Page 1

`

TAG

22355 TAG Way

Dulles, VA 20166

SV-2001-THS Computer

Operations Manual

273-MNL-001

P/N 1008775

Page 2

Operations Manual

1 Copyright © 2009 Technology Advancement Group (TAG)

All rights reserved. This publication and its contents are proprietary to TAG. No part of

this publication may be reproduced in any form or by any means without the written

permission of TAG, 22355 TAG Way, Dulles, Virginia 20166-9310.

TAG has made every effort to ensure the correctness and completeness of the material

in this document. TAG shall not be liable for errors contained herein. The information in

this document is subject to change without notice. TAG makes no warranty of any kind

with regard to this material, including, but not limited to, the implied warranties of

merchantability and fitness for a particular purpose.

1.1 Trademarks

All trademarks, marks, names, or product names referenced in this publication are the

property of respective owners, and TAG neither endorses nor otherwise sponsors any

such products or services referred to herein.

Document Number: 273-MNL-001 Page 2 of 58

SV-2001-THS Computer

Version A. 08/25/2010

Page 3

Operations Manual

2 About TAG

2.1 Summary of Qualifications

TAG has served as a leading provider of IT solutions to DoD customers over the past

20+ years and has a long-standing and respected history of providing Systems

Engineering, Electronic Equipment and Program Management support to US Military

warfighters. Headquartered in Dulles, Virginia, TAG’s state-of-the-art 35,000 sq. ft.

engineering and manufacturing facility provides all the infrastructure, equipment, and

manpower necessary to engineer, design, test, manufacture, and certify products to the

rugged requirements of the tactical combat theater. Our facilities in Dulles, VA, San

Diego, CA, and St. Louis, MO, allow for rapid deployment of products and support

across the globe.

TAG quickly, efficiently, and cost-effectively tailors rugged solutions for large DoD

programs with specific MIL-STD requirements. TAG’s comprehensive Quality

Assurance (QA) policy – enforced through application of our UL-registered ISO

9001:2000 certified processes – enables TAG to rapidly deploy systems and solutions

that reliably withstand the stresses of the tactical environment. Today, there are over

20,000 TAG systems deployed across various weapons platforms throughout the US

Military. TAG effectively balances all corporate assets – our people, expertise,

infrastructure, and experience – to consistently and successfully execute and deliver to

the DoD.

TAG’s success lies in focusing on the

corporate Mission Statement and leveraging

the tenets of our business model to ensure

the customer’s expectations are exceeded

throughout lengthy program lifecycles.

TAG’s Mission is to resolve our customers’ IT

challenges with World-Class:

Engineering;

Manufacturing and Integration; and

Lifecycle Management

TAG has a proven track record in

implementing these tenets to serve as a trusted advisor to our Government customers.

TAG uses this foundation to ensure risk is mitigated, expectations are exceeded, and

the customer can consistently rely on the company, our equipment, and our services.

SV-2001-THS Computer

Document Number: 273-MNL-001 Page 3 of 58

Version A. 08/25/2010

Page 4

Operations Manual

2.2 Core Competences

2.2.1 Engineering

TAG’s engineering methodology is built upon Multi-Disciplinary Optimization (MDO) and

rigorous design reviews. Although PMs drive the schedule at TAG, Engineering

leverages Computer-Aided Design (CAD) tools, Computational Fluid Dynamics (CFD)

modeling, rapid prototyping processes, and diverse test equipment and facilities to

ensure requirements are being met at every step of the design. TAG Engineering

follows a proven design-review process, ensuring all entrance and exit criteria are met

at each stage. Rigorous documentation is compiled to demonstrate requirement

compliance, risks are mitigated, and decisions are prudent – throughout the design

process.

TAG prides itself on its engineering

laboratories and facilities. Over the past

three years, TAG has invested in several

pieces of equipment that allow TAG to test

and certify products directly onsite to the

harshest environmental requirements of

military standards – including the MIL-STD810F and DO 160D.

TAG’s onsite test equipment currently

includes a Highly Accelerated Lifecycle

Testing (HALT) Chamber, an

Electromagnetic Interference (EMI) test chamber, and a high-/low-temperature thermal

test chamber. TAG’s facility also provides:

A floor plan designed to support a cellular manufacturing model with modular

assembly lines

A dedicated 24-hour system burn-in room

A modern production status tracking and Enterprise Resource Planning (ERP)

system with external web collaboration capabilities

Dedicated Quality Assurance workstations for system compliance and validation

inspection

2.2.2 Manufacturing and Integration

TAG implements Cellular Manufacturing processes through our compartmentalized,

state-of-the-art production facility to minimize waste byproducts and maximize

production efficiency. TAG’s manufacturing facility is physically partitioned to model the

SV-2001-THS Computer

Document Number: 273-MNL-001 Page 4 of 58

Version A. 08/25/2010

Page 5

Operations Manual

major philosophies of Lean Manufacturing. Consistent with the model, each of TAG’s

production cells are capable of operating in isolation; however personnel and tools are

shared across all cells to streamline manufacturing operations, costs, and the

production/integration scheduling. TAG’s floor technicians are cross-trained in multiple

disciplines so they can be redistributed to any cell that encounters production

bottlenecks, which ensures optimal efficiency.

2.2.3 Lifecycle Management

TAG’s world-class Program Management discipline models the renowned

methodologies of the Project Management Institute (PMI) to ensure successful

completion of the task at hand. Our Program Managers (PMs) serve as the voice of the

customer – driving requirements to which the rest of TAG’s organization answers. As

an explicit tenet of TAG’s corporate mission statement, the PMs not only track cost,

schedule, and technical compliance throughout a project’s period of performance, but

also ensure the customer is supported well beyond it.

