Tadiran Telecom Swift Inverter 9U, Swift Inverter 24U, Swift Inverter Series, Swift Inverter 36U, Swift Inverter 12U Service Manual

...

Swift Inverter

Split-Type Air Conditioner

CONTENTS

Part I : Technical Information ............................................................................. 1

1. Summary ............................................................................................................ 1

1-1 Appearance .........................................................................................................................1

1-2 Model List ............................................................................................................................3

2. Outline Dimension Diagram ................................................................................ 3

3. Specification sheet ............................................................................................... 5

4. Function and Control ........................................................................................ 10

4-1 H-Style .............................................................................................................................. 10

4-2 L-Style ............................................................................................................................... 14

5. Refrigerant System Diagram ............................................................................. 21

5-1 Cooling Only...................................................................................................................... 21

5-2 Cooling & Heating............................................................................................................. 22

6. Electrical Part ................................................................................................... 24

6-1 Wiring Diagram ................................................................................................................. 24

6-2 PCB Printed Diagram ........................................................................................................ 26

Part II : Installation and Maintenance ............................................................... 27

7. Main Tools for Installation and Maintenance...................................................... 27

8. Installation........................................................................................................ 28

8-1 Notes for Installation ........................................................................................................ 28

8-2 Installation of Indoor Unit ................................................................................................. 29

8-3 Installation of outdoor Unit ............................................................................................... 32

8-4 Check after installation and test operation ...................................................................... 35

9. Maintenance ..................................................................................................... 37

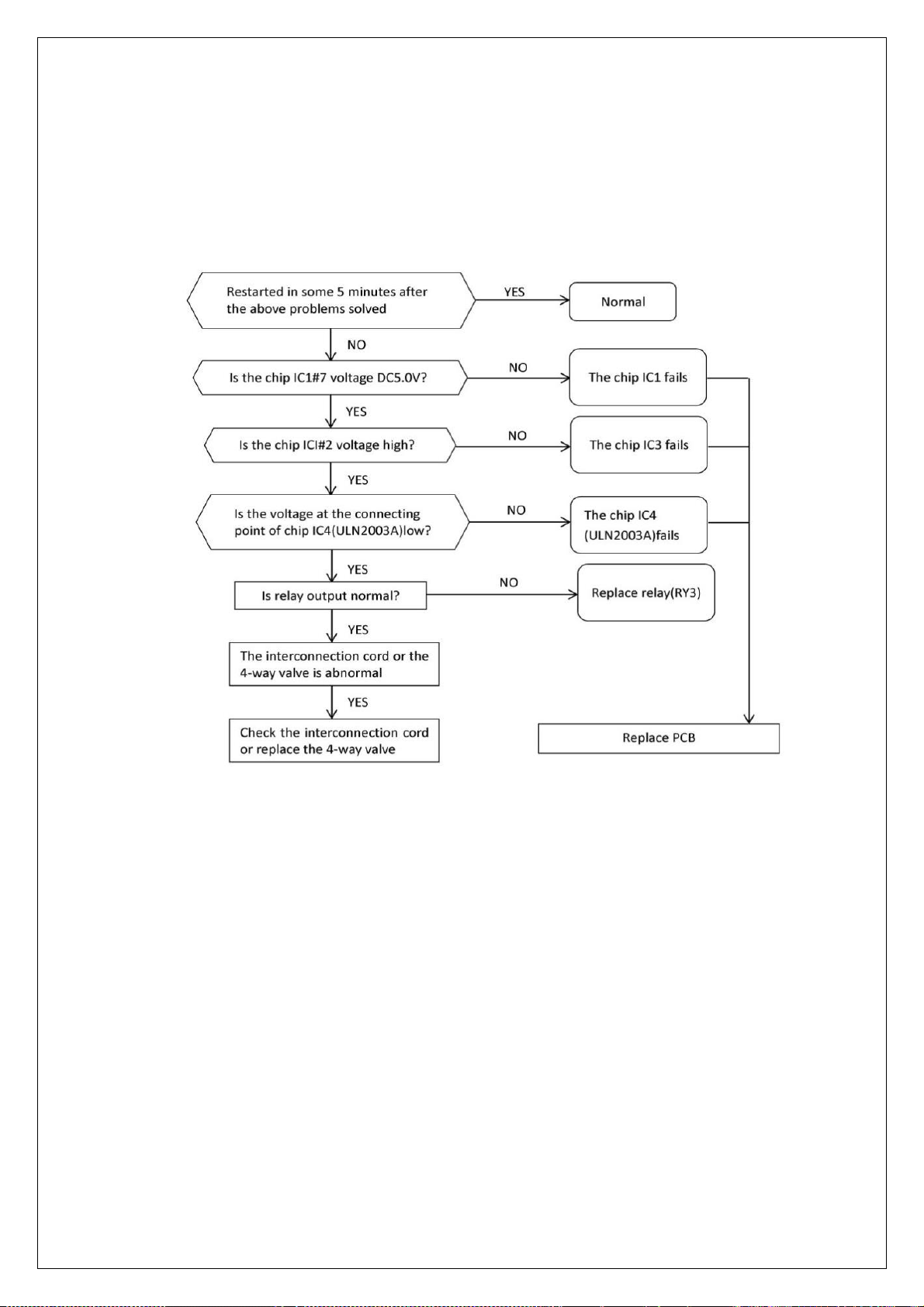

9-1 Troubleshooting Guide ..................................................................................................... 37

9-2 Common Parameters ....................................................................................................... 59

9-3 Troubleshooting for Normal Malfunction .......................................................................... 61

10. Removal Procedure ......................................................................................... 69

10-1 Indoor Unit ..................................................................................................................... 69

10-2 Outdoor Unit ................................................................................................................... 83

11. Exploded Views and Parts List ......................................................................... 89

11-1 Indoor Unit ..................................................................................................................... 89

11-2 Outdoor Unit ....................................................................................................................97

Appendix ............................................................................................................ 103

Common Sensor R-T Analysis Table ............................................................................... 103

Part I : Technical Information

1. Summary

1-1 Appearance

Indoor Unit

1

Outdoor Unit

9K

12K

18K

24K

36K

Note: The outdoor grille can be replaced.

2

1-2 Model List

NO.

MODEL

NO.

MODEL

1

3

5

Cooling

capacity

Boundary Dimension

W×H×D (mm)

Package Size

W×H×D (mm)

800×300×198

850*370*270

850×300×198

900×370×270

970×315×235

1025*385*305

1100×330×235

1180×400×317

1250×360×253

1340*445*355

Platform

Boundary Dimension

W1(W2)×H×D(mm)

Base footing center size

A×B(mm)

Package Size

W×H×D(mm)

730(780)×545×285

540×280

850×620×370

800(860)×545×315

545×315

920×620×400

900(950)×700×350

630×350

1020×770×430

Swift Inverter 9U 2 Swift Inverter 12U

Swift Inverter 18U 4 Swift Inverter 24U

Swift Inverter 36U

2. Outline Dimension Diagram

The following data is for reference only and the actual size may vary.

Indoor Unit

9000BTU

12000BTU

18000BTU

24000BTU

36000BTU

Outdoor Unit

9K

12K

18/24/36K

3

Note:

1. The main body size of the front shape after normal installation: width × height ×

depth (mm). An example of the dimension measurement is shown in the figure.

a) Width direction:

Width 1: Not include the size of the stop valve.

