- 1 -

- 2 -

PREFACE

PREFACE

PREFACE

PREFACE

This manual is only a guide to assist you and is not a complete or comprehensive manual of all

aspects of maintaining and repairing your engine. The equipment you have purchased is a complex

piece of machinery .

We

recommend that you consult with a dealer if you have doubts or concerns

as to your expensive or ability to properly maintain or repair your engine.

You

will save time and

the inconvenie nce of having to go back to the store if you choose to write or call us concerning

missing parts, service questions, operating advance, and /or assembly questions. Our air

compressors have the following features:

Air cooled

Four-stroke gasoline internal combustion engine

Recoil starter(Optional electric start)

Large fuel tank

The air-cooled gasoline air compressors are widely used when electrical power is scarce. Air

compressors provide a portable mobile solution in supplying a pneumatic

air

supply for field

operations during project construction.

This manual will explain h ow to operate and service your

air

compressor set.

If you have any questions or suggestions about this manual, please contact your local dealer or us.

Consumers should notice that this manual might differ slightly from the actual product as more

improvements are made to our products. Some of the pictures in this ma n ual may differ slightly

from the actual product as well

.We

reserves the right to make the changes at any time without

notice and without incurring any obligation.

- 3 -

TABLE

TABLE

TABLE

TABLE OF

OF

OF

OF THE

THE

THE

THE CONTENTS

CONTENTS

CONTENTS

CONTENTS

Page

Page

Page

Page number

number

number

number

CHAPTER

CHAPTER

CHAPTER

CHAPTER 1.

1.

1.

1. TECHNICAL

TECHNICAL

TECHNICAL

TECHNICAL SPECIFICATIONS

SPECIFICATIONS

SPECIFICATIONS

SPECIFICATIONS AND

AND

AND

AND

DATA

DATA

DATA

DATA

1

1

1

1

CHAPTER

CHAPTER

CHAPTER

CHAPTER 2.

2.

2.

2. EQUIPMENT

EQUIPMENT

EQUIPMENT

EQUIPMENT DESCRIPTION&KNOWING

DESCRIPTION&KNOWING

DESCRIPTION&KNOWING

DESCRIPTION&KNOWING YOUR

YOUR

YOUR

YOUR

AIR

AIR

AIR

AIR COMPRESSOR

COMPRESSOR

COMPRESSOR

COMPRESSOR

2

2

2

2

CHAPTER

CHAPTER

CHAPTER

CHAPTER 3.

3.

3.

3. SAFETY

SAFETY

SAFETY

SAFETY PRECAUTIONS

PRECAUTIONS

PRECAUTIONS

PRECAUTIONS

3

3

3

3

Prevention

Prevention

Prevention

Prevention from

from

from

from accidental

accidental

accidental

accidental butns

butns

butns

butns

3

3

3

3

Engine

Engine

Engine

Engine safety

safety

safety

safety precautions

precautions

precautions

precautions

3

3

3

3

Air

Air

Air

Air tank

tank

tank

tank safety

safety

safety

safety

4

4

4

4

CHAPTER

CHAPTER

CHAPTER

CHAPTER 4.

4.

4.

4. PREPARATION

PREPARATION

PREPARATION

PREPARATION BEFORE

BEFORE

BEFORE

BEFORE OPERATION

OPERATION

OPERATION

OPERATION

4

4

4

4

Air

Air

Air

Air compressor

compressor

compressor

compressor oil

oil

oil

oil

4

4

4

4

Engine

Engine

Engine

Engine oil

oil

oil

oil

4

4

4

4

F

F

F

F uel

uel

uel

uel

5

5

5

5

A

A

A

A ir

ir

ir

ir cleaner

cleaner

cleaner

cleaner

5

5

5

5

P

P

P

P ressure

ressure

ressure

ressure control

control

control

control valve

valve

valve

valve

5

5

5

5

CHAPTER

CHAPTER

CHAPTER

CHAPTER 5.

5.

5.

5. STARTING

STARTING

STARTING

STARTING THE

THE

THE

THE AIR

AIR

AIR

AIR COMPRESSOR

COMPRESSOR

COMPRESSOR

COMPRESSOR

6

6

6

6

CHAPTER

CHAPTER

CHAPTER

CHAPTER 6.

6.

6.

6. STOPPING

STOPPING

STOPPING

STOPPING THE

THE

THE

THE ENGINE

ENGINE

ENGINE

ENGINE

7

7

7

7

CHAPTER

CHAPTER

CHAPTER

CHAPTER 7.

7.

7.

7. MAINTENANCE

MAINTENANCE

MAINTENANCE

MAINTENANCE

7

7

7

7

Engine

Engine

Engine

Engine oil

oil

oil

oil change

change

change

change

7

7

7

7

A

A

A

A ir

ir

ir

ir filter

filter

filter

filter service

service

service

service

9

9

9

9

Drive

Drive

Drive

Drive belt

belt

belt

belt

9

9

9

9

C

C

C

C leaning

leaning

leaning

leaning the

the

the

the air

air

air

air compressor

compressor

compressor

compressor

10

10

10

10

S

S

S

S ediment

ediment

ediment

ediment cup

cup

cup

cup cleaning

cleaning

cleaning

cleaning

10

10

10

10

S

S

S

S park

park

park

park plug

plug

plug

plug service

service

service

service

10

10

10

10

C

C

C

C arburetor

arburetor

arburetor

arburetor adjustment

adjustment

adjustment

adjustment

11

11

11

11

P

P

P

P utting

utting

utting

utting the

the

the

the air

air

air

air compressor

compressor

compressor

compressor in

in

in

in storage

storage

storage

storage or

or

or

or transporting

transporting

transporting

transporting

11

11

11

11

CHAPTER

CHAPTER

CHAPTER

CHAPTER 8.

8.

8.

8. TROUBLESHOOTING

TROUBLESHOOTING

TROUBLESHOOTING

TROUBLESHOOTING

12

12

12

12

CHAPTER

CHAPTER

CHAPTER

CHAPTER 9.

9.

9.

9.

