Page 1

Tait Orca 5000 Portable Radios

Service Manual

June 2003

IPN: M5000-00-105

Page 2

Preface

Contacting Tait Electronics Ltd

The contact details for your nearest Tait Electronics regional office, can be found on the Tait

Website: http://www.taitworld.com/

Enquiries and comments

If you have any enquiries regarding this manual, or any comments, suggestions and notifications

of errors, please contact Customer Support, Tait Electronics Ltd, Christchurch, New Zealand, or

refer to the Tait Website.

Conventions

Throughout this manual, the following conventions are used:

■ Names of software screen, field and menu names are referred to in bold sans serif font. For

example:

Check that the information in the Radio Model fields (Specifications screen) is correct.

■ The xxxx-character is used as a wildcard in product codes and part numbers, to indicate unspec-

ified characters.

Disclaimer

There are no warranties extended or granted by this manual. Tait Electronics Ltd accepts no

responsibility for damage arising from use of the information contained in the manual or of the

equipment and software it describes. It is the responsibility of the user to ensure that use of such

information, equipment and software complies with the laws, rules and regulations of the applicable jurisdictions.

Updating equipment and manuals

In the interests of improving performance, reliability or servicing, Tait Electronics Ltd reserve the

right to update their equipment and/or manuals without prior notice.

Copyright

All information contained in this manual is the property of Tait Electronics Ltd. All rights are

reserved. This manual may not, in whole or in part, be copied, photocopied, reproduced, translated, stored, or reduced to any electronic medium or machine-readable form, without prior written

permission from Tait Electronics Limited. All trade names referenced are the service mark, trademark or registered trademark of the respective manufacturers.

ii June 2003 IPN: M5000-00-105

Page 3

Publication history

Publication Date Product Code

May 2001 M5000-00-100

June 2001 M5000-00-101

September 2001 M5000-00-102

May 2002 M5000-00-103

September 2002 M5000-00-104

June 2003 M5000-00-105

June 2003 IPN: M5000-00-105 iii

Page 4

iv June 2003 IPN: M5000-00-105

Page 5

Contents

Part A: Introduction

Servicing Tait Orca 5000 portable radios

Servicing Tait Orca 5000 portable radios .................................................................................

Servicing Tait Orca 5000 portable radios Servicing Tait Orca 5000 portable radios

WWW technical support ..................................................................................................................... A-3

What does this manual contain? .......................................................................................................... A-3

Calibration service kit .......................................................................................................................... A-3

Programming kit .................................................................................................................................. A-4

The Tait Orca 5000 series of portable radios

The Tait Orca 5000 series of portable radios ............................................................................

The Tait Orca 5000 series of portable radios The Tait Orca 5000 series of portable radios

The Tait Orca product code ................................................................................................................. A-5

Operating instructions ......................................................................................................................... A-5

Accessories ........................................................................................................................................... A-5

Important information

Important information .............................................................................................................

Important information Important information

Basic servicing precautions .................................................................................................................. A-9

Programming ....................................................................................................................................... A-9

............................................................................................................. A-9

..........................................................................................................................................................................................................................

................................................................................. A-3

..................................................................................................................................................................

............................................................................ A-5

........................................................................................................................................................

A-3

A-3A-3

A-5

A-5A-5

A-9

A-9A-9

Calibrating ......................................................................................................................................... A-10

Test facilities ...................................................................................................................................... A-10

Basic maintenance ............................................................................................................................. A-10

Servicing Intrinsically Safe radios

Servicing Intrinsically Safe radios ...........................................................................................

Servicing Intrinsically Safe radios Servicing Intrinsically Safe radios

Intrinsically Safe radios ...................................................................................................................... A-11

IS PCB servicing requirements ........................................................................................................... A-11

FM approval ....................................................................................................................................... A-11

FM approved products ....................................................................................................................... A-11

FM approved accessories ................................................................................................................... A-11

........................................................................................... A-11

......................................................................................................................................................................................

Part B: Radio specifications and circuit descriptions

Radio specifications

Radio specifications ..................................................................................................................

Radio specifications Radio specifications

General specifications ........................................................................................................................... B-3

Receiver performance ........................................................................................................................... B-3

Transmitter performance ..................................................................................................................... B-4

TOP-Axxxx 66-88MHz radio specifications.......................................................................................... B-5

.................................................................................................................. B-3

....................................................................................................................................................................................................................................

A-11

A-11A-11

B-3

B-3B-3

TOP-Bxxxx 136-174MHz radio specifications ...................................................................................... B-6

TOP-Cxxxx 174-225MHz radio specifications ...................................................................................... B-7

TOP-Gxxxx 336-400MHz radio specifications...................................................................................... B-8

TOP-Hxxxx 400-470MHz radio specifications...................................................................................... B-9

TOP-Ixxxx 450-530MHz radio specifications ..................................................................................... B-10

June 2003 IPN: M5000-00-105 v

Page 6

TOP-Jxxxx 806-870MHz radio specifications...................................................................................... B-11

TOP-Kxxxx 896-941MHz radio specifications .................................................................................... B-12

Circuit descriptions

Circuit descriptions .................................................................................................................

Circuit descriptions Circuit descriptions

Transmitter ........................................................................................................................................ B-13

Transmit (Tx) audio ........................................................................................................................... B-13

Receiver .............................................................................................................................................. B-13

Receive (Rx) audio .............................................................................................................................. B-13

DSP .................................................................................................................................................... B-14

Synthesiser and VCO .......................................................................................................................... B-14

Power supplies ................................................................................................................................... B-14

Accessory connector interface ............................................................................................................ B-15

Universal band versus wideband IF filtering ...................................................................................... B-15

................................................................................................................. B-13

..................................................................................................................................................................................................................................

Part C: Diagnostics and fault finding

Test facilities

Test facilities .............................................................................................................................

Test facilities Test facilities

Error codes ........................................................................................................................................... C-3

............................................................................................................................. C-3

..........................................................................................................................................................................................................................................................

B-13

B-13B-13

C-3

C-3C-3

Test commands ..................................................................................................................................... C-5

Calculating the parameters required for test command 101 ................................................................. C-7

Fault finding charts

Fault finding charts ...................................................................................................................

Fault finding charts Fault finding charts

Radio cannot be switched on ................................................................................................................ C-9

Cannot change channel ...................................................................................................................... C-10

No serial communication ................................................................................................................... C-11

Receive faults ...................................................................................................................................... C-12

Cannot transmit ................................................................................................................................. C-13

No transmit audio .............................................................................................................................. C-14

...................................................................................................................C-8

......................................................................................................................................................................................................................................

Part D: Servicing the radio

Servicing the radio

Servicing the radio ...................................................................................................................

Servicing the radio Servicing the radio

Screw head types .................................................................................................................................. D-3

Disassembling the radio

Disassembling the radio ..........................................................................................................