Width 2: Include the size of the stop valve.

b) Height direction: including the height of the mounting foot;

c) Depth direction: not include the size of mounting foot but include the size of the

large-area parts such as panel grille

2. Base footing center size A × B.

4

3. Specification sheet

Product Model

Nameplate

Parameter

Rated Capacity

Cooling

W

2650

Heating

W

2650

Dehumidifying

Kg/h

/

Rated Power Consumption

Cooling

W

660

Heating

W

670

Rated Running Current

Cooling

A

3.2

Heating

A

3.3

Electric heating power

W / Max. Input Power

W

1540

Max. Input Current

A 7 EER Cooling

W/W

SEER23

COP Heating

W/W

SCOP10

Power supply source

V/Ph/Hz

208~230V-1-60Hz

Refrigerant

R410A

Refrigerant Charged

g

1000

Max. Discharge Pressure

Mpa

4.15

Max. Suction Pressure

Mpa

1.15

Air Flow Volume

m3/h

650

Noise level

dB(A)

40

Noise level

dB(A)

51

Indoor unit weight (Net )

Kg

10

Outdoor unit weight (Net )

Kg

28

Indoor unit

configuration

evaporator

Tube

Length

mm

602

Diameter

mm

7

Fan system

Fan motor

Model

Pcs

D-310-13-8C

Dimension

Net Dimension(W*D*H)

mm

800×300×198

Packing Dimension(W*D*H)

mm

850*370*270

Connection

Stop Valve

Liquid Valve

Dg4

Gas Valve

Dg8

Outdoor unit

configuration

Compressor Model

ASD102RKQA6JT6

Compressor

Brand

HIGHLY

Fan system

Fan motor

Model

D-24-8

Condenser

Tube

Length

mm

702

Diameter

mm

7

Dimension

Net Dimension (W*D*H)

mm

730×545×285

Packing Dimension (W*D*H)

mm

850*370*620

Container Loading 20/40/40HC

Set

250

Operation temp. range-Cooling

℃

16~52

Operation temp. range-Heating

℃

-15~30

Swift Inverter 9U

5

Product Model

Swift Inverter 12U

Nameplate

Parameter

Rated Capacity

Cooling

W

3500

Heating

W

3600

Dehumidifying

Kg/h

/

Rated Power Consumption

Cooling

W

970

Heating

W

1025

Rated Running Current

Cooling

A

4.8

Heating

A

5.0

Electric heating power

W / Max. Input Power

W

1650

Max. Input Current

A

7.5

EER Cooling

W/W

SEER22

COP Heating

W/W

SCOP10

Power supply source

V/Ph/Hz

208~230V-1-60Hz

Refrigerant

R410A

Refrigerant Charged

g

1150

Max. Discharge Pressure

Mpa

4.15

Max. Suction Pressure

Mpa

1.15

Air Flow Volume

m3/h

700

Noise level

dB(A)

41

Noise level

dB(A)

53

Indoor unit weight (Net )

Kg

10

Outdoor unit weight (Net )

Kg

32

Indoor unit

configuration

evaporator

Tube

Length

mm

652

Diameter

mm

7

Fan system

Fan motor

Model

Pcs

D-310-13-8C

Dimension

Net Dimension(W*D*H)

mm

850×300×198

Packing Dimension(W*D*H)

mm

900×370×270

Connection

Stop Valve

Liquid Valve

Dg4

Gas Valve

Dg8

Outdoor unit

configuration

Compressor Model

ASN108D32UFZ

Compressor

Parameter

Brand

GMCC

Fan system

Fan motor

Model

D-40-8

Condenser

Tube

Length

mm

860

Diameter

mm

7

Dimension

Net Dimension (W*D*H)

mm

800×545×315

Packing Dimension (W*D*H)

mm

920×400×620

Container Loading 20/40/40HC

Set

210

Operation temp. range-Cooling

℃

16~52

Operation temp. range-Heating

℃

-15~30

6

Product Model

Swift Inverter 18U

Nameplate

Parameter

Rated Capacity

Cooling

W

5300

Heating

W

5300

Dehumidifying

Kg/h

/

Rated Power Consumption

Cooling

W

1395

Heating

W

1370

Rated Running Current

Cooling

A

6.8

Heating

A

6.7

Electric heating power

W / Max. Input Power

W

1900

Max. Input Current

A 9 EER Cooling

W/W

SEER21

COP Heating

W/W

SCOP10

Power supply source

V/Ph/Hz

208~230V-1-60Hz

Refrigerant

R410A

Refrigerant Charged

g

1600

Max. Discharge Pressure

Mpa

4.15

Max. Suction Pressure

Mpa

1.15

Air Flow Volume

m3/h

1100

Noise level

dB(A)

46

Noise level

dB(A)

54

Indoor unit weight (Net )

Kg

14

Outdoor unit weight (Net )

Kg

48

Indoor unit

configuration

evaporator

Tube

Length

mm

722

Diameter

mm

7

Fan system

Fan motor

Model

Pcs

D-310-30-8

Dimension

Net Dimension(W*D*H)

mm

970×315×235

Packing Dimension(W*D*H)

mm

1025*385*305

Connection

Stop Valve

Liquid Valve

Dg4

Gas Valve

Dg13

Outdoor unit

configuration

Compressor Model

ATD141RDPA8JTA

Compressor

Parameter

Brand

HIGHLY

Fan system

Fan motor

Model

D-69-8

Condenser

Tube

Length

mm

886

Diameter

mm

7

Dimension

Net Dimension (W*D*H)

mm

900×350×700

Packing Dimension (W*D*H)

mm

1020*430*770

Container Loading 20/40/40HC

Set

148

Operation temp. range-Cooling

℃

16~52

Operation temp. range-Heating

℃

-15~30

7

Product Model

Swift Inverter 24U

Nameplate

Parameter

Rated Capacity

Cooling

W

7000

Heating

W

7050

Dehumidifying

Kg/h

/

Rated Power Consumption

Cooling

W

1800

Heating

W

1950

Rated Running Current

Cooling

A

9.77

Heating

A

10.55

Electric heating power

W / Max. Input Power

W

3200

Max. Input Current

A

16

EER Cooling

W/W

SEER20

COP Heating

W/W

SCOP11

Power supply source

V/Ph/Hz

208~230V-1-60Hz

Refrigerant

R410A

Refrigerant Charged

g

1620

Max. Discharge Pressure

Mpa

4.15

Max. Suction Pressure

Mpa

1.15

Air Flow Volume

m3/h

1380

Noise level

dB(A)

50

Noise level

dB(A)

57

Indoor unit weight (Net )

Kg

16

Outdoor unit weight (Net )

Kg

49

Indoor unit

configuration

evaporator

Tube

Length

mm

850

Diameter

mm

7

Fan system

Fan motor

Model

Pcs

D-310-50-8A

Dimension

Net Dimension(W*D*H)

mm

1100×330×235

Packing Dimension(W*D*H)

mm

1180×400×317

Connection

Stop Valve

Liquid Valve

Dg4

Gas Valve

Dg13

Outdoor unit

configuration

Compressor Model

ATD186UKPA9LT6

Compressor

Parameter

Brand

HIGHLY

Fan system

Fan motor

Model

D-69-8

Condenser

Tube

Length

mm

886

Diameter

mm

7

Dimension

Net Dimension (W*D*H)

mm

900×350×700

Packing Dimension (W*D*H)

mm

1020*430*770

Container Loading 20/40/40HC

Set

138

Operation temp. range-Cooling

℃

16~52

Operation temp. range-Heating

℃

-15~30

8

Product Model

Swift Inverter 36U

Nameplate

Parameter

Rated Capacity

Cooling

W

10500

Heating

W

10550

Dehumidifying

Kg/h

/

Rated Power Consumption

Cooling

W

3990

Heating

W

3640

Rated Running Current

Cooling

A

21

Heating

A

19

Electric heating power

W / Max. Input Power

W

4750

Max. Input Current

A

25

EER Cooling

W/W

SEER 16.5

COP Heating

W/W

SCOP 8.2

Power supply source

V/Ph/Hz

208~230V-1-60Hz

Refrigerant

R410A

Refrigerant Charged

g

2500

Max. Discharge Pressure

Mpa

4.15

Max. Suction Pressure

Mpa

1.15

Air Flow Volume

m3/h

1600

Noise level

dB(A)

53

Noise level

dB(A)

60

Indoor unit weight (Net )

Kg

16

Outdoor unit weight (Net )

Kg

58

Indoor unit

configuration

evaporator

Tube

Length

mm

987

Diameter

mm

7

Fan system

Fan motor

Model

Pcs

D-310-50-8A

Dimension

Net Dimension(W*D*H)

mm

1250×360×253

Packing Dimension(W*D*H)

mm

1340*445*355

Connection

Stop Valve

Liquid Valve

Dg8

Gas Valve

Dg13

Outdoor unit

configuration

Compressor Model

KTF310D43UMP

Compressor

Parameter

Brand

GMCC

Fan system

Fan motor

Model

D-69-8

Condenser

Tube

Length

mm

868

Diameter

mm

7

Dimension

Net Dimension (W*D*H)

mm

900×350×700

Packing Dimension (W*D*H)

mm

1020*430*770

Container Loading 20/40/40HC

Set

125

Operation temp. range-Cooling

℃

16~52

Operation temp. range-Heating

℃

-15~30

9

4. Function and Control

Note

All the figures above are the

displays after being initially

electrified or re-electrified after

power off. In actual operations,

the remote controller screen

displays related items only.

