Tacony Truvox Multiwash II Series, Truvox MW340, Truvox MW240/PUMP, Truvox MW240, Truvox MW340/PUMP User Manual

...

ORIGINAL INSTRUCTIONS

CAUTION – READ THESE INSTRUCTIONS BEFORE USING

THE MACHINE

USER MANUAL

BEDIENUNGSANLEITUNG

MANUEL D'UTILISATION

EN

DE

FR

Multiwash II (Corded Models)

Commercial Floor Cleaning Machine

03-5977-0000 Issue 8 (02-19)

IMPORTANT

BEFORE USE READ THESE INSTRUCTIONS AND RETAIN FOR FUTURE REFERENCE

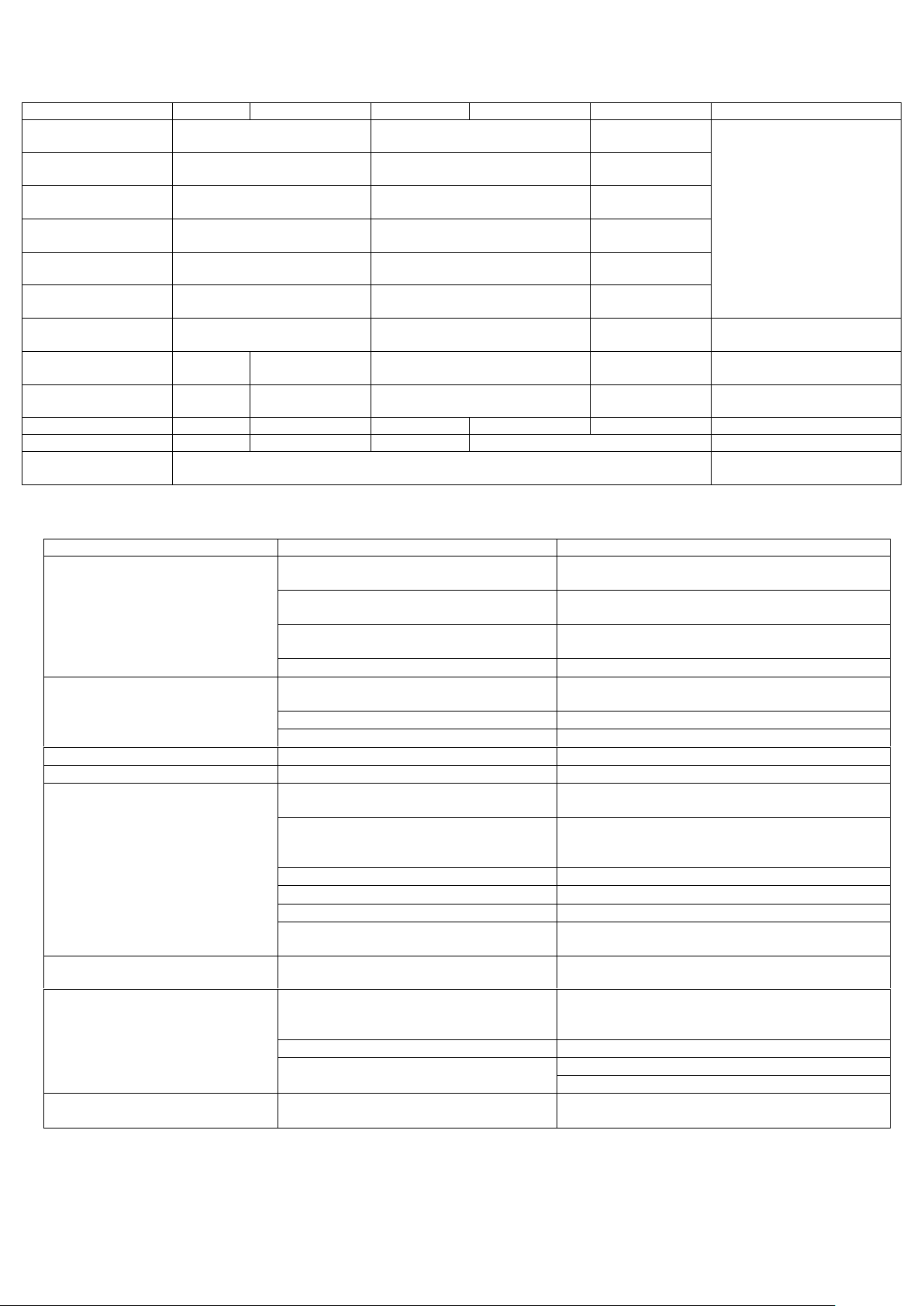

Model

Multiwash II

240

Multiwash II

240 (Pump)

