Page 1

TB9100 base station

P25 CG console gateway

Calibration Software

User’s Manual

MBA-00004-05

Issue 5

February 2007

Page 2

© Tait Electronics Limited February 2007

Contact Information

Tait Radio Communications

Corporate Head Office

Tait Electronics Limited

P.O. Box 1645

Christchurch

New Zealand

For the address and telephone number of regional

offices, refer to the TaitWorld website:

We b s it e : http://www.taitworld.com

Technical Support

For assistance with specific technical issues, contact

Technical Support:

E-mail: support@taitworld.com

We b s it e : http://support.taitworld.com

Copyright and Trademarks

All information contained in this manual is the property

of Tait Electronics Limited. All rights reserved.

This manual may not, in whole or in part, be copied,

photocopied, reproduced, translated, stored, or reduced

to any electronic medium or machine-readable form,

without prior written permission from Tait Electronics

Limited.

The word TAIT and the TAIT logo are trademarks of

Tait Electronics Limited.

All trade names referenced are the service mark,

trademark or registered trademark of the respective

manufacturers.

Disclaimer

There are no warranties extended or granted by this

manual. Tait Electronics Limited accepts no

responsibility for damage arising from use of the

information contained in the manual or of the

equipment and software it describes. It is the

responsibility of the user to ensure that use of such

information, equipment and software complies with the

laws, rules and regulations of the applicable

jurisdictions.

Enquiries and Comments

If you have any enquiries regarding this manual, or any

comments, suggestions and notifications of errors,

please contact Technical Support.

Updates of Manual and Equipment

In the interests of improving the performance, reliability

or servicing of the equipment, Tait Electronics Limited

reserves the right to update the equipment or this

manual or both without prior notice.

Intellectual Property Rights

This product may be protected by one or more patents

of Tait Electronics Limited together with their

international equivalents, pending patent applications

and registered trade marks: NZ338097, NZ 508054,

NZ508340, NZ508806, NZ 508807, NZ 509242,

NZ509640, NZ509959, NZ 510496, NZ511155,

NZ511421, NZ516280/519742, NZ 519118,

NZ519344, NZ520650/537902, NZ 522236,

NZ524369, NZ524378, NZ 524509, NZ 524537,

NZ524630, NZ530819, NZ 534475, NZ 534692,

NZ535471, NZ536945, NZ 537434, NZ 546295,

NZ547713, NZ521450, AU2003281447,

AU2002235062, AU2004216984, AU2005207405,

CA2439018, CA2554213, EU03784706.8,

EU02701829.0, EU04714053.8, EU 05704655.9,

GB23865476, GB2386010, GB 2413249,

GB0516092.4, US11,232716, US 10/597339, US10/

520827, US10/468740, US 5,745,840, US10/547653,

US10/546696, US 10/547964, US 10/523952, US 11/

572700.

This product may also be made under license under one

or more of the following U.S. Patents: 4,590,473

4,636,791 4,716,407 4,972,460 5,146,497 5,148,482

5,164,986 5,185,795 5,185,796 5,271,017 5,377,229

5,502,767.

The IMBE™ voice coding Technology embodied in

this product is protected by intellectual property rights

including patent rights, copyrights and trade secrets of

Digital Voice Systems, Inc. This voice coding

Technology is licensed solely for use within this

Communications Equipment. The user of this

Technology is explicitly prohibited from attempting to

decompile, reverse engineer, or disassemble the Object

Code, or in any other way convert the Object Code

into a human-readable form. Protected by U.S. Patents

5,870,405 5,826,222 5,754,974 5,701,390 5,715,365

5,649,050 5,630,011 5,581,656 5,517,511 5,491,772

5,247,579 5,226,084 and 5,195,166.

To our European Customers

Tait Electronics Limited is an

environmentally responsible company

which supports waste minimization and

material recovery. The European Union’s

Waste Electrical and Electronic Equipment

Directive requires that this product be disposed of

separately from the general waste stream when its

service life is over. Please be environmentally

responsible and dispose through the original supplier,

your local municipal waste “separate collection” service,

or contact Tait Electronics Limited.

Page 3

TB9100 Calibration Software User’s Manual Contents i

Contents

Preface ..............................................................................................................iii

Typographical Conventions ..............................................................iii

Associated Documentation ...............................................................iii

Publication Record ..........................................................................iv

Basic Tasks .........................................................................................................1

Using the TB9100 Calibration Software .................................................1

About the Toolbar ............................................................................2

About the Status Bar ..........................................................................2

Equipment Required .............................................................................. 3

Calibration Overview .............................................................................3

Field Calibration ................................................................................ 4

Service Center Calibration .................................................................4

P25 Console Gateway Calibration .....................................................5

Selecting the Communications Port ........................................................5

Setting Up the Equipment ......................................................................6

Connecting the Calibration Software ......................................................7

Disconnecting from the Base Station/Reciter .........................................7

Troubleshooting ..................................................................................... 7

Adjusting the Frequency Setup ........................................................................8

Adjusting the Receiver Lock Band .........................................................8

Tuning a UHF Receiver Front End ........................................................9

Tuning a VHF Receiver Front End ...................................................... 11

Adjusting the Exciter Lock Band .......................................................... 13

Selecting the Exciter Sub-band .............................................................14

Calibrating the Reciter ....................................................................................15

Calibrating the Exciter .......................................................................... 15

Automatically Tune the Frequency Control Loop (FCL) .................15

Calibrating the FCL .........................................................................15

Calibrating the VCO ....................................................................... 17

Calibrating the RSSI ............................................................................. 18

Calibrating the Balanced Line ...............................................................20

Calibrating the Unbalanced Lines .........................................................21

Carrier Frequency Offset Adjustment .................................................... 21

Calibrating the Power Amplifier ....................................................................25

Calibrating the PA Bias ......................................................................... 25

Calibrating the Forward and Reverse Detector Bias Voltages ................26

Calibrating the PA Power .....................................................................26

Troubleshooting Tips ...................................................................... 28

Calibrating the Power Management Unit .....................................................29

Page 4

ii Contents © Tait Electronics Limited February 2007

Calibrating the PMU Output Voltage .................................................. 29

Index .................................................................................. 31

Page 5

TB9100 Calibration Software User’s Manual Preface iii

Preface

Welcome to the TB9100 Calibration Software User’s Manual. This manual

provides you with information about the Tait TB9100 Calibration Software in

PDF format. You can view it online or print it if you want a paper copy. It

describes how to use Version 03.06 of the Calibration Software.

Typographical Conventions

‘File > Exit’ means ‘click File on the menu bar, then select Exit’.

Associated Documentation

■ Online Help. The Calibration Software also has online Help. It contains

more or less the same information as this manual. To view it, start the

Calibration Software, then press F1 or click the Help icon on the toolbar. If

you are in a dialog box, click the Help button.

■ TBA0STU/TBA0STP CTU Operation Manual. This manual (MBA-00013-

xx) provides detailed information about the Calibration and Test Unit.

■ TB9100 Installation and Operation Manual (MBA-00002-xx).

■ TB8100 Service Manual (service centers only). A glossary of terms is available

in this manual (MBA-00016-xx).

■ TB9100 Reciter Service Manual (service centers only).

For additional documentation, see the prefaces of the TB9100 Installation and

Operation Manual and the TB9100 Customer Service Software User’s Manual

or the CSS online Help.

Technical notes are published from time to time to describe applications for

Tait products, to provide technical details not included in manuals, and to offer

solutions for any problems that arise. Look for them on Tait's technical support

website.

Page 6

iv Preface © Tait Electronics Limited February 2007

Publication Record

Issue Date Description

MBA-00004-01 January

2005

First release of the this manual. It describes

Version 02.03 of the Tait TB9100 Calibration

Software.

MBA-00004-02 March

2005

First full release of the this manual. It

describes Version 02.05 of the Tait TB9100

Calibration Software and Version 01.10 of

the TB9100 base station.

MBA-00004-03 August

2005

Minor updates. The manual describes Version

02.07 of the Tait TB9100 Calibration

Software and Version 1.2 of the TB9100 base

station. Front end tuning is explained

separately for UHF and VHF receivers.

MBA-00004-04 May 2006 Describes Version 03.00 of the Tait TB9100

Calibration Software and Version 2.1x of the

TB9100 base station. Calibration for K-band

base stations, analog gateways, and receiveonly base stations. Murata tuning tool now

not used for UHF (H-band and K-band)

receiver front end, as a different helical filter

is fitted.