SV-2001-THS Computer

Document Number: 273-MNL-001 Page 5 of 58

Version A. 08/25/2010

Page 6

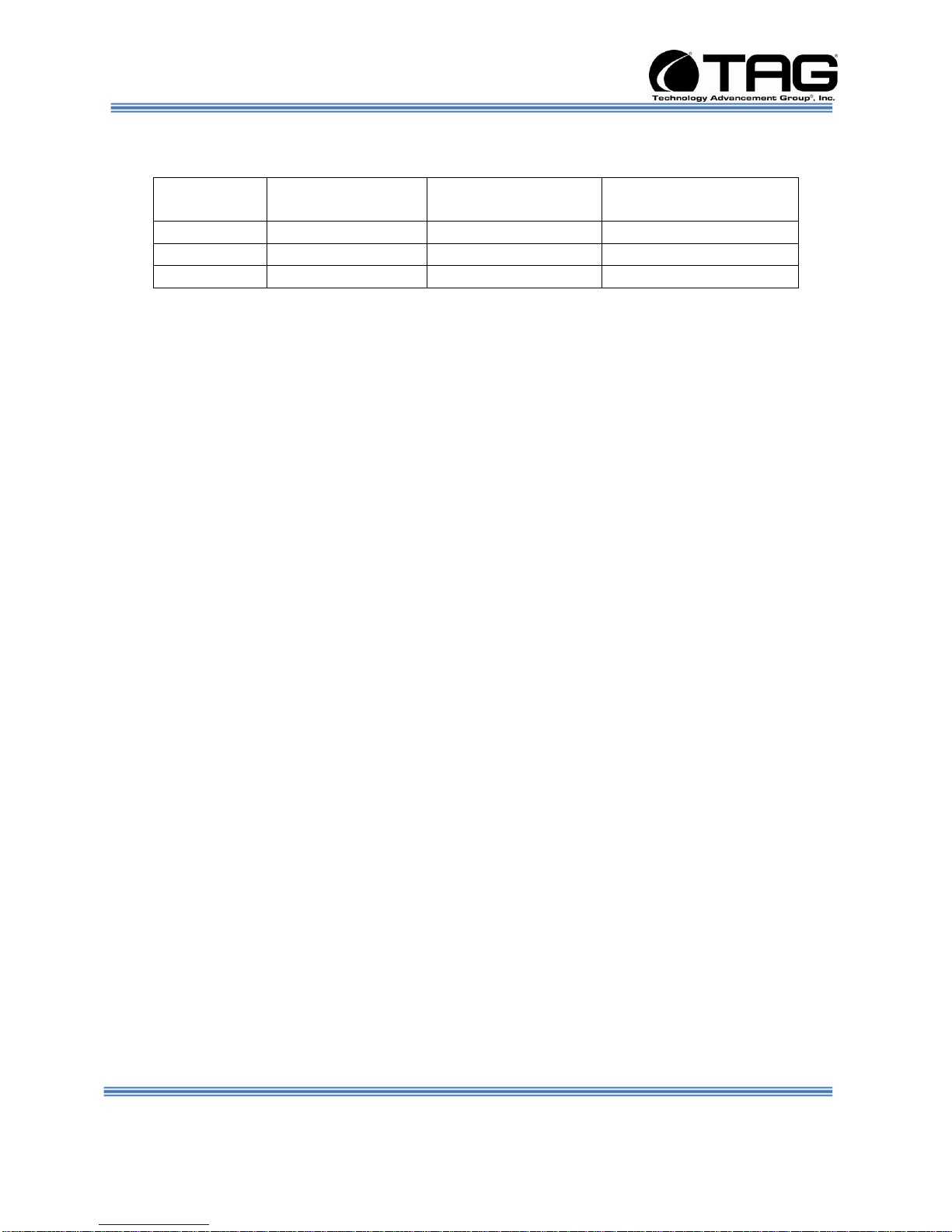

Date

Version Number

Updated By

Description of

Changes

08/25/2010

A

Alan Huckerby

Author

Operations Manual

Document Revision History

Document Number: 273-MNL-001 Page 6 of 58

SV-2001-THS Computer

Version A. 08/25/2010

Page 7

Operations Manual

3 About This Manual

3.1 Scope and Audience

This manual provides information on the SV2001-THS Computer. The SV-2001-THS

Computer allows for up to 2 cores in a 2U

chassis and up to 4GB of RAM. The SV-2001THS Computer features Core 2 Duo processor

to maximize processing performance, while

reducing power dissipation.

The SV-2001-THS is ideal for deployable

situations where such high density computing

minimizes size, weight, and power.

3.1.1 Organization:

This manual is divided into the following

chapters and appendix:

Chapter 1 Cautions and Warnings when

handling the SV-2001-THS Computer.

Chapter 2 provides detailed information on the

external and internal Computer components.

Chapter 3 provides procedures for replacing

hot-swappable and LRU components, as well

as for replacing or adding system memory.

Document Number: 273-MNL-001 Page 7 of 58

SV-2001-THS Computer

Version A. 08/25/2010

Page 8

Operations Manual

Table of Contents

Contents

1 Copyright © 2009 Technology Advancement Group (TAG) .................................................... 2

1.1 Trademarks................................................................................................ ........................ 2

2 About TAG ............................................................................................................................. 3

2.1 Summary of Qualifications ................................................................................................ 3

2.2 Core Competences ............................................................................................................. 4

2.2.1 Engineering ................................................................................................................. 4

2.2.2 Manufacturing and Integration ..................................................................................... 4

2.2.3 Lifecycle Management ................................................................................................ . 5

3 About This Manual.................................................................................................................. 7

3.1 Scope and Audience .......................................................................................................... 7

3.1.1 Organization: ................................ ............................................................................... 7

4 Safety Instructions ................................................................................................................... 13

4.1 Types of warnings used in this manual............................................................................... 13

4.1.1 Safety Symbols and Labels .......................................................................................... 13

4.1.2 Conventions ................................................................................................................. 13

5 Computer Overview ................................................................................................................ 16

5.1 Product Information ........................................................................................................... 16

5.2 SV-2001-THS Computer ................................................................................................... 16

5.2.1 Specifications .............................................................................................................. 17

5.2.2 Additional specifications .............................................................................................. 18

5.2.3 Computer Highlights.................................................................................................... 18

5.2.4 SV-2001-THS Computer ............................................................................................. 18

5.2.5 I/O Connectors............................................................................................................. 19

5.3 Computer Components ...................................................................................................... 19

5.4 SV-2001-THS Computer Motherboard .............................................................................. 20

5.4.1 Connector and Component Locations ........................................................................... 21

5.4.2 Specifications .............................................................................................................. 22

5.5 Serial PCI Card................................ .................................................................................. 24

5.5.1 Specifications .............................................................................................................. 24

5.6 IRIG PCI Card ................................................................................................................... 26

5.6.1 Specifications .............................................................................................................. 26

5.6.2 System hard Drive Specifications................................................................................. 27

5.7 System Memory ................................................................................................................ 28

5.7.1 Identifying System Memory......................................................................................... 28

6 Procedures ................................................................ ............................................................... 30

6.1 Computer Startup .............................................................................................................. 30

6.2 Computer Shutdown .......................................................................................................... 30

6.3 TAG Approved BIOS ........................................................................................................ 30

6.3.1 Common BIOS Settings ............................................................................................... 31

Document Number: 273-MNL-001 Page 8 of 58

SV-2001-THS Computer

Version A. 08/25/2010

Page 9

Operations Manual

6.3.2 BIOS Configuration for SV-2001-THS ........................................................................ 35

6.4 Upgrading and Replacing System Components .................................................................. 50

6.4.1 Preventing Static Electricity ......................................................................................... 50

6.5 Power Supply Cable Retention Bracket Installation ........................................................... 51

6.6 Replacing a Hard Drive ..................................................................................................... 53

6.6.1 25” Solid State SATA Hard Drive ............................................................................... 53

