Congratulations

on

your

purchase

of the Micro Lathe II. It should

provide years of service with little

maintenance. Y'our lathe is covered

by a 2 year labor and material

unconditional fact9ry warranty-

HAPPY

MACHININGI!

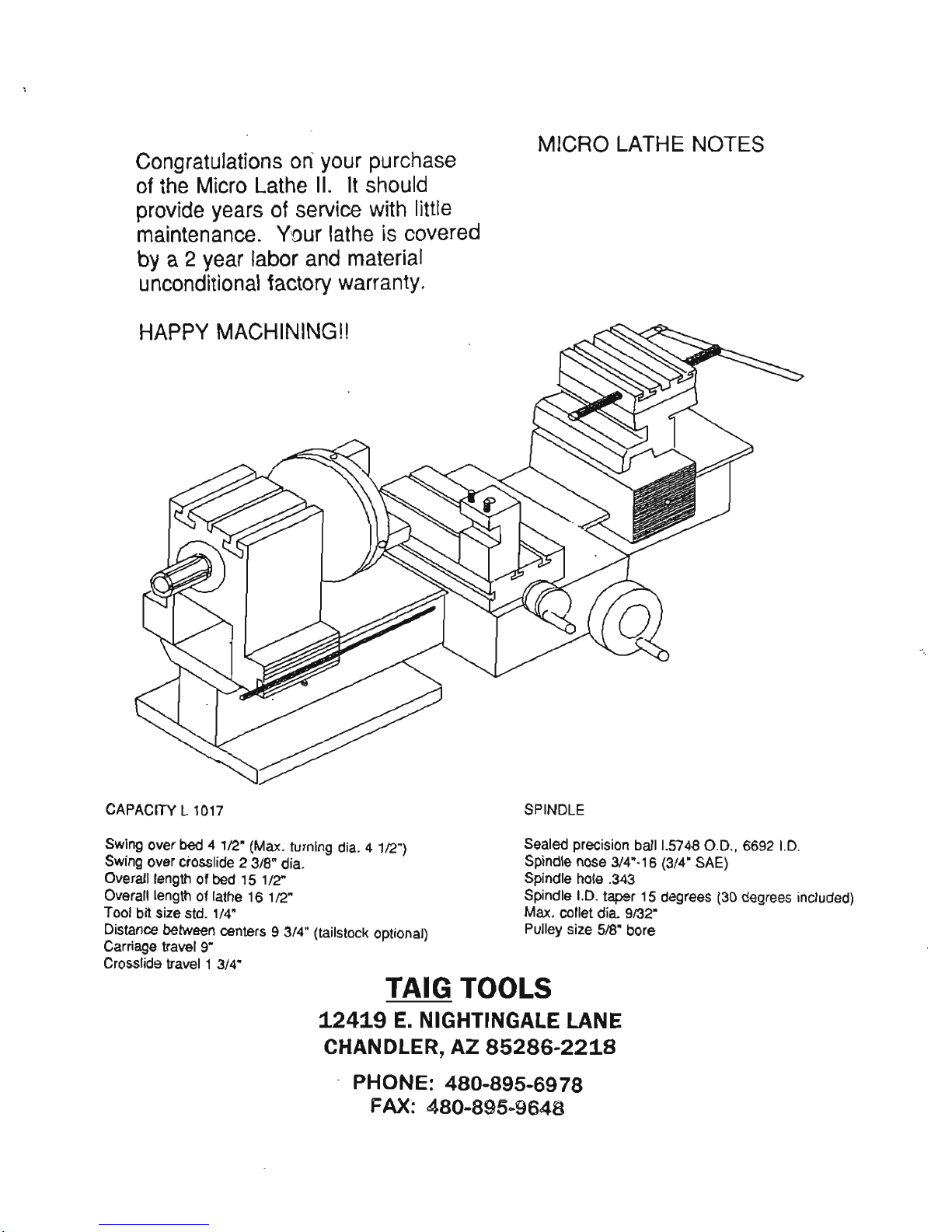

CAPACITY L

1017

Swing

ov~r

bed 4 1/2" (Max. turning dia. 4 1/2")

Swing

over cross

fide23/S"

dia.

