Page 1

TAG

22355 TAG Way

Dulles, VA 20166

`

SV-1002-X2 Server

Operations Manual

282-MNL-009

P/N 1008826, 1009006, 1008871

Page 2

Operations Manual

1 Copyright © 2009 Technology Advancement Group (TAG)

All rights reserved. This publication and its contents are proprietary to TAG. No part of

this publication may be reproduced in any form or by any means without the written

permission of TAG, 22355 TAG Way, Dulles, Virginia 20166-9310.

TAG has made every effort to ensure the correctness and completeness of the material

in this document. TAG shall not be liable for errors contained herein. The information in

this document is subject to change without notice. TAG makes no warranty of any kind

with regard to this material, including, but not limited to, the implied warranties of

merchantability and fitness for a particular purpose.

1.1 Trademarks

All trademarks, marks, names, or product names referenced in this publication are the

property of respective owners, and TAG neither endorses nor otherwise sponsors any

such products or services referred to herein.

Document Number: 282-MNL-009 P/N1008826, 1009006, 1008871 Page 2 of 44

SV-1002-X2 Server

Version A. 10/25/2010

Page 3

Operations Manual

2 About TAG

2.1 Summary of Qualifications

TAG has served as a leading provider of IT solutions to DoD customers over the past

20+ years and has a long-standing and respected history of providing Systems

Engineering, Electronic Equipment and Program Management support to US Military

warfighters. Headquartered in Dulles, Virginia, TAG’s state-of-the-art 35,000 sq. ft.

engineering and manufacturing facility provides all the infrastructure, equipment, and

manpower necessary to engineer, design, test, manufacture, and certify products to the

rugged requirements of the tactical combat theater. Our facilities in Dulles, VA, San

Diego, CA, and St. Louis, MO, allow for rapid deployment of products and support

across the globe.

TAG quickly, efficiently, and cost-effectively tailors rugged solutions for large DoD

programs with specific MIL-STD requirements. TAG’s comprehensive Quality

Assurance (QA) policy – enforced through application of our UL-registered ISO

9001:2000 certified processes – enables TAG to rapidly deploy systems and solutions

that reliably withstand the stresses of the tactical environment. Today, there are over

20,000 TAG systems deployed across various weapons platforms throughout the US

Military. TAG effectively balances all corporate assets – our people, expertise,

infrastructure, and experience – to consistently and successfully execute and deliver to

the DoD.

TAG’s success lies in focusing on the

corporate Mission Statement and leveraging

the tenets of our business model to ensure

the customer’s expectations are exceeded

throughout lengthy program lifecycles.

TAG’s Mission is to resolve our customers’ IT

challenges with World-Class:

Engineering;

Manufacturing and Integration; and

Lifecycle Management

TAG has a proven track record in

implementing these tenets to serve as a trusted advisor to our Government customers.

TAG uses this foundation to ensure risk is mitigated, expectations are exceeded, and

the customer can consistently rely on the company, our equipment, and our services.

SV-1002-X2 Server

Document Number: 282-MNL-009 P/N1008826, 1009006, 1008871 Page 3 of 44

Version A. 10/25/2010

Page 4

Operations Manual

2.1.1 Core Competences

TAG’s engineering methodology is built upon Multi-Disciplinary Optimization (MDO) and

rigorous design reviews. Although PMs drive the schedule at TAG, Engineering

leverages Server-Aided Design (CAD) tools, Computational Fluid Dynamics (CFD)

modeling, rapid prototyping processes, and diverse test equipment and facilities to

ensure requirements are being met at every step of the design. TAG Engineering

follows a proven design-review process, ensuring all entrance and exit criteria are met

at each stage. Rigorous documentation is compiled to demonstrate requirement

compliance, risks are mitigated, and decisions are prudent – throughout the design

process.

TAG prides itself on its engineering

laboratories and facilities. Over the past

three years, TAG has invested in several

pieces of equipment that allow TAG to test

and certify products directly onsite to the

harshest environmental requirements of

military standards – including the MIL-STD810F and DO 160D.

TAG’s onsite test equipment currently

includes a Highly Accelerated Lifecycle

Testing (HALT) Chamber, an

Electromagnetic Interference (EMI) test chamber, and a high-/low-temperature thermal

test chamber. TAG’s facility also provides:

A floor plan designed to support a cellular manufacturing model with modular

assembly lines

A dedicated 24-hour system burn-in room

A modern production status tracking and ENTERprise Resource Planning (ERP)

system with external web collaboration capabilities

Dedicated Quality Assurance workstations for system compliance and validation

inspection

2.1.2 Manufacturing and Integration

TAG implements Cellular Manufacturing processes through our compartmentalized,

state-of-the-art production facility to minimize waste byproducts and maximize

production efficiency. TAG’s manufacturing facility is physically partitioned to model the

major philosophies of Lean Manufacturing. Consistent with the model, each of TAG’s

production cells are capable of operating in isolation; however personnel and tools are

shared across all cells to streamline manufacturing operations, costs, and the

Document Number: 282-MNL-009 P/N1008826, 1009006, 1008871 Page 4 of 44

SV-1002-X2 Server

Version A. 10/25/2010

Page 5

Operations Manual

production/integration scheduling. TAG’s floor technicians are cross-trained in multiple

disciplines so they can be redistributed to any cell that encounters production

bottlenecks, which ensures optimal efficiency.

2.1.3 Lifecycle Management

TAG’s world-class Program Management discipline models the renowned

methodologies of the Project Management Institute (PMI) to ensure successful

completion of the task at hand. Our Program Managers (PMs) serve as the voice of the

customer – driving requirements to which the rest of TAG’s organization answers. As

an explicit tenet of TAG’s corporate mission statement, the PMs not only track cost,

schedule, and technical compliance throughout a project’s period of performance, but

also ensure the customer is supported well beyond it.