6.7 Removing the Computer Cover.......................................................................................... 53

6.8 Adding or Replacing System Memory ............................................................................... 54

6.8.1 Install system memory. ................................................................................................ 55

Appendix ...................................................................................................................................... 56

7 Contract Drawing SV-2001-THS ............................................................................................. 57

Document Number: 273-MNL-001 Page 9 of 58

SV-2001-THS Computer

Version A. 08/25/2010

Page 10

Operations Manual

List of Figures

Figure 5-1 SV-2001-THS Computer ..................................................................................... 16

Figure 5-2 SV-2001-THS Computer Components and Connectors. (Front View). .......... 18

Figure 5-3 I/O Connectors (Rear View)................................................................................ 19

Figure 5-4 Computer Motherboard ................................................................ ....................... 20

Figure 5-5 Computer Mother Board Block Diagram. .......................................................... 21

Figure 5-6 Serial PCI Card. ................................................................................................... 24

Figure 5-7 IRIG PCI Card. ..................................................................................................... 26

Figure 6-1 BIOS Setup. ......................................................................................................... 35

Figure 6-2 Standard CMOS Features Screen. .................................................................... 35

Figure 6-3 Main Page Screen. .............................................................................................. 36

Figure 6-4 CPU Feature Screen. ................................................................ .......................... 36

Figure 6-5 Delay Prior to Thermal. ....................................................................................... 37

Figure 6-6 Advanced BIOS Features Screen. ..................................................................... 37

Figure 6-7 Hard Disk Boot Priority Screen. .......................................................................... 38

Figure 6-8 MPS Version Control Screen. ............................................................................. 38

Figure 6-9 Advanced Chipset Features. .............................................................................. 39

Figure 6-10 DRAM Timing Selectable Screen. ................................................................... 39

Figure 6-11 PCI Express Root Port Function Screen. ........................................................ 40

Figure 6-12 PCI Express Port Screen. ................................................................................. 40

Figure 6-13 Integrated Peripherals. ...................................................................................... 41

Figure 6-14 Integrated Peripherals Screen.......................................................................... 41

Figure 6-15 OnChip IDE Device Screen. ............................................................................. 42

Figure 6-16 Integrated Peripherals Screen.......................................................................... 42

Figure 6-17 Onboard Device Screen. ................................................................................... 43

Figure 6-18 Integrated Peripherals Screen. ......................................................................... 43

Figure 6-19 Integrated Peripherals Screen.......................................................................... 44

Figure 6-20 Super I/O Screen. .............................................................................................. 44

Figure 6-21 Power Management Setup Screen. ................................................................. 45

Figure 6-22 Power Management Setup. .............................................................................. 45

Figure 6-23 PCI Express PM Function Screen. .................................................................. 46

Figure 6-24 Power Management Screen. ............................................................................ 46

Figure 6-25 PnP/PCI Configurations Screen. ...................................................................... 47

Figure 6-26 PnP/PCI Configurations Screen. ...................................................................... 47

Figure 6-27 AwardBIOS CMOS Setup Utility Screen. ........................................................ 48

Figure 6-28 PC Health Status Screen. ................................................................................. 48

Figure 6-29 Frequency Control Screen. ............................................................................... 49

Figure 6-30 Frequency Control Screen. ............................................................................... 49

Figure 6-31 Grounding Wrist Strap ....................................................................................... 50

Figure 6-35 25” Solid State SATA Hard Drive. .................................................................... 53

Figure 6-36 DIMM Module Bank ........................................................................................... 55

Figure 7-1 Contract Drawing SV-2001-THS ........................................................................ 57

Document Number: 273-MNL-001 Page 10 of 58

SV-2001-THS Computer

Version A. 08/25/2010

Page 11

Operations Manual

List of Tables

Table 5-1 Mother Board Specifications. ............................................................................... 23

Document Number: 273-MNL-001 Page 11 of 58

SV-2001-THS Computer

Version A. 08/25/2010

Page 12

Operations Manual

Chapter 1

Cautions and Warnings.

Electronically distributed. Subject to user discretion when printed.

Document Number: 273-MNL-001 Page 12 of 58

SV-2001-THS Computer

Version A. 08/25/2010

Page 13

DANGER

WARNING

CAUTION

These warnings and cautions indicate

situations or practice that might result in

property damage

Operations Manual

4 Safety Instructions

4.1 Types of warnings used in this manual

Read this manual thoroughly, paying special attention to

the cautions and warnings.

4.1.1 Safety Symbols and Labels

4.1.2 Conventions

4.1.2.1 Important Messages

4.1.2.2 Warnings

SV-2001-THS Computer

Document Number: 273-MNL-001 Page 13 of 58

Version A. 08/25/2010

Important messages appear where

mishandling of components is possible or when

work orders can be misunderstood. These

messages also provide vital information

associated with other aspects of system

operation. The word “important” is written as

“IMPORTANT,” both capitalized and bold and

is followed by text in italics. The italicized text

is the important message.

Warnings appear where overlooked details

may cause damage to the equipment or result

Page 14

Operations Manual

in personal injury. Warnings should be taken

seriously. Warnings are easy to recognize. The

word “warning” is written as “WARNING,” both

capitalized and bold and is followed by text in

italics. The italicized text is the warning

message.

4.1.2.3 Cautions

Cautionary messages should also be heeded

to help you reduce the chance of losing data or

damaging the system. Cautions are easy to

recognize. The word “caution” is written as

“CAUTION,” both capitalized and bold and is

followed by text in italics. The italicized text is

the cautionary message.

4.1.2.4 Notes

Notes inform the reader of essential but noncritical information. These messages should be

read carefully as any directions or instructions

contained therein can help you avoid making

mistakes. Notes are easy to recognize. The

word “note” is written as “NOTE.”

Document Number: 273-MNL-001 Page 14 of 58

SV-2001-THS Computer

Version A. 08/25/2010

Page 15

Operations Manual

Chapter 2

SV-2001-THS Computer.

Electronically distributed. Subject to user discretion when printed.

SV-2001-THS Computer

Document Number: 273-MNL-001 Page 15 of 58

Version A. 08/25/2010

Page 16

Operations Manual

5 Computer Overview

5.1 Product Information

This chapter provides an introductory overview

of the TAG family of tactical Computers. TAG

Computers are highly customizable; the

specific components vary depending on the

mission requirements. Your system may

contain components not described in this

chapter. For detailed information on these

components, refer to the manufactures website

or contact TAG Technical Support at

tech.support@tag.com.

TAG's tactical Computers combine state-ofthe-art mechanical, thermal and electrical

engineering to create customized systems that

perform above and beyond end user or

program specifications.