MBA-00004-05 February

2007

Describes Version 03.06 of the Tait TB9100

Calibration Software and Version 3.0x of the

TB9100 base station. The FCL and VCO

calibration wizards have been improved.

Page 7

TB9100 Calibration Software User’s Manual Basic Tasks 1

Basic Tasks

The TB9100 Calibration Software is a Windows-based software program that

allows you to adjust the switching ranges of Tait TB9100 base stations (both

receiver and transmitter), and to flatten the receiver response across that

switching range.

The Calibration Software is also used to calibrate the reciter, the PA, and the

PMU after servicing.

Using the TB9100 Calibration Software

When you start the Calibration Software, the main program window appears.

The main program window has four tabs. The Calibration Wizards displayed

on each tab are only visible once you are connected to the reciter or the base

station.

When the Calibration Software is connected to the reciter or base station, you

can view further details (such as module number, type, serial number, band, and

hardware version) about the currently selected module by clicking Show

Details.

Frequency Setup

tab

Shows the Calibration Wizards that take you step-by-step through the

frequency setup.

Reciter Calibration

tab

Shows the calibration procedures that you can perform on the reciter. The

Calibration Wizard takes you step-by-step through the procedure you have

selected.

PA Calibration tab Shows the calibration procedures that you can perform on the power amplifier.

The Calibration Wizard takes you step-by-step through the procedure you

have selected.

PMU Calibration

tab

Shows the procedure that you can perform on the PMU.

Menu bar

Toolbar

Calibration

Wizards

Status bar

Page 8

2 Basic Tasks © Tait Electronics Limited February 2007

About the Toolbar

The toolbar gives you quick access to commonly used menu commands. For

example, instead of selecting Base Station > Calibrate, you can click the

Calibrate icon on the toolbar.

Connect Connects the Calibration Software to the base station and opens the

communication channels.

Switch Base

Station

Lets you select another base station to calibrate if there are multiple base stations

in the rack (not currently supported).

Calibrate Runs the Calibration Wizard for the currently selected task.

Options Allows you to set the COM port and default calibration mode.

Help Opens the online help for the window you are currently in.

About the Status Bar

The status bar provides you with useful information that supplements the

display in the main window.

Miscellaneous messages

COM port in use

Page 9

TB9100 Calibration Software User’s Manual Basic Tasks 3

Equipment Required

You need the following equipment for field calibration:

■ Calibration and Test Unit (CTU, order code TBA0STU), which comes

complete with the cables you will need for connection to the reciter/PA and

the PC. For more information about the CTU, please refer to the CTU

Operation Manual.

■ Tool kit (order code TBA0ST2) which comprises tuning tools and the

required screwdrivers in a tool pouch. The ceramic-tipped Murata tuning

tool is used for most procedures, but the metal-tipped Johanson 8777 tuning

tool with its narrower blade is needed for tuning the front end of H-band

and K-band receivers.

■ 10-30 V DC power supply (if the PMU does not have a 12 V or 24 V

auxiliary power supply module)

■ RS-232 cable

■ RF attenuator (optional – depends on the setup)

You may also need the following additional equipment:

■ Frequency counter with an accuracy of 50 parts per billion or better and a

current calibration certificate

■ Modulation meter (the calibration software supports the Agilent 8920, the

Aeroflex IFR2975, and the R & S CMS54)

■ RF signal source

■ AC millivoltmeter (one with a differential input may be required for

“Calibrating the Balanced Line” on page 20)

Refer to the individual procedures for equipment setup diagrams.

Calibration Overview

Any calibration process creates digital values and a calibration date, which are

stored in the base station. The CSS can display the date of the last calibration.

Many calibration procedures initially clear the stored digital values. If you do

not complete the procedure or the stored digital values are outside acceptable

limits, the module is left uncalibrated. An uncalibrated reciter cannot be put

into Run mode. An uncalibrated PA generates a calibration invalid alarm.

If the procedure you are performing requires access to tuning holes, you need

to remove the reciter from the subrack and connect to it via the CTU.

The following tables summarize, for each procedure, whether or not you need

to remove the reciter from the subrack, and what equipment (in addition to a

PC with the Calibration Software) you will need.

Page 10

4 Basic Tasks © Tait Electronics Limited February 2007

Field Calibration

The following procedures can be carried out in the field.

In addition, the following procedures should be carried out if the base station

fails a modulation fidelity test.

Service Center Calibration

The following procedures may need to be carried out after a module has been

serviced. They are in addition to the field procedures listed above.

Note: Replacing or repairing a board module may mean that the

module’s product code, product type (frequency band), serial

number, and/or hardware version need to be re-entered or altered.

To do this, your Calibration Software needs a dongle. The Service Manual

indicates when a module detail needs re-entering or altering.

Reciter

Procedure Connection Equipment Required

Adjusting receiver lock band Outside subrack Murata tuning tool

Tuning the receiver Outside subrack Murata tuning tool,

Johanson tuning tool (for Hband and K-band reciters),

CTU

Calibrating the RSSI Inside subrack RF signal source

Adjusting exciter lock band Outside subrack Murata tuning tool

Calibrating the TCXO

(see “Carrier Frequency Offset

Adjustment” on page 21)

Outside subrack Murata tuning tool,

Frequency counter, RF

attenuator (only if using PA)

Procedure Connection Equipment Required

Automatically tuning FCL Inside subrack None

Calibrating the FCL modulation Outside subrack Murata tuning tool,

modulation meter, RF

attenuator (only if using PA)

Calibrating the VCO modulation Outside subrack Murata tuning tool,

modulation meter, RF

attenuator (only if using PA)

Procedure Connection Equipment Required

Calibrating the balanced lines

(the analog line)

Inside subrack CTU, AC millivoltmeter

(perhaps with differential

input)

Page 11

TB9100 Calibration Software User’s Manual Basic Tasks 5

Power Amplifier

Power Management Unit

Receive-Only Base Station Calibration

The reciter in a TB9100 receive-only base station differs only in the absence of

a Transmit enable feature license. (The TB8100 receive-only reciter is a

hardware variant with no transmit capability.) Accordingly, the calibration

software reports the reciter type as standard. You need to carry out receiverrelated calibration procedures. Procedures related to the exciter can be carried

out but serve no purpose.

P25 Console Gateway Calibration

The current P25 Console Gateway is effectively a reciter without feature

licenses for transmitting and receiving. Accordingly, the calibration software

reports the reciter type as standard. You need to carry out procedures that relate

to the analog line. Procedures related to the exciter and receiver can be carried

out but serve no purpose.

Selecting the Communications Port

Before you connect to a base station, you should first define the

communications (COM) port that you want to use.

To select the COM port

1. Select Tools > Options.

2. Select the port that you want to use from the COM Port list.

Note: The available COM ports are detected by the program and

appear in the list.

3. Click OK.

The COM port you selected is now shown on the status bar.

Procedure Connection Equipment Required

Calibrating the PA bias Inside subrack None required

Calibrating the forward &

reverse detector bias voltages

Inside subrack None required

Calibrating the PA power Inside subrack None required

Procedure Connection Equipment Required

Output voltage calibration Inside subrack Digital multimeter

Page 12

6 Basic Tasks © Tait Electronics Limited February 2007

Setting Up the Equipment

For field calibration procedures, you need to remove the reciter from the

subrack to gain access to tuning holes. If a CTU is required for one procedure,

it is probably easiest to use it for all your procedures. If it is not required, you

can connect the PC directly to the reciter.

To set up the equipment

1. Remove the reciter from the subrack, following the instructions in the

Installation and Operation Manual. (Note that for some service center

procedures, the reciter can be left in the subrack.)

2. Connect the reciter and the PC to the CTU according to the diagram

below.

■ Connect the reciter’s analog RJ-45 socket (labeled AUD) to the CTU’s

RJ-45 using the RJ45 cable

■ Connect the reciter’s 9-way serial connector (labeled DIG) to the CTU’s

9-way male connector using the 9-way cable.

■ Connect your PC to the CTU by plugging an RS-232 cable into the 9-

way serial port labeled 10101.

(If you are not connecting via the CTU, connect the PC to DIG using the

RS-232 cable. No other connections are required.)

Note: Tait recommends that you disable the PC’s hardware

handshaking. The DIG connector is used for digital I/O as well as

for RS-232 and this could interfere with the handshaking.

