Page 1

Instruction Sheet

A

X – Pump Block (XPB)

102-202

SUPERSEDES: July 1, 2010

EFFECTIVE: October 1, 2010

Plant ID#: 001-3883

WARNING SYMBOL: THIS SYMBOL INDICATES THE PRESENCE OF HAZARDS WHICH

CAN CAUSE SEVERE PERSONAL INJURY, SUBSTANTIAL PROPERTY DAMAGE OR

EVEN DEATH IF IGNORED.

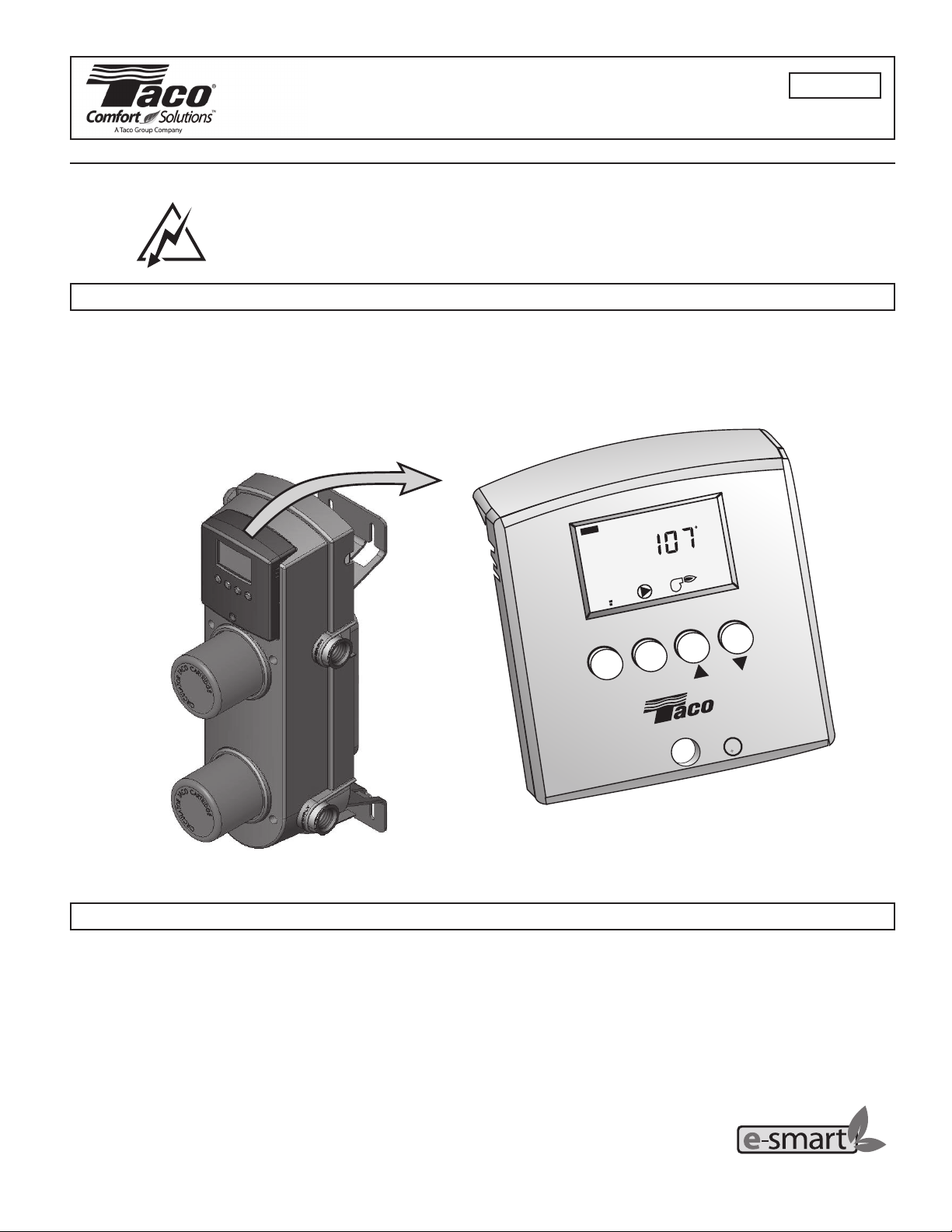

General

The Taco X – Pump Block (XPB) represents a breakthrough in the design, control and installation of heating systems. The patent

pending design combines a variable speed mixing control (VSMC), heat source circulator, system circulator, and heat exchanger into a

single unit. This combination delivers complete isolation between the heat creation source side of the system (boiler, water heater, etc.)

and the heat delivery side of the system (radiant tubing, glycol based snowmelt, baseboard, etc.). Extremely versatile, the

X – Pump Block can be set up to operate in outdoor reset, setpoint or delta T limiting mode.

VIEW

MIX SUP

%

1

F

DEM

X – PUMP BLOCK (XPB) VARIABLE SPEED MIXING CONTROL (VSMC)

