W

W

T-KD20 Instantaneous Water

Heater Installation Manual and Owner’s Guide

Flash Water Heater

Model T-KD20

Suitable for potable water heating and space heating

FEATURING

• ENDLESS HOT WATER

• ON DEMAND

• COMPACT, SPACE SAVING

• ENERGY CONSERVING

• COMPUTER CONTROLS

• COMPUTERIZED SAFETY

• NO PILOT LIGHT

This product must be installed and

serviced by a licensed plumber, a

licensed gas fitter, or a professional

service technician and/or in accordance

with all local code. Improper installation

and/or operation, or installation by an

unqualified person, will void the warranty.

Operation of this unit creates carbon

monoxide gas and flue gases which can

cause serious injury or death. In addition,

if the information in this manual is not

followed exactly, a fire or explosion may

result causing property damage, personal

injury or death.

Takagi Industrial Co. USA Inc.

3-B Goodyear

Irvine, CA 92618

Toll Free (888) 882-5244 USA

Toll Free (877) 877-4935 CANADA

www.Takagi.com

ARNING

ARNING

CONTENTS

Specification …………. 2

Introduction …………..3

For your safety …………..3-4

Installation …………. 5

• General …………. 5

• Accessories …………. 5

• Indoor Installation …………. 6

• Venting Instructions …………..6 -8

• Gas Supply/Gas Pipe sizing………..9-10

• Water Connection …………. 10-11

• Electrical Connection …………. 11

• Initial operation …………. 12

Normal operation …………. 12

• Flow …………. 12-13

• Temperature setting …………. 13

• Freeze Protection Device …………. 13-14

• Maintenance and Service …………..14-15

• Error codes …………..15

Wiring diagram …………..16

For your Safety …………..17

Danger …………..18

Application …………..19

• Space Heating …………..19

• Dual-purpose heating …………..20

• Storage Tank …………..21

• Re-Circulation …………..21

Optional Items …………..22

Component Diagram …………23-25

Component Diagram …………..26

Output temperature Chart …………..27

Natural Gas Input Min. 20,000 Btu

Max. 185,000 Btu

LPG Input Min. 19,000 Btu

Max. 175,000 Btu

Gas Connection ¾” NPT

Water Connections ¾” NPT

Water Pressure Min. 15 psi

Max. 150 psi

Natural Gas Pressure Inlet Min. 5” WC

Max. 10.5” WC

LP Gas Pressure Inlet Min. 11” WC

Max. 14” WC

Manifold Pressure Natural 2.3” WC

Propane 2.5” WC

Weight 60 lbs.

Dimensions 24.5”x16.5”x8.3”

Ignition Electronic Ignition

Electrical Supply AC 120 V

• Check the rating plate to ensure this

product matches your specifications;

• Before installing in areas over 4,500 feet

above sea level, contact Takagi;

• Takagi is constantly improving its products

therefore specifications are subject to

change without prior notice.

SPECIFICATIONS

*** NOTE ***

- 2 -

INTRODUCTION

This manual provides information necessary

for the installation, operation, and maintenance

of the Model T-KD20 water heater. This unit

includes a fan enabling sidewall (power)

venting and an advanced electronic ignition

system.

The model description is listed on the rating

plate which is attached to the front cover of the

water heater. Please read all installation

instructions completely before installing this

product. If you have any problems or

questions regarding this equipment, consult

with Takagi or its local representative.

Experiences have shown that most operating

problems are caused by improper installation.

The T-KD20 Water Heater is an instantaneous,

tankless water heater designed to supply

endless hot water to your entire household

and/or commercial facility utilizing total

efficiency. The principle behind the T-KD20

Water Heater is simple. Once you open a hot

water tap, water flows through the T-KD20

Water heater. Once a minimum of 0.75 GPM is

achieved, the flow sensor automatically

commands the computer to turn on the fan,

activate the electronic igniter and open the gas

valves. The computer monitors water

temperature, water flow rate and gas flow to

ensure that you get the right amount of hot

water at the correct hot water temperature.

After the burners are ignited, the “fire on” lamp

is lit. The computer will modulate the gas

supply valve and water flow. 0.75 gallons per

minute is required to turn the burners on; after

the burners are ignited, the flow rate can be

lowered to 0.6 gallons per minute to maintain

the heater on. It is advisable to open further

the cold tap rather than decreasing the hot tap

to adjust the water temperature. As long as

you have water, gas and electricity, you will get

an endless flow of hot water. Open a hot water

tap to turn on your water heater. Close the tap

to turn off your water heater.

FOR YOUR SAFETY

The installer is responsible for the correct

installation of your Flash T-KD20 Water

Heater. Installation and service must be

performed by a qualified installer (for

example, a licensed plumber or gas fitter)

otherwise the warranty by Takagi will be

void.

PLEASE READ THIS MANUAL CAREFULLY

AND FOLLOW ALL DIRECTIONS.

1. Follow all local codes, or in the absence of

local codes, follow the most recent edition

of the National Fuel Gas Code, ANSI

Z223.1/NFPA 54 in the USA or the

CAN/CSA B149.1 Natural Gas and

Propane Installation Code in Canada.

2. Properly ground the unit in accordance with

all local codes or in the absence of local

codes, with the National Electrical Codes,

ANSI/NFPA 70 in the USA or CSA

standard C22.1 Canada Electrical Code

Part 1 in Canada.

3. Carefully plan where you intend to install

your T-KD20 Water Heater. Ensure that

your heater will have enough combustible

air and proper ventilation and locate your

heater where water leakage will not do

damage to surrounding areas. If there is a

possibility of water damage, install a

suitable drain pan under the unit which will

not restrict combustible airflow.

4. Check the rating plate for the correct gas

type, gas pressure, water pressure and

electrical rating. If this unit does not match

your requirements, do not install.

- 3 -

Rating plate

5. If any problem should occur, turn off all hot

water taps and turn off the gas. Then call a

trained technician or the Gas Company or

the manufacturer.

6. WARNING: Do not disconnect the

electrical supply if the ambient temperature

will drop below freezing. The Freeze

Prevention Device only works if the unit

has electrical power. The Freeze

Prevention Device is rated for temperatures

down to 5 ºF (-15 ºC) in a wind free

environment. Refer to the section on

Winterizing and the Freeze Prevention

Device for more information. The Warranty

will not be covered if the heat exchanger is

damaged due to freezing.

7. WARNING: Water temperatures over

125ºF can cause severe burns instantly or

death from scalding. The water

temperature is set at 122ºF (50ºC) from the

factory to minimize any scalding risk.

Before bathing or showering always check

the water temperature.

8. WARNING: Do not use this appliance if

any part has been in contact with or been

immersed water. Immediately call a trained

technician to inspect and/or service the unit

if necessary.

9. WARNING: Do not store or use gasoline or

other flammables, vapors or liquids in the

vicinity of this appliance.

GENERAL

The T-KD20. Water Heater is an

instantaneous, tankless water heater designed

to supply endless hot water to your entire

household and/or commercial facility utilizing

total efficiency. The principle behind the TKD20 Water Heater is simple. Once you open

a hot water tap, water flows through the TKD20 Water heater. Once a minimum of 0.75

GPM is achieved, the flow sensor

automatically commands the computer to turn

on the fan, activate the electronic igniter and

open the gas valves. The computer monitors

water temperature, water flow rate, and gas

flow to insure that you get the right amount of

hot water at the correct hot water temperature.

