GemWave™

C220 Chip & Medio L120/L121

Technical Description

Version 1.0

GEMPLUS

March 22 2000

C220 Chips & L120/L121 Couplers - Technical Description

Version 1.0

CONTENTS

GEMWAVE L120/L121 SMART TRACKING ........................................................................ 2

1 THEORY OF OPERATION................................................................................................... 2

2 COMPARISON WITH LOW FREQUENCY SYSTEMS .................................................................... 4

3 GEMWAVE SMART LABELS............................................................................................... 4

4 GEMWAVE ANTENNAS..................................................................................................... 5

4.1 Antenna field regions ............................................................................................ 6

4.2 External loop antenna (Standard) ........................................................................... 7

4.3 Dual polarized loop antenna.................................................................................. 7

4.4 Truck mounted loop antenna................................................................................. 8

4.5 AC206 Metal mounted antenna.............................................................................. 8

5 GEMWAVE MEDIO L120/L121 COUPLERS ........................................................................ 9

51 Coupler functions.................................................................................................. 9

5.2 System construction ...........................................................................................10

53 RF Section ..........................................................................................................10

54 CPU Section .......................................................................................................13

5.5 Power Supply......................................................................................................16

GEMWAVE C220 & L120/L121 SMART TRACKING

The GemWave Smart Tracking system offers extremely low cost smart labels for

use in shorter read range high volume areas such as library book identification,

transport and logistical labels, waste management etc. Read range is limited to

around 500-mm but the system offers very high read rates (up to 70 times per

second) making it ideal for use on high speed production lines.

Standard Features for these systems include:

• Low Cost Smart Labels

• High Read Speed

• High immunity to industrial noise

• Full I/O capabilities

• Networking capabilities

1 Theory of operation

The operation of the system can be explained by considering the three major

components of the system. These are the coupler, the antenna and the smart

label.

GEMPLUS COMPANY CONFIDENTIAL Page 2

C220 Chips & L120/L121 Couplers - Technical Description

P

P

P

P

k

Q

Q

Version 1.0

When a smart label is to be read, the coupler transmits an electromagnetic

signal to the labels via the antenna(s). Some of the transmitted energy is incident

on the label, some of this RF (AC) energy is then rectified into a DC level and

used to power the microchip while the remainder is used to carry the smart

label’s unique code back to the coupler.

The process of superimposing the smart labels unique code onto the carrier

frequency is referred to as modulation.

In total, 128 bits1 are transmitted including error detection information, taking a

typical time of 2.4 or 1.2ms (for long and short modes respectively). This data is

picked up by the antenna and decoded. The decoding process occurs in real

time in order to maximize the multiple label reading capabilities of the

L120/L121 couplers.

The power transfer mechanism between the smart label and the coupler is quite

unique and is worthy of a brief discussion. It can easily be shown that the power

transfer ratio of a near field interrogation system is given by

r

2

k QQ

t

t r=

Where

r is the power received by the smart label.

t is the power transmitted by the antenna.

is the coefficient of coupling.

r is the quality factor of the smart label antenna.

t is the quality factor of the transmit antenna.

Thus in order to maximize the received power within the smart label the quality

factors of both the interrogator and the smart label antennas should be made as

high as possible. Practical limitations to this include allowing enough bandwidth

to pass the reply sidebands and the susceptibility of the antenna to detuning due

to environmental influences.

Furthermore, in this type of system, a signal power fall off of approximately

60.log(distance) applies. This implies that the field strength is high in the

immediate vicinity of the antenna but a very low level exists in the far field, hence

well confined interrogation regions can be easily created. Under these

conditions, it can be shown that sixty four times more input power to the antenna

is required to double the read range.

When specifying GemWave C220 systems, it is important to keep in mind the

vortex nature of magnetic fields. This implies always ensuring an adequate path

for the field to circulate. It is also equally important to have a clear understanding

of the field patterns produced by these antennas to ensure that the smart labels

are in the correct orientation to read. For the best performance, the smart labels

GEMPLUS COMPANY CONFIDENTIAL Page 3

C220 Chips & L120/L121 Couplers - Technical Description

Version 1.0

must always have their coil perpendicular to the direction of the field. If the smart

label is placed parallel to the field it will receive no power and will not work.

2 Comparison with low frequency systems

At these relatively low frequencies (13.56 MHz) there are several operational

characteristics that make these systems attractive for many applications.

Perhaps, the most significant of these is cost. Since at these frequencies all the

necessary components have been completely integrated into the proprietary

microchip, the smart label production costs are kept to a minimum. The next

most important characteristic of this frequency is that it allows much faster data

rates than its lower frequency counterparts.

The sub carrier modulation on the GemWave C220 chip allows greater than 70

reads per second to be achieved compared to 10 for our lower frequency

competitors.

Further advantages include the relative immunity to attenuation by non-metallic

objects placed in the interrogation path and the inherent hard cut off that ensures

the interrogation field is clearly defined.

Whilst being low enough in frequency not to be impaired by environmental

hazards that degrade the performance of UHF systems (such as water), HF

frequencies are considered to be high enough to be less susceptible to man

made noise due to motors, welding equipment, computers etc. that plague low

frequency systems often to the point of rendering them useless.

3 GemWave C220 Smart Labels

One of the major advantages of working in the 13.5MHz ISM band is the level of

integration possible in the smart labels. The tag antenna is less complex than for

the lower frequency systems because the value of inductance required to

resonate the tag decreases with increasing frequency. The tuning capacitor can

be integrated, which is impossible (or least uneconomical) at lower frequencies.

Low power semiconductor processes have not yet reached a level where UHF

tags can be completely integrated2, mainly due to efficiency of the rectifiers at

these frequencies.

There is a wide range of standard GemWave tags available for these systems

that are suitable for use in a variety of applications. These are presented in the

various GEMPLUS GemWave Marketing information sources.

Of the several GemWave chips we are concentrating on the proprietary

GemWave C220 chip, which not only features completely integrated rectifiers,

modulators and tuning capacitors but also contains a 128-bit EEPROM cell that

GEMPLUS COMPANY CONFIDENTIAL Page 4

C220 Chips & L120/L121 Couplers - Technical Description

MODULATOR

FSK OSCILLATOR

DC GENERATION

EEPROM

Lantenna

Cantenna

Cchip

C220

MEMORY

ANTENNA

Version 1.0

allows contactless programming. A simplified block diagram of a complete

C220 smart label is shown in Figure 1.

Figure 1: Simplified block diagram of a GemWave C220 Smart label

The GemWave C220 chip uses a Differential Frequency Shift Keyed (DFSK)

sub carrier where a logic “0” forces a change in frequency of the sub carrier

oscillator. This gives the chip excellent performance in noisy environments typical

for industrial installations.

The need for error correction and detection means that only 733 out of 128 bits

are available for use by the customer during programming.

It is important to realize that the maximum read range that can be achieved with

these systems is a function of the smart label size and antenna size, their relative

positions to each other and the power available at the antenna.

It should be noted that C220 based smart labels are not suitable for extreme high

temperature applications due to the temperature limitations of the microchip’s on

board EEPROM memory.

4 GemWave antennas

GemWave antennas use the current flowing in the antenna inductor to produce

the AC magnetic field that is used to power the smart labels. It is important with

these systems to always ensure an adequate path for this field to circulate. This

implies that if either the smart label or the antenna is to be mounted on or near

metal to ensure that the coil is always perpendicular to the metal.

In some circumstances, it is necessary to tune the antennas at the time of

installation since the environment cannot always be predicted at the time of

GEMPLUS COMPANY CONFIDENTIAL Page 5

C220 Chips & L120/L121 Couplers - Technical Description

Version 1.0

manufacture. However most of the time the antenna will perform adequately as

long as care is taken with respect antenna installation.

A wide variety of antennas suitable for GemWave systems have been developed

because of the wide range of applications for this technology requiring different

antenna configurations. The Professional Services Team at GEMPLUS is

always prepared to discuss antenna(s) for your applications.

It should be noted that GEMPLUS is currently in the process of reviewing an

antenna tuning aid that will soon be made available to our customers for these

systems. This will allow antennas to be tuned by customers with inexpensive test

equipment.

4.1 Antenna field regions

The field created by GemWave antennas can be considered to be relatively

omnidirectional. However, the field is more concentrated is certain regions and

smart label orientation with respect to the antenna is important to ensure

optimum performance.