Multiwash II

340

Multiwash II

340 (Pump)

Multiwash II

440 (Pump)

Product Code

MW240

MW240/PUMP

MW340

MW340/PUMP

MW440/PUMP

Voltage AC (~)/

Frequency

V/Hz

230/50

230/50

230/50

230/50

230/50

Motor Power (+ pump)

W

400

400 + 26

600

600 + 26

1000 + 26

Solution tank capacity

litres

1.2 3 1.7 4 4

Productivity Rate

m²/h

650

650

930

930

1150

Brush width

cm

24

24

34

34

44

Brush speed

rpm

650

650

650

650

650

Brush pressure

g/cm²

250

250

250

250

250

Sound pressure level

dB(A)

68

69

69

69

71

Dimensions (L x W x H)

cm

38 x 34 x 112

38 x 34 x 112

38 x 44 x 112

38 x 44 x 112

38 x 54 x 112

Weight

kg

20

22

23

25

28

Cable length

m

12

12

12

12

12

Warranty

1 year subject to conditions

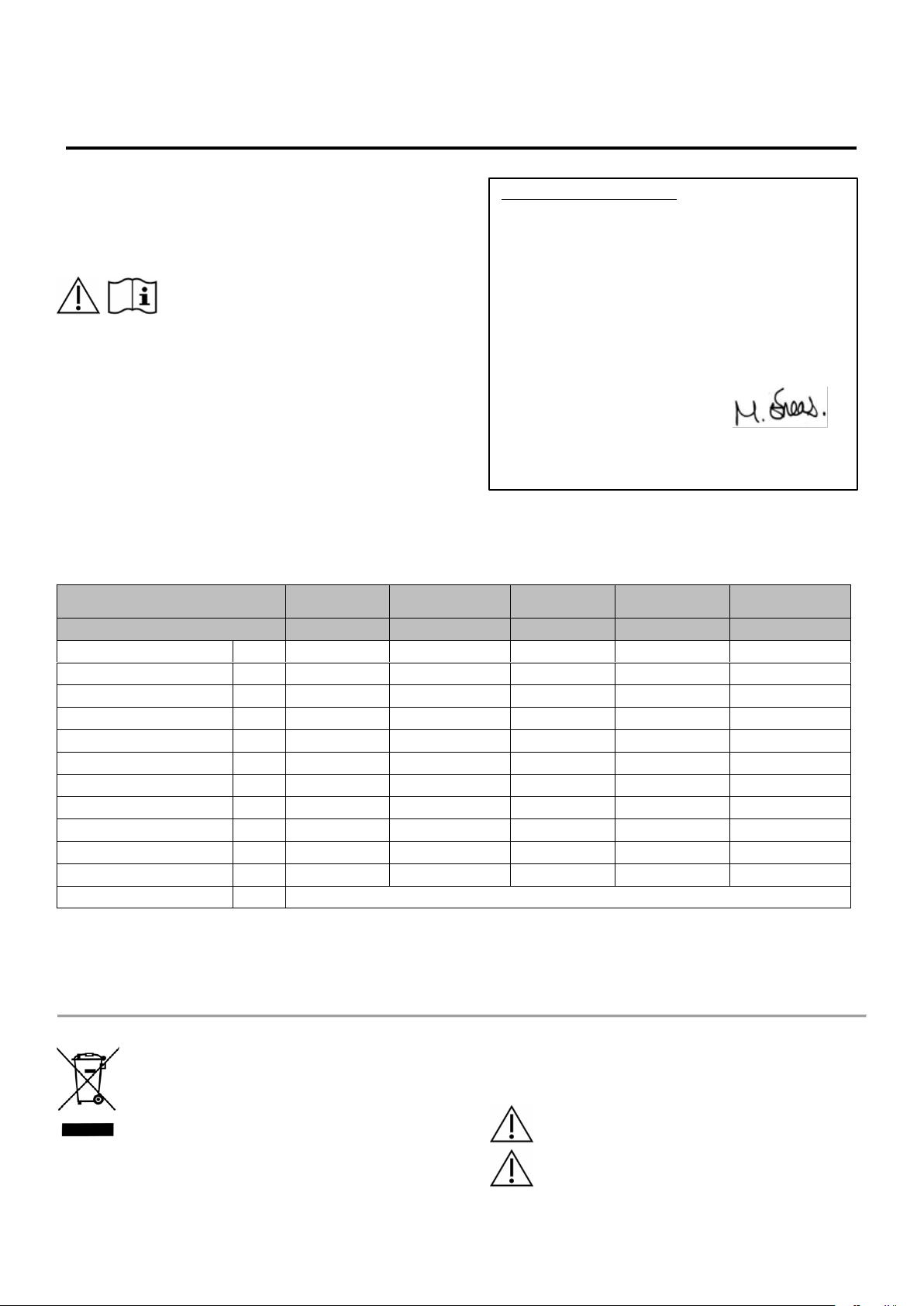

EC Declaration of Conformity

This machine is in conformity with the following EU directives:

Truvox International Limited

SO30 2JR, UK

Malcolm Eneas

Southampton, 15/11/2018

INTRODUCTION

The following instructions contain important information about

the machine and safety advice for the operator. Equipment must

be operated, serviced and maintained in accordance with the

manufacturer’s instructions. If in doubt contact the supplier of

your machine.

Read all instructions before using the

machine

PRODUCT INFORMATION

The Multiwash floor cleaning machines are designed for use on

smooth, even floors in indoor areas. They can be used on most

floor surfaces including short-pile carpet, wood, PVC, rubber

and stone. This machine is for indoor use only. The machine is

intended for commercial use, for example in hotels, schools,

hospitals, factories, shops, offices, rental businesses and other

than normal housekeeping purposes.

TECHNICAL SPECIFICATIONS

Machine Type: Floor cleaning machine

Model: MW240…, MW240/PUMP…, MW340…,

MW340/PUMP…, MW440/PUMP…

Machinery Directive 2006/42/EC

The EMC Directive 2014/30/EU

Applied harmonised standards:

EN60335-1, EN60335-2-72, EN55014-1, EN55014-2,

EN62233, EN61000-3-2, EN61000-3-3

Unit C (East), Hamilton Business Park,

Manaton Way, Botley Road,

Hedge End, Southampton,

Operations Manager

Handle vibration does not exceed 2.5 m/s² when operating on a smooth hard surface.

