www.banggood.com

1

Manual

1. Instrument introduction

VAC8010F is a multi-function meter based on 2.4 wireless data transmission

technology. It can display various physical parameters such as voltage, current, power,

capacity, energy, temperature and running time in real time. The battery can be

realized separately through two reserved relay interfaces. Charge and discharge

management and overvoltage, undervoltage, overcurrent protection. Moreover, the

meter uses a 2.4-inch color liquid crystal as a display, and the display data is more

comprehensive, clear, and easy to observe.

2. Instrument characteristics:

1. Wirelessly transmit data to avoid interference caused by complicated wiring

between the display and the detection module, and the wiring is more convenient.

2. Hall sensor is used to realize non-contact detection current, without disconnecting

the wire, safe, reliable and convenient.

3. Voltage, current, power, temperature, capacity, percentage of remaining capacity,

and running time are displayed simultaneously.

4. Dual relay interface, can manage charging and discharging separately.

5. With charging overvoltage, discharge undervoltage, charging overcurrent,

discharge overcurrent protection.

6. With power-off memory function, you can record the AH number and WH

number before power-off.

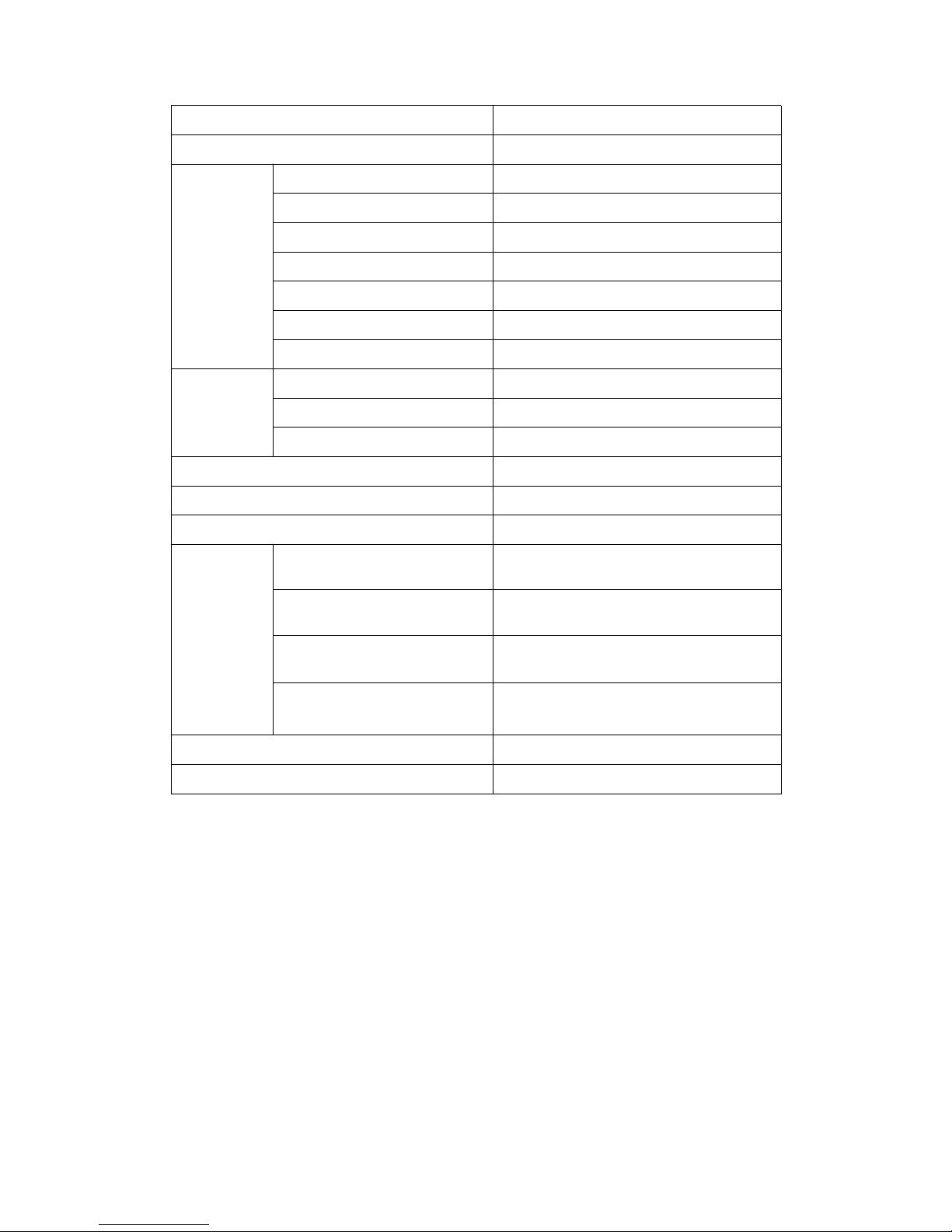

3. Technical indicators

Item

Specification

Input

voltage

Measuring range when

self-powered

6V~80V

Measuring range when

externally powered

0~120V

Input current measurement range

0~100A

www.banggood.com

2

External supply voltage

6-60V

Display method

2.4 inch color LCD display

Measuring

range

Voltage

0.01V~120V

Current

0.1A~100A

Capacity

0.001AH~65000.00AH

Energy

0.000KWH~9999KWH

Time

0~100 hour

Power value

999KW

Temperature

1~100℃

Accuracy

Voltage

±1%+2

Current

±2%+5

Temperature

±1.5℃

Measurement rate

5 times / sec

Relay delay time

(0-60)S

Communication distance

Open single group 10 meters

Protection

type and

setting

range

OVP (overvoltage

protection)

0.01V~500V

LVP (undervoltage

protection)

0.01~500V

OCP (Charge Overcurrent

Protection)

0-500A

NCP (discharge

overcurrent protection)

0-500A

Display panel size

87*49*14 (mm)

Measuring board size

114*54*28 (mm)

4. Display description

