Page 1

Library Security Pedestal 3 Clear

User's Guide

Revision 2.1

December 2009

Page 2

Library Security Pedestal 3

Publishing Information

Disclaimer and Limitation of Liability

All information herein is either public information or is the property of and owned solely by TAGSYS who shall have and

keep the sole right to file patent applications or any other kind of intellectual property protection in connection with such

information.

Nothing herein shall be construed as implying or granting to you any rights, by license, grant or otherwise, under any

intellectual and/or industrial property rights of or concerning any of TAGSYS’ information.

This document can be used for informational, non-commercial, internal and personal use only provided that:

The copyright notice below, the confidentiality and proprietary legend and this full warning notice appear in all

copies.

This document shall not be posted on any network computer or broadcast in any media and no modification of

any part of this document shall be made.

Use for any other purpose is expressly prohibited and may result in severe civil and criminal liabilities.

The information contained in this document is provided “AS IS” without any warranty of any kind. Unless otherwise

expressly agreed in writing, TAGSYS makes no warranty as to the value or accuracy of information contained herein.

The document could include technical inaccuracies or typographical errors. Changes are periodically added to the

information herein. Furthermore, TAGSYS reserves the right to make any change or improvement in the specifications

data, information, and the like described herein, at any time.

Therefore TAGSYS assumes no liability and is not responsible for customer applications or product or software that

include TAGSYS products.

TAGSYS HEREBY DISCLAIMS ALL WARRANTIES AND CONDITIONS WITH REGARD TO THE INFORMATION

CONTAINED HEREIN, INCLUDING ALL IMPLIED WARRANTIES OF MERCHANTABILITY, FITNESS FOR A

PARTICULAR PURPOSE, TITLE AND NON-INFRINGEMENT. IN NO EVENT SHALL TAGSYS BE LIABLE, WHETHER

IN CONTRACT, TORT OR OTHERWISE, FOR ANY INDIRECT, SPECIAL OR CONSEQUENTIAL DAMAGES OR ANY

DAMAGES WHATSOEVER INCLUDING BUT NOT LIMITED TO DAMAGES RESULTING FROM LOSS OF USE,

DATA, PROFITS, REVENUES, OR CUSTOMERS, ARISING OUT OF OR IN CONNECTION WITH THE USE OR

PERFORMANCE OF INFORMATION CONTAINED IN THIS DOCUMENT.

TAGSYS does not and shall not warrant that this product/system/equipment will be resistant to all possible attacks, and

shall not incur, and disclaims, any liability in this respect. Even if each product is compliant with current security

standards in force on the date of their design, security mechanisms' resistance necessarily evolves according to the

state-of-the-art in security and notably under the emergence of new attacks. Under no circumstances shall TAGSYS be

held liable for any third party actions, and in particular in case of any successful attack against systems or equipment

incorporating TAGSYS products.

TAGSYS disclaims any liability with respect to security for direct, indirect, incidental or consequential damages that result

from any use of its products. It is further stressed that independent testing and verification by the person using the

product is particularly encouraged, especially in any application in which defective, incorrect, or insecure functioning

could result in damage to persons or property, denial of service, or loss of privacy.

© 2000-2008 TAGSYS. All rights reserved.

TRADE MARKS. TAGSYS is a registered trademark of TAGSYS S.A, all rights reserved. ARIO, FOLIO and other

TAGSYS products referenced in these pages are either trademarks or registered trademarks of TAGSYS S.A. Other

products and company names mentioned in these pages may be the trademarks of their respective owners.

Microsoft, Visual C++, Windows, and Windows NT are either registered trademarks or trademarks of Microsoft

Corporation in the U.S.A. and/or other countries.

I-Code is a registered trademark of NXP.

Tag-It is a registered trademark of Texas Instruments.

Printed in France.

TAGSYS – 180 Chemin de St Lambert, F-13821 LA PENNE SUR HUVEAUNE, France.

Tel: +33 (0) 4.91.27.57.00 / fax: +33 (0) 4.91.27.57.01

Document Reference: DOC12984B1

2/68 Revision 2.1 December 2009

Page 3

Library Security Pedestal 3 User's Guide

Read This First

Welcome to the TAGSYS L-SP3 Electronic Article Detection system. This user’s guide is designed

to help you get up and running quickly using this high-quality Radio Frequency Identification (RFID)

Anti-Theft system. It describes all you need to know about how to install and use the TAGSYS

EAS/AFI system and its associated applications.

It provides a step-by-step guide for the following procedures:

Installation of the L-SP3 EAS/AFI Detection and RFID Data Retrieval system

Configuring the system for use in your library

Personalizing your product with your own preference settings

After you become familiar with the basic functions of the product, you can use the rest of this

handbook as a reference for less common tasks, for maintaining your system, and also as a

source of information if you have problems operating the system.

This End User’s Guide is designed for all CIT (Certified Integrators by TAGSYS) and for TAGSYS

Expert Network customers implementing a low-cost and high-performance RFID solution.

This document does not assume any in-depth knowledge of Radio Frequency Identification (RFID)

technology, but personnel in charge of pedestal installation need to follow a minimum training or

have previous experience in RFID equipment installation.

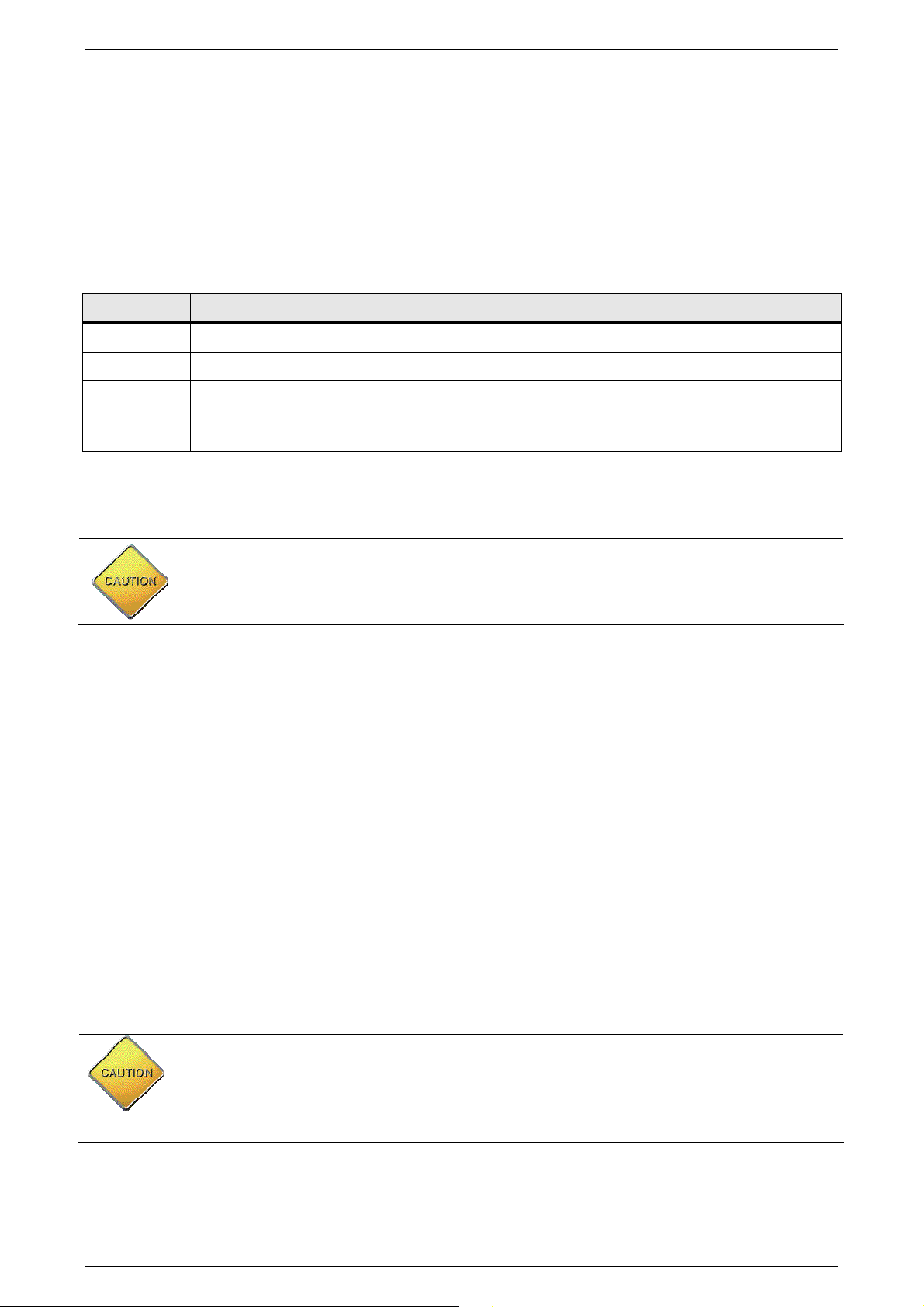

Conventions

Symbol Meaning

CAUTION: A note that advises users that a specific action could result in

loss of data or damage the hardware.

WARNING: A note that advises users that a specific action may result in

physical harm.

A note that provides additional information that helps the user

performing a task or obtaining the most out of the product.