Table of Contents

TYPICAL PIPING ------------------------------------------------ 2

GETTING READY ----------------------------------------------- 3

APPLICATION ---------------------------------------------------- 3

DESIGN PROCEDURE ----------------------------------------- 3

INSTALLATION OF X – PUMP BLOCK ------------------- 4

OUTDOOR RESET MODE ------------------------------------ 5

OUTDOOR RESET SETTINGS ------------------------------ 5

SETPOINT AND DELTA T MODE --------------------------- 6

SETPOINT AND DELTA T SETTINGS --------------------- 7

MENU

PATENT PENDING

ITEM

X - PUMP BLOCK

U

C

TM

XPB-1

L

R

US

HEAT SOURCE OPERATION MODE ---------------------- 7

SET UP OF VARIABLE SPEED MIXING CONTROL -- 8

DISPLAY OPERATION ---------------------------------------- 11

TROUBLE SHOOTING ---------------------------------------- 13

ERROR MESSAGES ------------------------------------------ 14

REPLACING CARTRIDGE ASSEMBLY ------------------ 14

TECHNICAL DATA --------------------------------------------- 15

CLEANING ------------------------------------------------------- 16

LIMITED WARRANTY STATEMENT ---------------------- 16

Taco resource – saving product

1 of 16

Page 2

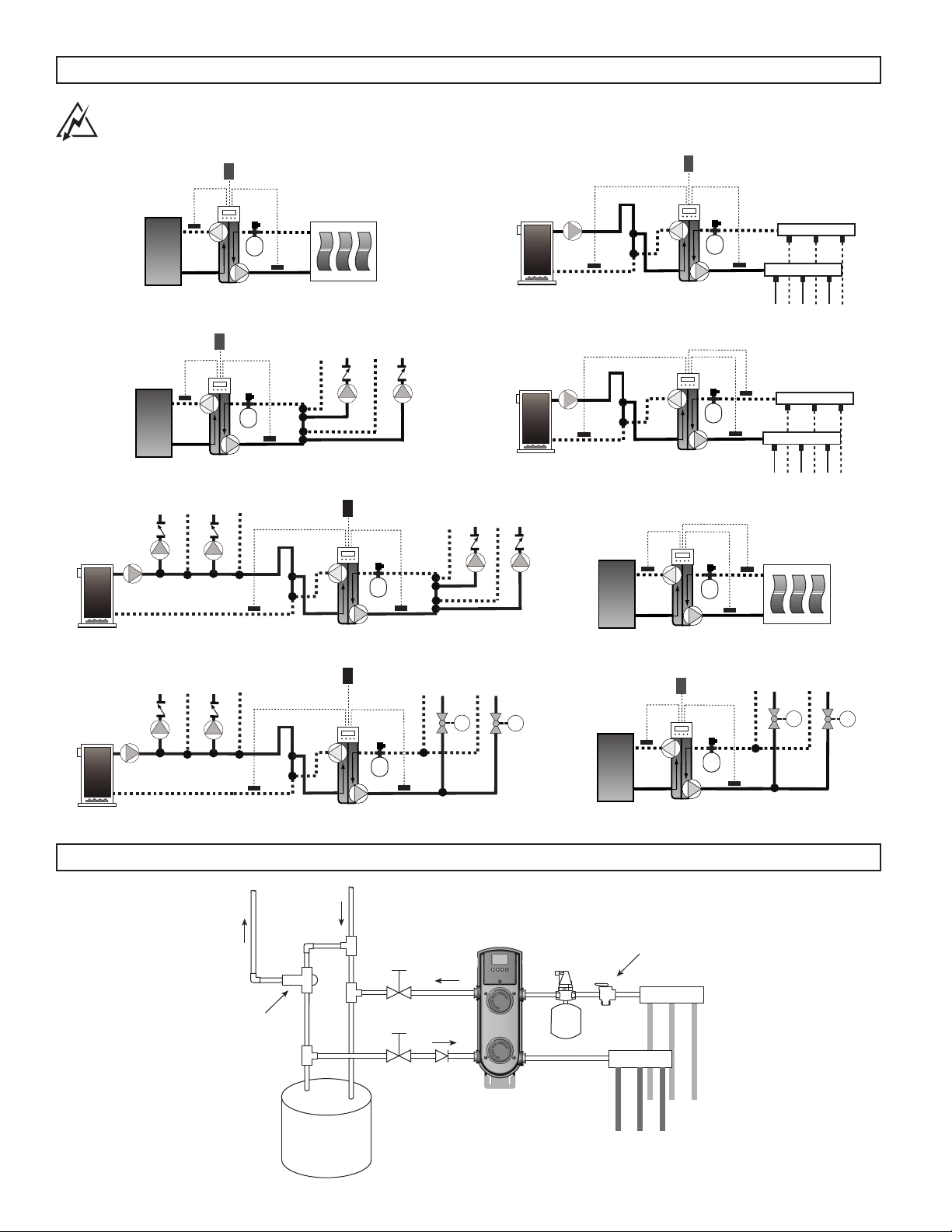

Typical Piping

Warning! Must Install a Pressure Relief Valve and Expansion Tank on Secondary Side

in addition to Units Installed on Primary Side of System.

Outdoor

Sensor

Pressure

Relief

Exp

Tank

Output to

System

Supply

Sensor

HEAT

SOURCE

Return

Sensor

Input from

Heat Source

Outdoor

Sensor

Pressure

Relief

Exp

Tank

Output to

System

Supply

Sensor

Return

Sensor

Input from

Heat Source

Radiant Manifold - Return

Radiant Manifold - Supply

X - Pump Block (XPB)

Outdoor

Sensor

HEAT

SOURCE

Return

Sensor

Input from

Heat Source

Pressure

Relief

Exp

Tank

Output to

System

Supply

Sensor

X - Pump Block (XPB), Multiple Zones - Circulators

Outdoor

Sensor

Pressure

Relief

Exp

Tank

Return

Sensor

Input from

Heat Source

Output to

System

Supply

Sensor

X - Pump Block (XPB), Multiple Temperature System – Circulators

Outdoor

Sensor

M

Return

Sensor

Input from

Heat Source

Pressure

Relief

Exp

Tank

Output to

System

Supply

Sensor

Relief

Exp

Tan k

System

System

Supply

Sensor

System

Return

Sensor

X - Pump Block (XPB), Primary / Secondary Piping

Pressure

Return

Sensor

Input from

Heat Source

Output to

X - Pump Block (XPB), Setpoint Temp with delta T

System

Supply

Sensor

System

Return

Sensor

Return

Sensor

HEAT

SOURCE

Input from

Heat Source

Pressure

Relief

Exp

Tan k

Output to

System

X - Pump Block (XPB), delta T Snow Melt System

Outdoor

Sensor

HEAT

SOURCE

Return

Sensor

Input from

Heat Source

Pressure

Relief

Exp

Tank

Output to

System

Supply

Sensor

M

Radiant Manifold - Return

Radiant Manifold - Supply

M

M

X - Pump Block (XPB), Multiple Temperature System – Circulators and Zone Valves

Typical Installation

Tempering

Valve

Domestic

Hot

Supply

MIX

Hot

C

H

WATER

HEATER

Cold

Cold

Supply

Check

Valve

2 of 16

X-PUMP

BLOCK

X - Pump Block (XPB), Multiple Zones - Zone Valves

Relief

Air

Separator

Valve

Return

Exp.

Tank

RADIANT

SYSTEM

Supply

Page 3

Getting Ready

Ensure that the contents of this package are complete. If any of the contents are missing or damaged, please contact your local Taco

sales representative for assistance.

Contents should include the following:

• One X – Pump Block, preassembled

unit consists of the following parts:

- One Variable Speed Mixing Control (VSMC)

• One Taco Outdoor Sensor

• Two Taco Strap-on Sensors

• One Instruction Sheet

- One Green Enclosure

- Two Casings with Circulators Attached

- One Heat Exchanger

- One Power Cord (6 feet)

Application

The Taco X – Pump Block (XPB) is a complete mixing system with an attached heat exchanger for system isolation. Integral to the unit

is a variable speed heat source circulator, constant speed system circulator, heat exchanger, and the electronics to drive it all. With

only four piping connections needed, the XPB greatly reduces the time and space required for installation. The heat exchanger

provides complete isolation between fluid on the heat source side and the fluid on the system side. The XPB can be set up to operate

as an outdoor reset control, a setpoint control or a delta T limiting control, creating flexibility never seen before in a single unit.