After the burners are ignited, the “fire on” lamp

is lit. The computer will modulate the gas

supply valve and water flow 0.75 gallons per

minute is required to turn the burners on;, after

the burners are ignited, the flow rate can be

lowered to 0.6 gallons per minute to maintain

the heater on. It is advisable to increase the

cold tap rather than decreasing the hot tap to

adjust the water temperature. As long as you

have water, gas and electricity, you will get an

endless flow of hot water. Open a hot water tap

to turn on your water heater. Close the tap to

turn off your water heater.

10. WARNING: Do not reverse the water

and/or gas connections as this will damage

the gas valves and can cause severe injury

or death. Following the diagram below

when installing your water heater:

- 4 -

INSTALLATION

GENERAL

All gas water heaters require careful and

correct installation to ensure safe and efficient

operation. This manual must be followed

exactly. Read the “For Your Safety” section at

the beginning of this manual.

1. The gas regulator is preset at the

factory; it is computer controlled and

should not need adjustment;

2. Maintain proper space for servicing.

Install the unit so that it can be

connected or removed easily;

3. The electrical connection requires a

means for switching off the power

supply;

4. If you will be installing the unit in a

contaminated area with a high level of

dust, sand, flour, aerosols or other

contaminants, they can become

airborne and enter and buildup within

the fan and burner causing damage to

the unit. The warranty will not cover

damage caused to the unit due to

installation in a contaminated

environment that has not been

converted.

5. Particles from these objects may clog

the air vent or reduce the functions of

the rotating fan and cause improper

burning of the gas. Regular

maintenance is recommended for these

types of environment.

6. Do not install the unit where the

exhaust vent is pointing into any

opening in a building or where the

noise may disturb your neighbors.

Make sure the clearance from the vent

termination to the doorway or opening

to prevent exhaust from entering. Take

a look at page 8.

7. Some chemicals used in a beauty salon

may affect the flame sensor. Water

heater may not work properly. Please

consult with Takagi, when the water

heater is installed in a beauty salon.

8. Water hardness may affect the water

heater. Water heater may be damaged.

The warranty will not cover damage

caused by water quality.

Direct Vent: Also known as Sealed

Combustion. Systems are all air for

combustion is derived directly from the outside

atmosphere and all flue gases are discharged

to the outside atmosphere. All Takagi products

flue gas vents are pressurized, requiring

careful sealing of all joints.

Category III Vent: A system that operates with

a positive vent static pressure and with a vent

gas temperature. T-KD20 flue gas vents are

positive pressure, it requires perfect seal of all

vent pipe joints.

Accessories

Check that the installation manual, the

extension cable and the warranty card were

included with the unit.

- 5 -

INDOOR INSTALLATION

When installed indoors, the T-KD20 water

heater shall be located in an area to maintain

the following minimum clearances around the

unit:

Indoor Installation Service Clearances

Left side of heater 6”

Front (Maintenance space) 24”

Back of heater 1”

Right side of heater 2”

Top of heater 12"

The diagram below details the required

clearances around the unit:

Wall Hanging Installation

For a wall mount installation, use TK-BK01

brackets to securely attach the T-KD20 to the

wall.

Locate the heater as desired, but follow all

applicable local codes, as well as the indoor or

outdoor clearances that apply to the

installation.

Standing Installation

If the unit is to be installed standing on a

surface, adjust the legs so that the unit stands

securely and is level (legs can be adjusted up

to 1”).

Do not install the unit standing directly on a

combustible surface. Use a 3” noncombustible base.

Use the included L brackets to connect the unit

to a wall to ensure that it does not fall over.

These brackets will maintain the required 1”

clearance between the back of the unit and a

combustible surface.

- 6 -

Combustion Air and Ventilation

This water heater must be vented in

accordance with the section “Venting of

Equipment" of the latest edition of the Natural

Fuel Gas Code, ANSI Z223.1 and all

applicable local building codes. In Canada,

follow section 7 of the CAN/CSA B149.1

Natural Gas and Propane Installation Code.

Combustible Air Supply

The T-KD20 is direct vent (Sealed

Combustion) system that all combustible air

supplies from outside building. The T-KD20

must be installed in a location where the

proper amount of combustible air will be

available to it at all times without obstructions.

As combustible air supply pipe can be used

suitable 3” pipe such as, steel, PVC or ABC

pipe supply air pipe.

WARNING: Improper venting of this appliance

can result in excessive levels of carbon

monoxide which can result in severe personal

injury or death.

VENTING INSTRUCTIONS

General

- 7 -

Exhaust Vent

This is a Category III appliance and must be

vented accordingly. The vent system must be

sealed air tight. All seams and joints must be

sealed with high heat resistant silicone sealant

or UL listed aluminum adhesive tape having a

minimum temperature rating of 350ºF. For best

results, a vent system should be as short and

straight as possible.

This unit requires 4”, Category III approved,

single wall stainless steel vent pipe or any

other Category III approved, non-combustible,

corrosion-resistant material. The following are

UL listed manufacturers: ProTech Systems Inc.

(FasNSeal), Flex-L Inc., Z-Flex Inc. (Z-Vent III)

and Heat-Fab Inc. (Saf-T Vent). Follow the

vent pipe manufacturer’s instructions when

installing the vent pipe. Do not common vent

this appliance with any other vented appliance.

The maximum length of exhaust vent piping

must not exceed 25 ft. deducting 5 ft. for each

elbow used in the venting system. Do not use

more than 3 elbows.

Diam

eter

4” 3 Ea. 25 ft

For each elbow added, deduct 5 ft. from

max. Vent length.

Horizontal Length

Max.

No. of

Elbow

No. of Elbows Max. Vertical or

Max. Vertical or

Horizontal run in

Length

0 25 ft.

1 20 ft.

2 15 ft.

3 10 ft.

When installing the vent system, all applicable

national and local codes must be followed. If

you install thimbles, fire stops or other

protective devices and they penetrate any

combustible or noncombustible construction,

be sure to follow all applicable national and

local codes.

When the horizontal vent run exceeds 5 ft., the

following criteria must be observed:

• Support the vent run at 3 ft intervals with

overhead hangers.

• Slope the vent run downwards toward the

vent terminator at a rate of ¼” per foot.

Vent Termination

A sidewall vent terminator must be used when

the water heater is vented through a sidewall.

Takagi recommends the use of its part No.TKTV05. The vent terminator provides a means of

installing vent pipe through the building wall

and must be located in accordance with ANSI

Z223.1/NFPA 54, or in Canada with CAN/CSAB149.1 and local applicable codes.

Locate the vent terminator so that it cannot be

blocked by snow. Most codes require that the

terminator be at least 12 inches above grade,

but the installer may determine if it should be

higher depending on the job site condition and

applicable codes.

WARNING: Improper installation can cause

nausea or asphyxiation, severe injury or death

from carbon monoxide and flue gases

poisoning. Improper installation will void

product warranty. For high altitude installation

above 4,500 feet, contact Takagi on how to

handle this situation.

General rules for venting the T-KD20 water

heater are:

1. Place the water heater as close as possible

to the vent terminator;

2. The vent collar of the water heater must be

fastened directly to an unobstructed vent

pipe.

3. Do not weld the vent pipe to the water

heater collar.