Disassembling the radio Disassembling the radio

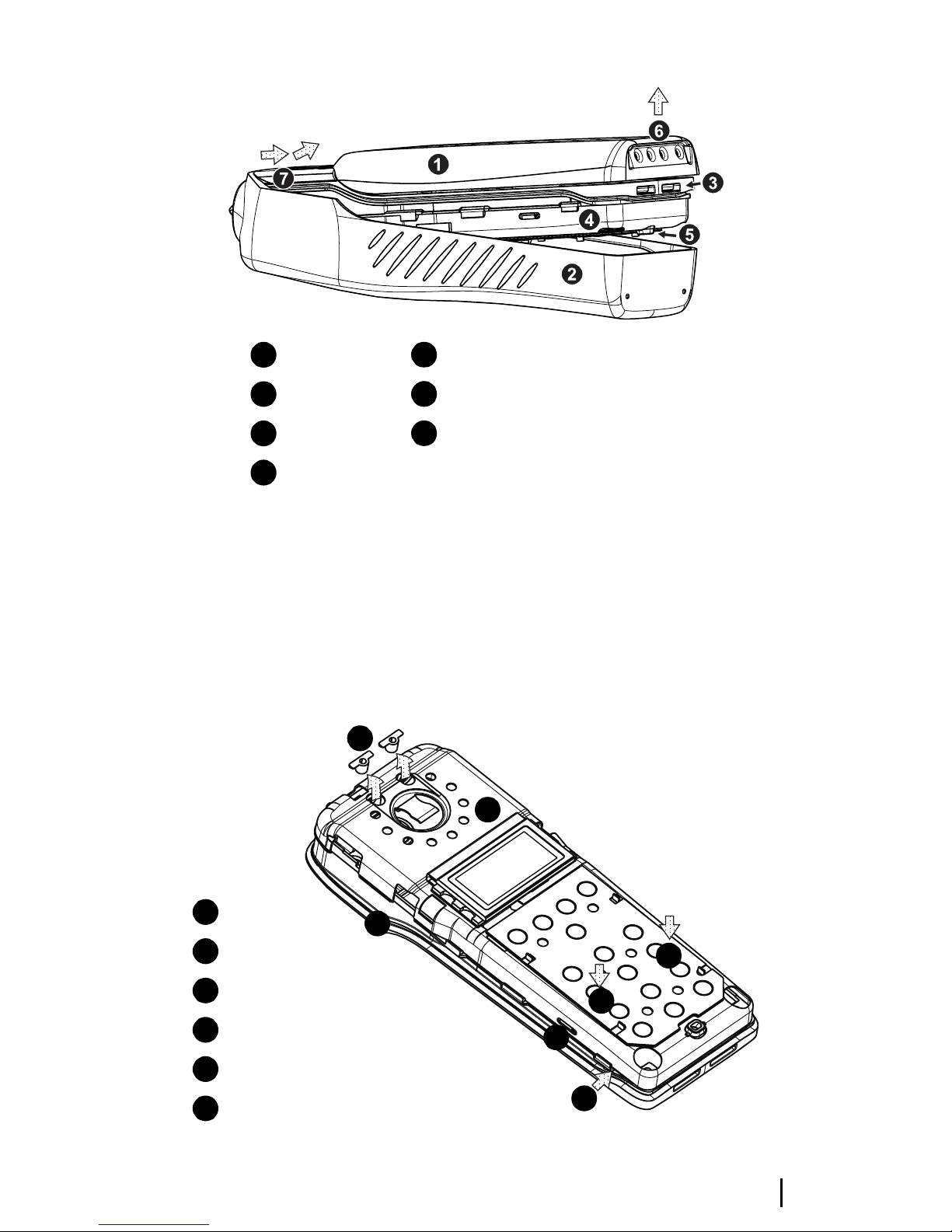

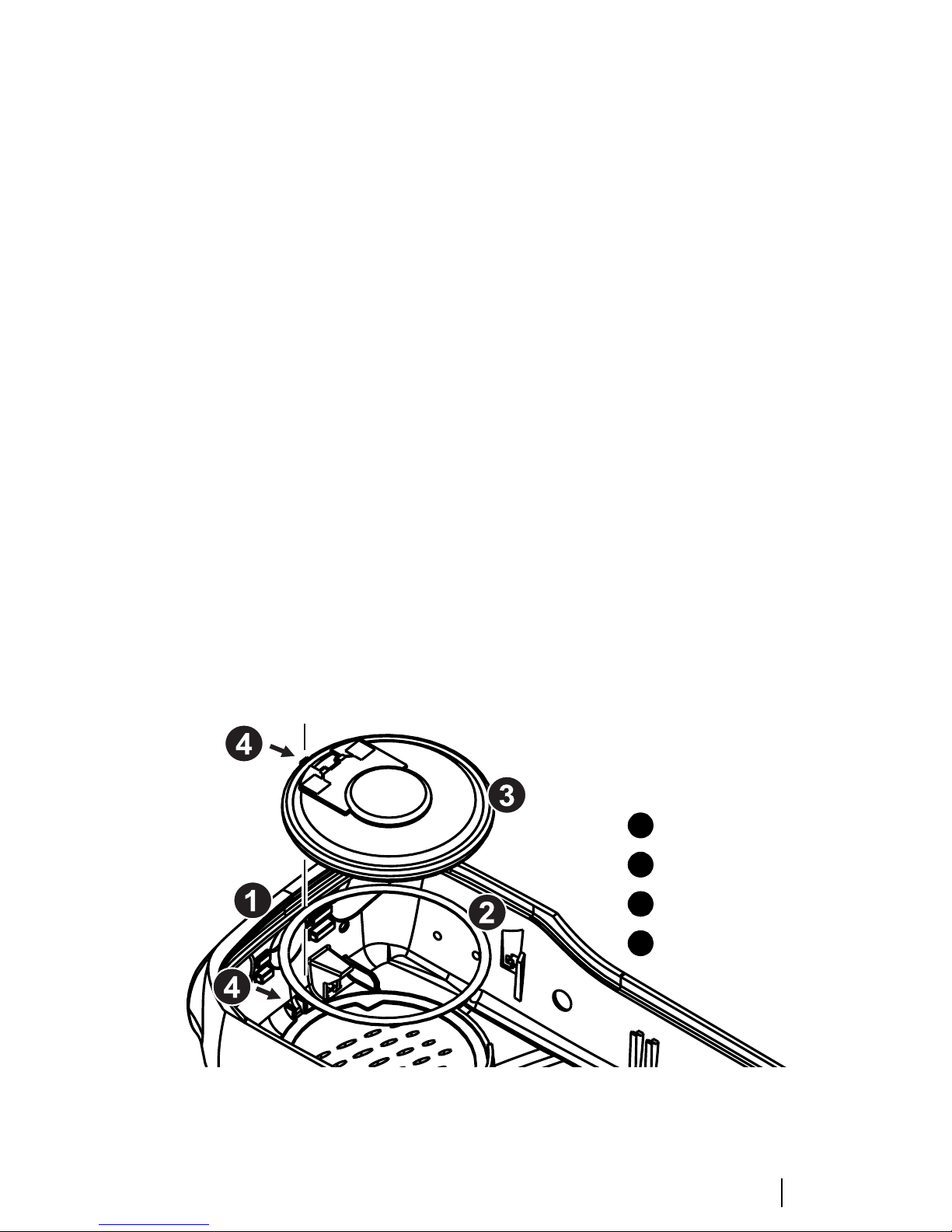

Removing the front panel from the chassis ..........................................................................................D-4

Removing the shield sub-assembly from the chassis ............................................................................ D-5

................................................................................................................... D-3

......................................................................................................................................................................................................................................

.......................................................................................................... D-4

....................................................................................................................................................................................................................

C-8

C-8C-8

D-3

D-3D-3

D-4

D-4D-4

Removing the PCB from the chassis .....................................................................................................D-6

Removing the rear panel ......................................................................................................................D-7

Replacing key mechanical and ancillary devices

Replacing key mechanical and ancillary devices ......................................................................

Replacing key mechanical and ancillary devices Replacing key mechanical and ancillary devices

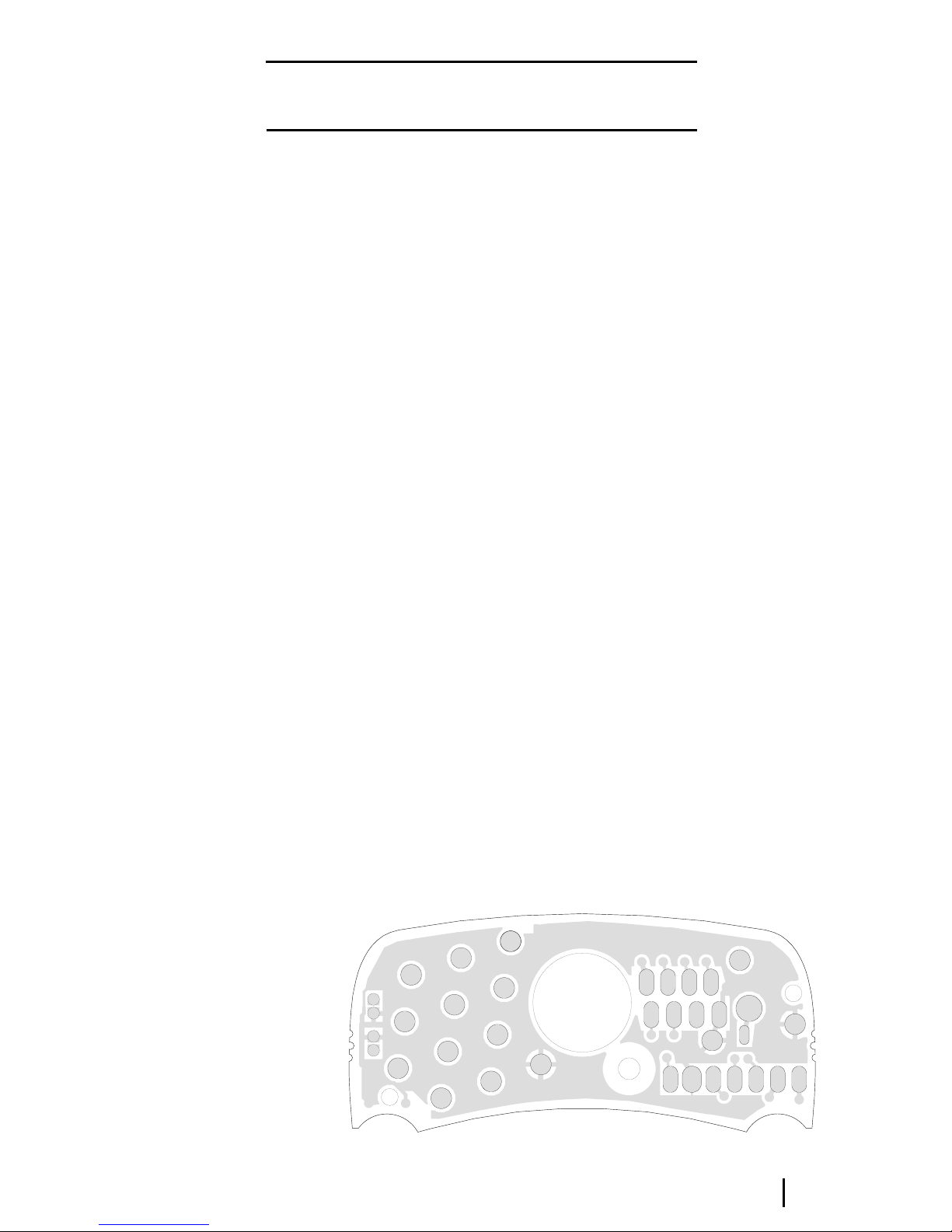

Replacing the lens (Orca 5015/2x/35/40) ...........................................................................................D-8

Replacing the PTT keypad ....................................................................................................................D-8

Replacing the speaker ........................................................................................................................... D-9

vi June 2003 IPN: M5000-00-105

...................................................................... D-8

............................................................................................................................................

D-8

D-8D-8

Page 7

Replacing the LCD display (Orca 5015/2x/35/40) .............................................................................. D-9

Replacing the shield, user interface PCB and polyester dome (Orca 5015/2x/35/40) ....................... D-12

Replacing the antenna connector, channel selector switch and volume control switch ..................... D-12

Replacing the microphone .................................................................................................................D-12

Replacing the battery and speaker contacts .......................................................................................D-12

Replacing the tact switch ....................................................................................................................D-12

Replacing the chassis .......................................................................................................................... D-13

Reassembling the radio

Reassembling the radio ..........................................................................................................