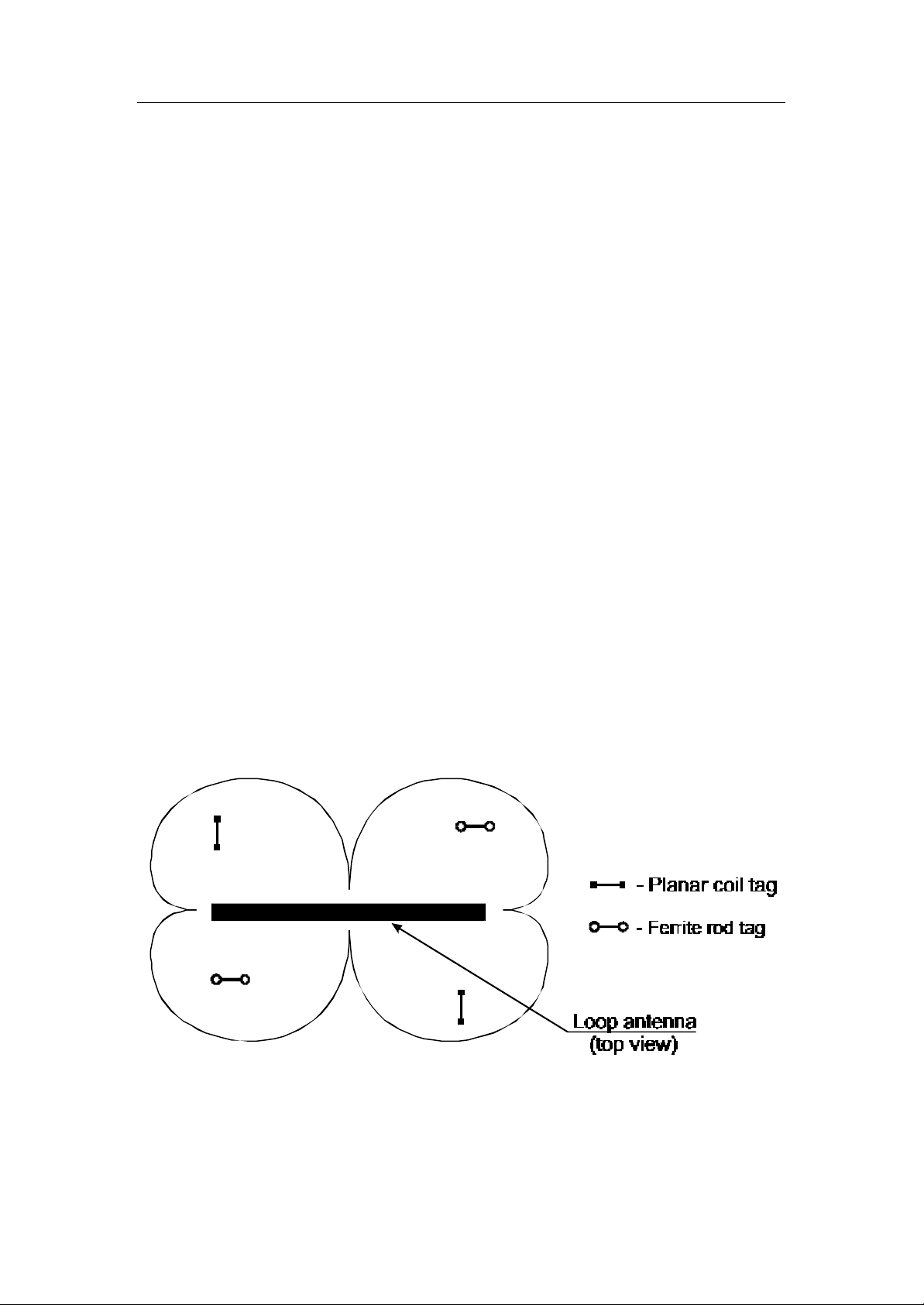

If it is accepted that the field is circulating around the conductors of the antenna,

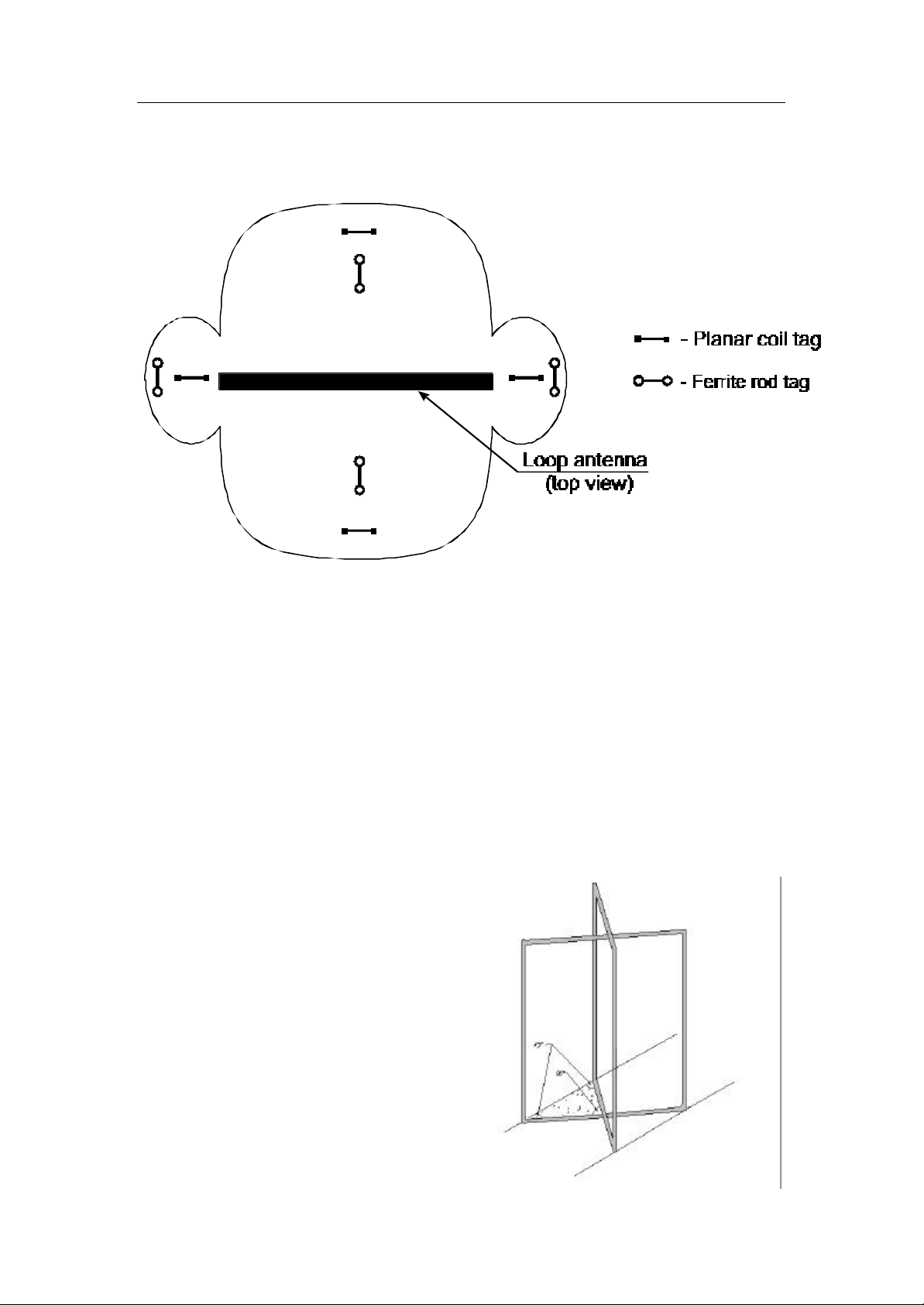

then Figure 2 and Figure 3 show the regions of space where the field will be able

to excite a smart label in different orientations. (i.e. the points at which the

magnetic field will be at ninety degrees to the smart label’s coil)

The field regions shown in Figure 2 will give a shorter read range than the

regions in figure 3, however, this orientation can be useful in certain applications.

Figure 2: Field regions for a planar loop antenna for non-optimum smart label

presentation

GEMPLUS COMPANY CONFIDENTIAL Page 6

C220 Chips & L120/L121 Couplers - Technical Description

Version 1.0

An example of a planar coil smart label is a Folio20 and an example of a ferrite

rod smart label is a TC251.

Figure 3 : Field region s for a planar loop antenna for optimum smart label

presentation

4.2 AC201, AC202 and AC212 loop antennas

This range of standard antennas available with GemWave L120 and L121

systems provide a good range of size and performance options. Please refer to

the Data sheet for each of these devices.

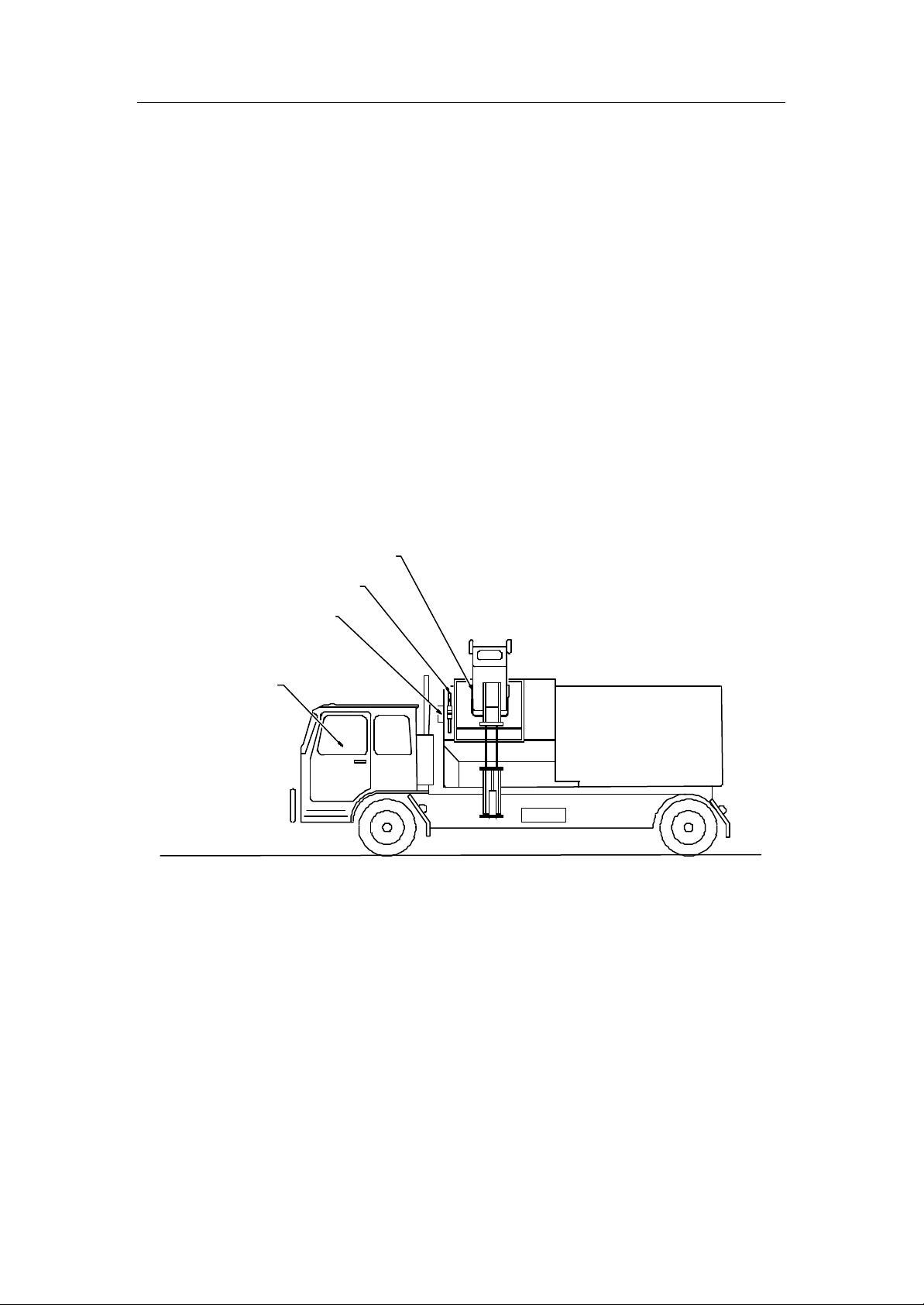

4.3 Dual polarized loop antenna

This antenna was originally developed to

identify cattle in a raceway, however its

simple construction and ruggedness

makes it an ideal for any applications

that require fast accurate identification

where smart label orientation cannot be

guaranteed. The larger size originally

made would require a site license for

legal operation, smaller versions for

conveyor application etc. can be made.