4. The weight of the vent stack must not rest

on the water heater.

5. The vent must be easily removable from

the top of the water heater for normal

service and inspection of the unit.

6. The water heater vent must not be

connected to any other gas appliance or

vent stack.

7. Avoid locating the water heater vent

terminator near any air intake devices or

air-conditioning units. These fans can pick

up the exhaust flue products from the water

heater and return them to the building. This

can create a health hazard.

8. Avoid using an oversized vent pipe or using

extremely long runs of the pipe.

- 8 -

Canada U.S.A

Clearance above grade, veranda, porch,

A

deck, or balcony.

Clearance to window or door that may be

B

opened.

Clearance to permanently closed window * * *

C

Vertical clearance to ventilated soffit located

above the vent terminator within a horizontal

D

distance of 2 feet (61cm) from the center

line of the terminator.

Clearance to unventilated soffit * * *

E

Clearance to outside corner * * *

F

Clearance to inside corner * * *

G

Clearance to each side of center line

H

extended above meter/regulator assembly

Clearance to service regulator vent outlet. 3 feet * *

I

Clearance to non-mechanical air supply inlet

to building or the combustion air inlet to any

J

other application.

Clearance to mechanical air supply inlet. 6 feet 3 feet 3 feet

K

Clearance above paved sidewalk or paved

L

driveway located on public property.

Clearance under veranda, porch deck, or

M

balcony.

*For clearances not specified in ANSI Z223.1 / NFPA 54 or CAN/CSA-B149, please use clearances in accordance

with local installation codes and the requirement of the gas supplier.

Direct vent and

other than Direct Vent

1 foot 1 foot 1 foot

3 feet 1 foot

* * *

3 feet * *

3 feet 1 foot

7 feet * 7 feet

1 foot * *

Direct vent Other than Direct Vent

4 feet from below or

side opening. 1 foot

from above opening.

4 feet from below or

side opening. 1 foot

from above opening.

- 8 -

p

anufacture

y

GAS SUPPLY AND GAS PIPE SIZING

TO TURN OFF GAS TO

1. Turn off all electric power to the water

heater if service is to be performed.

2. Turn the manual gas valve located on the

outside of the unit clockwise 3 to the off

osition.

FOR YOUR SAFETY, READ

A. This water heater does not have a pilot. It

is equipped with an electronic ignition

device that automatically lights the burner.

Do not try to light the burner manually;

B. BEFORE OPERATING, check all around

the water heater area for gas leaks. Be

sure to check next to the floor as some

gases are heavier than air and will settle

on the floor;

C. Use only your hand to turn the gas valve

knob. Never use tools. If the knob will not

turn by hand, do not attempt to repair it.

Call a qualified service technician. Force

or attempted repair may result in a fire or

explosion.

D. WARNING: Conversion of this unit from

natural gas to propane or propane to

natural gas cannot be done in the field.

Contact your local distributor to get the

correct unit for your gas type. Conversion

done by anyone other than the

m

r will void all warrant

.

Check that the type of gas matches the rating

plate located on the cover of your water heater.

The minimum and maximum inlet gas pressures

are:

Natural Gas Min. 5” WC - Max. 10.5” WC

Propane Gas Min. 11” WC - Max. 14” WC

Gas pressure below this specified range for the

T-KD20 and/or insufficient gas volume will

adversely affect performance. Inlet gas pressure

must not exceed the above maximum values; gas

pressure above the specified range will cause

dangerous operating conditions and damage to

the unit. Until testing of the main gas line supply

pressure is completed, ensure the gas line to the

T-KD20 is disconnected to avoid any damage to

the water heater.

Size the gas pipe appropriately to supply the

necessary volume of gas required for the T-KD20

(185,000 BTUH) using ANSI233.1/NAPA 54 in

the USA or CAN/CSA B149.1 in Canada or local

codes. Install a manual gas shut-off valve

between the T-KD20 and the gas supply line.

When the gas connections are completed, it is

necessary to perform a gas leak test either by

applying soapy water to all gas fittings and

observing for bubbles or by using a gas leak

detection device. Always purge the gas line of

any debris before connecting to the heater gas

inlet.

Pipe Sizing Example: This table below is for

Natural gas piping supply straight to the water

heater without any tabs to other gas appliances

Recommend Gas pipe size for

T-KD20 Water Heater (Example for NG)

Distance from Gas Meter Pipe Size (inches)

0' - 30' 3/4"

30' - 100' 1"

100' – 200’ 1-1/4"

- 9 -

Natural Gas Supply Piping

Maximum Capacity of Natural Gas Based on a 0.60 specific gravity at a 0.5” WC pressure drop

Pipe Size kBTU of Natural Gas

Length 10’ 20’ 30’ 40’ 50’ 60’ 70’ 80’ 90’ 100’ 125’ 150’ 200’

¾” 372 255 205 175 156 142 130 121 114 107 95 86 74

1” 702 482 387 331 293 266 245 228 213 202 179 162 139

1 ¼” 1441 990 795 680 603 546 503 468 439 415 367 332 285

1 ½” 2158 1483 1191 1019 903 819 753 701 658 621 550 499 427

2” 4155 2856 2293 1963 1740 1576 1450 1349 1266 1195 1060 960 822

Propane (LP) Gas Supply Piping

Maximum Capacity of Propane (LP) Gas Based on 11” WC supply pressure at a 1.0” WC pressure drop

Pipe Size kBTU of Propane

Length 10’ 20’ 30’ 40’ 50’ 60’ 70’ 80’ 90’ 100’ 125’ 150’ 200’

¾” 567 393 315 267 237 217 196 185 173 162 146 132 112

1” 1071 732 590 504 448 409 378 346 322 307 275 252 213

1 ¼” 2205 1496 1212 1039 913 834 771 724 677 630 567 511 440

1 ½” 3307 2299 1858 1559 1417 1275 1181 1086 1023 976 866 787 675

2” 6221 4331 3465 2992 2646 2394 2205 2047 1921 1811 1606 1496 1260

WATER CONNECTIONS

FOR YOUR SAFETY, READ

Do not use this water heater if any part

has been submersed under water.

Immediately call a qualified service

technician to inspect the water heater and

to replace any damaged parts.

All pipes, pipe fittings, valves and other

components, including soldering materials,

must be suitable for potable water systems. A

manual shut off valve must be installed on the

cold water inlet to the water heater between

the main water supply line and the T-KD20. In

addition, a manual shut off valve is also

recommended on the hot water outlet of the

unit. If the T-KD20 is installed within, or

subjected to, a closed loop water system, such

as one having an anti-backflow device in the

cold water supply line, a thermal expansion

tank must be installed. Contact the water

supplier or local plumbing inspector on how to

control this situation.

After installation of the water heater is

complete, purge the water line to remove all

the debris and air from the line. Failure to do

so may cause damage to the heater. There is

a wire mesh filter within the cold inlet to trap

debris from entering your heater. This will need

to be cleaned periodically to maintain optimum

flow.

Unit Draining & Filter Cleaning Procedures

To drain your unit, please follow these

instructions carefully:

1. Turn off the power supply to the T-KD20

Water Heater.

2. Close the manual gas shut off valve

located on the gas supply line.

3. Close the manual water shut off valve

located on the water supply line.

4. Open all hot water taps in the house.

(Bathroom, kitchen, laundry room, etc.).