Overall length

of

bed 15 1/2"

Overall lengthoflathe 16 1/2" .

Tool bit size std. 1/4"

Distance between centers 9 3/4" (tailstock optional)

Carriage traver 9"

Crosslide travel 1 3/4"

MICRO LATHE NOTES

SPINDLE

Sealed precision ball

1.5748

0.0.,6692

1.0.

Spindle nose 3/4"..16 (3/4" SAE)

Spindle hole .343

Spindle

1.0.

taper15degrees (30 degrees included)

Max.

collet dia. 9/32"

Pulley size

5/8"

bore

TAIG TOOLS

12419

E.

NIGHTINGALE LANE

CHANDLER, AZ

85286-2218

PHONE: 480-895-6978

FAX: 480-8900.9648

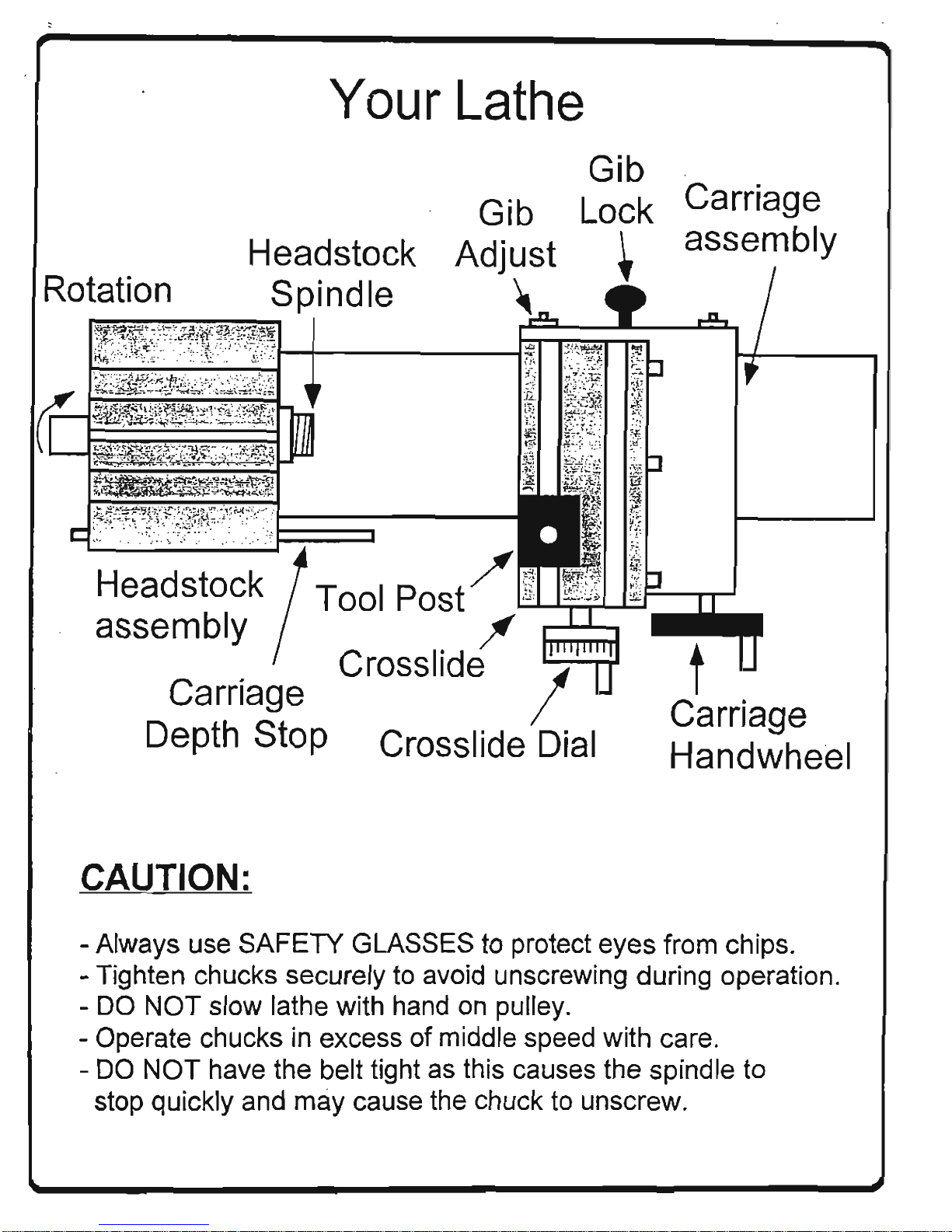

Your Lathe

t

Carriage

"Handwheel

Gib

Lock Carriage

~

assembly

Gib

Adjust

~

Headstock

Spindle

~;.

Headstock Tool Post/

......

~f

...........

--.......!i-----.

......

assembly

;t

Crosslide I

Carriage

Depth Stop Crosslide Dial

~~i~::'~~?:F~:Y~;:~lt~~~~::,;?;-:!;~::""::",I------

..

-.~

;.'

'."~-."::

.~::.~):

~_.,

'

.::/1--

....

Rotation

CAUTION:

- Always use SAFETY GLASSES to protect eyes from chips.

- Tighten chucks securely to avoid unscrewing during operation.

- DO

NOT

slow lathe with hand

on

pulley.

- Operate chucks in excess of middle speed with care.

-

DO

NOT

have the belt tight as this causes the spindle to

stop quickly and may cause the chuck to unscrew.

CAUTIONII

Always Wear Approved Safety Glasses

when Operating Lathe. Tighten Chucks

Securelyto Prevent Chuckfrom Unscrewing.

Do Not Slow Lathe

by.

Placing Hand on

Pulley. Do Not Over Tighten Belt. Keep

Hands Away from Cutting Tool When

Making Cuts.

The

Taig Lathe

is

extremely well constructed

and

requires little'

maintenance. However,

the

lathe must

be

kept clean. After working ajob,

thoroughly clean the

lathe

of

all

debris

with

a soft cloth

and

a small

brush.

Make

sure the spindle threads have

been

thoroughly cleaned

and

oil

the

bed

to prevent corrosion.

If

the

lathe

is

not

to

be

used for extended

periods, remove

the

drive belt

and

cover

the

lathe. Always check lathe

components for ease

of

operation

and

lubricate

as

necessary.

Use

light

oil-10 weight-such

as

automatic transmission fluid orincold weather

WD

40.

Loosen

chucks or faceplate every few days

as

condensation may rust tools

on

spindle, especially near water or

in

high

humidity areas.