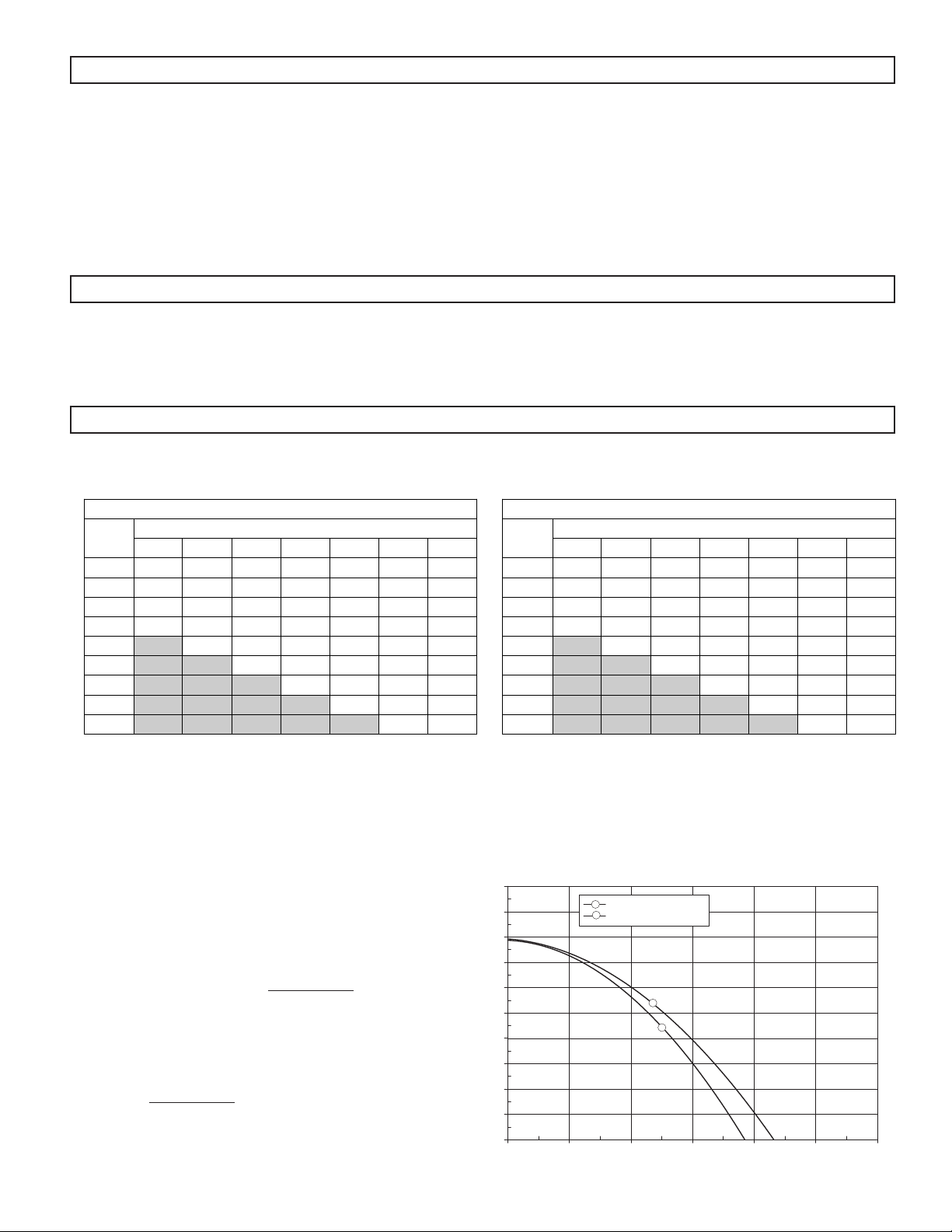

Design Procedure

1. Verify BTU capacity of X-Pump Block using charts below.

BTU/H Capacity @ 10 degree Delta T Across System

X-Pump BTU Capacities*

System

Temp.

120/100 130/110 140/120 150/130 160/140 170/150 180/160

70/80 29,900 29,900 29,900 29,900 29,900 29,900 29,900

80/90 29,800 29,800 29,800 29,800 29,800 29,800 29,800

190/100 29,800 29,800 29,800 29,800 29,800 29,800 29,800

100/110 4,500 29,700 29,700 29,700 29,700 29,700 29,700

110/120 5,500 29,600 29,600 29,600 29,600 29,600

120/130 6,000 29,600 29,600 29,600 29,600

130/140 6,500 29,500 29,500 29,500

140/150 7,000 29,400 29,400

150/160 7,500 29,300

* Assuming 6 gpm Flow on Radiant Side of XPB

Heat Source Temperature Range

BTU/H Capacity @ 20 degree Delta T Across System

X-Pump BTU Capacities*

System

Temp.

120/100 130/110 140/120 150/130 160/140 170/150 180/160

60/80 59,900 59,900 59,900 59,900 59,900 59,900 59,900

70/90 59,800 59,800 59,800 59,800 59,800 59,800 59,800

180/100 27,000 59,800 59,800 59,800 59,800 59,800 59,800

190/110 4,500 29,000 59,700 59,700 59,700 59,700 59,700

100/120 5,500 31,500 59,600 59,600 59,600 59,600

110/130 6,000 33,500 59,600 59,600 59,600

120/140 6,500 35,500 59,500 59,500

130/150 7,000 37,600 59,400

140/160 7,500 39,700

Heat Source Temperature Range

2. Using the pump curve located below, ensure that the System Pump of the X – Pump Block will provide adequate head and flow for

the system in which it is to be installed. If flow rate is unknown, then use Equation No. 1 below to determine required flow.

3. Using the pump curve located below, ensure that the Heat Source Pump of the X – Pump Block will provide adequate head and flow

for the system in which it is to be installed. If flow rate is unknown, then use Equation No. 1 below to determine required flow.

4. Use Equation No. 1 to verify flow rates. Example: 25000 BTU

radiant load with supply temperature of 100° and return

temperature of 90°.

EQUATION NO. 1:

Flow Rate (GPM) =

BTU's

500 x delta T

EXAMPLE:

25,000

500 (100 - 90)

= 5 GPM

20

18

16

14

12

10

HEAD (ft)

8

6

4

2

0

024681012

PUMP CURVES

1

SYSTEM SIDE

2

HEAT SOURCE SIDE

1

2

FLOW (gpm)