PART

PART

PART

PART

LISTINGS

LISTINGS

LISTINGS

LISTINGS

1

1

1

1 3

3

3

3

- 2 -

CHAPTER

CHAPTER

CHAPTER

CHAPTER 1.TECHNICAL

1.TECHNICAL

1.TECHNICAL

1.TECHNICAL SPECIFICATION

SPECIFICATION

SPECIFICATION

SPECIFICATION AND

AND

AND

AND

DATA

DATA

DATA

DATA

Technical specifications in S1 units

Technical specifications and date in English units

Item Model

TA011

Compressor

Speed (rpm)

1100

Max. pressure (MPa)

0.8

Air flow rate (m ³ /min)

0.34

Air tank capacity (L)

36

Engine

Engine Model

168F

Type

Air cooled 4-stroke25 included single cylinder

Bore × Store (mm)

68 × 45

Displacement (cc)

163

Speed (rpm)

3600

Max. power output (kw)

4.1

Ignition system

Transistoriz ed ignition (TCI)

Start mode

Recoil manual start

Fuel tank capacity (L)

3.6

Lube-oil capacity (L)

0.6

Dry weight (kg)

82

Dimension (L × W × H)

(mm)

1155 × 455 × 625

Item Model

TA011

Compressor

Speed (rpm)

1100

Max. pressure (PSI)

116

Air flow rate (cfm)

11.9

Air tank capacity (USgal)

9.51

Engine

Engine Model

168F

Type

Air cooled 4-stroke25 included single cylinder

Bore × Store (in.)

2.68 × 1.77

Displacement (cu.in)

9.95

Speed

3600

Max. power output (HP)

5.5

Ignition system

Transistoriz ed ignition (TCI)

Start mode

Recoil manual start

Fuel tank capacity (USgal)

0.95

Lube-oil capacity (OZ.)

20.25

Dry weight (lbs)

181

Dimension (L × W × H)

(in)

45.5 × 17.9 × 24.6

- 3 -

CHAPTER

CHAPTER

CHAPTER

CHAPTER 2.EQUIPMENT

2.EQUIPMENT

2.EQUIPMENT

2.EQUIPMENT DESCRIPTION

DESCRIPTION

DESCRIPTION

DESCRIPTION &

&

&

& KNOWING

KNOWING

KNOWING

KNOWING

YOUR

YOUR

YOUR

YOUR AIR

AIR

AIR

AIR COMPRESSOR

COMPRESSOR

COMPRESSOR

COMPRESSOR

Please read this manual and follow the procedures covered in this manual. Become familiar with

the air compressors functions, applications and limitations.

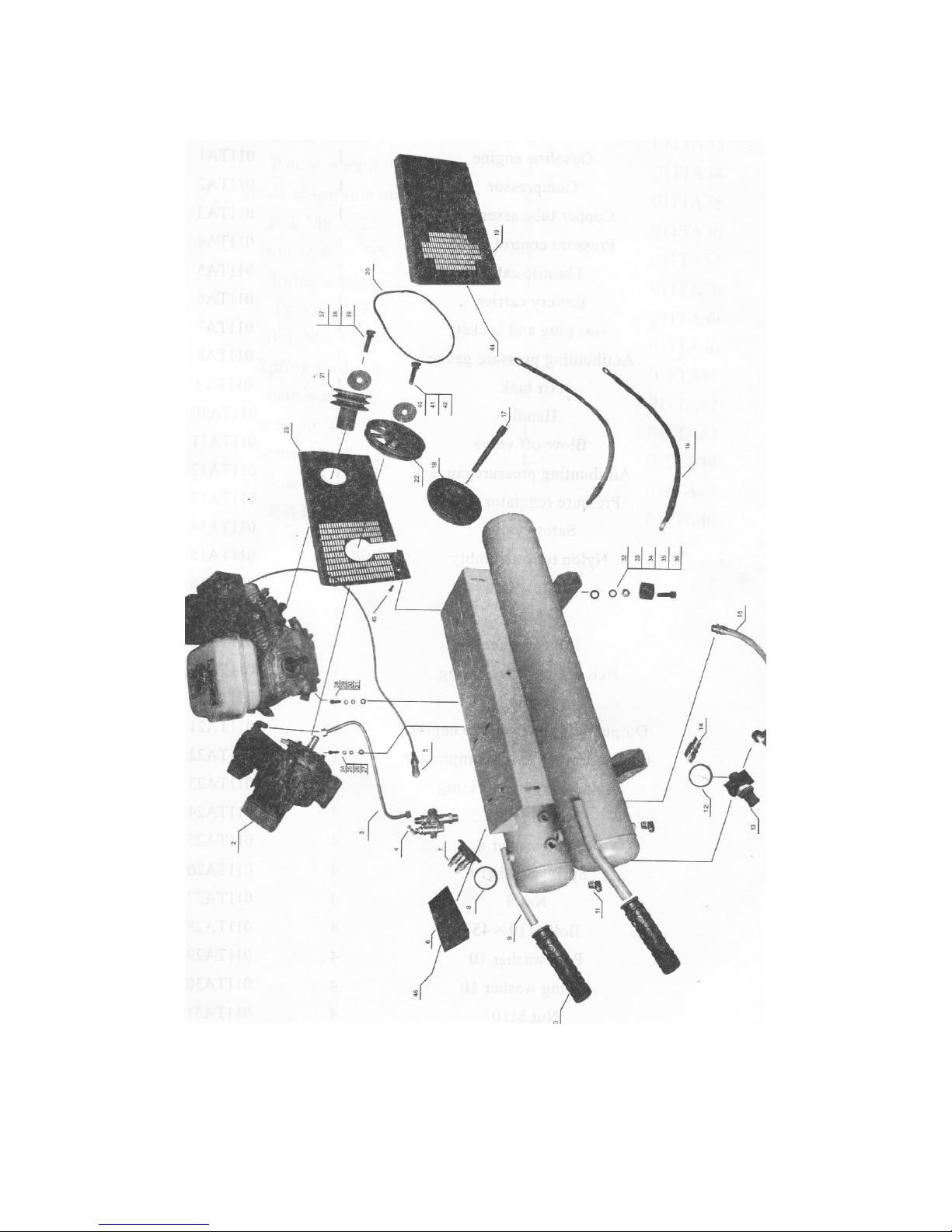

Below is diagram of the locations of the various controls and functions of the

air

compressor.