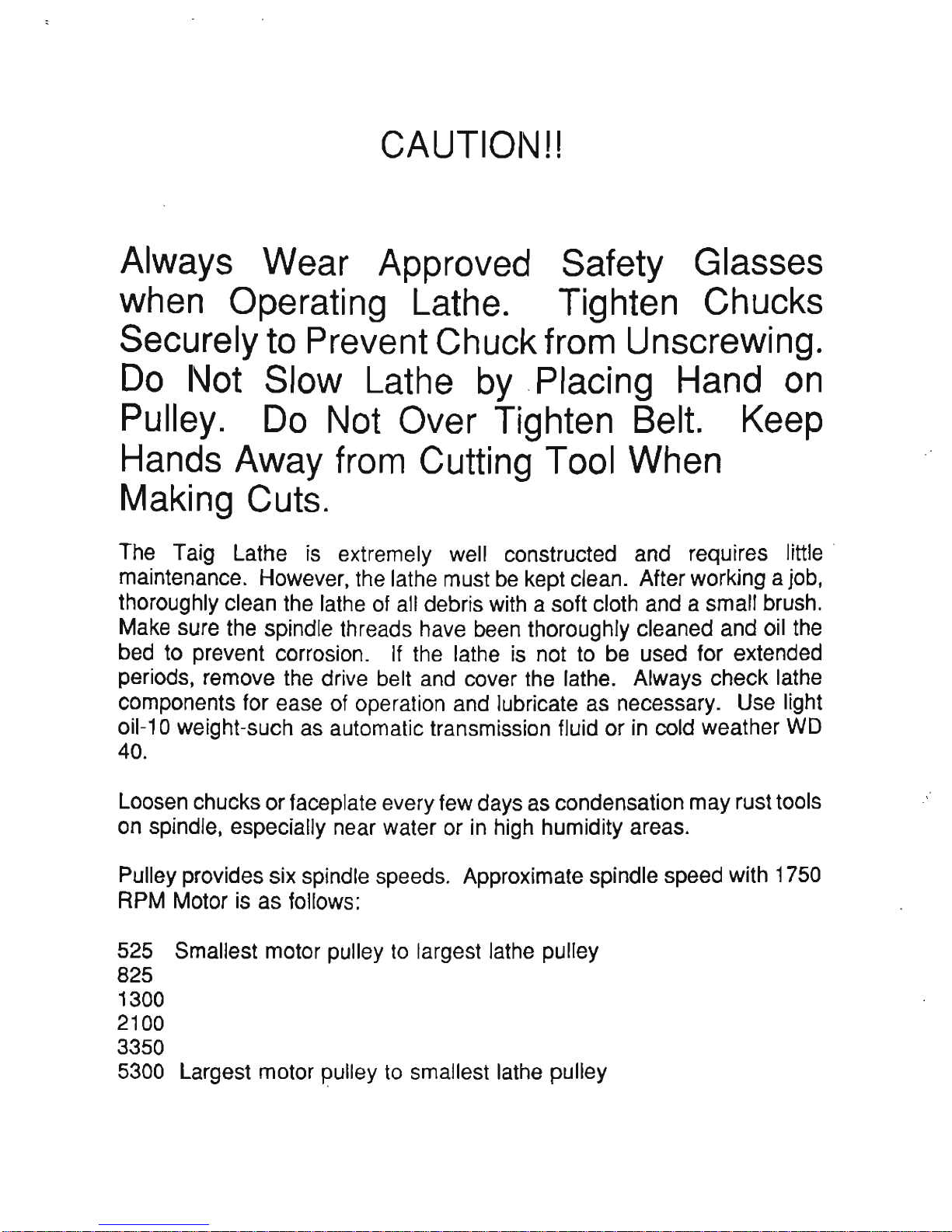

Pulley provides six spindle speeds. Approximate spindle speed with

1750

RPM

Motorisas follows:

525 Smallest motor pulley

to

largest

lathe

pulley

825

1300

2100

3350

5300

largest motor pulley to smallest lathe pulley

The motor should sit on an angle

with the weight of the motor

on

the

belt. The motor bracket should

be loose on the board to allow

the motor to be raised in order

to change speeds. Make

sure

the

belt contacts properly.

\A!j:\sll

t R 1

~

r.1~

:=hd~=~

rMG8N1'ING-BOARb'~'~:

,-,,,-.,

,',::':

,-,.:..,

,',::

\-1

~

"

~

" >

'-;1

;:;;

.-.

')

. "

)...

,

,)...