3 of 16

Page 4

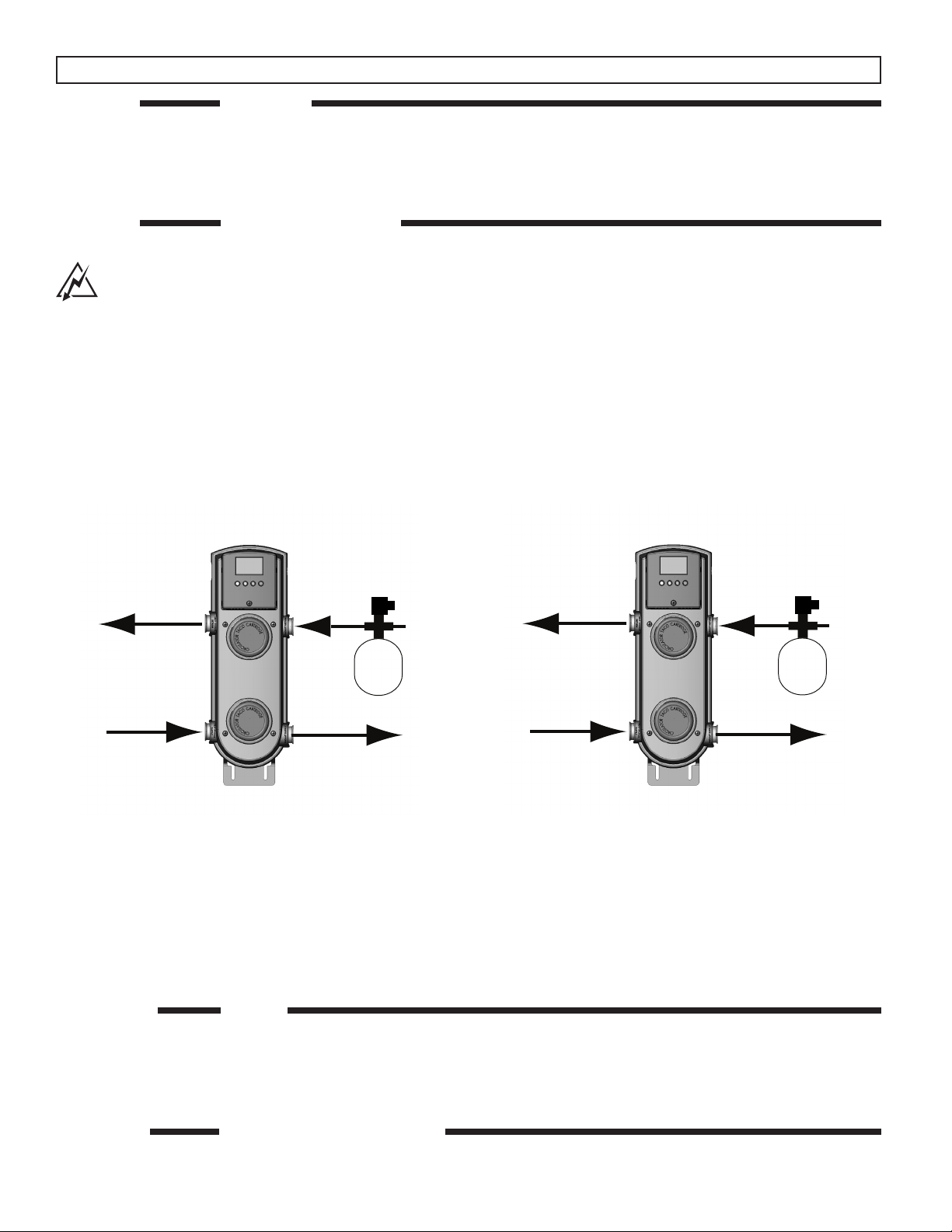

Installation of the X – Pump Block

STEP ONE MOUNTING

1. Mounting position – The X – Pump Block must be mounted in the vertical position with the Variable Speed Mixing Control (VSMC)

located at the top of the X – Pump Block.

2. Mount the X – Pump Block, using the attached brackets, to a solid surface capable of supporting 23.5 pounds.

3. Using four suitable screws or bolts (1⁄4”), fasten the X – Pump Block to the selected location. Ensure that at least two of the mounting

screws are attached to a wall stud or similar surface.

STEP TWO PIPING CONNECTIONS

Warning! Must Install a pressure relief valve and expansion tank on secondary side in addition to units

installed on primary side of system. Note! Heat should never be applied to X – Pump Block connections

or damage to housing and/or electronics may result.

1. Using proper piping practices, connect the supply to the radiant heating system to the Radiant Supply (bottom right hand connection) as indicated on the plastic cover of the X – Pump Block. Ensure that a proper isolation valve is installed.

2. Using proper piping practices, connect the return from the radiant heating system to the Radiant Return (top right hand connection)

as indicated on the plastic cover of the X – Pump Block. Ensure that a proper isolation valve is installed.

3. Using proper piping practices, connect the supply from the heat source to the Heat Source Supply (bottom left hand connection) as

indicated on the plastic cover of the X – Pump Block. Ensure that a proper isolation valve is installed.

4. Using proper piping practices, connect the return to the heat source to the Heat Source Return (top left hand connection) as

indicated on the plastic cover of the X – Pump Block. Ensure that a proper isolation valve is installed.

5. When using a non-condensing heat source as heat source, connect the Heat Source Supply and Heat Source Return lines of the

X – Pump Block to the heat source loop using standard Primary Secondary piping practices.

Pressure

Relief

Exp

Tank

Heat Source

Return

Variable

Flow

Heat Source

Supply

Radiant

Return

Constant

Flow

Radiant

Supply

Pressure

Relief

Exp

Tank

Heat Source

Return

Constant

Heat Source

Supply

Flow

Snow

Melt

Return

Variable

Flow

Snow Melt

Supply

Refer to Page 2 for More Piping Diagrams

When using the X - Pump Block on snow melting systems, it is recommended to switch the system pump motor with the variable

speed pump motor to protect the brazed plate heat exchanger from freezing up.

Follow the instructions for cartridge replacement (page 14) to disassemble the X – Pump.

Unbolt the fixed speed system pump motor (lower) and switch it with the heat source variable speed pump motor (upper).

This now insures constant flow on the heat source side of heat exchanger by the fixed speed pump to minimize the chance of freeze

up. The snow melt system pump is now variable speed and both the System Supply Sensor and System Return Sensor must be

installed and in Setpoint with delta T max mode.

STEP THREE FILLING

1. Fill both system and heat source with tap water – The system must be filled before operating the circulator. The bearings are water

lubricated and should not be allowed to operate dry. Filling the system will result in immediate lubrication of the bearings. It is always

good practice to flush a new system of foreign matter before starting the circulator.

2. Circulator operation – Operate the circulators for 5 minutes immediately after filling system to purge remaining air from the bearing

chamber. This is especially important when installing the circulator during the off-season.

STEP FOUR ELECTRICAL CONNECTIONS

1. Observe all applicable codes when connecting to power supply. The motors are impedance protected, and do not require overload

protection. The pumps cannot run backwards.