GEMPLUS COMPANY CONFIDENTIAL Page 7

C220 Chips & L120/L121 Couplers - Technical Description

ANTENNA

READER

Version 1.0

Figure 4: Dual polarized loop antenna

This antenna provides omnidirectional reading in the vertical plane and will read

a smart label placed anywhere within the loops. It can be constructed in almost

any size ranging up to 820mm x 2000mm for doorway access.

It should be noted that this antenna has also been adapted to allow complete

omnidirectional reading in all planes and is available in a 1m cubic arrangement

(AC205 3D Portal Antenna).

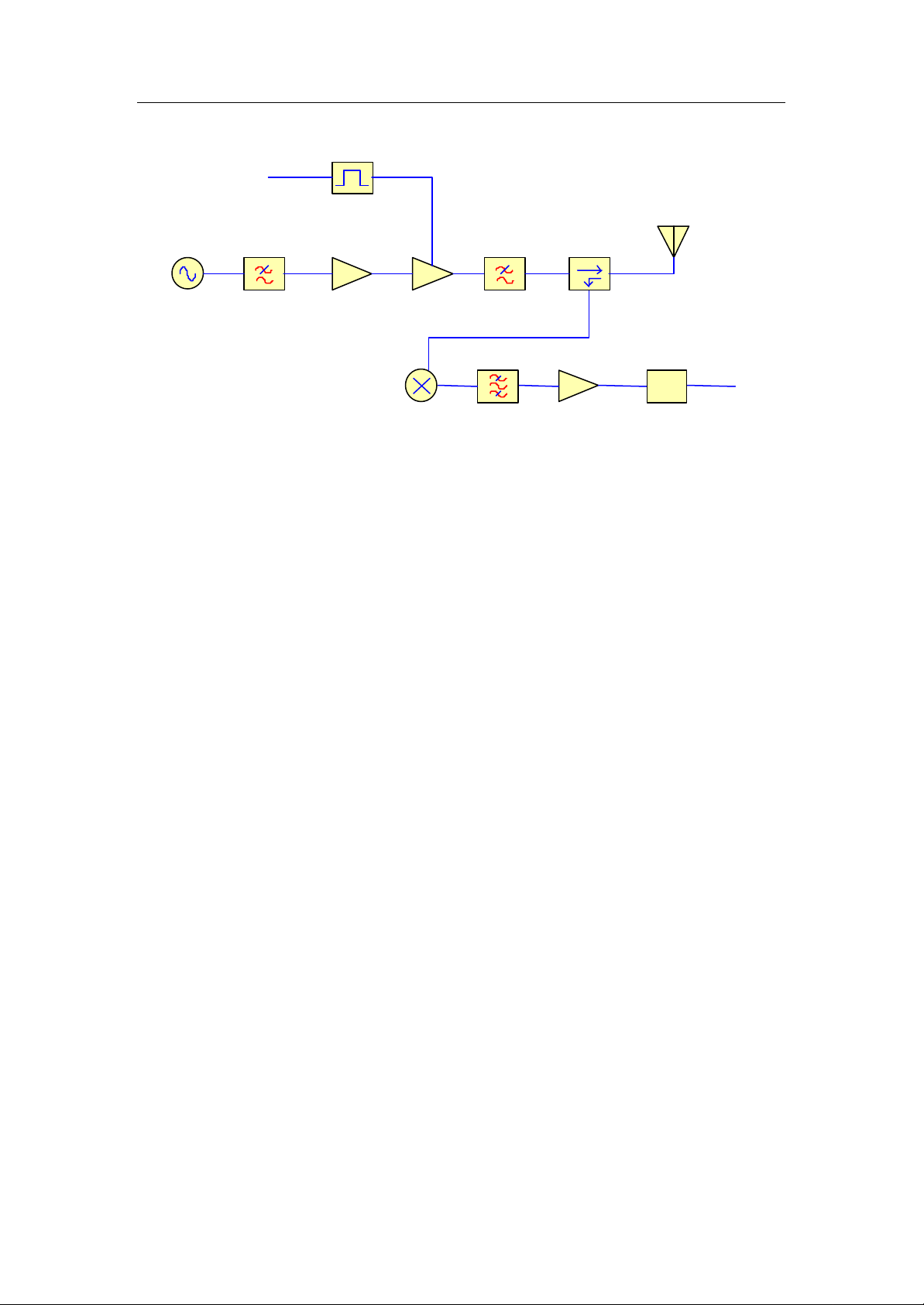

4.4 Truck mounted loop antenna

This antenna measuring 600mm by 350mm is used in the waste management

industry and boasts a read range of up to 500mm. It is similar in construction to

the larger loops and can be adopted for other applications with similar

requirements.

ISD MEDIUM FREQUENCYTAG

ON BOARD COMPUTER /

DATA LOGGER

Figure 5: Waste management application using truck mounted loop antenna

4.5 AC206 Metal Mount antenna

These antennas available with GemWave L120/L121 systems provide an

antenna that can be used in metallic environments where loop type antennas

cannot be used. It is tuned for use directly mounted to metal. We have used it on

Forklifts, in conveyor systems and in various other applications.

GEMPLUS COMPANY CONFIDENTIAL Page 8

C220 Chips & L120/L121 Couplers - Technical Description

Version 1.0

GemWave L120 & L121 Couplers

The GemWave L120/L121 couplers were the first HF near field RFID systems

available in the world. They have proven to be extremely robust in harsh

environments where lower frequency systems have failed due to high levels of

industrial noise. The coupler can both read labels and also program them.

5.1 L120/L121 Coupler functions

The primary functions of the Medio L120/L121 coupler are to provide the

following:

• The generation of a RF signal of the required frequency, power level

and pulse width (or continuous signal as required) for use as the

interrogation rf power a portion of which is backscattered by the smart

label.

• Reception of the reply signal from an identification smart label placed

in the RF field.

• Decoding of the unique identity code from a smart label reply and

output the result to one or more peripherals devices.

• Producing a programming signal to write new data into the C220

smart label.

Some of the secondary functions include:

• Control and monitoring of various digital inputs and output bits for

interfacing to external equipment or additional interrogators.

• Operation of a set of relay changeover contacts for the control of

external functions.

• Data transfer to and from external peripherals using two available

serial ports. These ports can be hardware configured for a range of baud

rates, parity settings and stop bits. One port provides RS232 capabilities

only whilst the second can be configured for RS232, RS422 or RS485.

• Storage of smart label replies in battery backed SRAM for

transmission to external peripherals at a later time.

• Time and date stamping of smart label replies using a battery backed

real time clock.

GEMPLUS COMPANY CONFIDENTIAL Page 9

C220 Chips & L120/L121 Couplers - Technical Description

Version 1.0

• RF multiplexing of the transmitter and receiver signal in multi-antenna

configurations.

5.2 System construction

The Interrogator Unit is housed in a polycarbonate plastic moulded case (IP55

for L120 and IP65 for L121 (these may be changed to metallic style Eddystone

enclosures in the near future).

Standard electrical connections are made via two separate connectors. The first,

a three-pin male, carries the power for the unit. The second, an eight-pin female,

provides communications and I/O signals.

The standard electronics consist of a transceiver module and power supply. The

transceiver module is composed of RF and CPU boards and will be explained in

the following sections. The transceiver module and power supply is mounted on

a base plate, which is placed inside the enclosure. This base plate can be easily

removed for servicing.

The power supply provides +12 V that is required for the various functions within

the system (the RF board also provides +5 V for the CPU board). The standard

power supply can be configured for either 240 or 110 volts AC mains input and

is located on the base plate adjacent to the transceiver. Other power supply

options may be available on request.