Alternatively, use a special DB9 cable that has only three connectors (for pins

2, 3, and 5).

3. Connect the CTU to the 10-30V DC power supply using the power cable

supplied. If the base station’s PMU has a 12 V or 24 V auxiliary power

output, you can use this as the power supply. A connector is supplied with

the CTU. The reciter must also be supplied with power, but do not power

it up yet.

PC

BASE STATION

CALIBRATION TEST UNIT

RS-232

RJ45

CTU

Reciter

Power

supply

ETH

AUD

RS-232

Power cable

DIG

Page 13

TB9100 Calibration Software User’s Manual Basic Tasks 7

Connecting the Calibration Software

Before you can begin calibrating, you must establish a connection between the

calibration software and the reciter.

To connect to the reciter

1. Make sure that the equipment is set up but that the reciter is not powered

up.

2. Start the Calibration Software program, and check that the correct COM

port is selected.

3. Click Connect to start the connection process.

4. When you see the “Waiting for logon prompt from Reciter” screen, power

up the reciter. If it is already on, turn it off, and then on.

5. When the Calibration Software program has successfully connected to the

reciter (this can take up to 30 seconds), the Calibration Wizards are

displayed in the main window.

You are now ready to tune and calibrate the reciter.

Disconnecting from the Base Station/Reciter

Once calibration is completed, end the process as follows.

1. Click Disconnect.

Important: Disconnecting when a calibration process is not

completed may leave the base station in an uncalibrated state.

2. Exit the Calibration Software.

3. Turn the base station off and then on again to take it out of calibration

mode. The base station is now in Standby mode, ready for configuration.

Troubleshooting

Application Errors All application errors are recorded in a log file called

“CCTMCOMMSLog.log”. The data, time, location, and any other useful

information is stored in this file, which may be helpful when troubleshooting.

The file is saved in the Calibration Software’s application folder.

Verifying the

Software Version

If you need to verify the version of the Calibration Software, select

Help > About.

Commands

Record

All the commands sent and received by Calibration Software are saved in a file

called “CCTM.log”. The date, time, command number, and parameters are all

stored in this file, which may be helpful when troubleshooting.

The file is also saved in the Logfiles subfolder and stores up to 1000 of the most

recent logged items.

Page 14

8 Adjusting the Frequency Setup © Tait Electronics Limited February 2007

Adjusting the Frequency Setup

Before the TB9100 base station is installed, connected, and configured, you

must prepare it for operation by adjusting the switching range of the receiver,

optimizing the receiver response across the switching range, and adjusting the

exciter lock band or selecting an exciter sub-band.

Note: If the required switching range for the base station has already

been defined, you don’t need to perform these procedures.

Tip: Use the TB9100 CSS to monitor the base station and find out

its current switching range.

Important: Be careful when using the tuning tool. Applying too

much pressure or attempting to turn the tool beyond the end of the

range can crack the tuning slug. Unscrewing a slug too far can

remove it completely.

Adjusting the Receiver Lock Band

The first step in preparing the TB9100 base station for operation is to adjust the

receiver lock band (switching range). The lock band is the range of frequencies

that the receiver is calibrated to operate on.

To adjust the receiver lock band

1. Set up the equipment and connect the Calibration Software to the reciter.

2. Select the Frequency Setup tab, and double-click Set Receiver VCO. The

Set Receiver VCO Wizard appears. The display varies, depending on the

reciter band.

3. Enter the Center Frequency (which must be a multiple of 500 kHz) of the

lock band that you want to use, and click Next.

4. Insert the Murata tuning tool into the correct receiver VCO tuning hole for

the reciter type (see below) and then click Next.

5. Adjust the receiver VCO trimmer until the actual band matches the desired

band. The bands turn green. Click Finish. This stores the lock band in the

reciter. The icon on the Frequency Setup tab indicates that this task is

complete. Proceed to tune the front end.

Page 15

TB9100 Calibration Software User’s Manual Adjusting the Frequency Setup 9

Tuning a UHF Receiver Front End

The second step in tuning the reciter frequency is to tune the receiver front

end, by adjusting the helical filters. Tuning aims to maximize the receiver’s

sensitivity and to optimize its response across the lock band (switching range).

To help you do this, there is a graph of the RSSI readings in step two of the

Tune Receiver Front End Wizard. A number of RSSI readings are measured

across the switching range. These readings are then continually averaged to

produce the graph.

Important: After tuning the reciter front end, you must re-calibrate the RSSI.

This requires a signal generator.

Otherwise the value reported by the CSS will

be in error, RSSI gating levels will be incorrect in analog mode, and voting

will be inaccurate in both modes.

You should aim to achieve a response that looks something like this:

Receiver VCO tuning hole for

H band (380–520 MHz) and

K band (792–824 MHz).

Receiver VCO tuning hole for

B band (136–174 MHz)

Page 16

10 Adjusting the Frequency Setup © Tait Electronics Limited February 2007

Setup

To tune the front end of a UHF (H-band) receiver, follow these steps.

1. Make sure that the equipment is correctly set up and that the Calibration

Software is connected to the reciter.

2. Select the Frequency Setup tab, and double-click Tune Receiver Front

End. The Tune Receiver Front End Wizard appears.

Note: If you haven’t adjusted the receiver lock band in the current

session, an alert appears, recommending that you run the Set

Receiver VCO wizard first. If the lock band needs adjusting, click

Yes and carry out that procedure first. If you are confident that the lock band

is correct, click No.

3. Connect the CTU’s noise source to the receiver input, turn the noise source

on, and then click Next.

4. Click Coarse (fast) and use the tuning tool to roughly adjust the front-end

helical filters on the receiver. As you do so, observe the graphical RSSI

readings across the lock band. Adjust to maximize the response across the

entire switching band.

Note: For final fine tuning, you may find it helpful to select a more

sensitive scale, so that you can see the graphical reading in more

detail.

6

4

3

1

2

5

1 PC 2 RS-232 cable 3 Programming port

4 CTU 5 Noise source 6 Reciter

First set

Second set

Helical

filters:

Page 17

TB9100 Calibration Software User’s Manual Adjusting the Frequency Setup 11

Use the tuning tools as follows.

a. Insert the Johanson tuning tool into the first hole of the first (horizontal)

set. You can start with the hole on the left side and proceed along to the

hole on the right, or vice versa. On K-band reciters, the third hole tends

to tune with the slug well out of the filter body. Be careful not to

unscrew the slug completely.

b. Tune each of the resonators in the first set once to give the best response.

c. Insert the Johanson tuning tool into the first hole of the second (vertical)

set. You can start with the top hole and proceed down to the bottom

hole, or vice versa. (For version 4.00 or earlier H-band reciters, use the

Murata tuning tool on this set instead, as instructed by the wizard.)

d. Tune each of the resonators in the second set once to give the best

response.

e. Repeat this procedure as necessary to refine the response.

5. Once you have roughly tuned the front-end helical filters, click Fine

(slow). Repeat the above procedure to fine tune the front-end helical filters

until the response is peaked in the middle of the lock band and not more

than -1 dB at the ends of the band.

Note: When using the Fine (slow) setting, you may notice a slight

delay as the reading from tuning the front-end helical filters takes

approximately one second to appear on the graph.

6. Click Finish. An alert appears, asking that you calibrate the RSSI. The icon

on the Frequency Setup tab indicates that this task is complete.

7. Re-calibrate the RSSI (see “Calibrating the RSSI” on page 18).

Tuning a VHF Receiver Front End

The second step in tuning a VHF reciter is to tune the receiver front end, by

adjusting trimmer capacitors. Tuning aims to maximize the receiver’s sensitivity

and to optimize its response across the lock band (switching range).

To help you do this, there is a graph of the RSSI readings in step two of the

Tune Receiver Front End Wizard. A number of RSSI readings are measured

across the switching range. These readings are then continually averaged to

produce the graph.

Important: After tuning the reciter front end, you must re-calibrate the RSSI.

This requires a signal generator.

Otherwise the value reported by the CSS will

be in error, RSSI gating levels will be incorrect in analog mode, and voting

will be inaccurate in both modes.

You should aim to achieve a response that looks something like this:

Page 18

12 Adjusting the Frequency Setup © Tait Electronics Limited February 2007

Setup

To tune a VHF (B-band) receiver front end, follow these steps.

1. Make sure that the equipment is correctly set up and that the Calibration

Software is connected to the reciter.

2. Select the Frequency Setup tab, and double-click Tune Receiver Front

End. The Tune Receiver Front End Wizard appears.