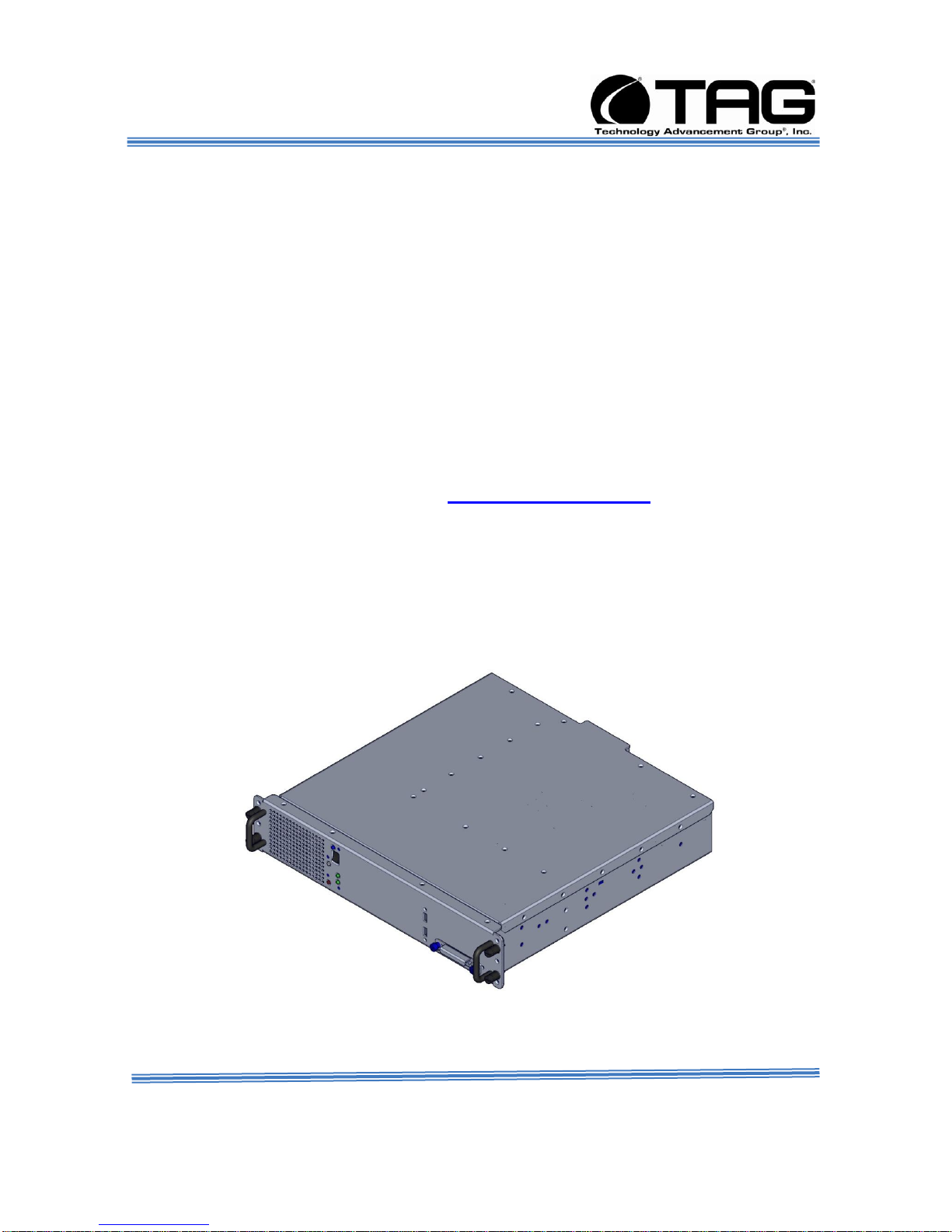

5.2 SV-2001-THS Computer

Document Number: 273-MNL-001 Page 16 of 58

Figure 5-1 SV-2001-THS Computer

SV-2001-THS Computer

Version A. 08/25/2010

Page 17

Operations Manual

5.2.1 Specifications

Chassis & power supply:

2U Heavy-duty aluminum rack-mount chassis.

Chassis is designed to EIA-310-D Standards.

3.469”H (2U) x 19”W x 17”D.

Cooling system developed specifically for

harsh environments.

Front accessible on/off switches.

Processor & Cache:

Intel Core2 Duo CPU (T7400, 2.166GHz, 2MB

2nd level cache, 667MHz FSB).

Core2 Duo Motherboard

Accepts Intel Core 2 Duo Processor, 667 Mhz

FSB.

Intel 945 GME Chipset.

On-board Serial ATA Controllers.

(6) USB 2.0 ports. ((4) Rear, (2) Front.)

(3) Serial Ports ((2) On board, (1) PCI

Expansion Card)

(2) 10/100/1000 Ethernet Ports.

PS/2 Keyboard and Mouse Port.

Low Profile Expansion Slots. (1) PCI-Express

x16, (1) PCI-Express x4, 2x PCI.

Expandable to 4GB DDR2 RAM.

System Components:

4GB DDR2 RAM.

(1) 80GB removable Solid State (SATA) hard

drive with rugged metal carrier and receiver.

(1) Low Profile PCI Serial Card.

(1) Spectrum PCI-E IRIG Time Code

Processor.

Document Number: 273-MNL-001 Page 17 of 58

SV-2001-THS Computer

Version A. 08/25/2010

Page 18

Operations Manual

5.2.2 Additional specifications

Total Weight: 16.8lbs.

Input voltage range is 100V to 240V range.

Input frequency range is 60hz nominal but can

go from 63 to 47 hertz

Power supply max available power is 460

watts.

Inrush current at 115VAC is 8 amps max

Inrush current at 230VAC is 4 amps max

Power supply efficiency is 65%

5.2.3 Computer Highlights

The SV-2001-THS is unlike any other

Computer that is currently on the market. The

SV-2001-THS is ideal for use in deployable

situations where the product’s compact size,

high density computing, minimized size,

weight, and power make for a highly portable,

rugged and reliable system.

Contains an intelligent fan controller

(acoustically optimized, environmentally

aware).

Small-form factor chassis.

Proven to function in a variety of operating

temperature ranges from 0C TO 50C.

5.2.4 SV-2001-THS Computer

Figure 5-2 SV-2001-THS Computer Components and Connectors. (Front View).

SV-2001-THS Computer

Document Number: 273-MNL-001 Page 18 of 58

Version A. 08/25/2010

Page 19

Operations Manual

5.2.5 I/O Connectors

Figure 5-3 I/O Connectors (Rear View).

5.3 Computer Components

This section provides an overview of the most

common components installed in the SV-2001THS Computer. Information is also provided on

how to identify specific components within your

Computer. For detailed information on the

specific components installed in your

Computer, refer the manufactures website.