Some functions are optional

and don’t work according to

4-1 A-Style

1) Remote Controller Introduction

Introduction for Buttons on Remote Controller

:

the model.

1. ON/OFF

* Press this button to turn on/off the unit.

* This will clear the existing timer and SLEEP settings.

2.℃/℉

* Press this button to set the temperature display to Fahrenheit, which is displayed by

default in Celsius. The “℃” will not be displayed on the LCD.

* Press this button again to restore the temperature display to Celsius.

Note: Temperature display in Fahrenheit is not available for some models. When

temperature is displayed in Fahrenheit on the remote controller, it might be in Celsius

on the unit, the function and operation of which will not be affected.

3. SPEED

* Press this button, you can select the fan speed as follows:

Note: AUTO air speed is not available in FAN mode.

4. DISPLAY

* Press this button to turn on/off the display. This is for the convenience of users who

are unconformable sleeping with the backlight on.

5. iFEEL

* Press this button to set the temperature display on the remote controller to ambient

temperature and press this button again to set it to preset temperature.

6. TIMER

* With the unit ON, press this button to set OFF timer or with it OFF to set ON timer.

Low → Mid → High → Auto

10

* Press this button once, a "ON(OFF)" will flash. Press “▲”or “ ▼” to set the number

of hours in which the unit will be turned ON/OFF, with an interval of 0.5 hour if less

than 10 hours, or 1 hour if longer than 10 hours and a range of 0.5-24 hours.

* Press it again to confirm the setting the "ON (OFF)" will stop flashing.

* If the timer button is not pressed longer than 10 seconds after the "ON (OFF)" start

flashing, the timer setting will be exited.

* If a timer setting is confirmed, pressing this button again will cancel it.

Note: When a ON timer is set, all function buttons (except SLEEP DISPLAY and

iFEEL can't be set ) are valid and when the ON time set is up, the unit will operate as

preset.

7. This button has two functions.

a. HEALTH

* Press this button with the unit ON to activate health related functions, such as

negative ion, electrostatic precipitation, PM2.5 removal, etc, depending on the actual

configuration of each model.

* Press this button again to deactivate the HEALTH function.

b. iCLEAN

* Press this button with the unit OFF, the remote controller will display "CL" and the

unit will automatically clean dust off the evaporator and dry it, to increase the cooling

and heating efficiency.

* The iCLEAN function runs for approximately 30 minutes, during which if the unit

is turned on with the remote controller or this button is pressed again, the iCLEAN

will be deactivated.

8. ▲ or ▼

* Each time the "▲" is pressed, the temperature setting will increase by 1℃ and each

time the "▼" is pressed, it will decrease by 1℃.

* a. lf the type of controller remote is YKR-H/101E or YKR-H/102E setting

temperature range is 16℃ ~32℃(60℉~90℉).

b. lf the type of controller remote is YKR-H/132E setting temperature range is 20℃

~28℃ (68℉~82℉).

c. Some area don't have the YKR-H/132E.Local regulation and actual object shall

prevail.

Note: The temperature cannot be set in AUTO or FAN mode, thus these two buttons

are not functional.

9. TURBO

* Press this button only in COOL or HEAT mode to set TURBO on or off to speedy

the cooling or heating.

* When TURBO is on the air speed is HIGH.

* When TURBO is off the air speed will restore to previous status.

10. MODE

* Press this button you can select the running mode as follows:

AUTO → COOL → DRY → HEAT →FAN

Note: HEAT mode is not available for cool only units.

11. SLEEP

11

* Press this button to enter SLEEP mode, which the unit will exit after 10 hours of

continuous operation and restore to the previous status.

Note: The SLEEP function cannot be activated in FAN mode.

12. SWING

* Press this button to activate up/down swing and press it again to fix the swing

position.

13. SWING

* Press this button to activate left/right swing and press it again to fix the swing

position.

14. Anti-F

* The Anti-F functions when the unit is turned off with the remote controller in COOL,

DRY or AUTO mode. It will operate in HEAT mode (FAN mode for cool only units),

with the internal fan running with weak flow for 3 minute before stop, to remove the

moisture within the evaporator so as to prevent it from giving bad smell from mold.

* This function is not set in the factory. You may set it or cancel it any time you want

as follows: With both the unit and the remote controller OFF, point the remote

controller at the unit and press

"Anti-F" button once, the buzzer will sound 5 times after 5 times, indicating this

function is set. Once set, this function will remain valid except when the unit is power

off or until it is canceled.

* To cancel Anti-F:

1. Power off the unit.

2. With both the unit and the remote controller OFF, point the remote controller at the

unit and press this button once, the buzzer will sound 3 times after 5 times, indicating

this function is canceled.

Note:

* With Anti-F activated, it is advised not to turn ON the unit again before it is fully

OFF.

*Anti-F function will be invalid when OFF timer is set.

15.This button has two functions.

a. ELE.H (Optional)

* If this button is pressed in HEAT mode, the electric heating will be turned on/off.

b. ECO (Optional)

* If this button is pressed in COOL mode, the unit will enter the ECO mode which has

the lowest electricity consumption, and exit it automatically 8 hours after.

* Changing modes or turning off the remote controller will automatically cancel the

ECO function.

* Press ECO button in ECO mode to exit this mode. Note: The ECO mode only works

for inverter units.

2) Introduction for mode settings

★Automatic operation mode

1. Press the "MODE" button, select the automatic operation mode.

2. By pressing the "SPEED" button, you can select the fan speed from LOW, MID,

HIGH, AUTO.

3. Press the "ON/OFF" button, the air-conditioner starts to operate.

4. Press the "ON/OFF" button again, the air-conditioner stops.

Note: In the fan operation mode the temperature settings is non-effective.

★Cooling/Heating operation mode

12

1. Press the "MODE" button, select the Cooling or Heating operation mode.

2. By pressing the "▲"or "▼"button, you can set the temperature the display changes

as you touch the button.

3. By pressing the "SPEED" button, you can select the fan speed from LOW, MID,

HIGH, AUTO.

4. Press the "ON/OFF" button, the air-conditioner starts to operate.

5. Press the "ON/OFF" button again, the air-conditioner stops.

Note: The cold wind type has no heating function.

★Fan operation mode

1. Press the "MODE" button, select the fan operation mode.

2. By pressing the "SPEED" button, you can select the fan speed from LOW, MID,

HIGH.

3. Press the "ON/OFF" button, the air-conditioner starts to operate.

4. Press the "ON/OFF" button again, the air-conditioner stops.

Note: In the fan operation mode the temperature settings is non-effective.

★Drying operation mode

1. Press the "MODE" button, select the drying operation mode.

2. By pressing the "▲"or "▼"button, you can set the temperature the display changes

as you touch the button.

3. By pressing the "SPEED" button, you can select the fan speed from LOW, MID,

HIGH, AUTO.

4. Press the "ON/OFF" button, the air-conditioner starts to operate.

5. Press the "ON/OFF" button again, the air-conditioner stops.

★Backlight function (for remote controllers with such function only)

The remote controller has a backlight which can be turned on by pressing any button

for the convenience of operation in darkness. The backlight will be automatically

turned off if there is no operation within 10 seconds.