SV-1002-X2 Server

Document Number: 282-MNL-009 P/N1008826, 1009006, 1008871 Page 5 of 44

Version A. 10/25/2010

Page 6

Date

Version

Number

Updated By

Description of

Changes

10/25/2010

A

Alan Huckerby

Author

Operations Manual

Document Revision History

Document Number: 282-MNL-009 P/N1008826, 1009006, 1008871 Page 6 of 44

SV-1002-X2 Server

Version A. 10/25/2010

Page 7

Operations Manual

3 About This Manual

3.1 Scope and Audience

This manual provides information on the SV1002-X2 Server. The SV-1002-X2 Server

allows for up to 2 cores in a 1U chassis and up

to 96GB of RAM. The SV-1002-X2 Server

features Multi-core Xeon Processors to

maximize processing performance, while

reducing power dissipation. The Server is ideal

for deployable situations where such high

density computing minimizes size, weight, and

power.

3.1.1 Organization:

This manual is divided into the following

chapters and appendix:

Chapter 1 Cautions and Warnings when

handling the SV-1002-X2 Server.

Chapter 2 provides detailed information on the

external and internal Server components.

Chapter 3 provides procedures for replacing

hot-swappable and LRU components, as well

as for replacing or adding system memory.

Document Number: 282-MNL-009 P/N1008826, 1009006, 1008871 Page 7 of 44

SV-1002-X2 Server

Version A. 10/25/2010

Page 8

Operations Manual

Table of Contents

Contents

1 Copyright © 2009 Technology Advancement Group (TAG) ......................................... 2

1.1 Trademarks ............................................................................................................ 2

2 About TAG ................................................................................................................... 3

2.1 Summary of Qualifications ...................................................................................... 3

2.1.1 Core Competences ........................................................................................... 4

2.1.2 Manufacturing and Integration ........................................................................... 4

2.1.3 Lifecycle Management ...................................................................................... 5

3 About This Manual ....................................................................................................... 7

3.1 Scope and Audience .............................................................................................. 7

3.1.1 Organization: ................................ ..................................................................... 7

4 Safety Instructions ....................................................................................................... 11

4.1 Types of warnings used in this manual ................................................................... 11

4.1.1 Conventions ...................................................................................................... 12

5 Server Overview .......................................................................................................... 14

5.1 Product Information ................................................................................................ 14

5.1.1 SV-1002-X2 Server ................................ ................................ ........................... 14

5.1.2 SV-1002-X2 Server ................................ ................................ ........................... 15

5.1.3 Specifications .................................................................................................... 15

5.1.4 Additional specifications .................................................................................... 17

5.1.5 Server Highlights ............................................................................................... 18

5.1.6 SV-1002-X2 Server ................................ ................................ ........................... 18

5.1.7 Server Components .......................................................................................... 21

5.1.8 SV-1002-X2 Server Integrated Server RAID Module ........................................ 25

5.1.9 Q-Logic PCI-Express Dual Port Fibre Channel HBA ......................................... 27

5.1.10 Riser Card ....................................................................................................... 28

5.1.11 Matrox XTOA-FESLPAF PCIe Fiber Interface card ........................................ 29

5.1.12 Specifications .................................................................................................. 29

5.1.13 3.5” Hard Drive ................................................................................................ 30

6 Procedures .................................................................................................................. 34

6.1.1 Server Startup ................................................................................................... 34

6.1.2 Server Shutdown ............................................................................................... 34

6.1.3 Upgrading and Replacing System Components ................................................ 35

6.1.4 Power Supply Cable Retention Bracket Installation .......................................... 36

6.1.5 Replacing a Hard Drive ..................................................................................... 38

6.1.6 Adding or Replacing System Memory ............................................................... 38

6.1.7 Install System Memory. ..................................................................................... 39

6.1.8 Troubleshooting ................................................................................................ 40

Appendix A ........................................................................................................................ 42

7 Contract Drawing SV-1002-X2 SERVER ..................................................................... 43

Document Number: 282-MNL-009 P/N1008826, 1009006, 1008871 Page 8 of 44

SV-1002-X2 Server

Version A. 10/25/2010

Page 9

Operations Manual

List of Figures

Figure 5-1 SV-1002-X2 P/N 1008826, P/N 1008871 Server ......................................... 14

Figure 5-2 SV-1002-X2 P/N 1009006 Server ................................................................ 15

Figure 5-3 SV-1002-X2 P/N 1009006 Server Components and Connectors. (Front

View). ............................................................................................................................ 18

Figure 5-4 SV-1002-X2 P/N 1008826, P/N 1008871 Server Components and

Connectors. (Front View). ............................................................................................. 19

Figure 5-5 SV-1002-X2 P/N 1008826 Server I/O Connectors (Rear View). .................. 19

Figure 5-6 SV-1002-X2 P/N 1009006 Server I/O Connectors (Rear View). .................. 20

Figure 5-7 SV-1002-X2 P/N 1008871 Server I/O Connectors (Rear View). .................. 20

Figure 5-8 SV-1002-X2 S5520UR Server Board ................................ .......................... 21

Figure 5-9 Server Board S5520UR Layout. ................................................................... 22

Figure 5-10 Integrated Server RAID Module ................................................................. 25

Figure 5-11 Q-Logic PCI-Express Dual Port Fibre Channel HBA (SV-1002-X2 ............ 27

Figure 5-12 1U PCIeX16 Riser Card ............................................................................. 28