Document Number: 273-MNL-001 Page 19 of 58

SV-2001-THS Computer

Version A. 08/25/2010

Page 20

Operations Manual

5.4 SV-2001-THS Computer Motherboard

Figure 5-4 Computer Motherboard

SV-2001-THS Computer

Document Number: 273-MNL-001 Page 20 of 58

Version A. 08/25/2010

Page 21

Operations Manual

5.4.1 Connector and Component Locations

Figure 5-5 shows the layout of the Computer

board.

Figure 5-5 Computer Mother Board Block Diagram.

Document Number: 273-MNL-001 Page 21 of 58

SV-2001-THS Computer

Version A. 08/25/2010

Page 22

Processor

System

CPU

(65nm)

Intel® Core™ 2

Duo

Intel® Core™

Duo

Intel®

Celeron M

Max.

Speed

2.16 GHz

2.0 GHz

1.86 GHz

L2

Cache

2 MB/4 MB

2 MB

1 MB

Chipset

Intel 945GME + ICH7M-DH

BIOS

Award® 4 Mbit FWH

Front Side Bus

533/667 MHz

Expansion Slot

PCIe x16

4.0 GB/s per direction, 1 slot

PCIe x4

1.0 GB/s per direction, 1 slot

PCI

32-bit/33 MHz, 2 slots

Memory

Techn

ology

Dual channel DDR2 400/533/667 SDRAM

Max. Capacity

4 GB

Socket

240-pin DIMM x 2

Graphics

Embed

ded

Intel GMA 950 sharing 224 MB system memory

LVDS

Single channel 18-bit/Dual channel 36-bit LVDS

TV-Out

Supports both S-video and composite video

(TV-out function is not supported during POST

stage)

Add-on

PCIe x16 slot

Ethernet

Interface

10/100/1000 Base-T

Controller

GbE LAN1: Intel 82573L, GbE

LAN2: Intel 82573L

Connector

RJ-45 x 2

SATA

Max. Data

Transfer Rate

300 MB/s

Channel

2

EIDE

Mode

ATA 100/66/33

Channel

1 (Max. two devices)

Operations Manual

5.4.2 Specifications

SV-2001-THS Computer

Document Number: 273-MNL-001 Page 22 of 58

Version A. 08/25/2010

Page 23

I/O Interface

VGA

1

LAN

1 (for VG version); 2 (for G2

version)

USB

8 (USB 2.0, 480Mbps; 4

external ports and 4 onboard

pin headers)

Audio

2 (Line-Out and Mic-In)

Serial

2 (1 of RS-232/422/485 on

pin header, 1 of RS-232 on

rear I/O)

Parallel

1 (SPP/EPP/ECP)

FDD

1

PS/2

2 (keyboard and mouse)

Watchdog Timer

Output

System reset

Interval

Programmable 1 ~ 255 sec/

min

Power

Requirement

Typical

Intel Core Duo-T2400 1.83GHz (667FSB)

DDR2 667 1GB SDRAM X2

+5 V

+3.3 V

+12 V

2.4 A

3 A

1.5 A

Environment

Operating

NonOperating

Temperature

0 ~ 60° C (32 ~ 140°

F), depends on

CPU’s speed and

cooler solution.

-20 ~

70°

C (4~15

0° F)

Physical Characteristics

Dimensions (W x D)

244 mm x

244 mm (9.6"

x 9.6")

Operations Manual

Table 5-1 Mother Board Specifications.

SV-2001-THS Computer

Document Number: 273-MNL-001 Page 23 of 58

Version A. 08/25/2010

Page 24

Operations Manual

5.5 Serial PCI Card

Features

A low profile form factor PCI card made for

space constrained system designs.

Supports 32-/64-bit, 3.3V/5V PCI and PCI-X

slots.

One high-speed 16550 UART serial port (9-

pin) supports data rate up to 230 Kbps.

Will work as standard RS232 port or with 5V or

12V power output for devices that require

power (such as handheld scanners, table

scanners, POS displays, etc.). Configurable via

jumpers with Silkscreened settings on PCB.

5.5.1 Specifications

Document Number: 273-MNL-001 Page 24 of 58

Figure 5-6 Serial PCI Card.

Regulatory approval(s): FCC Class B (DoC) &

CE.

SV-2001-THS Computer

Version A. 08/25/2010

Page 25

Operations Manual

RoHS-compliant.

Chip: CyberPro.

Bus type: 32-bit PCI.

Port type: One 9-pin RS232 serial port.

IRQ sharing reduces IRQ conflicts.

Built-in 32-byte FIFO buffers dramatically.

increase data transmit/receive speed,

especially under Windows multitasking

environment.

4-layer PCB board: separate layers for data &

grounding. Greatly reduces signal noise & loss.

Delivers reliable high-speed data transfers.

Enhanced bracket design to prevent bending.

Connected to PCB with washered screws for a

more secure connection.

Supports 3.3V operation with 5V tolerance.

Conforms to PCI v2.2 universal card standard.

PCI-X & 64-bit compatible.

Supports PME # (Power Management Event).

Allows device to request a change in system

power state (wake up system).

Document Number: 273-MNL-001 Page 25 of 58

SV-2001-THS Computer

Version A. 08/25/2010

Page 26

Operations Manual

5.6 IRIG PCI Card

The IRIG PCI Card with optional GPS, is a

complete synchronized timecode

reader/generator package offering flexibility

and easy integration of precise timing into an

embedded computing application. It supports

multiple prioritized timing inputs. When an input

is lost, the unit automatically switches to the

next input.

Figure 5-7 IRIG PCI Card.

5.6.1 Specifications

Low-Profile PCIe Form Factor.

PCIe x1 Local Bus Operation.

Zero Latency Time Reads.

±100ns Accuracy to Input.

Auto-detects and prioritizes GPS and Time

Code Inputs.

IRIG AM/DCLS Time Code Outputs.

1PPS Input.

Multiple External Event Time Capture/Interrupt.

SV-2001-THS Computer

Document Number: 273-MNL-001 Page 26 of 58

Version A. 08/25/2010

Page 27

Operations Manual

Programmable Periodic Output/Interrupt (1Hz–

10MHz).

Programmable Time Match Output/Interrupt.

Optional GPS Synchronization.

Optional OCXO Upgrade.

CE and RoHS Compliant.

Synchronization to Precision Time Protocol

option.

5.6.2 System hard Drive Specifications

The Intel® X18-M/X25-M SATA Solid State

Drive (SSD) delivers leading performance in

industry standard 2.5” form factor while

simultaneously improving system

responsiveness for mobile applications over

standard rotating drive media or hard

diskdrives.

Power Management

5 V (2.5”) SATA Supply Rail

SATA Interface Power Management

OS-Aware Hot Plug/Removal

Power Specifications

Active: 0.150 W TYP

Idle: 0.060 W TYP

Temperature

Operating: 0o C to 70o C

Non-Operating: -55o C to 95o C.