December 2009 Revision 2.1 3/68

Page 4

Library Security Pedestal 3

If you need assistance

Please contact your nearest TAGSYS sales representative or the TAGSYS Welcome Desk at:

Telephone: +33 (0) 4 91 27 57 00

Fax: +33 (0) 4 91 27 57 01

E-Mail: info@tagsysrfid.com

Website http://www.tagsysrfid.com

Contact for Comments

We welcome your feedback to help us provide high quality documentation.

For technical comments, please contact our Welcome Desk:

Telephone: +33 (0) 4 91 27 57 00

Fax: +33 (0) 4 91 27 57 01

E-Mail: info@tagsysrfid.com

Please remember to quote the Document Reference number DOC12984B1, your job title and your

company.

Quality Issues

TAGSYS implements stringent quality controls at all stages of its manufacturing process. However,

should you find a defect with this product, please notify your TAGSYS Quality Service

representative using the dedicated Product Return Form.

Telephone: +33 (0) 4 91 27 57 00

Fax: +33 (0) 4 91 27 57 02

E-Mail:

RMA@tagsysrfid.com

4/68 Revision 2.1 December 2009

Page 5

Table of Contents

PUBLISHING INFORMATION __________________________________________________________ 2

D

ISCLAIMER AND LIMITATION OF LIABILITY

___________________________________________________ 2

READ THIS FIRST ____________________________________________________________________ 3

C

ONVENTIONS

I

F YOU NEED ASSISTANCE

C

ONTACT FOR COMMENTS

Q

UALITY ISSUES

_________________________________________________________________________ 3

________________________________________________________________ 4

_______________________________________________________________ 4

_______________________________________________________________________ 4

LIST OF FIGURES ____________________________________________________________________ 8

LIST OF TABLES _____________________________________________________________________ 9

1

FOR YOUR SAFETY ____________________________________________________________ 10

1.1 G

1.2 C

1.3 I

1.3.1 O

ENERAL USE

ARE AND MAINTENANCE

MPORTANT SAFETY INFORMATION

PERATING ENVIRONMENT

___________________________________________________________________ 10

__________________________________________________________ 10

_______________________________________________________ 11

___________________________________________________ 11

2

CERTIFICATION________________________________________________________________ 12

2.1 O

2.1.1 P

2.1.2 E

2.2 S

2.3 R

2.3.1 IN E

2.3.2 IN USA (FCC D

3

3.1 F

3.2 B

4

4.1 R

4.1.1 W

4.1.2 E

4.1.3 N

4.2 L-SP3 RFID S

4.3 L-SP3 P

4.3.1 T

CCUPATIONAL HEALTH

UBLIC EXPOSURE

MPLOYEES EXPOSURE

AFETY NOTICES

EGULATORY NOTICES

UROPE

SYSTEM OVERVIEW____________________________________________________________ 16

EATURES

RIEF

INSTALLATION_________________________________________________________________ 19

ECOMMENDATIONS BEFORE INSTALLATION

IRE FEED SHEATHS

LECTRICAL SAFETY RULES

ETWORK CABLE INSTALLATION

OOLS REQUIRED

_______________________________________________________________________ 16

L-SP3 D

EDESTAL

_________________________________________________________________ 12

(CE

AND

IRECTIVE

ESCRIPTION

YSTEM COMPONENTS

_________________________________________________________________ 21

___________________________________________________________ 12

______________________________________________________________ 12

__________________________________________________________ 12

____________________________________________________________ 12

RTTE D

IRECTIVES

) ____________________________________________ 13

)_________________________________________________________ 14

_________________________________________________________ 17

___________________________________________ 19

____________________________________________________________ 19

_______________________________________________________ 20

____________________________________________________ 20

_________________________________________________ 21

_______________________________________________________________ 21

December 2009 Revision 2.1 5/68

Page 6

Library Security Pedestal 3

4.3.2 P

4.3.3 I

5

5.1 C

5.1.1 S

5.1.2 G

5.1.3 EAS M

5.2 U

5.2.1 S

5.2.2 W

5.2.3 S

5.3 P

5.4 C

5.4.1 I

5.4.2 C

5.4.3 TCP/IP C

5.4.4 M

5.4.5 B

5.4.6 A

5.5 P

5.5.1 R

5.5.2 R

5.5.3 A

LACEMENT OF PEDESTALS

NSTALLING THE PEDESTAL

_______________________________________________________ 21

________________________________________________________ 22

CONFIGURATION ______________________________________________________________ 28

HIP CONFIGURATION

CANNING DURATION PER PEDESTAL

LOBAL SCANNING DURATION

ODE VERSUS

NDERSTANDING THE

TANDARD SYNCHRONIZATION MODE

IRELESS SYNCHRONIZATION

YNCHRONIZATION BY A PAIR OF WIRES

ARAMETERS CONFIGURATION OF THE ETHERNET INTERFACE

ONFIGURATION OF THE

NSTALLING THE CONFIGURATION SOFTWARE

OMMUNICATION CONFIGURATION

ONFIGURATION AND FIRMWARE UPGRADE

ONITORING PEDESTAL ACTIVITY

ASIC PEDESTAL CONFIGURATION

DVANCED PEDESTAL CONFIGURATION

EOPLE COUNTER & BUZZER SOUND MANAGEMENT

ESETTING THE COUNTER DISPLAY

ESETTING THE REMOTE PEOPLE COUNTER

DJUSTING THE LEVEL OF THE BUZZER SOUND

_____________________________________________________________ 28

________________________________________________ 28

_____________________________________________________ 28

AFI M

ODE

____________________________________________________ 29

L-SP3 S

YNCHRONIZATION PROCESS

______________________________ 29

_______________________________________________ 29

_____________________________________________________ 31

_____________________________________________ 31

____________________________ 35

L-SP3 _____________________________________________________ 35

________________________________________ 35

_________________________________________________ 38

___________________________________ 40

__________________________________________________ 41

_________________________________________________ 45

_____________________________________________ 52

____________________________________ 55

________________________________________________ 55

_________________________________________ 55

_______________________________________ 55

6

OPERATION ___________________________________________________________________ 56

6.1 T

6.2 S

6.3 N

6.4 S

7

7.1 S

7.2 S

8

8.1 S

9

9.1 M

9.2 E

9.3 LSP3 C

HEORY OF OPERATION

TARTING THE SYSTEM

ORMAL OPERATION

HUTDOWN

MAINTENANCE ________________________________________________________________ 57

ERVICING THE PEDESTALS

ERVICING THE ELECTRONICS UNIT

TROUBLESHOOTING ___________________________________________________________ 59

OURCES OF INTERFERENCE

TECHNICAL SPECIFICATIONS __________________________________________________ 61

ECHANICAL DATA

LECTRICAL DATA

______________________________________________________________________ 56

LEAR MECHANICAL DRAWINGS

____________________________________________________________ 56

____________________________________________________________ 56

______________________________________________________________ 56

________________________________________________________ 57

__________________________________________________ 57

_______________________________________________________ 59

________________________________________________________________ 61

________________________________________________________________ 61

_______________________________________________ 61

10 PERFORMANCE TEST __________________________________________________________ 63

10.1 T

6/68 Revision 2.1 December 2009

EST CONDITIONS

_______________________________________________________________ 63

Page 7

10.2 T

EST PROCEDURE

_______________________________________________________________ 63

11 WARRANTY CONDITIONS ______________________________________________________ 65

11.1 W

11.2 G

11.3 H

ARRANTY EXCLUSIONS

ENERAL PROVISIONS

OW TO RETURN DEFECTIVE PRODUCTS

__________________________________________________________ 65

____________________________________________________________ 66

____________________________________________ 66

December 2009 Revision 2.1 7/68

Page 8

Library Security Pedestal 3

List of Figures

Figure 1: FCC maximum Power and Region settings (Uplink Data Rate) 15

Figure 2: LSP3 Clear Panel Overview 17

Figure 3: Safety Electrical Installation Using Power Cord 20

Figure 4: Clearance Distances around Pedestals 22

Figure 5: Light Barrier Orange and Green LED Lit when positioning Correct 23

Figure 6: Top view of correct L-SP3 installation and In/Out Counter Directions 24

