Page 1

Please Note: A qualified structural engineer

should be consulted prior to mounting an

antenna on a tower or support structure.

Instruction Sheet

30377001 Rev. H

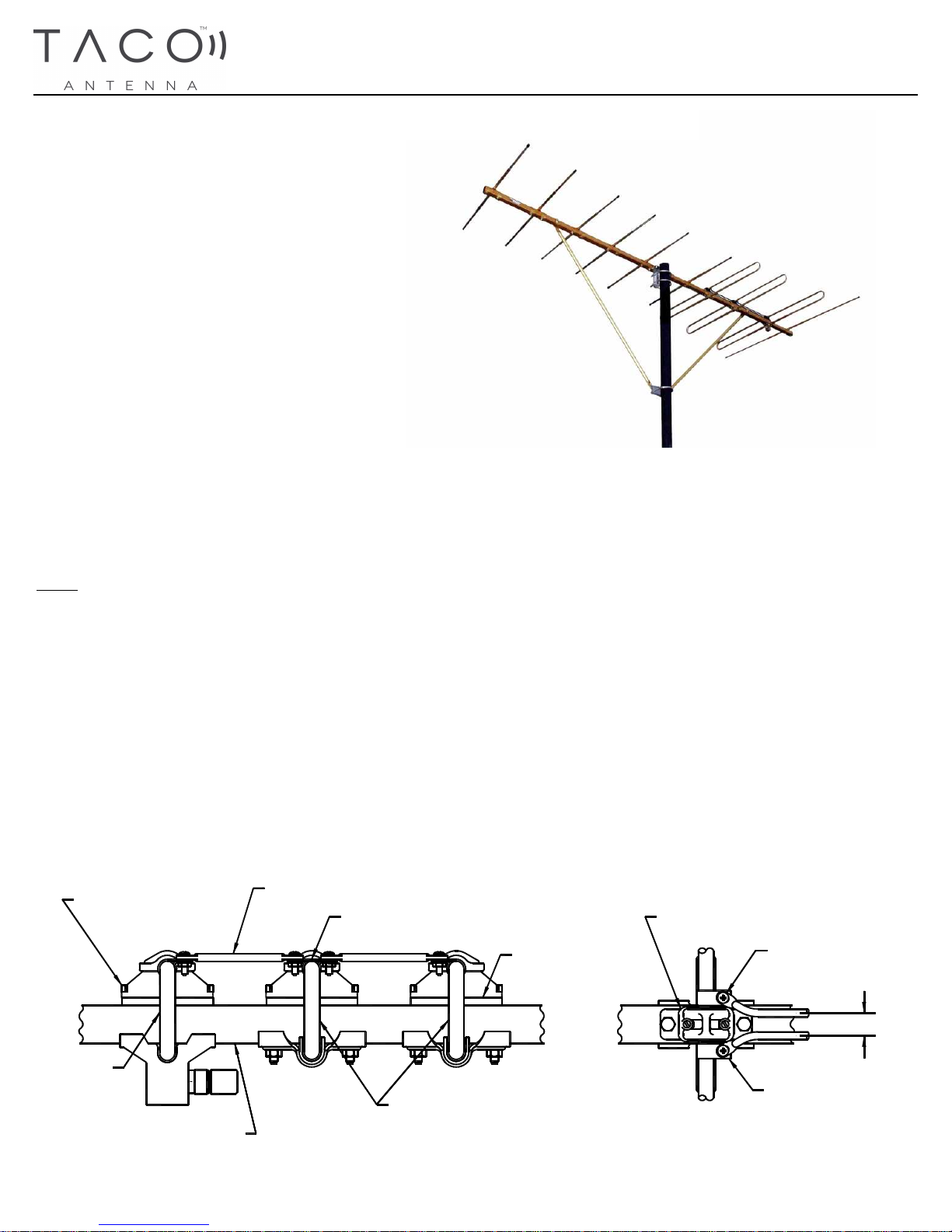

TACO RUGGEDIZED YAGI ANTENNA

FOR MODELS:

Y81-A, -2, -3.

Y-101-65, -4, -B, -5, -6, -C, -FM, -D,-H, -E.

