Page 1

O-RM01-E

(9911)

USIR'S

MANUAL

PARTS

,

LAME

ATTACHMIN1

LIST

/J/J/J

TA.JINlA

[Y[Y[Y

Page 2

FOREWORD

FOREWORD

This User's Manual and Parts List describes the using and setting methods for the lame

attachment.

Please read through this manual

setting the attachment.

of

The contents

[IMPORTANT SAFETY INSTRUCTIONS]

[SETTING

[EMBROIDERY USING LAME FILM]

[PARTS LIST]

Always keep this manual at hand whenever you need.

If

you do not use the lame attachment, keep this manual for future use.

This manual may contain discrepancies in detailed information when compared with actual

product

ued research and improvements

If

TAJIMA

due

any question about the unit

distributor.

this manual are largely divided into the following sections.

THE LAME ATTACHMENT]

to differences

carefully and understand the contents before operating

in

machine models for which the product is used and also contin-

of

the product.

or

contents

of

this manual arises, please consult your local

or

(CG11)

Page 3

IMPORT ANT

SAFETY

INSTRUCTIONS

IMPORTANT

Correct work is required for safe handling (using and setting)

Please read the IMPORTANT SAFETY INSTRUCTIONS

carefully

items written under

which require your special attention on the using

Items

specified

to ensure safety during using and setting the attachment.

Signal word definition is given below.

Indicates a potentially hazardous situation which,

or

moderate injury (*1) or property damage.

*1:

{S)

SAFETY

and do not attempt operation

following the warning symbol and signal word. These items must be strictly observed

INSTRUCTIONS

in

of

the machine before you thoroughly understand the

IMPORTANT SAFETY INSTRUCTIONS.

and

of

the lame attachment.

this instruction manual and parts list

setting

of

the lame attachment are

A CAUTION

if

not avoided, may result in minor

An

injury that does not necessitate hospitalization or visit

Prohibited

items

to

a hospital over a

long

period.

0 : Items

The information which gives

NOTE.

that

must

details

be

followed

carefully

or

supplements the explanation appears under the title

to

ensure safe operation.

A CAUTION

Before carrying

power switch OFF.

If

you attempt an operation with the power switch ON, the machine could

operate unexpectedly and

out

operation described in this manual, make sure turn the o

could cause injuries.

A CAUTION

Oily chips

When cleaning the ATH device, make sure to completely remove lame film

chips.

Thread

of

lame film may adhere

will not

be

trimmed correctly

to

the ATH knife

if

lame film chips remain on the ATH knife.

or

the rotary hook. o

ii

(CG11)

Page 4

CONTENTS

CONTENTS

• FOREWORD ................................................................................................................................................ i

• IMPORTANT SAFETY INSTRUCTIONS ....................................................................................................

• SETIING

1.

2.

"ll

t.l.

THE

LAME ATIACHMENT ....................................................................................................... 1

FUNCTIONS

OF

LAME ATIACHMENT ........................................................................................... 1

PARTS ............................................................................................................................................... 1

ILI~"T"AI

11'1\:> I 1"\L.LII'I"-.:'

I

1._11"'

TU~

Inc

I

Al.tr=

1\.TTAr"-UI.aL~IT

LI"\IVIt;:.

/"'\I

I

1"'\VniVI~I't

I

······································•••·········••·•·•••·•••·••••·····••••••···••••••••-.

3-1. Attaching the Positioning Thread Plate ................................................................................... 2

3-2. Attaching the Tension Release Set.. ....................................................................................... 3

· Attaching the Tension Release Set A ..................................................................................... 3

4.

SETIING LAME FILM ....................................................................................................................... 5

5.

ADJUSTING LAME FILM TENSION ................................................................................................. 7

&

EiviBROIDERY

1.

DESIGN DATA .................................................................................................................................. 8

· Attaching the Tension Release Sets

3-3.

Attaching the Roller-type Middle Thread Guide Set ................................................................ 4

4-1. Tension Release

4-2. Tension Release

USING

SetA

Sets

LAiviE

............................................................................................................ 6

C, D and

FILrvi

.......................................................................................................... 8

C,

D and E .................................................................... 4

E ........................................................................................... 7

ii

.,

2.

LAME

FILM

AND 3-D EMBROIDERY ............................................................................................... 8

• PARTS LIST .........................................................................................................................