, J

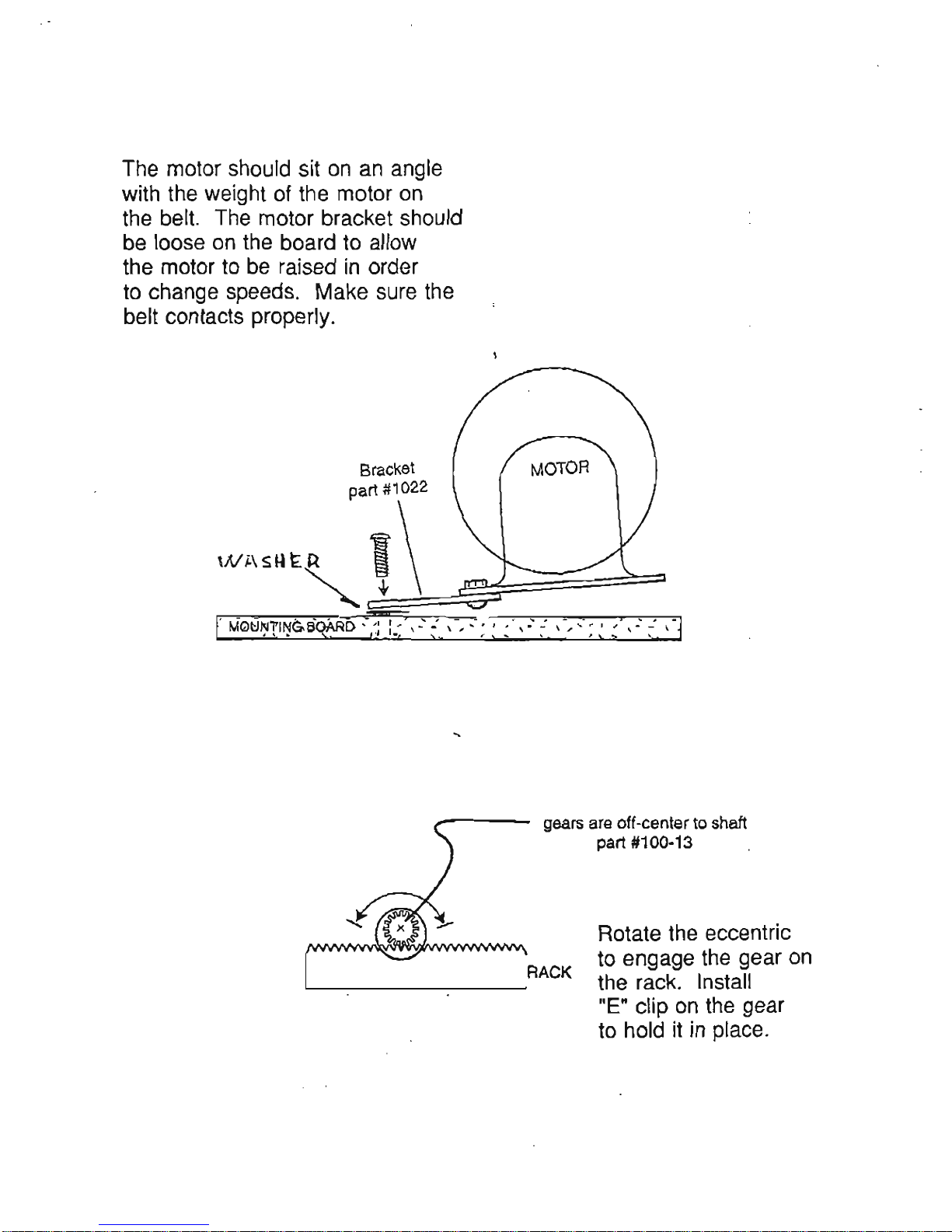

gears

are

off-centertoshaft

part #100·13

RACK

Rotate the eccentric

to engage the gear on

the rack. Install

"E" clip

on

the gear

to hold it

in

place.