Noise levels measured at a distance of 1 meter from machine and 1.6 metres above floor, when washing a hard floor. Measurements

recorded using a hand held meter.

Above dimensions are approx. Since the company’s policy is to continuously improve the product, there could be changes without

prior notice.

WASTE ELECTRICAL & ELECTRONIC EQUIPMENT

(WEEE)

Do not dispose of this device with unsorted waste.

Improper disposal may be harmful to the

environment and human health. Please refer to

your local waste authority for information on

return and collection systems in your area.

1 02-19

IMPORTANT SAFETY ADVICE

The safety information described in this manual provides basic

precautions and supplements standards in force in the country

where the machine is used.

This symbol warns the operator of hazards and unsafe

practices which could result in severe personal injury

or death.

WARNING – to reduce the risk of injury,

electric shock or fire.

1. This machine must only be used for the manufacturer’s

approved application as described in this manual.

2. The machine must be unpacked and assembled in

accordance with these instructions before connecting to

the electrical supply.

3. Only genuine accessories and spare parts provided with the

machine or those approved by the manufacturer should be

used. The use of other accessories may impair the safety of

the machine. All repairs must be performed by a qualified

service agent.

4. DO NOT modify the machine from its original design.

27. DO NOT leave the machine connected to the electricity

supply when not in use, always remove the plug from the

socket-outlet.

28. WARNING DO NOT fill the machine with water hotter

than 40ºC.

USE ON ESCALATORS

29. Ensure the machine is positioned at the bottom of the

escalator with the escalator moving towards the operator.

5. Operators must be fully trained in the use of the machine in

accordance with these instructions, able to perform regular

user maintenance and the correct selection of accessories.

6. Operators should be physically capable to manoeuvre,

transport and operate the machines.

7. Operators should be able to recognise unusual operation of

the machine and report any problems.