End

of Volume

iii

(CG11)

Page 5

II

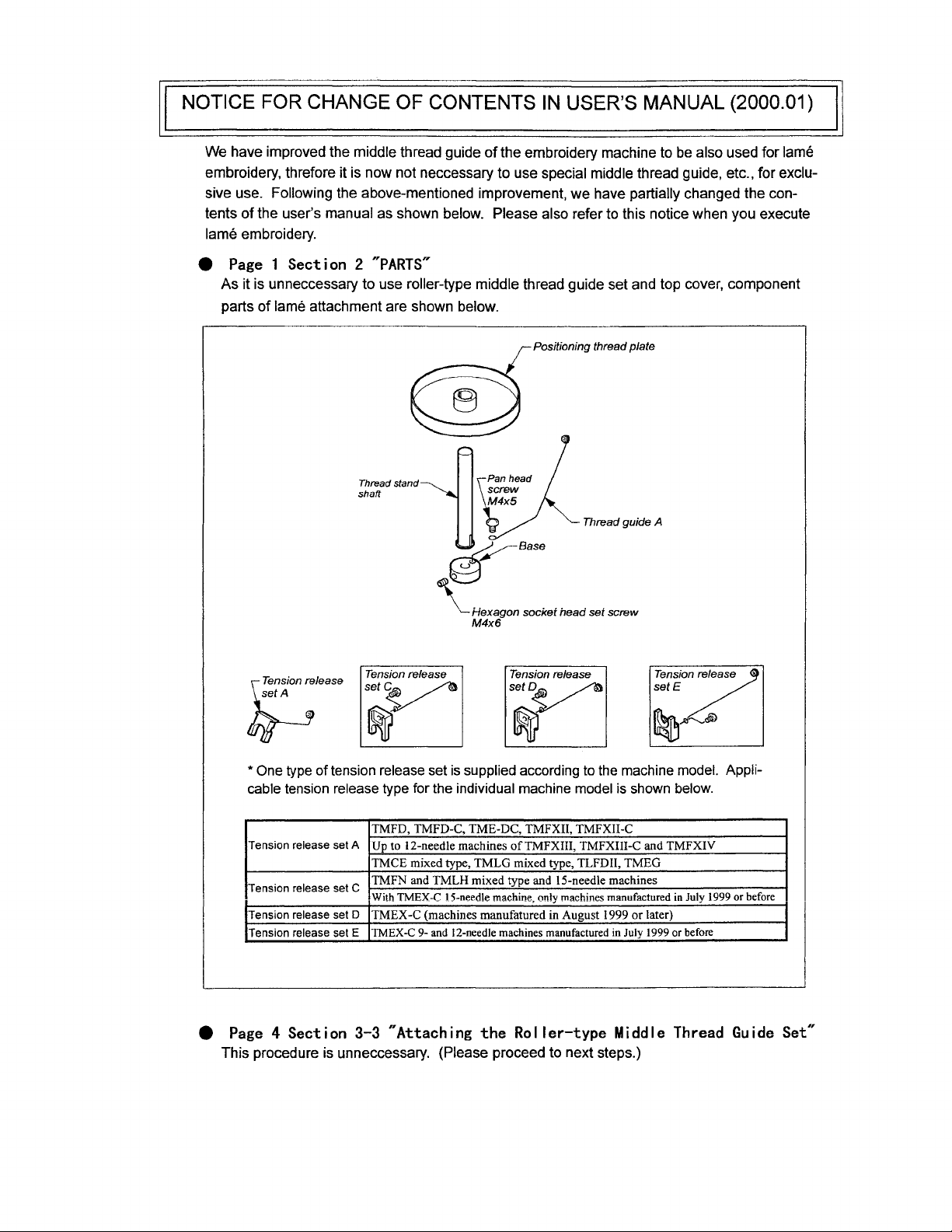

NOTICE FOR CHANGE OF CONTENTS

IN

USER'S MANUAL (2000.01) I

We have improved the middle thread guide

embroidery, threfore it is now not neccessary to use special middle thread guide, etc., for exclusive use. Following the above-mentioned improvement,

of

tents

lame embroidery.

tt

the user's manual as shown below. Please also refer to this notice when you execute

Page

1 Section 2

As

it is unneccessary to use roller-type middle thread guide set and top cover, component

parts

of

lame attachment are shown below.

~PARTS~

Thread stand

shaft

of

the embroidery machine to be also used for lame

we

have partially changed the con-

Positioning thread plate

Thread guide A

~Base

\~:7~on

:lease

Tension release

set~

\_Hexagon

M4x6

socket head set screw

Tension release

y

~

*One

type of tension release set

cable tension release type for the individual machine model

Tension release

Tension release

Tension release

Tension release

4t

Page

4 Section 3-3

This procedure is unneccessary. (Please proceed to next steps.)

~

is

supplied according to

TMFD, TMFD-C,

set

A

Up

to 12-needle machines

TMCE mixed type,

TMFN and TMLH mixed type and 15-needle machines

set

C

With

TMEX-C

set

D

TMEX-C

set E TMEX-C

9- and

~Attaching

TME-DC,

TMLG

!5-need!e machine, only machines manufactured

(machines manufatured in August 1999

12-need1e

TMFXII, TMFXII-C

ofTMFXIII,

mixed type, TLFDII,

machines manufactured

the

Roller-type

TMFXIII-C and

Tension release

setE

the

machine model. Appli-

is

shown

below.