5.3 RF Section

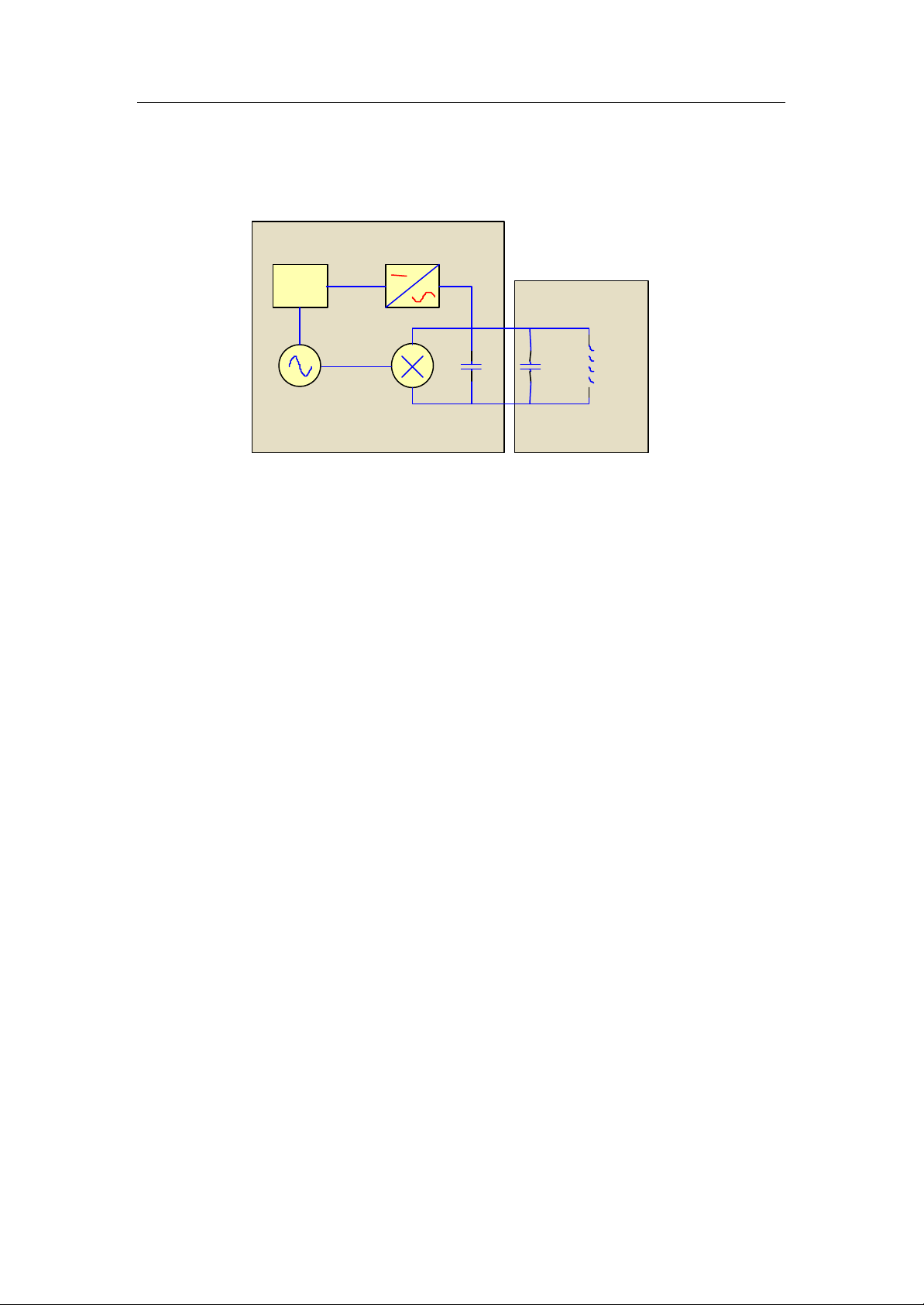

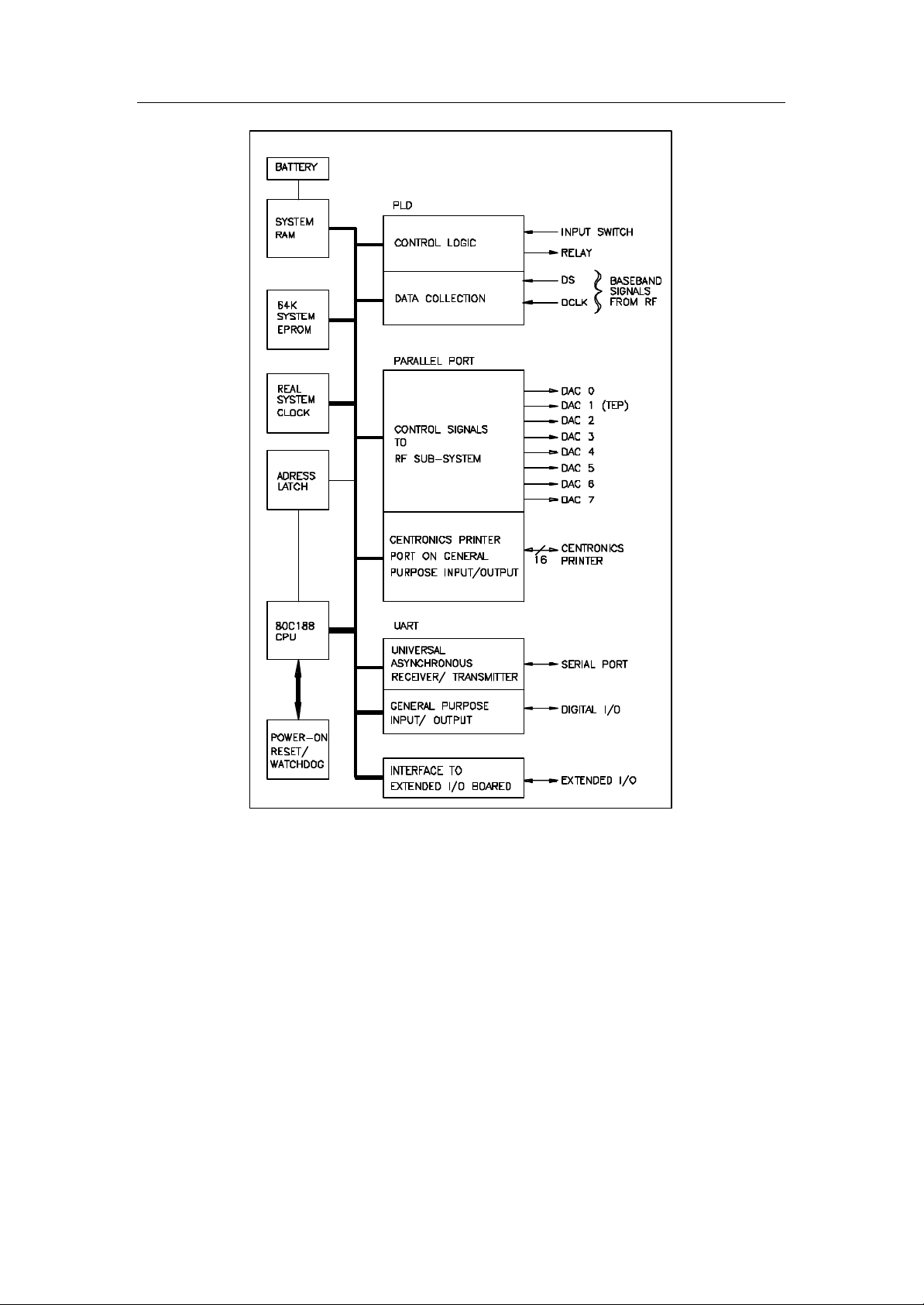

A simple block diagram of the GemWave L120 RF section is shown in Figure 6.

It should be noted that there is a quadrature receiver section rather than the

single channel receiver shown.

GEMPLUS COMPANY CONFIDENTIAL Page 10

C220 Chips & L120/L121 Couplers - Technical Description

Version 1.0

TEP

PULSE MODULATOR

ANTENNA

DIRECTIONAL COUPLER

OSCILLATOR

LPF LPF

AMPLIFIER POWER AMPLIFIER

DOWN CONVERTER

Note that there are 2

Baseband Channels I

and Q

BPF

AMPLIFIER

PLD

Decoded Tag

Data

Figure 6: Block diagram of a GemWaveL120/L121Smart Tracking System

A brief description of the major blocks is given in the following sections

5.3.1 Oscillator

The GemWave L120/L121 coupler features a low noise 13.56 MHz crystal

oscillator as its frequency source. The output of the oscillator is filtered to remove

unwanted harmonics before entering the power amplifier. (O/P level of the

oscillator section is –6.5 dBm @ Tx on Schematic 000869.SCH p2/10)

5.3.2 Transmit chain

The transmitter chain provides amplification and pulse modulation of the RF

signal. The signal level is lifted to a level of approximately 1 watts (30dBm) peak

for injection into the antenna. Modulation of the signal is performed under the

control of the CPU Section via the MOD Signal. CW and pulsed operation as

well as smart label programming are all valid modes of operation.

5.3.3 Directional Coupler

The directional coupler on these systems is located on the RF board, after the

PA.

5.3.4 Receiver chain

GEMPLUS COMPANY CONFIDENTIAL Page 11

C220 Chips & L120/L121 Couplers - Technical Description

Version 1.0

The receiver used in the L120 and L121 systems is based on the homodyne

architecture. The received signal is mixed in both an In-phase and a Quadrature

channel making the receive chain very robust and largely immune to phasing,

cable length and other problems that plague some RFID systems.

The down conversion process in these systems is achieved using 2 Active

Mixers. The signal proceeds through a band pass filter to limit the noise

bandwidth and to remove any remaining RF that may be present. The signal is

then amplified with a low noise high gain base band amplifier and fed into a PLD

where demodulation takes place.

The output of the PLD is in the form of completely decoded smart label numbers

which are “piped to the System CPU. There is a buffer of 16 smart label numbers

as well as the provision for an asynchronous label time-out. It should be noted

that once a label has been read and reported, it will not be again until 16 other

labels have been decoded and pushed the original one out of the buffer or until

the asynchronous label time-out has occurred.

GEMPLUS COMPANY CONFIDENTIAL Page 12

C220 Chips & L120/L121 Couplers - Technical Description

Version 1.0

5.4 CPU Section

The L120/L121 CPU system contains the necessary digital logic for the control

of system functions and the decoding of smart label replies under the control of

an 80C188XL embedded controller. In a standard configuration, the CPU sets

up two way system communications via RS232 on serial port O. This port can be

configured for a range of baud rates, parity and stop bits. Unless otherwise

specified, this port is configured as:

• 9600 bits per second

• No parity

• Eight bits per character

• One stop bit.

A functional block diagram of the board is shown in Figure 7 and a brief

description of important blocks follows.

In GemWave L12/L121 systems, the coupler default settings are stored in the 50

bytes of RAM available on the battery back Real Time Clock (RTC). Hence a

real time clock is available as standard on this system.

Some standard features of this board include:

• A parallel port which is available for use as either unbuffered

digital I/O or as a Centronics printer port.

GEMPLUS COMPANY CONFIDENTIAL Page 13

C220 Chips & L120/L121 Couplers - Technical Description

Version 1.0

Figure 7: Functional block diagram of a GemWave L120/L121 CPU system

5.4.1 System Watchdog

The 'watchdog' can be used to trap software 'hanging' and also protects the

128k system RAM in the event of a power failure. It does this by switching the

RAM to an on-board lithium battery until power is restored.

5.4.2 Data Collection Sub-System

GEMPLUS COMPANY CONFIDENTIAL Page 14

C220 Chips & L120/L121 Couplers - Technical Description

Version 1.0

The demodulated smart label replies are fed as TTL level signals to the data

collection system. When the PLD has new label information a system interrupt

process is used to copy the data into the CPU.

5.4.3 Application specific options

The following options are available on the main board at the time of manufacture.

• A de-bounced input switch connected to a CPU interrupt.

• A SPDT Relay.

• Two digital input and three buffered digital output bits are

available for user specification.

The CPU may also be fitted with one of two additional boards to assist for

special function operation:

Extended I/O

• Point to point RS422 or RS485 Communications

• RS232 with full modem control

• Parallel port for additional I/O, which can also implement

Centronics Printer Port.

• 2 additional buffered Output bits

• 2 additional buffered Input bits

• Extra 8 way DIP Switch for User Inputs

Network Card

• Serial Port 0: RS232 3 wire for Coupler Communications

• Serial Port 1: RS422 or RS485 Multi-drop Communications

with RTS / CTS available, or RS232 with full modem control

• additional 8 way DIP Switches for User Selections

• Real Time Clock for time-stamping other timing duties

5.4.4 Communications Interface

GEMPLUS can implement the following protocols as standard options. User

specified protocols are available on request.