Figure 7: People Counter View when facing light barrier and counter display 24

Figure 8: Light Beam Crossing Detection Cells & Display 24

Figure 9: Side view of correct L-SP3 installation 25

Figure 10: Pedestal Mountings 26

Figure 11: L-SP3 Clear Bottom Plastic Cover (4 screws) 26

Figure 12: Chronogram Sample (1 Master/ 4 Slaves) 29

Figure 13: 3 Pedestals Configuration Example and Token Propagation 31

Figure 14: Detailed of Wire Synchronization Assembly 32

Figure 15: PEM Connectors & Cables Location 33

Figure 16: Advanced Settings Tab Sections and Fields 34

Figure 17: Communication Configuration Tab (connected to a L-SP3) 38

Figure 18: TCP/IP Configuration Window 39

Figure 19: TCP/IP Configuration and Firmware Upgrade Tab 40

Figure 20: Pedestal Monitoring Tab 41

Figure 21: Database Window 44

Figure 22: Basic Pedestal Configuration Tab 45

Figure 23: Multi-gate configuration with two different IDs 47

Figure 24: GPIO Pulse & Pause Field 48

Figure 25: Peripherals & GPIO Green Connector Pin Out & Location 48

Figure 26: Internal Circuit of GPIO and External Supply Wiring in Output Mode 49

Figure 27: Connection of a Switch as an Input Device. 50

Figure 28: Connection of a Source and Sink Current Supply as an input Device 51

Figure 29: Advanced Pedestal Configuration Tab 52

Figure 30: Master/Slaves Synchronization Antenna Best Configuration 53

Figure 31: Asynchronous Event Notification Subfield. 54

Figure 32: People Counter & Detection Cells Location 55

Figure 33: Mains Fuses Location and Ratings 57

Figure 34: Mechanical Dimensions of Pedestal Base Fixing Plate 61

Figure 35: Outer Dimensions of LSP3 Clear Panel 62

Figure 36: Tag Orientation 63

Figure 37: Example 63

Figure 38: Test Chart 64

8/68 Revision 2.1 December 2009

Page 9

List of Tables

Table 1: L-SP3 System Components 21

Table 2: Description of Buzzer & Counter board Components 25

Table 3: Scanning Duration No Tag in field 28

Table 4: Global scanning duration versus Synchronisation mode 28

Table 5: GPIO Pins - Electrical Characteristics Max Ratings 49

Table 6: Troubleshooting Table 59

December 2009 Revision 2.1 9/68

Page 10

Library Security Pedestal 3

1 For Your Safety

1.1 General Use

The L-SP3 is designed to be rugged and reliable and to provide years of trouble-free

service. Please observe the following general tips:

Take care not to scratch the device. Keep the device clean. When working with the device,

use only TAGSYS-approved accessories.

This device is not waterproof and should not be exposed to rain or moisture. Under extreme

conditions, water may enter the circuitry.

Protect the device from extreme temperatures. For example, do not place the device in a

windowed area where the sun may cause extreme temperatures, and keep it away from

heaters and other heat sources.

Do not store or use the device in any location that is extremely dusty, damp, or wet.

Use a soft, damp cloth to clean the device. If the surface of the device becomes soiled,

clean it with a soft cloth moistened with a diluted window-cleaning solution.

1.2 Care and Maintenance

This device is a high end design and should be handled with care to maintain its

appearance in public locations. The suggestions below will further increase the lifetime and day

to day appearance of this device.

Keep the device dry. Precipitation, humidity and liquids contain minerals that will corrode

electronic circuits and tarnish transparent plastic parts.

Do not store the device in dusty, dirty areas. Its moving parts can be damaged.

Regularly dust the large transparent part using a soft cloth and antistatic liquid.

Do not store in hot areas. High temperatures can shorten the life of electronic devices,

damage batteries and warp or melt certain plastics.

Do not store in cold areas. When the device warms up (to its normal temperature), moisture

can form inside the device, which may damage electronic circuit boards.

Do not attempt to open the device during operation, outside installation and maintenance

periods. Non-professional handling of the device may damage it.

Handle the device with care. Shocks may break internal circuit boards.

Do not paint the device. Paint may clog the device’s moving parts and prevent proper

operation. Paint with metallic contents may limit device performances.

If the device or any accessory are not working properly, take it to your nearest qualified

TAGSYS representative.

Do not clean the device, particularly the transparent plastic parts, with harsh

chemicals, cleaning solvents or strong detergents. Gently wipe the device with a soft

cloth slightly dampened in a mild soap-and-water solution. Eliminate any residual

moisture with another clean and wet soft cloth.

Also regularly apply specific antistatic products for Acrylic Surfaces.

10/68 Revision 2.1 December 2009

Page 11

1.3 Important Safety Information

1.3.1 Operating Environment

When connecting the device or any accessory to another device, read its user’s guide for

detailed safety instructions. Do not connect incompatible products.

As with any RF equipment, users are advised that the equipment should only be used in its normal

operating position.

December 2009 Revision 2.1 11/68

Page 12

Library Security Pedestal 3

2 Certification

2.1 Occupational Health

TAGSYS L-SP3 EAS System has been designed and tested to be in conformity with the

European Standard EN 50364 “Limitation of human exposure to electromagnetic fields from

devices used in Electronic Article Surveillance (EAS), Radio Frequency Identification (RFID) and

similar applications” in conjunction with the European Standard EN 50357 describing how to

evaluate the exposure level.

2.1.1 Public Exposure

The Library RFID pedestals are designed assuming that patrons cross the detection area within a

couple of seconds on their way in and out of the Library at a normal walking pace. General public

should not stand in the detection area for more than 10 to 20 seconds.

Librarian should make sure that nobody stands still in the Gate

Detection Area in between two RFID Pedestals to avoid unnecessary

prolonged Exposure to Electromagnetic Field.

2.1.2 Employees Exposure

The operators are located apart from the principal detection zone and as a matter of fact,

not subject to exposure.

(Please see section 4.3.2 “Placement of Pedestals”)

For servicing operations it is recommended to deactivate the RFID

system.

2.2 Safety Notices

The L-SP3 has been tested to be in conformity with the EN standard 60950-1: “Information

Technology Equipment Safety”

It is the responsibility of the CIT (Certified Integrators by TAGSYS) to install the L-SP3 as

described in TAGSYS Product Manuals or TAGSYS Documentation.

Modification of any TAGSYS Library System is prohibited without the written consent of TAGSYS.

Unauthorized modifications may void the conformity of the equipment to safety specifications and

will void the TAGSYS warranty.

2.3 Regulatory Notices

An RFID system typically composed of an RF emission device such as the L-SP3 connected

to an antenna is subject to national regulations that may differ by country.

One important item to consider is the maximum permissible magnetic field intensity at a distance of

10 meters from the antenna that must not exceed 60dBµA/m in Europe and 38dBµA/m in US.

The L-SP3 meets these limits.

12/68 Revision 2.1 December 2009

Page 13

2.3.1 In Europe (CE and RTTE Directives)

The L-SP3 complies (CE Declaration of Conformity granted) with the European EMC

directive.

The L-SP3 complies with the requirements of the Telecommunication Terminal Equipment Act

(FTEG) and the RTTE Directive 1995/5/EC.

It is the responsibility of the TAGSYS Reseller to install the L-SP3 as described in this User’s

Guide or TAGSYS Documentation.

Any modification of the L-SP3 is prohibited without the written consent of TAGSYS. Unauthorized

modifications may void the conformity of the equipment to CE and RTTE Directives and will void

the TAGSYS warranty.

It is the responsibility of the CIT (Certified Integrators by TAGSYS) to

install the L-SP3 as described in this Reference Guide or in TAGSYS

Documentation.

If an L-SP3 is further integrated in a different product, it is the

responsibility of the manufacturer of this complementary product to

obtain the required approvals for this product.

December 2009 Revision 2.1 13/68

Page 14

2.3.2 In USA (FCC Directive)

L-SP3 Clear

WARNING TO USERS IN THE UNITED STATES

FEDERAL COMMUNICATIONS COMMISSION (FCC) RADIO

INTERFERENCE STATEMENT 47 CFR Section 15.105(b)

This equipment has been tested and found to comply with the limits for a Class B digital

device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable

protection against harmful interference in a residential installation. This equipment generates uses

and can radiate radio frequency energy and if not installed and used in accordance with the

instructions may cause harmful interference to radio communications. However, there is no

guarantee that interference will not occur in a particular installation. If this equipment does cause

harmful interference to radio or television reception, which can be determined by turning the

equipment off and on, the user is encouraged to try to correct the interference by one or more of

the following measures:

▪ Reorient or relocate the receiving antenna.

▪ Increase the separation between the equipment and receiver.

▪ Connect the equipment into an outlet on a circuit different to that to which the receiver is

connected.

▪ Consult the dealer or an experienced radio/TV technician for help.

NO UNAUTHORIZED MODIFICATIONS

47 CFR Sections 15.21

CAUTION: This equipment may not be modified, altered, or changed in any way without signed

written permission from TAGSYS SA. Unauthorized modification may void the equipment

authorization from the FCC and will void the TAGSYS warranty.

ANTENNA REQUIREMENT

47 CFR Sections 15.203

CAUTION: This equipment must be professionally installed. The installer shall be responsible for

ensuring that the proper antenna is employed so that the limits in this part are not exceeded. Nonprofessional installation or installation of the equipment with an improper antenna may void the

equipment authorization from the FCC and will void the TAGSYS warranty.

The L-SP3 has been designed to comply with Part 15 of the FCC Rules.

Operation is subject to the following two conditions: (1) The system devices may not cause harmful

interference, and (2) The library system devices must accept any interference received, including

interference that may cause undesired operation.