TMFXIV

TMEG

in

July 1999 or

or

later)

in

July

1999

or before

Middle Thread

before

Guide

Set"

Page 6

SETTING THE LAME ATTACHMENT

SETTING THE LAME ATTACHMENT

1.

2.

FUNCTIONS

A lame attachment is designed to perform embroidery using lame film.

OF

LAME

ATTACHMENT

PARTS

Component parts

Thread

stand

of

a lame attachment are shown below.

shaft

Thread

guide A

~Base

~Hexagon

W.4x6

socket

head

set

screw

Top

cover

•

This

cover

machines

and after July

is

necessary for

manufactured in

of

1999.

Tension

~!t"~ion

~lease

release

y

~

One

type

of

*

Applicable tension release type for the individual machine models is

shown

Tension release set A

Tension release set

Tension release set D

Tension release set E

tension release

below.

C

TMFD, TMFD-C, TME-DC, TMFX

Up

to 12-needle machines

TMFXIV

TMCE mixed type, TMLG mixed type,TLFD

TMFN and TMLH mixed type and 15-needle machines

With TMEX-C 15-needle machine, only

manufactured before July

TMEX-C (machines manufactured after August

TMEX-C 9- and 12-needle machines manufactured before

of

July

Tension

release

y

set

is supplied according

1999

Tension

setE~

~

to

the machine model.

IT,

TMFX II-C

of

TMFX III, TMFX

of

1999

relea/

II,

TMEG

machines

of

III-C

1999)

and

(CG11)

Page 7

SETTING THE LAME ATTACHMENT

3.

INSTALLING THE LAME ATTACHMENT

A CAUTION

Do not ride on the table when installing the lame attachment. Otherwise, the table

may be bent.

If

you must ride on the table to perform the necessary work, mount the table sup-

port.

3-1. Attaching the Positioning Thread Plate

1. Attach the thread guide A (1) to the base (2) using pan head screw M4 x 5 (3).

1

~2

2.

Set the base (2) on the thread stand stud (4)

ening the set screw (5) with the base (2) positioned

·

of

the thread stand plate and fix the base (2) by tight-

at

the lower end position.

NOTE:

Attach the base (2) in the direction

with the adjacent thread cone. For

the rear right direction as shown

below.

2

so

that the thread guide A (1) will

example, the thread guide A (1) should

not

interfere

be

set in

(CG11)

Page 8

SETTING THE LAME ATTACHMENT

3. After inserting the positioning thread plate (7) into the thread stand shaft

thread stand stud

(4).

t

76~~

u

4

3-2. Attaching the Tension Release Set

The procedure

type.

for

attaching the tension release set differs depending

(6),

set them

on

the tension release set

on

the

e

Tension

e Tension release sets

3-2-1. Attaching the Tension Release Set A

Fit the tension release set A (1) to the neck

release

set

A ........................................................ : ..........

C,

D and

E:

................................................. p.4

p.3

of

the No. 1 tension on the individual tension base.

3

(CG11)

Page 9

SETTING

THE

LAME ATTACHMENT

3-2-2. Attaching the Tension Release Sets

Fit the thread release set

thread stand section.

C,

D or E (2) to the thread guide (3) right above the corresponding

e Thread release set C and D

C, D and

E

e Thread release set E

3-3. Attaching the Roller-type Middle Thread Guide Set

NOTE: The machines shipped before June

Therefore, change

the procedure described below.

1.

Remove the attaching screws (1).

2. After removing the attaching screws (2), detach the top cover (3).

3

only the middle thread guide for these machines by referring

of

1999 have a removable middle thread guide.

4

(CG11)

Page 10

SETTING THE LAME ATTACHMENT

3. Attach the lame attachment top cover (4) using the attaching screws (2) and attach the roller-type

middle thread guide set (5) to it using the attaching screws

NOTE: Use the attaching screws

5

(1)

and

(1

).

(2)

removed in steps 1 and

2.

4.

SETTING LAME FILM

The procedure for setting lame film differs depending on the tension release set type.

e Tension release

e Tension release sets

NOTE: Pay attention

* Unwind lame

* When threading lame film through the needle eye, pull the film gently between

setA

................................................................... p.6

C,

D and

E:

................................................. p.7

to

the

following points when unwinding lame film.

film

gently.

plate

will

turn excessively causing the film

tioning thread plate

the thread guide and the individual thread guide and, also,

film is pulled only

threading difficult.

at

If

the film is pulled forcibly, the positioning thread

turns

excessively,

the needle, the film

stop

will

to

be

it

by hand.

be

unwound

stretched

too

much.

at

the needle.

to

be

cut

or

If

the posi-

If

the

making

5

(CG11)

Page 11

SETTING THE LAME ATTACHMENT

4-1. Tension Release Set A

Set lame film

in

the manner as shown below.