www.banggood.com

3

1

Battery remaining capacity column chart

8

Single run time

cumulative value

2

Cumulative remaining AH number

9

Output status

display directory

3

Cumulative energy

A

Percentage of

remaining battery

capacity

4

The time required for the battery to be fully charged

or discharged (calculated based on charge and

discharge current and capacity)

B

Power value

5

Wireless communication signal indication

C

Function option

directory

6

Key lock indication

D

Measured voltage

value

7

Real-time measurement of temperature values

E

Measured current

value

www.banggood.com

4

5. Measuring board interface descriptions

1

Discharge relay control interface

2

Charging relay control interface

3

USB2.0 interface (can supply power to the display board)

4

Voltage measurement interface

5

External power supply interface

6

External power supply and self-power supply selection interface

7

Relay switch button

6. Wiring

1) Self-powered wiring diagram

Note: If the battery (power supply) under normal operation has a voltage range of

(6-80V), you can use its own power supply wiring. First, adjust the jumper cap of the

power supply selection interface to “2W”, and then connect it. The positive and

negative poles of the battery (power supply) are connected to the voltage

measurement port “+Bat-”; note that “+” is connected to the positive pole of the

battery (power supply), “-” is connected to the negative pole of the battery (power

supply), and the positive and negative poles of the power supply are not connected.

Wrong or reverse, connect the positive pole of the battery (power supply) to the

positive pole of the load, the negative pole of the battery (power supply) to the

negative pole of the load through the Hall sensor, the current direction flowing

through the Hall sensor and the power-on arrow of the Hall sensor When the

direction is the same, the measured current will show a positive value, otherwise the

measured current will show a negative value.

www.banggood.com

5

2) External power supply wiring diagram

Note: If the voltage range of the tested battery (power supply) is not working (6-80V),

the external power supply wiring mode can be used. First, adjust the jumper cap of

the power supply selection interface to “ 3W ”, and the external power supply.