WARING: DO NOT exceed the air compressors tank capacity. The tank has a factory preset

pressure release valve. Changing the settings on this valve will void your warranty and we assume

no responsibility for accidents and injuries resulting from user modifications.

Our products are continuously being changed and improved. Every effort has been made to ensure

that information in this manual is accurate and up to date. However, we reserve the right to change,

alter or otherwise improve the product and this manual at a ny time without prior notice.

- 4 -

CHAPTER

CHAPTER

CHAPTER

CHAPTER 3.SAFETY

3.SAFETY

3.SAFETY

3.SAFETY PRECAUTIONS

PRECAUTIONS

PRECAUTIONS

PRECAUTIONS

In order to ensure safety for the consumer, please carefully follow instruction on being careful with

the air compressor.

Never operate the

air

compressor without the belt guard. Failing to do so can lead to serious

injuries as objects may get caught in the belt.

Keep visitors away and never allow children in the work area.

Operate the compressor ONLY outdoors. Never run the compressor indoors as the engine gives off

poisonous carbon monoxide, an odorless and colorless gas. Inhaling carbon monoxide will cause

nausea, fainting or death. Also, keep the

air

compressor at least 3 feet away from flammable matter

for adequate ventilation.

Wear

safety glasses and wear hearing protection when operating the unit.

Always inspect the unit for damage before operating the unit. Inspect the engine for oil leaks or

possible deterioration.

Check all fasteners for proper tightness at frequent intervals.

Do not wear loose clothing or jewelry as it can get caught in the moving mechanical parts of the

air

compressor. Also keep all fingers and other body parts away from the compressor as it may get

caught in the moving mechanical parts.

PREVENTION

PREVENTION

PREVENTION

PREVENTION FROM

FROM

FROM

FROM ACCIDENTAL

ACCIDENTAL

ACCIDENTAL

ACCIDENTAL BURNS

BURNS

BURNS

BURNS

Nevertouch the muffler and its cover when the engine is running. Never touch the muffler and

cover after the engine has been used, as the muffler remains hot for a good period of time.

T he discharge tube from the

air

compressortothe tank gets hot during operation, do not touch the

tube during operation.

ENGINE

ENGINE

ENGINE

ENGINE SAFETY

SAFETY

SAFETY

SAFETY PRECAUTIONS

PRECAUTIONS

PRECAUTIONS

PRECAUTIONS

Do not touch hot surfaces. Allow equipmenttofully cool down before touching.

- 5 -

After the air compressor has been run, the engine produces heat. The temperatures of the muffler

and nearby area can reach or exceed 160 ° F.Severe burns will occur on contact with skin.

Do not modify the

air

compressor in any way. The

air

compressor supplies the rated pressure and

rated airflow at its governed speed.

AIR TANK SAFETY

Do not attempt

to

adjust the safety valve. Also, never attempt

to

repair or modify a tank. The

fabrication involved in modifications of the tank will weaken the tank. Always replace worn,

cracked, or damaged tanks.

Operate the

air

compressor on level surfaces only. Inclined surfaces reduce the effective lubrication

of the engine.

Do not expose the

air

compressortoexcessive moisture, dust, dirt, or corrosive vapors.

CHAPTER

CHAPTER

CHAPTER

CHAPTER 4.PREPARATION

4.PREPARATION

4.PREPARATION

4.PREPARATION BEFORE

BEFORE

BEFORE

BEFORE OPERATION

OPERATION

OPERATION

OPERATION

Before starting the

air

compressor, verify the following conditions.