Threading hereafter can

made in the same manner

as ordinary thread.

be

6

(CG11)

Page 12

SETTING THE LAME ATTACHMENT

4-2. Tension Release Sets

Set lame film in the manner as shown below.

Threading hereafter can

made in the same manner

as ordinary thread.

C,

0 and E

be

t----Lame

film

5.

ADJUSTING LAME FILM TENSION

Check the lame film tension by pulling the film

eye so that the positioning thread plate turns slowly.

than the force needed for rayon yarn), the tension is correct.

For the under thread, adjust the tension a little higher than the tension set for rayon yarn.

in

the state the film is threaded through the needle

If the pulling force is 150 g (a little higher

7

(CG11)

Page 13

EMBROIDERY USING LAME FILM

EMBROIDERY USING LAME FILM

1.

2.

DESIGN DATA

Lame film is

and tatami stitch and embroidery with too short stitch

broken by a

high-quality goods, prepare the design that meets the following requirements.

e There are no overlap stitching

e Thread density

e The design does not contain stitches smaller than 0.6

0.1

to 0.3 mm wide. Overlap stitching on lame film, dense stitching like satin stitch

length may cause sewn lame film to be

needle or get fluffy.

in

satin or tatami stitching should

To

perform beautiful embroidery with lame film and produce

on

lame film.

be

0.5

mm

or more.

mm.

e There are no fray preventive stitches before thread trimming.

*1: Fray preventive stitches often cause

automatically processes fray preventive stitching, use the design data that does not include

such stitches.

LAME

3-D embroidery frequently generates satin stitches with thread density

lame film

film should

FILM

AND

tends

to

be broken

not be used for

3-D EMBROIDERY

or

gets fluffy due to a sticking needle

3-0

embroidery.

lame film to

be

broken or get fluffy. Since the machine

of

about 0.2 mm. Since

if

thread density is tight, lame

8

(CG11)

Page 14

•

LAME

PARTS LIST

ATTACHMENT

CONTENTS

............................................

RM-1

[Explanation of Marks #'s and

+ Please specify,

and embroidery space when you order us with the parts having

the part No.:

Ex.: TME-DC915 (450 x

[Model]

in

the following manner, your machine model, manufacturing number

[Emb. Space]

460)S

*'s

at End of Part No.]

01234

NO.

[Mfg. No.]

+ Please specify the number of needles on your machine's head

changing the

Ex.: The part Number, EK012345####

marks####

4-digit Numbers

into one of the 4-digit numbers below:

Machine Type

0300

0600

0900

1200

1500

........

........

........

........

........

3-nesdle machine

6-needle machine

9-needle machine

12-needle machine

15-needle machine

****

in

your parts order by

at the end of

(CG11)

Page 15

1

~R_M_-_

____

~MEATTACHMENT------------------------------------l

11

12

13

~

~

~~io---

~

~

~~

~

1

14~

~13

(COil)

Page 16

LAME

No.

1

Positioning Thread Plate

2 Thread Stand Shaft

3 Base

4

Hexagon Socket Head Set Screw

5

Thread Guide A

Pan Head Screw

6

Tension Release Set A

7

Tension Release Set C

8

Spring Hook A

9

Tension Release Spring 8

10

Pan Head Screw

11

12

Tension Release Set D

13

Spring Hook 8

14

Tension Release Set E

15

Tension Release Spring A

16

Top Cover

16

Top Cover

17 Roller-type Middle Thread Guide Set

18

Thread Guide

19

Round Countersunk Head Screw

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

NOTE:

As

for

parts with marks #

Name

or

•,

please follow

ATTACHMENT

No.

Part

RM0101100000

RM0101200000

RM0101300000

SS8204060TNO

RM0101400000

SS4104050SDO

RM0102SOOOOO

RM0107COOOOO

RM0105AOOOOO

RM0106BOOOOO

SS4103050SDO

RM0107DOOOOO

RM0105BOOOOO

RM0107EOOOOO

RM0106AOOOOO

CX067100##f#

CXC67100####

RM0104SO###f

FX0626110000

SM:5000535CL

our

instruction

on

Table

of

Contents, in

Remark

M4X6

M4X5

For the applicable models, refer

For the applicable models, refer

M3X5

For the applicable models, refer

For the applicable models, refer

For Jumbo rotary hook

9/64X40X3.5

your

parts order.

RM-1

to

2.

to

2.

to

2.

to

2.

(CGll)

"Parts".

"Parts".

"Parts".

"Parts".

Loading...

Loading...