Reassembling the radio Reassembling the radio

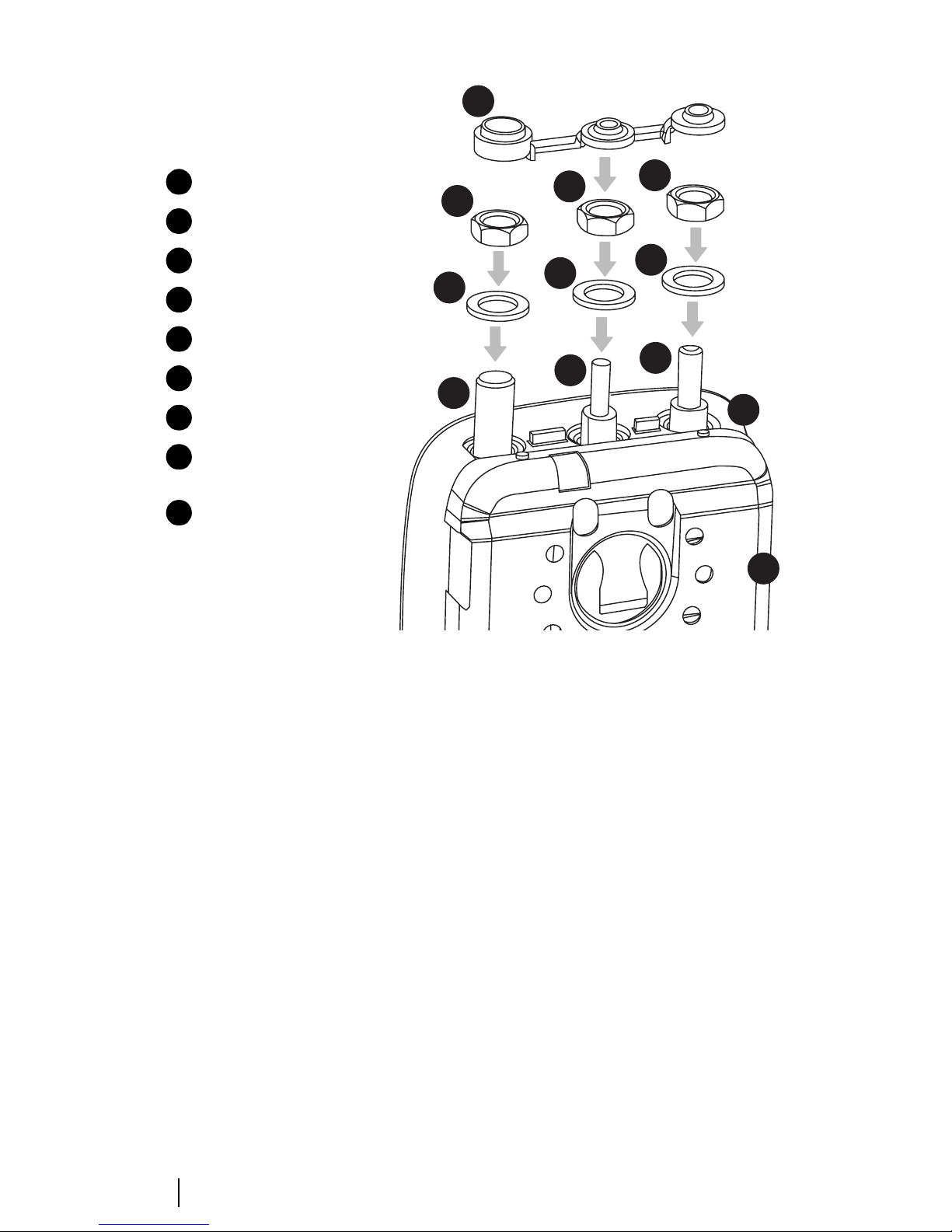

Rear panel reassembly and replacing the auxiliary flexible PCB ........................................................ D-14

Fitting the PCB to the chassis and replacing the RF out assembly ...................................................... D-15

Fitting the shield to the chassis .......................................................................................................... D-15

Fitting the front panel to the chassis .................................................................................................. D-16

Spares kits

Spares kits ..............................................................................................................................

Spares kits Spares kits

Information contained in the tables ................................................................................................... D-17

PCB Product Codes ............................................................................................................................ D-17

Orca 5010/11/30 spares kit (TOPA-SP-401G) .................................................................................. D-18

.............................................................................................................................. D-17

............................................................................................................................................................................................................................................................

.......................................................................................................... D-14

....................................................................................................................................................................................................................

D-14

D-14D-14

D-17

D-17D-17

Orca 5035 spares kit (TOPA-SP-402G) .............................................................................................. D-19

Orca 5015/2x/40 spares kit (TOPA-SP-403G)................................................................................... D-20

Orca 5010/11/30 re-skinning kit (TOPA-SP-404) ............................................................................. D-21

Orca 5035 Re-skinning kit (TOPA-SP-405)........................................................................................ D-21

Orca 5020/40 Re-skinning kit (TOPA-SP-406).................................................................................. D-21

Orca 5015/2x/35/40 User Interface PCB and Shield (TOPA-SP-407) ............................................... D-22

Orca 5015/21 Re-skinning kit (TOPA-SP-408).................................................................................. D-22

Part E: Battery packs and chargers

Battery packs

Battery packs .............................................................................................................................

Battery packs Battery packs

Battery shift life ..................................................................................................................................... E-3

Disposing of used nickel-cadmium batteries .........................................................................................E-4

Battery chargers

Battery chargers ........................................................................................................................

Battery chargers Battery chargers

Desktop fast charger

Desktop fast charger ..................................................................................................................

Desktop fast charger Desktop fast charger

Fast charger operation .......................................................................................................................... E-6

Using the fast charger ............................................................................................................................E-9

.............................................................................................................................E-3

..........................................................................................................................................................................................................................................................

........................................................................................................................E-5

................................................................................................................................................................................................................................................

..................................................................................................................E-6

....................................................................................................................................................................................................................................

E-3

E-3E-3

E-5

E-5E-5

E-6

E-6E-6

Repairing the fast charger ...................................................................................................................E-10

Desktop trickle charger

Desktop trickle charger ...........................................................................................................

Desktop trickle charger Desktop trickle charger

Trickle charger operation .................................................................................................................... E-12

Using the trickle charger .....................................................................................................................E-13

Repairing the trickle charger ...............................................................................................................E-13

June 2003 IPN: M5000-00-105 vii

...........................................................................................................E-12

......................................................................................................................................................................................................................

E-12

E-12E-12

Page 8

Troubleshooting ..................................................................................................................................E-14

Multi-charger

Multi-charger ..........................................................................................................................

Multi-charger Multi-charger

Multi-charger operation ......................................................................................................................E-15

Repairing the multi-charger ................................................................................................................E-15

Fuse replacement ................................................................................................................................E-16

.......................................................................................................................... E-15

....................................................................................................................................................................................................................................................

Part F: Accessories

Tait Orca 5000 accessory connector

Tait Orca 5000 accessory connector .........................................................................................

Tait Orca 5000 accessory connector Tait Orca 5000 accessory connector

Screw head types ...................................................................................................................................F-3

Connecting an accessory .......................................................................................................................F-3

Connecting a headset ............................................................................................................................F-5

Accessory connector signal descriptions ...............................................................................................F-6

7.5 mm Accessory adaptor

7.5 mm Accessory adaptor ........................................................................................................

7.5 mm Accessory adaptor 7.5 mm Accessory adaptor

Tait Orca vehicle kit

Tait Orca vehicle kit ................................................................................................................

Tait Orca vehicle kit Tait Orca vehicle kit

Product codes ......................................................................................................................................F-10

Update to the vehicle kit ......................................................................................................................F-10

........................................................................................................ F-8

................................................................................................................................................................................................................

................................................................................................................ F-10

................................................................................................................................................................................................................................

......................................................................................... F-3

..................................................................................................................................................................................

E-15

E-15E-15

F-3

F-3F-3

F-8

F-8F-8

F-10

F-10F-10

Installing a vehicle kit ..........................................................................................................................F-10

Vehicle kit operation ...........................................................................................................................F-10

Vehicle kit specifications .....................................................................................................................F-12

Servicing the vehicle kit ....................................................................................................................... F-13

Spares kits ...........................................................................................................................................F-14

Vehicle kit spares kit (TOPA-SP-301).................................................................................................. F-15

Vehicle kit reskinning kit (TOPA-SP-302)........................................................................................... F-16

Custom modifications ......................................................................................................................... F-17

Vehicle kit circuit descriptions ............................................................................................................F-19

Part G: Additional information

Glossary

Glossary ................................................................................................................................

Glossary Glossary

Accessory connector compatibility

Accessory connector compatibility ..........................................................................................

Accessory connector compatibility Accessory connector compatibility

...................................................................................................................................

................................................................................................................................................................................................................................................................

.......................................................................................... G-8

....................................................................................................................................................................................

... G-3

......

G-3

G-3G-3

G-8

G-8G-8

viii June 2003 IPN: M5000-00-105

Page 9

A

PART

Introduction

This part provides an introduction to servicing Tait Orca 5000

portable radios. It includes an outline of the Tait Orca 5000 range

of products and precautions that should be taken before servicing

Tait Orca 5000 portable radios.

Detailed servicing instructions and information about spare parts

are found in Part D: Servicing the radio.

Contents

Servicing Tait Orca 5000 portable radios

Servicing Tait Orca 5000 portable radios ......................................................