AIR

AIR

AIR

AIR COMPRESSOR

COMPRESSOR

COMPRESSOR

COMPRESSOR OIL

OIL

OIL

OIL

●

Verify

that

air

compressor head is filled with 10W-30 viscosity oil. Running the

air

compressor without oil will cause severe damage

to

the air compressor head

ENGINE

ENGINE

ENGINE

ENGINE OIL

OIL

OIL

OIL

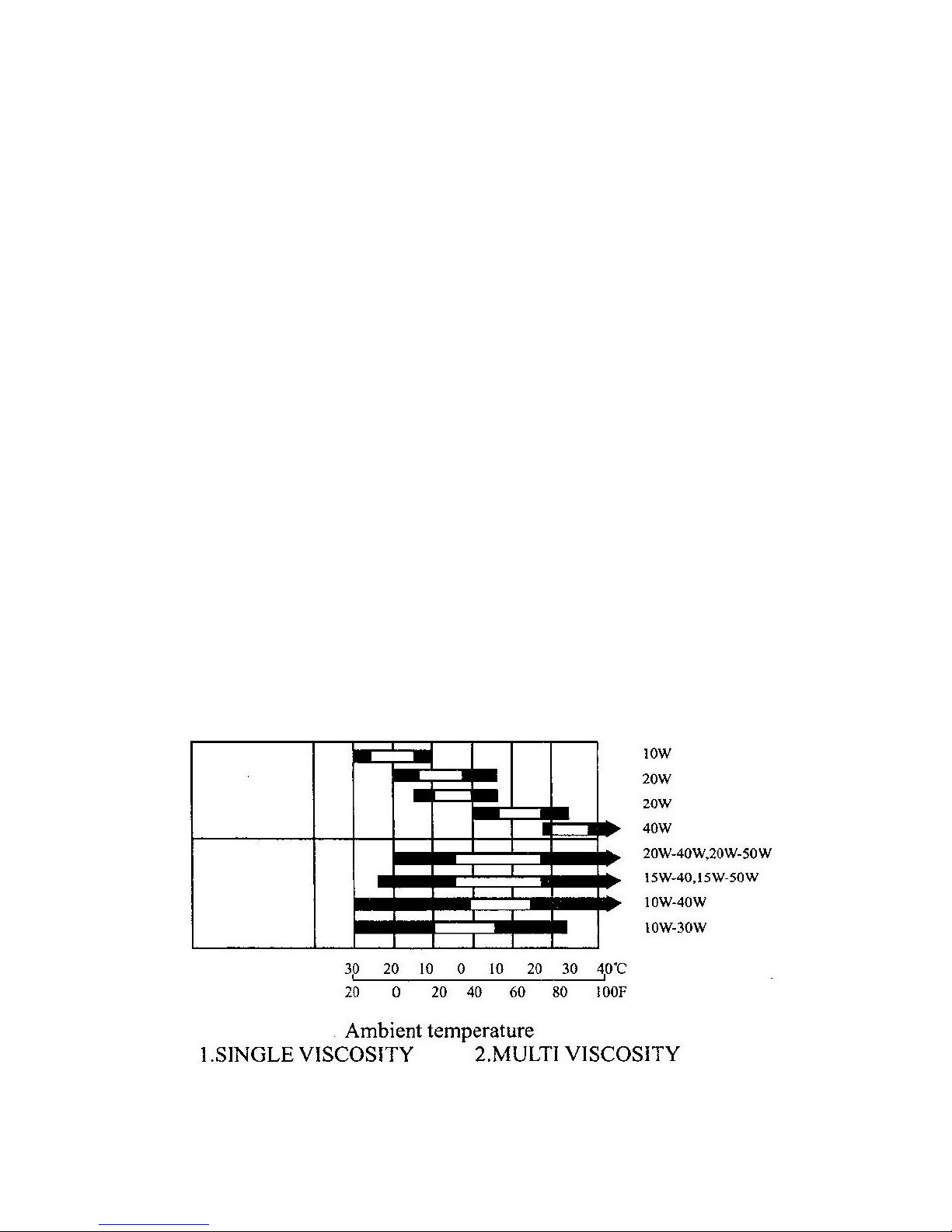

● Fill the engine with SAE 10W-30 engine oil for general use or follow the table below.

- 6 -

● Make sure the

air

compressor is on a level surface and make sure the oil dipstick is on

tight.

FUEL

FUEL

FUEL

FUEL

● Add gasoline and never fill the fuel tank indoors. Also, be sure

to

install the fuel tank cap

on tight after filling.

● DO NOT overfill the fuel tank. Always allow room for fuel expansion.

● Never fill the fuel tank when the engine is running or hot . Allow the unittocool for two

minutes before refueling. DO NOT light a cigarette or smoke when filling the fuel tank.

AIR

AIR

AIR

AIR CLEANER

CLEANER

CLEANER

CLEANER

● Remove the wing nut holding down ● Reinstall the

air

cleaner element

the air cleaner cover and secure the cover by setting

● Remove the

air

cleaner cover and the cover spring

airfilter

● Check the air cleaner element

to

PRESSURE

PRESSURE

PRESSURE

PRESSURE CONTROL

CONTROL

CONTROL

CONTROL

VALVE

VALVE

VALVE

VALVE

be sure they are clean and in

good condition . ● Put the control valve is in the up

position before starting the air

compressor .

● If the

air

filter is

dirty,

remove

and clean the element

● W ash in solvent

● Squeeze

● Soak oil

● Squeeze dry

- 7 -

CHAPTER

CHAPTER

CHAPTER

CHAPTER 5.STARTING

5.STARTING

5.STARTING

5.STARTING THE

THE

THE

THE AIR

AIR

AIR

AIR COMPRSSOR

COMPRSSOR

COMPRSSOR

COMPRSSOR

Turn the fuel valve

to

the ON position Turn the engine switch

to

the ON

p osition. With the recoil starter, pull the

h andle fast.

Move the choke levertothe CLOSED Gradually move the choke lever to

position. OPEN position when the engine

Note: If the engine is warm or the

air

up.

Temperature is high, do not use the choke

Move the throttle control lever slightly

to

Adjust the throttle control lever

the left. until you reach the desired speed.

- 8 -

CHAPTER

CHAPTER

CHAPTER

CHAPTER 6.STOPPING

6.STOPPING

6.STOPPING

6.STOPPING THE

THE

THE

THE ENGINE

ENGINE

ENGINE

ENGINE

I n the event of an emergency, turning the engine switch

to

the “ off ” position can stop the engine.

Under regular conditions, follow these procedures

● Shift the throttle lever fully

to

the right.

● Turn the engine switch

to

the off position.

● Turn the fuel valve

to

the off position.

Note:

Note:

Note:

Note: When

When

When

When operating

operating

operating

operating your

your

your

your engine

engine

engine

engine in

in

in

in high

high

high

high altitudes,

altitudes,

altitudes,

altitudes, the

the

the

the fuel

fuel

fuel

fuel air

air

air

air mixture

mixture

mixture

mixture may

may

may

may be

be

be

be

affected

affected

affected

affected by

by

by

by the

the

the

the high

high

high

high altitude

altitude

altitude

altitude condition.

condition.

condition.

condition. In

In

In

In high

high

high

high altitudes,

altitudes,

altitudes,

altitudes, performance

performance

performance

performance is

is

is

is

decreased

decreased

decreased

decreased and

and

and

and fuel

fuel

fuel

fuel consumption

consumption

consumption

consumption is

is

is

is increased.

increased.

increased.

increased. Please

Please

Please

Please consult

consult

consult

consult with

with

with

with your

your

your

your local

local

local

local

dealer

dealer

dealer

dealer for

for

for

for details

details

details

details on

on

on

on adjusting

adjusting

adjusting

adjusting your

your

your

your engine

engine

engine

engine high

high

high

high altitude

altitude

altitude

altitude conditions.

conditions.

conditions.

conditions.

P ull the recoil handle slowly until pressure is felt by your hand, this means the piston is on the

compression stroke; where the intake and exhaust valves are closed and then let the handle recoil

back into the engine. This natural position will prevent ru st from occurring when the engine is

being stored for long periods of time.

Note: Only perform step 5 when the engine is off. Doing so otherwise will damage the engine.

CHAPTER

CHAPTER

CHAPTER

CHAPTER 7.MAINTENANCE

7.MAINTENANCE

7.MAINTENANCE

7.MAINTENANCE

AIR

AIR

AIR

AIR COMPRESSOR

COMPRESSOR

COMPRESSOR

COMPRESSOR

Check the oil level of both the engine and

air

compressor head daily before operating the

air

compressor.

ENGINE

ENGINE

ENGINE

ENGINE OIL

OIL

OIL

OIL CHANGE

CHANGE

CHANGE

CHANGE

Engine oil is a critical factor in determining the life of your engine. Change the engine oil on time.

Change the engine oil more frequently if the engine is used in dusty areas.

Changing the oil while the engine is still warm will yield best results for the engine.