December 2009 Revision 2.1 14/68

Page 15

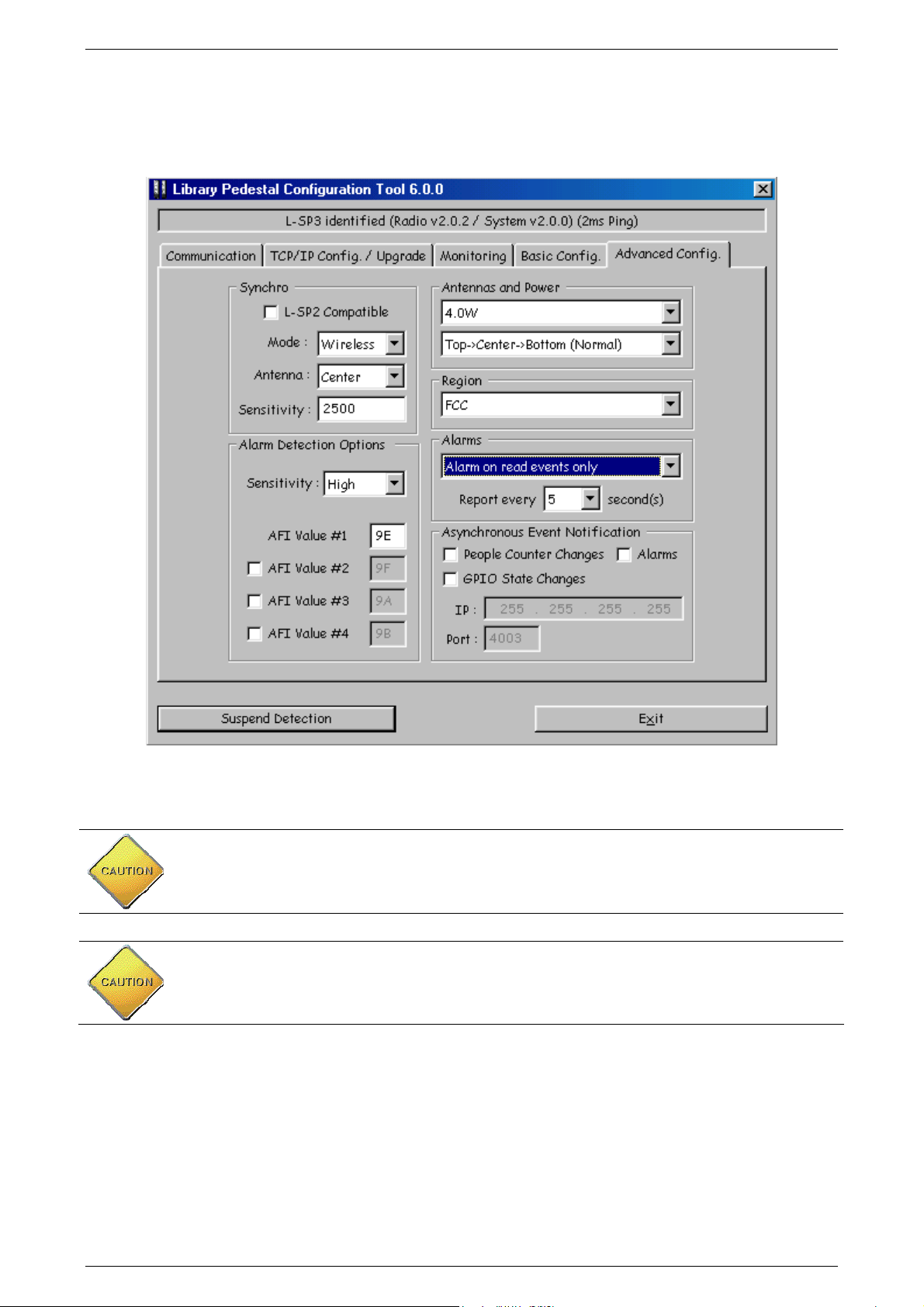

Figure 1: FCC maximum Power and Region settings (Uplink Data Rate)

CAUTION: In any case, for operational configuration this value should not exceed 4W to be in

compliance with FCC. The “Antennas and Power” parameter in “Advanced Configuration” Tab

does not allow setting a higher power value than 4.0W at most. Please see above Figure 1:

FCC maximum Power and Region

CAUTION: ISO15693 uplink data rate you should not exceed 1.65kbits/s in order to comply

with FCC standard certification. To do so, set the “Region” parameter in “Advance

Configuration” Tab to “FCC”. See above Figure 1: FCC maximum Power and Region

settings

.

settings

.

December 2009 Revision 2.1 15/68

Page 16

3 System Overview

3.1 Features

Being a standalone solution, TAGSYS security pedestal do not need to be linked to the

library database, and can still operate when the Integrated Library System (ILS) is down or under

maintenance. The security pedestal does not require additional equipment to operate.

The L-SP3 pedestal features:

Multi-protocol features which makes it compatible with ISO15693 chips

NXP proprietary EAS mode supported for the C370 (NXP SLI), C370-L (NXP SLI-L)

chips

AFI mode supported, with configurable AFI value (Multiple AFI values, up to 4)

TAGSYS proprietary C220/C320 EAS burst detection support

TAGSYS proprietary C320 256 bits memory reading in NSNT single tag mode.

Multiple items Read-Memory supported in EAS mode for C370 (NXP SLI), C370-L

(NXP SLI-L)

Standard Multiple items Read-Memory supported in AFI mode using the optional

command Read Multiple Blocks as described by the ISO15693-3

Enhanced Multiple items Read-Memory supported in AFI mode for C370 (NXP SLI),

C370-L (NXP SLI-L), Tag-it ™HFI (Texas Instruments) chips, LRI-2K (STM).

Read-Memory Data Model: up to 896-bits (28 blocks of 32bits)

One electronic system block embedded into bottom of Pedestal

A remotely accessible people counter based on dual photoelectric sensors coupled to a

reflector, allowing in and out traffic monitoring.

Ethernet Networking Link communication for set up, database and patron counter value

retrieval

Asynchronous Event Notification over the Network: pedestal sends automatically data

upon Book Detection, Patron Counter change, GPIO level change or Pedestal fault

detection.

Trigger input to quickly power up and down remotely the pedestals using light cells

before and after the pedestal area. This lowers down the radio emission levels to the

strict minimum necessary.

One Extra Open Drain Output to drive External Alarm Device: Webcam, Extra Remote

Display or Sound

This is a cost effective security system as it only requires a single RFID tag for both anti-theft and

identification purposes.

16/68 Revision 2.1 December 2009

Page 17

3.2 Brief L-SP3 Description

Figure 2: LSP3 Clear Panel Overview

December 2009 Revision 2.1 17/68

Page 18

The components of the L-SP3 EAS system are contained within the L-SP3 pedestal. At

least two pedestals are required for each EAS gate. A set of pedestals is known as a gate and may

consist of several pedestals. Please see section 4 “Installation” for more information.

The L-SP3 is built in a one frame:

An L-SP3 Electronics unit is used to control each pedestal. This electronics unit

generates the RF signal transmitted by the antennas and picks up the reply from the

RFID tag. If an activated RFID tag is detected, the electronics unit will activate the

LED/buzzer alarm

These antennas are sensitive receivers used to detect the theft bit status and the AFI

value of the RFID tag as it passes through the EAS gate

Visual and audible warning devices

A remotely accessible people counter equipped with dual light barrier photoelectric

sensors.

To operate, the L-SP3 will only need an IEC power supply cable, avoiding unnecessary mains

cable wiring up.

An IEC Mains Supply Cord Outlet is available to allow daisy chaining. A series of up to 5 pedestals

can be powered up from a single wall socket.

18/68 Revision 2.1 December 2009

Page 19

4 Installation

4.1 Recommendations before Installation

4.1.1 Wire Feed Sheaths

Within the framework installation you need at least a power supply cable sheath and an

Ethernet cable sheath to connect to the Ethernet network. These sheathed cables will be located at

the bottom center of the pedestal as shown in Figure 10.

If needed according to the installation configuration, extra sheathed cables need to placed

for wire synchronization, Trigger cable and to remotely switch the RF on & off and I/O cables to

drive external devices (Camera, Remote alarms…).

The L-SP3 is delivered without any IEC terminated plug power supply cable or Telecommunication

cable. It is up to the Local installation personnel to use the appropriate IEC Power Cord according

to local electrical regulations.

Use appropriate IEC power cord according to the local regulations to

power up and interconnect the pedestals.

The Power Supply Cord is the LSP3 Product Main Disconnecting Device,

It should be easily accessible at any time to Disconnect the pedestals

from the mains power supply.

December 2009 Revision 2.1 19/68

Page 20

4.1.2 Electrical Safety Rules

The L-SP3 is powered up via a Mains Supply IEC Cord.

A group of up to 5 Pedestals can be daisy chained and powered via a single IEC power

cord connected to a wall socket. The mains wall socket should provide at least 2 Ampere and be

protected by a differential circuit breaker limiting the current to 5 Ampere maximum.

Figure 3 here below shows how to connect the L-SP3 pedestals to the mains.

Figure 3: Safety Electrical Installation Using Power Cord

LSP3 Pedestals Aisle

Wall

Socket

IEC Power Cord

The electrical installation must be carried on by qualified personnel only.

For each country where installation takes place, an adequate IEC power

supply Cord must be used, fitting the local wall socket layout.

4.1.3 Network cable installation

The L-SP3 Pedestal delivery package does not include an Ethernet cable to connect to a Local

Area Network for remote operation. We recommend the use of a Shielded Ethernet cable, UTPCat 5.

