Page 1

1W1220-1

OFF

1 2 3 4 5 6 7 8

OFF

1 2 3 4 5 6 7 8 9 10

Gas Conversion-110U,310U,510U Series 200

This water heater is configured for Natural Gas from the factory. However, if a field conversion to Propane Gas is

necessary, the conversion kit supplied with the water heater must be used and installed by a qualified service agency*.

Before you install the components in this Propane Gas conversion kit, verify the type of gas that will be used to fuel the

unit. WARNING! An improper field conversion could cause potentially dangerous conditions that may cause an

explosion or fire resulting in property damage, bodily injury or both.

• This conversion kit shall be installed by a qualified service agency* or a gas utility service technician in

accordance with Manufacturer’s written instructions and all applicable codes and requirements of the

authority having jurisdiction. The information in these instructions must be followed to minimize the risk

of fire or explosion or to prevent property damage, personal injury or death. The qualified service agency*

is responsible for the proper installation of this kit. The installation is not proper and complete until

WARNING

* A qualified service agency is any individual, firm, corporation or company which either in person or through a

representative is engaged in and is responsible for the connection, utilization, repair or servicing of gas utilization

equipment or accessories; who is experienced in such work, familiar with all precautions required, and has

complied with all of the requirements of the authority having jurisdiction.

the operation of the converted appliance is checked as specified in the manufacturer’s instructions

suppied with the kit.

• If your water heater has been converted to use a different gas type in the past, the manufacturer

does NOT recommend converting it again.

• IN CANADA, THE CONVERSION SHALL BE CARRIED OUT IN ACCORDANCE WITH THE REQUIREMENTS

OF THE PROVINCIAL AUTHORITIES HAVING JURISDICTION AND IN ACCORDANCE WITH THE

REQUIREMENTS OF THE CSA-B149.1, NATURAL GAS AND PROPANE INSTALLATION CODE.

100272467

Tools Required:

• Phillips Screwdriver / Manometer / Gas Leak Detector

Included Items: 100270585

LP Gas Manifold Nozzles

with nozzle gaskets

Manifold gasket Gas Conversion Label Spare screws

Ensure that each manifold nozzle includes

a gasket prior to installation.

