Page 1

Application:

Taco Zone Sentry Zone Valves can be used in a wide variety of heating and (non condensing) cooling applications,

primarily designed for use with baseboard, fan coils, radiators, convectors, air handlers, heat pumps and radiant

applications. Refer to the Product Specifications section for

choosing the correct style valve for your application.

General Installation Information / Operation:

The Zone Sentry is the most technologically advanced

zone valve ever made. It’s also simple to install and operate. The valve body can be installed in any position and

in any orientation. The actuator’s electrical connections

must be mounted over the port that requires flow when

power is applied to the actuator. (See Figure 1.) The back

of the valve makes for a simple, secure and fast wiring

hook-up. A green LED light shows full functionality of the

valve’s operation and thermostat status. Under a no power

situation the manual override button located on the top

of the valve allows the ball to be rotated up to 90°.

Before mounting the body refer to Figure 2 for any clearance requirements.

Use of a solder with a melting point below 600°F is recommended. Do not overheat! Make sure the ball valve is

in the FULL OPEN position to the port that is being soldered. Direct flame tip away from the center of the valve.

Cool valve quickly with a wet rag to prevent overheating.

Solder build-up on the ball valve may prevent proper

opening and closing of the valve.

Valve body may be submerged for leak testing before the

actuator is attached.

Step by Step Valve Installation:

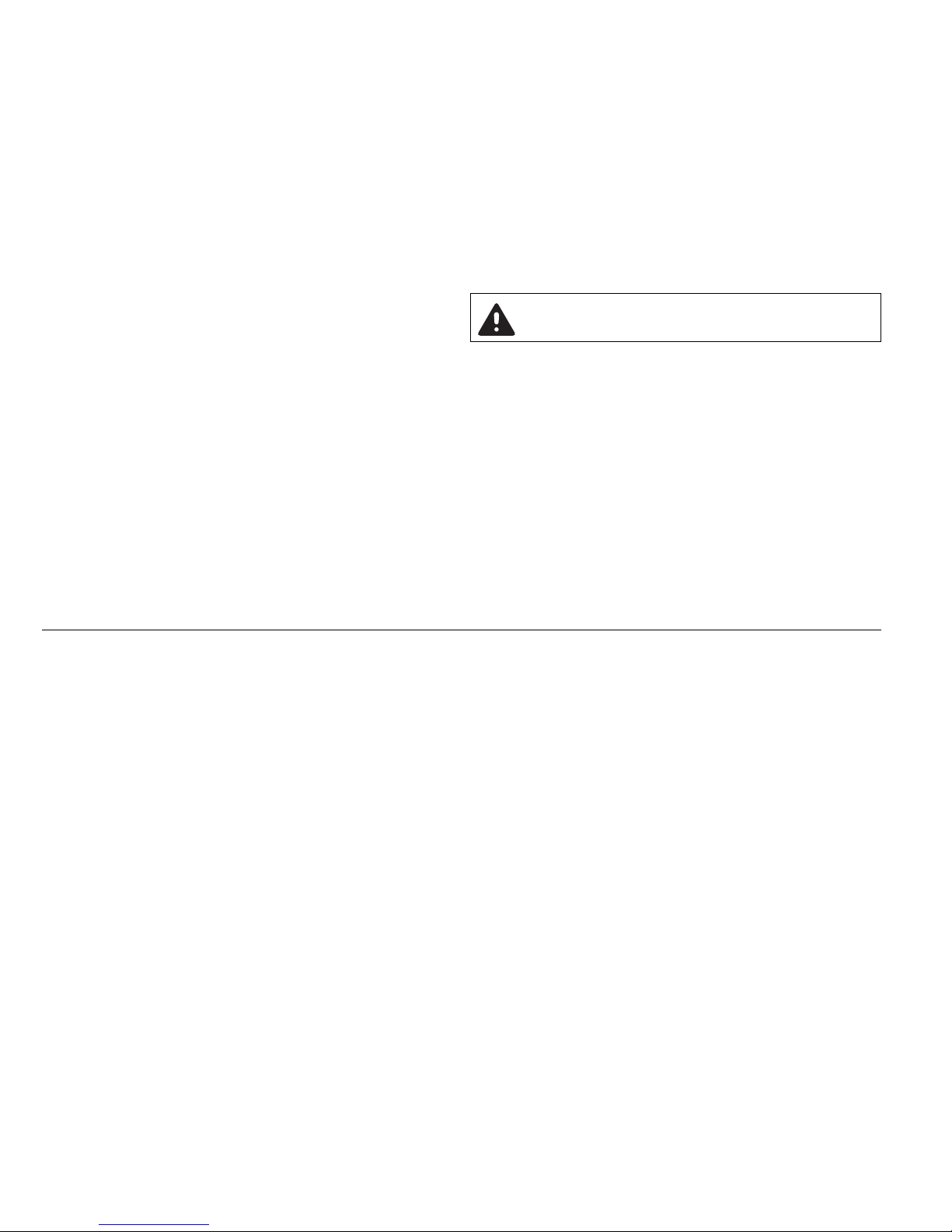

1. Remove actuator from the valve body. Push in and

hold the release clip at the front of the actuator, pull

the actuator away from the body (approx.