3) Precautions

• Before first time use of the remote controller install the batteries and ensure the

"+"and "_" poles are correctly positioned.

• Ensure the remote controller is pointed to the signal receiving Window and that

there is no obstruction in between and the distance is 8m at the maximum.

• Do not let the remote controller drop or fling it at will.

Do not let any liquid in the remote controller.

Do not expose the remote controller directly to the sunlight or excessive heat.

• If the remote controller does not function normally remove the batteries for 30

second before reinstall them. If that doesn't work replace the batteries.

• When replacing the batteries do not mix the new batteries with old ones or mix

batteries of different types which could cause failure of the remote controller.

• If the remote controller is not to be used for a long period of time remove the

batteries first lest the leakage from them may damage the remote controller.

• Properly dispose the discarded batteries.

Note:

1. This is a universal remote controller which provide all the function buttons. Please

understand that some of the buttons may not function, depending on the specific air

conditioner you have purchased. (If a specific function is not available on the air

conditioner, pressing the corresponding button will simply have no respond.)

2. HEAT and ELE.H functions are not available for cool only models, thus these two

13

buttons do not work correspondingly.

Battery use and replacement

1. Slide to open the cover according to the direction indicated by the arrowhead.

2. Insert two brand new batteries (7#) and position the batteries to the right electric

poles (+ & -).

3. Put back the cover.

4-2 B-Style

1) Remote Controller Introduction

● Read this “instructions” carefully so that you can use the air-conditioner safely

and correctly.

● Take good care of the “instructions” so that it can be referred to at any time.

14

Note : remote controller outside buttons only valid when surface cover is closed.

①“ON/OFF”button

* Press this button,the unit will be started or stopped, which can clear the timer or

sleeping function of last time.

②“SPEED”button

* Press this button, speed will change as below:

③“ ”or “ ”button

*When press “ ”button, the setting temperature will be increased by 0.5℃. When

press “ ”button, the setting temperature will be decreased by 0.5℃

* The temperature will be changed quickly by pressing the button continuously and setting

temperature range is 16℃to 32℃.

④“COOL”button

* Press the COOL button, the mode of operation is shifted into cooling.

⑤“HEAT”button

* Press the HEAT button, the mode of operation is shifted into heating.

* Note: cooling only unit has no heating function.

⑥“SWING”button(SWING and SWING )

* Press this button to open up/down(left/right) swing function, press it again, fix

louver position.

* Up/down(left/right) setting is only valid in this mode, it will not affect louver

position in other modes.

* Up/down(left/right) swing has memory function, it can keep primary setting when

turn off then turn on or switch from other modes to primary mode.

15

NOTE:

This manual introduces function for all of the remote control, maybe you press one

button without any reaction, well, the air-conditioner you bought hasn't this function.

1.“ON/OFF”button

* Press this button, the unit will be started or stopped, which can clear the timer or

sleeping function of last time.

2.“MODE”button

* Press this button, the running mode will change as below:

AUTO→COOL→DRY→HEAT→FAN

* Note: cooling only unit has no heating function.

3. “SPEED”button

* Press this button,speed will change as below:

4. “TURBO”button

* Set turbo on or off(the characters of turbo will appear or disappear)by pressing this

key under cooling or heating mode.

* Once energized, the unit will be defaulted to be turbo off.

* This function can not be set under auto, dry or fan mode, and characters of turbo

won’t appear.

16

5. “SILENCE” button

* Set silence on or off(the characters of silence will appear or disappear)by pressing

this key.

* Once energized, the unit will be defaulted to be silence off.

6. “TIMER”button

* On the status of the unit on, press this button to set timer off. On the status of the

unit off, press this button to set timer on.

* Press this key once, words H on (off) will appear and flicker. In which case, press

button to adjust time (press “ / ” button to adjust time (press / value

quickly), the setting time range is from 0.5 to 24 hr. ; press this key once again to fix

the time, then remote controller will send out the signal immediately and H on/off will

stop flickering.

* If the time of that no press timer button under flickering status is above 10s, the

timer setting will quit.

* If the timer has been set, press this button once again to quit it.

7.“HEALTH” button

* Press this button, you can turn on or off the health function.

8.“SLEEP” button

* Press the SLEEP button, the sleeping indicator light of indoor unit flashes on.

* The air-conditioner runs in sleeping mode for 10 hours and quit sleep mode, recover

back to former mode.

* The unit will turn off automatically if the timing mode are running out of time.

Note: press the MODE or ON/OFF button, the remote controller clears sleeping mode

away.

9.“iFEEL” button

* Press this button can be used to set the feeling function. The LCD shows the actual

room temperature when the function set and it shows the setting temperature when the

function cancelled.

* This function is invalid when the appliance at the Fan mode.

10.“DISPLAY” button

* In display mode, press button once, shut off display, press it again, LCD will show

ambient & setting temperature after flashing 5s.

It's convenient for users who are not adapt to noctilucence and it's also convenient for

checking ambient&setting temperature anytime.

11.“iCLEAN” button

* When remote controller is at the off state, press “iCLEAN” button, the unit runs

“iCLEAN” function .

* The purpose of this function is to clean dust on evaporator and dry the inside water

of evaporator and to prevent the evaporator going moldy due to water deposition and

boasting strange smell.

* After setting “iCLEAN” function, press “iCLEAN” button or “ON/OFF” button to

quit it.

17

* The clean function will be stop working after about 30 minutes running working

without any operation.

12.“ELE.H” button(only for hot pump type)

* In heating mode, press this button, the mode of operation is shifted into

supplementary electric heating.

13.“Anti-FUNGUS” button

* The purpose of this function is to dry the inside of the evaporator and to prevent the

evaporator from going mouldy due to water deposition and thus dispersing strange

smell.

* This function is controlled by the remote controller under cooling, dry and auto

(cooling and dry) modes, the horizontal wind guiding bars are at the initial position

for cooling. The A/C runs under heating mode(the cooling only A/C only runs under

fan mode), the internal fan runs for 3 minutes with weak wind before stop.

* This function has not been set in the factory. You may freely set and cancel this

function. The setting method is: under “off” status of the A/C and the remote

controller, point the remote controller toward the A/C and continuously press

“Anti-FUNGUS” button for one time, the buzzer keep beeping five times again after

five times beep, indicating that this function is ready. In case this function has been

set, unless the whole A/C is powered off or the function is manually cancelled, the

A/C then has this function as default.

* To cancel the function: 1. Under “off” status of the A/C and the remote controller,

point the remote controller toward the A/C and continuously press

“Anti-FUNGUS”button for one time, the buzzer keep beeping three times again after

five times beep, indicating that this function has been cancelled; 2. Power off the

whole A/C.

* When this function is on, it is suggested not to restart the A/C before it is

completely stop.

* This function will not run in case of time stop.

14.“SPOT SWING” button

* Press this button, the horizontal wind direction vanes can swing automatically, when

you have the desired vertical wind direction.

* Press it again, the horizontal wind direction vanes will be stopped at the situation of

your choice.

15.“ECO” button

* In cooling mode, press this button, the unit will runs “ECO” economic operation

mode which costs the least power consumption.

* After running for 8h, it will automatically exit, otherwise, press this button once

again to quit it.

* Note: The unit will turn off automatically if the timing mode are running out of

time.

2) Introduction for mode settings

18

★Fix batteries

1. Slide open the cover according the direction indicated by arrowhead.

2.Put into two brand new batteries (7#), position the batteries to right electric poles (+

&-).

3.Put back the cover.

★Automatic operation mode

1. Press the ON/OFF button, the air-conditioner starts to operate.

2. Press the MODE button, select the automatic operation mode.

3. Press the SPEED button, you can select fan speed. You can select fan speed from

LOW, MID, HIGH, AUTO.

4. Press the button again, the air-conditioner stops.

★Cooling/Heating operation mode(cold wind type has no heating function)

1.Press the ON/OFF button, the air-conditioner starts to operate.

2.Press the MODE button, select the Cooling or Heating

3.Press the “△”or “▽”button, set the temperature, temperature can be set at 1℃

difference range from 16-32℃.

