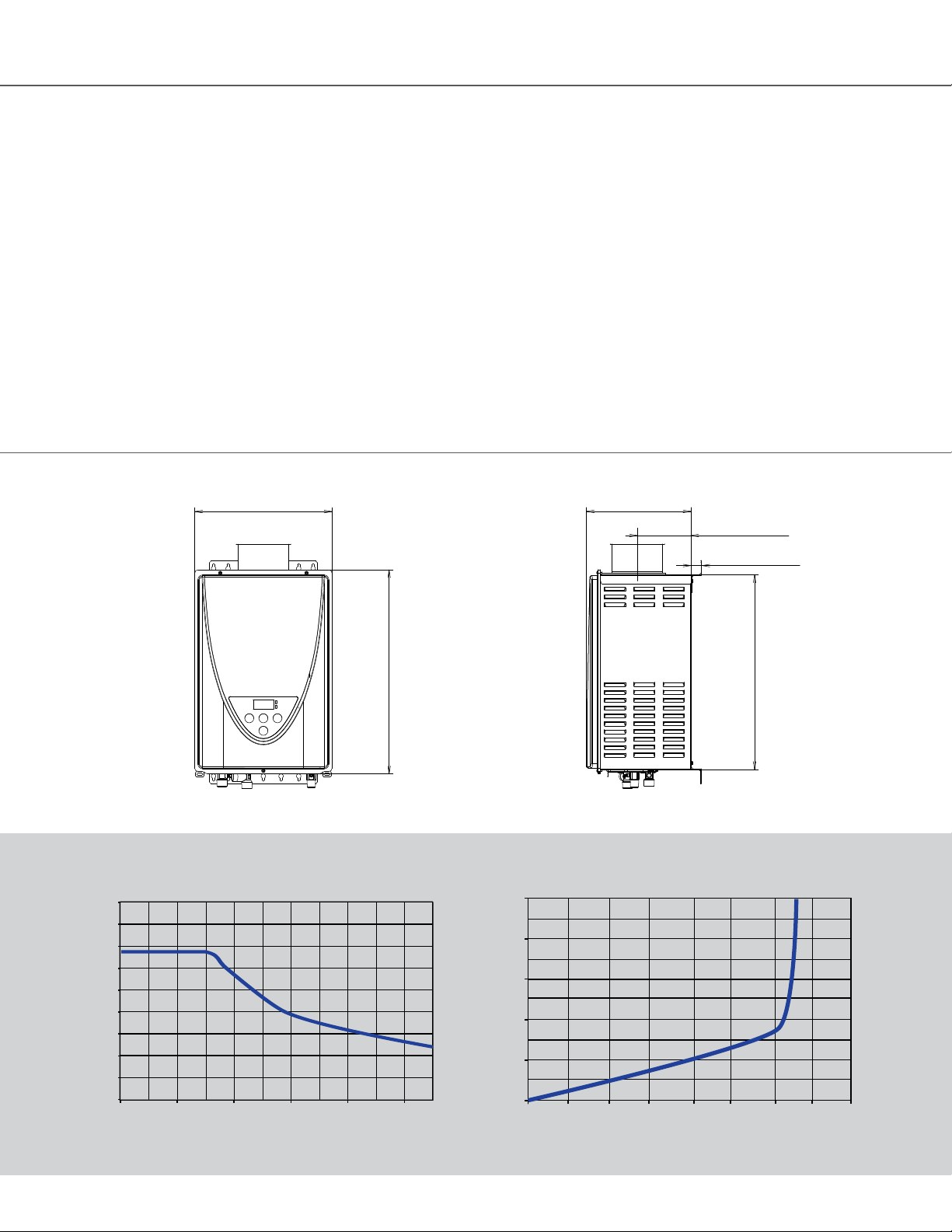

ANSI Z21.10.3 • CSA 4.3

COMMERCIAL

Specifications

M50: Flow Rate vs. Temperature Rise M50: Pressure Loss

Indoor and Outdoor Installation Options

Power Vent or Power Direct Vent Design

Low NOx Emissions

Flow Rate up to 14.5 GPM

• Values based on factory testing. 0.4 GPM required for

continuous fire after initial ignition

Water Pressure: 15-150 psi

• Pressure Only Relief Valve Requires (Min 380,000 btu/h,

150 psi).