When the residual water flow has ceased,

close all hot water taps.

5. Have a bucket or pan to catch the water

from the unit’s drain plugs. Remove the

drain plugs to drain all the water out of the

unit.

6. Wait a few minutes to ensure all water has

drained from unit.

7. At this time, please check the water filter

located within the cold inlet. With a tiny

brush, clean the water filter of any debris

which may have accumulated and reinsert

the filter back into the cold water inlet.

8. Securely screw the drain plugs back into

place. Hand- tighten only

- 10 -

To re-start your heater, follow these steps:

1. Make sure all hot water taps are closed

and the drain plugs are securely attached.

2. Purge the water line of debris.

3. Open the manual water shut-off valve

located on the water supply line.

4. Open all the hot water taps to verify water

flows to the taps. Then close the hot water

taps.

5. Open the manual gas shut-off valve located

on the gas supply line.

6. Turn on the power supply to the T-KD20

Water Heater.

Note: Do not reverse the hot outlet and cold

inlet connections to the T-KD20 Water Heater.

This will not activate the water heater.

Pressure Relief Valve

The FLASH T-KD20 has a high-temperature

shut off switch built in as a standard safety

feature (called a Hi-Limit switch) therefore a

“pressure only” relief valve is required.

This unit does not come with an approved

pressure relief valve. An approved pressure

relief valve must be installed on the hot water

outlet. The pressure relief valve must conform

to ANSI Z21.22 or CAN 1-4.4 and installation

must follow local code.

The discharge capacity must be at least

185,000 BTU/hr. The discharge piping for the

pressure relief valve must be directed so that

the hot water cannot splash on anyone or on

nearby equipment. Attach the discharge tube

to the pressure relief valve and run the end of

the tube to within 6" from the floor. This

discharge tube must allow free and complete

drainage without any restrictions.

If the pressure relief valve installed on the TKD20 discharges periodically, this may be due

to a defective thermal expansion tank or

defective pressure relief valve.

The pressure relief valve must be manually

operated periodically to check for correct

operation.

ELECTRICAL CONNECTIONS

WARNING: Follow the electrical code

requirements of the local authority having

jurisdiction. In the absence of such

requirements, follow the latest edition of the

National Electrical Code ANSI/NFPA 70 in the

U.S. or the latest edition of CSA C22.1

Canadian Electrical Code, Part 1, in Canada.

The heater must be electrically grounded. Do

not attach the ground wire to either the gas or

the water piping. Plastic pipe or dielectric

unions may isolate the water heater

electrically.

CAUTION: When servicing or replacing parts

within the T-KD20, label all wires prior to

disconnection to facilitate an easy and error

free reconnection. Wiring errors can cause

improper and dangerous operation. Verify

proper operation after servicing.

The FLASH T-KD20 water heater requires AC

120V 60 Hz electrical power supply that is

properly grounded.

• An on/off switch controlling the main power

to the T-KD20 must be provided for service

reasons;

• Connect the power supply to the T-KD20

exactly as shown in the wiring diagram;

A green screw is provided in the junction box

to ground the connection.

Wiring diagrams are also located on the

inside panel of the appliance.

- 11 -

INITIAL OPERATION

For your safety please read before

operating the unit for the first time.

Once you have properly installed the unit and

before firing it for the first time, check the gas

and water connections for leaks. Open the

main gas supply valve to the unit using only

your hand to avoid any spark. Never use tools.

If the knob will not turn by hand, do not try to

force it; call a qualified service technician.

Force or attempted repair may result in a fire or

explosion due to gas leaks. Be sure to check

next to the bottom of the unit because some

gases are heavier than air and may settle

towards the floor.

CAUTION: IF YOU SMELL GAS:

1. Do not try to start the water heater.

2. Do not touch any electric switch; do not

use any phone in your building.

3. Immediately call your gas supplier from

a neighbor’s phone. Follow the gas

supplier’s instructions.

4. If you cannot reach your gas supplier,

This water heater does not have a pilot light. It

is equipped with an electronic ignition device

which automatically lights the burner. Do not

try to light the burner manually. Check for

proper venting and combustible air to the

heater. Purge the gas and water lines to

remove any air pocket. Do not use this water

heater if any part has been submersed under

water. Immediately call a qualified service

technician to inspect the water heater and to

replace any parts that have been under water.

Once the above checks have been completed,

follow these steps to turn on your unit:

1. Close the manual gas control valve located

2. Fully open the manual water control valve

3. Open a hot water tap to verify that water is

4. Fully open the manual gas control valve

5. Turn on the 120 volt 60 Hz power supply to

6. Now you are ready to enjoy hours of

call the fire department.

on the gas line.

on the water supply line.

flowing to that tap. Then close the hot

water tap.

installed.

the FLASH T-KD20 water heater.

endless hot water.

NORMAL OPERATION

To Turn on Your FLASH T-KD20 water heater.

1. Open a hot water tap.

2. Burners ignite. “Fire On” lamp is lit.

3. Mix cold water with the hot to get the

correct temperature water.

To "Turn off your FLASH water heater

1. Close the hot water tap

“Fire On” lamp extinguishes.

The flow rate through the FLASH T-KD20 is

limited to a maximum of 6.9 GPM. The

temperature setting, along with the supply

temperature of the water will determine the

flow rate output of the unit. Please refer to the

temperature/gallons per minute chart at the

back of this manual to determine the likely flow

rates based on your local ground water

temperature and your desired outlet water

temperature combination.

Based on the United States Department of

Energy method of testing water heater output,

the T-KD20 is rated for 228 gallons per hour

(GPH), or 3.8 gallons per minute (GPM), when

raising the water temperature by 77°F (for

example from 43°F to 120°F). Refer to the

following chart of typical household plumbing

fixture flow rates to determine what the FLASH

T-KD20 can do in a household application.

- 12 -

FLOW

Household Flow Rates

Appliance / Use

Lavatory Faucet 1.0

Bath Tub 4.0

Shower 2.0

Kitchen Sink 1.5

Dishwasher 1.5

Washing Machine 2.0

Taken from UPC 1997

Flow Rate

(GPM)

WARNING

Hot Water Heater temperatures over

125°F can cause severe burns instantly or

death from scalding. The outlet hot water

temperature of the FLASH T-KD20 water

heater is factory set at 122°F. Feel the

water temperature before bathing or

showering. Do not leave children, the

disabled or the elderly unattended as they

are at the highest risk of being scalded.

Temperature limiting valves are available,

ask professional person.

TEMPERATURE SETTINGS

There are 4 preset temperatures that you can

select from by adjusting the dipswitch settings

on the computer board. The temperature has

been preset at the factory to122ºF (50ºC). The

computer will electronically control this

temperature. At a fixture, mix cold water with

hot to get the water temperature you desire. If

you desire a hot water temperature other than

the 4 preset settings, please purchase the

optional temperature remote controller (part

No. TK-RE02). With this optional TK-RE02 you

can set the temperature from 99ºF to 176ºF.

Please carefully read the instructions prior to

installing the TK-RE02 as failure to do so could

damage the temperature controller and/or the

water heater, which will void the warranty.

Hot Water Output Temperature Setting:

With the FLASH T-KD20 Water Heater, the

output hot water temperature can be adjusted

either manually from the main computer

board’s dipswitches or with the optional remote

controller (Part TK-RE02, from 99°F to 176°F).