When the oil is still warm, you get rapid and complete draining of the oil.

Oil change procedures

1. Remove the oil filler cap and drain plug

to

drain the oil.

2. Install the drain plug, and tighten it securely.

- 9 -

3. Refill with the recommended oil and check the oil level.

4. Install the oil filler cap.

The engine oil capacity is .60 liters or .16 gallons.

The gear oil capacity of the 1/2 reduction is .50 liters or .13 gallons.

The gear oil capacity of the 1/6 reduction is .15 liters or .03 gallons.

Note: Do not touch motor oil for long periods of time. Used motor can cause skin cancer if it comes

in contact with the skin for prolonged periods of time. Getting cancer from used motor oil is

unlikely unless you handle used motor oil on a day basis.

To

be safe always wash your hands

thoroughly with soap and water as soon as possible after handing used oil.

Below a maintenance schedule.

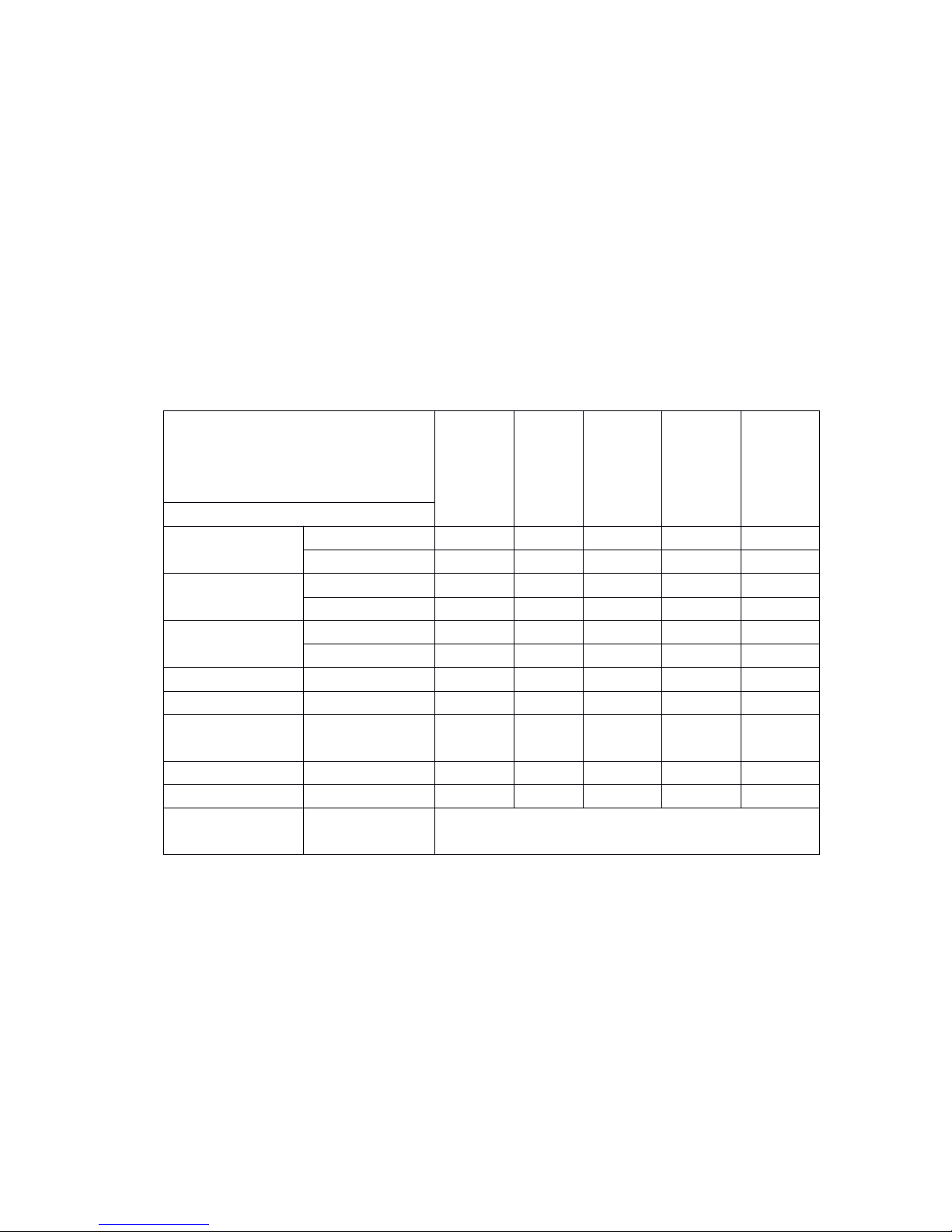

REGULAR SERVICE PERIOD

Performed at every indicated

month or operating hour interval,

whichever comes first

Each use

First

month

or

20 Hrs.

Every

3 month

or

50 Hrs.

Every

6 month

or

100 Hrs.

Every

year

or

300 Hrs.

ITEM

Engine oil

C heck level

0

C hange00

Reduction gear oil

(applicable model only)

C heck level

0

C hange

0

Air cleaner

C heck level

0

C lean

0 (1)

Sediment cup

Clean

0

Spark plug

Check-clean

0

Spark arrester

(optional part)

Clean

0

Valve

clearance

Check-Adjust

0 (2)

Fuel tank and strainer

Clean

0 (2)

Fuel line

Check

(Replace if necessary)

Every 2 year (2)

- 10 -

AIR

AIR

AIR

AIR FILTER

FILTER

FILTER

FILTER SERVICE

SERVICE

SERVICE

SERVICE

A

dirty or clogged air filter will prevent

air

fro, flowing freely in

to

the carburetor assembly. Always

keep the air filter clean or replace if necessary. Also, if the

air

filter is dirty or clogged, the

performance of the engine goes down. If operating the engine in a dusty area, service the

air

filter

more frequently as dust particles will clog the filter at a faster rate. Never run the engine without an

air

filter, dust particles may get into the intake system and damage the engine. Rapid engine wear

will occur if the engine is run without the

air

filter.

Do not w a sh the airfilter if it is the paper type. Also, never use the gasoline

to

wash

air

filter

elements because gasoline is highly flammable and dangerous.Afire or explosion could occur.