8. This machine is not intended for use by persons (including

children) with reduced physical, sensory or mental

capabilities, or lack of experience and knowledge, unless

they have been given supervision or instruction concerning

use of the machine by a person responsible for their safety.

9. Keep children and unauthorised persons away from the

machine when in use. DO NOT use as a toy.

10. DO NOT use if it has been damaged, left outdoors or

dropped in water.

11. DO NOT use where hazardous dust is present.

12. DO NOT use in an explosive atmosphere.

13. DO NOT pick up or use near flammable or combustible

fluids, hazardous dusts or vapours.

14. CAUTION - If it is suspected that there is hazardous dust

or flammable/corrosive material, stop cleaning the area

immediately and consult your superior.

15. DO NOT use to clean up any burning or lighted materials

such as cigarettes, matches, ashes or other combustible

objects.

16. Only use the machine on firm level surfaces. DO NOT

use on a gradient or slope of more than 2%.

17. DO NOT use on rough uneven surfaces e.g. industrial or

coarse concrete surfaces.

18. DO NOT use outdoors e.g. on patios, decks or rough

surfaces.

19. CAUTION - This machine is for dry indoor use only and

should not be used or stored outdoors in wet conditions.

20. Take care when using a machine near the top of stairs to

avoid overbalancing.

21. DO NOT cover the machine when in use.

22. DO NOT run the machine dry, as this could damage the

floor surface or the machine itself.

23. DO NOT leave machine running unattended.

24. Keep hair, loose clothing, hands, feet and all other parts of

the body away from openings and moving parts.

25. DO NOT put any object into openings. DO NOT use

with any opening blocked; keep free of dust, debris and

anything that may reduce airflow.

26. DO NOT use volatile or combustible solvents (e.g.

diesel/petrol/IPA/trichloromethane) nor any corrosive,

toxic or highly irritant substances to wash floors, even if

diluted. In the event of accidental contact with any such

substances(e.g. due to spills) follow the decontamination

procedures in force at the user site.If in any doubt about

the condition of the machine, contact Truvox or the

dealer/agent who supplied the machine.

2 02-19

30. DO NOT operate the machine with a damaged power

cord or plug, or after the machine malfunctions or is

damaged in any way. Contact an authorised Service Agent

for repair or adjustment.

31. The machine must be kept clean and in good condition with

regular inspections of the power cord and plug for signs of

any damage. If any parts are damaged they shall only be

replaced by an approved part by the manufacturer, its

service agent or a similar qualified person in order to avoid

a hazard.

32. Only replace the power cord with the type specified in the

instruction manual.

33. When unplugging, pull the plug, not the power cord.

34. WARNING: Keep the power cord clear of moving parts.

35. DO NOT kink or twist the power cord and keep cord

away from heated surfaces.

36. The power cord plus any extension leads should not

exceed 30 metres in total. The cross section of an

extension cable wiring must be at least 2.5mm².

37. DO NOT pull or carry by the power cord. DO NOT use

cord as a handle, close door on cord or pull cord around

sharp edges or corners.

38. Switch off the machine before removing the plug.

39. DO NOT operate switches or touch the mains plug with

wet hands as this may cause electric shock.

40. This machine should always be connected to a fully earthed

power supply of the right voltage and frequency.

41. The machine shall be disconnected from its power source

when not in use and before commencing cleaning of the

machine or maintenance and when replacing parts or

accessories, by removing the plug from the socket-outlet.

CLEANING AGENTS

1. When using cleaning and care agents, the manufacturer’s

danger warnings must be followed and protective goggles

and clothing must be worn.

2. Only use low-foaming, non-combustible cleaning agents

which DO NOT contain generally health-hazardous

substances.

3. Please ensure that after each use any chemical residue is

rinsed out with clean water.

BRUSH IDENTIFICATION

Red, Blue, White and Yellow brush buttons are packed with the

machine. Simply plug the buttons into the hole in the brush as

shown. Clear identification, by colour coding, helps prevent

cross contamination.

TRANSPORTING THE MACHINE

Take extreme care when moving the machine up or down

steps or stairs.

Incorrect lifting techniques may result in personal injury.

We advise that the manual handling regulations are

followed. Carefully wrap the power cord and store in dry

indoor location.

DO NOT expose the machine to rain or moisture.