Connect the positive and negative poles to “+Vext-”, pay attention to “+” to the

positive pole of the external power supply, and “- ” to the negative pole of the

external power supply; then connect the positive and negative poles of the battery

www.banggood.com

6

(power supply) to the voltage measurement port “+Bat”. -", pay attention to "+" to

the positive pole of the battery (power), "-" to the negative pole of the battery

(power supply). Do not connect the positive and negative poles of the battery (power

supply) to the positive pole of the load. Connect the positive pole of the battery

(power supply) to the positive pole of the load. The negative pole of the battery

(power supply) is connected to the negative pole of the load through the Hall sensor

when flowing through the Hall sensor. When the current direction is the same as the

direction of the power-on arrow of the Hall sensor, the measured current will show a

positive value, otherwise the measured current will show a negative value.

(Three-wire connection relay wiring diagram)

www.banggood.com

7

3) Charging relay wiring instructions

Note: The working power supply of the relay is provided by an external power supply.

If the relay is connected, an external power supply with the same working voltage as

the relay should be provided. Connect the control port of the relay to the interface of

the charging controller. If you want to control the positive pole of the charging, pass

the positive line through the relay. If you want to control the negative pole of the

charging, connect the negative line to the relay. When the relay is connected, the

"IN" light is used. It will light up and will go out as a reminder when disconnected.

www.banggood.com

8

4) Discharge relay wiring instructions

Note: The working power supply of the relay is provided by an external power supply.

If the relay is connected, an external power supply with the same working voltage as

the relay should be provided. Connect the control port of the relay to the discharge

controller interface. If you want to control the positive pole of the discharge, pass the

positive line through the relay. If you want to control the negative pole of the

discharge, connect the negative line to the relay. When the relay is connected, the

"OUT" light It will light up and will go out as a reminder when disconnected.

www.banggood.com

9

7. Wiring note:

Select the appropriate wiring method according to the range of voltages measured to

ensure that the input voltage is within the tolerance of the instrument.

Note: The input voltage range of its own power supply: 6V~80V;

External power supply input voltage range: 0V~120V.

8. Feature introduction and settings

(1) “NCP” charging overcurrent protection value. If the value is greater than 0, the

protection will be activated. If it is equal to 0, the protection function will not be

activated. When setting the parameters, click the up or down button to move the

cursor to “NCP”, then click the OK button. Enter the parameter setting interface of

Figure (8-1). After entering the page, it will prompt the nature and range of the set

parameters, then click the up or down button to change the size of the set parameter

value. Note: The current display line will be set when the parameter is set. Change to

red and display the wireless return value of the set parameter. When the set

parameter value and the current display line data match, the data setting is

completed (ignoring the decimal point), then click OK to return to the initial interface

to complete the parameter. Settings and save.

PIC.(8-1)

(2) "OCP" discharge overcurrent protection value. If the value is greater than 0, the

protection will be started. If it is equal to 0, the protection function will not be

activated. When setting the parameters, click the up or down button to move the

cursor to “OCP”, then click the OK button to enter the parameter setting interface of

the figure (8-2). The parameters are set in the same way as “NCP”.

www.banggood.com

10

PIC.(8-2)

(3) “OVP” charging overvoltage protection value. If the value is greater than 0, the

protection will be started. If it is equal to 0, the protection function will not be

activated. When setting the parameters, click the up or down button to move the

cursor to “OVP”, then click the OK button to enter the parameter setting interface of

the figure (8-3). The parameters are set in the same way as “NCP”.

PIC.(8-3)

(4) "LVP" discharge undervoltage protection value. If the value is greater than 0, the

protection will be started. If it is equal to 0, the protection function will not be

activated. When setting the parameters, click the up or down button to move the

cursor to “LVP”, then click the OK button to enter the parameter setting interface of

the figure (8-4). The parameters are set in the same way as “NCP”.

www.banggood.com

11

PIC.(8-4)

(5) “OUT” output control item, the yellow cursor moves to this position, click “OK”

key to open the relay or switch the working status of the two relays.