3

⁄4"). (See

Figure 3.)

2. Open the valve to the full open position of the first

port to be soldered (port A or B).

3. Clean and prepare the valve and pipe using the

proper techniques required prior to soldering.

4. Fit the valve into the piping system.

5. Solder the port of the valve that you placed in the

full open position, directing the flame away from

the center of the valve.

6. Turn the opening of the valve to the second port to

be soldered. (the opposite port of the one just completed.)

7. Repeat step 5 for the second port.

8. Solder the third port (bottom port). This port is

always in the full open position.

9. Immediately cool the valve with a wet towel.

Instruction Sheet

Zone Sentry 3-way Diverting Valve

102-426

SUPERSEDES: New EFFECTIVE: April 1, 2011

Plant ID# 001-3997

CAUTION: Actuator must be removed from

the valve body before soldering (see

Figure 3). Ball valve must be in the full open

position to the port that is being soldered.

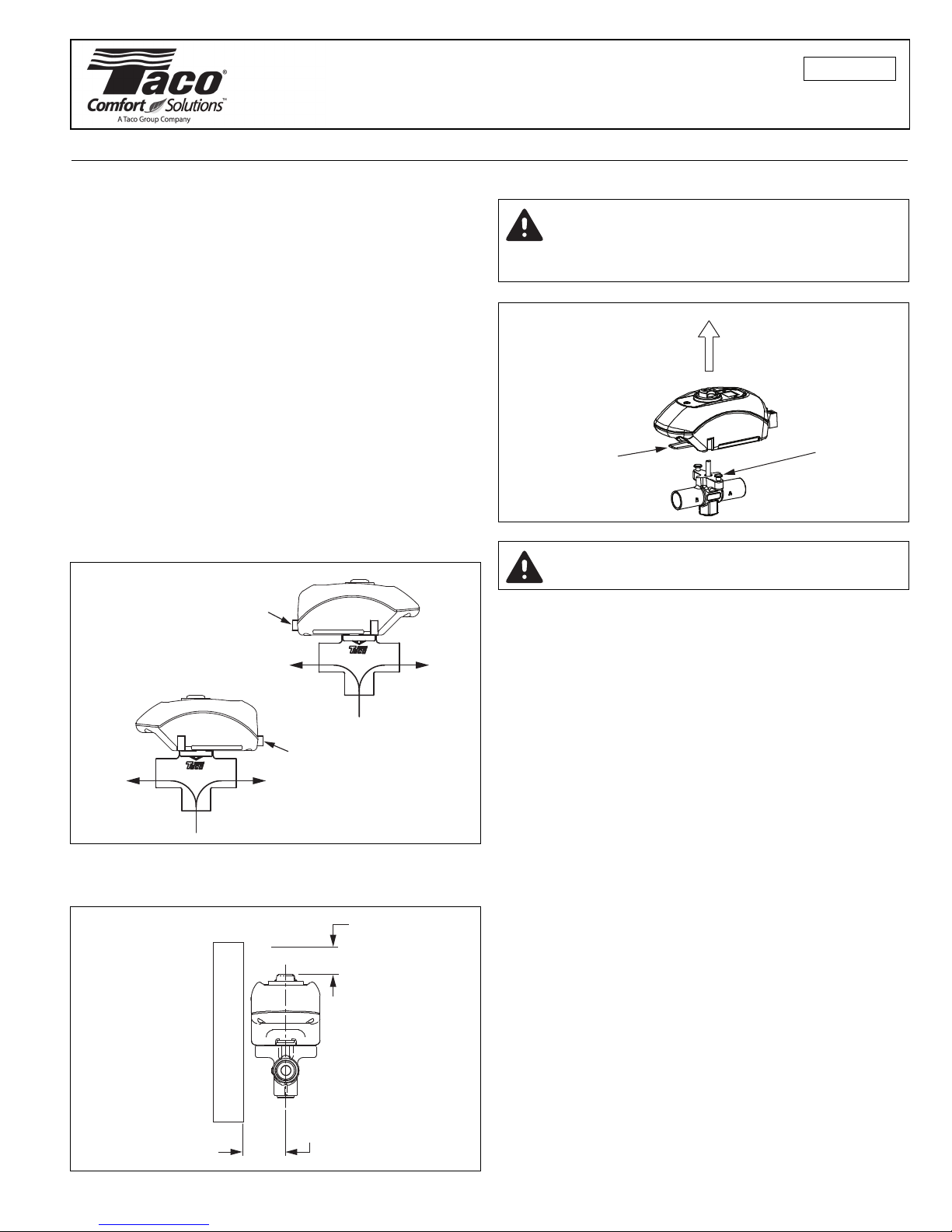

13⁄8" CLEARANCE

3

⁄4" CLEARANCE

W

A

L

L

Figure 2

A

C

B

A

C

B

CALL

CALL

NO CALL

NO CALL

ELECTRICAL

CONNECTION

ELECTRICAL

CONNECTION

Figure 1

L

OCKING

POST

Step 1:

Push in and hold

release clip at the

front of the actuator.

Step 2:

Move actuator away from the

valve body approximately 3⁄4"

to disengage locking posts

and stem.

Figure 3: Operator

Removal

CAUTION: Installation should only be performed by a qualified professional.

Page 2

Installing the Actuator on the Valve Body:

1. Position the actuator so that the “D” shaped valve

stem aligns with the “D” shaped drive cavity in the

operator

2. Slide the actuator onto the valve stem and rotate to

align the valve’s 2 locking posts with the mating

holes in the actuator. Push in the release clip and

slide the actuator down flush to the valve body.

3. Verify that the actuator is locked by pulling it away

from the valve body without pushing in the clip.

(Do not use excessive force.)

Mode of Operation:

1. Upon initial field installation the capacitor requires

a full charge, up to 25 seconds before the valve starts

to turn. Charging time will vary (typically less) during normal operation.

2. When the capacitor is charging the green LED light

will FLASH.

3. Once the capacitor is charged the green LED will

stop flashing but remain ON, at this point the

valve’s actuator will rotate the ball valve. The green