Reliability

Read Error Rate (BER): 1 sector per 1015

SV-2001-THS Computer

Document Number: 273-MNL-001 Page 27 of 58

Version A. 08/25/2010

Page 28

Operations Manual

5.7 System Memory

The type and amount of system memory, or

RAM (random access memory), on your

computer depends on the motherboard

installed and how it was configured.

5.7.1 Identifying System Memory

Refer to your TAG SV-2001-THS serial

number. Once you have identified the serial

number contact TAG technical support to

assist you in determining the type and amount

of memory in your system. TAG technical

support contact information is located on last

page of this manual.

For information on replacing or upgrading your

system memory, refer to “Adding and

Replacing System Memory on page 50.”

Document Number: 273-MNL-001 Page 28 of 58

SV-2001-THS Computer

Version A. 08/25/2010

Page 29

Operations Manual

Chapter 3

Procedures.

Electronically distributed. Subject to user discretion when printed.

Document Number: 273-MNL-001 Page 29 of 58

SV-2001-THS Computer

Version A. 08/25/2010

Page 30

Operations Manual

6 Procedures

The procedures within this Chapter contain

relevant information to ensure your SV-2001THS Computer maintains its maximum

performance potential.

6.1 Computer Startup

1. Check to make sure that all the cables are

seated and connected correctly to the back of

the unit such as keyboard, mouse, monitor

video and power cables.

2. Press ON hard power ON/OFF switch at rear

of computer. (Figure 5.3).

3. Then Press the power switch ON to start the

computer (power switch is located in the front

of the unit). (Figure 5.2).

4. Once the unit starts, System will go thru Power

On self Test (POST) (no action is required at

this time).

5. Type in the correct user name and password

and then press enter to login.

6. Once the operator is logged on they can use

the computer as they wish.

NOTE: These instructions are assuming the

Computer is not connected to any network.

6.2 Computer Shutdown

1. Save any data that is needed and then close

application

2. Once all data is saved and applications are

closed it is now safe to shut down the

computer.

6.3 TAG Approved BIOS

The BIOS (basic input/output system) is the

program stored on the CMOS that the

Computer's microprocessor uses to get the

SV-2001-THS Computer

Document Number: 273-MNL-001 Page 30 of 58

Version A. 08/25/2010

Page 31

Operations Manual

system started after you turn it on. The BIOS

also manages data flow between the

computer's operating system and attached

devices such as the hard disk, video adapter,

keyboard, and mouse.

CAUTION: The BIOS installed on your

Computer was loaded and tested with all

the devices initially installed in your

system. If you desire to have the BIOS

updated, consult TAG technical support in

advance as updates to your approved BIOS

may cause your system to become unstable

or inoperable.

6.3.1 Common BIOS Settings

6.3.1.1 Printer Parallel Port Uni., Bi-Directional, Disable,

Enable, ECP, EPP.

Settings in the CMOS enable you to configure

a parallel port to use Enhanced Parallel Port

(EPP) or Enhanced Parallel Port (ECP). ECP.

EPP and ECP are bi-directional standards,

operate in 8-bit, and allow data transfer speed

of approximately 2 MB/s. Some of the main

differences are that ECP supports Direct

Memory Access (DMA) and data compression,

which enables higher transfer rates.

It is also possible to completely disable the

parallel port in the BIOS. Most BIOS' allow you

to set the DMA channel, when the port mode is

set to ECP.

6.3.1.2 Com / Serial Port

Most personal computers have two serial ports.

In the BIOS you can assign

COM1/COM2/COM3/COM4 to serial port 1 or

2.

Document Number: 273-MNL-001 Page 31 of 58

SV-2001-THS Computer

Version A. 08/25/2010

Page 32

Operations Manual

Most BIOS' also allow you to set the I/O and

IRQ but this is mostly done automatically.

6.3.1.3 Hard Drives

Most modern BIOS' allow automatic detection

of disk parameters. The settings can be

individually configured for the primary master

and slave device and the secondary master

and slave device. The following are some of

the primary settings that apply to hard drives

as well as CD/DVD-ROM drives, tape backup

drive, etc.

Common disk types are:

User-defined Cylinders, Heads, Sectors (CHS)

values.

Auto-automatically detects hard disks

parameters at every startup.

1-46-predefined combinations of CHS values.

CDROM-used for AT Attachment Packet

Interface (ATAPI) CD-ROM drives.

ARMD-used for ATAPI ZIP and LS 120 drives.

DVDROM.

Size - Determines the capacity of the drive CHS

values:

Number of Cylinders.

Number of Heads.

Number of Sectors.

LBA (Large Block Addressing)-technology to

overcome the 528 MB limit.

6.3.1.4 Boot Sector Virus

A common setting related to hard drives. When

enabled, the BIOS issues a warning

message/beep if an attempt is made to write to

the boot sector or partition table of a hard disk.

Document Number: 273-MNL-001 Page 32 of 58

SV-2001-THS Computer

Version A. 08/25/2010

Page 33

Operations Manual

6.3.1.5 Memory

Parity adds an extra bit (odd or even) to the 8bit data-string to ensure data integrity in

memory modules. Its successor, ECC,

provides improved data integrity by adding

information about individual bits.

6.3.1.6 Boot Sequence

This setting is used to control the order that the

BIOS uses during the boot process to look for

a boot device from which to load the operating

system. For example:

CD.

Floppy.

Hard Disk.

6.3.1.7 Date and Time

The Date and Time is set in the BIOS, stored in

CMOS, and maintained by CMOS battery.

6.3.1.8 Passwords

In most cases a user (startup) password and a

supervisor (setup) password can be set in the

CMOS. When a Setup password is required,

the computer will prompt for it when you try to

access the BIOS setup. When a Startup

password is configured, the computer will

prompt for it at every startup.

The CMOS password can be reset by shorting

the "CMOS restore to factory defaults jumper"

or by temporarily removing the CMOS battery.

6.3.1.9 Plug and Play BIOS

Document Number: 273-MNL-001 Page 33 of 58

Today's BIOS' are Plug and Play (PnP)-aware.

This means they are able to automatically

SV-2001-THS Computer

Version A. 08/25/2010

Page 34

Operations Manual

assign resources such as IRQ and DMA to

PnP devices.

Information about PnP devices is stored in a

separate area of non-volatile CMOS memory,

called the Extended System Configuration

Database (ESCD). Both the PnP BIOS and the

operating system can access this area and

communicate with each other about resource

settings assigned to PnP devices as well as

non-PnP devices. For example, when a fixed

interrupt request (IRQ) is manually assigned to

a particular device using Device Manager,

Windows will write this information to the

ESCD on shutdown thereby preventing the

BIOS from assigning the same IRQ to a PnP

device at startup.

You can also reserve IRQs for non-PnP

devices in the CMOS setup, this will prevent

the BIOS from assigning these reserved

resources to PnP devices, a common example

is a legacy sound card that needs IRQ 5.