4.Press the SPEED button, you can select fan speed. You can select fan speed from

LOW, MID, HIGH, AUTO.

5.Press the button again, the air-conditioner stops.

★Fan operation mode

1. Press the ON/OFF button, the air-conditioner starts to operate.

2. Press the MODE button, select the Cooling or Heating operation mode.

3. Press the SPEED button, you can select fan speed. You can select fan speed from

LOW, MID, HIGH.

4. Press the button again, the air-conditioner stops.

Remark: In the circulation operation mode, to set the temperature is non-effective.

★Drying operation mode

1. Press the ON/OFF button, the air-conditioner starts to operate.

2. Press the MODE button, select the Dry operation mode.

3. Press the “△”or “▽”button, set the temperature, temperature can be set at 1℃

difference range from16-32℃.

4. Press the SPEED button, you can select fan speed. You can select fan speed from

LOW, MID, HIGH, AUTO.

5. Press the button again, the air-conditioner stops.

3) Precautions

1.Aim the remote controller towards the receiver on the air- conditioner.

• The remote controller should be within 8 meters away from the receiver.

19

• No obstacles between the remote controller and receiver.

• Do not drop or throw the remote controller.

• Do not put the remote controller under the forceful sun rays or heating facilities and

other heating sources.

• Use two 7# batteries, do not use the electric batteries.

• Take the batteries out of remote controller before stop its using for long.

• When the noise of transmitting signal can't be heard indoor

unit or the transmission symbol on the display screen doesn't

flare, batteries need be replaced.

• If reset phenomenon occurs on pressing the button of the remote controller, the

electric quantity is deficient and new batteries need to be substituted.

• The waste battery should be disposed properly.

Note:

* The picture is general remote controller, contains almost all of the function buttons.

They may be slightly different from material abject(depend on model).

* All the figures above are the displays after being initially electrified or re-electrified

after power off. In actual operations, the remote controller screen displays related

items only.

* The cooling only units don’t have the function of heating or electric heating. When

the remote controller turns to such function buttons, the units will not result such

effect. Please don’t turn the remote controller to such buttons.

20

5. Refrigerant System Diagram

Indoor heat exchanger

(Evaporation)

Compressor

(Compression)

Outdoor heat exchanger

(Condensation)

Capillary

(Throttling)

Steam-gas of low pressure

Super cooled liquid of high

pressure

Liquid of low

(also a little gas)

Gas of high pressure &

temperature

Indoor Unit

Outdoor Unit

5-1 Cooling Only

Cooling Mode

Cooling Cycle

pressure

21

5-2 Cooling & Heating

Indoor Unit

Outdoor Unit

Indoor heat exchanger

(Evaporation)

Compressor

(Compression)

Outdoor heat exchanger

(Condensation)

Capillary

(Throttling)

Steam-gas of low pressure

Super cooled liquid of high

pressure

Liquid of low

(also a little gas)

Gas of high pressure

& temperature

4-way valve

(Heat pump only)

Cooling Mode

Cooling Cycle

pressure

22

Heating Mode

Indoor Unit

Outdoor Unit

Indoor heat exchanger

(Evaporation)

Compressor

(Compression)

Outdoor heat exchanger

(Condensation)

Capillary

(Throttling)

Steam-gas of low

Super cooled liquid of high

pressure

Super cooled liquid of

low pressure

Gas of high pressure

& temperature

4-way valve

(Heat pump only)

Heating Cycle

pressure

23

6. Electrical Part

The diagrams listed below for reference only, please refer to the actual product.

6-1 Wiring Diagram

Indoor Unit

24

Outdoor Unit

Outdoor Unit Electric Chart

W(T/C)

V(S)

U(R)

Compressor

U V W

Blue

Black

Red

L-1

L-2

Reactor

11326007000545

CN88

Some models have no content

inside dashed frame

25

Part II : Installation and Maintenance

7. Main Tools for Installation and Maintenance

27

8. Installation

8-1 Notes for Installation

Important Notices

Before installation, please contact with local authorized maintenance center, if

unit is not installed by the authorized maintenance center, the malfunction may

not solved, due to discommodious contact.

The air conditioner must be installed by professionals according to the national

wiring rules and this manual.

To move and install air conditioner to another place, please contact our local

special service center.

Requirements For Installation Position

Avoid places of inflammable or explosive gas leakage or where there are strongly

aggressive gases.

Avoid places subject to strong artificial electric/magnetic fields.

Avoid places subject to noise and resonance.

Avoid severe natural conditions (e.g. heavy lampblack, strong sandy wind, direct

sunshine or high temperature heat sources).

Avoid places within the reach of children.

Shorten the connection between the indoor and outdoor units.

Select where it is easy to perform service and repair and where the ventilation

good.

The outdoor unit shall not be installed in any way that could occupy an aisle,

stairway, exit, fire escape, catwalk or any other public area.

The outdoor unit shall be installed as far as possible from the doors and windows

of the neighbors as well as the green plants.

Requirements for operations at raised height

When carrying out installation at 2m or higher above the base level, safety belts

must be worn and ropes of sufficient strength be securely fasten to the outdoor

unit, to prevent falling that could cause personal injury or death as well as

property loss.

Requirements of the mounting structure

The mounting rack must meet the relevant national or industrial standards in

terms of strength with welding and connection areas rustproofed.

The mounting rack and its load carry surface shall be able to withstand 4 times or

above the weight of the unit, or 200kg, whichever is heavier.

The mounting rack of the outdoor unit shall be fastened with expansion bolt.

Ensure the secure installation regardless of what type of wall on which it is

installed, to prevent potential dropping that could hurt people.

Electrical Safety Requirements

Be sure to use the rated voltage and air conditioners dedicated circuit for the

power supply, and the power cord diameter must meet the national requirements.

Be sure to use the rated voltage and air conditioners dedicated

When the maximum current of air conditioner is ≥16A, it must use the air switch

or leakage protection switch equipped with protection devices.

The normal operating range is 90%-110% of the local rated voltage.

28

The minimum clearance between the air conditioner and the combustibles is 1.5

NO.

Name

Quantity

Unit

1

Indoor Unit

1

Set

2

Remote Controller

1

PC 3 Batteries(7#)

2

PC 4 Instructions

1

Set 5 Drain pipe

1

PC

m.

The power cable enables communication between the indoor and outdoor units.

You must first choose the right cable size before preparing it for connection.

Grounding Requirements

The air conditioner is the type I electrical appliance and must ensure a reliable

grounding.

Do not connect the grounding wire to a gas pipe, water pipe,lightning rod,

telephone line, or a circuit poorly grounded to the earth.

The grounding wire is specially designed and shall not be used for other purpose,

nor shall it be fastened with a common tapping screw.

Others

The connection method of the air conditioner and the power cord and the

interconnection method of each independent element shall be subject to the

wiring diagram affixed to the machine.

The model and rating value of the fuse shall be subject to the silkscreen on

corresponding controller or fuse sleeve.

8-2 Installation of Indoor Unit

Installation Parts-checking

Packing list of the indoor unit

NOTE:

※ All accessories shall be subject to actual packaging material, and if there is any

difference, please understand.

Selection of Installation location

29

Mounting plate

1. The wall for installation of the indoor unit shall be hard and firm, so as to prevent

vibration.

2. Use the "+" type screw to fasten the peg board, horizontally mount the peg board

on the wall, and ensure the lateral horizontal and longitudinal vertical.

3. Pull the peg board by hand after the installation, to confirm whether it is solid.

Wall-through Hole

1. Make a hole with an electric hammer or a

water drill at the predetermined position on

the wall for piping, which shall slant

outwardly by 5°-10°.

2. To protect the piping and the cables from

being damaged running through the wall,

and from the rodents that may inhabit in

the hollow wall, a pipe protecting ring shall

be installed and sealed with putty.

Note: Usually, the wall hole is Φ60mm~

Φ80mm. Avoid pre-buried power wire

and hard wall when making the hole.