4 of 16

Page 5

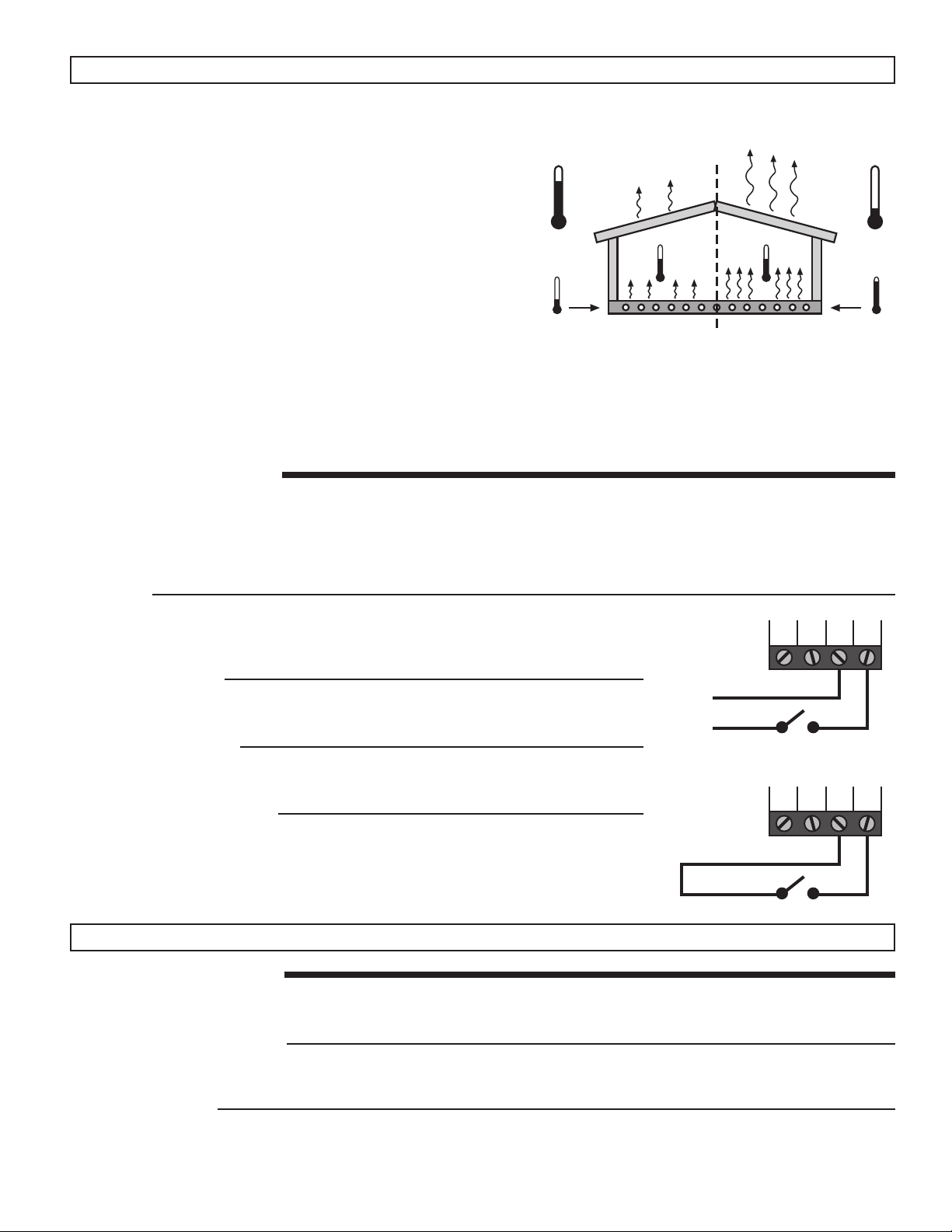

Outdoor Reset Mode of Operation

In order to properly control a hot water heating system, the amount of heat

supplied to the building must equal the amount of heat lost by the building.

The amount of heat delivered into a building depends on the temperature of

the water in the heating unit and the surface area of the heating unit. Heating units with a small surface area, such as baseboard radiators, require a

higher water temperature than heating units with a larger surface area such

as radiant floors.

The amount of heat lost from a building depends on the outdoor temperature. As the outdoor temperature becomes colder, the amount of heat a

building loses increases.

The operation of a hot water heating system can generally be improved by

adjusting the supply water temperature to the system as the outdoor temperature changes. Using this approach, the heat input to the building can be

matched to the heat lost from the building. This method of controlling the

supply water temperature to a heating system greatly improves the comfort

of the system and is known as Outdoor Reset.

When a Taco Outdoor Sensor is connected to the Variable Speed Mixing Control (VSMC), the VSMC provides outdoor reset. When

operating in the outdoor reset mode of operation, the installer must set the Outdoor Design Temperature and the Design Supply Temperature in order to establish the relationship between the outdoor temperature and the supply water temperature. This is known as

setting the Heating Curve.

SEQUENCE OF OPERATION

When the VSMC receives a Demand and it is not in warm weather shut down (WWSD), the VSMC turns on the system pump and

calculates a Mixing Target temperature. The variable speed heat source side pump is then operated to maintain the Mixing Target

temperature at the mixing supply sensor.

The heat source contact operates as described in the Heat Source Operation section. The VSMC also provides heat source protection

as described in the Heat Source Operation section.

DEMAND

The VSMC requires a demand signal before it will begin operation. The VSMC can use

either a powered or an unpowered demand signal. Once a demand signal is received, the

VSMC displays the demand icon in the display and operates as described above.

Powered Demand

The VSMC recognizes a Powered Demand Signal when 24 V (ac) is applied across the

Com and Heat Dem terminals.

Unpowered Demand

The VSMC recognizes an Unpowered Demand signal when a switch is closed between

the Com and Heat Dem terminals (relay type thermostat or end switch on zone control).

SYSTEM PUMP OPERATION

The VSMC has an internal system pump contact. This contact turns on when the VSMC

has a mixing demand and is not in a WWSD. The integrated system pump as well as an

external heat source pump may be controlled by this relay. By providing proper flow in the

heat source loop, the heat source temperature can be accurately controlled based on the

mixing load.

Powered

Demand

C

24 V (ac)

R

Unpowered

Demand

Boil Out

Switch

Boil Out

Switch

Com Heat

Com Heat

Outdoor Reset Settings

HEATING CURVE SETTINGS

In order to establish the heating curve, the VSMC must be given two points to work with. The first point is the Outdoor Reset Starting

Point and the second point is the Design Condition.

Outdoor Reset Starting Point

The Outdoor Reset Starting Point for the VSMC is fixed at 72°F. This means that when the outdoor temperature is 72°F, the VSMC

calculates a required supply water temperature (Mix Target) of 72°F.

Dem

Dem

Design Conditions

The design conditions represent the supply water temperature required to satisfy the heating system on the typical coldest day of

the year. These are the conditions that are used when calculating the size of the heating equipment needed to heat the building.

The Design Conditions are made up of an outdoor temperature (Outdoor Design) and a supply water temperature (Design Supply).

5 of 16

Page 6

Outdoor Design

The Outdoor Design temperature is the average coldest day of the

year for the area in which the building is located.

Outdoor Reset

Design Supply

The Design Supply temperature is the supply water temperature that

is required to heat the building when the outdoor air temperature is

as cold as the Outdoor Design temperature.

Mix Maximum

Mix

Design

Maximum System Supply

Some systems, such as hydronic radiant floor heating, may require the

maximum supply water temperature to be limited in order to protect

WWSD

certain system components from high temperatures. The VSMC has a

Maximum Supply setting that can be used to limit the maximum temperature that the control is allowed to use for a Mixing Target (MIX TRG)

temperature.

Outdoor

Design

Minimum System Supply

Some applications, such as floor warming, may require the minimum

supply water temperature to be limited in order to provide a certain

level of occupant comfort. The VSMC has a Minimum Supply setting

that can be used to limit the minimum temperature that the control is

allowed to use for a Mixing Target (MIX TRG) temperature. This mini-

Starting

Point

70 60 50 40 30 20 10 0 -10 -20

Outdoor Temperature (F)

mum applies as long as the VSMC has a demand and is not in WWSD.

Warm Weather Shut Down (WWSD)

When the outdoor temperature is warmer than the WWSD setting, the VSMC turns off the heat source and the system pump. If a

demand is received while the VSMC is in a WWSD, the VSMC indicates that the demand has been received by displaying the

Demand pointer however, the MIX TRG remains as “- - -”. The VSMC has a freeze protection feature that does not allow the supply

water temperature to drop below 35°F (2°C) as long as there is a mixing demand signal.

150

140

130

120

110

100

90

Supply Temperature (F)

80

70

60

Setpoint and Delta T Mode of Operation

In certain applications, it is desirable to maintain a fixed supply water temperature. This type of application is a setpoint application.

Examples of setpoint applications include heat pump loops, reheat coils and floor warming.

In specialized applications, such as snow melting, it is desirable to limit the rate of temperature increase in the system from the system‘s

starting temperature to its operating setpoint. This is desired in order to prevent thermal shock of the system. This type of application is

a Delta T application.

If the VSMC is to operate as a setpoint control, the Outdoor Design temperature must be set to OFF and the Mixing Target temperature

must be set to the desired temperature.