Instructions on changing the

air

filter

● Take the wing nut off and remove the

air

filter cover. Remove the elements and separate

them. Check the elements for tears and holes. If holes or tears are present, replace the

air

filter elements.

● The foam element can be washer. W arm water and household detergent will work fine

for washing the foam filter element. After washing, rinse it thoroughly with water and

allow the elementtodry. Soak the element in clean engine oil and squeeze the oil out. If

these is too much oil left in foam element, the engine will smoke during startup

●

Tap

lightly several times on a hand surface

to

remove excess dirt from the paper filter.

Never brush on the paper clement as this just forces more dirt into the paper element. Use

compressed airtoblow from the inside ourtoremove the excess dirt.

DRIVEBELT

DRIVEBELT

DRIVEBELT

DRIVEBELT

Belts will stretch in normal use.Aproperly adjusted belt will deflect 1/2 inch with a 5 pound force.

To

adjust the belt tension, follow the procedures below.

● Remove the belt guard

● Loosen the four fasteners holding the engine

to

the base-plate.

● Shift the engine in the proper direction so that the desired tension is achieved.

● Align the belt and pulleys before tightening down the engine.

- 11 -

CLEANING

CLEANING

CLEANING

CLEANING THE

THE

THE

THE AIR

AIR

AIR

AIR COMPRESSOR

COMPRESSOR

COMPRESSOR

COMPRESSOR

Air compressor maintenance consists of keeping the unit clean and dry. Be sure

to

store the unit in a

clean and dry environment, where it will not be exposed

to

excessive dust, dirt, moisture or any

corrosive vapors. Cooling slots should always be clean and free from clogs.

Note: Do not use a garden hose

to

clean the air compressor.

Water

can enter the fuel and intake

system and cause problems.

●

To

cle a n the air compressor, use a damp cloth

to

wipe the exterior surface.

● Use a soft bristle brush

to

loosen caked on dirt of oil .

● Use a vacuum cleanertopick up loose dirt and debris.

● Compressed air (nottoexceed 25psi) may be used

to

blow away dirt.

SEDIMENT

SEDIMENT

SEDIMENT

SEDIMENT CUP

CUP

CUP

CUP CLEANING

CLEANING

CLEANING

CLEANING

Turn the fuel valve off a nd remove the sediment cup with the O-ring. Wash them thoroughly in

non-flammable solvent. Dry them thoroughly and reinstall them tightly. Turn the fuel valve ON

and look for leaks.

Note: Try nottospill fuel, if the fuel is spilled, clean the area first before starting the engine. The

engine will create a spark when started, so if there is fuel around, it may ignite the fuel causing a

serious fire or explosion.

SPARK

SPARK

SPARK

SPARK PLUG

PLUG

PLUG

PLUG SERVICE

SERVICE

SERVICE

SERVICE

● Remove the wire from the spark plug.

● Use a deep socket or spark plug sockettoremove the spark plug.

● Check for mechanical damage and or carbon buildup.

● If the spark plug is fouled, replace spark plug with new one.

● Spark plugs may come pre gapped, if not an ordinary gap of. 7mm or.028 inches would

do just fine.Tofix a gap, bead the side of the electrode with a spark plug gapping tool.

Note: Make sure the replacement spark plug is in the correct heat range. An incorrect heat range

spark plug can damage your engine. Also, never tough the muffler during or after the engine has

been run.

● Make sure the spark plug washer is in good condition or brand-new.

● Threat the spark plug in by hand first before using a tool. This will prevent stripping the

threads on the cylinder head assembly and the spark plug.

- 12 -

● After the spark plug has seated, tighte n the spark plug with a spark plug wrench

to

compress the washer.

Note: For new spark plugs, tighten an extra1/2 turn after the spark plugs seats

to

compress the

washer. If installing a used spark plug; tighten 1/8-1/2 turn. The spark plug must be securely

tightened, or the spark plug can become very hot and damage the engine.

CARBURETOR

CARBURETOR

CARBURETOR

CARBURETOR ADJUSTMENT

ADJUSTMENT

ADJUSTMENT

ADJUSTMENT

● Start the engine and allow ittowarm up.

● While the engine is idling, turn the pilot screw in or outtothe setting that produces the

highest speed.

Note: Be careful nottotighten the pilot screw against its seat. Tightening the pilot screw against its

seat will damage the seat.

● When the pilot screw is adjusted correctly, turn the throttle stop screw

to

achieve the

standard idle speed; which is about 1,400 100rpm.

PUTTING

PUTTING

PUTTING

PUTTING THE

THE

THE

THE AIR

AIR

AIR

AIR COMPRESSOR

COMPRESSOR

COMPRESSOR

COMPRESSOR IN

IN

IN

IN STORAGE

STORAGE

STORAGE

STORAGE OR

OR

OR

OR

TRANSPORTING

TRANSPORTING

TRANSPORTING

TRANSPORTING

Please follow these instructions before storing your engine.

● Clean the storage area.

● Drain the fuel into a suitable container.

● Remove the sediment cup and clean thoroughly

● Replace the sediment cup and tighten securely.

● Drain the fuel from the carburetor by loosening the dialing scram. Drain the fuel into a

suitable container.

Note: Do not smoke near gasoline. Also do not allow flames or sparks near gasoline because

gasoline is extremely flammable.

● Chang the engine oil while engine is still warm.

● Take the spark plug out and put some oil into the combustion chamber. Then use the recoil

starter and crank the engine a few times

to

mix the oil around in the chamber. Put the spark

plug back on being careful nottostrip the threads.

● Pull the starter rope until resistance is felt. This is when the intake and exhaust valves are

closed and the piston is on the piston is on the compression stroke.