Route of Pipeline

1. Depending on the position of the unit, the piping may be routed sideway from the

left or the right ( Fig 1 ), or vertically from the back( Fig 2 )(depending on the pipe

length of the indoor unit). In the case of sideway routing, cut off the outlet cutting

stock of the opposite side.

2. The power cord may be routed separately from the piping. Cut off the outlet cutting

stock and then run the power cord through the hole, keeping the remaining part as

a protection from rodents.

30

Drain pipe connection

The size of pipe(mm)

Torque(N·m)

Φ6/Φ6.35

15~25

Φ9 /Φ9.5 2

35~40

Φ12/Φ12.7

45~60

Φ15.88

73~78

Φ19.05

75~80

1. Remove the mountings and pull the indoor unit pipe out of the housing.

used is shown in the following table.

1. Use the insulation sleeve to wrap the joint part the

indoor unit and the connection pipe, and then use

insulating material to pack and seal insulation pipe,

to prevent generation of condensate water on the

2. Connect the water outlet with drain pipes, and

make the connection pipe, cables, and the drain hose

3. Use plastic cable ties to wrap the connecting

pipes, cables and drain hose. Run the pipe sloping

1. Hang the indoor unit on the peg board, and move

the unit from left to right to ensure that the hook is

2. Push toward the lower left side and the upper right

side of the unit toward the peg board, until the hook

2. Connect the connecting pipe to the indoor unit:

Aim at the pipe center, tighten the Taper nut with fingers, and then tighten the T

nut with a torque wrench, and the direction

is shown in diagram on the right. The torque

Tightening torque table

Wrap the Piping

joint part.

Fixing the Indoor Unit

straight.

Fixing the indoor unit

properly positioned in the peg board.

is embedded in the slot and makes a "click" sound.

Electric Connection Requirement

● Loosen the screws and remove from the unit.

● Connect the cables respectively to the corresponding

terminals of the terminal board of the indoor unit (see the

wiring diagram), and if there are signals connected to the

plug, just conduct butt joint.

31

●Ground wire: Remove the grounding screw out of the electric bracket, cover the

NO.

Name

Quantity

Unit

1

Outdoor Unit

1

Set

2

Connecting pipe

2

PC 3 Plastic Strap

1

ROLL

4

Pipe Protection Ring

1

Set

5

Luting (putty)

1

PACKET

Wiring Diagram

grounding wire end onto the grounding screw and screw it into the grounding hole.

● Fix the cable reliably with fasteners (Pressing board).

● Put the E-parts cover back in its original place and fasten it with screws.

NOTE:

※ This manual usually includes the wiring mode for the different kind of A/C.

We cannot exclude the possibility that some special type of wiring diagrams

are not included.

※ The diagram are for reference only. If the entity is difference with this wiring

diagram, please refer to the detailed wiring diagram adhered on the unit which

you purchased.

8-3 Installation of outdoor Unit

Packing list of the outdoor unit

Selection of Installation location

32

Install the connection pipe

Piping length

Amount of refrigerant to be added

≤5M

Not needed

5- 15M

CC≤12000Btu

20g/m

CC≥18000Btu

30g/m

Connect the Outdoor Unit with Connecting Pipe: Aim the

When prolonging the piping, extra amount of refrigerant

must be added so that the operation and performance of the

air conditioner will not be compromised.

1. Loosen the screws and remove E-parts cover from the unit.

fasten it with screws.

counter-bore of the connecting pipe at the stop valve, and

tighten the Taper nut with fingers. Then tighten the Taper

nut with a torque wrench.

★

Note: This table is for reference only.

Wiring Connection

2. Connect the cables respectively to the corresponding terminals of the terminal board of

the outdoor unit (see the wiring diagram),and if there are

signals connected to the plug, just conduct butt joint.

3. Ground wire: Remove the grounding screw out of the

electric bracket, cover the grounding wire end onto the

grounding screw and screw it into the grounding hole.

4. Fix the cable reliably with fasteners (Pressing board).

5. Put the E-parts cover back in its original place and

33

Wiring diagram

Wiring Diagram

NOTE:

※ This manual is usually includes the wiring mode for the different kind of A/C. We

cannot exclude the possibility that some special type of wiring diagrams are not

included.

※ The diagram are for reference only. If the entity is difference with this wiring

diagram, please refer to the detailed wiring diagram adhered on the unit which you

purchased.

Expelling the air

★Outdoor unit refrigerant discharging method

After the pipe side connection is complete, proceed as follows.

34

★Vacuum Pumping Method (R410A refrigerant evacuation must use the

1. To prevent air leakage and spilling tighten all connecting nut of all flare tubes.

connections are free of air leakage.

When the unit is heating, the condensing

water and defrosting water can be out

Install the outdoor drain elbow in Φ25

hole on the base plate, and joint the drain

hose to the elbow, so that the waste water

formed in the outdoor unit can be drained

out to a proper plate.

vacuum pumping method)

Before working on the air conditioner, remove the cover of the stop valve(gas and

liquid valves)and be sure to retighten it afterward.(to prevent the potential air leakage)

2. Connect the stop valve, charge hose,

manifold valve, and vacuum pump.

3. Fully open the handle Lo of the

manifold valve and apply vacuum for

at least 15 minutes and check that

the compound vacuum gauge reads

-0.1MPa(-76cmHg).

4. After applying vacuum, fully open the

stop valve with a hex wrench.

5. Check that both indoor and outdoor

Outdoor condensation drainage(Heat pump type only)

reliably through the drain house.

Installation:

8-4 Check after installation and test operation

1. Check after installation

★ Electrical Safety Check

① If the supply voltage is as required.

② If there is any faulty or miss connection in each of the power, signal and

grounding wires.

③ If the grounding wire of the air conditioner is securely grounded.

★ Installation Safety Check

① If the installation is secure.

35

② If the water drain is smooth.

③ If the wiring and piping are correctly installed.

④ Check that no foreign matter or tools are left inside the unit.

★ Leak test of the refrigerant

Depending on the installation method, the following methods may be used to check

for suspect leak, on areas such as the four connections of the outdoor unit and the

cores of the cut-off valves and t-valves:

① Bubble method: Apply of spray a uniform layer of soap water over the suspected

leak spot and observe carefully for bubble.

② Instrument method: Checking for leak by pointing the probe of the leak detector

according to the instruction to the suspect points of leak.

2. Test operation

★ Test preparation

※Verify that all piping and connection cables are well connected.

※Confirm that the values at the gas side the liquid-side are fully open.

※Connect the power cord to an independent power socket.

※Install batteries in remote control.

★ Test Operation method

① Turn on the power and push the ON/OFF switch button of the remote controller to

start the air conditioner.

② Select COOL, HEAT (not available on cool-only models), SWING and other

operation modes with the remote controller and see if the operation is ok.

36

9. Maintenance

No.

Error Name

Reference Code

1

Internal temperature sensor error

E1

2

External coil sensor error

E2

3

Internal coil sensor error

E3

4

Internal fan error of wall mounted air

conditioner(PG motor)

E4

5

Internal fan error of wall mounted air

conditioner(DC motor)

E4

6

Sliding door error of floor standing

E4

7

Internal and external communication error

E5(5E)

8

External DC fan error (3-core terminal motor)

F0

9

Module protection error

F1

10

PFC protection error

F2

11

Compressor startup error

F3

12

Exhaust sensor error

F4

13

Pressing top head sensor error

F5

14

External temperature sensor error

F6

15

OVP or UVP error

F7

16

Main external control panel and module panel

communication error

F8

17

Outdoor EE error

F9

18

Recirculated sensor error(four-way valve switch

error)

FA

19

Cabinet internal fan error (see E4 for

troubleshooting)

Fb

20

Function protection prompt of frequency

conversion external machine

See the Error List

9-1 Troubleshooting Guide

Many error codes many appears on this air conditionor, and this troubleshooting

guide is prepared for the maintenance personnel to detect the error position and the

parts to be replaced during the troubleshooting process. In this Guide, the

Troubleshooting Method is guided by the Error Name, and the Reference Code under

the General Index is the error code of the internal unit of the mainstream model

supplied by the Company.