Note: If you haven’t adjusted the receiver lock band in the current

session, an alert appears, recommending that you run the Set

Receiver VCO wizard first. If the lock band needs adjusting, click

Yes and carry out that procedure first. If you are confident that the lock band

is correct, click No.

3. Connect the CTU’s noise source to the receiver input, turn the noise source

on, and then click Next.

4. Click Coarse (fast) and use the Murata tuning tool to roughly adjust the

four front-end trimmers on the receiver (see below). You can do this in any

order. As you do so, observe the graphical RSSI readings across the lock

band. Adjust to optimize the response across the entire switching band.

Note: For final fine tuning, you may find it helpful to select a more

sensitive scale, so that you can see the graphical reading in more

detail.

5. Once you have roughly tuned the trimmers, click Fine (slow). Repeat the

above procedure until the response is flat in the middle of the lock band and

not more than -1 dB at the ends of the band.

Note: When using the Fine (slow) setting, you may notice a slight

delay as the reading from tuning the trimmers takes approximately

one second to appear on the graph.

6. Click Finish. An alert appears, asking that you calibrate the RSSI. The icon

on the Frequency Setup tab indicates that this task is complete.

7. Re-calibrate the RSSI (see “Calibrating the RSSI” on page 18).

6

4

3

1

2

5

1 PC 2 RS-232 cable 3 Programming port

4 CTU 5 Noise source 6 Reciter

Page 19

TB9100 Calibration Software User’s Manual Adjusting the Frequency Setup 13

Adjusting the Exciter Lock Band

If you are preparing the base station for operation, adjusting the exciter lock

band is the third step in tuning the reciter. Alternatively, this procedure can be

performed independently of the other two calibration wizards on the

Frequency Setup tab. Adjusting the exciter lock band defines the range of

frequencies that the base station is able to transmit on.

Note: When performing this procedure, you don’t need to

terminate the exciter output port. An internal output pad means that

there is a good impedance match at this interface.

To calibrate the exciter lock band

1. Set up the equipment and connect the Calibration Software to the reciter.

2. Select the Frequency Setup tab, and double-click Set Exciter VCO. The

Set Exciter VCO Wizard appears.

3. Enter the center frequency (which must be a multiple of 500 kHz) of the

lock band that you want to use, and click Next.

4. Insert the Murata tuning tool into the correct exciter VCO tuning hole (see

below) and adjust the trimmer until the actual band matches the desired

band. The bands turn green. Click Finish.

Once you have finished adjusting the exciter lock band, the icon on the

Frequency Setup tab indicates that this task is complete.

Trimmer holes for receiver

front-end tuning

(B band 136–174 MHz)

Exciter VCO tuning hole

for H band

(380–520 MHz)

Exciter VCO tunin

g

hole for B band

(136–174 MHz)

Page 20

14 Adjusting the Frequency Setup © Tait Electronics Limited February 2007

Selecting the Exciter Sub-band

The lock band of K-band exciters does not normally need adjusting. Instead

you select a sub-band. These exciters have two VCOs and the one you select

determines the sub-band that is displayed on CSS monitoring screens and that

has its lock range determined in diagnostic tests. However, exciters can always

operate on frequencies in either sub-band.

Equipment ■ Murata tuning tool

■ CTU

To select the exciter sub-band

1. Ensure you are already connected to the reciter (see “Connecting to a

Reciter Outside the Subrack” on page 8).

2. Select the Frequency Setup tab, and double-click Set/Select Exciter

VCO. The Set/Select Exciter VCO Wizard appears.

3. Select the check box to skip the tuning steps and then click Next.

Alternatively, if the reciter RF board has been repaired, you need to adjust

the lock band. Select one of the two available lock bands and then click

Next. Insert the Murata tuning tool into the correct exciter VCO tuning

hole (see below) and adjust the trimmer until the actual band matches the

desired band. The bands turn green. Click Next.

4. Select one of the two available lock bands. This specifies the lock band used

for display and for diagnostic tests.

5. Click Finish.

If you adjusted the lock band, the icon on the Frequency Setup tab

indicates that this task is complete. If you simply selected the sub-band, the icon

is unchanged, indicating that there was no adjustment.

Exciter VCO tuning hole for

K band (850-869 MHz)

Exciter VCO tuning hole for

K band (762-776 MHz)

Page 21

TB9100 Calibration Software User’s Manual Calibrating the Reciter 15

Calibrating the Reciter

The reciter is fully calibrated in the factory, but if the reciter is serviced you may

need to perform the following procedures:

■ Calibrating the Exciter

■ Calibrating the RSSI

■ Calibrating the Balanced Line

To compensate for frequency drift, you may need to perform the following:

■ Carrier Frequency Offset Adjustment

All these procedures can be done independently of each other, although it is

recommended that you tune the receiver before you calibrate the RSSI.

Important: It is recommended that only accredited service centers

and Tait engineers perform these procedures.

Calibrating the Exciter

You will need to calibrate the exciter if you have made component-level repairs

to it. There are three steps:

1. Auto-tune the FCL

2. Calibrate the FCL

3. Calibrate the VCO

Automatically Tune the Frequency Control Loop (FCL)

Tuning the FCL calibrates the voltage levels used in the detectors for the FCL.

To automatically tune the FCL

1. Set up the equipment and connect the Calibration Software to the reciter.

2. Select the Reciter Calibration tab, and double-click FCL Auto Tuning.

The FCL Auto Tuning Wizard appears.

3. Click Calibrate to automatically tune the FCL.

The icon on the Reciter Calibration tab indicates that this task is complete.

You will now need to calibrate the FCL.

Calibrating the FCL

This is step two of calibrating the exciter. Once you have auto-tuned the FCL,

you should calibrate it.

Equipment ■ Murata tuning tool

■ Modulation meter

■ RF attenuator (only required if you are using a PA)

Page 22

16 Calibrating the Reciter © Tait Electronics Limited February 2007

Setup

To calibrate the FCL

1. Make sure that the equipment is set up and that the Calibration Software is

connected to the reciter.

2. Select the Reciter Calibration tab, and double-click FCL Calibration. The

FCL Calibration Wizard appears.

3. In the drop-down list, select the model of the test set you will use for the

calibration.

4. Set the modulation meter according to the instructions in the wizard, and

then click Next. (If you are using a PA, it will now transmit.)

5. Insert the tuning tool into the correct exciter VCO tuning hold (see below)

and adjust the trimmer until the actual band matches the desired band. The

bands turn green. Click Next.

6. If the modulation meter cannot auto-tune, set its frequency to the displayed

value. This is the mid-point of the actual band, as determined by step 2 of

the wizard. Click Next.

7. Use the slider to adjust the deviation at 1 kHz until it is 2.11 kHz or 2107

Hz

RMS (3 kHz peak).

8. Select the 30 Hz Modulation Test and adjust the deviation at 30 Hz until it

is 2.11 kHz or 2107 Hz

RMS (3 kHz peak).

9. Repeat steps 7 and 8 until the deviation is 2.11 kHz or 2107 Hz RMS at

both 1 kHz and 30 Hz. Aim for an accuracy of +/- 10 Hz.

10.Click Finish. (If you are using a PA, it will now stop transmitting.)

When you have finished calibrating the FCL, the icon on the Reciter

Calibration tab indicates that this task is complete.

You will now need to calibrate the VCO.

1 Reciter 3 RF attenuator (only required if using a PA)

2 PA (optional) 4 Modulation meter

1

2

3

4

Page 23

TB9100 Calibration Software User’s Manual Calibrating the Reciter 17

Calibrating the VCO

This is step three of calibrating the exciter.

Once you have tuned and calibrated the FCL, you calibrate the VCO at

frequencies across the whole lock band. This involves selecting a sub-band,

adjusting the lock band trimmer, and then moving on-screen sliders to adjust

the deviation to 3 kHz for each of a set of frequencies.

Equipment ■ Murata tuning tool

■ Modulation meter

■ RF attenuator (only required if you are using a PA)

Setup

To calibrate the VCO

1. Make sure that the equipment is set up and that the Calibration Software is

connected to the reciter.

2. Select the Reciter Calibration tab, and double-click VCO Calibration.

The VCO Calibration Wizard appears.

3. In the drop-down list, select the test set model you will use for the

calibration.

4. Set the modulation meter according to the instructions in the wizard, and

then click Next. (If you are using a PA, it will now transmit.)