- 13 -

CHAPTER

CHAPTER

CHAPTER

CHAPTER 8.TROUBLESHOOTING

8.TROUBLESHOOTING

8.TROUBLESHOOTING

8.TROUBLESHOOTING

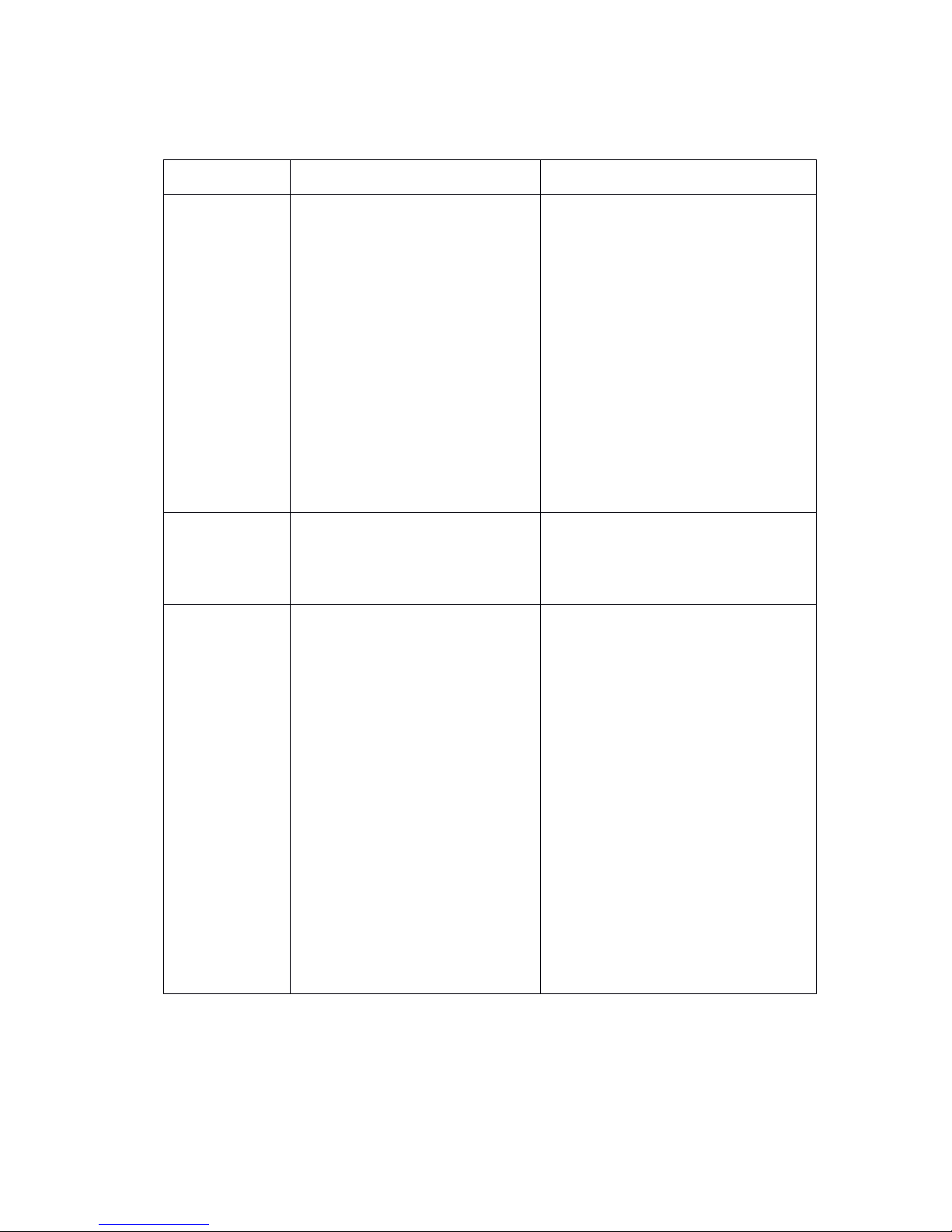

Symptom

Probable cause

Corrective Action

Low discharge

pressure

1.

Air demand exceeds pump

capacity.

2.

Leaking air

3.

Restricted

air

intake

4.

Blown gaskets

5.

Leaking or damaged valves

1.

Decrease

air

demand or use a larger

capacity

air

compressor

2.

Listen for high pitched escaping air.

Apply soap solution to all fittings and

connections. Bubbles will appear at

points of leakage. Tighten or replace

leaking fittings or connections.

3.

Clean

air

filter element.

4.

Replace faulty gaskets.

5.

Remove head and inspect for valve

breakage, misaligned valves,

damaged valve seats, etc. Replace

defective parts and reassemble.

Pump

overheating and

damaging air

filter.

1.

Insulating gasket between filter

and head is missing.

2.

Brolen valves blown gasket.

1.

Install gasket.

2.

Replace valves or install new gaskets.

Excessive noise

or abnormal

noise

1.

Loose motor or losse pulley.

2.

Low oil in crankcase

3.

Worn connecting rods

4.

Worn piston pin

5.

Piston hitting valve plate

6.

Noisy check valve.

1.

Tighten engine mount bolts and

pulley setscrews.

2.

Refill oil to the proper level. Also, if

always

low,

check for possible

damage to bearings or oil leaks.

3.

Replace connecting rod. Maintain oil

level and change oil more frequently.

4.

Remove old piston pin, measure abd

verify specifications are within limits.

If not, replace piston pin and replace

oil more frequently.

5.

Remove the compressor head and

valve plate for carbon deposits or

other foreign objects. Replace the

head and valve plate and use a new

gasket.

6.

Replace.