Servicing Tait Orca 5000 portable radios Servicing Tait Orca 5000 portable radios

WWW technical support ...................................................................................... A-3

What does this manual contain? ........................................................................... A-3

...................................................... A-3

............................................................................................................

A-3

A-3A-3

Calibration service kit ........................................................................................... A-3

Programming kit ................................................................................................... A-4

Conventions .......................................................................................................... A-4

The Tait Orca 5000 series of portable radios

The Tait Orca 5000 series of portable radios .................................................

The Tait Orca 5000 series of portable radios The Tait Orca 5000 series of portable radios

The Tait Orca product code ................................................................................... A-5

Operating instructions .......................................................................................... A-5

Accessories ............................................................................................................ A-5

Important information

Important information .................................................................................

Important information Important information

Basic servicing precautions ................................................................................... A-9

Programming ........................................................................................................ A-9

Calibrating .......................................................................................................... A-10

Test facilities ....................................................................................................... A-10

Basic maintenance ............................................................................................... A-10

Servicing Intrinsically Safe radios

Servicing Intrinsically Safe radios ...............................................................

Servicing Intrinsically Safe radios Servicing Intrinsically Safe radios

Intrinsically Safe radios ....................................................................................... A-11

................................................................................. A-9

..................................................................................................................................................................

............................................................... A-11

..............................................................................................................................

................................................. A-5

..................................................................................................

A-5

A-5A-5

A-9

A-9A-9

A-11

A-11A-11

Page 10

IS PCB servicing requirements ............................................................................ A-11

FM approval ........................................................................................................ A-11

FM approved products ........................................................................................ A-11

FM approved accessories ..................................................................................... A-11

A - 2 June 2003 IPN: M5000-00-105

Page 11

Servicing Tait Orca 5000 portable radios

The Tait Orca 5000 series is a range of portable

high performance, microprocessor-controlled

radios manufactured using an RF-shielded PCB

and high-density SMD components.

Servicing of Tait Orca 5000 portable radios is

limited to key mechanical and ancillary devices. These include:

■ the front panel assembly;

■ the lens (Orca 5015/2x/35/40);

■ the PTT keypad;

■ the speaker;

■ the keypad;

■ the LCD display (Orca 5015/2x/35/40);

■ the shield, complete with user interface

PCB assembly and polyester dome (Orca

5015/2x/35/40);

■ the main PCB assembly;

■ the antenna connector;

■ the channel selector switch;

■ the volume control switch;

WWW technical support

Tait Electronics Ltd provides product support

at the following address:

http://www.taitworld.com/support

What does this manual contain?

This manual is supplied as part of the Tait Orca

5000 service kit (TOPA-SV-117G), and

provides the following:

■ general information and specifications on

the Tait Orca 5000 series of portable

radios;

■ basic circuit descriptions;

■ information on finding and servicing non-

PCB-related faults;

■ information on Tait Orca 5000 battery

packs and chargers;

■ information on interfacing accessories to

Tait Orca 5000 portable radios; and

■ a glossary of key terms.

■ the microphone;

■ the speaker contacts;

■ the battery contacts;

■ the PTT tact switch;

■ the RF out assembly

■ the auxiliary flexible PCB

■ the rear panel; and

■ the chassis.

The repair of PCB-related faults is the responsibility of Technical Support at Tait Electronics

Ltd. Detailed schematics and component

location information for the main PCB may

also be obtained from Technical Support.

Contact your Tait dealer for more information.

Calibration service kit

The TOPA-SV-117G service kit contains:

■ calibration test unit (TOPA-SV-004);

■ radio calibration cable for connecting the

radio to the calibration test unit (TOPASV-007G);

■ 9 pin RS232 to modular phone jack

programming lead for connecting the

calibration test unit to a PC (TOPA-SV-

019);

■ DC service adaptor (TOPA-SV-005);

■ SMA to N-type RF test lead for connecting

to the radio’s antenna connector (TOPASV-006);

June 2003 IPN: M5000-00-105 Servicing Tait Orca 5000 portable radios A - 3

Page 12

■ T6 driver bit and 8 mm socket (TOPA-SV-

011);

■ this manual; and

■ TOP Programming Utilities (TPU) CD-

ROM (IPN 406-00003-xx).

Other items required for calibration but not

included as part of the service kit are:

■ RF communications test set (e.g. HP8920,

MI2945/55, CMS52);

■ digital current meter capable of measur-

ing current up to 3 A, accurate to two

decimal places.;

■ DC power supply, 7.5 V, 3 A for portable

radios; and

■ TOPA-SV-A07 if calibrating TOP-Axxxx-

xx 66 -88MHz product.

Programming kit

The TOPA-SV-116 kit for programming Tait

Orca 5000 radios contains:

■ accessory connector to modular phone

socket programming cable for connecting

the radio to the programming lead

(TOPA-SV-003G); and

■ 9 pin RS232 to modular phone jack

programming lead for connecting the

programming cable to a PC (TOPA-SV-

019); and

■ TOP Programming Utilities (TPU) CD-

ROM (IPN 406-00003-xx).

A - 4 Servicing Tait Orca 5000 portable radios June 2003 IPN: M5000-00-105

Page 13

The Tait Orca 5000 series of portable radios

There are eight Tait Orca 5000 series portable

radio products:

■ Orca 5010/11 - low tier conventional

■ Orca 5015 - mid tier conventional

■ Orca 5020/21 - high tier conventional

■ Orca 5030 - low tier trunked

■ Orca 5035 - mid tier trunked

■ Orca 5040 - high tier trunked

This manual includes information specific to

all the Orca 5000 portable radios. As new

features and enhancements occur, new

revisions of this manual will be released.

The Tait Orca product code

The characters in the Tait Orca 5000 product

code provide information about the radio’s

functional parameters and various hardware

options, according to the scheme outlined in

Figure A-1. For more information on available

products, contact your nearest Tait dealer.

technical support Website:

http://www.taitworld.com/support

2. In this manual, when the term TOP x is

used (e.g. TOP A or TOP B), it indicates the

specific frequency band. TOP A will therefore refer to an A band Orca, and TOP B to

a B band Orca.

Operating instructions

A user’s guide is available for each radio.

Copies can be obtained through Technical

Support.

Accessories

Table A-1 shows the accessories available for

Tait Orca 5000 portable radios. Of these accessories, only the chargers are serviceable.

For more information on chargers, see Part E:

Battery packs and chargers. The battery packs

available for Tait Orca 5000 portable radios

are also described in Part E.

Figure A-1: Tait Orca 5000 Product Code Scheme

The Tait Orca Product Code has the following

structure:

TOP-abcde-mn

where:

TOP - Family designator

a - Frequency band

b - Channel spacing/IFBW

c - User interface

d - Air interface

e - Compliance-relevant changes

m - Badging

n - Custom variations not affecting

radio/EMC compliance

Notes:

1. The complete Tait Orca product code

standard can be downloaded from the

New chassis

A new chassis and accessory connector have

been introduced in September 2002. This

provides greater strength to the accessory

connector. Old accessories are however no

longer compatible with the new chassis, nor

will the new accessories fit the old chassis. See

“Accessory connector compatibility” on

page G-8. Information specific to the old

chassis or accessories can be found in version

M5000-00-103 of the Tait Orca 5000 service

manual.

The new accessory connectors have a different

shape quarter turn tip, no hooks on the locating posts and a green dot on the outside at the

lower left corner

The new chassis has a different shape hole for

the connector’s quarter turn tip, and a green

June 2003 IPN: M5000-00-105 The Tait Orca 5000 series of portable radios A - 5

Page 14

seal behind. Figure A-2 illustrates the difference. Radios factory fitted with the new chassis

also have a product code with the format

TOP-xxxxx-Bx.

need to remove the rear accessory cover.

Remove the battery, then insert the end of a

key underneath the bottom edge of the accessory cover. Lift to remove the cover.

Figure A-2: Changed chassis hole

Fitting an accessory

To fit some accessories to the radio, you will

When attaching or removing an accessory,

ensure that the lever is in the upright position.

Keeping the accessory connector parallel to the

radio, engage the two posts at the base of the

connector with the rear panel. Once the accessory is in position, rotate the lever 90 degrees

counterclockwise to lock it in place. See Figure

A-3.

Removing an accessory

When removing an accessory, press the lock

spring tab before rotating the clip clockwise.

See Figure A-4.

Fitting a non-Tait accessory

See Part F: Accessories for information on using

non-Tait accessories with Tait Orca 5000

portable radios.