5. Adjust the exciter lock band trimmer until the actual band matches the

desired band. The bands turn green.

6. Click Next. Step 3 of the wizard appears.

Exciter VCO tuning hole

for H band

(380–520 MHz)

Exciter VCO tuning hole for

B band (136–174 MHz)

Exciter VCO tuning hole for

K band (850-869 MHz)

Exciter VCO tuning hole for

K band (762-776 MHz)

1 Reciter 3 RF attenuator (only required if using a PA)

2 PA (optional) 4 Modulation meter

1

2

3

4

Page 24

18 Calibrating the Reciter © Tait Electronics Limited February 2007

7. Calibrate each of the frequencies shown. Follow these steps.

a. Click the option button alongside a frequency.

b. If the modulation meter cannot auto-tune, set its frequency to the

selected value.

c. Using the Fine and Coarse arrows, adjust the slider until the deviation

shown on the modulation meter is 3000 Hz (peak).

d. Repeat steps a) and b) until all frequencies for the band are calibrated.

This enables the Next Band button.

8. Click Next Band and repeat steps 4) through 6). Repeat until all

frequencies in all bands have been calibrated.

9. If you are connected to a K-band reciter, click Next. Select one of the two

sub-bands. This

determines the sub-band that is displayed on CSS monitoring

screens and that has its lock range determined in diagnostic tests. However,

exciters can always operate on frequencies in either sub-band.

10.Click Finish. (If you are using a PA, it will now stop transmitting.)

When you have finished calibrating the VCO, the icon on the Reciter

Calibration tab indicates that this task is complete.

You should now adjust the exciter lock band because it was re-tuned several

times during this procedure. This means that the exciter is no longer on the

required frequency. If you have P25 test equipment, we also recommend that

you carry out a modulation fidelity test to verify the adequacy of the FCL and

VCO calibration for digital P25 transmissions.

Calibrating the RSSI

Calibrating the RSSI (received signal strength indicator) ensures that the

reciter's internal RSSI values accurately reflect the actual received signal

strength. Changing the receiver's lock band can alter the calibration accuracy by

about 1 dB.

Note: Ensure that the receiver’s lock band has already been adjusted

to the required setting before carrying out this procedure. (See

“Adjusting the Receiver Lock Band” on page 8.)

Equipment ■ RF signal source

Setup

To calibrate the RSSI

1. Make sure that the equipment is set up and that the Calibration Software is

connected to the reciter.

1

2

1 RF signal source

2 Reciter

Page 25

TB9100 Calibration Software User’s Manual Calibrating the Reciter 19

2. Select the Reciter Calibration tab, and double-click RSSI Calibration. An

alert appears, recommending that you tune the receiver. If the receiver

needs tuning, click Yes and carry out that procedure before continuing.

If you are confident that the receiver is correctly tuned, click No. The RSSI

Calibration Wizard appears.

3. Apply a signal (modulated at 1 kHz tone, 3kHz deviation peak) at the base

station’s center frequency. Use the CTU to confirm that the tone is being

output on the line, and then click Next.

4. Set the RF input signal to a level of -80 dBm, and then click Next.

5. Vary the RF level, and check that the value shown in the RSSI Gain Setting

box corresponds with the value shown on your test instrument. This is to

make sure the RSSI is correctly calibrated. Click Finish.

When you have finished calibrating the RSSI, the icon on the Reciter

Calibration tab indicates that this task is complete.

Page 26

20 Calibrating the Reciter © Tait Electronics Limited February 2007

Calibrating the Balanced Line

This procedure is carried out on the analog line if the reciter network board has

been replaced or repaired. It adjusts the gain, so that when you set line levels

using the CSS, the actual line level correctly reflects the CSS settings. (Refer to

the TB9100 Customer Service Software User’s Manual for further information.)

Equipment ■ CTU

■ AC millivoltmeter

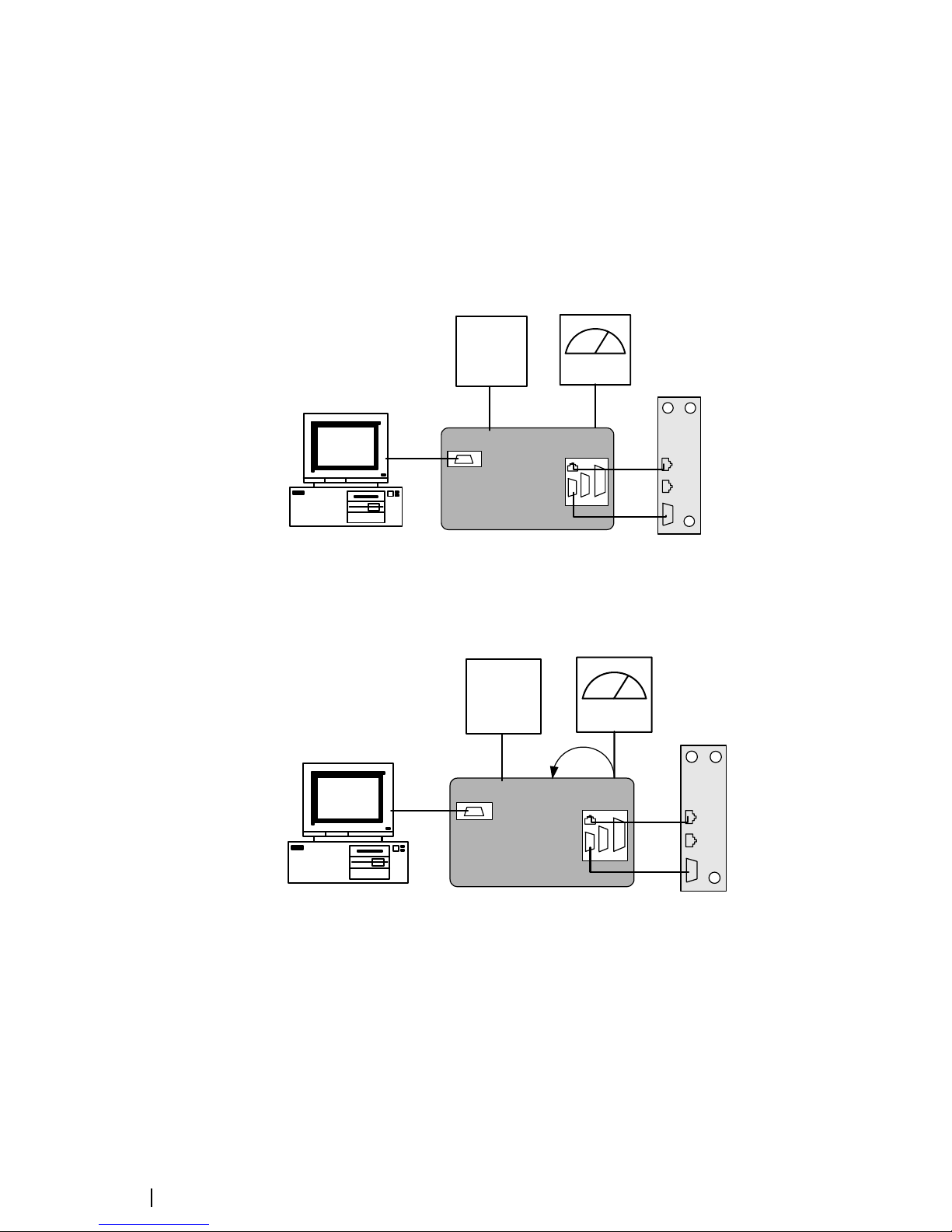

Setup for Line Out

Setup for Line In

To calibrate the analog input and output lines

1. Make sure that the equipment is set up and that the Calibration Software is

connected to the reciter.

2. Select the Reciter Calibration tab, and double-click Balanced Line

Calibration. The Balanced Line Calibration Wizard appears.

3. Attach an AC millivoltmeter and terminate the output in 600 ohms (either

using the load on the CTU or looping the balanced output to the balanced

input), and then click Next.

4. Adjust the slider in the dialog box until the audio level on the millivoltmeter

reads 1 V

PP (0.354 VRMS).

PC

Power

supply

BASE STATION

CALIBRATION TEST UNIT

RS-232

RJ45

CTU

Reciter

ETH

AUD

Power cable

DIG

AC millivoltmeter

Line

output

Power

supply

BASE STATION

CALIBRATION TEST UNIT

RS-232

RJ45

ETH

AUD

Power cable

DIG

AC millivoltmeter

Line

output

Line input

Page 27

TB9100 Calibration Software User’s Manual Calibrating the Reciter 21

Note: Click Coarse to roughly adjust the audio level, and once you

get within range, click Fine for more precise control over the

settings. To move up or down 10 mV

PP, click either side of the

slider bar.