The dipswitches can set four hot water output

temperatures 104°F, 113°F, 122°F, and 176°F

(the factory set temperature is 122°F). could

damage the temperature controller and/or the

water heater, which will void the warranty.

FREEZE PROCTECTION DEVICES

This unit comes equipped with heating blocks

to prevent freezing which can damage the heat

exchanger. For this freeze prevention system

to operate, there has to be electrical power to

the unit. Damage to the heat exchanger

caused by freezing temperatures due to power

loss is not covered under the warranty.

The unit has been rated for temperatures down

to 5ºF (-15ºC) in a wind free environment. If

you install the water heater in an area that is

subject to temperatures (including wind chill)

below 5ºF (-15ºC), this will void the warranty

and Takagi will not be responsible for any

damage to the heat exchanger as a result of

freezing. In any areas subject to freezing

temperatures, Takagi strongly recommends

the use of its back flow prevention flue damper

(Part No. TK-TV03) to reduce the amount of

cold air entering through the exhaust venting

when the water heater is off.

- 13 -

If you will not be using your heater for a long

period of time or if the temperatures (including

the wind chill) will drop below 5 ºF (-15 ºC),

turn off your heater and drain the unit of water

(see ‘Unit Draining & Filter Cleaning’ section

above for draining instructions). This will keep

your unit from freezing and being damaged.

CAUTION: Only the pipes within the water

heater are protected by the anti-freeze devices

on the T-KD20. Any hot or cold water pipes

located outside of the unit will not be protected.

Properly protect and insulate these pipes from

freezing.

CAUTION: Label all wires prior to

disconnection when servicing controls. Wiring

error can cause improper and dangerous

operation. Verify proper operation after

servicing.

The FLASH T-KD20 water heater requires an

electrical power supply from 120 VAC 60 Hz

circuit and be properly grounded.

• A means for switching on/off the 120 VAC

power supply must be provided for service

reasons.

• Wire the heater exactly as shown in the

wiring diagram.

• A green screw is provided in the junction

box for grounding connection.

MAINTENANCE AND SERVICE

WARNING: Turn off the electrical power

supply and close the manual gas control

valve and the manual water control valve

before servicing.

Do this immediately after installation.

1. Clean the cold-water inlet filter (figure

below).

2. Be sure that all openings for combustion

and ventilation air are not blocked.

3. Check that the exhaust vent pipe is not

blocked.

4. Check the gas pressure.

5. Keep the area around the water heater

clear. Remove any combustible materials,

gasoline or any flammable vapors and

liquids.

The unit should be checked once a year or as

necessary by a licensed technician. If repairs

are needed, any repairs should be done by a

licensed technician.

The following systems and parts should be

checked at least once a year:

1. Venting system

2. Burner

3. Manual operation of the pressure relief

valve to ensure correct operation.

4. Periodic cleaning of the water filter (figure

above).

5. Heat exchanger. Remove the thermistor

and check for a mineral coating. A mineral

coating on the thermistor requires flushing

the heat exchanger with a de-scaling

solution. Scale build up will void your

warranty and shorten the life of your water

heater.

OPEN

CLOSE

Filter

- 14 -

Common Trouble Shooting

The T-KD20 can burn gas at a maximum input

rate of 185,000 BTUH. This puts a limit on the

possible output temperature and flow

capabilities. If the water doesn’t seem hot

enough, compare the flow and temperature

that is being attained to the T-KD20 flow vs.

temperature chart (See flow chart on the last

page of this manual). If the unit is not

performing according to the chart, first check

that the gas supply pipe is sized properly and

that the gas pressure is within the required

range. If the gas line is sized properly, check

the plumbing for mixing valves, thermostatic

valves, anti-scald devices, single handled

faucets with built in temperature or pressure

compensators valves and hot and cold crossed

connections. If the unit is performing in

accordance with the flow chart, it may be

undersized for the application. If the unit is

performing according to the chart, the output

temperature can be adjusted using the TKRE02 or the dipswitches on the unit.

It Takes Too Long to Get Hot Water

The T-KD20 takes three seconds to ignite and

three more seconds to heat the incoming

ground water up to the set temperature. The

time it takes to deliver hot water from the TKD20 to your fixtures depends on the length of

piping between the two. The longer the

distance, the more time it will take. If you

would like to receive hot water to your fixtures

quicker, you may want to consider a hot water

recirculation system.

The T-KD20 Will Not Initiate

First check the flow rate through the unit. If the

flow is less than .75 GPM, the unit will not

initiate. Check the filter for any debris or

damage. If you have installed a combination

system (a T-KD20 doing both domestic hot

water and space heating), completely isolate

the heating system temporarily to ensure flow

is not backfeeding through your heating

system to supply the domestic water (bypassing the T-KD20).

If neither of those remedies start the unit, press

the lower green button marked “test (off)” on

the GFCI inside the unit. If the red light above it

does not come on, there is a problem with the

electrical supply to the unit. If that red light

does come on, hit the “reset (on)” button and

open a hot water faucet to re-try the unit. If the

problem persists contact Takagi for instructions

ERROR CODES

All Takagi units are self diagnostic for safety

and convenience when trouble shooting. If

there is a problem with the installation or the

unit, it will display a numerical error code on

the TK-RE02 (if installed) or at the bottom left

corner of the computer board to communicate

the source of the problem. Consult the

following chart for the cause of an error code:

The T-KD20 consists of five major control

operations: Temperature control, Gas control,

Water control, Burner Control, and Main

computer control

.

Computer Board

Burning (red) LED: Blinking

Power (green) LED: OFF

Burning (red) LED: OFF

Power (green) LED: Blinking

Blinking Alternately

Blink Simultaneously

TK-RE02 Check Point

11 Igniter

12 Flame Detector

51 Main Gas Valve

72 Pre Post Check

03 Wrong Gas, Dip Switch

14 Hi-Limit Switch

70 Computer Board

71 Proportional Valve

61 Fan Motor Burning LED and Power LED:

21 Vent Pipe

31 Thermistor Burning LED and Power LED:

65 Water Control Valve

- 15 -

WIRING DIAGRAM T-KD20

Wiring Diagram

A wiring diagram is located on the inside front panel of the appliance.

Electrical Rating: 120 VAC, 60 Hz, 0.8 A.

Note: If any of the original wiring supplied with this appliance must be replaced, it must be replaced with

appliance wiring material (180c) or its equivalent. Replacement wires are available through Takagi.

16

FOR YOUR SAFETY READ BEFORE OPERATING

WARNING: If you do not follow these instructions exactly, a fire or

explosion may result causing property damage, personal injury or loss of

life.

A. This water heater does not have a pilot. It is equipped with an ignition device that

automatically lights the burner. Do not try to light the burner by hand.

B. BEFORE OPERATING smell all around the water heater area for evidence of

leaking gas. Be sure to smell next to the floor because some gas is heavier than air

and will settle on the floor.

WHAT TO DO IF YOU SMELL GAS.

• Do not try to light any appliance.

• Do not touch any electric switch, do not use any phone in your building

• Immediately call your gas supplier from a neighbor's phone. Follow the gas

supplier's instructions.

• If you cannot reach your gas supplier, call the fire department.

C. Use only your hand to turn the gas valve knob. Never use tools. If the knob will not

turn by hand, don't try to repair it. Call a qualified service technician. Force or

attempted repair may result in a fire of explosion.