Figure A-3: Fitting an accessory with a D-Clip

Figure A-4: Removing an accessory with a D-Clip

A - 6 The Tait Orca 5000 series of portable radios June 2003 IPN: M5000-00-105

Page 15

Table A-1: Tait Orca 5000 accessories

Type of accessory Product code Description

Antennas TOPA-AN-101 130-230 MHz 3" helical

TOPA-AN-102 336-540 MHz 3" helical

TOPA-AN-201 136-340 MHz 6" helical

TOPA-AN-212 400-940 MHz 6" wave whip

TOPA-AN-203 896-941MHz 7" gain

TOPA-AN-204 806-870M 1/2 wave gain

TOPA-AN-205 896-941M 1/2 wave gain

TOPA-AN-301 66-88MHz 10" helical

Audio accessories

TOPA-AA-001G Speaker microphone, -10 to 60°C, two function buttons

TOPA-AA -002G Speaker microphone, -30 to 60 °C, heavy duty, two function buttons

TOPA-AA -003G Speaker microphone, -30 to 60 °C, MIL spec

TOPA-AA-004G Speaker microphone, -30 to 60 °C, MIL spec, with antenna socket

TOPA-AA-005G 7.5 mm accessory adaptor

TOPA-AA-006G Tait Orca accessory connector kit

TOPA-AA-007G Tait Orca RF accessory connector kit

TOPA-AA -008 Speaker microphone, -30 to 60 °C, MIL spec, no function buttons, high/low vol-

ume*

TOPA-AA-009 2-wire palm microphone and earphone, -30 to 75°C*

TOPA-AA-010 3-wire lapel microphone and earphone, -30 to 75°C*

TOPA-AA-011 Light weight single speaker headset with in-line PTT, -30 to 75°C*

TOPA-AA-012 Over-the-head headset with noise cancelling boom microphone, -30 to 75°C*

TOPA-AA-013 Behind-the-head headset with noise cancelling boom microphone, -30 to 75°C*

TOPA-AA-101G Speaker microphone, -10 to 60 °C, two function buttons (with D-Clip)

TOPA-AA-102G Speaker microphone, -10 to 60 °C, heavy duty, two function buttons (with D-Clip)

TOPA-AA-103G Speaker microphone, -10 to 60 °C, MIL spec (with D-Clip)

TOPA-AA-104G Speaker microphone, -30 to 60°C, MIL spec, with antenna socket (with D-Clip)

TOPA-AA-106G Tait Orca 5000 accessory connector kit (with D-Clip)

TOPA-AA-107G Tait Orca 5000 RF accessory connector kit (with D-Clip)

* For use with

T952-051 Earphone kit with coil cord and 2.5 mm plug, -30 to 75 °C (for use with TOPA-

TOPA-AA-005G

Batteries TOPB100 1100 mAh NiCd battery pack

TOPB200 1500 mAh NiCd battery pack

TOPB200-IF 1500 mAh NiCd battery pack (intrinsically safe)

TOPB400 1500 mAh NiMH battery pack

TOPB500 2000 mAh NiMH battery pack

TOPB600 1100 mAh NiCd battery pack (slim)

TOPB700 1500 mAh NiMH battery pack (slim)

June 2003 IPN: M5000-00-105 The Tait Orca 5000 series of portable radios A - 7

AA-003G, TOPA-AA-004G, TOPA-AA-008, TOPA-AA-103G & TOPA-AA-104G)

Page 16

Type of accessory Product code Description

Battery chargers TOPA-CH-100 Desktop trickle charger

TOPA-CH-200 Desktop fast charger

TOPA-CH-300 Six-way multi-charger

Plug packs

(for TOPA-CH-200)

Carrying accessories TOPA-CA-001 Heavy duty carry case

T952-012 Australia, New Zealand and China (230 V 50 Hz input; plug configuration: )

T952-022 Singapore and Middle East (230 V 50 Hz input; plug configuration: )

T952-032 Mainland Europe (230 V 50 Hz input; plug configuration: )

T952-042 USA and Canada (115 V 60 Hz input; plug configuration: )

T952-052 UK and Hong Kong (230 V 50 Hz input; plug configuration: )

TOPA-CA-002 Heavy duty holster

TOPA-CA-003 38 mm belt clip x 10

TOPA-CA-004 Accessory port cover x 10

TOPA-CA-005 55 mm belt clip

TOPA-CA-006 55 mm belt clip x 10

TOPA-CA-101 Heavy duty carry case (with D-Clip)

TOPA-CA-102 Holster carry case (with D-Clip)

TOPA-CA-103 Belt loop

TOPA-CA-104G D-Clip

TOPA-CA-105 Handstrap

Warning!

The following accessories have the old accessory connector and are still available for

Tait Orca series portable radios. Do not

attempt to fit to the

attempt to fit to the new chassis

attempt to fit to the attempt to fit to the

new chassis.

new chassisnew chassis

purchase. These accessories only fit the older

Table A-2: Tait Orca 5000 portable radio accessories with the old connector

Type of accessory Product code Description

Audio accessories TOPA-AA-001 Speaker microphone, -10 to 60 °C, two function buttons

TOPA-AA -002 Speaker microphone, -30 to 60°C, heavy duty, two function buttons

TOPA-AA-003 Speaker microphone, -30 to 60°C, MIL spec

TOPA-AA-004 Speaker microphone, -30 to 60°C, MIL spec, with antenna socket

TOPA-AA-005 7.5 mm accessory adaptor

TOPA-AA-006 Tait Orca accessory connector kit

TOPA-AA-007 Tait Orca RF accessory connector kit

Do not

Do not Do not

A - 8 The Tait Orca 5000 series of portable radios June 2003 IPN: M5000-00-105

Page 17

Important information

Basic servicing precautions

Tait Orca 5000 portable radios require specialised servicing techniques and should only be

serviced at an approved Tait service centre

equipped with the necessary facilities.

Figure A-5: Typical anti-static bench setup

1

2

Warning!

Repairs attempted with incorrect equipment

or by untrained personnel may result in

permanent damage.

Standard anti-static procedures should be

followed; a typical setup is shown in Figure A-5.

If in doubt, contact Tait Electronics Ltd or your

nearest Tait dealer.

3

4

to building earth (not

1

mains earth) via 1 M

series resistor

conductive wrist strap

2

conductive rubber

3

bench mat

metal frame

4

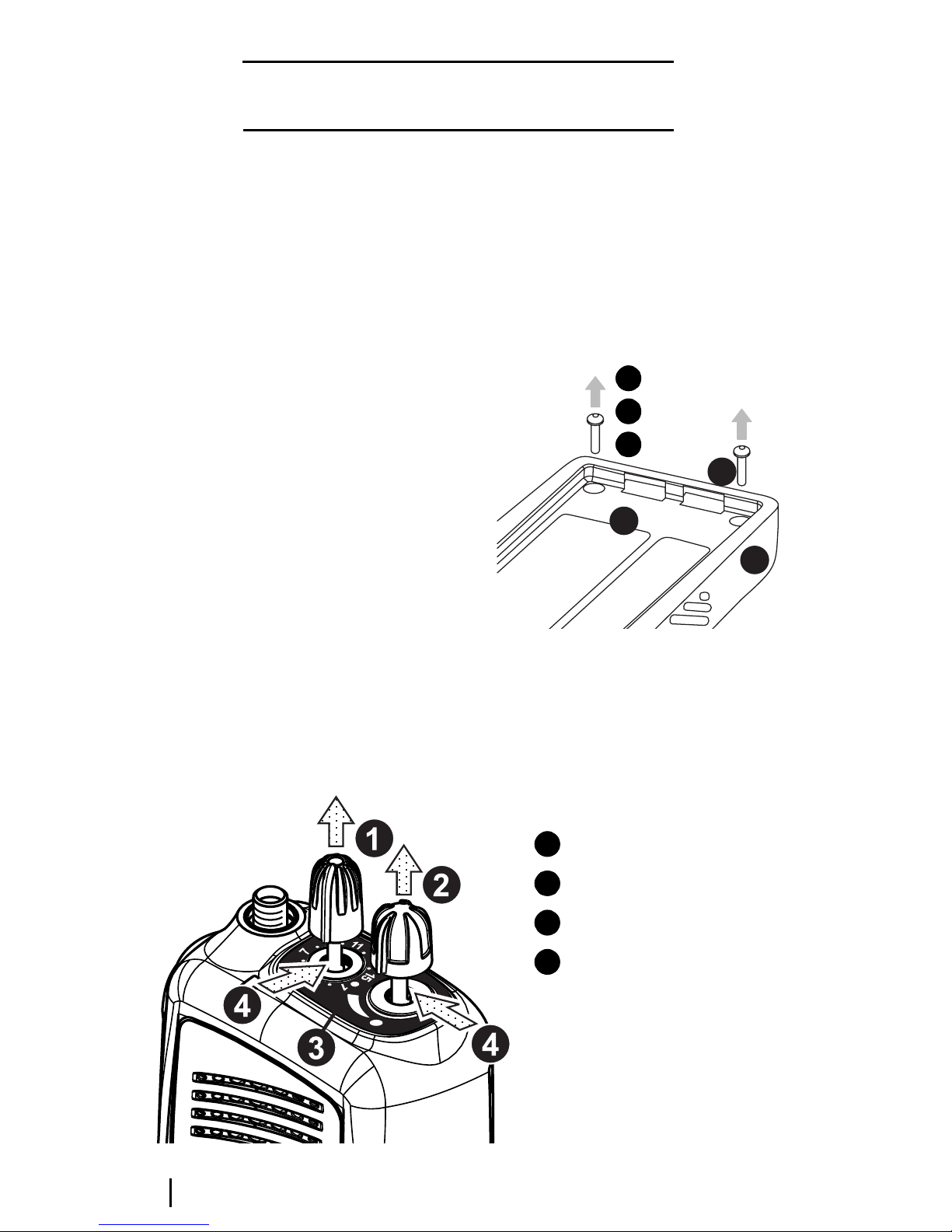

Torx head 1.8x5 mm screws should be

removed using the supplied Torx T6 driver.

When replacing these screws, set the driver to

2in.lb (0.23Nm).

Caution: CMOS devices

This equipment contains CMOS devices,

which are susceptible to damage from static

charges. Care when handling these devices is

essential. For correct handling procedures,

refer to manufacturers’ data books covering

CMOS devices, such as Philips Data Handbook

Covering CMOS Devices or Motorola CMOS

Data Book Section 5 (Handling Procedures).

Screw head types

Torx recess head screws and Pozidriv recess

head screws require the correct sized driver to

achieve best performance. Most of the screws

in Tait Orca 5000 portable radios are Torx

head screws, and so a Torx T6 driver bit is

supplied as part of the service kit. Some earlier

radios have Pozidriv screws.

Pan head Pozidriv M2x8 mm and M2x5 mm

screws should be removed using a number 1

Pozidriver. When replacing these screws, set

the driver to 2in.lb (0.23Nm).