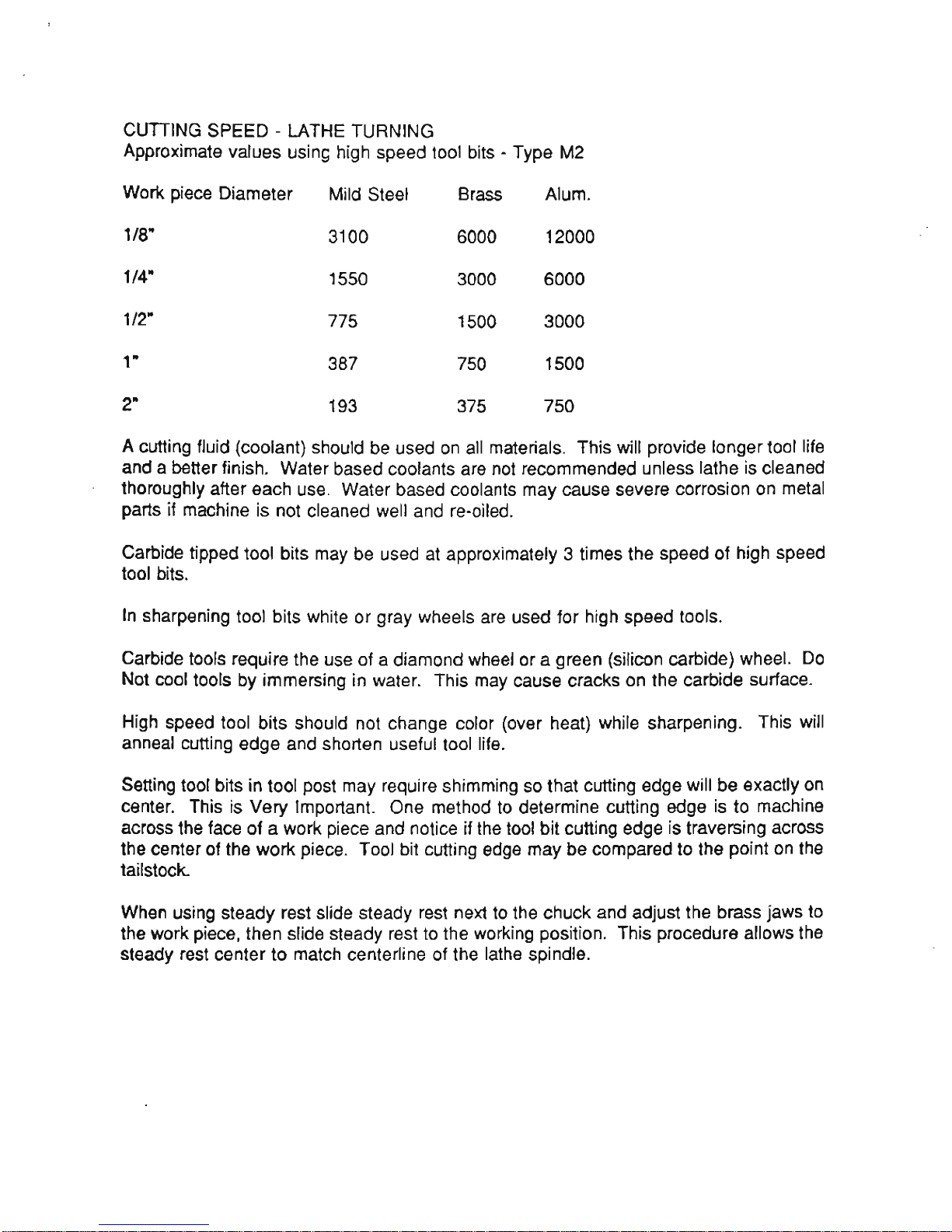

CUTIING

SPEED - LATHE TURNING

Approximate values using high speed tool bits - Type M2

Work piece Diameter

Mild Steel Brass Alum.

1/8"

3100

6000

12000

1/4"

1550

3000

6000

1/2"

775

1500

3000

1"

387

750

1500

2"

193

375 750

Acutting fluid (coolant) should be used on all materials. This will provide longer tool life

and a better finish. Water based coolants are not recommended unless lathe is cleaned

thoroughly after each use.

Water

based coolants

may

cause severe corrosion on metal

parts

if

machine is not cleaned well

and

re-oiled.