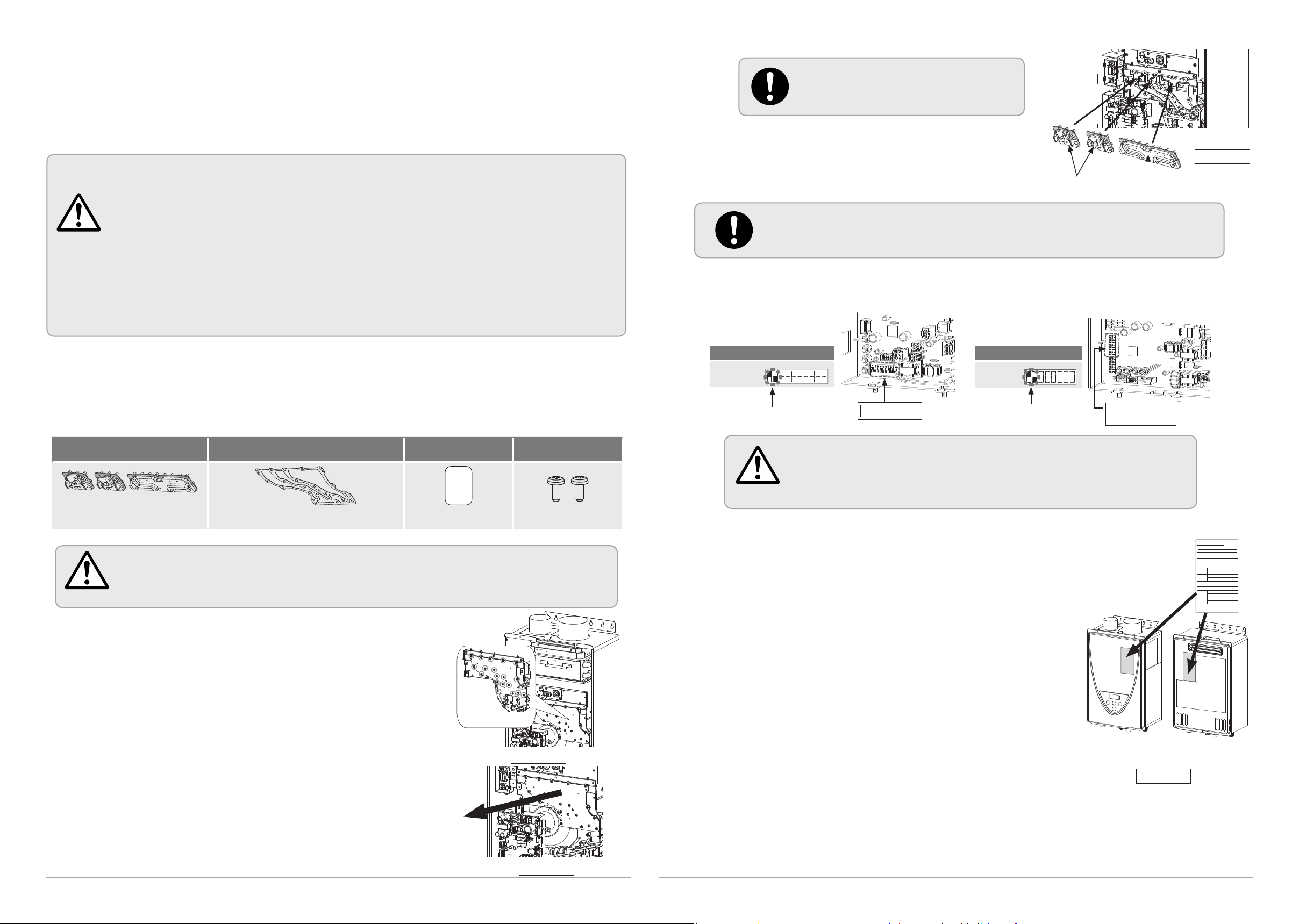

10.Install each LP Gas Manifold Nozzle as shown in Figure 3.

NOTE: The parts are keyed and cannot be installed incorrectly.

11.After making sure that the manifold nozzles are secure, install the

manifold cover using the 20 screws that were removed during

step 5. See Figure 1.

Small LP Gas

Manifold Nozzles

Large LP Gas

Manifold Nozzle

Figure 3

Hand tighten the screws. Do not overtighten as this may damage or crack the components.

Do not use a powered screwdriver.

12. Set the DIP switches on the PCB to the correct position for propane. See the figures below for the proper propane

DIP switch settings.

Gas type

Propane

ON

Change to the above posion.

(No.1 SW : ON No.2 SW : OFF)

WARNING

110U / 310U

<Upper bank of

DIP switches>

Gas type

ON

DIP switches

Propane

Change to the above posion.

(No.1 SW : ON No.2 SW : OFF)

• Turn off the power before changing the DIP switch settings.

• Only change the DIP switches specified above for the conversion to propane.

• Failure to properly set the DIP switches could cause carbon monoxide

poisoning, resulting in severe personal injury or death.

510U

Upper bank of

DIP Switches

Qty: 2 Small / 1 Large

Qty: 1

Part No. : 319143-581

Qty: 1

Before servicing the water heater, make sure that electrical power and gas service to the

water heater is turned OFF. Failure to do so may result in bodily injury, death, or property

WARNING

damage.

Procedure:

1. Turn off power supply.

2. Turn off both gas and water valves to the water heater.

3. Remove the front cover.

4. Once the front cover is removed, place it in a safe location to prevent accidental

damage. With the internal components exposed, locate the gas manifold near

the center of the unit.

5. Use a Phillips screwdriver to remove the 20 screws on the manifold plate

shown in Figure 1.

6. Remove the manifold plate. (Figure 2)

7. Remove the manifold gasket from the manifold plate. Discard the gasket.

8. Install the new manifold gasket onto the manifold plate. Ensure that the gasket

is in good condition and not compromised in any way. If it is damaged, do not

install the gasket. Replace it with a new one. (Part number: 319143-581)

9. Refer to Figure 3 and identify the proper location for each LP Gas Manifold

Nozzle. The nozzle attachments are of two types: small and large. The smaller

nozzle attachments are for the left two sections and the larger one is for the right

section.

Remove

the 20 screws.

Qty: 2

Figure 1

Figure 2

13. Verify that the gas supply pressure is within an acceptable range. For instructions, see “Gas Supply and Gas Pipe

Sizing for Propane” on the reverse side of this instruction sheet.