- 14 -

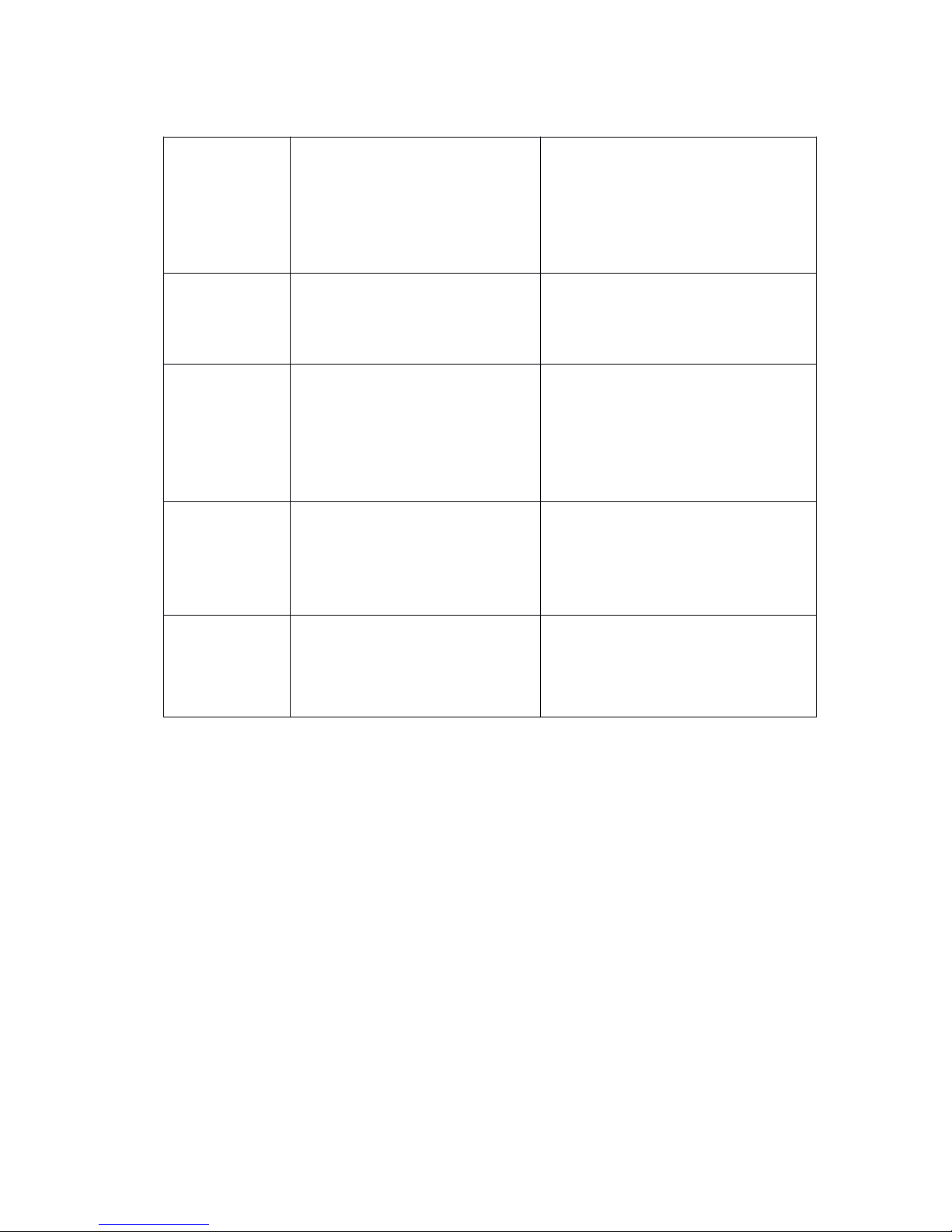

Note: Please refer to the engine owner’s manual for troubleshooting with the engine.

Large quantities

of oil in air

supply

1.

Worn piston rings.

2.

Air intake clogged

3.

Oil level in compressor head to

high

4.

Wrong oil viscosity

1.

Replace with new rings.

2.

Clean

air

filter

3.

Drain some of the oil.

4.

Use 10W - 30

Water in

D ischarge air.

1.

Water

increases with humid

weather

1. Drain tank daily.

2. Add a filter to reduce the amount of

water in the air line

Tank does not

hold pressure

when compressors

off and shut off

valve is closed.

1.

Worn check valve

2.

Check all connections and

fittings for leaks.

3.

Check tank for cracks or pin

hoies.

1.

Repiace check valve

2.

Tighten

3.

Repiace tank. Never repair a

damaged tank.

Excessive

vibration

1.

Loose fasteners

2.

Belt need replacement.

3.

Belt alignment

1.

Tighten

2.

Replace with correct size

3.

Align engine and air compressor

pulleys.

Pressure switch

continuously

blows air out the

unloader valve

1. Malfunctioning check valve

1. replace the check valve if the unloader

valve bleeds off constantly

- 15 -

CHAPTER

CHAPTER

CHAPTER

CHAPTER 9.PART

9.PART

9.PART

9.PART LISTINGS

LISTINGS

LISTINGS

LISTINGS

- 16 -

Number

Number

Number

Number

Part

Part

Part

Part Description

Description

Description

Description

Qty

Qty

Qty

Qty

Part

Part

Part

Part Number

Number

Number

Number

1

Gasoline engine

1

011TA1

2

Compressor1011TA2

3

Copper tube assembly

1

011TA3

4

Pressure control

Valve

1

011TA4

5

Throttle cable1011TA5

6

Battery carrier

1

011TA6

7

Gas plug and socket

1

011TA7

8

Antihunting pressure guage

1

011TA8

9

Air tank1011TA9

10

Handle1011TA10

11

Blow-off valve

1

011TA11

12

Antihunting pressure gauge

1

011TA12

13

Pressure regulator

Valve

1

011TA13

14

Safety

Valve1011TA14

15

Nylon tube assembly

1

011TA15

16

Battery line2011TA16

17

Axle1011TA17

18

Rubber wheel

1

011TA18

19

Belt pulley outer casing

1

011TA19

20

Strap1011TA20

21

Output belt pully of the engine

1

011TA21

22

Belt pulley of the air compressor

1

011TA22

23

Belt pulley inner casing

1

011TA23

24

Bolt M8 × 33.54011TA24

25

Pain washer 84011TA25

26

Spring washer 8

4

011TA26

27

Nut 84011TA27

28

Bolt M10 × 454011TA28

29

Pain washer 10

4

011TA29

30

Spring washer 10

4

011TA30

31

Nut 104011TA31

32

Acorn nut 184011TA32

- 17 -

Number

Number

Number

Number

Part

Part

Part

Part Description

Description

Description

Description

Qty

Qty

Qty

Qty

Part

Part

Part

Part Number

Number

Number

Number

33

Spring washer 8

4

011TA33

34

Pain washer 84011TA34

35

Shock absorption mat

4

011TA35

36

Bolt M8 × 254011TA36

37

Bolt 7/16 ”× 25

1

011TA37

38

Spring washer

1

011TA38

39

Pain washer1011TA39

40

Bolt M8 × 351011TA40

41

Spring washer 8

1

011TA41

42

Pain washer 81011TA42

43

Split pin 4 × 35

1

011TA43

44

Screw M8 × 121011TA44

45

Bolt M8 × 201011TA45

46

Bolt M8 × 121011TA46

Loading...

Loading...