Figure 5-13 PCIe Interface Card. (SV-1002-X2 P/N 1008826) ...................................... 29

Figure 5-14 3.5” Hard Drive ........................................................................................... 30

Figure 6-1 Grounding Wrist Strap.................................................................................. 35

Figure 6-2 SV-1002-X2 Server(Rear View) ................................................................... 37

Figure 6-3 Power Supply Cable Retention Bracket. ...................................................... 37

Figure 6-4 Secure Power Supply Cable Retention Bracket. .......................................... 37

Figure 6-5 3.5 SAS Hard Drive. ..................................................................................... 38

Figure 6-6 DIMM Module Bank ..................................................................................... 39

Figure 7-1 Contract Drawing SV-1002-X2 Server ......................................................... 43

List of Tables

Table 5-1 Power Output. ............................................................................................... 17

Table 5-2 Server Board Components ............................................................................ 24

Table 6-1Trouble Shooting Guide ................................................................................. 41

SV-1002-X2 Server

Document Number: 282-MNL-009 P/N1008826, 1009006, 1008871 Page 9 of 44

Version A. 10/25/2010

Page 10

Operations Manual

Chapter 1

Cautions and Warnings.

Electronically distributed. Subject to user discretion when printed.

Document Number: 282-MNL-009 P/N1008826, 1009006, 1008871 Page 10 of 44

SV-1002-X2 Server

Version A. 10/25/2010

Page 11

These warnings and cautions indicate

situations or practice that might result in

property damage or injury. These hazard

indicators are not present on all TAG

products; they are only present where

applicable.

Operations Manual

4 Safety Instructions

4.1 Types of warnings used in this manual

Read this manual thoroughly, paying special attention to

the cautions and warnings. Safety Symbols and Labels

Document Number: 282-MNL-009 P/N1008826, 1009006, 1008871 Page 11 of 44

SV-1002-X2 Server

Version A. 10/25/2010

Page 12

Operations Manual

4.1.1 Conventions

4.1.1.1 Important Messages

Important messages appear where

mishandling of components is possible or when

work orders can be misunderstood. These

messages also provide vital information

associated with other aspects of system

operation. The word “important” is written as

“IMPORTANT,” both capitalized and bold and

is followed by text in italics. The italicized text

is the important message.

4.1.1.2 Warnings

Warnings appear where overlooked details

may cause damage to the equipment or result

in personal injury. Warnings should be taken

seriously. Warnings are easy to recognize. The

word “warning” is written as “WARNING,” both

capitalized and bold and is followed by text in

italics. The italicized text is the warning

message.

4.1.1.3 Cautions

Cautionary messages should also be heeded

to help you reduce the chance of losing data or

damaging the system. Cautions are easy to

recognize. The word “caution” is written as

“CAUTION,” both capitalized and bold and is

followed by text in italics. The italicized text is

the cautionary message.

4.1.1.4 Notes

Notes inform the reader of essential but noncritical information. These messages should be

read carefully as any directions or instructions

contained therein can help you avoid making

mistakes. Notes are easy to recognize. The

word “note” is written as “NOTE.”

SV-1002-X2 Server

Document Number: 282-MNL-009 P/N1008826, 1009006, 1008871 Page 12 of 44

Version A. 10/25/2010

Page 13

Operations Manual

Chapter 2

SV-1002-X2 Server.

Electronically distributed. Subject to user discretion when printed.

Document Number: 282-MNL-009 P/N1008826, 1009006, 1008871 Page 13 of 44

SV-1002-X2 Server

Version A. 10/25/2010

Page 14

Operations Manual

5 Server Overview

5.1 Product Information

This chapter provides an introductory overview

of the TAG family of tactical Servers. TAG

Servers are highly customizable; the specific

components vary depending on the mission

requirements. Your system may contain

components not described in this chapter. For

detailed information on these components,

refer to the manufactures website or contact

TAG Technical Support at

tech.support@tag.com.

TAG's tactical Servers combine state-of-the-art

mechanical, thermal and electrical engineering

to create customized systems that perform

above and beyond end user or program

specifications.