Programming

For information on programming Tait Orca

5000 portable radios, refer to:

■ the Tait Orca Trunked Programming Appli-

cation User’s Manual or the online help;

■ the Tait Orca Conventional Programming

Application User’s Manual or the online

help.

The User’s Manuals are on the TOP Programming Utilities (TPU) CD-ROM, which is

included, together with this manual, as part of

the calibration service kit.

June 2003 IPN: M5000-00-105 Important information A - 9

Page 18

Calibrating

For information on calibrating Tait Orca 5000

portable radios, refer to:

■ the Tait Orca Calibration Application User’s

Manual or the online help.

The User’s Manual is on the TOP Programming Utilities (TPU) CD-ROM, which is

included, together with this manual, as part of

the calibration service kit.

Test facilities

Standard test facilities provide a way of testing

the radio’s functions independently of normal

radio operation. See Part C: Diagnostics and

fault finding for a description of the test facilities available for Tait Orca 5000 portable

radios.

Troubleshooting

If you are experiencing difficulty operating

your Tait Orca portable radio check the following items:

■ Is the battery firmly attached to the radio?

■ Is the battery sufficiently charged?

■ Is the battery charger working properly?

■ Is the antenna damaged?

If all appears to be in order but your radio still

fails to operate properly, consult your local

Tait dealer for assistance.

Basic maintenance

Your Tait Orca portable radio requires no

regular maintenance other than ensuring that

the battery has sufficient charge and that no

damage has occurred to the antenna or the

battery pack.

General care

■ Wipe the battery contacts, accessory

connector contacts and radio display with

a dry lint-free cloth to remove any dirt, oil

or grease.

■ Use a cloth dampened with clean water to

clean the radio’s case and display lens, but

do not immerse the radio in fluids.

■ Do not allow the radio to come into

contact with detergents, alcohol, aerosol

sprays or petroleum-based products as

they may permanently damage the case.

■ Avoid high temperatures. If the radio

overheats, it will cease to function. You

will hear two short high-pitched beeps.

A - 10 Important information June 2003 IPN: M5000-00-105

Page 19

Servicing Intrinsically Safe radios

Intrinsically Safe radios

Intrinsically Safe (IS) radios are certified by a

third party to be safe to use in particular

hazardous locations.

Tait Orca 5000 IS portable radios can be

identified by one or more of the following:

■ Yellow labels

■ IS circle logo

■ FM diamond logo

A radio with any of these features must only be

serviced by an agency certified by both the

approval authority and Tait Electronics Ltd.

Any unauthorised repair or substitution of

parts invalidates the intrinsic safety rating and

the third party IS approval.

APPROVED

IS PCB servicing requirements

Tait Orca 5000 IS portable radios must be

returned to an authorised Tait branch or

subsidiary for servicing. Any unauthorised

repair or substitution of parts invalidates the

intrinsic safety rating.

FM approval

■ TOP-x25x0-B2

■ TOP-x25x0-T2

■ TOP-x26x0-B2

■ TOP-x26x0-T2

For more information about the Tait Orca

product code, refer to page page A-5.

FM approved accessories

The following accessories are approved for use

with the Tait Orca 5000 IS portable radios.

■ TOPB200-IF NiCd IS battery pack

■ TOPA-AA-003G rugged speaker-micro-

phone

■ TOPA-AA-004G RF speaker-microphone

■ TOPA-AA-005 adapter (required for use

with TOPA-AA-012/013)

■ TOPA-AA-012 heavy duty headset with

noise cancelling microphone (over the

head)

■ TOPA-AA-013 heavy duty headset with

noise cancelling microphone (behind

neck)

Tait Orca 5000 IS portable radios and accessories are approved by Factory Mutual Corporation (FM) to the following ratings:

■ IS/I/1/CD/T3C Ta=40°C

■ NI/I/2/ABCD/T3C Ta=40°C

See Table A-3 on page A-12 for more detail on

these ratings.

FM approved products

Radios with the following product code have

FM IS approval:

■ TOP-x24x0-B2

■ TOP-x24x0-T2

June 2003 IPN: M5000-00-105 Servicing Intrinsically Safe radios A - 11

■ T952-051 rugged earphone kit (optional

for use with TOPA-AA-003/004)

TOPB200-IF IS battery pack

The shift life of the TOPB200-IF IS battery

pack may be reduced by up to 10 percent when

compared to its non-IS equivalent.

The battery pack should not be charged in a

hazardous location.

Page 20

Table A-3: FM ratings

Approval Class Division Group Temperature Rating

Intrinsically Safe:

The unit is unable to

cause ignition under

normal or abnormal

operating conditions.

Incentive:

The unit is unable to

cause ignition under

normal operating conditions.

Class I:

Gas or petroleum type

environment.

Class I:

Gas or petroleum type

environment.

Division 1:

Hazardous mixtures

are normally present.

Division 2:

Hazardous mixtures

are present abnormally.

Groups C & D:

Ethylene and propane gases.

Groups A, B, C & D:

Acetylene, hydrogen,

ethylene and propane

gases.

T3C:

160°C

T3C:

160°C

A - 12 Servicing Intrinsically Safe radios June 2003 IPN: M5000-00-105

Page 21

Radio specifications and circuit

B

PART

descriptions

This part outlines the radio specifications and circuit descriptions

for Tait Orca portable radios.

Contents

Radio specifications

Radio specifications ......................................................................................

Radio specifications Radio specifications

General specifications ............................................................................................ B-3

Receiver performance ............................................................................................ B-3

Transmitter performance....................................................................................... B-4

TOP-Axxxx 66-88MHz radio specifications ........................................................... B-5

TOP-Bxxxx 136-174MHz radio specifications ....................................................... B-6

TOP-Cxxxx 174-225MHz radio specifications ....................................................... B-7

TOP-Gxxxx 336-400MHz radio specifications ....................................................... B-8

TOP-Hxxxx 400-470MHz radio specifications....................................................... B-9

...................................................................................... B-3

............................................................................................................................................................................

B-3

B-3B-3

TOP-Ixxxx 450-530MHz radio specifications ...................................................... B-10

TOP-Jxxxx 806-870MHz radio specifications....................................................... B-11

TOP-Kxxxx 896-941MHz radio specifications ..................................................... B-12

Circuit descriptions

Circuit descriptions .....................................................................................

Circuit descriptions Circuit descriptions

Transmitter ..........................................................................................................B-13

Transmit (Tx) audio .............................................................................................B-13

Receiver ................................................................................................................B-13

Receive (Rx) audio ................................................................................................B-13

DSP ......................................................................................................................B-14

Synthesiser and VCO ............................................................................................B-14

Power supplies .....................................................................................................B-14

Accessory connector interface ..............................................................................B-15

Universal band versus wideband IF filtering ........................................................B-15

..................................................................................... B-13

..........................................................................................................................................................................

B-13

B-13B-13

Page 22

B - 2 June 2003 IPN: M5000-00-105

Page 23

Radio specifications

Tables B-1, B-2 and B-3 show information

common to all the radios. For detailed information on each band, refer to the performance

figures outlined in Tables B-4 to B-11.

The performance figures are typical figures,

unless otherwise stated, for equipment operating at standard room temperature.

The test methods used to obtain these figures

are those described in the European Telecommunication Standard ETS 300-086. Where

applicable, the EIA figure is also given.

Details of test methods and the conditions that

apply for type approval testing in all countries

can be obtained from Tait Electronics Ltd.

Important notes for Tables B-4 to B-11

With regard to the typical performance

figures, specifications are subject to change

without notice and shall not form part of any

contract. They are issued for guidance purposes only. For further information please check

with your nearest Tait office or authorised

dealer who can confirm that the radio meets

applicable regulatory requirements.

* Tait Orca products have an intermediate

(universal) IF bandwidth and can be

programmed per channel for 2.5, 4.0 or 5.0

kHz deviation to cover any channel spacing.

See “Universal band versus wideband IF

filtering” on page B-15.

Table B-1: General specifications

Parameter Performance

Supply voltage 6.0 to 9.0 V

Standard test voltage 7.5 V

Table B-2: Receiver performance

Parameter Performance

Audio

Minimum load

impedance

Rated power

Distortion

Response

Spurious emissions

to 1 GHz

1 to 4 GHz

(136-470 MHz)

1 to 12.75 GHz

(>470 MHz)

Group delay variation ±50

13 Ω

500 mW (1kHz, 60%

deviation into 16 Ω)

<5% (1kHz, 60% deviation

at rated power into 16 Ω)

-6 dB/oct +1, -3 dB

(relative to 1 kHz),

300-2550 Hz (narrowband)

300-3000 Hz (wideband)

-57 dBm (conducted and

radiated)

-47 dBm (conducted and

radiated)

-47 dBm (conducted only)

µs (at detected audio

output)

bandwidth 300-3000 Hz

† TOPB600 batteries are recommended for use

with conventional radios (Orca 501x/2x)

only.