14. Turn power ON and turn on the gas supply.

15. Check for gas leaks around the manifold plate as follows:

a. Turn on a nearby hot water faucet.

b. Wait until a consistent flame is seen through the sight

glass.

Gas Conversion

Label

This water heater was converted on

/ / (month-day-year)

to Propane gas with kit No. 100270585

by

(name and address of organizaon making this conver-

sion, who accepts the responsibility for the correctness

of this conversion).

110U

310U

Model

Indoor

Indoor

(AT-KJr3U-IN)

(AT-K5U-IN)

Min. 8.0” W.C. (1.99 kPa)

Inlet Gas Pressure

Max. 14.0” W.C. (3.48 kPa)

Min.

0.45 0.45 0.45

inches WC

Manifold Gas

Pressure

Max.

1.70 2.60 3.10

inches WC

Min.

15,000 15,000 15,000

BTU/h

BTU Input

Max.

140,000 190,000 199,000

BTU/h

110U

310U

Model

Outdoor

Outdoor

(AT-KJr3U-OS)

(AT-K5U-OS)

Min. 8.0” W.C. (1.99 kPa)

Inlet Gas Pressure

Max. 14.0” W.C. (3.48 kPa)

Min.

0.51 0.51 0.51

inches WC

Manifold Gas

Pressure

Max.

1.85 3.20 3.40

inches WC

Min.

15,000 15,000 15,000

BTU/h

BTU Input

Max.