• RS232 (3 wire)

• RS232 Full Modem

• RS422 Point to Point

• RS422 Point to Point with RTS / CTS

• RS422 Multi-drop ( 4 wire )

GEMPLUS COMPANY CONFIDENTIAL Page 15

C220 Chips & L120/L121 Couplers - Technical Description

Version 1.0

• RS422 Multi-drop with RTS / CTS

• RS485 Multi-drop ( 2 wire )

• Wiegand

• Centronics Printer Port

• Relay Logic Outputs

• Phone Line Modems

5.5 Power Supply

The standard power supply is a 16 watt linear supply capable of providing the

transceiver with the require regulated +12V supply.

1

128 bits when the tag is in long mode, 72 bits when in short mode.

2

While at least one fully integrated UHF tag is available, the performance is far poorer than tags with

even just a couple of external components.

3

Note that in short mode this is reduced to 40.

GEMPLUS COMPANY CONFIDENTIAL Page 16

DRAFT ONLY

SUBJECT TO CHANGE

V3.06 SOFTWARE

GemWave

TM

MEDIO L120/MEDIO L121

Protocol Guide

Version 3.06

GEMPLUS

June 2000

Revision Date Written by Verify by Validated by

3.01 March 2000

3.05 05 May 2000 Alfio. R. Grasso

3.06 02 June 2000 Alfio R. Grasso

© GEMPLUS 2000 1/34

1. OBJECTIVE ........................................................................................................................................................4

2. COMMAND HIERARCHY ............................................................................................................................4

2.1 SERIAL COMMUNICATION.............................................................................................................................4

2.2 COMMAND FORMAT .......................................................................................................................................4

2.2.1 Checksum calculation...........................................................................................................................4

2.2.2 Checksum Example:..............................................................................................................................5

2.3 DIALOG MODES...............................................................................................................................................5

3. COMMANDS......................................................................................................................................................6

3.1 READ COMMANDS..........................................................................................................................................6

3.2 PROGRAM COMMANDS..................................................................................................................................7

3.3 CONFIGURATION COMMANDS......................................................................................................................8

3.4 ERROR MESSAGES.......................................................................................................................................... 8

4. COMMUNICATION WITH THE READER:...........................................................................................9

4.1 POWER UP S TATE...........................................................................................................................................9

4.2 L121 SYSTEMS -COMPANION MODE AND LOCKED ANTENNAS..............................................................9

4.3 COMPANION MODE......................................................................................................................................10

4.3.1 Single Companion Antenna Mode ....................................................................................................10

4.3.2 Dual Companion Antenna Mode......................................................................................................11

4.3.3 Triple Companion Antenna Mode....................................................................................................11

4.4 LOCKED ANTENNA....................................................................................................................................... 11

4.5 BATTERY BACKUP ....................................................................................................................................... 12

Input Switch Period.......................................................................................................................................12

4.6 STATUS BITS ON THE LABEL......................................................................................................................12

4.7 COMMAND EXECUTION...............................................................................................................................13

5.1 INPUT S WITCH...............................................................................................................................................14

5.2 RESPONSE FORMAT TO READ COMMANDS................................................................................................14

5.3 READ COMMANDS........................................................................................................................................15

5.3.1 High Speed, Continuous Wave, Sorted Read ‘B’............................................................................15

5.3.2 High Speed, Pulsed, Sorted, Multiplexed Read ‘H’.......................................................................15

5.3.3 High speed, Pulsed, Unsorted, Multiplexed Read ‘K’ ...................................................................16

5.3.4 Low Speed, Pulsed, Sorted, Multiplexed Read ‘M’........................................................................16

5.3.5 Low Power Pulsed, Sorted Unique Read ‘U’..................................................................................18

5.3.6 High Speed, Pulsed, Sorted, Status Bits Read (‘?’) :.....................................................................18

5.4 PROGRAM COMMANDS................................................................................................................................20

5.4.1 Verification in all Program Commands...........................................................................................20

5.4.2. Alternate Specification of the Status Bits.......................................................................................20

5.4.3 Program Data Entry Schemes...........................................................................................................20

5.4.4 Program the lower half ‘1’ .................................................................................................................21

5.4.5 Program the upper half ‘2’................................................................................................................22

5.4.6 Program ALL Fields ‘P’....................................................................................................................23

5.4.7 Program Status Bits ‘S’......................................................................................................................24

5.4.8 Program the Security Bit (EAS), conditional ‘T’............................................................................24

5.5 CONFIGURATION COMMANDS....................................................................................................................25

5.5.1 Configure the Serial Port Program ‘C’...........................................................................................25

5.5.2 Set All Application Parameters to Default Values ‘D‘..................................................................26

5.5.3 Exhibit Application Settings ‘E’........................................................................................................27

5.5.4 Frequency of Label Reply Rate (Label Time Out)‘F’....................................................................27

5.5.5 GTA Menu ‘G’ or ‘g’...........................................................................................................................28

5.5.6 Configure the Input Switch ‘I’...........................................................................................................28

5.5.7 Quit ‘q’ or ‘Q’......................................................................................................................................29

5.5.8 Relay Function ‘R’...............................................................................................................................30

5.5.9 What am I (‘W’) :.................................................................................................................................30

5.5.10 Easy Command Mode (‘EASY’) :....................................................................................................31

5.6 INVALID COMMAND.....................................................................................................................................31

6.0 REFERENCE.................................................................................................................................................32

6.1 COMMANDS...................................................................................................................................................32

© GEMPLUS 2000 2/34

6.2 ERROR MESSAGES........................................................................................................................................ 33

6.2.1 Syntax Error.........................................................................................................................................33

6.2.2 Check Sum Error ..................................................................................................................................33

6.2.3 Invalid Data Error ...............................................................................................................................33

6.2.4 Lower Half Locked with different data Error.................................................................................33

6.2.5 Lower Half Locked Error...................................................................................................................33

6.2.6 Verify Error...........................................................................................................................................33

6.2.7 Can’t read Label Error ......................................................................................................................33

6.2.8 Multiple Labels Error.........................................................................................................................34

6.2.9 Invalid Command Error.....................................................................................................................34

6.2.10 Unknown Error..................................................................................................................................34

© GEMPLUS 2000 3/34

1. Objective

This application provides a common interface for all Gemplus Tag applications, for

L120/121 readers.

This application is designed to be used in-conjunction with an application program,

written by Gemplus VAR’s, and running on a PC, under Windows 95/98 or NT.

However, a human readable interface is available under the GTA interface, which can

be used with Hyper Terminal under Windows 95/98/NT or terminal under Windows

3.1.

2. Command Hierarchy

2.1 Serial Communication.

There is one serial port, set to RS232 serial communication. This port can be

configured as detailed in section 5.5.1. The factory settings and the default in the

event of battery corruption are configured to be 9600 Baud, No Parity, 8 Data bits, 1

stop bit and no flow control. If the parameters stored in battery backed RAM are

forgotten by the user, entering the ESC key during the first second after power up,

will force the serial port settings back to the default. Hence, under normal operation

no command should be issued to the reader during the first 1 second after power up.

Additionally, to facilitate easy mode interaction with the user, for debugging

purposes, or code development, the user can enter EASY mode see section 5.5.10, by

entering the ‘?’ character during the first second after power on.

2.2 Command format

Commands and responses format :

<STX> <MESSAGE> <ETX> <CHK>

1 byte variable 1 byte 2 bytes

where <STX> ASCII code for STX (02 Hex)

<ETX> ASCII code for ETX (03 Hex)

<MESSAGE> A variable length message, containing the command

and any parameters. They are separated with comma.

<CHK> These 8 bits are transmitted as 2 ASCII characters

<CHK High> and <CHK Low>,

As the ETX character is used as an escape character under some operating systems,

the ETX character can be replaced with the ETB (17 Hex) for any command. If the

ETB character is used, then all responses from the reader will use the terminating

character ETB instead of ETX, until a new command is issued with the ETX

character. For clarity, the rest of this document will use ETX.

2.2.1 Checksum calculation

The checksum represents the 8 bit exclusive OR of all the characters of the message

and including the STX and ETX. These 8 bits are transmitted as 2 ASCII characters

<CHK High> and <CHK Low>. Each character represents the hexadecimal value of

the 4 bits of each nibble with the most significant nibble transmitted first, and upper

case characters to represent values greater than 9.

© GEMPLUS 2000 4/34

2.2.2 Checksum Example:

GTA MENU

Suppose the user enters the string <STX>EASY<ETX>0F.

The checksum is set to zero, and the first character <STX> (02 in Hex) is “exclusive

ored” with the checksum (00 in Hex) to give a new checksum (02 in Hex). This is

represented as 00 ^ 02 = 02. If we repeat this for every character between the <STX>

and <ETX> characters we get the following sequence.

02 ^ 45 = 47

47 ^ 41 = 06

06 ^ 53 = 55

55 ^ 59 = 0C

0C ^ 03 = 0F

At the end we get the final checksum which is 0F, and hence the command is

accepted.

All commands and responses, except the ESC command during the first 3 seconds,

respect this format.

All commands are in upper case, with the exception of the g and q commands, which

can be in either case.

For clarity only the message field is documented in the following sections of this text.

All commands and responses have an <STX> pre-pended and an <ETX>, <CHK

High> and <CHK Low> appended to the message field.

2.3 Dialog modes

There are 2 ways to control the reader :

§ The secured command protocol, described in this document,

§ The GTA menu with basic commands, described in the document gta_ext.doc

Specific commands are used to change mode.

POWER UP MODE ([command],ESC,?)

<STX>Q<ETX>50

IDLE MODE

<STX>G<ETX>46Q

Where 50 and 46 are the 2 ASCII characters of the check sum<CHK High> and

<CHK Low>, of the string <STX>Q<ETX> and <STX>G<ETX> respectively.

© GEMPLUS 2000 5/34

Frame in ASCII Hexadecimal Comments

<STX>Q<ETX><CHK high><CHK Low> 02 51 03 35 30. Checksum in ASCII 50

<STX>G<ETX><CHK high><CHK Low> 02 47 03 34 36. Checksum in ASCII 46

3. Commands.

High Speed, Pulsed, Unsorted, Multiplexed

All commands in this section, and their responses are of the form

<STX> <MESSAGE> <ETX> <CHK>

1 byte variable 1 byte 2 bytes

For example to set all application parameters the command string and its response is:

Command String

<STX>D<ETX>45 : ASCII CODES (HEXADECIMAL) 02 44 03 34 35

Response String

<STX>OK<ETX>05 ASCII CODES (HEXADECIMAL) 02 4F 4B 03 30 35

Most commands require additional data, and this data is comma delimited. If a

command does not specify a response, then the message of such a response is OK.