Y-102B-F, -G, -120, -130, -150.

The Yagi dipoles and parasitic elements are all identified with a letter i.e. A, B, C, D and E. These markings will be

found on the crossarm indicating the location these elements are to be assembled on the crossarm (See Figure 6).

The antenna main mounting clamp holes are located in the crossarm perpendicular to the element holes. The dipole

insulators and parasitic elements mount to the same side of the crossarm.

Note: All Y-101 and Y-81 series Yagi have a two-piece crossarm. The antenna main mounting clamp is used to

assemble the two halves together and for this purpose four (4) 3/8” Dia. Bolts are supplied.

Start with the director element and the dipole elements and assemble them to their marked locations on the

crossarm as shown in Figure 1. Shims are supplied with Y-101-65, -4, -B, -5, -6, -C, -FM, -D,-H, and –E, to be

assembled with the dipole elements as shown in Figure 1. The dipoles are attached with 2 ¼ or 2 ½ (for models with

shims) inch long 1/4 inch bolts.

Next assemble the feedlines connecting the dipole elements as shown using feedline clamps and 5/8 inch long

10-32 screws (See Figure 2). Attach feedlines at dipoles to top of clamps with a centre-to-centre spacing of 3/4 inch

(See Figure 2).

HEX HEAD SCREW

1/4-20 UNC X 2 1/4 or 2 1/2 in.

(5.72/6.35 cm) LONG

DIPOLE

CROSSARM

NOTE:

Shims are supplied with Y-101-65, -4, -B, -5, -6, -C, -FM, -D,-H, and –E only.

FEEDLINE

FEEDLINE CLAMP

DIPOLE

FIGURE 1 F

SHIM (see note)

PLASTIC INSULATOR

ROUND HEAD SCREW

#10-32 UNF X 5/8 in.

(1.59 cm) LONG

3/4 in. (1.91 cm)