When transporting the machine ensure that all

components, tanks and removable parts are securely

fastened, and that the power cord and plug are not trailing.

Do not lift or transport the machine whilst containing liquid

as this will add considerably to the weight.

When transporting the machine the handle should be

locked in the upright position.

STORAGE

Always switch off the machine after use.

Store the machine in a dry indoor area only.

Wrap the power cord around the cable winder ensuring

that the plug is not trailing on the floor.

Always switch off, empty, wipe down and dry the machine

after use.

Both the solution and recovery tanks should be emptied

and flushed out with clean water to ensure the seals and

pumps are free from any cleaning detergents.

MAINTENANCE

WARNING - Before undertaking maintenance

operations or adjustments switch off machine

and unplug from the electricity supply.

IMPORTANT – All other servicing and repairs should

only be performed by a Truvox engineer or Authorised

Service Agent.

IMPORTANT – Should the machine fail to operate please

refer to the fault diagnosis section in the back of this instruction

manual. If the problem / remedy is not listed please contact

Truvox Customer Service Department for rapid attention.

The machine requires minimum maintenance apart from the

following checks by the operator prior to use:

Body of the machine - Clean with a damp cloth.

Power cord - Regularly inspect sheath, plug and cord

anchorage for damage or loose connection. Only replace

the power cord with the type specified in these

instructions.

Brushes - For maximum life, wash the brushes regularly.

Ensure machine is in Transport mode when not in use.

Store additional brushes in a vertical position to avoid

bending of bristles. Check for permanent bending of bristles

in a particular direction. This may occur if the machine is

operated for several days without removing the brushes,

which is not recommended. If this occurs, reverse the

brush so that the bent bristles are automatically

straightened.

Wiper Blade - After years of use the wiper blade may wear.

If this occurs the water collection performance will

decrease. It should be replaced by an authorised service

agent.

Solution tank filter (Standard) - The filter prevents clogging

of the drip holes in the tank. Periodically clean the filter to

ensure uniform discharge of liquid. In case of non-uniform

discharge from the drip holes, back flush the tank in running

water. Clean the drip holes.

Solution feed filter (Pump) - The filter prevents clogging of

the spray nozzle and should be periodically cleaned.

Nozzle maintenance (Pump) - If the spray of the nozzle

becomes blocked, slide the nozzle cover off and remove

the nozzle. Wash the nozzle in clean water, ensuring that

the nozzle is clear before refitting.

AFTER SALES SERVICE

Truvox machines are high quality machines that have been

tested for safety by authorised technicians. It is always apparent

that after longer working periods, electrical and mechanical

components will show signs of wear and tear or ageing. To

maintain operational safety and reliability the following service

interval has been defined: Every year or after 250 hours. Under

extreme or specialised conditions and/or insufficient

maintenance, shorter maintenance intervals are necessary. Use

only original Truvox spare parts. Use of other spare parts will

invalidate all warranty and liability claims. Should you require

after sales service please contact the supplier from whom you

purchased the machine, who will arrange service. Repairs and

servicing of Truvox products should only be performed by

trained staff. Improper repairs can cause considerable danger to

the user.

GUARANTEE

Your product is guaranteed for one year from the date of

original purchase, or hire purchase, against defects in materials

or workmanship during manufacture. Within the guarantee

period we undertake at our discretion, to repair or replace free

of charge to the purchaser, any part found to be defective,

subject to the following conditions:

CONDITIONS

1. Claims made under the terms of the guarantee must be

supported by the original invoice/bill of sale issued at the

time of sale, or the machine Serial No.

2. For claims under this guarantee contact the supplier from

whom you purchased the product who will arrange the

appropriate action. Do not initially return the product as

this could result in transit damage.

3. Neither Truvox nor its distributor shall be liable for any

incidental or consequential loss.

4. This guarantee is governed by the laws of England.

5. This guarantee does not cover any of the following:

Periodic maintenance, and repair or replacement of

parts due to normal wear and tear.

Damage caused by accident, misuse or neglect, or the

fitting of other than genuine Truvox parts.

Defects in other than genuine Truvox parts, or

repairs, modifications or adjustments performed by

other than a Truvox service engineer or authorised

service agent.

Costs and risks of transport relating directly or

indirectly to the guarantee of this product.

Consumable items such as, brushes, drive discs, filters

and vacuum skirts.