If the VSMC is to operate as a Delta T control, a mixing return sensor must be installed, the Outdoor Design temperature must be set to

OFF and both the Delta T Max setting and the Mixing Target temperature must be set to the desired temperature.

In both of these applications, the outdoor sensor is not to be installed.

SEQUENCE OF OPERATION

When the VSMC receives a Demand, the system pump is turned on.

If the Delta T Max setting is set to OFF, the variable speed injection pump is operated to maintain the mixing supply sensor at the

Mixing Target temperature set by the installer.

If the Delta T Max setting is not set to off, the variable speed heat source pump is operated to maintain the mixing supply sensor at

either the Mixing Return temperature plus the Delta T Max setting or the Mixing Target temperature set by the installer whichever is

lower. The heat source contact operates as described in the Heat Source Operation section. The VSMC also provides heat source

protection as described in the Heat Source Operation section.

DEMAND

The VSMC requires a demand signal before it will begin operation. The VSMC can use

either a powered or an unpowered demand signal. Once a demand signal is received, the

VSMC displays the demand pointer in the display and operates as described above.

Powered

Demand

Boil Out

Com Heat

Dem

Powered Demand

The VSMC recognizes a Powered Demand Signal when 24 V (ac) is applied across the

Com and Heat Dem terminals.

6 of 16

C

24 V (ac)

R

Switch

Page 7

Unpowered Demand

The VSMC recognizes an Unpowered Demand signal when a switch is closed between

Unpowered

Demand

Boil Out

Com Heat

the Com and Heat Dem terminals (relay type thermostat or end switch on zone control).

SYSTEM PUMP OPERATION

The VSMC has an internal system pump contact. This contact turns on when the VSMC

has a mixing demand. The system pump as well as an external heat source pump may be

controlled by this relay. By providing proper flow in the heat source loop, the heat source

Switch

temperature can be accurately controlled based on the mixing load.

Setpoint and Delta T Settings

Outdoor Design

The Outdoor Design temperature must be set to OFF.

Mixing Target

The Mixing Target temperature is set to the desired operating temperature of the system.

Delta T Max

The Delta T Max temperature is set to the maximum temperature difference that is desired between the system return temperature

and the system supply temperature. In order to adjust this setting, a system return sensor must be connected to the control.

Dem

Setpoint

Mix Supply = Mix Target

Time

150

140

130

120

110

100

90

Supply Temperature (F)

80

70

60

Mix Target

Start

Delta T Maximum

Mix Supply

Mix Return

Maximum Delta T

Time

120

110

100

90

80

70

60

Supply Temperature (F)

50

40

30F

Heat Source Operation

The VSMC operates the heat source in two basic modes of operation. The VSMC can either “Control” the heat source or “Enable” the

heat source. The mode of operation is determined by the Heat Source Sensor location. The heat source sensor location is determined

using the DIP switch on the back of the circuit board. If the DIP switch is set to ON, the heat source sensor is to be located on the heat

source supply. If the DIP switch is set to OFF, the heat source sensor is to be located on the heat source return.

• If the DIP switch is set to On, the VSMC will “Control“ the heat source (sensor on supply).

• If the DIP switch is set to Off, the VSMC will “Enable” the heat source (sensor on return).

• If the Heat Source Sensor has not been installed, the VSMC will “Enable” the heat source.

Variable Speed Mixing Control

1

HEAT SOURCE CONTROL

When the VSMC controls the heat source, the VSMC opens and closes the heat source contact in order to control the temperature of

the heat source supply water temperature. When the VSMC is controlling the heat source temperature, the VSMC will determine the

heat source supply water temperature that is required to satisfy the demands of the system. The VSMC will also determine a differential that is sufficient to minimize short cycling of the heat source. The VSMC will then cycle the heat source using these parameters.

Differential

An on / off heat source must be operated with a differential in order to prevent short cycling. When the supply water temperature

drops 1/2 of the differential below the required heat source supply temperature, the heat source is turned on. The heat source is then

7 of 16

ONOFF

Page 8

kept on until the supply water temperature rises 1/2 of the differential above the required heat source supply temperature. If the

differential is too wide, there can be large supply water temperature swings; however, if the differential is too narrow, the heat source

short cycles and operates inefficiently. This control automatically calculates the heat source differential in order to achieve an

appropriate balance between temperature swings and heat source efficiency. This also permits the control to adapt to changing

loads and conditions. The VSMC only operates the heat source once the output of the injection circulator exceeds 10% of flow.

HEAT SOURCE ENABLE

When the VSMC “Enables” the heat source, the VSMC opens and closes the heat source contact based on the output of the variable

speed pump. The actual temperature and cycling of the heat source is then determined by other controls or the aquastats on the heat

source itself.

When operating in the heat source enable mode, the heat source contact turns on once the variable speed output exceeds 25%. The

heat source contact shuts off if the output of the variable speed drops below 5% for more than three minutes or if the demand is

removed from the VSMC.

HEAT SOURCE PROTECTION (HEAT SOURCE MINIMUM)

Cool water is often returned to the heat source from low temperature radiant floor heating systems or snow melting systems. This cool

heat source return water may cause the heat source to operate at such a low temperature that the flue gases condensate. Alternatively, when the heat source surfaces are hot due to previous loads such as domestic hot water generation, the large temperature

difference (Delta T) between the heat source and its return water can cause the heat source to become thermally shocked. Proper

protection of the heat source under these circumstances is required.

When a heat source sensor is connected to the control, the VSMC is capable of providing heat source protection. When providing heat

source protection, the VSMC limits the output of the variable speed pump in order to reduce the amount of cool water being returned

to the heat source. This allows the heat source temperature to increase to a point that avoids flue gas condensation.

Heat Source Protection with Heat Source Enable

When the Heat Source Sensor is set to the “Return” setting the control begins to back off the variable speed pump when the heat

source temperature drops below the Heat Source Minimum Setting.

Heat Source Protection with Heat Source Control

When the Heat Source Sensor is set to the “Supply” setting the control begins to back off the variable speed pump when the heat

source temperature drops 1/2 of the Differential below the Heat Source Minimum Setting.

Note: If a heat source sensor is not installed, the VSMC cannot provide heat source protection.

Set Up of Variable Speed Mixing Control

CAUTION

Improper installation and operation of this product could result in damage to the equipment and possibly personal injury. It is your

responsibility to ensure that this product is installed in a safe manner according to all of the applicable codes, standards and instructions. The electronic control contained in this product is not intended as a primary limit control. Removal of the PC Board from its

enclosure can result in damage to the control and possibly even personal injury. Refer to qualified personnel for servicing.

STEP ONE - REMOVING THE VARIABLE SPEED MIXING CONTROL FROM THE X – PUMP BLOCK

• Remove the screw from the front of the control.

• Grasp the front of the control and remove it from the green plastic enclosure surrounding the injection mixing block.

• Wiring to the control is connected to the back of the circuit board using either the indicated spade connectors, molex connectors or

the snap on terminal plugs. These may need to be disconnected to fully remove the control.

8 of 16

Page 9

STEP TWO - INSTALLING THE SENSORS

Outdoor Sensor

Note: The temperature sensor is built into the plastic enclosure.

If the X – Pump Block is to be used in the outdoor reset mode, the Outdoor Sensor must be

installed. If the X – Pump Block is to be used in either the setpoint or a delta T mode, the

Outdoor sensor is not required and does not need to be installed. (See pages 5 to 7 for a

complete description of the available modes.)