FEEDLINE CLAMP

IGURE 2

Page 2

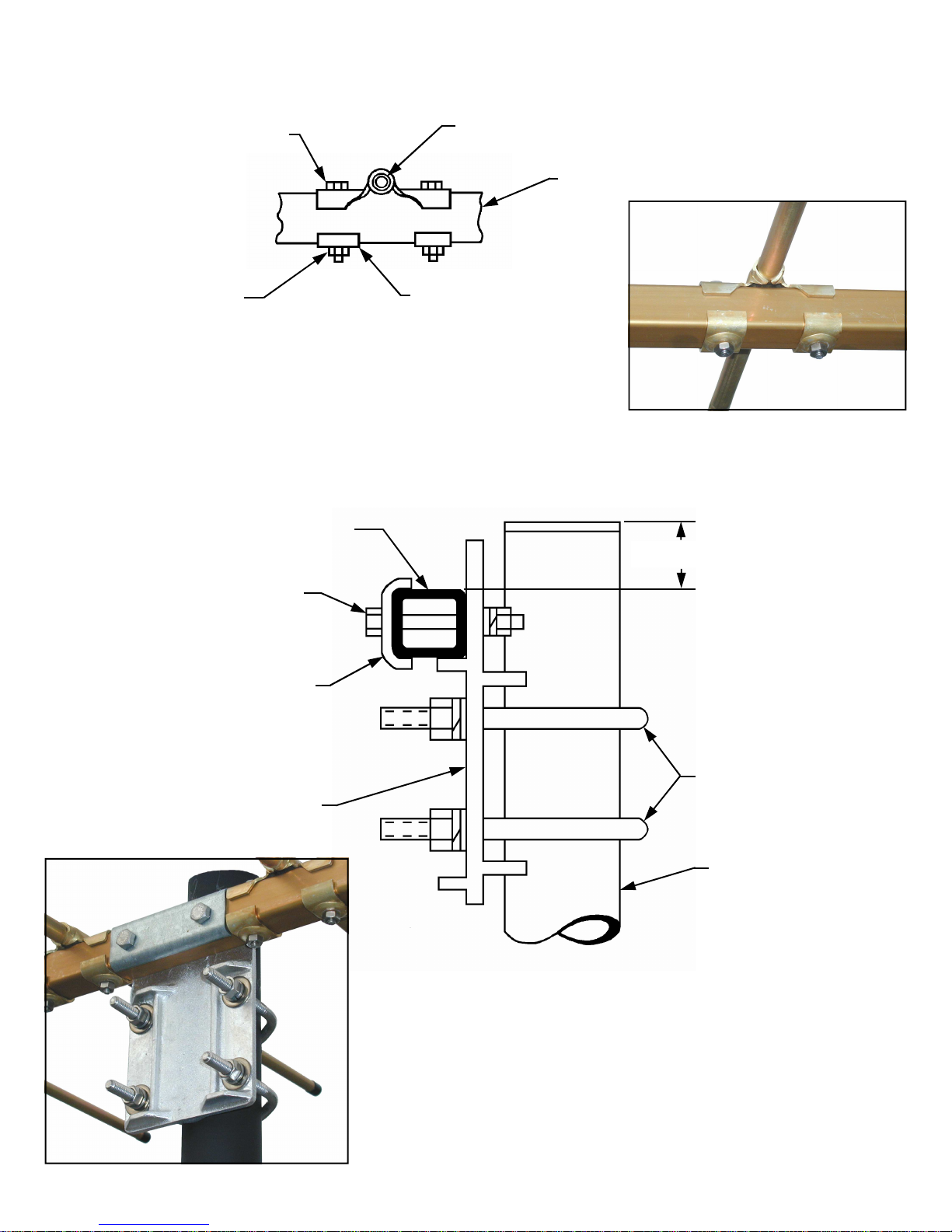

The Parasitic Elements “A”, “B”, and “E” are mounted onto the crossarm at their match marked

locations, with 2 ¼” long, 1/4” Bolts, Reinforcing Clips, Lockwashers and Nuts as shown in Figure 3.

HEX HEAD SCREW

1/4-20 UNC X 2 ¼ in.

(5.72 cm) LONG

LOCKWASHER & NUT

ELEMENT

CROSSARM

REINFORCING

CLIP

FIGURE 3

The antenna main Mounting Clamp is assembled to the crossarm at the unmarked holes (perpendicular

to the element holes) with 2¼” long, 3/8” diameter Hex Head Bolt as shown in Figure 4.

CROSSARM

2 in.(5.08 cm) approx.

HEX HEAD SCREW

3/8-16 UNC X 2¼ in.

(5.72 cm) LONG

REINFORCING CLAMP

MOUNTING PLATE

3/8 in. (.95 cm) DIA. U-BOLTS

MAST

FIGURE 4

Page 3

The antenna Braces are assembled to the crossarm at the unmarked holes (perpendicular to the

element holes) with 1/4” x 2½” Hex Head Bolts, Reinforcing Clip, Washer, Lockwasher and Hex Nut.

The opposite ends of the braces are assembled to the mast (mounting pipe) using the channel and 3/8”

U-Bolt, Washer, Lockwasher and Hex Nut assembly as shown in Figure 5.

REINFORCING CLIP

1/4” x 2½” HEX

HEAD BOLT

CROSSARM

BRACE

3/8” DIA U-BOLT

MAST

BRACE

CHANNEL

FIGURE 5

SAFETY PRECAUTIONS

1. To protect your antenna and equipment from lightning damage, you should use a lightning arrestor. Attach the

lightning arrestor to the downlead at the point where it enters the building. Drive a ground rod at least 4 feet

into the ground. Use ground wire to connect the antenna mast and the lightning arrestor to the ground rod.