20/68 Revision 2.1 December 2009

Page 21

4.2 L-SP3 RFID System Components

The components included in the L-SP3 RFID System package are listed in Table 1

Table 1: L-SP3 System Components

Quantity Description

1

8

1

L-SP3 Pedestal

40 mm Philips-head, countersunk screws with a diameter of 6 mm

2 ways 3.81mm Green Screw Tightening Plugs Vertical Cable Entry for

Synchronization Cable

1

4 ways 3.81mm Green Push-On Plugs Vertical Cable Entry for I/O Wiring

4.3 L-SP3 Pedestal

CAUTION: This equipment is intended for indoor use only under the

conditions described in this document. Should it be used outside these

conditions cannot be guaranteed, and is not recommended. Please read

section 1 “Publishing Information” before installation or use.

4.3.1 Tools Required

The following tools are required during installation:

Measuring Tape

Square

Hand Drilling Machine with 4 mm, 8-mm and 19-mm drilling bits

Philips-head screwdriver

Spirit Level

4.3.2 Placement of Pedestals

Pedestals must be mounted between 800mm and 980 mm apart (edge to edge) for

maximum reliable performance. There should be at least one pair of pedestals at each

entrance/exit point of the library. There should be a pedestal at each edge of the entrance, and a

clear space of at least 500 mm around the edge of the pedestals to ensure that the antennas will

not be detuned. This clear space must not contain any metallic objects, but may contain some

substrates such as non-metallic/non-conductive building materials such as wood, glass,

chipboards and plasterboards.

CAUTION: In case several Pedestal rows (group of Pedestals) to be

installed it is mandatory every L-SP3 being positioned in the same

direction (all people counter of each looking toward the same direction).

This would prepare the installation for future implementation of direction

sensing.

Be cautious to properly align the pedestal in order to centre the photoelectric beam sensor on the

reflector of the next pedestal.

December 2009 Revision 2.1 21/68

Page 22

CAUTION: Each L-SP3 should be installed within following tolerances:

C

A

B

Horizontal angular alignment tolerance with reference to pedestals

alignment: 0° +/-2°

Vertical angular tolerance with reference to ground surface : 90° +/-1°

CAUTION: Each L-SP3 must be installed at least 2 meters away from

sliding doors. Metal frames do pick up & radiate stray Radio ham

electromagnetic field which can lead to false triggering. Prior to

installation a site survey is highly recommended.

Figure 4: Clearance Distances around Pedestals

A: Indicates the distance (6 ft.

6in.) to a permanent librarian

position.

B: Indicates the distance (8 ft.)

from other RFID stations.

F 30 ft. (9.1 m)

C: Indicates the recommended

distance (36 in. face panel to

face panel) between

pedestals.

D: Indicates the minimum

distance (31½ in.) between a

pedestal and large metal

object.

6 ft. 6 in. (2 m)

31½ in. (80 cm)

36 in.

E: Indicates the minimum

distance (20 in.) between a

pedestal and small metal

object.

F: Indicates the minimum

distance (30 ft.) between

Master pedestals (specific

synchronization ID, see

section 5.2 “Understanding

the L-SP3 Synchronization

Process”).

8 ft. (2.4 m)

(91.4 cm)

20 in. (50 cm)

4.3.3 Installing the Pedestal

Once the L-SP3 will be powered, the photoelectric sensors will emit a red light beam. To

precisely align the sensors and the reflector, an orange LED is present on the back of the

photoelectric sensor. When the orange LED is continuously on, the sensor and the reflector are

perfectly aligned.

To see these LED, one must first unscrew the Plastic Bottom Cover covering the dual cells

(see picture of 5.5.1 Resetting the Counter Display).

On the contrary when the orange LED is blinking or off, then you have to adjust the photoelectric

sensor, so that the red light beam is centered with the opposite reflector. This operation is

achieved using a white paper to clearly see where the red light beam is pointed at. When perfectly

centered, the orange LED will continuously be ON.

On figure 7 below, the two Beam Crossing Cells support is shown. To do a fine adjustment of 2

beams, use a hexagonal key to screw or unscrew the top left screw (to adjust height of beams) and

the bottom right screw (to adjust the lateral positioning of the beams). They are spring loaded to

improve accuracy and keep in place the two sensors after adjustment.

22/68 Revision 2.1 December 2009

Page 23

Special attention must be taken for the 2 pedestals positioning:

They must be positioned facing each others

They must be parallel

They must be well aligned and well centered.

The orange LED must be continuously ON when powered (See Figure 5)

If the orange LED still blinks when perfectly aligned and centered, check that the spacing

does not exceeds the recommended values.

For correct In & Out counter operation, the pedestals must be placed according to the

library flow of patrons. See Figure 6 and Figure 7 for In & Out counting direction.

Figure 5: Light Barrier Orange and Green LED Lit when positioning Correct

Before final Installation, do make sure that the Entrance flow is in line

with the in Counter Increment Direction Described in Figures Figure 6

and Figure 7.

There is no mean to change the In & Out Counter Direction by software

afterward.

Then the 2 pedestals can be secured to the ground.

A good positioning will ensure the two red LED beams to be back scattered by the reflector as

shown below. See Figure 5 for LED positioning.

December 2009 Revision 2.1 23/68

Page 24

Way in Counter

Left Hand Light Beam

Right Hand Light

LCD Counter Display

Buzzer Level Adjust

Right Hand

Reflector

Parallel

Reflector

Left Hand

In Counter

Out Counter

1

2

3 4

5

6

7

8

Figure 6: Top view of correct L-SP3 installation and In/Out Counter Directions

Light Beam

Light Beam

Incremented

Incremented

Figure 7: People Counter View when facing light barrier and counter display

Figure 8: Light Beam Crossing Detection Cells & Display

24/68 Revision 2.1 December 2009

Page 25

Ground

Reflector

Table 2: Description of Buzzer & Counter board Components

Reference n° Designation

1 Buzzer Volume Adjustment

2 Buzzer

3 Photoelectric Reflex Switch Red Beam

4 Photoelectric Reflex Switch Red Beam

5 LCD Display & Counter

6 Counter Reset Push Button

7 Hexagonal Screw for Light Beam Vertical Alignment

8 Hexagonal Screw for Light Beam Horizontal Alignment

On Figure 8 above, the two Beam Crossing Cells support is shown. To do a fine adjustment of the

2 beams, use a hexagonal key to screw or unscrew the top left screw (to adjust height of beams ref

7 circled) and the bottom right screw (to adjust the lateral positioning of the beams ref 8 circled).

They are spring loaded to improve accuracy and keep in place the two sensors after adjustment.

Figure 9: Side view of correct L-SP3 installation

December 2009 Revision 2.1 25/68

Page 26

After having defined the location of the pedestals, refer to the mechanical drawing of the pedestalmounting diagram (Figure 10). The pedestal is fastened to the floor using screws that are strong

enough to support the weight of an average adult falling against the pedestal.

Figure 10: Pedestal Mountings

1. Identify and mark the location of the holes to be drilled for mounting the pedestal to the ground.

The use of a tape measure and a square is recommended.

2. Drill the cable access and mounting holes according to the type of ground surface:

a. Wooden floor: Drill eight holes with a diameter of 4 mm for the mounting screws and

one hole with a diameter of 19 mm for the cable access.

b. Cement floor: Drill eight holes with a diameter of 8 mm for the cement floor plugs and

one hole with a diameter of 19 mm for the cable access. It may be necessary to provide

a groove for the power supply cable connected to the L-SP3 Electronics Unit. Insert the

concrete floor plugs into the mounting holes.

CAUTION: Always use a protective sleeve for main power cable, which

match to the flammability grade of the product. Mains power cable must

be a 3 wire (line, neutral and earth), multi stranded copper wire,

minimum section of 0.75 mm²/ 3A)

Figure 11: L-SP3 Clear Bottom Plastic Cover (4 screws)

26/68 Revision 2.1 December 2009

Page 27

3. Remove the pedestal from the box.

4. Remove the plastic cover from the both sides after removing the 4 fixing screws.

5. Engage the power supply cable in the electric sheath and the Ethernet cable in the other

sheath (please refer to section 4.1.1 “Wire Feed Sheaths”).

6. Place the pedestal base over the mounting holes. Insert and fasten the screws in the mounting

holes according to the type of ground surface:

Wooden floor: Insert the screws directly into the mounting holes and tighten the screws in

place.

Concrete floor: Insert the screws into the concrete floor plugs and tighten the screws in

place.

When tightening the screws in place, first tighten the screws in place ¾

of the way. Once all screws are in place, then tighten each screw

progressively, one after each other to ensure that the floor bracket is

solidly fixed into place and completely vertically aligned. The use of a

level may be required.

7. Plug in the mains IEC power cord from the previous pedestal if daisy chained or from the wall

mounted socket. See figure in Chapter Electrical Safety Rules

No Live AC mains 110/230V during installation!

Make sure there is no power supply current before carrying on the

connection operations.

To do so, unplug the IEC Power Cord from the wall socket.

8. Once all the L-SP3 pedestal have been installed, close the micro circuit-breaker (Figure 3) to

power up the system before starting configuration operations. Please see section 5

“Configuration”.

9. After the configuration has been carried on, replace the two plastic covers and tighten the 4

fixing screws.

December 2009 Revision 2.1 27/68

Page 28

5 Configuration

All configuration operations of L-SP3 systems are carried on with the L-SP3 Configuration Utility

Software.