LED will remain ON as long as the thermostat is calling (the unit is powered).

4. Once the thermostat is satisfied the green LED will

turn OFF and the valve will rotate 90° into its normal position or non powered position.

WARNING: Do not use zone valves on indirect

water heaters without a tempering device.

Product Specifications:

Maximum Operating Pressure: 300 PSI (2,100 kPa)

Maximum Shutoff Pressure: 125 PSI (875 kPa)

Fluid Temperature Range: 20° to 240°F, (-7° to 115°C) @ 135°F (57°C) ambient

Service: Closed systems

Optional open system configuration (high oxygen content)

Up to 50% Glycol

Ball Rotation Speed: Full Open to Full Close (90° turn), 5 seconds (after charge time)

Full Close to Full Open (90° turn), 5 seconds (after charge time)

Seat Leakage: Drop-Tight Close-Off

Electrical Rating: 24 VAC, 60 HZ, 0.48 Amps

Do not use more than 12 zone valves per 40VA transformer.

Power Consumption, Charging: 11.4 Watts, 0.48 Amps max

Power Consumption, Power On: 1.44 Watts, 0.06 Amps max

Heat Anticipator Setting: 0.5 Amps

End Switch Rating: 1 Amp @ 24 VAC

Materials of Construction, Actuator:

Body: High Performance Engineered Polymer

Gears: High Performance Internally Lubricated Engineered Polymer

Materials of Construction, Valve:

Body: Forged Bronze

Stem: Brass

Press Ring: Brass

Ball: Brass (Chrome Plated)

Seat: Modified Teflon

®

O-rings: EPDM

Page 3

WARNING: Wiring connections must be

made in accordance

with all applicable electrical

codes.

WARNING: To prevent

electrical shock, dis-

connect electric power

to system at main fuse or circuit breaker box until installation is complete. When a

service switch is installed,

more than one disconnect

switch may be required to

deenergize this device for

servicing.

Zone Sentry Installation and Wiring Diagrams

LED

Motor

Circuit

End Switch

c

w/y

Simplified Internal

Schematic:

Thermostats

Transformer

To “T” Terminals

on Boiler Control

Transformer Relay

T

T

Up to 12 Valves per

40va Transformer

L1 (Hot)

L2

24 v

End Switch

Rh/Rc

w/y

Rh/Rc

w/y

Rh/Rc

w/y

w/y

c

End Switch

w/y

c

End Switch

w/y

c

Typical Zone Sentry Zone Valve Wiring:

NOTE 1: Some power robbing thermostats require the use of a resistor (always use the resistor provided by the thermostat manufacturer with the Zone Sentry). Consult the thermostat instructions for the

resistor installation.