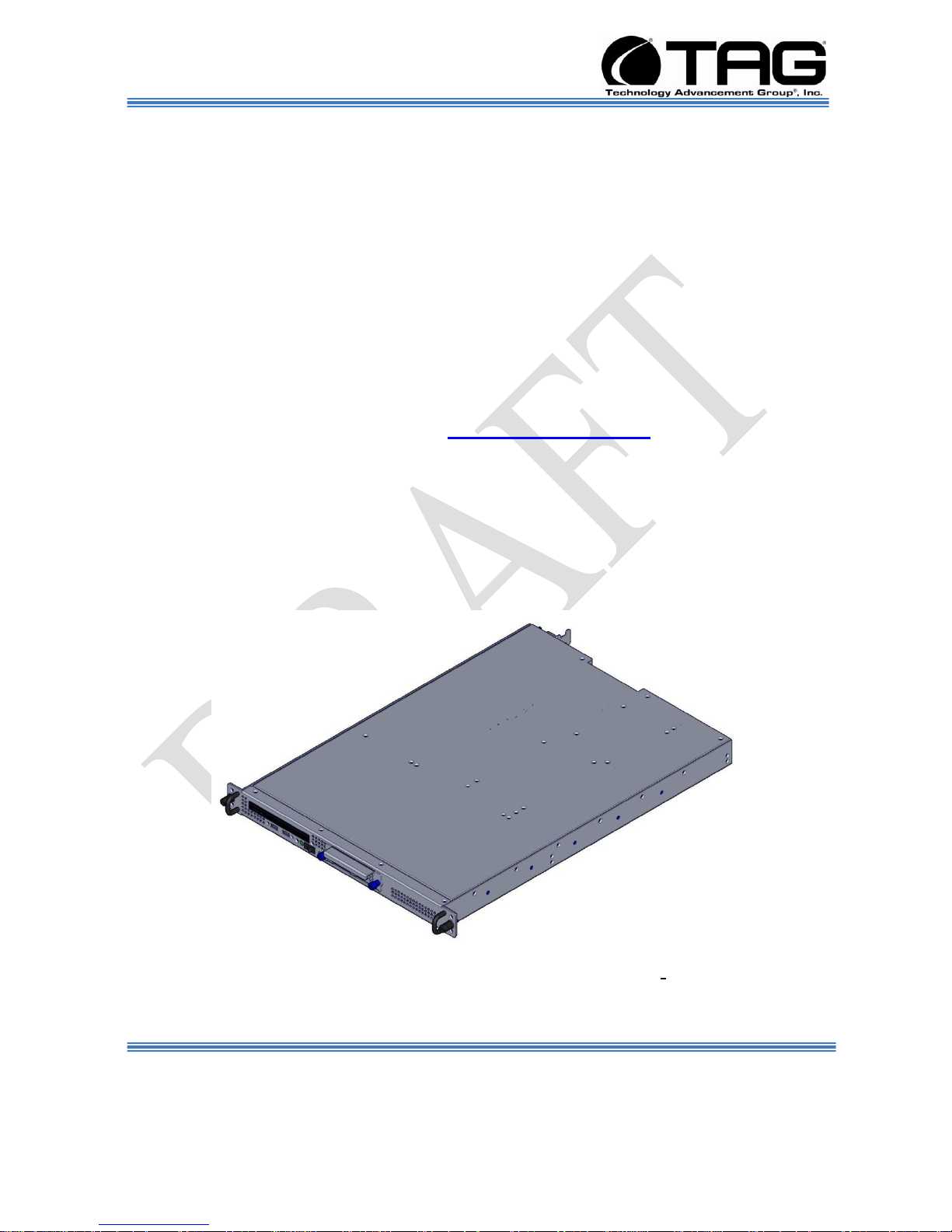

5.1.1 SV-1002-X2 Server

Figure 5-1 SV-1002-X2 P/N 1008826, P/N 1008871 Server

Document Number: 282-MNL-009 P/N1008826, 1009006, 1008871 Page 14 of 44

SV-1002-X2 Server

Version A. 10/25/2010

Page 15

Operations Manual

5.1.2 SV-1002-X2 Server

Figure 5-2 SV-1002-X2 P/N 1009006 Server

5.1.3 Specifications

Chassis & power supply:

1U Heavy-duty aluminum rack-mount chassis.

Chassis is designed to EIA-310-D Standards.

1.719”H (1U) x 16.88”W x 24.070”D.

Cooling system developed specifically for

harsh environments.

Front accessible on/off switches.

Processor & Cache:

Single Intel Quad Core Xeon Processor L5618

(1.87GHz,12MB Cache, 5.86 GT/s Intel QPI).

I/O

External connections:

DB-15 Video connector

RJ-45 serial Port A connector

Two RJ-45 Network Interface Connectors for

10/100/1000 Mb

Document Number: 282-MNL-009 P/N1008826, 1009006, 1008871 Page 15 of 44

Four USB 2.0 connectors

Internal connections:

One USB 2x5 pin header, supporting two USB

2.0 ports

SV-1002-X2 Server

Version A. 10/25/2010

Page 16

Operations Manual

One low-profile USB 2x5 pin header to support

low-profile USB solid state drives

One DH-10 Serial Port B header

One SSI-EEB compliant front panel header

One SSI-EEB compliant 24-pin main power

connector

One SSI-compliant 8-pin CPU power connector

One SSI-compliant power supply SMBus

connector.

P/N 1008826 System Components:

12GB ECC DDR3 RAM (3x4GB modules)

Single 300GB removable SAS hard drive with

rugged metal carrier & receiver

Matrox XTOA-FESLPAF PCI-E Fibre interface

card (interface to Matrox remote graphics unitsupplied and warranted by TRS)

Slim- line SATA DVD-RW/CD-RW drive

24” 1U Slides

P/N 1008871 System Components:

12GB ECC DDR3 RAM (3x4GB modules)

Single 300GB removable SAS hard drive with

rugged metal carrier & receiver

Slim- line SATA DVD-RW/CD-RW drive

24” 1U Slides

P/N 1009006 System Components:

24GB ECC DDR3 RAM (6x4GB modules)

Dual 300GB Hot Swap removable SAS hard

drives with rugged metal carrier & receivers

(configured in a RAID 1)

Slim- line SATA DVD-RW/CD-RW drive

Q-Logic (P/N-QLE 2562-CK) PCI-Express Dual

Port Fibre Channel; HBA

24” 1U Slides

Document Number: 282-MNL-009 P/N1008826, 1009006, 1008871 Page 16 of 44

SV-1002-X2 Server

Version A. 10/25/2010

Page 17

Operations Manual

Normal Output

Voltage

Load Current (A)

Min Max

Regulation Tolerance

Max Min

+5V

0.5A 25A

+5% -5%

+12V

2A 40A

+5% -5%

-12V

0A 0.8A

+5% -5%

+3.5V

0.5A 25A

+5% -5%

+5V sb

0.1A 3.5A

+5% -5%

5.1.4 Additional specifications

Power Input

Input voltage range is 100V to 240V range

(With + - 10% tolerance).

Input frequency range is 60hz nominal but can

go from 47 ~ 63 to hertz.

Steady-State Current 8A/4A at any low/high

range input voltage.