Carbide tipped tool bits may be used at approximately 3 times the speed of high speed

tool bits.

In sharpening tool bits white

or

gray wheels are used for high speed tools.

Carbide tools require the use of a diamond wheel or a green (silicon carbide) wheel. Do

Not cool tools by immersing in water. This may cause cracks on the carbide surface.

High speed tool bits should not change color (over heat) while sharpening. This will

anneal cutting edge and shorten useful tool life.

Setting tool bits in tool post may require shimming so that cutting edge will

be

exactly on

center. This is

Very Important. One method to determine cutting edge is to machine

across the face of a work piece and notice if the tool bit cutting edge is traversing across

the center of the

work

piece. Tool bit cutting edge may be compared to the point on the

tailstock.

When using steady rest slide steady rest next to the chuck and adjust the brass jaws to

the work piece,

then

slide steady rest to the working position. This procedure allows the

steady rest center

to

match centerline of the lathe spindle.

Micro

Lathe

Headsock

PART #1026

DEPTH

STOP

J

TIIf

«1J~l.6-1

---.-..ft

....

ulICJilrnB

Lathe

Chuck

DelJlll

Slop

I

Ilstal

I

ed

ill

SpiJldle

• Used to provide stop for workpiece held

in

chuck

• Parts held

in

chuck

Inay

be

I11achined

to

saine length

• Jaws are independently adjusted

in

pairs. Four-jaw chucks are by far

tile

ITIOst vesatile

of

all

Cllucks

• Parts Inay

be

machined to run very

true. This will require more time

to

center than a three-jaw. Setting a

workpiece off-center creates crankshaft and cam shapes

Adjust

In

paIrs

PART #1030 FOUR-JAW CHUCK

• Hardened steel with steps

Reversible range

1/8

- 3 1/4 ins.

Your options for workpiece mounting hardwareare as fonows:

Part

1030: 4

Jaw

Oluck

Part

1050: 3

Jaw

Chuck

-----

....

PART #1035·. FACE PLATES

Stop

• Faceplates are used to run shafts

between centers and to fixture spe-

cial

jobs

• Holes can

be

drilled and tapped

i1

needed in faceplate

Faceplate

\Vorkpiece

Special

Stops

Use of Clarnps

Faceplate

Angle

Bracket

PART #1036 1 X 1IN. SQUARE

ANGLE BRACKETS

(2 PIECES)

·.,.

...

'Part1035: Faceplate

'Part

1036:

Anv).e

Bl'ackets----r

·

PART#1040

PARTffl042

COLLET

CLOSER

Collet is used

fOl·

sInaI

J

dialnetel· sllaft \vork alld

holding cutters for nlilJing.

Sizes are

1/8, 5/32, 3/16, 7/32,

1/4 &.9/32 iIlclles -- 5/16

illCll

is a stub c.ollet

of

3"/8

illclles

ill

depth.

• Advantages

of

collets are they are fast and accurate and spindle

nlay

be

run at

InaxinlUll1

speed on

altllninUITI

and brass.

• Collets will accept material

that

is

.001 over collet size to .004

under collet size. Bar stock

is

nonnaJly within this tolerance.

Blanl{ Collet #1043

Center

Mark

• Used to modify

staIldal·d screws

•

Ivtay

be

used to

l1lake

special sizes

Drill and tap so screw

will protrude

Macllille llead to

suit

~,

arbornut---

Part

1052: Full Circle

Jaw

Part

1040: Collet

Part

1042: Collet

Coser

Nut

Part

1026: Depth Stop

Part

1043: Blank Collet

collet (slotted, drilled and threaded)

depth stop (drilled and threaded)

blank collet (solid-not

~hined)

collet closer

nut

.~~~

/

PART

#1050

THREE-JAW

CHUCI( ·

To achieve best accuracy

soft

jaws

lTIllSt

be trued on

spindle chuck will be used

011

• Part

#1050

is 3 1/4 inches in

dialnetel·

• All steel scroll

chuck

with

alulninun top

jaws

(commonly

called soft

jaws)

• Three

jaw

chucks

are

used to

hold round and hex material.