Example: “internal coil sensor error” is coded as E3 in the error code of the internal

unit, but appears as flash-out via the trouble light of the external machine. However,

their troubleshooting method is the same, and use the same table as well.

General index:

37

Example:

Explanation

of error

Cause: explain the principle of the specific error.

Inspection path: The basic order of troubleshooting. Related key

position

Tools required

for inspection

Tools that should be carried for such troubleshooting, and

replacing parts that may be necessary for such error.

Frequent

problematic

part

Any possibly broken part related to the error may be the parts that

need to be replaced.

Inspection

procedure

and key

points

All the troubleshooting procedures for the reference of

maintenance staff are prepared from simple to complex, from

surface to internal, and from test to replacement. Although these

key points do not cover all the error, and difficult or special

problems are not included as well, but they can cover most of the

common error.

Special

attention

Here are some often-overlooked problems for the reference of the

maintenance personnel.

The problems in the market are always more than we think, so it is necessary for the

maintenance personnel to understand the principle of air conditioning operation, and

to make a flexible judgment of the fault in combination with the actual conditions. We

we qlcome the maintenance personnel to constantly put forward new problems in the

actual work, record the solutions and enrich our troubleshooting guide list.

38

(1)E1- internal temperature sensor error

Explanation of

error

Cause: The detection of short circuit or open circuit of internal

temperature sensor during the inspection of main control panel in the

internal machine, indicated by “internal temperature sensor error”.

Inspection path: Sensor→Sensor wire→Connectors→Main internal

control panel

Tools required

for inspection

Multimeter, 15KΩ standard sensor(25℃)

Frequent

problematic part

Internal temperature sensor, main internal control panel

Inspection

procedure and

key points

1. Check whether there’s resistance problem, short circuit or open

circuit in the sensor; the resistance value shall be within a reasonable

range (15KΩ under the temperature of 25℃ for frequency conversion

machine)

2. Check whether the sensor wire is broken.

3. Check whether the terminal connectors are well fixed; check

whether the weld between the terminal and the main control panel is

loose, and pull the terminal slightly for inspection if necessary.

4. Check whether the sensor is affected with damp.

5. In case no standard sensor is available at present, replace the internal

temperature sensor by other sensor asides, and then check whether the

error still exists; if the error disappears, replace the sensor; if the error

still exists, check the main internal control panel and change if

necessary.

Special attention

Most internal temperature sensors of the frequency conversion

machine have a resistance value of 15KΩ.

Do not use improper sensor during repairing and maintenance, or it

may led to the wrong temperature sensing of the machine, the start

error or shutdown error. You can switch the air conditioner to the

“Blowing” mode, and judge the accuracy of sensor though

environmental temperature displayed on the screen.

In case a sensor with the resistance value over 15KΩ is used, the

detected temperature will be much lower than the actual temperature,

which may lead to the shutdown error under heating mode, or the

startup error under cooling mode.

In case a sensor with the resistance value below 15KΩ is used, the

detected temperature will be much higher than the actual temperature,

which may lead to the startup error under heating mode, or the

shutdown error under cooling mode.

39

(2)E2 -external coil sensor error

Explanation of

error

Cause: The detection of short circuit or open circuit of external coil

sensor during the inspection of main external control panel, indicated

by “external coil sensor error”.

Inspection path: Sensor→Sensor wire→Connectors→Main external

control panel

Tools required

for inspection

Multimeter, 20KΩ standard sensor (25℃)

Frequent

problematic part

External coil sensor, main external control panel

Inspection

procedure and

key points

1. Check whether there’s resistance problem, short circuit or open

circuit in the sensor; the resistance value shall with a reasonable range

(about 20KΩ for frequency conversion machine)

2. Check whether the sensor wire is broken.

3. Check whether the terminal connectors are well fixed; check

whether the weld between the terminal and the main control panel is

loose, and pull the terminal slightly for inspection if necessary.

4. Check whether the sensor is affected with damp. The coil sensor is

quite easy to be affected with damp in case the lead of coil sensor is

above the copper pipe.

5. In case no standard sensor is available at present, replace the

temperature sensor of external coil by other sensor asides, and then

check whether the error still exists; if the error disappears, replace the

sensor; if the error still exists, check the main internal control panel

and change if necessary.

Special attention

Most internal temperature sensors of the frequency conversion

machine have a resistance value of 20KΩ.

Do not use improper sensor during repairing and maintenance, or it

may led to the start of protection mode due to wrong temperature

sensing of the machine, or the protection error.

In case a sensor with the resistance value over 20KΩ is used, the

detected temperature will be much lower than the actual temperature,

which may lead to the frequent entering of defrost mode, the illusory

defrosting or the protection error during the cooling process.

In case a sensor with the resistance value below 20KΩ is used, the

detected temperature will be much higher than the actual temperature,

which may lead to defrost error during the heating process, or the start

of protection during the cooling process.

40

(3)E3 -internal coil sensor error

Explanation of

error

Cause: The detection of short circuit or open circuit of internal coil

sensor during the inspection of main internal control panel, indicated

by “internal coil sensor error”.

Inspection path: Sensor→Sensor wire→Connectors→Main internal

control panel

Tools required

for inspection

Multimeter,, 5KΩ or 20KΩ standard sensoe(25℃)

Frequent

problematic part

Internal temperature sensor, main internal control panel

Inspection

procedure and

key points

1. Check whether there’s resistance problem, short circuit or open

circuit in the sensor; the resistance value shall with a reasonable range

(about 20KΩ for frequency conversion machine)

2. Check whether the sensor wire is broken.

3. Check whether the terminal connectors are well fixed; check

whether the weld between the terminal and the main control panel is

loose., and pull the terminal slightly for inspection if necessary.

4. Check whether the sensor is affected with damp. The coil sensor is

quite easy to be affected with damp in case the lead of coil sensor is

above the copper pipe.

5. In case no standard sensor is available at present, replace the

temperature sensor of internal coil by other sensor asides, and then

check whether the error still exists; if the error disappears, replace the

sensor; if the error still exists, check the main internal control panel

and change if necessary.

Special attention

Most internal temperature sensors of the frequency conversion

machine have a resistance value of 20KΩ.

Do not use improper sensor during repairing and maintenance, or it

may led to the start of anti-frosting or overheat protection mode due to

wrong temperature sensing of the machine.

In case a sensor with the resistance value over 20KΩ is used, the

detected temperature will be much lower than the actual temperature,

which may lead to the high pressure of cold-blast protection system

during the heating process, or the frequent start of anti-freezing

protection during the cooling process.

n case a sensor with the resistance value below 20KΩ is used, the

detected temperature will be much higher than the actual temperature,

which may lead to the frequent start of overheat protection mode

during the heating or the overload protection during the cooling

process.

41

(4)E4 -Internal fan error of wall mounted air conditioner(PG motor)

Explanation of

error

Cause: PG motor is equipped with speed feedback signal line. When

the feedback signal of speed is not received by the main internal

control panel, it has no way to recognize the rotating speed of motor,

which will be indicated as “Internal fan error”. Main causes for the

disappearance of speed feedback signal are as follows:

The fan is stucked; 2. The speed feedback component in the fan is

broken; 3. Error of receiving circuit for the speed feedback signal from

the main internal control panel.

Tools required

for inspection

Multimeter, A PG motor in normal working condition

Frequent

problematic part

Mechanical jam problem of internal fan, PG motor, main internal

control panel

Inspection

procedure and

key points

1. Check whether the fan can work for a period of time before the error

occurs. If yes, the reason of mechanical jam can be exclude.

2. Disconnect the power supply and move the fan blade of internal

machine by hand to see if there’s any resistance. Some occasional

internal fan error may relate to bearing coordination.

3. Reconnect the drive wire and speed feedback wire, thus to exclude

any fan error due to connector loosening.

4. Check whether the plug-in terminal of speed feedback on the control

panel is loose, and pull the terminal slightly for inspection if necessary.