Power supply max available power is 550

watts.

Inrush current at 20/40Amps @ 115/230 VAC.

Inrush current at 230VAC is 4 amps max

Power Factor Correction can reach the target

of 95% @ 115/230VAC, Full Load.

Power Output

Table 5-1 Power Output.

SV-1002-X2 Server

Document Number: 282-MNL-009 P/N1008826, 1009006, 1008871 Page 17 of 44

Version A. 10/25/2010

Page 18

Operations Manual

5.1.5 Server Highlights

The SV-1002-X2 Server is unlike any other

Server that is currently on the market. The SV1002-X2 Server is ideal for use in deployable

situations where the product’s compact size,

high density computing, minimized size,

weight, and power make for a highly portable,

rugged and reliable system.

Contains an intelligent fan controller

(acoustically optimized, environmentally

aware).

Small-form factor chassis.

Proven to function in a variety of operating

temperature ranges from 0C TO 50C.

5.1.6 SV-1002-X2 Server

Figure 5-3 SV-1002-X2 P/N 1009006 Server Components and Connectors. (Front

Document Number: 282-MNL-009 P/N1008826, 1009006, 1008871 Page 18 of 44

View).

SV-1002-X2 Server

Version A. 10/25/2010

Page 19

Operations Manual

Figure 5-4 SV-1002-X2 P/N 1008826, P/N 1008871 Server Components and

Connectors. (Front View).

Figure 5-5 SV-1002-X2 P/N 1008826 Server I/O Connectors (Rear View).

Document Number: 282-MNL-009 P/N1008826, 1009006, 1008871 Page 19 of 44

SV-1002-X2 Server

Version A. 10/25/2010

Page 20

Operations Manual

Figure 5-6 SV-1002-X2 P/N 1009006 Server I/O Connectors (Rear View).

Figure 5-7 SV-1002-X2 P/N 1008871 Server I/O Connectors (Rear View).

Document Number: 282-MNL-009 P/N1008826, 1009006, 1008871 Page 20 of 44

SV-1002-X2 Server

Version A. 10/25/2010

Page 21

Operations Manual

5.1.7 Server Components

This section provides an overview of the most

common components installed in the SV-1002X2 Server. Information is also provided on how

to identify specific components within your

Server. For detailed information on specific

components installed in your Server, TAG

Technical Support at: tech.support@tag.com.

5.1.7.1 SV-1002-X2 S5520UR Server Board

Figure 5-8 SV-1002-X2 S5520UR Server Board

Document Number: 282-MNL-009 P/N1008826, 1009006, 1008871 Page 21 of 44

SV-1002-X2 Server

Version A. 10/25/2010

Page 22

Operations Manual

5.1.7.2 Server Board Connector and Component Layout

Figure 5-7 shows the board layout of the server

board. Each connector and major component

is identified by a number or letter, a description

is given in Table 5-2.

Figure 5-9 Server Board S5520UR Layout.

Document Number: 282-MNL-009 P/N1008826, 1009006, 1008871 Page 22 of 44

SV-1002-X2 Server

Version A. 10/25/2010

Page 23

Operations Manual

Feature

Description

Processors

Support

One or two Intel® Xeon® Processor 5500 Series with a 4.8

GT/s, 5.86 GT/s, or 6.4 GT/s Intel® QPI link interface and Thermal

Design Power (TDP) up to 95 W.

One or two Intel® Xeon® Processor 5600 Series with a 6.4

GT/s Intel® QPI link interface and Thermal Design Power (TDP) up

to 130 W.

Enterprise Voltage Regulator-Down (EVRD) 11.1

Memory

Support for 800/1066/1333 MT/s ECC registered (RDIMM) or

unbuffered (UDIMM) DDR3 memory.

12 DIMMs total across 6 memory channels (3 channels per

processor).

Chipset

Intel® 5520 Chipset IOH

Intel® 82801Jx I/O Controller Hub (ICH10R)

I/O Control

External connections:

DB-15 Video connector

RJ-45 serial Port A connector

Two RJ-45 Network Interface Connectors for 10/100/1000 Mb

Four USB 2.0 connectors

Internal connections:

One USB 2x5 pin header, supporting two USB 2.0 ports

One low-profile USB 2x5 pin header to support low-profile

USB solid state drives

One DH-10 Serial Port B header

Six SATA II connectors

Two I/O module Mezzanine connectors for optional I/O

Module support

emote

Management Module 3

SATA SW RAID 5 Activation Key Connector

One SSI-EEB compliant front panel header

One SSI-EEB compliant 24-pin main power connector

One SSI-compliant 8-pin CPU power connector

One SSI-compliant power supply SMBus connector

System Fan

Support

Six 4-pin fan headers supporting 2 processor fans, 2 memory fans,

and up to 2 system fans

One 26-pin custom system fan header for use in an Intel® Server

Chassis

Feature

Description

5.1.7.3 Server Board S5520UR Components

Document Number: 282-MNL-009 P/N1008826, 1009006, 1008871 Page 23 of 44

SV-1002-X2 Server

Version A. 10/25/2010

Page 24

Operations Manual

Add-in Adapter

Support

One riser slot supporting both full-height and low-profile 1U and 2U

PCI Express* riser cards

Video

On-board ServerEngines* LLC Pilot II Controller

Integrated 2D Video Controller

32 MB DDR2 Memory

Hard Drive

Support for six ICH10R SATA II ports

Intel® Matrix RAID Technology with Software RAID levels 0/1/10

Optional support for Software RAID 5 with activation key

LAN

Two 10/100/1000 ports provided by Intel® 82575 PHYs

Security**

Trusted Platform Module

Server

Management

On-board ServerEngines* LLC Pilot II Controller

Integrated Baseboard Management Controller (Integrated

BMC), IPMI 2.0 compliant

Integrated Super I/O on LPC interface

Support for Intel® Server Management Software 3.1

Table 5-2 Server Board Components

SV-1002-X2 Server

Document Number: 282-MNL-009 P/N1008826, 1009006, 1008871 Page 24 of 44

Version A. 10/25/2010

Page 25

Operations Manual

5.1.8 SV-1002-X2 Server Integrated Server RAID Module

For 1U and 2U servers, the unique module

shape and specialized PCI Express*

connector provide the ability to easily

implement a robust RAID solution in

popular 1U and 2U form factor systems,

without sacrificing a valuable risercard

slot or using a chassis with low-profile add-in

card cut-outs...