•

The

self

centering ability

enables all three

jaws

to

move

at

tIle

same

ti

me.

Belt

~~-

Rotate ring to Inove

jaws

Close

jaws

on

washer

Washer

o

Set

depth Stop

rod to prevent

tool

bit frOll1 washer

1

051

Soft Jaws

( 3 pieces with 6

screws)

1

000

)

Spare Jaws same as supplied with chuck.

~_

Soft Jaws may be machined with steps

such

as

this.

Reverse Jaws as shown to cut steps.

Advantages

of

Soft Jaws

10 Will not damage work piece

as normal hard jaws

do.

2. Greater accuracy can be obtained when

machining jaws for a specific size and

used

on

the same

lathe.

Remember:

When using any chuck always mark workpiece and chuck

jaws so that the part is

in

the same relationshipifremoved

and replaced in chuck - A good idea is to paint one

jaw

with nail polish.

PART #1052 FULL CIRCLE

J~W

."

\ @

'1

Sho\vn \vith steps

• To bore

jaws,

place 1/4 inch

diameter pin

in

center

• Jaws

may

be

cut

with steps to

hold thin disks

or

clock gears

• Thin wall tubes that regular three-

jaws

would damage

may

be held by

machining

jaws

to

exact

size

of

tube so that almost 100% contact

on

tube

will be achieved

Part

1200: Top Slide (Compound)

A compound is used for angles and short tapers

on

the work piece. The

positive length may be achieved by having the compound

90 degrees to

the crosslide and by using the dial on the compound to control the length

of

the

cut.

The compound will attach to either "tee" slot of the crosslide and will rotate

and be clamped at any angle. The tool bit is clamped directly on the table

of

the

compound.

PART #1152.

DIE

HOLDER

•Threads Inay

be

put on a part \vith a button-die. This

is

a round

piece

of

tooled steel with thread-cutting grooves.

The

dialneters

of

small button-dies are 13/16 and 1.00 inches. In this size,

threads may be cutfrom 0-80 to 1/2 inch.

Die

The

purpose

of

a die holder is to align

alld allow the button-die to cut a

tl·ue and

untapered thread..When scre\ving the

button die on workpiece, always have a

45 degree chalnfer (edge brake) on end

of

shaft

to be threaded.

Die

I-Iolder

..---Slide

Button-Die

WORKPlECE I··{ELD

ON

CENTER

BY t-IEA DS

Toe

1\

CHUCK

OR

COLLET

Part

1220: Milling i\ttachment

Approximate

cutting

speed

using

high

speed

end

mills

in

RPM.

Alum.

Brass

Steel

3/16 dia. 2100 1300 525

1/8.dia. 3350 2100 825

1/16 dia. 5300 5300

2100

longer

tool

life

and

better

finishes

may.beobtained

using

a

cutting

fluid.

For

steel a

pipe

thread

cutting

oil

works

very

wen.

For

alum.orbrass

keroseneordiesel

fuel

may

be

used.

The·l220

Milling

Attachment

provides vertical

travelofapprox.13/4

inches.

The

crosslide dial

provides

travel

in·.001

increments

direct reading.

The

cutters

(end

mills)

are

heldinthe

spindle

with

the

colletstoprovide

maximum

ridgidty. Miniature

end

mills

c~me

with

3/16

dia.

bodies

and

various

size

cutting

diameters. The

end

mills

will cut

all

materials

steel,

alum.

t

brass

and

plastics.

o 0

o

o

Carbide

tipped

router

bits

with

1/4

inch

diameter

body

maybeused

·for

cutting

alum

.•

brass,

plastics

and

wood.

They

are

not

recommended

for

steel.

Carbide

tools

should

run

at least

4

times

faster

than

high

speed

end

mills

of comparable

size.

Loading...

Loading...