5. Click Next. The balanced output is now calibrated.

6. Note the level of the AC millivoltmeter, and then turn off the 600 ohm

load.

7. Connect the analog output to the analog input. Verify that the

millivoltmeter reading is substantially unchanged. (This confirms that the

input provides a 600 ohm impedance.)

8. Click Finish. The balanced input is now calibrated.

When you have finished calibrating the analog line, the icon on the

Reciter Calibration tab indicates that this task is complete.

Calibrating the Unbalanced Lines

This procedure is not carried out on the TB9100. The TB9100 does not have

an unbalanced line.

Carrier Frequency Offset Adjustment

The TCXO (temperature compensated crystal oscillator) provides a reference

frequency from which all other RF frequencies are derived. TB9100 reciters

have a voltage-controlled TCXO with a pot for adjusting the reference

frequency to remove any carrier frequency offset. The Carrier Freq Offset

Adjustment wizard provides assistance with this procedure.

This procedure is not normally needed in the field for VHF base stations. For

UHF and above, Tait recommends that the reciter TCXO is checked after 3

months service and adjusted if the error is > 0.5 ppm.

Annual checks should be made thereafter to detect any frequency drift. The

reciter TCXO should only be adjusted if the actual transmit frequency has

drifted more than 0.5 ppm from the configured value.

Tait recommends that the TCXO is calibrated to within 0.1ppm.

Page 28

22 Calibrating the Reciter © Tait Electronics Limited February 2007

Equipment ■ Torx 10 screwdriver (to remove the reciter cover)

■ Tuning tool

■ Frequency counter with an accuracy of 50 parts per billion or better. The

equipment must either have its own internal high-accuracy reference or be

locked to an external reference such as the Tait T805.

■ RF attenuator (only required if you are using a PA)

Important: The accuracy of the calibrated TCXO frequency is only

as good as the accuracy of the frequency counter.

Setup

You need direct access to the TCXO circuitry on the reciter RF board. This

involves removing the reciter RF cover.

Important: The reciter contains devices that are susceptible to

damage from static charges. You must handle these devices

according to the recommended ESD precautions.

To adjust the carrier frequency

1. Remove the reciter from the subrack.

2. Remove the M3 Torx screws securing the reciter RF cover to the heatsink

and to the front and rear panels. (The RF side of the reciter can be identified

by the two BNC connectors on that side of the reciter’s rear.) Lift off the

RF cover.

3. Make sure that the equipment is set up and that the Calibration Software is

connected to the reciter.

4. Select the Reciter Calibration tab, and double-click Carrier Freq Offset

Adjustment. The Carrier Freq Offset Adjustment wizard appears.

5. Attach an appropriate load and frequency counter (or a test set) to the exciter

or PA output, and then click Next.

The exciter now begins transmitting on the center frequency of its lock

band. The Wizard displays a message similar to the following:

“Adjust RV1400 to set frequency within 0.1ppm or 48Hz of 485 MHz”

6. Use the tuning tool to adjust the TCXO tuning control (RV1400) so that

the reciter is transmitting exactly on frequency.

The following shows where the tuning control is located on B-band and Hband reciters:

1

2

3

4

1 Reciter 3 RF Attenuator pad (optional)

2 PA ( o p t i onal) 4 Frequency counter

Page 29

TB9100 Calibration Software User’s Manual Calibrating the Reciter 23

The following shows where the tuning control is located on K-band

reciters:

7. Click Finish. Transmission ceases and the icon on the Reciter

Calibration tab indicates that this task is complete.

8. Replace the reciter RF cover, as follows.

a. Slide the cover into place over the front and rear panels. Make sure the

holes in the cover line up with the threaded holes in the heatsink and

front and rear panels.

b. Press the cover firmly into place and screw in the M3 Torx screws, first

on the flat face, then on the edge face.

Important: Excessively tightening the screws can damage the thread

of the aluminium heatsink. Tait recommends that you use a T10

torque driver set to 0.5 Newton meters (4.5 lbf.in).

Page 30

24 Calibrating the Reciter © Tait Electronics Limited February 2007

Page 31

TB9100 Calibration Software User’s Manual Calibrating the Power Amplifier 25

Calibrating the Power Amplifier

The PA is fully calibrated in the factory, but if the PA is serviced you may need

to perform the following procedures:

■ Calibrating the PA Bias

■ Calibrating the Forward and Reverse Detector Bias Voltages

■ Calibrating the PA Power

Perform the procedures in the above order.

Important: It is recommended that only accredited service centers

and Tait engineers perform these procedures.

Calibrating the PA Bias

The driver and final transistors of the power amplifier must be biased at a

constant current. Since the characteristics of individual transistors vary slightly,

the bias current is calibrated for each device.

If either the driver or final transistor, or the PCB modules themselves, are

replaced during servicing, you should perform this procedure to calibrate the

bias current for the new device.

The bias current required for each amplifier stage is stored within the PA.

During the calibration process, the microprocessor adjusts the gate bias voltage

to obtain the required bias current for each stage.

The stage bias calibration sets up the amplifier’s DC operating conditions.

These DC conditions will be upset if there is RF present during calibration. It

is important to disconnect the RF cable from the PA input to avoid this.

The other conditions which must be met to ensure a successful calibration are

as follows:

■ No other Calibration Wizards are running

■ The supply voltage is within the range 27-29 V (for 12 V PAs, assume that

the internal voltage is within this range)

■ The temperature of each stage is within the range 5-50°C

To calibrate the PA stage bias current

1. Make sure that the equipment is set up and that the Calibration Software is

connected to the reciter.

2. Select the PA Calibration tab, and double-click Calibrate PA Bias.

3. Ensure that the exciter RF is isolated from the PA by disconnecting the

SMA connector on the PA front panel.

4. Click Calibrate to calibrate the PA bias.

When you have finished calibrating the power amplifier bias, the icon on

the PA Calibration tab indicates that this task is complete.

Page 32

26 Calibrating the Power Amplifier © Tait Electronics Limited February 2007

Calibrating the Forward and Reverse Detector Bias Voltages

The RF detectors, used for measuring the forward and reverse power, operate

with a small bias current. The resulting bias voltage from each detector (with

no RF present) is read and stored inside the PA. These voltages are used when

calculating the Antenna VSWR (Voltage Standing Wave Ratio).

You should calibrate the forward and reverse detector bias voltages:

■ If the Low Pass Filter (LPF)/directional coupler PCB module is replaced

■ After servicing of any components in the detector circuitry (such as the

detector diodes) on the LPF/ directional coupler PCB

To calibrate the forward and reverse detector bias voltages

1. Make sure that the equipment is set up and that the Calibration Software is

connected to the reciter.

2. Select the PA Calibration tab, and double-click Calibrate Fwd/Rev

Detector Bias Voltages.

3. Ensure that the PA is not transmitting and that there is no RF source present

at the PA RF input or output by disconnecting the input SMA connector

on the PA front panel and the ‘N’ type output connector from the rear of

the PA. Click Calibrate.

When you have finished, the icon on the PA Calibration tab indicates that

this task is complete.

Calibrating the PA Power

The power amplifier (PA) receives the RF signal from the reciter and amplifies

it to the required level, in watts, as requested by the reciter. The desired output

power is determined by the reference voltage for the power control loop.

The PA power control loop is calibrated at a single frequency, generally in the

center of the operating band.

You perform the calibration procedure to define – for each power level – the

reference DAC (Digital-to-Analog Converter) value and forward detector

voltage.

You should only need to re-calibrate the PA power if:

■ The Low Pass Filter (LPF)/directional coupler PCB module is replaced

■ Any repairs are carried out on the forward and reverse detector circuitry on

the Low Pass Filter/directional coupler PCB module

■ You require a more accurate power calibration on a specific frequency

Equipment

■ Either an inline power meter and 50 ohm load with a high power rating, or

■ A terminating power meter and appropriate 50 ohm attenuator with a high

power rating

Page 33

TB9100 Calibration Software User’s Manual Calibrating the Power Amplifier 27

Setup for Inline

Power Meter

Note: Cables and connectors can easily cause a power loss of several

watts if either too long or poorly terminated. Always use the

shortest possible leads (or connectors instead of leads) between the

PA and power meter set-up.