5.1.8.1 Integrated Server RAID Module

Figure 5-10 Integrated Server RAID Module

5.1.8.2 RAID Module Specifications

RAID Levels

Option 1: Entry Hardware RAID 0, 1, and 1E

Option 2: Software RAID 0, 1, 10

Option 3: Software RAID 5 (requires optional

AXXRAKSW5)

Option 4: Pass-through SAS

Fault Tolerance Features

Distributed Sparing

SV-1002-X2 Server

Document Number: 282-MNL-009 P/N1008826, 1009006, 1008871 Page 25 of 44

Version A. 10/25/2010

Page 26

Operations Manual

Hot Spare Support

Expander Support

Enclosure Management

S.M.A.R.T. Support

RAID support before operating system loaded

Intel® RAID Software

Intel® Embedded RAID II Configuration Utility

Intel® RAID Web Console 2

Intel® SAS Flash

I/O Processor

LSISAS1064E

Drive Types

SAS or SATA 3Gb/s

Maximum Drives

Up to 122 physical devices supported with SAS

mode and up to 14 devices with RAID

0/1/1E/10E

Tape drives supported as a pass-through

devices in RAID modes

Connectors

Four SATA x1 SAS internal connectors

PCI Interface

PCI Express* x4

Form Factor

Custom 1U capable for server boards with the

appropriate module connector

Data Transfer Rates

Up to 3 GB/s per port

Operating Temperature

Maximum ambient: 60°C

Operating Voltage.

+3.3V

Document Number: 282-MNL-009 P/N1008826, 1009006, 1008871 Page 26 of 44

SV-1002-X2 Server

Version A. 10/25/2010

Page 27

Operations Manual

5.1.9 Q-Logic PCI-Express Dual Port Fibre Channel HBA

QLE2562 Host Bus Adapter. The QLE2562 is a

PCI Express, dual port, Fibre Channel (FC)

Host Bus Adapter (HBA).

Figure 5-11 Q-Logic PCI-Express Dual Port Fibre Channel HBA (SV-1002-X2

P/N 1009006).

Features

Virtualization optimized

Power optimized

Reliability, Availability, Serviceability (RAS)

optimized

Security optimized

Management optimized

Fibre Channel 8Gb to PCI Express x8

3200 MBps (full-duplex)

200,000 initiator and target IOPS per port

StarPower™ technology

Document Number: 282-MNL-009 P/N1008826, 1009006, 1008871 Page 27 of 44

SV-1002-X2 Server

Version A. 10/25/2010

Page 28

Operations Manual

5.1.10 Riser Card

Figure 5-12 1U PCIeX16 Riser Card

Features

1 Slot PCI-e Passive Riser.

1 full-size x16 physical x16 electrical slot.

Document Number: 282-MNL-009 P/N1008826, 1009006, 1008871 Page 28 of 44

SV-1002-X2 Server

Version A. 10/25/2010

Page 29

Operations Manual

5.1.11 Matrox XTOA-FESLPAF PCIe Fiber Interface card

The interface card installed in the server

converts outgoing bus data to an optical signal

and converts incoming bus data back to an

electrical signal. The card transmits and

receives this optical data to and from the

remote graphics unit via fiber-optic cable. Extio

has integrated graphics, audia, and USB

hardware that process the bus data as if it

were part of an add-in card directly installed in

a server expansion slot.

Figure 5-13 PCIe Interface Card. (SV-1002-X2 P/N 1008826)

5.1.12 Specifications

Document Number: 282-MNL-009 P/N1008826, 1009006, 1008871 Page 29 of 44

Bus Type: PCI Express x 1 (works in PCIe x1,

x4 and x16

Dimensions: 2.7" x 2.7"

SV-1002-X2 Server

Version A. 10/25/2010

Page 30

Operations Manual

5.1.13 3.5” Hard Drive

3.5-inch 15K RPM ENTERprise hard

disk drive features a host of innovations. The

300GB, 4-platter configuration provides low

power consumption, high reliability, and faster

internal data rates. Interface options include

3Gb/sec SAS, 68/80-pin U320 SCSI and

4Gb/sec Fibre Channel.

Figure 5-14 3.5” Hard Drive

5.1.13.1 3.5”, SAS, Hard Drive

Functional Specifications

Storage capacity (formatted)1 300.0 GB

Disks 1 2 4

Heads (read/write) 2 4 8

Bytes/sector 512.

Seek time Track to track Read: 0.2 ms (typ.) /

Write: 0.4 ms (typ.)

Average Read: 3.4 ms (typ) / Write: 3.9 ms

(typ)

SV-1002-X2 Server

Document Number: 282-MNL-009 P/N1008826, 1009006, 1008871 Page 30 of 44

Version A. 10/25/2010

Page 31

Operations Manual

Full track Read: 8.0 ms (typ) / Write: 9.0 ms

(typ)

Average latency time 2.00 ms

Rotational speed (RPM) 15,000

Areal density 112.8 Gbits/sq. in.