140,000 190,000 199,000

BTU/h

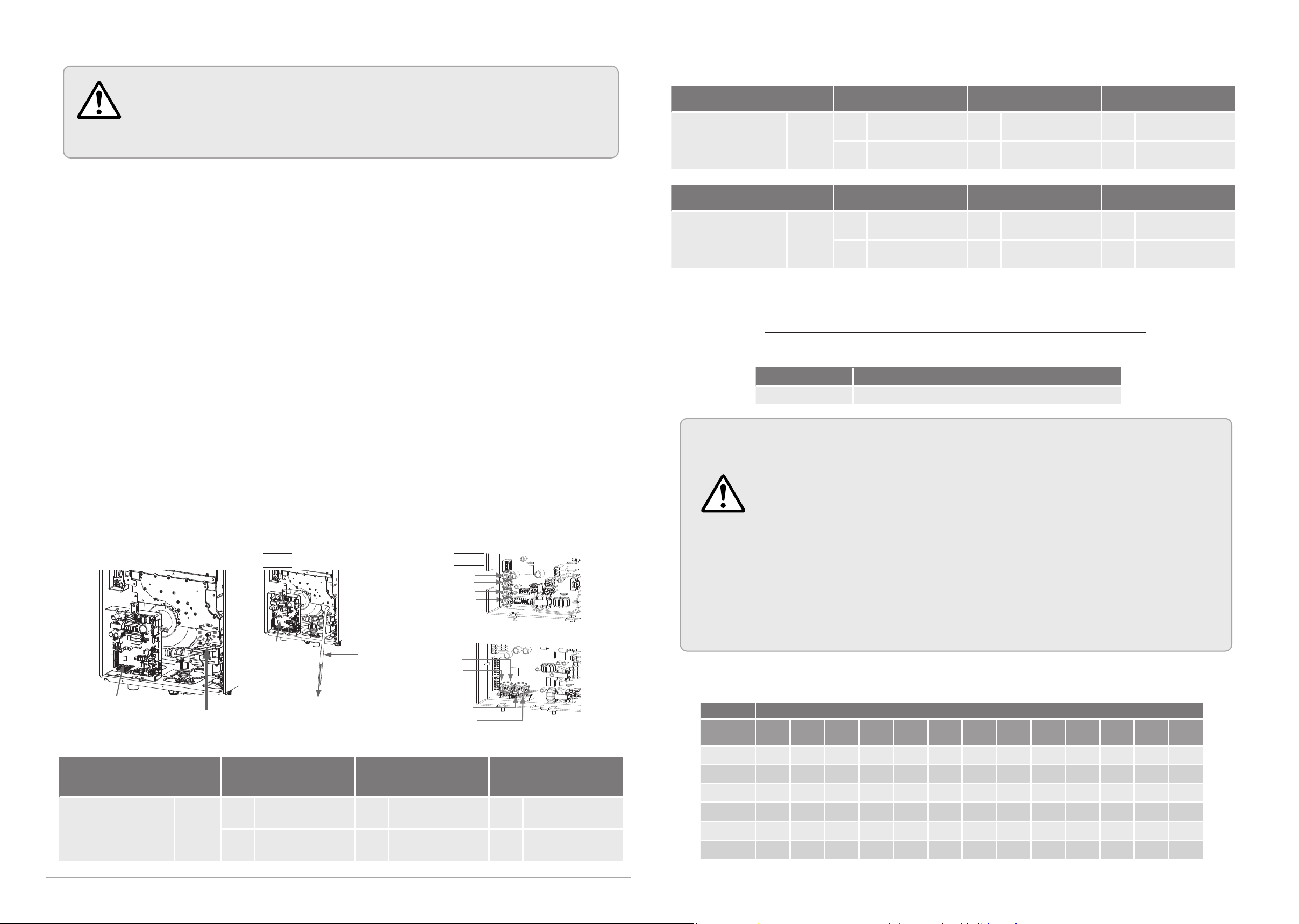

Affix the label on the front cover in a conspicuous location

as close as possible to the rating plate on the side case.

510U

Indoor

(AT-D3U-IN)

510U

Outdoor

(AT-D3U-OS)

1W1240

c. Check for gas leaks by running a gas leak detector

along the edges of the manifold plate. If you find a leak, stop operating the

water heater and turn the gas supply off. Replace the manifold gasket with a

new one. (Part number: 319143-581)

16. Turn the water supply off.

17. After the water heater has completed its post-purge process, turn off the gas

supply and turn off power to the water heater.

18. Verify the static and dynamic gas pressures for the water heater. Refer to the

installation manual for instructions.

19. Check the manifold pressures as described on the reverse side of this instruction

sheet.

20. Install the front cover with four screws for Indoor models and three screws for

Indoor

model

Figure 4

Outdoor

model

Outdoor models.

21. Fill out all items on the gas conversion sticker with a permanent marker. Affix the label on the upper section of the

front cover of the heater as shown in Figure 4.

22. Restart the water heater according to the Installation Manual and Owner’s Guide. Verify proper operation before

returning the water heater to service.

(continued overleaf)

Page 2

Adjusting the manifold pressure can cause unexpected combustion conditions during operation,

which can cause a health hazard, damage the water heater, and/or shorten its lifespan.

Therefore, the manifold pressure must only be changed by a qualified service agency or a gas

WARNING

utility service technician in accordance with Manufacturer’s written instructions and all applicable

codes and requirements of the authority having jurisdiction.

Checking maximum and minimum manifold pressure

i. Ensure that the water heater is not in operation.

ii. Remove the screw off the manifold port of the water heater. (Fig.A)

iii. Connect a manometer to the manifold port using a silicon tube (Fig. B). Ensure that this connection is secure enough to

prevent a gas leak.

iv. Turn on power supply to the water heater.

v. Turn on both gas and water valves to the water heater.

vi. Turn on hot water fixtures to produce a high flow. If an isolation valve is installed, hook up a water hose to the hot outlet

and run water at maximum rate.

vii. Verify the MAX and MIN settings as follows:

a. Press and hold the “MAX” button on the computer board. (See Figure C.)

b. Compare the reading on the manometer to the values in the table on the right. If it does not fall within the

acceptable range, refer to “Adjusting maximum manifold pressure.”

c. Press and hold the “MIN” button on the computer board. (See Figure C.)

d. Compare the reading on the manometer to the values in the table on the right. If it does not fall within the

acceptable range, refer to “Adjusting minimum manifold pressure.”

Adjusting maximum manifold pressure

• Press and hold down the “MAX” button on the computer board. While holding down the “MAX” button, press either the

“Increase” or “Decrease” button to increase or decrease the manifold gas pressure, respectively (Fig. C). Do not push

the increase or decrease button for more than two seconds at a time. Refer to the manometer to verify that pressure

has been set to the desired value.

Adjusting minimum manifold pressure

• Press and hold down the “MIN” button on the computer board. While holding down the “MIN” button, press either the

“Increase” or “Decrease” button to increase or decrease the manifold gas pressure, respectively (Fig. C). Do not push the

increase or decrease button for more than two seconds at a time. Refer to the manometer to verify that pressure has

been set to the desired value.

viii. After gas pressure has been set, turn off the power supply and turn off both gas and water valves. Next, remove the

manometer tube, and replace the port screw securely. If the screw isn’t fastened securely at this time, it may cause a gas leak.