2. Keep antenna and downlead a safe distance from any power lines.

Page 4

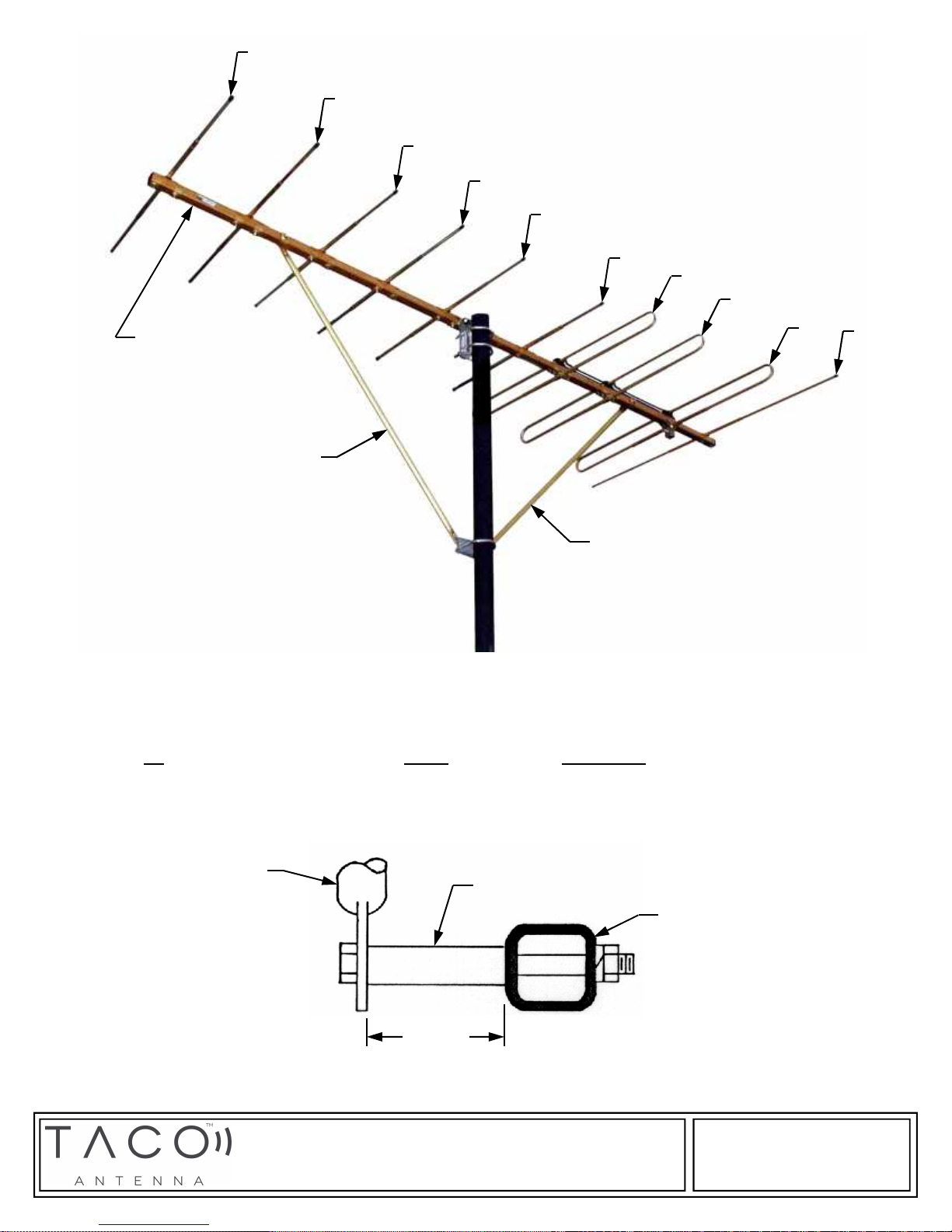

A

A

A

A

A

B

C

C

CROSSARM

D

BRACE

BRACE

E

FIGURE 6

For stacking antennas in an array on a limited frame, the antenna support braces can be inverted or installed going up

at an angle instead of going down at an angle. CAUTION must be used to insure that the

antenna radiators be oriented in spaces identical (in phase condition), therefore to eliminate any interference between brace and antenna, a 2 in. spacer (not supplied) must be installed between antenna

crossarm and brace bars as shown in Figure 7.

BRACE

SPACER (NOT SUPPLIED)

CROSSARM

2.00 in.

FIGURE 7

(See Figure 5 for normal installation)

29 Sharp Rd, Box 1206

Brantford, Ont., Can., N3T 5L8

www.wadeantenna.com

Loading...

Loading...