Once a command has executed, the reader waits for additional user commands. No

command prompt is issued. Only the message field is described in the command

descriptions below.

Note : ASCII codes

Character Hexadecimal Control Equivalent

STX 02 ^B

ETX 03 ^C

The commands are in 3 groups. Group one is used to read labels, group 2 is used to

program labels, while group 3 is used to configure the reader. There are 21 commands

in the Command set, which consists of the following:

3.1 Read Commands

Command Section Example Description

B 5.3.1 <STX>B<ETX>43High Speed, Continuous Wave, Sorted Read

H 5.3.2 <STX>H<ETX>49High Speed, Pulsed, Sorted, Multiplexed Read

K 5.3.3 <STX>K<ETX>

4A

M 5.3.4 <STX>M,300<E

Read

Low Speed, Pulsed, Sorted Multiplexed Read

TX>53

U 5.3.5 <STX>U<ETX>54Low Power, Pulsed, Sorted, Unique Read

? 5.3.6 <STX>?<ETX>3EHigh Speed, Pulsed, Sorted, Status Bits Read

All read commands, other than ‘?’ have an optional parameter, which is the format of

the response, see section 5.2. In addition, the M command has an additional optional

parameter, which is the dwell time, see section 5.3.4.

The type of system and the functionality of the label determine the speed of reading.

For example, on a multiplexed L121 system, and in the presence of multiple labels in

the RF field, Low Speed-reading is mandatory to read multiple labels.

© GEMPLUS 2000 6/34

Continuous Wave RF is used on high-speed systems, and must be used only with

L120 systems, or L121 systems with antenna 1 locked.

Pulsed RF is used on high speed, low speed, single and multiple antenna systems. All

RF off times are 180 us. The table below details the RF pulse on time parameter for

each pulsed read command, H,K,M,U,?. In the table below CW refers to Continuous

Wave and TEP ON and GRT refer to internal system parameters, defined within the

GTA menu, which have the default values of 15 ms and 100 ms respectively. Also,

the value of the on time for the M command can be over-ridden by a command option.

Command Single

Antenna

Multiple

Antenna

H TEP ON TEP ON

K CW GRT

M GRT GRT

U TEP

ON,GRT

Not

applicable

? GRT GRT

Sorted reads means that the reader only report labels read that have not been

previously reported. The sort buffer is 16 deep. The system and application

parameter Label Time Out can be used to reset the sorter periodically. Unsorted

reading is when the sorter is bypassed, and all labels successfully decoded will be

reported.

The read range of the C220 label is greater than the program range. A low power read

is at the RF power level, in read mode, that will enable a label, positioned at the

maximum program range, to be correctly programmed at full Power. This low power

MUST be adjusted on site, to suit the target tags, the reader antenna and the

environment, please refer to L120 commissioning documentation.

3.2 Program Commands

Command Section Example Description

1 5.4.4 <STX>1,45

Program the Lower Half

6<ETX>2B

2 5.4.5 <STX>2,12

Program the Upper Half

3<ETX>2F

P 5.4.6 <STX>P,12

Program the Label with 123,456 and status T

3,456,T<ET

X>2E

S 5.4.7 <STX>S,F<

Program one or more Status Bits

ETX>38

T 5.4.8 <STX>T,1<

Program the Security Bit, conditional

ETX>48

All these commands have parameters.

© GEMPLUS 2000 7/34

3.3 Configuration Commands

Frequency of Label Reply Rates (Label Time

Command Section Example Description

C 5.5.1 <STX>C,D

Configure the Serial Port

EFAULT<E

TX>25

D 5.5.2 <STX>D<E

Set all Parameters to Default Values

TX>45

E 5.5.3 <STX>E<E

Exhibit Application Settings

TX>44

F 5.5.4 <STX>F,2<

ETX>59

G 5.5.5 <STX>G<E

Out)

Access the GTA Menu

TX>46

I 5.5.6 <STX>I,1,1

Configure Input Switch

00,1000,0<E

TX>79

Q 5.5.7 <STX>Q<E

Quit

TX>50

R 5.5.8 <STX>R,A,

Relay Function

300<ETX>2

1

W 5.5.9 <STX>W<E

What am I

TX>56

EASY 5.5.10 <STX>EAS

Easy Command Mode

Y<ETX>0F

3.4 Error Messages.

CONDITION

RESPONSE

Syntax Error detected in the command message 01

Check Sum Error in the command message 02

Invalid Data in the command message 03

Cannot Program, as the Label lower half is locked with other data 04

Lower Half LOCKED 05

Verify Error (data read after program different to data required) 06

Label cannot be read, to set un-allocated label fields. 07

Multiple Labels detected during a read 08

Invalid Command, unrecognised command 09

See Section 6.2 for details on error messages.

© GEMPLUS 2000 8/34

4. Communication with the reader:

4.1 Power Up State.

After initial power on, the reader executes the previous start up mode command,

executed prior to turning the power off, from the previous session. This command is

stored in battery backed RAM. In the event of battery failure, the read command will

be K mode, unsorted continuous wave (pulsed if more than 1 antenna on an L121

systems).

Prior to reading and reporting labels, the reader responds with the following message

to indicate which command it is using to read labels:

<command> [<,format>] [,<theft>] [,<period >]

1 byte 2 bytes 2 bytes variable

Where

<command> is one of either B,H,K,M, U, or T

<format> is one of either D,H or A, present if a read command

<theft> is one of either 0 or 1, present if the command was T

<period> is present only if the read command was M.

Note: If the T command was last used, the theft state reported in <theft> above, will

be used to program tags, and will also be reported in the message above.

Note: If the M command was last used, with a period parameter, that period parameter

is used, the period will also be reported in the message above.

If the “? Command” was last used, this is not recorded in battery backed RAM, and

the previous start up mode command will still be stored.

Reading and reporting, or Theft programming and reporting continues until the exit

sequence (quit command), 5.5.7 is received.

4.2 L121 Systems -Companion Mode and Locked Antennas

The purpose of the companion mode is both to save time, and decrease the user’s

involvement with the architecture of the reading system. Both 3D and 2D antenna

systems are employed by RF/ID companies to read planar labels in a 2D or 3D

environment. The fact that 3 antennas are required to read a planar label in all 3

dimensions should not be a concern of the user. All the user needs to know is that a

label was read, the actual orthogonal antennas that read the labels is of no

consequence.

© GEMPLUS 2000 9/34

4.3 Companion Mode

For L121 systems multiple antennas can be considered as a single antenna for

reporting purposes. For example, in a 3D portal system, a read point consists of 3

orthogonal antennas, placed such that the label can be in any orientation when it goes

through the RF field. For many applications, it is not important which of the 3

antennas read the label, and so the concept of companion antennas was developed,

which associates the 3 antennas as one antenna and then reports the label, with the

companion antenna number, rather than the antenna number. For other applications,

such as a doorway portal, 2 antennas are associated with the read point. Hence

companion mode can be single, dual or triple.

If the companion mode is set to either dual or triple, and a label is read on one of the

antennas in the companion set then the next RF pulse will occur on the first antenna of

the next companion set. For example, antenna count is set to 8, and companion mode

is set to dual, and the label is read on antenna 3, then next RF pulse will be on antenna

5, ie antenna 4 is skipped. Another example is, if antenna count is set to 6, companion

mode is set to triple and the label is read on antenna 2, then the next RF pulse will be

on antenna 4.

In the above, the 3D portal antenna is used to read the label, which may be entering

the antenna’s field in any orientation. The 3D portal consists of 3 separate antenna, as

can be seen by the three cables. If a label is read on any of the three antennas, it may

not be important to the user to know which one of the three antennas read the label,

only that the label was read. Hence, the user would define companion mode to triple.

4.3.1 Single Companion Antenna Mode

Antenna Companion Antenna

1 1

2 2

3 3

4 4

5 5

6 6

7 7

8 8

© GEMPLUS 2000 10/ 34

4.3.2 Dual Companion Antenna Mode

Antenna Companion Antenna

1 1

2 1

3 2

4 2

5 3

6 3

7 4

8 4

If the antenna count is not even, then the last companion set will only have one

antenna, for example antenna count is set to 7, then companion set 4 will have only

one antenna, antenna 8.

4.3.3 Triple Companion Antenna Mode

Antenna Companion Antenna

1 1

2 1

3 1

4 2

5 2

6 2

7 3

8 3

If the antenna count is not a multiple of 3, then the last companion set will have less

than 3 antenna, for example in the table above companion antenna set 3 has only 2

antennas, antennas 7 and 8.

4.4 Locked Antenna

It is also possible to have an L121 system, but lock all RF activity to one antenna.

This may be the case when demonstration equipment is being used, and the customer

may have purchased an L121 with multiple antennas, but now wants to evaluate the

L120 performance. Using a parameter locked antenna does this. Any antenna can be

locked (1 to 8). If no antennas are to be locked, then locked antenna is set to 0.

© GEMPLUS 2000 11/ 34

4.5 Battery Backup

This application uses the battery backed RAM to store application parameters. In the

event of battery backup these parameters will be set to the following:

Parameter Default Value

Last Read Command K

M Command Period 300 ms

Label Time Out 10 seconds

Relay Mode Automatic

Relay Period 300 ms

Input Switch Type 0

Input Switch Delay 100 ms

Input Switch Period 1000 ms

Input Switch Mode 0

Output Format Decimal

Baud rate 9600

Parity None

Data Bits 8

Stop Bits 1

Antenna Count 1

Companion Mode 1

Locked Antenna 1

Terminator ETX

Theft State 1 (set)

Trace Disabled

The antenna count, locked antenna number, companion mode and trace are system

parameters and can only be changed by the GTA menu.

4.6 Status Bits on the Label.

In most programming commands, the default label status bits are used in

programming the label. The obvious exceptions are when programming the theft bit,

and locking the label. Once a label has been locked, it cannot be unlocked.

Status bit Description Default

Program Speed Status The setting of the Speed Status bit,

Normal

programmed into the label, either normal

or fast.