5.1 Chip Configuration

For optimal performance the scanning duration (T_scan) should not exceed 250ms. T_scan

is the period to scan all pedestals of a group of N pedestals, i.e. a Master and (N-1) Slave

Pedestals. Depending on your chip configuration and the number of pedestals installed you can

determine the scanning duration of your installation.

5.1.1 Scanning duration per pedestal

Table 3: Scanning Duration No Tag in field

Synchronization process

C370/-L, Tag-It, ISO15693 EAS or one AFI,

detection only

C220/C320 EAS detection only

The scanning duration per pedestal will vary according to the configuration you selected. The

scanning duration will always include the synchronization process of 10ms.

Example 1: with a system using the 370-AFI in ETSI mode.

The scanning duration per pedestal will be: T_single _scan = (10ms+20ms) = 30ms

Example 2: with a system using the 370-AFI1-AFI2 in ETSI mode.

The scanning duration per pedestal will be: T_single _scan = (10ms+20ms+20ms) = 50ms

Example 3: with a system using the 370-EAS + C320-EAS in ETSI mode.

The scanning duration per pedestal will be: T_single _scan = (10ms+20ms+15ms) = 45ms

Duration per pedestal

in ETSI mode (ms)

10 10

20 100

15 15

Duration per pedestal

in FCC mode (ms)

5.1.2 Global scanning duration

The global scanning duration (T_scan) will depend on the synchronization mode you have

selected. Hardwired synchronization is faster than wireless synchronization.

Table 4: Global scanning duration versus Synchronisation mode

Synchronization Mode T_scan

Hardwired = T_single_scan x Nb_Pedestals

Wireless

Example 4: with a 4 pedestals system using 370-AFI1-AFI2 in ETSI mode.

The global scanning duration will be: T_scan = 50ms x 4 = 200ms if used hardwired.

The global scanning duration will be: T_scan = 50ms x ((2 x 4) – 2) = 300ms if used wireless.

28/68 Revision 2.1 December 2009

= T_single_scan x

((2 x Nb_Pedestals) – 2)

Page 29

Pt

Synchronization Burst

T_scan

5.1.3 EAS Mode versus AFI Mode

EAS mode is only supported by the C370 or C370-L (NXP chip). AFI mode is supported by most

ISO15693 chips, from major chip manufacturers (NXP, Texas Instrument, STM, Infineon,

MeMarin…).

EAS digital burst is a prime number data stream of 128 bits which is read out after sending a check

EAS command to the Tag. This dedicated EAS command in only implemented in NXP SLI chips.

C220 & C320 TAGSYS chips EAS signal is respectively 100kHz free running and 106kHz

synchronous burst sent by the chip at power on reset during a few ms when RF field is first

established and when EAS bit is set. This mode is only supported by TAGSYS which owns the

chip design. C220 supports only EAS detection, no memory content read out is possible. C320

supports both EAS detection and 256 bits memory content read out for data model support.

The AFI (Application Family Identifier) is an 8bit-field defined in the ISO15693 standard but not

mandatory. Whenever issuing an inventory command with a specific AFI code, only Labels with the

same matching AFI code will reply with its UID. Generally the code 9E is used to say that the book

has not been properly checked out, thus will be detected by the pedestals.

5.2 Understanding the L-SP3 Synchronization Process

5.2.1 Standard Synchronization Mode

To manage a group of pedestals, a synchronization burst is sent by the master pedestal to all

the slaves’ pedestals, a token being propagated back and forth as in a token ring process. This is

called the synchronization process.

Only one pedestal is defined to be the master who emits a synchronization burst to the next

slave in close proximity who in turns emits it to the next slave and so forth.

The other pedestals, configured as slaves, get the synchronization from the neighboring

pedestal and emits back to the next Slave of higher index.

Default Configuration of the L-SP3 is set to Master 2 Pedestals.

Figure 12: Chronogram Sample (1 Master/ 4 Slaves)

MASTER

SLAVE1

SLAVE2

SLAVE 3

SLAVE 4

December 2009 Revision 2.1 29/68

Page 30

Synchronization burst: start burst to synchronize the gates (Period of T Scan ms)

Processing time (Pt): depends on the number of tags to be detected and the settings. The

fastest is when only detection is used (EAS burst or AFI), the slowest when all features are

used (AFI + Read AFI + Read 16 blocks of memory). Refer to the figures in Table 3:

Scanning Duration.

Synchronization process for 3 pedestals:

1- The master scans the configured chip, then sends the synchronization burst to Slave1

2- Slave1 scans the configured chip, then sends the synchronization burst to Slave2

3- Slave2 scans the configured chip, and then sends the synchronization burst back to either

the master when in hardwire mode or to the Slave1 in wireless mode.

This process is repeated indefinitely.

In case the master does not receive back the synchronization burst from the last slave after a

defined period, it will automatically restart the synchronization process.

The number of pedestals is not limited to any particular number as long as each gate is close

enough to its neighboring pedestal and that the overall scanning time does not exceed a few

100ms to allow for a safe detection at 1m/s pace trough any gate.

30/68 Revision 2.1 December 2009

Page 31

5.2.2 Wireless Synchronization

In Standard Synchronization mode, section 5.2.1, if pedestals spacing

exceeds the recommendation of section 4.3.2 “Placement of Pedestals”,

wire synchronization becomes mandatory.

When more than two pedestals are installed, it is mandatory to install the Master on the far left or

right of the slave’s line for a better propagation and detection of the air synchronization burst.

Figure 13 below shows an example of optimal configuration. Slaves must be placed with the

correct index corresponding to its physical location in order to carry other the token allowing

starting to scan its 3 own antennas before handing over the token to the next neighboring pedestal.

Figure 13: 3 Pedestals Configuration Example and Token Propagation

Red Arrow: Wireless Synchronization Token hand over

Blue arrows: Wire Synchronization Token hand over

5.2.3 Synchronization by a pair of Wires

This mode is mandatory in noisy environments or when nearby RFID devices are placed too

near within a couple of meters from any pedestals preventing the installation using wireless

settings.

It is also mandatory when using too many pedestals (typically above 4 to 6 pedestals) as

wireless burst signal needs to go to the last slave N pedestal and then back going through all N

slaves before the master can scan its detection volume again. Processing time is thus equal to 2N

times Pt in wireless mode.

Using a synchronization cable, the token can be directly handed over by the last slave N to

the Master without having to go through all N Slaves pedestals again. Overall scanning time is thus

equal to N times Pt, half of the wireless time.

In this case the L-SP3 configuration settings have to be changed from “Wireless” to

“Hardwire” Synchronization in the L-SP3 Configuration Tool program, “Advanced Configuration”

last tab. See Figure 12 to see the correct fields to be modified. There will always be one & only one

December 2009 Revision 2.1 31/68

Page 32

L-SP3 Master and all others pedestals set as Slaves. Each pedestal is connected to the other

using ideally a twisted pair cable. This cable will propagate the synchronization signal to all

pedestals in parallel.

Wire connection:

First prepare a cable of appropriate length to connect 2 consecutive Electronics as shown in

Figure 14 and Figure 15. A minimum wire gauge of 22AWG (0.2mm²) is enough, preferably a

twisted pair. Screw at each extremity of the cable a 2-way connector with ground wire at the same

position for each module. If more than 2 pedestals are used to form the aisle, then connect the

wires in parallel to go to the next pedestal until you reach the last one.

Figure 14: Detailed of Wire Synchronization Assembly

Then unscrew the 4 screws to open the bottom plastic cover panel of each pedestal forming

the aisle to gain access to the Product Electronic Module and connect the top 2-way connector as

shown in Figure 15 thereafter.

32/68 Revision 2.1 December 2009

Page 33

Buzzer & Alarm Display Connector

24 Volts Power Supply Cable

Unshielded 2

-

wire Synchronization

Cable connecting all Pedestals

GPIO#1 & GPIO#2

Figure 15: PEM Connectors & Cables Location

Shielded CAT5 Ethernet Cable

December 2009 Revision 2.1 33/68

Page 34

Figure 16: Advanced Settings Tab Sections and Fields

Steps to undergo:

1. Prepare a 2 wire cable of appropriate length and number of connectors to wire up each

pedestal. Use the 3.81 mm Push-On Green Plugs Vertical Cable Entry provided.

2. Connect all pedestals Synchronization to the Synchronization I/O as shown on Figure 11.

3. Set each pedestal to hardwire synchronization modifying the “Mode” in the “Synch” Section

of the “Advanced Configuration” tab of the L-SP3 Pedestal Configuration Tool.

4. Write down the MAC address of each pedestal. Use the test button in “Monitoring” tab to

locate it: the connected pedestal will ring and its display lit.

5. Power up the whole system (every pedestal must be powered up) and check that the

synchronization process works properly detecting a book in each passageway.

6. Put the cover panel back into place and secure it with the 4 screws

34/68 Revision 2.1 December 2009

Page 35

5.3 Parameters Configuration of the Ethernet Interface

Don’t forget to power up your installation before carrying on the

following steps

The first step is to allocate a unique IP address to each L-SP3. This operation will allow

identifying each L-SP3 on site before configuring them on the Ethernet network.