6.3.1.10 Power Management

Modern motherboards provide Advanced

Configuration and Power Management

Interface (ACPI) settings such as wake-up,

power button function and standby/suspend

timers. These functions are configured in the

CMOS Setup.

Document Number: 273-MNL-001 Page 34 of 58

SV-2001-THS Computer

Version A. 08/25/2010

Page 35

Operations Manual

6.3.2 BIOS Configuration for SV-2001-THS

1. On the Main page, Default Setting is Standard

CMOS Features. Press ENTER. (Figure 6-1).

Figure 6-1 BIOS Setup.

2. No changes for Standard CMOS Features.

Press ESCAPE to return to the main screen.

(Figures 6-2).

Figure 6-2 Standard CMOS Features Screen.

Document Number: 273-MNL-001 Page 35 of 58

SV-2001-THS Computer

Version A. 08/25/2010

Page 36

Operations Manual

3. On the Main page, Scroll down and select

Advanced BIOS Features. Press ENTER.

(Figures 6-3).

Figure 6-3 Main Page Screen.

4. In Advanced BIOS Features. Select CPU

Feature then press ENTER. (Figure 6-4).

Figure 6-4 CPU Feature Screen.

Document Number: 273-MNL-001 Page 36 of 58

SV-2001-THS Computer

Version A. 08/25/2010

Page 37

Operations Manual

5. No changes for Delay Prior to Thermal. Press

ESCAPE to return to the main screen. (Figure

6-5).

Figure 6-5 Delay Prior to Thermal.

6. On the Advanced BIOS Features page, Scroll

down and select Hard Disk Boot Priority.

Press ENTER. (Figure 6-6)

Figure 6-6 Advanced BIOS Features Screen.

Document Number: 273-MNL-001 Page 37 of 58

SV-2001-THS Computer

Version A. 08/25/2010

Page 38

Operations Manual

7. No changes for Hard Disk Boot Priority.

Default Selected Ch2 M. Press ENTER.

(Figure 6-7)

Figure 6-7 Hard Disk Boot Priority Screen.

8. Scroll down and select MPS Version Control

for OS[1.4]. Press ESCAPE to return to the

main screen. (Figure 6-8)

Figure 6-8 MPS Version Control Screen.

Document Number: 273-MNL-001 Page 38 of 58

SV-2001-THS Computer

Version A. 08/25/2010

Page 39

Operations Manual

9. On the Main Screen scroll down and select

Advanced Chipset Features. Press ENTER.

(Figure 6-9)

Figure 6-9 Advanced Chipset Features.

10. No changes for DRAM Timing Selectable.

Default Selected [By SPD]. Press ENTER.

(Figure 6-10)

Figure 6-10 DRAM Timing Selectable Screen.

Document Number: 273-MNL-001 Page 39 of 58

SV-2001-THS Computer

Version A. 08/25/2010

Page 40

Operations Manual

11. Scroll Down and select PCI Express Root

Port Function No changes press ENTER.

(Figure 6-121)

Figure 6-11 PCI Express Root Port Function Screen.

12. No changes for PCI Express Boot Port

Function. Defaults Selected. Press ESCAPE

to return to the Main Screen. (Figure 6.12).

Figure 6-12 PCI Express Port Screen.

Document Number: 273-MNL-001 Page 40 of 58

SV-2001-THS Computer

Version A. 08/25/2010

Page 41

Operations Manual

13. On the Main Screen scroll down and select

Integrated Peripherals. Press ENTER.

(Figure 6-13)

Figure 6-13 Integrated Peripherals.

14. No Change on the Integrated Peripherals

Screen. Defaults Selected. Press ENTER.

(Figure 6-14)

Figure 6-14 Integrated Peripherals Screen.

Document Number: 273-MNL-001 Page 41 of 58

SV-2001-THS Computer

Version A. 08/25/2010

Page 42

Operations Manual

15. No Change on the OnChip IDE Device page.

Defaults Selected. Press ENTER. (Figure 6-15)

Figure 6-15 OnChip IDE Device Screen.

16. No Changes on the Integrated Peripherals

page. Scroll down and select Onboard

Device. Press ENTER. (Figure 6-16)

Figure 6-16 Integrated Peripherals Screen.

Document Number: 273-MNL-001 Page 42 of 58

SV-2001-THS Computer

Version A. 08/25/2010

Page 43

Operations Manual

17. No Changes on the Onboard Devices page.

Press ENTER. (Figure 6.17).

Figure 6-17 Onboard Device Screen.

18. No Changes on the Integrated Peripherals

page. Scroll down to Super I/O Devices. Press

ENTER. (Figure 6.18).

Figure 6-18 Integrated Peripherals Screen.

Document Number: 273-MNL-001 Page 43 of 58

SV-2001-THS Computer

Version A. 08/25/2010

Page 44

Operations Manual

19. Scroll Down and select Super I/O Device.

Press ENTER. (Figure 6.19).

Figure 6-19 Integrated Peripherals Screen.

20. No Changes on the Super I/O Device

page. Default selections. Press ESCAPE to

return to the Main Page. (Figure 6.20).

Document Number: 273-MNL-001 Page 44 of 58

Figure 6-20 Super I/O Screen.

SV-2001-THS Computer

Version A. 08/25/2010

Page 45

Operations Manual

21. On the Main Screen scroll down and select

Power Management Setup. Press

ENTER. (Figure 6-21).

Figure 6-21 Power Management Setup Screen.

22. No Change on the Power Management

Setup Screen. Defaults Selected. Press

ENTER. (Figure 6-22)

Figure 6-22 Power Management Setup.

Document Number: 273-MNL-001 Page 45 of 58

SV-2001-THS Computer

Version A. 08/25/2010

Page 46

Operations Manual

23. No Change on the PCI Express PM

Function screen. Default Selected. Press

ENTER. (Figure 6-23)

Figure 6-23 PCI Express PM Function Screen.

24. No Changes on the Power Management

page. Scroll down and select PWRON

After PWR-Fail. Press Escape to return to

the Main Screen. (Figure 6-24).

Figure 6-24 Power Management Screen.

Document Number: 273-MNL-001 Page 46 of 58

SV-2001-THS Computer

Version A. 08/25/2010

Page 47

Operations Manual

25. On the Main Page. Scroll down and select

PnP/PCI Configurations. Press ENTER.

(Figure 6.25).

Figure 6-25 PnP/PCI Configurations Screen.

26. On the PnP/PCI Configurations Screen

Default Reset Configuration Data is

selected. Press ENTER. (Figure 6-26).

Figure 6-26 PnP/PCI Configurations Screen.