Data transfer To/from media 179MB/sec rate

To/from host SAS: 3Gb/sec, SCSI: 320MB/sec,

FCAL: 4Gb/sec

Recording code 60/62 MEEPRML

Interface Dual Port SAS (RC Series), SCA-2

80Pin (NC Series), 68Pin Wide (NP Series),

Dual Port FCAL (FC series)

Head positioning method Rotary VCM

Start time 30 s (typ)

Stop time 30 s (typ)

Buffer size SCSI 8 MB

SAS, FC 16 MB

Physical Specifications

Power Voltage 5 V ± 5%, 12 V ± 5%

requirements Spin-up 12 V ± 5% @ 2.5 A

(peak)

A (peak < 100 us)

5 V ± 5% @ 0.8 A

Idle (typ.) SAS 12.8 W

SCSI 12.4 W

FC 13.4 W

Dimensions (HxWxD) 25.4 mm x 101.6 mm x

146.0 mm

Weight 800 g

Ambient Operating 5°C to 55°C (HDD surface

60°C max) temperature Non-operating -40°C to

70°C

Gradient 20°C/Hour (max)

Relative Operating 5% to 95% (non-

condensing)

humidity Non-operating 5% to 95% (non-

condensing)

Max. wet bulb 29°C (operating)

Vibration Operating 0.6 mm (5 to 20 Hz) / 1.0

G (20 to 300 Hz)

Document Number: 282-MNL-009 P/N1008826, 1009006, 1008871 Page 31 of 44

SV-1002-X2 Server

Version A. 10/25/2010

Page 32

Operations Manual

Non-operating 3.1 mm (5 to 20 Hz) / 5.0 G (20

to 300 Hz)

Shock Operating 65 G max. (2 ms)

Non-operating 250 G max. (2 ms)

Altitude Operating 3,048 m (max.) (operation)

Non-operating 12,192 m (max.)

Acoustic Noise (idle sound power) (typ.) </=

3.6 bels (idle)

Reliability Specifications

Mean time between failures (MTBF) 1,400,000

hours

Error rates Unrecoverable errors 1 per 1015

bits read

Seek errors 10 per 108 seeks

Document Number: 282-MNL-009 P/N1008826, 1009006, 1008871 Page 32 of 44

SV-1002-X2 Server

Version A. 10/25/2010

Page 33

Operations Manual

Chapter 3

Procedures.

Electronically distributed. Subject to user discretion when printed.

Document Number: 282-MNL-009 P/N1008826, 1009006, 1008871 Page 33 of 44

SV-1002-X2 Server

Version A. 10/25/2010

Page 34

Operations Manual

6 Procedures

The procedures within this Chapter contain

relevant information to ensure your SV-1002X2 Server maintains its maximum performance

potential.

6.1.1 Server Startup

1. Check to make sure that all the cables are

seated and connected correctly to the back of

the unit such as keyboard, mouse, monitor

video and power cables.

2. Then Press the power switch ON to start the

server (power switch is located in the front of

the unit). (Figure 5.2).

3. Once the unit starts, System will go thru Power

On self Test (POST) (no action is required at

this time).

6.1.2 Server Shutdown

1. Press the Power ON/OFF Switch.

Document Number: 282-MNL-009 P/N1008826, 1009006, 1008871 Page 34 of 44

SV-1002-X2 Server

Version A. 10/25/2010

Page 35

Operations Manual

6.1.3 Upgrading and Replacing System Components

6.1.3.1 Preventing Static Electricity

This section provides procedures for replacing

all hot-swappable and LRU components,

including procedures for replacing or adding

system memory.

The components inside your server are

extremely sensitive to static electricity, also

known as electrostatic discharge (ESD). ESD

can permanently damage electrostatic

discharge-sensitive components in your

Server.

To prevent ESD damage, follow these

guidelines before opening the Server case:

1. Turn off the Server and unplug the power

cord before opening the case.

2. Wear a grounding wrist strap and attach it to

a bare metal part of the Server, workbench, or

other grounded connection.

Figure 6-1 Grounding Wrist Strap

3. Do not insert any object into the vent holes on

the case or the power supply. Touch a bare

metal surface on the back of the server, a bare

metal surface on your workbench, or other

grounded object before handing DIMMs or

other components.

Document Number: 282-MNL-009 P/N1008826, 1009006, 1008871 Page 35 of 44

SV-1002-X2 Server

Version A. 10/25/2010

Page 36

____1.0 :Initial Check Points

____1.1

VERIFY the Work Permit

instructions have been completed.

Operations Manual

Before working with server components,

follow these guidelines:

1. Avoid static-causing surfaces such as carpeted

floors, plastic, and packing foam.

2. Remove components from their antistatic bags

only when you are ready to use them. Do not

lay components on the outside of antistatic

bags because only the inside of the bags

provide electrostatic protection. Always hold

memory modules and components by their

edges or their metal mounting brackets.

3. Avoid touching the edge connectors and

components on the cards. Never slide memory

modules or components over any surface.

6.1.3.2 Removing the Server Cover

The location of the mounting screws securing

the Server cover varies per Server model. To

remove the cover, use a Phillips screwdriver to

remove all screws from the sides and top of the

cover.

NOTE: It is important to make note of the

location from which screws are removed

since different screw lengths may be used

to secure the cover.

CAUTION

It is not safe to operate TAG Servers

without the cover in place. Failure to take

this precaution may result in personal

injury and system damage.