• Remove the screw from the center of the sensor and pull the front cover off of the sensor.

• The outdoor sensor can either be mounted directly to an outside wall or onto a standard

electrical box. Wiring can enter the sensor either through the bottom or the back of the plastic

enclosure.

• The sensor should be mounted on a wall which best represents the heat load on the building

(i.e. a north facing wall for most buildings and a south facing wall for buildings with a large south

facing glass area). The sensor should not be installed near heat sources such as exhaust

vents or window openings.

• The sensor should be installed at an elevation above the ground that will prevent accidental

damage or tampering and above snow line.

• Ensure that the sensor is installed in a sheltered location out of direct sunlight and rain.

• Connect a two conductor wire to the terminal block in the Outdoor Sensor and run the wires

from the Outdoor Sensor back to the Radiant Mixing Control’s location.

Installing the System and Heat Source Sensors

Note: These sensors are designed to be mounted on a pipe or in a temperature well.

• These sensors can be strapped directly to the pipe using the cable tie provided with the

sensors. Insulation should be installed around the sensors to reduce the effect of air currents

on the temperature measurement. Care should be taken not to over-tighten the cable tie as

this can cause damage to the sensor.

• The System Supply Sensor is to be installed on the System Supply pipe. This sensor is

required at all times.

• If a Heat Source Sensor is used, install the heat source sensor on either the heat source

supply or the heat source return. Ensure that the DIP switch on the back of the circuit

board of the VSMC is set to ON if the sensor is installed on the heat source supply and

set to OFF if the sensor is installed on the heat source return. If heat source control and

heat source protection are not required in the application, the heat source sensor does not

need to be installed.

• If a System Return Sensor is to be used, install the sensor on the system return pipe. This

sensor is only required if the VSMC is operating in the Delta T mode.

STEP THREE - WIRING THE VSMC

• Before wiring the control, ensure that power to all circuits is off.

• Ensure that all wires are stripped to a minimum of 3⁄8" (9 mm) in order to ensure proper connection to the low voltage terminals.

• Provide a separate circuit with a minimum 15 A capacity in order to insure proper operation.

Wiring Power to the VSMC

Using the supplied line cord, connect the white wire with the 1⁄4 inch female

spade connector to the 1⁄4 inch male spade connector labelled “N” on the

back of the VSMC circuit board. Connect the black wire with the 1⁄4 inch

female spade connector to the 1⁄4 inch male spade connector labelled “H” on

the back of the VSMC circuit board. Connect the green wire to the ground

screw located on the casting of the X – Pump Block.

Wiring to the X – Pump Block

Wiring to the Variable Speed Pump

Connect the variable speed pump’s three pin molex connector from the

X – Pump Block to the matching three pin molex connector labelled “Var”

on the back of the VSMC circuit board.

Wiring the X – Pump Block System Pump

Connect the system pump’s four pin molex connector from the X – Pump

Block to the matching four pin molex connector labelled “Sys” on the back

of the VSMC circuit board.

967-01

Use copper

conductors only

Com Sup Sys

Ret

Power: 120 V +/- 10%

R

50/60 Hz, 750 VA

Var. Speed: 120 V

CUS

(ac) 1A

158033

BOILER

Com Boil Out Com Heat

Pmp Relay: 120 V

(ac) 5 A, 1/6 hp

Dem

Injection Mixing

Meets Class B

Canadian ICES

FCC Part 15

Sys

T1A 250V

Pmp

Var

ON

OFF

1

2

3

4

5

Man

H

N

9 of 16

Page 10

Wiring the Sensors

Do not apply power to the sensors or the sensor terminals as this will damage either the sensors or the control.

Begin by removing the eight (8) pin plug-in terminal block from the VSMC’s circuit board. To do

this, pull the terminal block directly away from the circuit board.

Ret

ComCom Sup

System Supply Sensor (Required)

Connect the two wires from the System Supply Sensor directly to the “Com” and “Sup” terminals of the terminal block. The System Supply Sensor is used to measure the supply temperature being delivered to the system.

Ret

ComCom Sup

System Return Sensor (Delta T Limiting Mode)

Connect the two wires from the System Return Sensor directly to the “Com” and “Sys Ret”

terminals of the terminal block. The System Return Sensor is used to measure the return

temperature from the system.

Ret

ComCom Sup

Heat Source Sensor (Optional)

Connect the two wires from the Heat Source Sensor directly to the “Com” and “Boil” terminals

of the terminal block. The Heat Source Sensor is used to measure the heat source temperature.

Boil OutSys

Boil OutSys

Boil OutSys

Com Heat

Dem

Com Heat

Dem

Com Heat

Dem

Outdoor Sensor (Reset Mode)

Connect the two wires from the Outdoor Sensor directly to the “Com” and “Out” terminals of

Ret

Boil OutSys

ComCom Sup

Com Heat

Dem

the terminal block. The outdoor sensor is used to measure the outdoor air temperature.

Wiring the External Heat Source Pump (Optional)

Using a 3⁄16 inch female spade connector, connect the hot side of the heat source pump circuit to the male spade connector labelled

“Pmp” located on the back of the VSMC circuit board. Connect the neutral side of the heat source pump circuit to the neutral (N) side

of the VSMC’s input power supply. When using this option the line cord should be removed and the VSMC hard wired.

Wiring the Heat Demand (Required)

Ret

Boil OutSys

ComCom Sup

Com Heat

Dem

The Heat Demand circuit can be wired using either a powered signal or an unpowered switch

closure.

Powered Heat Demand

Powered Demand

If a powered demand is being used, connect the switched side of the 24 V (ac) demand circuit

to the “Heat Dem” terminal of the terminal block. Connect the second side of the

24 V (ac) demand circuit to the “Com” terminal of the terminal block.

Unpowered Demand

If an unpowered demand is being used, connect one side of the demand switch to the “Heat

Dem” terminal of the terminal block. Connect the second side of the demand switch to the

C

24 V (ac)

R

Unpowered Heat Demand

Ret

Switch

Boil OutSys

ComCom Sup

Com Heat

Dem

“Com” of the terminal block (relay type thermostat or end switch on zone control).

Wiring the Heat Source

Begin by removing the two (2) pin plug-in terminal block from the VSMC’s circuit board. To do

this, pull the terminal block directly away from the circuit board.

Switch

The Heat Source Relay is a switch that is to be used in the heat source circuit. There is no power

available on these terminals from the VSMC. Connect the Heat Source relay in series with the

Boiler

control circuit of the heat source.

STEP FOUR - RECONNECTING THE TERMINAL BLOCKS

Insert the eight (8) pin plug-in terminal block into the eight (8) pin terminal header on the VSMC circuit board. Press firmly until it snaps

into place.

Insert the two (2) pin plug-in terminal block into the two (2) pin terminal header on the VSMC circuit board. Press firmly until it snaps

into place.

STEP FIVE - MOUNTING THE VSMC

• Begin by pushing all excess wiring back into the X – Pump Block.

• Place the VSMC into the X – Pump Block’s plastic enclosure.

• Insert the screw into the hole located on the face of the VSMC and tighten the screw to fasten the VSMC to the X – Pump Block

Enclosure. Do not overtighten.