To calibrate the PA transmit power

1. Make sure that the equipment is set up and that the Calibration Software is

connected to the reciter.

2. Select the PA Calibration tab, and select Calibrate PA Power.

3. Ensure that the power meter and a 50 ohm load (VSWR < 1.2:1) with a

high power rating are connected to the power amplifier RF output, and

then click Next.

4. Check that the PA RF input is connected to the reciter RF output, and that

the PA and the reciter are connected by a control bus, and then click Next.

5. For each power level shown, use the slider to adjust the DAC setting to get

the required power output, and then click Next Power to move to the next

line.

Note: Click Coarse to roughly adjust the DAC setting, and once

you get within range, click Fine for more precise control over the

settings. To move up or down one DAC value, click either side of

the slider bar.

Note: You must perform the calibration in sequence from the lowest

to the highest step. The DAC setting must be greater than the

previous one otherwise the value will not be stored in the PA, and

you cannot move to the next line.

6. When you have completed adjusting the DAC settings, click Finish.

When you have finished, the icon on the PA Calibration tab indicates that

this task is complete.

1 3

2

4

5

1 Reciter 3

PA

5 Load

2 16-way cable 4 RF Power Meter

Page 34

28 Calibrating the Power Amplifier © Tait Electronics Limited February 2007

Troubleshooting Tips

DAC Settings When you adjust the DAC settings, the values for the DAC Setting, Coupler

Fwd Voltage, and Control Voltage should always increase as the power level

increases. If these values do not increase, there is either a fault with the PA or

the previous step was not calibrated correctly. If you make a mistake in the

calibration table, you must start again from step 1.

Control Voltage The Control Voltage is shown in the table to indicate the operation point

within the power control loop. The range of the control voltage is from 0 V to

7.5 V. If the control voltage reaches its limit before achieving maximum power

in the table, this indicates either a faulty gain stage in the PA or low RF input

power to the PA.

VSWR The VSWR (Voltage Standing Wave Ratio) is monitored at the RF output of

the PA during calibration. The software will not allow calibration into a load

VSWR > 1.3:1. If a calibration step cannot be stored, check that the load

VSWR is <1.3:1. It is recommended that the load should have an input

VSWR <1.2:1.

Page 35

TB9100 Calibration Software User’s Manual Calibrating the Power Management Unit 29

Calibrating the Power Management Unit

There is only one calibration procedure for the PMU: calibrating its output

voltage.

Calibrating the PMU Output Voltage

Calibrating the PMU output voltage adjusts the voltage to be 28.00 V. This

procedure is only carried out when a replacement control card or

microprocessor is fitted to the PMU. Normally, the output voltage will be

accurate without calibration.

Note: Re-calibrating the PMU output voltage may in fact result in

it failing to meet the published specification of +/- 0.5% accuracy.

This is because control cards are calibrated in the factory under half-

load, giving a voltage that is closer to 28.00 V under varying loads.

To calibrate the output voltage

1. Make sure that the equipment is set up and that the Calibration Software is

connected to the reciter.

2. Select the PMU Calibration tab.

3. Double-click Output Voltage Calibration. The Calibrate Output

Voltage wizard appears.

4. Connect a digital multimeter to the PMU output and read the output

voltage.

5. Enter the voltage into the PMU Voltage box and click Calibrate.

6. When the wizard indicates that the calibration completed successfully, click

Finish.

Page 36

30 Calibrating the Power Management Unit © Tait Electronics Limited February 2007

Page 37

TB9100 Calibration Software User’s Manual Index 31

Index

A

AC millivoltmeter 3

analog line, calibrating 20

audio level

calibrating

20

B

Balanced Line Calibration Wizard 20

band 1

entering 4

base station

disconnecting from

7

receive only 5

C

Calibrate Fwd/Rev Detector Bias Voltages

Wizard

26

Calibrate Output Voltage wizard 29

Calibrate PA Bias Wizard 25

Calibrate PA Power Wizard 27

Calibration and Test Unit 3

connecting up 6

calibration wizards 1

FCL Auto Tuning Wizard 15

RSSI Calibration Wizard 19

Set Exciter VCO Wizard 13, 14

Tune Receiver Front End Wizard 10, 12

Carrier Freq Offset Adjustment Wizard 22

carrier frequency, calibrating 21

COM port, selecting 5

control voltage 28

coupler fwd voltage 28

CTU

connecting up

6

E

equipment 3

tuning tool 14

exciter

adjusting lock band

13

calibrating 15, 15

component repairs to 15

F

FCL (Frequency Control Loop)

calibrating

15

FCL Calibration Wizard 16

frequency

defining range of

13

G

gate bias voltage, adjusting 25

H

hardware version

entering

4

J

Johanson 8777 tuning tool 3

L

lock band

adjusting on exciter

13

adjusting on receiver 8

log files

application errors

7

commands received and sent 7

M

module number 1

Murata tuning tool 3

P

P25 Console Gateway 5

PA

calibrating bias current

25

calibrating transmit power 26

faulty gain stage 28

low RF input power 28

viewing details of 1

PMU

calibrating output voltage

29

power supply 3

product code

entering

4

R

receive-only base station 5

receiver

Page 38

32 Index © Tait Electronics Limited February 2007

adjusting lock band 8

tuning front end helical filters 9, 11

reciter

calibrating

15

connecting to (outside subrack) 6

tuning the frequency 8

viewing details of 1

Reference DAC 26

resonators

see front end helical filters

RF attenuator

see equipment

RF detectors

calibrating bias voltage of

26

RSSI (Received Signal Strength Indicator)

tuning receiver

9, 11

S

serial number 1

entering 4

Set Receiver VCO Wizard 8

status bar 2

switching range

adjusting

8

definition 8

T

TCXO (Temperature Compensated Crystal

Oscillator)

calibrating

21

tool kit 3

toolbar 2

troubleshooting 7

PA power calibration 28

tuning tool 3

V

VCO Calibration Wizard 17

version

of Calibration Software

7

VSWR

calibrating bias voltages used to calculate

26

may prevent calibration 28

W

wizards 1

Page 39

TB9100 Calibration Software User’s Manual Tait General Software Licence Agreement 33

Tait General Software Licence Agreement

This legal document is an Agreement between you (the

“Licensee”) and Tait Electronics Limited (“Tait”). By using any

of the Software or Firmware items prior-installed in the related

Tait product, included on CD or downloaded from the Tait

website, (hereinafter referred to as “the Software or Firmware”)

you agree to be bound by the terms of this Agreement. If you do

not agree to the terms of this Agreement, do not install and use

any of the Software or Firmware. If you install and use any of the

Sof tw are or Fir mwa re that will be de eme d t o be accept an ce of t he

terms of this licence agreement.

The terms of this Agreement shall apply subject only to any

express written terms of agreement to the contrary between Tait

and the Licensee.

Licence

TAIT GRANTS TO YOU AS LICENSEE THE NON-EXCLUSIVE

RIGHT TO USE THE SOFTWARE OR FIRMWARE ON A SINGLE

MACHINE PROVIDED YO U MAY ONLY:

1. COPY THE SOFTWARE OR FIRMWARE INTO ANY MACHINE

READABLE OR PRINTED FORM FOR BACKUP PUR POSES IN

SUPPORT OF YOU R USE OF THE PROGRAM ON THE SINGLE

MACHINE (CERTAIN PROGRAMS, HOWEVER, MAY INCLUDE

MECHANISMS TO LIMIT OR INHIBIT COPYING, THEY ARE

MARKED “COPY PROTECTED”), PROVIDED THE COPYRIGHT

NOTICE MUST BE REPRODUCED AND INCLUDED ON ANY SUCH

COPY OF THE SOFTWARE OR FIRMWARE;

AND / OR

2. MERGE IT INTO ANOTHER PROGRAM FOR YO UR USE ON

THE SINGLE MACHINE (ANY PORTION OF ANY SOFTWARE OR

FIRMWARE MERGED INTO ANOTHER PROGRAM WILL

CONTINUE TO BE SUBJECT TO THE TER MS AND CONDITIONS

OF THIS AGREEMENT).

THE LICENSEE MAY NOT DUPLICATE, MODIFY, REVERS E

COMPILE OR REVERSE ASSEMBLE ANY SOFTWARE OR

FIRMWARE IN WHOLE OR PAR T.