5. Replace the motor in the faulted air conditioner with other PG motor

(do not fix it with the fan for the time being), if the main control panel

still indicates “internal fan error”, then replace the main internal

control panel; if the error disappears, replace the internal fan.

Special attention

The main internal control panel will not indicates “internal fan

error” when the internal fan is still rotating; sometimes such error will

not be reported when obvious fan problems exist (such as the

low-speed rotation due to damaged fan capacitors, or non-uniform

rotating speed due to abnormal speed feedback.

Therefore, patience of the maintenance staff is required for the

troubleshooting of fan error. You shall compare it with the normal

condition, and detect and solve the problem in a flexible way.

42

(5) E4- Internal fan error of wall mounted air conditioner (DC motor)

Explanation of

error

Cause: The internal fan of some highly energy efficient models is DC

motor using a green plug through which the main internal control panel

can drive the motor and sense the current rotational speed feedback.

When the main internal control panel cannot receive the rotational

speed feedback signal of the motor, it will indicate “DC motor error”.

Disappearance of the rotational speed feedback signal may be caused

by:

1 The motor is stuck and cannot work; 2 The speed feedback element

inside the fan is destroyed; 3 There’s something wrong with the speed

feedback signal receiving circuit of the main internal control panel.

Inspection path: Is DC motor stuck by foreign matter→motor

destroyed → Motor terminal connectors→Main internal control panel

Tools required

for inspection

Multimeter, a DC motor in normal working condition

Frequent

problematic part

Mechanical jam of internal fan, internal DC motor, main internal

control panel

Inspection

procedure and

key points

1. Check whether the fan accelerates to extremely high speed before

the error occurs. If it can work for a period, the reason of mechanical

jam can be excluded.

2. Plug and unplug the terminal of the DC motor again to exclude any

fan error due to connector loosening, and pull the terminal slightly for

inspection if necessary.

3. Replace the motor in the faulted air conditioner with other DC motor

to plug in the main internal control panel (do not fix it with the fan for

the time being), if the main control panel still indicates “DC motor

error”, then replace the main internal control panel; if the error

disappears, replace the DC motor.

4. Multimeter can be used to distinguish whether it is main control

panel problem or motor problem by: connect the motor with the main

control panel and pay attention to the second (yellow) and fourth

(black) wire from the outermost side among four lines of the terminal

of the DC motor. After the air conditioner powers on in the cooling

mode for a while, the voltage between the yellow and black wires

should rise gradually and the motor should accelerates slowly, if the

DC motor still won’t rotate, then the DC motor is destroyed.

Special attention

Five lead wires division: Count from the outermost side of the four

wires of the DC motor terminal, the first blue wire is the speed

feedback wire with a voltage of 0.5-5V when the fan rotates; the

second yellow wire is the motor driving wire with a voltage of

2.0-7.5V when the fan rotates; the second white wire is 15V power

cord with a voltage of 15V in normal condition; the fourth black wire

is 0V DC earth wire which is the benchmark of all the voltage tests; the

fifth (red) wire is 310V wire which is strong with a voltage of 310V in

normal condition, so be careful of electric shock.

43

(6) E4- Sliding door error of floor standing

Explanation of

sliding door

error

Cause: For the model with upper and lower sliding doors, the position

of trap door is sensed via the upper and lower photoelectric switches.

When the sliding door closes, it will move upward until the upper

photoelectric switch senses the sliding door; when the sliding door

opens, it will move downward until the lower photoelectric switch

senses the sliding door. When the photoelectric switch cannot sense the

position of the sliding door normally, it will indicate “sliding door

error”.

Inspection path: Mechanical jam of sliding plate →Synchronous

motor → Can synchronous motor connect to 220V power →

photoelectric switch connection wire → Photoelectric switch → Main

internal control panel

Tools required

for inspection

Multimeter, photoelectric switch in normal condition

Frequent

problematic part

Mechanical jam of sliding plate, photoelectric switch, reversible

synchronous motor, main internal control panel

Inspection

procedure and

key points

1. Power on and observe whether there is mechanical jam in the sliding

plate. Note that new machines may be fixed by tapes, remove them.

2. If the sliding door slides normally when the machine powers on and

off but it still indicates “sliding door error”, then there’s something

wrong with the photoelectric switch.

3. If the sliding door does not slide when the machine powers on and

off, check the reversible synchronous motor to see whether the motor

is connected to 220V power or the motor’s wire is damaged.

4. If there is something wrong with the photoelectric switch, replace it

with another one in normal condition and repeat the above procedures.

If the error disappears, then it’s photoelectric problem; if not, then it’s

main internal control panel problem.

Special attention

1. Please confirm that it is a new sealed one when replacing the

photoelectric switch.

2. There are two photoelectric switches, so check the upper one when

the error occurs when powering off and check the lower one when the

error occurs when powering on.

3. Terminals connected to upper and lower photoelectric switches

should be connected accordingly because they have different colors.

Otherwise, it will lead to reverse switches for the sliding plate.

44

(7) E5(5E) -Internal and external communication error

Explanation of

error

Cause: The frequency converter needs internal and external

communication.When the communication cannot be reached, the

internal and external units will indicate “internal and external

communication error”. Only “main internal control panel, connecting

cable and main external control panel” are related to communication;

but sometimes the communication error will be indicated when the

external unit has no power and the internal unit cannot connect with

the external unit due to other errors, then such situation shall be

distinguished from “pure communication error” and treated in a

different way.

Inspection path: Check if the external unit can power on and work

(normally, the indicator light will turn off after lighting for several

seconds, relay picks up, and PTC won’t heat seriously)

1. Can power on and work: Are the internal unit and external unit

matched→is the phase sequence of connecting wires of internal and

external units correct (the live wire of the internal unit connects with

that of the external unit, the null wire of the internal unit connects with

that of the external unit)→Connecting wires touched well→Main

internal control panel replacement→Main external control panel

replacement

2. Cannot power on and work: Can AC 220V be delivered to the

terminal block of the external unit→Can the bridge rectifier and

module panel generate DC 310V→Can the main external control panel

generate a low voltage power supply of DC 5V→Does the main

external control panel show the status of periodical reset.

Tools required

for inspection

Multimeter, main internal control panel in normal condition

Frequent

problematic part

Connecting wire phase sequence and contact, main internal control

panel, main external control panel, module panel

Inspection

procedure and

key points

1. Firstly, the IDU and the ODU should be matched and connected

properly.

2. Observe the main external control panel, turn on the air conditioner,

three lights are all lighted up then off and the relay pulls in. If not, it is

power supply problem.

3. Connect the black signal line S to terminal N of ODU. Turn on the

A/C, if "E5" is still reported, the main external control panel need to be

replaced. If "E5" is still reported at this time, go to step 4.

4. Change a new main internal control panel, if the error code E5

remains, then the problem should be on the main external control

panel.

45

Special attention

When the external unit not power on: If the internal terminal board

does not transmit 220V power, replace the main internal control panel;

if the external terminal board has 220V power, first check if (fuse,

reactor and bridge rectifier) are normal. There is still something wrong,

replace the whole set of external control unit; for the control unit

composed of several function boards, try disconnecting the

weak-current data wires among several control boards and then power

the external unit on, if the main control panel can be powered on and

initialized successfully, then it’s the module panel problems; if the

main external control panel still cannot be powered on and initialized,

replace the main external control panel.

46

(8) F0- External DC fan error (3-core terminal motor)

Explanation of

error

Cause: Our frequency changing external unit uses the 3-lead-wire DC

motor, or “externally driven DC motor” for short, after 2012. It has no

speed feedback circuit but 3 drive lead wires and its driving principle is

similar to that of the compressor. The main control panel will indicate

“external DC fan error” when it detects imbalanced current on the three

lead wires of the driving motor.

Inspection path: Is the DC fan stuck by foreign matters→Motor

terminal connectors→Main external control panel→Motor

Tools required

for inspection

Main external control panel in normal condition

Frequent

problematic part

Mechanical jam of external fan, main external control panel, external

DC motor

Inspection

procedure and

key points