Program Theft Status The setting of the Theft Status bit,

Set

programmed into the label, either set or

cleared

Program Length Status The setting of the Length Status bit,

Long

programmed into the label, either long or

short.

Program Lock Status The setting of the Locked Status bits,

Unlocked

programmed into the label, either locked

or unlocked.

© GEMPLUS 2000 12/ 34

4.7 Command Execution.

In most applications, a read command will be executing to read label. All of the

Configuration Commands, with the exception of the G command, can be issued at any

time while the reader is executing read command. These commands if received may

alter the nature of the current read command, for example if the input switch is

enabled to type 1, a read cycle will not begin, unless the input switch is activated.

If the G command, read commands, or program commands are received, then an error

message will be issued.

© GEMPLUS 2000 13/ 34

5. List of Commands

5.1 Input Switch.

Each reading command can be controlled by an external input switch, which may

interrupt the normal operation of the reader to carry out a pre-defined action.

There are 3 modes of operation of the input switch. The first mode (type 0) is to

disable the input switch. The second mode (type 1) is to delay RF reading of labels

until an interrupt occurs, while the third mode (type 2) is used to delay reporting of

labels which have been read and which are stored in a buffer.

The input switch is described in sections 5.5.6 below. For the sake of clarity in this

document, the effect of the input switch is not documented in the text of the read

commands, but it is still active.

If the input switch Type is 0, then reading and reporting are immediate.

If the input Switch Type is 1, then no read activity will begin until the interrupt is

received, and the appropriate delay has expired.

If the Input Switch Type is 2, then no output messages will be issued until the

interrupt is received.

Reading and subsequent reporting may also be terminated if the Input Switch Type is

1, and the period timer has expired.

5.2 Response format to read commands.

When a read command is active, and a response message is to contain a label reply.,

the message response in the following format:-

<ant>, <upper>, <lower>

2 bytes Variable variable

Where

<ant> : the companion antenna number (1 to 8) used to read the label

<lower> , <upper> ,the label contents, in the specified format, with leading zeros

suppressed, and if the label length is short, the upper field is set to 0.

The Output Formats are :

§ D for Decimal,

§ H for Hexadecimal,

§ A for alphanumeric.

The format of the reply is set to decimal by default.

However, the user can override the output format, by an optional command line

parameter. The output format is stored in battery backed RAM, so that upon start up,

it can be applied. However, this memory value is overridden, if the user specifies

another output format, used for any read command.

If the output format is alphanumeric, then the label data is interpreted as up to 6

alphanumeric characters stored in the lower half, and up to 5 alphanumeric characters

stored in the upper half.

© GEMPLUS 2000 14/ 34

Character set :

§ upper case (A..Z),

§ lower case (a..z),

§ numerical (0..9),

§ SPACE

Each alphanumeric character is stored as a 6-bit character (64 combinations). Hence

4 bits are not used in the lower half (D36, D37, D38, D39) and 3 bits are not used in

the upper half (D70, D71, D72).

5.3 Read Commands

The reader responds with the OK response message when a read command is issued,

to indicate that the read command is executing.

Reading and reporting continues until the exit sequence 5.5.7 is received.

Upon exiting the command the reader responds with the OK response message, to

indicate that the command has stopped. The antenna number is not reported in the OK

message.

To use an alternative output format, the user can issue the read command with an

optional parameter.

<read command> [,<format>]

1 byte 2 bytes

Where

<read command> is the read command identifier ( B,H, K, U, M, ?) . See below for

details.

<format> is optional and is one of either D,H or A. If the format is not present in the

command line, then it will default to Decimal. There is no format specifier for the

read status command (‘?’), the format is always decimal.

5.3.1 High Speed, Continuous Wave, Sorted Read ‘B’.

For this command to be executed, L121 systems must have the antenna locked to 1.

Label time Out is used to determine if a label previously read and reported is to be re-

reported.

Application Example Read B Command

This command is useful in library applications, at the book return chute, where for

example, more than one book may be placed in the return chute, and high speed

Continuous Wave operation is mandatory to capture all labels moving quickly in the

confined field of the book chute. The number of labels in the chute should be limited

to 5, if a larger population of labels need to be identified, then the chute should not be

used, but the labels kept stationery in the RF field for a period of 1 to 2 seconds.

It is for this reason that L121 systems, with an antennas count greater than 1, should

NOT BE used for book return chute applications, unless the antenna is locked to 1 and

the book chute antenna is physically connected to that antenna.

5.3.2 High Speed, Pulsed, Sorted, Multiplexed Read ‘H’.

This command is used on L121 systems to enable a reading system with multiple

antennas to read labels, which may be travelling at relatively high speed. The

assumption in this command is that only one label will be in the field at a time, but

that label will only be in the field for a limited time period.

© GEMPLUS 2000 15/ 34

As the label’s orientation with respect to the antenna(s) cannot be pre-determined, a

number of antennas in orthogonal planes are used to read the label. The RF is on each

antenna for a limited period of time, before the RF is switch onto the next antenna.

As soon as a label is read on an antenna, the RF is immediately switch to the next

antenna, in order to capture another label, which may be just entering the field.

Hence, the anti-collision capability of the C220 label is not activated because the RF

is switched, quickly.

Reading and reporting continues until the exit sequence 5.5.7 is received. Label time

Out is used to determine if a label previously read and reported is to be re-reported.

Companion mode and locked antenna parameters are used to determine which

antennas are energised, as described in 4.2, 4.3, 4.4.

Application Example Read H Command

This command could be used in a library application at the library staff counter

reader. Here the operator, “The Librarian” has been trained in the use of the RF/ID

equipment and understands the parameters of each command, and will NOT place

more than one label in the RF field. Where as the general library user, may not use the

equipment correctly, and an alternative command ‘U’ at 5.3.5 has been provided, for

the general user.

Another example is the use of the 3D portal on a high-speed conveyor belt system. In

this application the label’s orientation is not known. Since the label (only one in the

field) is travelling at high speed, high speed RF switching between the 3 orthogonal

antennas is required to reliably read the label.

5.3.3 High speed, Pulsed, Unsorted, Multiplexed Read ‘K’

This command is similar to the ‘B’ read command (5.3.1) above, except that all labels

read are reported, regardless of Label Time Out. In L121 systems, companion mode

and locked antenna parameters are used to determine which antennas are energised, as

described in 4.2, 4.3, 4.4.

Application Example Read K Command

This command could be used when the same label can be reported to the host, more

than once, in fact, every time the reader successfully reads the label. This can be used

to determine if the label is still in the field.

5.3.4 Low Speed, Pulsed, Sorted, Multiplexed Read ‘M’

This command is used on L121 systems to enable a reading system with multiple

antennas to read labels, which may be travelling at a slow speed. The assumption in

this command is that more than one label will be in the field at a time, but that those

labels will be in the field for a period of time, sufficient to read labels, exploiting the

C220 Anti-collision scheme, which is about 300 ms per antenna used. For example if

a 3D field is used, consisting of 3 multiplexed antennas, then the labels should be

guaranteed to be in the reading field for at least 900 ms.

As the label’s orientation with respect to the antenna(s) cannot be pre-determined, a

number of antennas in orthogonal planes are used to read the label. The RF is on each

antenna for a period of time, controlled by an internal timer. This internal timer is

known as the General Response Time in the GTA menu.

© GEMPLUS 2000 16/ 34

However, as indicated above, 300 ms is an optimum time for multiple labels in a 3D

portal application. Hence, this command has an optional parameter called the dwell

period, which is from 100 to 500 ms, and is used to change this period for M

commands. The period is also stored in battery backed RAM, in case the M command

was the last command issued, before power down, and hence will be the read

command executed at power on.

Changing the General Response time in the GTA menu will have the effect of

lengthening the program sequence, and this is not desirable. The RF is not switched,

until the expiration of this internal timer. If the optional parameter is not present, then

the General Response Time is used.

For example to issue the M command with a period of 300 ms, the command string

will be M,300

Reading and reporting continues until the exit sequence 5.5.7 is received. Label time

Out is used to determine if a label previously read and reported is to be re-reported.

Companion mode and locked antenna parameters are used to determine which

antennas are energised, as described in 4.2, 4.3, 4.4. However, the use of a locked

antenna defeats the purpose of this command.

The Command Format is :

M, [,period] [,<format>]

2 bytes 4 bytes

2 bytes

100 to 500ms

Where <period> and <format> are optional, and can be in any order.

<period> can be in the range 100 to 500 ms and

<format> is defined in section 5.3.

Application Example Read M Command

This command could be used in a laundry application, where multiple articles of

clothing may pass through an antenna system. Such antenna system could consist of

multiple individual antennas for two reasons. The first is that the volume of space

required for reading is large, and consequently more than one antenna is needed to

read the labels. Secondly, the label’s orientation cannot be pre-determined, and hence

2D or 3D RF fields are required. The key parameter is the time the labels are in the

RF field. This time should be at least 300 ms per antenna, so for example if 4

antennas are required, then the labels should be in the field of those antennas for 1.2

seconds. The maximum number of labels simultaneously in the field should be

limited to less than 10.

© GEMPLUS 2000 17/ 34

5.3.5 Low Power Pulsed, Sorted Unique Read ‘U’.

2 bytes

This command is only valid on L120 systems, or L121 systems that are LOCKED to

antenna 1.This command starts pulsed interrogation. This read is at a RF Power,

which reads labels at the distance, that full RF power will successfully program a

label. Naturally, this feature is dependent upon the type (size and form factor) of tag

being programmed, and the antenna connected to the reader. Hence, each reader will

need site adjustment, please refer to reader documentation for adjustment procedures.

Two pulses are initiated, the first pulse uses TEP ON time (usually 15ms), while the

second pulse is on for GRT (usually 100ms). If one and only one label is read in both

pulses, and it is the same tag in both pulses, and it is different to the last 16 labels

reported, or if label time out has expired, then that label is reported in a response

message. This above process continues until the quit command 5.5.7 is received.

Application Example Read U Command

This command can be used at a library self check out borrowing station. In this

application it is mandatory to ensure that one and only one label is in the field. The

‘U’ command can be used to search for labels that may be accidentally programmed,

if a program cycle were to be initiated.