Important Notice

THE SOFTWARE OR FIRMWARE MAY CONTAIN OPEN SOURCE

SOFTWARE COMPONENTS (“OPEN SOURCE COMPONENTS”).

OPEN SOURCE COMPONENTS ARE EXCLUDED FROM THE

TERMS OF THIS AGREEMENT EXCEPT AS EXPRESSLY STATED IN

THIS AGREEMENT AND ARE COVERED BY THE TERMS OF THEIR

RESPECT IVE LICENCES WHICH MAY EXCLUDE OR LIMIT ANY

WARRANTY FROM OR LIABILITY OF THE DEVELOPERS AND/OR

COPYRIGHT HOLDERS OF THE OPEN SOURCE COMPONENT

FOR THE PERFORMANCE OF THOSE OPEN SOURCE

COMPONENTS. YOU AGREE TO BE BOUND BY THE TERMS AND

CONDITIONS OF EACH SUCH LICENCE. FOR MORE

INFORMATION SEE:

http://support.taitworld.com/go/opensource

Title to Software

THIS AGREEMENT DOES NOT CONSTITUTE A CONTRACT OF

SALE IN RELATION TO THE SOFTWARE OR FIRMWARE SUPPLIED

TO THE LICENSEE. NOT WITHSTANDING THE LICENSEE MAY

OWN THE MAGNETIC OR OTHER PHYSICAL MEDIA ON WHICH

THE SOFTWARE OR FIRMWARE WAS ORIGINA LLY SUPPLIED, OR

HAS SUBSEQUENTLY BEEN RECORDED OR FIXED, IT IS A

FUNDAMENTAL TER M OF THIS AGREEMENT THAT AT ALL

TIMES TITLE AND OWN ERSH IP OF THE SOFTWARE OR

FIRMWARE, WHETHER ON THE OR IGINAL MEDIA OR

OTHERWISE, SHALL REMAIN VESTED IN TAIT OR THIRD

PARTIES WHO HAVE GRANTED LICENCES TO TAIT.

Ter m a n d Te r m i n a t io n

THIS LICENCE SHALL BE EFFECTIVE UNTIL TERMINATED IN

ACCORDANCE WITH THE PROVISIONS OF THIS AGREEMENT.

THE LICENSEE MAY TERMINATE THIS LICENCE AT ANY TIME BY

DESTROYING ALL COPIES OF THE SOFTWARE OR FIRMWARE

AND ASSOCIATED WRITTEN MATERIALS. THIS LICENCE WILL BE

TERMINATED AUTOMATICALLY AND WITHOUT NOTICE FROM

TAIT IN THE EVENT THAT THE LICENSEE FAILS TO COMPLY

WITH ANY TERM OR CONDITION OF THIS AGREEMENT. THE

LICENSEE AGREES TO DESTROY ALL COPIES OF THE SOFTWARE

OR FIRMWARE AND ASSOCIATED WRITTEN MATERIALS IN THE

EVENT OF SUCH TERMINATION.

Limited Warranty

THE SOFTWARE OR FIRMWARE (INCLUDING OPEN SOURCE

COMPONENTS) IS SUPPLIED BY TAIT AND ACCEPTED BY THE

LICENSEE “AS IS” WITHOUT WARRANTY OF ANY KIND EITHER

EXPRESSED OR IMPLIED, INCLUDING BUT NOT BEING LIMITED

TO ANY IMPLIED WAR RANTI ES AS TO MERCHANTABILITY OR

FITNESS FOR ANY PARTICULAR PURPOSE. THE LICENSEE

ACKNOWLEDGES THAT THE SOFTWARE OR FIRMWARE

(INCLUDING OPEN SOURCE COMPONENTS) IS USED BY IT IN

BUSINESS AND ACCORDINGLY TO THE MAXIMUM EXTENT

PERMITTED BY LAW NO TERMS OR WARRANTIES WHICH ARE

IMPLIED BY LEG ISLATION SHALL APPLY TO THIS AGREEMENT.

TAIT DOES NOT WARRANT THAT THE FUNCTIONS CONTAINED

IN THE SOFTWARE OR FIRMWARE (INCLUDING OPEN SOURCE

COMPONENTS) WILL MEET THE LICENSEE’S REQUIREMENTS OR

THAT THE OPERATION OF THE SOFTWARE OR FIRMWARE

(

INCLUDING OPEN SOURCE COMPONENTS) WILL BE

UNINTERRUPTED OR ERROR FREE.

Exclusion of Liability

IN NO CIRCUMSTANCES SHALL TAIT BE UNDER ANY LIABILITY

TO THE LICENSEE, OR ANY OTHER PERSON WHATSOEVER,

WHETHER IN TORT (INCLUDING NEGLIGENCE), CONTRACT

(EXCEPT AS EXPRESSLY PROVIDED IN THIS AGREEMENT),

EQUITY, UNDER ANY STATUTE, OR OTHERWISE AT LAW FOR

ANY LOSSES OR DAMAGES WHETHER GENERAL, SPECIAL,

EXEMPLARY, PUNITIVE, DIRECT, INDIRECT OR

CONSEQUENTIAL ARISING OUT OF OR IN CONNECTION WITH

ANY USE OR INABILITY OF USING THE SOFTWARE OR

FIRMWARE (INCLUDING OPEN SOURCE COMPONENTS).

THE LICENSEE’S SOLE REMED Y AGAINST TAIT WILL BE LIMITED

TO BREACH OF CONTRACT AND TAIT’S SOLE AND TOTAL

LIABILITY FOR ANY SUCH CLAIM SHALL BE LIMITED AT THE

OPTION OF TAIT TO THE REPAIR OR REPLACEMENT OF THE

SOFTWARE OR FIRMWARE OR THE REFUND OF THE PURCHASE

PRICE OF THE SOFTWARE OR FIRMWARE.

General

THE LICENSEE CONFIRMS THAT IT SHALL COMPLY WITH THE

PROVISIONS OF LAW IN RELATION TO THE SOFTWARE

OR FIRMWARE.

Law and Jurisdiction

THIS AGREEMENT SHALL BE SUBJECT TO AND CONSTRUED IN

ACCORDANCE WITH NEW ZEALAND LAW AND DISPUTES

BETWEEN THE PARTIES CONCERNING THE PROVISIONS

HEREOF SHALL BE DETERMINED BY THE NEW ZEALAND

COURTS OF LAW. PROVIDED HOWEVER TAIT MAY AT ITS

ELECTION BRING PROCEEDINGS FOR BREACH OF THE TER MS

HEREOF OR FOR THE ENFORCEMENT OF ANY JUDGEMENT IN

RELATION TO A BREACH OF THE TERMS HEREOF IN ANY

JURISDICTION TAIT CONSIDERS FIT FOR THE PUR POSE OF

ENSURING COMPLIANCE WITH THE TER MS HEREOF OR

OBTAINING RELI EF FOR BREACH OF THE TER MS HEREOF .

No Dealings

THE LICENSEE MAY NOT SUBLICENSE, ASSIGN OR TRANSFER

THE LICENCE OR THE PROGRAM EXCEPT AS EXPRESSLY

PROVIDED IN THIS AGREEMENT. ANY ATTEMPT OTHERWISE TO

SUBLICENSE, ASSIGN OR TRANSFER ANY OF THE RIGHTS,

DUTIES OR OBLIGATIONS HEREUNDER IS VOID.

No Other Terms

THE LICENSEE ACKNOWLEDGES THAT IT HAS READ THIS

AGREEMENT, UNDERSTANDS IT AND AGREES TO BE BOUND BY

ITS TERMS AND CONDITIONS. THE LICENSEE FURTHER AGREES

THAT SUBJECT ONLY TO ANY EXPRESS WRITTEN TERMS OF

AGREEMENT TO THE CONTRARY BETWEEN TAIT AND THE

LICENSEE THIS IS THE COMPLETE AND EXCLUSIVE STATEMENT

OF THE AGREEMENT BETWEEN IT AND TAIT IN RELATION TO

THE SOFTWARE OR FIRMWARE WHICH SUPERSEDES ANY

PROPOSAL OR PRIOR AGREEMENT, ORAL OR WRITTEN AND

ANY OTHER COMMUNICATIONS BETWEEN THE LICENSEE AND

TAIT RELATING TO THE SOFTWARE OR FIR MWARE.

Page 40

34 Tait General Software Licence Agreement © Tait Electronics Limited February 2007

Loading...

Loading...