By default the IP address is 169.254.0.100 (port 4001) (IPv4 Automatic

Private IP Addressing). Ask your network administrator to obtain a static

IP address for each of the pedestals connected to your local network.

The L-SP3 configuration will be carried on using a host computer connected to the local Ethernet

network.

You can localize the each gate thanks to their IP address. Their on site

location must be known to configure and set them as Slaves or Master.

5.4 Configuration of the L-SP3

“Library Pedestal Configuration Tool” is the software tool used to monitor and configure the

L-SP3 pedestal.

Before you configure the whole L-SP3, you need to have a clear vision of

which pedestals will be masters or slaves. (Refer to section 5.2

“Understanding the L-SP3 Synchronization Process”)

In a configuration with several pedestals, as all pedestals are set as

master by default, they will mutually perturb when powered on. So the

first step will be to set the appropriate pedestals as slaves.

The whole L-SP3 configuration is carried on from a host computer connected to the local

area network. Each L-SP3 is addressed thanks to its own IP.

5.4.1 Installing the Configuration Software

The Library Pedestal Configuration Tool is on the CD-Rom provided with the L-SP3.

Launching the Installer from the CD-ROM will display the following window:

December 2009 Revision 2.1 35/68

Page 36

Follow the installer steps:

36/68 Revision 2.1 December 2009

Page 37

After the Library Pedestal Configuration Tool is installed, a shortcut to the application will be added

to the desktop and to the Start Menu.

Double-click on the application shortcut to start the application.

December 2009 Revision 2.1 37/68

Page 38

5.4.2 Communication Configuration

Figure 17: Communication Configuration Tab (connected to a L-SP3)

This tab is used either:

• To establish connection to a pedestal when its IP address is known.

• To discover pedestals connected to the same network as the PC running the configuration

tool.

• To modify the TCP/IP configuration of a discovered pedestal (not including port) if this

address is not coherent with the address of the network it is connected to.

Connecting to a pedestal when its IP address is known

Select “Ethernet/Wifi” as the Com Mode, enters the pedestal IP address and Port in the

appropriate fields and click “Init Communication”. Status bar on top of the window area should now

display pedestal model and firmware revisions.

Click “Release Communication” to disconnect from a pedestal.

38/68 Revision 2.1 December 2009

Page 39

Discovering pedestals connected to the network

Click “Discover Devices” when not connected to a pedestal. After a few seconds, the list of

discovered pedestals (IP Address, Port and MAC address) is displayed. Double-Click an item in

the list to connect to the corresponding pedestal.

In case a pedestal is properly discovered but connection attempts fail, please make sure that :

• No other host is already connected to the pedestal.

• The IP address that appears in the list is correct and coherent with the address of the

network the pedestal is connected to. If the IP address is incorrect, please follow the

procedure below.

Modifying TCP/IP configuration of discovered pedestal (not including port)

First discover pedestals as described above. Then right-click the list item corresponding to the

pedestal whose IP address must be modified. Select “Configure TCP/IP” in the pop-up menu. The

following window appears:

Figure 18: TCP/IP Configuration Window

Fill the fields with the appropriate data then click “Apply and Reboot” to apply new configuration

and reboot pedestal. After a few seconds, you should be able to connect to the pedestal.

Click “Cancel” to cancel the operation.

This procedure is applicable even if connection to the pedestal is

impossible because another host is already connected to it, or because

its IP address is incoherent.

Another procedure is available to modify TCP/IP configuration of a

pedestal including port and without having to reboot it immediately (in

this case, changes will be applied upon next reboot). However, this

procedure requires that a connection is established to the pedestal (see

section below).

December 2009 Revision 2.1 39/68

Page 40

It is possible to revert to the default settings (DHCP active, fallback IP

address set to 169.154.0.100). To do so, power-off pedestal, press and

hold the LCD button, power-on pedestal, wait 5s then release LCD

button.

5.4.3 TCP/IP Configuration and Firmware Upgrade

Figure 19: TCP/IP Configuration and Firmware Upgrade Tab

This tab is used either:

• To upgrade System Firmware.

• To upgrade Radio Firmware.

• To modify TCP/IP Configuration, including port.

Upgrading System Firmware

Click “System Upgrade”, and then select the appropriate firmware file. A bar shows the progress of

the upgrade process. After upgrade is completed, you can decide to run the new firmware

immediately by rebooting the pedestal, or to wait for next reboot to run it.

Upgrading Radio Firmware

Click “Radio Upgrade”, and then select the appropriate firmware file. A bar shows the progress of

the upgrade process. After upgrade is completed, you can decide to run the new firmware

immediately by rebooting the pedestal, or to wait for next reboot to run it.

40/68 Revision 2.1 December 2009

Page 41

When upgrading both System and Radio firmware, it is advised to reboot

the pedestal only once after both upgrades are completed.

The EAS detection is suspended during the upgrade process.

Do not power-off pedestal during the upgrade process. Failure to respect

this procedure may corrupt pedestal firmware and require product to be

sent back to TAGSYS.

In case of a software failure during the upgrade process, do not poweroff the pedestal, restart the configuration software and try upgrading the

pedestal again.

Modifying TCP/IP configuration (including port)

Fill the fields with the appropriate values and click “Apply Changes”. You can then decide to apply

the new TCP/IP configuration immediately by rebooting the pedestal, or to wait for next reboot to

apply it.

5.4.4 Monitoring Pedestal Activity

Figure 20: Pedestal Monitoring Tab

December 2009 Revision 2.1 41/68

Page 42

This tab is used either:

• To check / update pedestal clock.

• To check / toggle GPIOs Level.

• To check antenna noise level.

• To check / configure people counter.

• To check alarms database.

Checking / Updating pedestal clock

Pedestal clock is displayed in real-time in the “Date & Time” section. Click “Synchronize Time” to

synchronize pedestal clock with computer clock.

Pedestal clock is used as a date stamp when a theft is committed.

Checking GPIO level

The two GPIO available to user can be monitored:

Display shows “High” when voltage level is above 2 Volt.

Display shows “Low” when voltage level is below 1 Volt.

See Table 3 for more detailed information.

Clicking with the mouse on GPIO text field, the Level value toggles between High & Low.

The effect will depend on the actual GPIO settings on Basic Configuration Tab.

GPIO #1 can be set as an Input Trigger for RF powering off/on as well as

an Output for driving an External Alarm Device

GPIO #2 can only be used as an Output for driving an External Alarm

Device

Checking antenna noise level

In “Antenna Noise Level” section, bar graphs provide a feedback regarding the ambient noise level

measured by each antenna. It is only provided as debug purpose and should not be seen as a

measure of performance. Green shows standard conditions as opposed to orange and red displays

warning of possible/likely performance reduction due to ambient noise level.

Checking / configuring people counter

The “People Counter” section displays the total number of people that crossed the IR sensor:

• Whatever the direction (In & Out) if no bidirectional IR sensor is installed.

• In each direction (In & Out) if bidirectional IR sensor is installed.

People counter value is battery backed-up, and is consequently restored

at power-up.

An icon briefly appears in real-time in “People Counter” section as the sensor IR beam is crossed.

42/68 Revision 2.1 December 2009

Page 43

Click on “Clear People Counter” button to reset people counter.

To reset people counter, you can also use a pointed element (for

example, a paper clip), insert it in the hole on the left of the display

window and press (not too strong) until zero is displayed.

Use the drop-list in the “People Counter” section to select which count is to be displayed on

pedestal LCD:

• “Display In + Out Counter” to display the sum of In and Out counters.

• “Display in Counter” to display In counter only.

• “Display out Counter” to display out counter only.

Pedestal must be rebooted for changes to take effect.

The drop-list is not available if no bidirectional IR sensor is installed. In

this case, pedestal LCD always displays the sum of In and Out counters.

Checking alarms database

Each time an item (with EAS/AFI activated) passes through the gates an entry is added to a local

database in pedestal memory. This entry holds the following information:

• The date and time to which the theft was committed.

• The chip type.

• If selected, the memory contents.

• If selected, the UID.

• The method used to detect the alarm (EAS or AFI).

A red icon appears in real-time in “Database” section as thefts are committed.

The “Database” section also shows the number of entries stored in pedestal memory in real-time.

To display database contents, click “Access Database”. Database is downloaded and the following

window is displayed:

December 2009 Revision 2.1 43/68

Page 44

Figure 21: Database Window

When this window is open and “suspend detection” check box is

selected then EAS/AFI detection is automatically suspended. It is

resumed when the window is closed.

If “suspend detection” check box is not selected then detection is not

suspended (in this case database download may be slower).

In “Database” window:

• Click “Refresh” to update database display.

• Click “Clear” to permanently erase pedestal database.

• Click “Close” to close the window.

You can access pedestal database from your own applications using the

provided SDKs (Win32/x86 native DLL, WinCE/Arm native DLL and JAVA

archive).

44/68 Revision 2.1 December 2009

Page 45

5.4.5 Basic Pedestal Configuration

Figure 22: Basic Pedestal Configuration Tab

This tab is used either:

• To select the chip to be detected as well as detection options.

• To configure inter-pedestal RF synchronization.

• To configure / test alarm duration.

• To configure the 2 GPIO available to user with predefined functions.