This guarantee does not affect your statutory rights, or your

rights against the supplier arising from their sales or purchase

contract. Truvox International Limited policy is one of continual

product development and we reserve the right to alter

specifications without prior notice.

3 02-19

RECOMMENDED SPARES & ACCESSORIES

Item

MW240

MW240/PUMP

MW340

MW340/Pump

MW440/Pump

Usage

Standard brush – black

(2 required)

90-0127-0000

90-0130-0000

90-0387-0000

All natural stone floors,

ceramic, mosaic, wood,

profiled rubber, vinyl, PVC;

smooth concrete

Standard brush –

yellow (PK of 2)

05-4755-0000

Standard brush – blue

(PK of 2)

05-4756-0000

Standard brush – green

(PK of 2)

05-4757-0000

Standard brush – red

(PK of 2)

05-4760-0500

Soft brush – grey

(2 required)

90-0133-0000

90-0131-0000

90-0388-0000

Side brush – black

(1 required)

90-0134-0000

90-0132-0000

90-0385-0000

For up-to-the-edge cleaning

Hard brush – blue

(2 required)

90-0089-0000

To suit individual floor

conditions, smooth concrete

Escalator brush – blue

(2 required)

90-0090-0000

90-0469-0000

For use on escalators

3 litre tank

90-0702-0000

4 litre tank 90-0103-0000

Trolley

(for all models)

05-3395-0500

For easier transport

Trouble

Reason

Remedy

Machine fails to start – no power

Transport working lever is in bottom

position (see picture 2 on page 18)

Change to operating position (see pictorial guide)

Motor overload protector has tripped

Wait for 1 hour to allow the motor temperature

to reach room temperature. Then try again.

Transport wheels not raising off the

ground when handle lowered

Check for debris and clean machine.

Lack of voltage / electrical supply

Check fuse *, power cord, plug and socket outlet

Machine fails to pick up water from

the floor

Incorrectly fitted / damaged recovery

tank

Refit or replace recovery tank

Worn brushes

Check brush pressure, if needed replace brushes.

Drum not rotating

See below

Drum not rotating

Debris around drum or base of machine

Clean drum and base of the machine.

Drum is rotating, but brushes are not

Debris around brushes

Clean or replace brushes

Machine fails to spray solution onto

the floor (MW240/Pump,

MW340/Pump & MW440/Pump only)

Faulty pump

If there is no noise present from the pump, check

that the pull cable is fitted correctly.

Incorrectly fitted / damaged pull cable

Refit / replace pull cable - this should be on the

right hand side of the machine from the operator's

position.

No solution in solution tank

Fill solution tank

Blocked jet

Clean jet

Blocked inline filter

Clean inline filter

Blocked filter or faulty valve in solution

tank

Clean / replace filter or valve

Machine only sprays when handle in

upright position

Lower handle bolts are loose

Tighten lower handle bolts

Machine fails to pour solution onto

the floor (MW240 & MW340 only)

Incorrectly fitted / damaged pull cable

Refit / replace pull cable - this should be on the

right hand side of the machine from the operator's

position.

Dirty filter in clean water tank

Empty solution tank and fill up with clean water

Blocked holes in outlet channel

Clean holes in outlet channel

Replace solution tank

Motor makes a humming noise but

does not turn

Debris around drum and base of the

machine

Clean drum and base of machine

FAULT DIAGNOSIS

The following simple checks may be performed by the operator. If the machine is still not working, please contact your local Service Agent:

* If the fuse blows several times, the machine should be checked by an authorised Service Agent.

PLEASE REFER TO THE BACK OF THE MANUAL FOR PICTORIAL INSTRUCTIONS

4 02-19

ACHTUNG

LESEN SIE DIESE ANLEITUNG VOR DER VERWENDUNG DES GERÄTES SORGFÄLTIG DURCH UND

BEWAHREN SIE SIE FÜR REFERENZZWECKE AUF

Modell

Multiwash II

240

Multiwash II

240 (Pump)

Multiwash II

340

Multiwash II

340 (Pump)

Multiwash II

440 (Pump)

Produktnummer

MW240

MW240/PUMP

MW340

MW340/PUMP

MW440/PUMP

Spannung AC (~)/Frequenz

V/Hz

230/50

230/50

230/50

230/50

230/50

Motorleistung (+ Pumpe)