Document Number: 273-MNL-001 Page 47 of 58

SV-2001-THS Computer

Version A. 08/25/2010

Page 48

Operations Manual

27. No Change on the AwardBIOS CMOS

Setup Utility Screen. Select PC Health

Status. Press ENTER. (Figure 6-27)

Figure 6-27 AwardBIOS CMOS Setup Utility Screen.

28. No Change on the PC Health Status

screen. Default Selected. Press ENTER.

(Figure 6-28)

Figure 6-28 PC Health Status Screen.

Document Number: 273-MNL-001 Page 48 of 58

SV-2001-THS Computer

Version A. 08/25/2010

Page 49

Operations Manual

29. Select Frequency Control. Press ENTER.

(Figure 6-29).

Figure 6-29 Frequency Control Screen.

30. On the Frequency Control screen. Default

selection Spread Spectrum. Press

ENTER. (Figure 6.30).

Figure 6-30 Frequency Control Screen.

Document Number: 273-MNL-001 Page 49 of 58

31. Press F10, then Y, and Enter to save the

changes and Exit BIOS.

SV-2001-THS Computer

Version A. 08/25/2010

Page 50

Operations Manual

6.4 Upgrading and Replacing System Components

6.4.1 Preventing Static Electricity

This section provides procedures for replacing

all hot-swappable and LRU components,

including procedures for replacing or adding

system memory.

The components inside your computer are

extremely sensitive to static electricity, also

known as electrostatic discharge (ESD). ESD

can permanently damage electrostatic

discharge-sensitive components in your

Computer.

To prevent ESD damage, follow these

guidelines before opening the Computer

case:

1. Turn off the Computer and unplug the power

cord before opening the case.

2. Wear a grounding wrist strap and attach it to

a bare metal part of the Computer, workbench,

or other grounded connection.

Figure 6-31 Grounding Wrist Strap

Document Number: 273-MNL-001 Page 50 of 58

3. Do not insert any object into the vent holes on

the case or the power supply. Touch a bare

metal surface on the back of the computer, a

SV-2001-THS Computer

Version A. 08/25/2010

Page 51

____1.0 :Initial Check Points

____1.1

VERIFY the Work Permit instructions

have been completed.

____1.2

VERIFY locks and tags are properly

attached to equipment.

____1.3

VERIFY all power is removed from

the Computer.

____2.0 Install AC Retainer

Bracket:

____2.1

SV-2001-THS-Computer. (Figure 6-

32).

Figure 6-32 SV-2001-THS Computer (Rear View)

Operations Manual

bare metal surface on your workbench, or

other grounded object before handing DIMMs

or other components.

Before working with computer components,

follow these guidelines:

1. Avoid static-causing surfaces such as carpeted

floors, plastic, and packing foam.

2. Remove components from their antistatic bags

only when you are ready to use them. Do not

lay components on the outside of antistatic

bags because only the inside of the bags

provide electrostatic protection. Always hold

memory modules and components by their

edges or their metal mounting brackets.

3. Avoid touching the edge connectors and

components on the cards. Never slide memory

modules or components over any surface.

6.5 Power Supply Cable Retention Bracket Installation

Document Number: 273-MNL-001 Page 51 of 58

SV-2001-THS Computer

Version A. 08/25/2010

Page 52

____2.3

Power Supply Cable Retention

Bracket. (Figure 6-33).

Figure 6-33 Power Supply Cable Retention Bracket.

____2.4

Secure Power Supply Cable

Retention Bracket by the THREE

supplied screws. (Figure 6-34).

Figure 6-34 Secure Power Supply Cable Retention Bracket

Operations Manual

Document Number: 273-MNL-001 Page 52 of 58

SV-2001-THS Computer

Version A. 08/25/2010

Page 53

Operations Manual

6.6 Replacing a Hard Drive

To remove the systems Hard Drive you need to

stop the hard drive and take it offline to remove

the logical software links to the hard drive, and

to reconfigure the file system so that it will

recognize the new drive. You will have to

reconfigure your application software.

Therefore it is strongly recommended that you

contact TAG Technical Support at

tech.support@tag.com before attempting to

exchange the hard drive. For more information

on contact information see Manual back page.

6.6.1 25” Solid State SATA Hard Drive

Figure 6-32 25” Solid State SATA Hard Drive.

6.7 Removing the Computer Cover

Document Number: 273-MNL-001 Page 53 of 58

The location of the mounting screws securing

the Computer cover varies per Computer

SV-2001-THS Computer

Version A. 08/25/2010

Page 54

Operations Manual

model. To remove the cover, use a Phillips

screwdriver to remove all screws from the

sides and top of the cover.

NOTE: It is important to make note of the

location from which screws are removed

since different screw lengths may be used

to secure the cover.

CAUTION

It is not safe to operate TAG Computers

without the cover in place. Failure to take

this precaution may result in personal

injury and system damage.

6.8 Adding or Replacing System Memory

This section lists the procedures for adding or

replacing system memory.

WARNING

Ensure that the system is powered-down

and all power sources have been

disconnected from the Computer prior to

removing or replacing system memory.

Failure to do so could result in serious

injury from electrical shock.

CAUTION

Printed circuit boards and hard drives

contain electronic components that are

extremely sensitive to static electricity.

Ordinary amounts of static from your

clothes or the work environment can

destroy components. Do not touch the

components or any metal parts without

taking proper antistatic precautions.

Document Number: 273-MNL-001 Page 54 of 58

SV-2001-THS Computer

Version A. 08/25/2010

Page 55

Operations Manual

6.8.1 Install system memory.

Unlatch both DIMM socket levers, as shown in Figure 6-62.

Figure 6-33 DIMM Module Bank

1. Note the location of the alignment notch.

2. Align the notches on the new module with the

notches on the memory and press it firmly into

the bank.

NOTE: The tabs on the sides of the memory

module should secure the DIMM

automatically. When the DIMM locks into

place, you will hear a click.

Document Number: 273-MNL-001 Page 55 of 58

SV-2001-THS Computer

Version A. 08/25/2010

Page 56

Operations Manual

Appendix

Document Number: 273-MNL-001 Page 56 of 58

SV-2001-THS Computer

Version A. 08/25/2010

Page 57

Chapter 3

SV-2001-THS Computer

Part Number: 1006446 Page 57 of 58

Version A. 07/12/10

7 Contract Drawing SV-2001-THS

Figure 7-1 Contract Drawing SV-2001-THS

NOTE: This Contract Drawing is subject to change. Contact TAG for latest drawing Tel: 1-800-824-7693

www.tag.com

Page 58

Contact Information

7.1.1

22355 TAG Way

Dulles, VA 20166

Tel: 1-800-824-7693

www.tag.com

Technical Support

USA 1-800-824-7693

Outside USA

While every precaution has been taken

to ensure the accuracy and completeness

of this literature. TAG assumes

no responsibility and disclaims and liability

for damage resulting from use of this information

or for any errors or omissions.

Loading...

Loading...