• 40 psi or above recommended for max. flow

Dimensions

Easy-Link up to 4 heaters or connect up to

10 heaters with a Multi-Unit Controller

Warranty

• 6-year limited warranty on heat exchanger in commercial

applications.

• 5-year warranty on all parts.

• Refer to takagi.com for further warranty details

M50: Flow Rate vs. Temperature Rise

16

14

12

10

8

6

Flow rate (gpm)

4

2

0

25 45 65 85 105 125 145

Temperature rise (°F)

Set temperature: 145°F or lower

Set temperature: 150°F or higher

M50: Pressure Loss

25

20

15

10

Pressure Loss (psi)

5

0

Flow Rate (gpm)

Set temperature: 145°F or lower

Set temperature: 150°F or higher

50

40

30

20

Head (ft)

10

0

16.014.012.010.08.06.04.02.00.0

40

CT-199 SERIES

The CT-199 is well suited for commercial applications such as small restaurants and beauty

salons. Complies with Ultra-Low NOx regulations. Utilizing commercial-grade copper alloy

for the heat exchanger tubing, the H3C is also suitable for combination space heating and

domestic recirculation systems. Indoor models have an integrated temperature controller and

outdoor models include a remote control as a standard feature. Indoor models are certified up

to 10,100 ft. altitude.

TCT-199I TCT-199O

Specifications

Gas Consumption Input Inlet Gas Pressure**

Model Number* Type

TCT-199I-N Natural 15,000 199,000 4.0 10.5 96% 0.93

TCT-199O-N Natural 15,000 199,000 4.0 10.5 96% 0.95

Model Number*

TCT-199I-N 10 3/4" NPT 3/4" NPT 12 12 3 4 71

TCT-199O-N 10 3/4" NPT 3/4" NPT 36 12 3 24 69

*For propane models, change “N” to “P”

**For propane models, minimum fire rate is 13,000 BTU/H, minimum inlet gas pressure is 8.0 in. W.C. and maximum inlet gas pressure is 14.0 in. W.C.

CT-199

Temperature

Settings

Electric 120 V

Maximum

GPM

Built In / without remote 120°F (default) 140°F

With 100112572 remote (max. distance 400’ from heater, non-polarized 20 gauge wiring.)

100°F to 185°F with 5°F intervals (16 options), 120°F Default Factory Setting

Minimum

(BTU/H)

Hot/Cold

Connections

89 W / 0.74 A

(Operation)

Maximum

(BTU/H)

Gas

Connection

4 W / 0.04 A

(Standby)

Minimum

(in. W.C.)

Top Bottom Side Front

Maximum

(in. W.C.)

Clearances (in.)

175 W / 1.5 A

(Freeze-Protection)

Thermal

Efficiency

UEF

Approx

Shipping

Weight (lbs)

41

ANSI Z21.10.3 • CSA 4.3

COMMERCIAL

Specifications

10-3/4" (272mm)

22-1/22" (570 mm)

2-5/8" (68 mm)

Exhaust

Intake

2-5/8" (65 mm)

5-3/4" (147 mm)

11-1/4" (285 mm)

1/2 (13 mm)

GAS 5-1/8" (131 mm)

HOT 5-1/2" (140 mm)

COLD 6-3/4" (172 mm)

Condensate drain port

Drain port 6" (152 mm)

120 VAC 6-7/8" (174 mm)

CT-199: Flow Rate vs. Temperature Rise

CT-199: Pressure Loss

Indoor and Outdoor Installation Options

Power Vent or Power Direct Vent Design

Ultra-Low NOx Emissions

Flow Rate up to 10 GPM

• Values based on factory testing. 0.4 GPM required for

continuous fire after initial ignition

Water Pressure: 15-150 psi

• Pressure Only Relief Valve Requires (Min 199,000 btu/h,

150 psi).

• 40 psi or above recommended for max. flow

Dimensions

17-3/4" (450 mm)

4" (102 mm)

∅

Female

7" (180 mm)

6-1/4" (159mm)

4" (101 mm)

4" (102 mm)

∅

Female

Easy-Link up to 4 heaters or connect up to

20 heaters with a Multi-Unit Controller

Create a Multi-Unit system with the

100112691 controller 96% thermal

efficiency

Warranty

• 6-year limited warranty on heat exchanger in commercial

applications.