Fig. A

Computer

board

Manifold port

Fig. B

Computer

board

To manometer

Silicone

Tube

Increase button

Decrease button

MIN. button

MAX. button

Increase button

Decrease button

Fig. C

MAX. button

MIN. button

110U / 310U computer board

510U computer board

BTU Input

Models for Propane

BTU Input

BTU/h

110U Indoor/Outdoor

AT-KJr3U-IN/OS

Max. 140,000 Max. 190,000 Max. 199,000

Min. 15,000 Min. 15,000 Min. 15,000

310U Indoor/Outdoor

AT-K5U-IN/OS

510U Indoor/Outdoor

AT-D3U-IN/OS

Manifold Pressure

Models for Propane

Manifold Pressure

Models for Propane

Manifold Pressure

Inch

W.C .

(Pa)

Inch

W.C .

(Pa)

110U Indoor

AT-KJr3U-IN

Max.

Min.

110U Outdoor

AT-KJr3U-OS

Max.

Min.

1.47 to 1.77

(366 to 440)

0.41 to 0.52

(102 to 129)

1.78 to 2.02

(443 to 503)

0.47 to 0.57

(117 to 142)

310U Indoor

AT-K5U-IN

Max.

Min.

310U Outdoor

AT-K5U-OS

Max.

Min.

2.42 to 3.00

(602 to 747)

0.41 to 0.52

(102 to 129)

3.02 to 3.41

(751 to 849)

0.47 to 0.57

(117 to 142)

GAS SUPPLY AND GAS PIPE SIZING FOR PROPANE

• The minimum and maximum inlet gas pressures for propane are:

Gas type Inlet gas pressure

Propane Min. 8.0” W.C. (1.99 kPa) – Max. 14.0” W.C. (3.48 kPa)

• Size the gas pipe to supply the necessary volume of gas for the water heater.

Refer to and follow the requirements listed in the current edition of ANSI Z223.1/NFPA 54

(USA), B149.1 (Canada), or local codes. Otherwise, flow capabilities and output temperatures will be limited.

• When the gas connections are completed, it is necessary to perform a gas leak test either

by applying soapy water to all gas fittings and observing for bubbles or by using a gas leak

WARNING

Maximum Capacity of Propane (LP) Based on 11" W.C. supply pressure at a 0.5" W.C. pressure drop

Pipe Size Length

Diameter

1/2"

3/4"

1"

1/4"

1

1/2"

1

2"

detection device.

i. The water heater and its individual shutoff valve must be disconnected from the gas

supply piping system during any pressure testing of that system at test pressures in

excess of 1/2 psi (3.5 kPa).

ii. The water heater must be isolated from the gas supply piping system by closing its

individual manual shutoff valve during any pressure testing of the gas supply piping

system at test pressures equal to or less than 1/2 psi (3.5 kPa).

• Regarding high altitude installation after gas conversion, refer to the “HIGH ALTITUDE

INSTALLATIONS” section of the installation manual. (P. 12)

-Propane (LP) Supply Piping-

10'

(3.0m)

268 184 148 126 112 101 93 87 82 77 68 62 53

567 393 315 267 237 217 196 185 173 162 146 132 112

1,071 732 590 504 448 409 378 346 322 307 275 252 213

2,205 1,496 1,212 1,039 913 834 771 724 677 630 567 511 440

3,307 2,299 1,858 1,559 1,417 1,275 1,181 1,086 1,023 976 866 787 675

6,221 4,331 3,465 2,992 2,646 2,394 2,205 2,047 1,921 1,811 1,606 1,496 1,260

20'

(6.1m)

30'

(9.1m)

40'

(12.2m)

50'

(15.2m)

60'

(18.3m)

70'

(21.3m)

80'

(24.4m)

90'

(27.4m)

100'

(30.5m)

510U Indoor

AT-D3U-IN

Max.

Min.

2.65 to 3.27

(659 to 814)

0.41 to 0.52

(102 to 129)

510U Outdoor

AT-D3U-OS

Max.

Min.

Unit: kBTU per hour

125'

(38.1m)

3.22 to 3.61

(801 to 898)

0.47 to 0.57

(117 to 142)

150'

(45.7m)

(61.0m)

200'

Loading...

Loading...