(6) “LCK” button lock control item, move the cursor to this option, click OK button to

select the option, click the up button to lock the button as shown in Figure 8-5. After

the button is locked, the button will not work, only long Press OK button 10S or more

to unlock if shown in 8-5.

PIC.(8-5)

(7) “BAT” battery total capacity setting item, move the cursor to this option, click OK

button to enter the parameter setting page as shown in Figure (8-6), and set the

parameters in the same way as “NCP”.

www.banggood.com

12

PIC.(8-6)

(8) “BPC” battery remaining capacity setting, you can estimate the remaining battery

capacity according to the actual use situation. With this option, you can set the

remaining capacity of the battery, which is more convenient for testing. When setting

the remaining capacity of the battery, the parameter setting is completed when the

real-time percentage and the set percentage are the same, as shown in Figure 8-7.

PIC.(8-7)

(9) “CER” current return function. If the actual current value is zero and the

instrument display value is not zero, move the cursor to this option and press OK to

zero the current.

(10) “RET” data reset function, if you want to return to zero watt hour and run

accumulated time value, move the cursor to this option, short press OK to reset

these two parameters to zero.

(11) "LNG" language switching function, the instrument parameters are preset with

Chinese and English interfaces to choose from, enter the parameter setting page as

shown in Figure 8-8, click the up or down button to switch the language type.

www.banggood.com

13

PIC.(8-8)

(12) "STI" relay power-on default output state setting option, if you select ON

power-on to automatically close the discharge relay, if you choose OFF charging and

discharging relay are not closed, you need to press the button to turn on or switch

charging and discharging, as shown in Figure 8-9.

PIC.(8-9)

(13) "SFH" search device function, this function can realize one-to-many

communication. By modifying the parameters corresponding to this option, the

display can communicate with the measurement module of different address bits,

and the detection data of different devices can be viewed at any time. The

parameters are set in the same way as "NCP".

PIC.(8-10)

www.banggood.com

14

(14) "DEL" relay delay action time setting option, if the protection parameter has

been set, when the instrument detects that the real-time data exceeds the set

parameter for less than the relay action delay time, the relay does not open; if the

instrument detection data exceeds the setting The time of the parameter is greater

than the delay time of the relay, and the relay is disconnected. The parameters are

set in the same way as "NCP".

PIC.(8-11)

(15) "FCH" communication address setting function, this function can change the

default communication address of the display and detection module, and set the

parameters in the same way as "NCP".

PIC.(8-12)

(16) "SNR" screen current value setting option, if the setting value of this option is

not 0, and the information screen time value is not 0, then when the actual current

value is less than the SNR setting value, the display device The display will be turned

off after the set real time is reached. When the actual current value is detected to be

greater than the set SNR value, the LCD will automatically light up. The parameters

are set in the same way as "NCP".

www.banggood.com

15

PIC.(8-13)

(16) "SNT" screen time setting option, if the SNT setting is 0, the display will never

be turned off. If the SNT value is greater than 0, the value of "SNR" is used to

implement the interest screen function. The parameters are set in the same way as

"NCP".

PIC.(8-14)

(17) “RFS” color reversal function. If this function is enabled, the displayed color

will be changed when the next display is powered on. Move the cursor to “RFS”,

click OK to enter the parameter setting page, and click the up button to confirm the

flip display color.

www.banggood.com

16

PIC.(8-15)

9. Precautions

1. Do not exceed the voltage and current range, otherwise the meter will be

damaged.

2. The positive and negative poles cannot be reversed, and the reverse may damage

the instrument.

3. The working temperature is -10 ~ 50 ° C, the storage temperature is -20 ~

70 ° C, and the instrument should be in a dry environment.

4. Do not attempt to disassemble the instrument. Failure to seal the package will void

the warranty.

Loading...

Loading...