June 2003 IPN: M5000-00-105 Radio specifications B - 3

RSSI

range

slope

-120 to -40 dBm

29 mV/dB (typical)

Page 24

Table B-3: Transmitter performance

Parameter Performance

Duty cycle 20%

(1 minute Tx, 4 minutes Rx at

maximum temperature and

voltage)

Group delay variation

bandwidth

Trunking data deviation

(as per MPT1327)

narrowband

mediumband

wideband

Audio response

below limiting

in limiting

above 3 kHz

input for 60%

deviation

distortion

µs (at mod audio out-

±50

put)

300-3000 Hz

1.5 kH z

2.4 kHz

3 kHz

6 dB/oct +1, -3 dB

(relative to 1 kHz)

300-3000 Hz

0 dB +0, -4 dB

(relative to maximum system deviation)

450-2550 Hz

-35 dB/oct min

5 mV

rms

<5% at 1 kHz

Ruggedness 2 minutes (into infinite

VSWR)

Stability 5:1 VSWR (all phase angles,

<-60 dBc)

B - 4 Radio specifications June 2003 IPN: M5000-00-105

Page 25

Table B-4: TOP-Axxxx 66-88MHz radio specifications

General Orca 501x/2x Orca 503x/40

Frequency Range 66-88MHz

Channel Spacing 12.5 / 20 / 25 kHz

Frequency Increments 5 or 6.25kHz

IF Bandwidth Universal Bandwidth (UB) 10kHz*

Frequency Stability +/-15ppm (-20 to -10°C); +/-10ppm (-10 to +60°C)

Current Consumption (Receiver Squelched) 80mA 100mA

Current Consumption (Standby with high economy duty

cycle)

Current Consumption (Receiver Rated Audio) 300mA

Transmitter current (Low/High power) 800mA/1.6A

Size, incl. 1500mAh NiMH battery (WxHxD) 66 x 154 x 41mm

Weight Orca 5010/11/30 Orca 5035 Orca 5015/2x/40

With TOPB600 1100mAh NiCd† 490g 510g 515g

With TOPB200 1500mAh NiCd 525g 545g 550g

With TOPB700 1500mAh NiMH 510g 530g 535g

With TOPB500 2000mAh NiMH 550g 570g 575g

40mA N/A

Receiver

Measurements as per: ETS 300-086

Intermediate frequencies 21.4MHz and 455kHz

Sensitivity 12dB SINAD < -119dBm

Sensitivity 20dB SINAD < -114dBm

Fixed Squelch Sensitivity 12dB SINAD or 16dB SINAD Nominal

Selectivity 70dB (NB), 75dB (WB)*

Spurious Response 70dB

Intermodulation 65dB

Blocking 94dB

Ultimate Signal to Noise Ratio (EIA) 39dB (NB), 44dB (WB)*

Audio Response (300 Hz - 2.55 kHz) Within +1 / -3dB of 6dB / Octave De-emphasis

Distortion (EIA) <5% @ 1kHz, 60% Deviation

Rated Audio Output > 500mW nominal

Tra nsm itt er

Measurements as per: ETS 300-086

Power Output (Low/Mid/High) 1 / 2.5 / 5W

Spurious Emissions (Cond. & Rad.) < -36dBm (0-1GHz), < -30dBm (1-4GHz)

Hum and Noise (EIA) 38dB (NB), 43dB (WB)*

Modulation Type* narrowband

wideband

10K0F3E

16K0F3E

Deviation Limiting Adjustable up to +/- 5kHz

Audio Response (300 Hz - 2.55 kHz) Within +1 / -3dB of 6dB / Octave Pre-emphasis

Distortion (EIA) <5% @ 1kHz, 60% Deviation

*, † See “Important notes for Tables B-4 to B-11” on page B-3.

June 2003 IPN: M5000-00-105 Radio specifications B - 5

Page 26

Table B-5: TOP-Bxxxx 136-174MHz radio specifications

General Orca 501x/2x Orca 503x/40

Frequency Range 136-174MHz

Channel Spacing 12.5 / 20 / 25 kHz

Frequency Increments 5 or 6.25kHz

IF Bandwidth Universal Bandwidth (UB) 10kHz*

Frequency Stability +/-2.5ppm (-30 to +60°C)

Current Consumption (Receiver Squelched) 80mA 100mA

Current Consumption (Standby with high economy duty

cycle)

Current Consumption (Receiver Rated Audio) 300mA

Transmitter current (Low/High power) 810mA/1.6A

Size, incl. 1500mAh NiMH battery (WxHxD) 66 x 154 x 41mm

Weight Orca 5010/11/30 Orca 5035 Orca 5015/2x/40

With TOPB600 1100mAh NiCd† 490g 510g 515g

With TOPB200 1500mAh NiCd 525g 545g 550g

With TOPB700 1500mAh NiMH 510g 530g 535g

With TOPB500 2000mAh NiMH 550g 570g 575g

40mA N/A

Receiver

Measurements as per: ETS 300-086

Intermediate frequencies 21.4MHz and 455kHz

Sensitivity 12dB SINAD < -119dBm

Sensitivity 20dB SINAD < -114dBm

Fixed Squelch Sensitivity 12dB SINAD or 16dB SINAD Nominal

Selectivity 70dB (NB), 75dB (WB)*

Spurious Response 70dB

Intermodulation 65dB

Blocking 94dB

Ultimate Signal to Noise Ratio (EIA) 37dB (NB), 42dB (WB)*

Audio Response (300 Hz - 2.55 kHz) Within +1 / -3dB of 6dB / Octave De-emphasis

Distortion (EIA) <5% @ 1kHz, 60% Deviation

Rated Audio Output > 500mW nominal

Transmitter

Measurements as per: ETS 300-086

Power Output (Low/Mid/High) 1 / 2.5 / 5W

Spurious Emissions (Cond. & Rad.) < -36dBm (0-1GHz), < -30dBm (1-4GHz)

Hum and Noise (EIA) 36dB (NB), 42dB (WB)*

Modulation Type* narrowband

wideband

Deviation Limiting Adjustable up to +/- 5kHz

Audio Response (300 Hz - 2.55 kHz) Within +1 / -3dB of 6dB / Octave Pre-emphasis

Distortion (EIA) <5% @ 1kHz, 60% Deviation

10K 0F3 E

16K 0F3 E

*, † See “Important notes for Tables B-4 to B-11” on page B-3.

B - 6 Radio specifications June 2003 IPN: M5000-00-105

Page 27

Table B-6: TOP-Cxxxx 174-225MHz radio specifications

General Orca 501x/2x Orca 503x/40

Frequency Range 174-225MHz

Channel Spacing 12.5 / 20 / 25 kHz

Frequency Increments 5 or 6.25kHz

IF Bandwidth Universal Bandwidth (UB) 10kHz*

Frequency Stability +/-2.5ppm (-30 to +60°C)

Current Consumption (Receiver Squelched) 80mA 100mA

Current Consumption (Standby with high economy duty

cycle)

Current Consumption (Receiver Rated Audio) 300mA

Transmitter current (Low/High power) 800mA/1.5A

Size, incl. 1500mAh NiMH battery (WxHxD) 66 x 154 x 41mm

Weight Orca 5010/11/30 Orca 5035 Orca 5015/2x/40

With TOPB600 1100mAh NiCd† 490g 510g 515g

With TOPB200 1500mAh NiCd 525g 545g 550g

With TOPB700 1500mAh NiMH 510g 530g 535g

With TOPB500 2000mAh NiMH 550g 570g 575g

40mA N/A

Receiver

Measurements as per: ETS 300-086

Intermediate frequencies 21.4MHz and 455kHz

Sensitivity 12dB SINAD < -119dBm

Sensitivity 20dB SINAD < -114dBm

Fixed Squelch Sensitivity 12dB SINAD or 16dB SINAD Nominal

Selectivity 70dB (NB), 75dB (WB)*

Spurious Response 70dB

Intermodulation 65dB

Blocking 94dB

Ultimate Signal to Noise Ratio (EIA) 37dB (NB), 42dB (WB)*

Audio Response (300 Hz - 2.55 kHz) Within +1 / -3dB of 6dB / Octave De-emphasis

Distortion (EIA) <5% @ 1kHz, 60% Deviation

Rated Audio Output > 500mW nominal

Tra nsm itt er

Measurements as per: ETS 300-086

Power Output (Low/Mid/High) 1 / 2.5 / 4W

Spurious Emissions (Cond. & Rad.) < -36dBm (0-1GHz), < -30dBm (1-4GHz)

Hum and Noise (EIA) 36dB (NB), 42dB (WB)*

Modulation Type* narrowband

wideband

10K0F3E

16K0F3E

Deviation Limiting Adjustable up to +/- 5kHz

Audio Response (300 Hz - 2.55 kHz) Within +1 / -3dB of 6dB / Octave Pre-emphasis

Distortion (EIA) <5% @ 1kHz, 60% Deviation

*, † See “Important notes for Tables B-4 to B-11” on page B-3.

June 2003 IPN: M5000-00-105 Radio specifications B - 7

Page 28

Table B-7: TOP-Gxxxx 336-400MHz radio specifications

General Orca 501x/2x Orca 503x/40

Frequency Range 336-400MHz

Channel Spacing 12.5 / 20 / 25 kHz

Frequency Increments 5 or 6.25kHz

IF Bandwidth Universal Bandwidth (UB) 10kHz*

Frequency Stability +/-2.5ppm (-30 to +60°C)

Current Consumption (Receiver Squelched) 85mA 100mA

Current Consumption (Standby with high economy duty

cycle)

Current Consumption (Receiver Rated Audio) 300mA

Transmitter current (Low/High power) 900mA/1.7A

Size, incl. 1500mAh NiMH battery (WxHxD) 66 x 154 x 41mm

Weight Orca 5010/11/30 Orca 5035 Orca 5015/2x/40

With TOPB600 1100mAh NiCd† 490g 510g 515g

With TOPB200 1500mAh NiCd 525g 545g 550g

With TOPB700 1500mAh NiMH 510g 530g 535g

With TOPB500 2000mAh NiMH 550g 570g 575g

40mA N/A

Receiver

Measurements as per: ETS 300-086

Intermediate frequencies 45.1MHz and 455kHz

Sensitivity 12dB SINAD < -119dBm

Sensitivity 20dB SINAD < -114dBm

Fixed Squelch Sensitivity 12dB SINAD or 16dB SINAD Nominal

Selectivity 66dB (NB), 72dB (WB)*

Spurious Response 70dB

Intermodulation 65dB

Blocking 94dB

Ultimate Signal to Noise Ratio (EIA) 36dB (NB), 42dB (WB)*

Audio Response (300 Hz - 2.55 kHz) Within +1 / -3dB of 6dB / Octave De-emphasis

Distortion (EIA) <5% @ 1kHz, 60% Deviation

Rated Audio Output > 500mW nominal

Transmitter

Measurements as per: ETS 300-086

Power Output (Low/Mid/High) 1 / 2.5 / 4W

Adjacent Channel Power 65dB (NB), 75dB (WB)*

Spurious Emissions (Cond. & Rad.) < -36dBm (0-1GHz), < -30dBm (1-4GHz)

Hum and Noise (EIA) 37dB (NB), 43dB (WB)*

Modulation Type* narrowband

wideband

Deviation Limiting Adjustable up to +/- 5kHz

Audio Response (300 Hz - 2.55 kHz) Within +1 / -3dB of 6dB / Octave Pre-emphasis

Distortion (EIA) <5% @ 1kHz, 60% Deviation

10K 0F3 E

16K 0F3 E

*, † See “Important notes for Tables B-4 to B-11” on page B-3.