D. Do not use this water heater if any part has been under water. Immediately call a

qualified service technician to inspect the water heater and to replace any damaged

parts.

OPERATING INSTRUCTIONS

1. STOP! Read the safety information above or in the Owners Manual.

2. Turn off all electric power to the water heater.

3. Do not attempt to light the burner by hand.

4. Turn the gas manual gas valve located on the outside of the unit clockwise ↻ to the

off position.

5. Wait five (5) minutes to clear out any gas. If you then smell gas. STOP! Follow "B"

in the safety information above on this label. If you don't smell gas, go to next step.

6. Turn the manual gas valve located on the outside of the unit counter clockwise ↺

to the ON position.

7. Turn on all electrical power to the water heater.

8. If the water heater will not operate, follow the instructions “to Turn Off Gas to water

heater" and Call your service technician or gas supplier.

TO TURN OFF GAS TO APPLIANCE

1. Turn off all electric power to the water heater if service is to be performed.

2. Turn the manual gas valve located on the outside of the unit clockwise ↻ to the off

position.

17

W

y

p

DANGER

Vapors from flammable liquids will explode and catch fire causing death or severe burns.

Do not use or store flammable products such as gasoline, solvents or adhesives in the

same room or area near the water heater.

Keep flammable products:

1. Far away from heater.

2. In approved containers.

3. Tightly closed

4. Out of children's reach

WARNING: Do not install water heater where flammable products will be stored.

Read and follow water heater warnings and instructions. If owner's manual is

missing, contact the retailer or manufacturer.

Vapors:

1. Cannot be seen

2. Vapors are heavier than air

3. Go a long way on the floor

4. Can be carried from other rooms

to the main burner by air currents.

ARNING

The outlet hot water temperature of the T-KD20 water heater is factory set at 122 °F.

WARNING: Use this heater at your own risk. The set outlet water temperature can cause

severe burns instantl

or death from scalds. Test the water before bathing or showering.

DANGER

Hot Water Heater temperature over 125 °F can cause

severe burns instantly or death from scalding.

Children, disabled and elderly are at the highest risk of

being scalded. Feel water temperature before bathing or

showering. Temperature limiting valves are available, ask

rofessional person.

WARNING: California Proposition 65 lists chemical substances known to the state to

cause cancer, birth defects, death, serious illness or other reproductive harm. This product

may contain such substances, be their origin from fuel combustion (gas, oil) or

components of the product itself.

18

p

k

p

Applications

Space Heating Applications

The T-KD20 can be used for potable hot water heating applications as well as space heating

applications.

WARNING

• Toxic chemicals used in boiler treatments such as alcohol, glycerol and glycol

group must not be introduced into the system when used for open loop potable

water and space heating.

• The FLASH T-KD20 can be used to supply potable water and space heating and

shall not be connected to any heating system or component(s) previously used

with non-potable water where any chemicals were added to the water heating

appliances.

• When the system requires water for space heating at temperatures higher than

required for other uses, a means such as a mixing valve shall be installed to

temper the water for those other uses in order to reduce scald hazard potential.

• Water temperature over 125 °F can cause severe burns instantly or death from

scalds.

• Chemicals such as diluted Glycol can be used for radiant floor, Hydro/fan coil air

or Baseboard heating only.

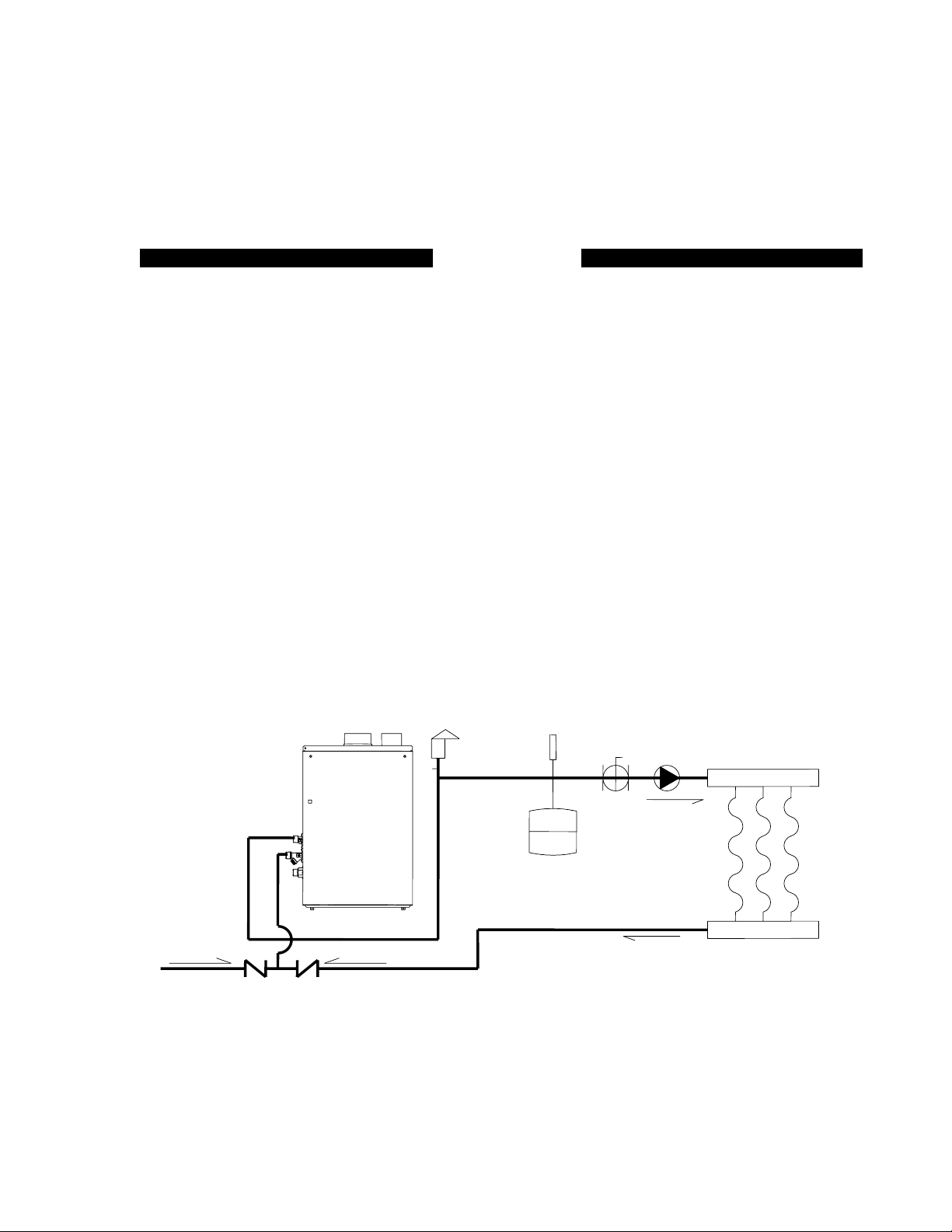

Basic System Drawings and Schematics

Heating application only:

Make u

water

Check valve

Warning: This illustration is for concept only. There are a wide variety of variations to the application

of controls and equipment presented applications. Designers must add all necessary safety and

auxiliary equipment to conform to code requirements and design practice.