W

400

400 + 26

600

600 + 26

1000 + 26

Füllmenge Laugentank

litres

1.2 3 1.7 4 4

Arbeitsleistung

m²/h

650

650

930

930

1150

Bürstenbreite

cm

24

24

34

34

44

Bürstendrehzahl

rpm

650

650

650

650

650

Bürstendruck

g/cm²

250

250

250

250

250

Geräuschpegel

dB(A)

68

69

69

69

71

Maße (L x B x H)

cm

38 x 34 x 112

38 x 34 x 112

38 x 44 x 112

38 x 44 x 112

38 x 54 x 112

Gewicht

kg

20

22

23

25

28

Kabellänge

m

12

12

12

12

12

Gewährleistung

1 Jahr unter Auflagen

EU-Konformitätserklärung

EN62233, EN61000-3-2, EN61000-3-3

Truvox International Limited

SO30 2JR, UK

Malcolm Eneas

Southampton, 15/11/2018

EINLEITUNG

Diese Bedienungsanleitung enthält wichtige Informationen zu

diesem Gerät sowie Sicherheitsanweisungen für den Benutzer.

Das Gerät muss im Einklang mit den Anweisungen des Herstellers

bedient, instand gehalten und gewartet werden. Wenden Sie sich

im Zweifelsfall an Ihren Fachhändler.

Lesen Sie die gesamte Anleitung vor

der Verwendung des Gerätes sorgfältig

durch.

PRODUKTINFORMATIONEN

Die Multiwash-Bodenreinigungsmaschinen sind für den Einsatz auf

glatten, ebenen Böden in Innenräumen bestimmt. Sie können auf

den meisten Bodenbelägen wie kurzflorigem Teppich, Holz, PVC,

Gummi und Stein verwendet werden. Diese Maschine ist nur für

die Verwendung in Innenräumen vorgesehen. Das Gerät ist für die

gewerbliche Nutzung, zum Beispiel in Hotels, Schulen,

Krankenhäusern, Fabriken, Ladengeschäften, Büros,

Vermietungsunternehmen und andere Zwecke außer der

normalen Haushaltsreinigung vorgesehen.

TECHNISCHE ANGABEN

Gerätetyp: Bodenreinigungsmaschine

Modell: MW240…, MW240/PUMP…, MW340…,

MW340/PUMP…, MW440/PUMP…,

Dieses Gerät entspricht den folgenden EU-Richtlinien:

Machinenrichtlinie 2006/42/EC

EMV-Richtlinie 2014/30/EU

Angewendete harmonisierte Normen:

EN60335-1, EN60335-2-72, EN55014-1, EN55014-2,

Unit C (East), Hamilton Business Park,

Manaton Way, Botley Road,

Hedge End, Southampton,

Operations Manager

Die Geräuschentwicklung wurde im Abstand von 1 Meter von der Maschine und 1,6 Metern über dem Boden beim Reinigen von

Hartboden gemessen. Die Messungen wurden mit einem Handmessgerät durchgeführt.

Die Griffvibration übersteigt 2,5 m/s² im Betrieb auf einer ebenen, harten Fläche nicht.

Die obenstehenden Abmessungen sind Richtwerte. Da sich unser Unternehmen der ununterbrochenen Weiterentwicklung seiner

Produkte verschrieben hat, können die Daten ohne Ankündigung geändert warden.

ELEKTRO- UND ELEKTRONIK-ALTGERÄTE (WEEE)

Entsorgen Sie dieses Gerät nicht im Hausmüll. Eine

unsachgemäße Entsorgung kann die Umwelt und die

Gesundheit schädigen. Wenden Sie sich für

Informationen über die Abgabe- und Sammelsysteme

in Ihrer Region an die lokale Entsorgungsstelle.

WICHTIGER SICHERHEITSHINWEIS

Die in diesem Handbuch beschriebenen Sicherheitshinweise geben

grundlegende Vorsichtsmaßnahmen an, die zusätzlich zu den

Normen in dem Land, in dem das Gerät benutzt wird, gelten.

Dieses Symbol warnt den Benutzer vor Gefahren und

unsicheren Praktiken, die zu schweren

Körperverletzungen oder Tod führen können.

WARNUNG – Um das Risiko eines Brandes, von

Stromschlag oder Verletzungen zu mindern.

5 02-19

Loading...

Loading...