B - 8 Radio specifications June 2003 IPN: M5000-00-105

Page 29

Table B-8: TOP-Hxxxx 400-470MHz radio specifications

General Orca 501x/2x Orca 503x/40

Frequency Range 400-470MHz

Channel Spacing 12.5 / 20 / 25 kHz

Frequency Increments 5 or 6.25kHz

IF Bandwidth Universal Bandwidth (UB) 10kHz*

Frequency Stability +/-2.5ppm (-30 to +60°C)

Current Consumption (Receiver Squelched) 80mA 100mA

Current Consumption (Standby with high economy duty

cycle)

Current Consumption (Receiver Rated Audio) 300mA

Transmitter current (Low/High power) 780mA/1.5A

Size, incl. 1500mAh NiMH battery (WxHxD) 66 x 154 x 41mm

Weight Orca 5010/11/30 Orca 5035 Orca 5015/2x/40

With TOPB600 1100mAh NiCd† 490g 510g 515g

With TOPB200 1500mAh NiCd 525g 545g 550g

With TOPB700 1500mAh NiMH 510g 530g 535g

With TOPB500 2000mAh NiMH 550g 570g 575g

40mA N/A

Receiver

Measurements as per: ETS 300-086

Intermediate Frequencies 45.1MHz and 455kHz

Sensitivity 12dB SINAD < -119dBm

Sensitivity 20dB SINAD < -114dBm

Fixed Squelch Sensitivity 12dB SINAD or 16dB SINAD Nominal

Selectivity 66dB (NB), 72dB (WB)*

Spurious Response 70dB

Intermodulation 65dB

Blocking 94dB

Ultimate Signal to Noise Ratio (EIA) 34dB (NB), 40dB (WB)*

Audio Response (300 Hz - 2.55 kHz) Within +1 / -3dB of 6dB / Octave De-emphasis

Distortion (EIA) <5% @ 1kHz, 60% Deviation

Rated Audio Output > 500mW nominal

Tra nsm itt er

Measurements as per: ETS 300-086

Power Output (Low/Mid/High) 1 / 2.5 / 4W

Spurious Emissions (Cond. & Rad.) < -36dBm (0-1GHz), < -30dBm (1-4GHz)

Hum and Noise (EIA) 35dB (NB), 41dB (WB)*

Modulation Type* narrowband

wideband

10K0F3E

16K0F3E

Deviation Limiting Adjustable up to +/- 5kHz

Audio Response (300 Hz - 2.55 kHz) Within +1 / -3dB of 6dB / Octave Pre-emphasis

Distortion (EIA) <5% @ 1kHz, 60% Deviation

*, † See “Important notes for Tables B-4 to B-11” on page B-3.

June 2003 IPN: M5000-00-105 Radio specifications B - 9

Page 30

Table B-9: TOP-Ixxxx 450-530MHz radio specifications

General Orca 501x/2x Orca 503x/40

Frequency Range 450-530MHz

Channel Spacing 12.5 / 20 / 25 kHz

Frequency Increments 5 or 6.25kHz

IF Bandwidth Universal Bandwidth (UB) 10kHz*

Frequency Stability +/-2.5ppm (-30 to +60°C)

Current Consumption (Receiver Squelched) 80mA 100mA

Current Consumption (Standby with high economy duty

cycle)

Current Consumption (Receiver Rated Audio) 300mA

Transmitter current (Low/High power) 870mA/1.7A

Size, incl. 1500mAh NiMH battery (WxHxD) 66 x 154 x 41mm

Weight Orca 5010/11/30 Orca 5035 Orca 5015/2x/40

With TOPB600 1100mAh NiCd† 490g 510g 515g

With TOPB200 1500mAh NiCd 525g 545g 550g

With TOPB700 1500mAh NiMH 510g 530g 535g

With TOPB500 2000mAh NiMH 550g 570g 575g

40mA N/A

Receiver

Measurements as per: ETS 300-086

Intermediate frequencies 45.1MHz and 455kHz

Sensitivity 12dB SINAD < -119dBm

Sensitivity 20dB SINAD < -114dBm

Fixed Squelch Sensitivity 12dB SINAD or 16dB SINAD Nominal

Selectivity 66dB (NB), 72dB (WB)*

Spurious Response 70dB

Intermodulation 65dB

Blocking 94dB

Ultimate Signal to Noise Ratio (EIA) 34dB (NB), 40dB (WB)*

Audio Response (300 Hz - 2.55 kHz) Within +1 / -3dB of 6dB / Octave De-emphasis

Distortion (EIA) <5% @ 1kHz, 60% Deviation

Rated Audio Output > 500mW nominal

Transmitter

Measurements as per: ETS 300-086

Power Output (Low/Mid/High) 1 / 2.5 / 4W

Spurious Emissions (Cond. & Rad.) < -36dBm (0-1GHz), < -30dBm (1-4GHz)

Hum and Noise (EIA) 34dB (NB), 40dB (WB)*

Modulation Type* narrowband

wideband

Deviation Limiting Adjustable up to +/- 5kHz

Audio Response (300 Hz - 2.55 kHz) Within +1 / -3dB of 6dB / Octave Pre-emphasis

Distortion <5% @ 1kHz, 60% Deviation

10K 0F3 E

16K 0F3 E

*, † See “Important notes for Tables B-4 to B-11” on page B-3.

B - 10 Radio specifications June 2003 IPN: M5000-00-105

Page 31

Table B-10: TOP-Jxxxx 806-870MHz radio specifications

General Orca 501x/2x Orca 503x/40

Frequency Range 806-870MHz Transmit

851-870MHz Receive

Channel Spacing 12.5 / 20 / 25 kHz

Frequency Increments 5 or 6.25kHz

IF Bandwidth Universal Bandwidth (UB) 10kHz*

Frequency Stability +/-1.5ppm (-30 to +60°C)

Current Consumption (Receiver Squelched) 85 mA 100mA

Current Consumption (Standby with high economy duty

cycle)

Current Consumption (Receiver Rated Audio) 300mA

Transmitter current (Low/High power) 780mA/1.3A

Size, incl. 1500mAh NiMH battery (WxHxD) 66 x 154 x 41mm

Weight Orca 5010/11/30 Orca 5035 Orca 5015/2x/40

With TOPB600 1100mAh NiCd† 490g 510g 515g

With TOPB200 1500mAh NiCd 525g 545g 550g

With TOPB700 1500mAh NiMH 510g 530g 535g

With TOPB500 2000mAh NiMH 550g 570g 575g

40 mA N/A

Receiver

Measurements as per: EIA

Intermediate frequencies 45.1MHz and 455kHz

Sensitivity 12dB SINAD < 0.25µV (-119dBm)

Sensitivity 20dB SINAD < 0.40 µV (-114dBm)

Fixed Squelch Sensitivity 12dB SINAD or 16dB SINAD Nominal

Selectivity 60dB (NB), 65dB (WB)*

Spurious Response 65dB

Intermodulation 65dB

Hum and Noise 32dB (NB), 38dB (WB)*

Audio Response (300 Hz - 2.55 kHz) Within +1 / -3dB of 6dB / Octave De-emphasis

Rated Audio Output > 500mW nominal

Tra nsm itt er

Measurements as per: EIA

Power Output (Low/Mid/High) 1 / 2 / 3W

Spurious Emissions (Cond. & Rad.) - 65dB

Hum and Noise 38dB (NB), 42dB (WB)*

Modulation Type* narrowband

wideband

10K0F3E

16K0F3E

Deviation Limiting Adjustable up to +/- 5kHz

Audio Response (300 Hz - 2.55 kHz) Within +1 / -3dB of 6dB / Octave Pre-emphasis

Distortion <5% @ 1kHz, 60% Deviation

*, † See “Important notes for Tables B-4 to B-11” on page B-3.

June 2003 IPN: M5000-00-105 Radio specifications B - 11

Page 32

Table B-11: TOP-Kxxxx 896-941MHz radio specifications

General Orca 501x/2x Orca 503x/40

Frequency Range 896-941MHz Transmit

935-941MHz Receive

Channel Spacing 12.5 / 20 / 25 kHz

Frequency Increments 5 or 6.25kHz

IF Bandwidth Universal Bandwidth (UB) 10kHz*

Frequency Stability +/-1.5ppm (-30 to +60°C)

Current Consumption (Receiver Squelched) 85 mA 100mA