For more details, contact Technical Department at (888) 882-5244

Pressure relief valve

Ex

Pump

ansion tan

Radiant, Hydro

or Baseboard

19

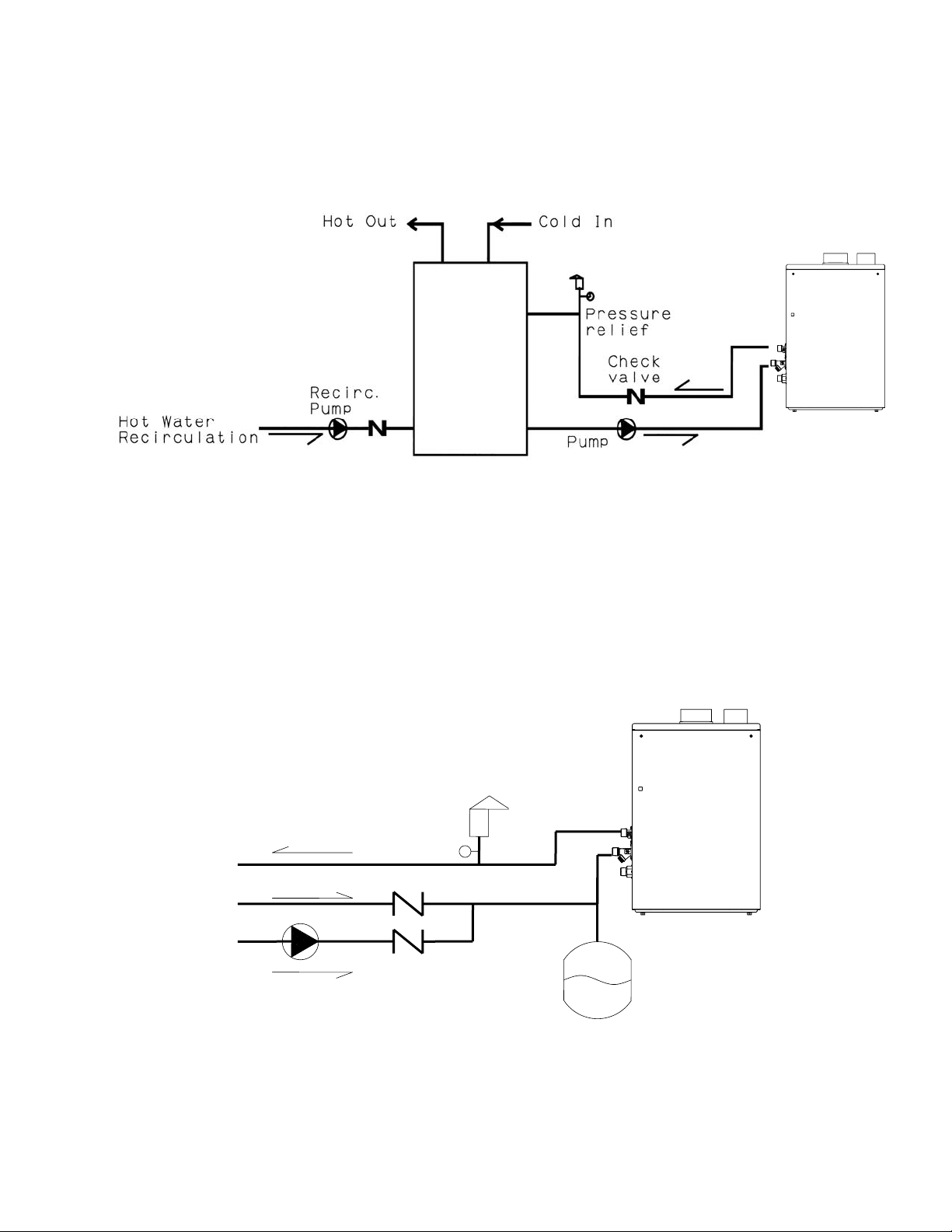

Dual-purpose hot water heating (Domestic and Space Heating)

Priority Control Devices such as a flow switch, an Aquastat or other

electronic controller can be used to prioritize the domestic water system over

the heating system.

Warning: Follow all local codes, or in the absence of local codes, follow the

most recent edition of the National Standard Code, ANSI Z21. 10.3.

Warning: This illustration is a concept design only. The reference to the

th

1/8

hole in check is only for the State of Massachusetts. There are a wide

variety of variations to the application of controls and equipment presented.

Designers must add all necessary safety and auxiliary equipment to conform

to code requirements and design practice. For more details, contact the

Takagi Technical Department at (888) 882-5244

20

p

T-KD20 with Storage Tank

This illustration is a concept design only.

GPM. If it is necessary to achieve higher flow rates with full pressure for longer periods of

time, then it can be installed in conjunction with a storage tank. A pump will be necessary to

keep the storage tank water hot. We suggest a high-head pump of 1/12 hp or greater

depending on the system.

The maximum flow rate through the T-KD20 is 6.9

Recirculation

Pressure relief valve

Temperature gauge

Hot water to house

Cold In

Hot water return

Pump

Check valve

ansion tank

Ex

This illustration is a concept design only. This system will also need a high-head pump of

1/12 hp or greater, depending on the application situation.

21

Optional Items

1. TK-RE02 Temperature Remote Controller

The TK-RE02 Temperature

Remote Controller has two

functions. It allows the output

temperature from the T-KD20 to

be adjusted within the range of

99 °F to 176 °F, and it also

works as a diagnostic tool that will give a concise

error code whenever there is a problem with the

unit. The temperature options are 99°F, 100°F,

102°F, 104°F, 106°F, 108°F, 109°F, 111°F,

113°F, 115°F, 117°F, 122°F, 131°F, 140°F,

158°F, and 167°F or 176°F. See the trouble

shooting section for information on possible error

codes.

3. TK-TV03 Vent Damper

The TK-TV03 Vent

Damper prevents the

backflow of air through

the exhaust vent. This is

a CSA tested Takagi

component. This helps

prevent harmful exhaust

gases from entering the

home, as well as helping to prevent the unit from

freezing in areas where cold air can be blown or

drawn into the exhaust system. Install this vent

damper in accordance with Takagi’s installation

instructions, and any applicable codes.

2. TK-TV05 Vent Terminator

This terminator can be used

where a T-KD20 is going to

be vented out through a

wall. This is a CSA

approved part of the unit.

Connect a Category III

Stainless vent pipe from the

top of the unit to the backside of this terminator to

exhaust flue gases through the wall without a

thimble. Install vent terminator in accordance with

manufacturer’s installation instructions and any

applicable local codes.

4. TK-BK01 Wall Mounting Brackets

The TK-BK01 Wall

Mounting Brackets

allow the T-KD20

to be installed

hanging from a

wall. It is not

necessary to

earthquake strap these heaters if these brackets

are used. If the unit is not going to be mounted

on a wall, the “L” brackets that are included with

every unit will be sufficient as earthquake

protection. Install unit and brackets according to

manufacturer’s installation instructions and any

applicable codes.