Selecting the chips to be detected as well as detection options

In the “Chips” section, first tick the family of chips to be detected:

• TAGSYS proprietary C220 asynchronous or C320 synchronous legacy chips

• ISO15693 synchronous chips: NXP, TI or Generic (no support of multiple memory Blocks

Reading in Inventory mode). Select the ISO15693 chip type from the drop-list.

• Or both C220/C320 and then ISO15693 EAS detection.

December 2009 Revision 2.1 45/68

Page 46

In the “Chips Options” section:

• Select the detection method to be used in the drop-list, i.e. “Use AFI”, “Use EAS”, or “Use

both EAS and AFI”.

• Select “Read UID” to have the pedestal trying to read the UID of stolen items.

Select “Read Memory” to have the pedestal trying to read the memory contents of stolen items. If

“Read Memory” is selected, you must specify the first block and number of blocks to be read in the

corresponding fields. You must also specify which blocks should be reported first (lowest or

highest) by selecting/unselecting the “Lowest Blocks First”

Configuring / Testing alarm duration

In the “Alarm Duration” section:

• Select the alarm duration in the drop-list.

• Click “Test” to trigger an alarm (this is useful either to test alarm duration, or to identify the

pedestal you’re connected to).

Configuring inter-pedestal RF synchronization

In the “Synchro” section:

• Select whether the pedestal is to be configured as the Master or as a Slave (1…8).

• Select the total number of pedestals (master and slaves) operating in close proximity and

sharing the same ID.

• Select ID (master and slaves of one system installation must share the same ID)

Only one Master can be selected with several slaves.

For example, in the library configuration shown below we have:

• System A with ID = 1 (M1 Master, S1, S2, S3 Slaves).

• System B with ID = 2 (M2 Master, S1, S2 Slaves).

The Masters are disposed as far as possible from each other not to perturb themselves (Please

refer to section 4.3.2 “Placement of Pedestals").

Two different IDs are used to be sure that each slave will be synchronized with the master from its

own system.

46/68 Revision 2.1 December 2009

Page 47

System A

ID = 1

System B

ID = 2

Nearby area with

M1 S1 S2 S3

M2

Figure 23: Multi-gate configuration with two different IDs

interferences

S1

S2

Once you have set the basic configuration, check that all the slaves are

well synchronized. To do so, L-SP3 electronics unit green LEDs should

flicker cyclically. If not, proceed to the advanced configuration stage.

Configuring General Purpose Input/Output

When needed, port #1 can be used as an input to remotely switch the RF Field on and off. This is

useful to limit the HF field generation to a strict minimum, i.e. whenever a person is about to enter

the detection passageway crossing a light barrier placed ahead of the pedestal and keep it on for a

fixed duration or whenever the person is exiting the RFID detection area using a second light

barrier beam crossing detector.

Refer to Figure 25 for the pin layout to wire the Input and output signals.

In section GPIO#1, select one of the available options:

• GPIO: Port has no predefined function; it can be driven remotely by Host PC via API.

• Input Trigger: when wired signal matches the Active Level Setting (“Low” or “High”) the

Radio Frequency Field will be turned On, Theft detection becoming active.

• Output Trigger: when Theft is detected (EAS or AFI signal setting the alarm), the Port

Signal level matches the Active Level Setting (“Low” or “High”). The output voltage level of

the port should match the active voltage to set the external alarm device wired up.

In section GPIO#2, select one of the available options:

December 2009 Revision 2.1 47/68

Page 48

• GPIO: Port has no predefined function; it can be driven remotely by Host PC via API.

• Output Trigger: when Theft is detected (EAS or AFI signal setting the alarm), the Port

Signal level matches the Active Level Setting (“Low” or “High”). The output voltage level of

the port should match the active voltage to set the external alarm device wired up.

Whenever the GPIO is set as an Output Trigger, It is possible to set a pulse Width and a Pause in

milliseconds. In Figure 24, the Pulse Width is set to 100ms. This means that whenever theft

detection occurs, the signal on port#2 will go from low to high for a minimum time of 100ms. If no

further detection occurs before the 100ms timing laps, then signal will drop to low level.

Whenever after the Pause timing, if a new detection occurs, signal will rise again to high level.

In the particular case of the Pause Timing set to 0ms, whenever detection will occur timing equal to

Pulse setting will be added up so that the active level will stay high as long as detection will occur

(so called retrigger configuration).

Setting pause timing to a value different from zero will force the output signal to low level for Pause

time after the Pulse time set, before being triggered again by a subsequent detection.

Figure 24: GPIO Pulse & Pause Field

Pin # Function

1 Ambient Light +24V

2 Ambient Light 0V Ground

3 Alarm +24V

4 Alarm 0V Ground

5 GPIO #1 Open Collector

6 GPIO #1 0V Ground

7 GPIO #2 Open Collector

8 GPIO #2 0V Ground

Figure 25: Peripherals & GPIO Green Connector Pin Out & Location

48/68 Revision 2.1 December 2009

Page 49

Table 5: GPIO Pins - Electrical Characteristics Max Ratings

Parameters Min. Typ. Max. Unit

Input Voltage Range 0 -- 28 V

Input Voltage (Low Level) 0 -- 0.9 V

Input Voltage (High Level) 1.5 -- 28 V

Output Voltage Range 0 -- 28 V

Maximum Continuous Output

Current

--

--

1.4 A

Output Over Current Protection 1.9 2.8 3.8 A

In output mode the LSP3 GPIO can only sink current to ground. User

needs to provide adequate DC Limited Current Supply to Port#1 and

Port#2 (Open Drain). See Figure 26 for detailed circuitry.

Figure 26: Internal Circuit of GPIO and External Supply Wiring in Output Mode

December 2009 Revision 2.1 49/68

Page 50

Figure 27: Connection of a Switch as an Input Device.

50/68 Revision 2.1 December 2009

Page 51

Figure 28: Connection of a Source and Sink Current Supply as an input Device

Applying negative voltage may destroy the GPIO!

Beware not to inadvertently toggle the GPIO from Input to Output Mode:

you may create a short circuit when using a high current source to

ground as an input device! Refer to Figure 28.

December 2009 Revision 2.1 51/68

Page 52

5.4.6 Advanced Pedestal Configuration

Figure 29: Advanced Pedestal Configuration Tab

This tab is used either:

• To configure advanced inter-pedestal RF synchronization parameters.

• To configure advanced alarm detection parameters.

• To configure advanced alarm signaling parameters.

• To configure antenna sequence, RF output power and region of operation.

• To configure the Asynchronous Event Notification over the network

Configuring advanced inter-pedestal RF synchronization parameters

In “Synchro” section, select whether synchronization should be compatible with L-SP2 pedestals.

Please note that some features may not be available when this mode is selected.

You can also select whether to use hardwire synchronization (see section 5.2.3) or wireless

synchronization (see section 5.2.2).

52/68 Revision 2.1 December 2009

Page 53

S1 M S2

Transmitting

Receiving

If wireless synchronization is selected:

• Select the antenna that should be used for emitting and receiving synchronization bursts.

• Select the synchronization burst detection sensitivity. If default value does not ensure the

correct synchronization of all slaves then it is possible to adjust the sensitivity of the nonsynchronized slaves. You just have to adjust the detection level until you get the required

synchronization (LEDs flickering cyclically). Sensitivity can be adjusted between 50 (high

sensitivity) and 2000 (low sensitivity).

A Value of 2500 & above is recommended for first installation to avoid

synchronization being blinded by nearby operating equipment and

noise.

Figure 30: Master/Slaves Synchronization Antenna Best Configuration

Antenna

Antenna

Best Air Synchronization Results are obtained when using the same

antenna for all Receiving and Transmitting antennas: all Top or all

Centre ones.

Configuring advanced alarm detection parameters

In “Alarm Detection Options” section:

• Select alarm detection sensitivity. Decrease sensitivity in case too many false alarms occur.

Configuring advanced alarm signaling parameters

In “Alarms” section:

December 2009 Revision 2.1 53/68

• Select up to four different AFI values as two hexadecimal digits. Items whose AFI matches

one of those values will trigger an alarm.

• Select the alarm report interval. If the same stolen item passes through the gate several

times, it will be reported only once every n seconds.

• Select whether or not the alarm should be triggered only if reading of UID/Memory of stolen

items was successful.

Page 54

Configuring antenna sequence, RF output power and region of operation

In “Antennas and Power” section:

• Select the RF output power. The output power can be lowered to avoid disturbing nearby

RFID systems (in such a case, check system performance). The output power can be

increased, but only to carry on tests.

• Select antenna sequence used when scanning the pedestal. Select “Top>Center>Bottom”

for standard operation or specifically an antenna for diagnosis operations (Top, Center or

Bottom).

In any case, for operational configuration output power should not

exceed 4W to remain compliant with Radio Regulations.

In “Region” section, select the EMC regulations applicable to your region (FCC or ETSI).

Configuring & Enabling Asynchronous Event Notification Mode

In this section, one can activate the useful Event Notification, a stand alone feature which

duplicates the database entry by sending to any PC on the network a data frame. This allows

sending alarm data whenever an event occurs in any pedestal without having to regularly pool the

pedestal database over the network. It limits the traffic over the network.

To activate the Event Notification, just tick at least one Event out of the 3 available. All Events can

be selected if needed.