6.1.4 Power Supply Cable Retention Bracket Installation

Document Number: 282-MNL-009 P/N1008826, 1009006, 1008871 Page 36 of 44

SV-1002-X2 Server

Version A. 10/25/2010

Page 37

____1.2

VERIFY locks and tags are properly

attached to equipment.

____1.3

VERIFY all power is removed from

the Server.

____2.0 Install AC Retainer

Bracket:

____2.1

SV-1002-X2 SERVER-Server.

(Figure 7.10).

Figure 6-2 SV-1002-X2 Server(Rear View)

____2.3

Power Supply Cable Retention

Bracket. (Figure 7.11).

Figure 6-3 Power Supply Cable Retention Bracket.

____2.4

Secure Power Supply Cable

Retention Bracket by the Two

supplied screws. (Figure 7.12).

Figure 6-4 Secure Power Supply Cable Retention Bracket.

Operations Manual

Document Number: 282-MNL-009 P/N1008826, 1009006, 1008871 Page 37 of 44

SV-1002-X2 Server

Version A. 10/25/2010

Page 38

Operations Manual

6.1.5 Replacing a Hard Drive

To remove the systems Hard Drive you need to

stop the hard drive and take it offline to remove

the logical software links to the hard drive, and

to reconfigure the file system so that it will

recognize the new drive. You will have to

reconfigure your application software.

Therefore it is strongly recommended that you

contact TAG Technical Support at

tech.support@tag.com before attempting to

exchange the hard drive. For more information

on contact information see Manual back page.

6.1.5.1 3.5” SAS Hard Drive

Figure 6-5 3.5 SAS Hard Drive.

6.1.6 Adding or Replacing System Memory

This section lists the procedures for adding or

replacing system memory.

WARNING

Ensure that the system is powered-down

and all power sources have been

disconnected from the Server prior to

removing or replacing system memory.

Failure to do so could result in serious

injury from electrical shock.

SV-1002-X2 Server

Document Number: 282-MNL-009 P/N1008826, 1009006, 1008871 Page 38 of 44

Version A. 10/25/2010

Page 39

Operations Manual

CAUTION

Printed circuit boards and hard drives

contain electronic components that are

extremely sensitive to static electricity.

Ordinary amounts of static from your

clothes or the work environment can

destroy components. Do not touch the

components or any metal parts without

taking proper antistatic precautions.

6.1.7 Install System Memory.

Unlatch both DIMM socket levers, as shown in Figure 6-

33.

Figure 6-6 DIMM Module Bank

1. Note the location of the alignment notch.

2. Align the notches on the new module with the

notches on the memory and press it firmly into

the bank.

NOTE: The tabs on the sides of the memory

module should secure the DIMM

automatically. When the DIMM locks into

place, you will hear a click.

Document Number: 282-MNL-009 P/N1008826, 1009006, 1008871 Page 39 of 44

SV-1002-X2 Server

Version A. 10/25/2010

Page 40

PROBLEM

POSSIBLE SOLUTION

DVD/CD-ROM:.

Won’t Eject

Does unit have power?

Enabled in CMOS?

Correct IDE cable?

Won’t Read Disc

Reseat cable

Try disc in a good known DVD/CD-ROM Drive

Verify that you have correct IDE cable for the M/B

DVD/CD-Rom Drive not being recognized in CMOS

Reseat IDE and power cable

Verify that you have the correct IDE cable for the M/B

Enable drive in CMOS

Led blinking all the time (defective drive)

Hard Drive

Post Can Not Find The Hard Drives

Check CMOS & verify that the drive is recognized

If the drive is not spinning, check power cable for voltage

If the drive is spinning, check data cable for correct

connection.

If the drive is not still recognized by post, try

performing the following procedures in order:

Reconnect or swap the drive data cable

Exchange the hard drive with one you know is in good

working condition.

If the known good hard drive does not work, then suspect

the system board

If the problem is solved by exchange one of the above

modules, try re-installing the old module to verify that the

problem was not caused by a bad connection.

No Power Supply.

Good power source?

Can you hear fans turning and drives motor spinning

up?

Operations Manual

6.1.8 Troubleshooting

Document Number: 282-MNL-009 P/N1008826, 1009006, 1008871 Page 40 of 44

SV-1002-X2 Server

Version A. 10/25/2010

Page 41

Hear any beeps?

See green light on mother board

Check the 20/24 pin ATX power connector for loose pins

If the previous checks failed replace power supply.

Operations Manual

Table 6-1Trouble Shooting Guide

SV-1002-X2 Server

Document Number: 282-MNL-009 P/N1008826, 1009006, 1008871 Page 41 of 44

Version A. 10/25/2010

Page 42

Operations Manual

Appendix A

Document Number: 282-MNL-009 P/N1008826, 1009006, 1008871 Page 42 of 44

SV-1002-X2 Server

Version A. 10/25/2010

Page 43

Operations Manual

SV-1002-X2 Server

Document Number: 282-MNL-009 P/N1008826, 1009006, 1008871 Page 43 of 44

Version A. 10/25/2010

7 Contract Drawing SV-1002-X2 SERVER

Figure 7-1 Contract Drawing SV-1002-X2 Server

NOTE: This Contract Drawing is subject to change. Contact TAG for latest drawing Tel: 1-800-824-7693

www.tag.com

Page 44

Contact Information

7.1.1

22355 TAG Way

Dulles, VA 20166

Tel: 1-800-824-7693

www.tag.com

Technical Support

USA 1-800-824-7693

Outside USA

While every precaution has been taken

to ensure the accuracy and completeness

of this literature. TAG assumes

no responsibility and disclaims and liability

for damage resulting from use of this information

or for any errors or omissions.

Loading...

Loading...