22

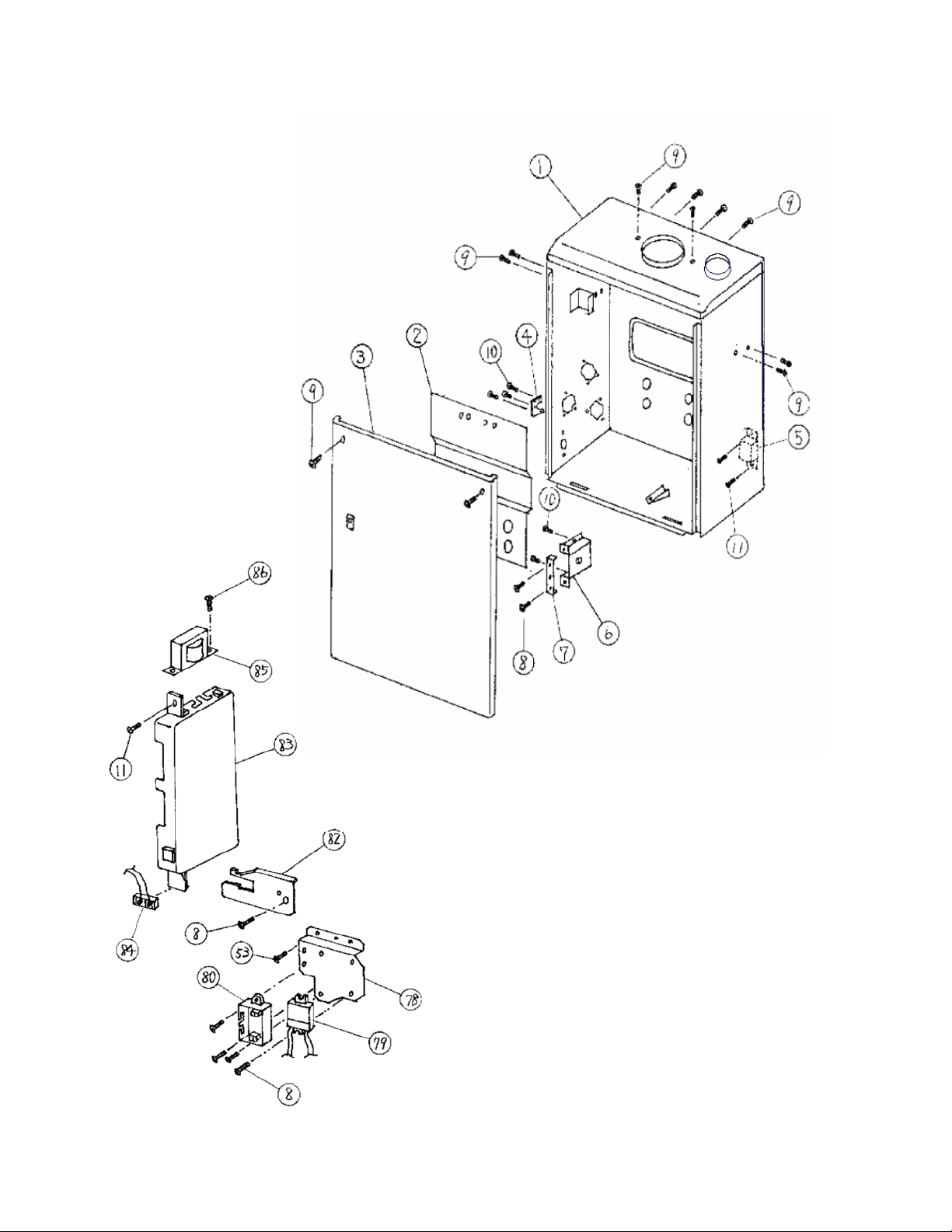

Component Diagram

Case

Computer board

23

Burner

Manifold

Computer

24

Heat Exchanger

Water Way

25

1

CASE ASSEMBLY

2

BACK GUARD PANEL ASSEMBLY

3

FRONT COVER

4

FIXING PLATE

5

TRANSFORMER

6

JUNCTION BOX

7

JUNCTION BOX COVER

8

SCREW

9

SCREW (COATED)

10

SCREW

11

SCREW

12

SILICON RING

13

HEAT EXCHANGER ASSEMBLY

14

HEAT EXCHNAGER FIXING PLATE (BACK)

15

HEAT EXCHANGER FIXING PLATE (FRONT)

16

SCREW

17

HI-LIMIT SWITCH

18

SCREW

19

QUICK RELEASE PLATE

20

O-RING

21

WATER CONTROL VALVE

22

O-RING

23

GASKET

24

QUICK RELEASE PLATE

25

QUICK RELEASE PLATE

26

SCREW

27

FLOW SENSOR

28

O-RING

29

INLET CONNECTION PIPE

30

O-RING

31

INLET THERMISTOR

32

O-RING

33

WATER INLET

34

FREEZE PROTECTION HEATER

35

SCREW

36

FILTER

37

INLET DRAIN PLUG

38

SCREW

39

OUTLET DRAIN PLUG

40

O-RING

41

WATER OUTLET

42

OUTLET THERMISTOR

43

SCREW

44

COMBUSTION CHAMBER

45

BURNER ASSEMBLY

T-KD20 PARTS LIST

46

SCREW

47

SPARK ELECTRODE HOLDER

48

SPARK ELECTRODE

49

FLAME SENSOR

50

SCREW

51

DAMPER

52

WIRE HOLDER

53

SCREW

54

MANIFOLD

55

GASKET

56

GASKET

57

GAS COUPLING

58

SCREW

59

O-RING

60

IGNITER

61

SCREW

62

IGNITER

63

GAS VALVE UNIT

64

O-RING

65

SCREW

66

GAS INLET FIXING PLATE

67

GAS INLET

68

FAN

69

SCREW

70

FAN DAMPER

71

THERMOSTAT

72

SCREW

73

SCREW

74

PRESSURE SWITCH

75

SILICON TUBE

76

PRESSURE SWITCH PORTPLATE

77

PRESSURE SWITCH PORT

78

POWER DISTRIBUTION PLATE

79

GROUND FAULT CIRCUIT INTERRUPTER

80

FUSE BOX

82

COMPUTER FIXING PLATE

83

COMPUTER BOARD

84

REMOTE CONTROL CONNECTION

85

COMPUTER TRANSFORMER

86

SCREW

87

OVERHEAT CUT-OFF FUSE

88

OVERHEAT CUT-OFF FUSE FIXING PLATE

89

FREEZE PROTECTION HEATER FIXING PLATE

90

FREEZE PROTECTION HEATER

26

Out Put Hot Water GPM

Out Put Temperature vs. GPM (Max.6.9 GPM) with Various Ground Water Temperature

Correct Gas pipe size can be expect this chart

8.0

7.0

6.0

5.0

4.0

3.0

2.0

1.0

0.0

40 F

50 F

60 F

70 F

90 95 100 105 110 115 120 125 130 135 140 150 160 165 170 175 180

6.1 5.5 5.1 4.7 4.3 4.0 3.8 3.6 3.4 3.2 3.0 2.8 2.5 2.4 2.3 2.2 2.2

6.9 6.7 6.1 5.5 5.1 4.7 4.3 4.0 3.8 3.6 3.4 3.0 2.8 2.6 2.5 2.4 2.3

6.9 6.7 6.1 5.5 5.1 4.7 4.3 4.0 3.8 3.4 3.0 2.9 2.8 2.6 2.5

6.9 6.7 6.1 5.5 5.1 4.7 4.3 3.8 3.4 3.2 3.0 2.9 2.8

Out put Hot Water Temperature

40 F 50 F 60 F 70 F

27

Loading...

Loading...