5.3.6 High Speed, Pulsed, Sorted, Status Bits Read (‘?’) :

The reader responds with the OK response message, to indicate that the Read ‘?’

command is executing. This command is used to report the status bits of a label. This

command starts pulsed interrogation, but at normal RF power. If a label is read, and it

is different to the last 16 labels reported, or if label time out has expired, then that

label status bits are reported in a response message. Companion mode and locked

antenna parameters are used to determine which antennas are energised, as described

in 4.2, 4.3, 4.4.

The response message will be:

<ant>, <tag response> <Lock>, <Length>, <Speed>, <Security>

as per 5.2 above

Variable, but

only in decimal

2 bytes

X LOCKED

U UNLOCKED

2 bytes

L LONG

S SHORT

2 bytes

F FAST

N NORMAL

1 byte

T THEFT ON

O THEFT OFF

format.

Where :

<ant> is the companion antenna, only present if antenna count is greater than 1

<Lock> is X for LOCKED or U for UNLOCKED

<Length> is L for LONG or S for SHORT

<Speed> is F for FAST or N for NORMAL

<Security> is T for THEFT ON or O for THEFT OFF

This above process continues until the quit command 5.5.7 is received

Upon exiting the command the reader responds with the OK response message, to

indicate that the command has stopped.

© GEMPLUS 2000 18/ 34

5.3.7 Read Command Example.

In this example let us assume that the Input Switch Type is 0 (label reading and

reporting is immediate) and the label is read on antenna 1. If the K command is

issued, and there is one tag in the field, and the tag is programmed with contents

123,456 the dialogue between the user (commands) and the reader (response

messages) will be as follows;

Commands Responses Comments

<STX>K<ETX>4A Read tag fields in decimal

<STX>OK<ETX>05 Acknowledge of K command

<STX>1,123,456<ETX>37 tag contents are sent in decimal

<STX>1,123,456<ETX>37 tag contents are sent in decimal

<STX>1,123,456<ETX>37 tag contents are sent in decimal

<STX>1,123,456<ETX>37 tag contents are sent in decimal

<STX>Q<ETX>50 Exit read

<STX>OK<ETX>05 Acknowledge of Q command

<STX>K,H<ETX>2E Read tag fields in hex

<STX>OK<ETX>05 tag contents are sent in hex

<STX>1,7B,1C8<ETX>0F tag contents are sent in hex

<STX>1,7B,1C8<ETX>0F tag contents are sent in hex

<STX>1,7B,1C8<ETX>0F tag contents are sent in hex

<STX>Q<ETX>50 Exit read

<STX>OK<ETX>05 Acknowledge of Q command

<STX>K,A<ETX>27 Read tag fields in alphanumeric

<STX>OK<ETX>05 Read tag fields in alphanumeric

<STX>1,0001X,000078<ET

X>66

<STX>1,0001X,000078<ET

X>66

<STX>1,0001X,000078<ET

X>66

<STX>1,0001X,000078<ET

X>66

tag contents are sent in

alphanumeric

tag contents are sent in

alphanumeric

tag contents are sent in

alphanumeric

tag contents are sent in

alphanumeric

<STX>Q<ETX>50 Exit read

<STX>OK<ETX>05 Acknowledge of Q command

© GEMPLUS 2000 19/ 34

5.4 Program Commands

5.4.1 Verification in all Program Commands.

All program commands contain a program sequence followed by a read, to verify that

the label has been correctly programmed.

5.4.2. Alternate Specification of the Status Bits.

It is also possible to specify alternative status bits, to use in all programming

commands, rather than use the default status bits. These status bits can be specified in

any order, using the single characters as specified below.

Status Bit Set Cleared

Locked X (Locked) U (Unlocked)

Length L (Long) S (Short)

Speed F (Fast) N (Normal)

Theft T (Theft On) O (Theft Off)

If conflicting status bit combinations are specified an error message will be issued. If

one or more status bits are not specified then the default value for that status bit will

be used.

5.4.3 Program Data Entry Schemes.

Data to be programmed can be entered in one of three ways. The first method is to

use a decimal representation of the data to be programmed; the second way is to use a

hexadecimal representation, while the third is to store alphanumeric characters.

The first 2 methods result in optimum use of the label’s memory, and give flexibility

to the application developer, as the interpretation of the bits stored in the tag memory

can be left to the developer. In this fashion the label is just used to store 40 bits of

data in the lower half (D0 to D39) and 33 bits of data in the upper half (D40 to D72).

The third method is non-optimum and restricts the developer to storing and retrieving

alphanumeric Data.

Character set :

§ upper case (A..Z),

§ lower case (a..z),

§ numerical (0..9),

§ SPACE

Each alphanumeric character is stored as a 6-bit character (64 combinations). Hence

4 bits are not used in the lower half (D36, D37, D38, D39) and 3 bits are not used in

the upper half (D70, D71, D72).

© GEMPLUS 2000 20/ 34

5.4.4 Program the lower half ‘1’

Alphanumeric

up to 6 alpha-numeric characters (upper and lower

This command is used to program the lower half of the label data.

Command format :

1, <lower> [,<format>] [,<status bits>]

2 bytes Variable 2 bytes variable

where :

<lower> the label data,

Valid numbers

Decimal Hexadecimal

Lower 40 bits 1,099,511,627,775 FFFFFFFFFF

<format> specify the format of the label data

Format Value Label data

Decimal D Decimal value, leading zeros suppressed

Hexadecimal H Hexadecimal value, upper case characters only

A

case)

<status bits> is the status bits as specified in 5.4.2.

Examples

(1) To program a label with the number 123 in decimal, the message will be 1,123.

(2) To program the label with 123 hexadecimal, the message will be 1,123,H.

(3) To specify that the label status bit Speed to be set to Fast, the command 1,123,F

will program the label with the status bit set to Fast, while all other status bits will be

set to the default values.

(4) To program a label with a string, the message will be 1,string,A

(5) To program a label with StRiNg and status bits set to LOCKED the message will

be 1,StRiNg,A,X

If the status bit length is set to Long, then the label is read to extract the upper half. If

the label cannot be read, then an error message will be issued.

If the length is set to Short, no programming of the upper half will take place.

For L121 systems, all programming is either performed on the locked antenna, or if

the antennas are unlocked on antenna 1. The number of antenna logically connected

to the L121 and the locked antenna status are can only be altered within the GTA

menu.

If the program and verify was successful, then the OK message response is issued,

otherwise an error message is issued.

© GEMPLUS 2000 21/ 34

5.4.5 Program the upper half ‘2’

Alphanumeric

up to 5 alpha-numeric characters (upper and lower

This command is used to program the upper half of the label data.

Command format :

2, <upper> [,<format>] [,<status bits>]

2 bytes Variable 2 bytes variable

where :

<upper> the label data,

Valid numbers Decimal Hexadecimal

Upper 33 bits 8,589,934,591 1FFFFFFFF

<format> specify the format of the label data

Format Value Label data

Decimal D Decimal value, leading zeros suppressed

Hexadecimal H Hexadecimal value, upper case characters only

A

case)

<status bits> is the status bits as specified in 5.4.2.

Examples

(1) To program a label with the number 123 in decimal, the message will be 2,123.

(2) To program the label with 123 hexadecimal, the message will be 2,123,H.

(3) To specify that the label status bit Speed to be set to Fast, the command 2,123,F

will program the label with the status bit set to Fast, while all other status bits will be

set to the default values.

(4) To program a label with a string, the message will be 2,string,A

(5) To program a label with StRiNg and status bits set to LOCKED the message will

be 2,StRiNg,A,X

If the status bit length is set to Short, and error message will be issued. The label is

read to extract the lower half. If the label cannot be read, then an error message will

be issued.

For L121 systems, all programming is either performed on the locked antenna, or if

the antennas are unlocked on antenna 1. The number of antenna logically connected

to the L121 and the locked antenna status are can only be altered within the GTA

menu.

If the program and verify was successful, then the OK message response is issued,

otherwise an error message is issued.

© GEMPLUS 2000 22/ 34

5.4.6 Program ALL Fields ‘P’

upper label data :up to 5 alpha-numeric characters

lower label data :up to 6 alpha-numeric characters

This command is used to program all sections of the C220 EEPROM.

Command format :

P, <upper>, <lower> [,format>] [,status bits>]

2 bytes variable variable 2 bytes variable

where :

<upper> the upper label data,

Valid numbers Decimal Hexadecimal

Upper 33 bits 8,589,934,591 1FFFFFFFF

<lower> the lower label data,

Valid numbers Decimal Hexadecimal

Lower 40 bits 1,099,511,627,775 FFFFFFFFFF

<format> specify the format of the label data

format Value Label data

decimal D Decimal value, leading zeros suppressed

hexadecimal H Hexadecimal value, upper case characters only

alphanumeric A

(upper and lower case)

(upper and lower case)

<status bits> is the status bits as specified in 5.4.2

Examples :

To program a label with the number 123 (upper half) and 456 (lower half) in decimal,

the command message will be P,123,456. However to program the label with 987

(upper) ABC (lower) hexadecimal, the command message will be P,987,ABC,H.

Similarly, as in 5.4.21 above, the status bits can be overridden.

In order to specify that the label status bit Speed to be set to Fast, the command

P,123,456,F will program the label with the status bit set to Fast, while all other status

bits will be set to the default values.

To program sections of the C220 memory, sections can be omitted. For example to

program the upper half with the number 123, the command would be P,123,, The ,,

indicates that the lower half is to be left. Any missing fields are extracted from the

label prior to programming, and in this example the lower half will be programmed

with the same data that was in the label, prior to the program command executing.

Similarly to program the lower half the command would be P,,123,H,X,F This will

leave the upper half alone, and lock the tag, setting the speed to fast, and the upper

half to 123 Hexadecimal. Similarly, any missing status bits, will be set to the default

status bits.

To lock a tag the command would be P,,,L, or to set the theft bit the command would

be P,,,T.

If the length is specified to be short, no programming of the upper half will take place.

Similarly, if the user specifies alphanumeric data for the tag data, then the format

must be set to A.

© GEMPLUS 2000 23/ 34

For L121 systems, all programming is either performed on the locked antenna, or if

2 bytes

the antennas are unlocked on antenna 1. The number of antenna logically connected

to the L121 and the locked antenna status are can only be altered within the GTA

menu.

If the program and verify was successful, then the OK message response is issued,

otherwise an error message is issued.

5.4.7 Program Status Bits ‘S’

This command is used to program the 4 status bits of the C220 EEPROM.

Command format :

S, <status bits> [,<status bits>]

2 bytes 1 byte variable

where