NOTE 2: The plug-in quick connects can be disconnected from the valve actuator for ease of wiring.

Insert the corresponding wire into the quick connects and tighten by turning the screw.

CAUTION: Do not jumper the power/motor (24 VAC) connection terminals, even temporarily. This

may cause damage to the thermostat’s heat anticipator or to the transformer.

Typical Installations for 3-way Valves Normally Closed to the Load

Typical Installations for 3-way Valves Normally Open to the Load

LOAD

LOAD

LOAD

LOAD

SUPPLY

SUPPLY

SUPPLY

SUPPLY

SUPPLY

SUPPLY

SUPPLY

SUPPLY

RETURN

RETURN

RETURN

RETURN

FLOW ON

NO CALL

FLOW ON

NO CALL

FLOW ON

NO CALL

FLOW ON

NO CALL

FLOW ON

CALL

FLOW ON

CALL

FLOW ON

CALL

FLOW ON

CALL

ELECTRICAL

CONNECTION

ELECTRICAL

CONNECTION

ELECTRICAL

CONNECTION

ELECTRICAL

CONNECTION

NOTE for 3-way: Actuator’s power connections must be mounted over the port requiring flow when

power is applied. The valve should always be installed so that the unpowered port is the one with the

highest percentage of time with flow.

Page 4

Taco, Inc. will repair or replace without charge

(at the company’s option) any product or part

which is proven defective under normal use

within three (3) years from the date of start-up or

three (3) years and six (6) months from date of

shipment (whichever occurs first).

In order to obtain service under this warranty, it

is the responsibility of the purchaser to promptly

notify the local Taco stocking distributor or Taco

in writing and promptly deliver the subject product or part, delivery prepaid, to the stocking distributor. For assistance on warranty returns, the

purchaser may either contact the local Taco

stocking distributor or Taco. If the subject product or part contains no defect as covered in this

warranty, the purchaser will be billed for parts

and labor charges in effect at time of factory

examination and repair.

Any Taco product or part not installed or operated in conformity with Taco instructions or which

has been subject to misuse, misapplication, the

addition of petroleum-based fluids or certain

chemical additives to the systems, or other

abuse, will not be covered by this warranty.

If in doubt as to whether a particular substance

is suitable for use with a Taco product or part, or

for any application restrictions, consult the

applicable Taco instruction sheets or contact

Taco at [401-942-8000].

Taco reserves the right to provide replacement

products and parts which are substantially similar in design and functionally equivalent to the

defective product or part. Taco reserves the right

to make changes in details of design, construction, or arrangement of materials of its products

without notification.

TACO OFFERS THIS WARRANTY IN LIEU OF

ALL OTHER EXPRESS WARRANTIES. ANY

WARRANTY IMPLIED BY LAW INCLUDING

WARRANTIES OF MERCHANTABILITY OR FIT-

NESS IS IN EFFECT ONLY FOR THE DURATION

OF THE EXPRESS WARRANTY SET FORTH IN

THE FIRST PARAGRAPH ABOVE.

THE ABOVE WARRANTIES ARE IN LIEU OF ALL

OTHER WARRANTIES, EXPRESS OR STATUTORY, OR ANY OTHER WARRANTY OBLIGATION ON THE PART OF TACO.

TACO WILL NOT BE LIABLE FOR ANY SPECIAL, INCIDENTAL, INDIRECT OR CONSEQUENTIAL DAMAGES RESULTING FROM THE

USE OF ITS PRODUCTS OR ANY INCIDENTAL

COSTS OF REMOVING OR REPLACING

DEFECTIVE PRODUCTS.

This warranty gives the purchaser specific

rights, and the purchaser may have other rights

which vary from state to state. Some states do

not allow limitations on how long an implied warranty lasts or on the exclusion of incidental or

consequential damages, so these limitations or

exclusions may not apply to you.

LIMITED WARRANTY STATEMENT

COMFORT MADE EASY.

®

TACO, INC., 1160 Cranston Street, Cranston, RI 02920 Telephone: (401) 942-8000 FAX: (401) 942-2360.

TACO (Canada), Ltd., 8450 Lawson Road, Unit #3, Milton, Ontario L9T 0J8. Telephone: 905/564-9422. FAX: 905/564-9436.

Visit our web site at: http://www.taco-hvac.com

Printed in USA

Copyright 2011

TACO, Inc.

Loading...

Loading...