STEP SIX - POWERING THE VSMC

Apply power to the VSMC circuit by plugging in the line cord.

10 of 16

Page 11

Display Operation

POWER UP

On power up, the control displays all segments for 2 seconds followed by the control version

number.

The control then automatically goes to the operating mode and displays either the outdoor

temperature or the mix supply temperature.

VIEW MENU

To advance to the next available View Item, press and release the ITEM button on the face of the control.

VIEW

ADJUST

TIME

SCHD

OUT

INDR

RET

DIFFMASS

DSGN

TERM

MINMAX

STG

MOTR UNOCC

XCHG

Opn WWSD

%

1

Cls

MIX

BOIL SUP

SETP TARG

ROOM

T

MoTuWeThFrSaSu

F DLY

BST

123

%

DHW 12

2

12

PURG

DHW

MODE

FC

min

hr %

AMPM

DEM

!

Outdoor Temperature

The outdoor temperature is displayed when the OUTDR element is turned on. This is the

current temperature at the outdoor sensor. The outdoor temperature is only displayed if

an outdoor sensor is installed and the Outdoor Design temperature is not turned off.

Mixing Supply Temperature

The mixing supply temperature is displayed when the MIX SUP elements are turned on.

This is the current temperature at the mixing supply sensor.

Mixing Return Temperature

The mixing return temperature is displayed when the MIX RET elements are turned on.

This is the current temperature at the mixing return sensor. The mixing return temperature

is only displayed if the Outdoor Design temperature is turned OFF and a mixing return

sensor is installed.

Mixing Target Temperature

The mixing target temperature is displayed when the MIX TARG elements are turned on.

This is the temperature the VSMC is currently trying to maintain at the supply sensor.

If “- - -” is displayed, the VSMC is either in WWSD or a demand for heat is not present.

OUT

VIEW

VIEW

VIEW

VIEW

F

%

1

%

1

RET

%

1

%

1

DEM

SUP

MIX

F

DEM

MIX

F

DEM

MIX

TARG

F

DEM

Heat Source Temperature

The heat source temperature is displayed when the BOIL element is turned on. This is the

VIEW

BOIL

F

current temperature at the heat source sensor. The heat source temperature is only displayed if a heat source sensor is installed.

%

1

DEM

ADJUST MENU

To switch between the View menu and the Adjust menu, press and release the MENU button on the face of the control. To advance to

the next available Adjust Item, press and release the ITEM button on the face of the control.

ADJUST

Mixing Target Temperature

The Mixing Target Temperature sets the desired supply temperature when operating in

the setpoint mode. This item is only available if the Outdoor Design setting is set to OFF.

11 of 16

MIX

TARG

F

Page 12

Delta T Maximum

The Delta T Maximum sets the maximum temperature difference between the mixing

return sensor and the mixing supply sensor. This item is only available if Outdoor Design

setting is set to OFF. If a mixing return sensor is not installed, set this item to OFF.

ADJUST

MAX

T

F

Outdoor Design Temperature

The Outdoor Design Temperature is the outdoor temperature used in the heat loss calculation. If the VSMC is used in the outdoor reset mode, this item is set to the typical coldest

outdoor temperature. If the VSMC is used in the setpoint mode, this item is set to OFF.

Mixing Design Temperature

The mixing design temperature is the supply temperature used in the heat loss calculation. This is the supply temperature that is required to heat the building when the outdoor

temperature is as cold as the outdoor design temperature. This item is only available if the

Outdoor Design setting is not set to OFF.

Mixing Maximum Temperature

The mixing maximum temperature is the highest temperature that the control is allowed to

use as a mixing target temperature. This item is only available if the outdoor design setting is not set to OFF.

Mixing Minimum Temperature

The mixing minimum temperature is the lowest temperature that the control is allowed to

use as a mixing target temperature. This item is only available if the outdoor design setting is not set to OFF.

OUT

ADJUST

DSGN

ADJUST

DSGN

ADJUST

ADJUST

MIN

F

MIX

F

MIX

F

MAX

MIX

Heat Source Minimum Temperature

The heat source minimum temperature item should be set to the lowest water temperature at which the heat source can operate without causing the heat source flue gases to

condense. Consult the heat source manufacturer for recommended minimum heat source

supply temperatures. This item is only available if a heat source sensor is connected to

the control.

Warm Weather Shut Down (WWSD)

The warm weather shut down is the outdoor temperature at which the system is shut

down. This item is only available if the outdoor design temperature is not set to OFF.

Units

The units of temperature in which all of the View and Adjust items are viewed in.

The control automatically goes back to the view menu when the buttons are left alone for 20 seconds

All settings will be saved even during power down of the control

ADJUST

MIN

ADJUST

ADJUST

BOIL

F

F

WWSD

F

12 of 16

Page 13

Trouble Shooting

As in any troubleshooting procedure, it is important to isolate the problem as much as possible. By using the Error Messages located on

page 14, the trouble shooting process can be greatly simplified. When an error message is displayed on the VSMC, refer to the error

messages on page 14 to identify the cause of the error and use standard testing procedures to confirm the fault. If you suspect an

external wiring fault, return to step three and carefully check all external wiring connections.

Once the fault has been corrected, press any button on the face of the control to clear the error message.

TEST ROUTINE

The main control functions of the VSMC can be tested by pressing and holding the UP button for more than three (3) seconds.

Continue to hold the UP button and the VSMC will test the outputs in the following sequence.

Step One

The variable speed output is increased from 0% to 100% over 10 seconds.

Step Two

The variable speed output is decreased from 100% to 0% over 10 seconds.

Step Three

The System Pump is turned on for 10 seconds.

Step Four

The Boiler Contact is turned on. After 10 seconds, the Boiler Contact and the

System Pump contact are turned off. The VSMC continues normal operation.

MANUAL OVERRIDE

In the event that the VSMC fails to operate, a manual operation switch is located

on the VSMC’s circuit board. When the manual operation switch is set to Man, the

variable speed pump and the system pump outputs are turned on. This operation

continues until the manual switch is returned to its original position.

967-01

CUS

BOILER

158033

Injection Mixing

Power: 120 V +/- 10%

R

50/60 Hz, 750 VA

Var. Speed: 120 V

(ac) 1A

Pmp Relay: 120 V

(ac) 5 A, 1/6 hp

Meets Class B

Canadian ICES

FCC Part 15

T1A 250V

ON

OFF

1

2

3

4

5

FUSE REPLACEMENT

The Variable Speed output of the VSMC is fuse protected. This fuse is located on

the circuit board on the back of the VSMC. This is a field replaceable item.

Fuse rating: 1 A 1⁄12 hp, fuse T1 A 250 V

Use copper

conductors only

Com Sup Sys

Ret

ADJUSTMENT OF SETTINGS

If the outdoor temperature is cold and the rooms are cold, increase the MIX DSGN

setting by 5°F (3°C) per day.

TESTING THE SENSORS

Do not apply voltage to the sensor or to the sensor input of the control as this will result in damage

to either the sensor, the control, or both the sensor and the control.

A quality testing meter capable of measuring up to 2,000,000 ohms and a good quality digital

thermometer are required to test the sensors. If a digital thermometer is not available, place a

second sensor next to the original sensor and compare the readings.

Begin by measuring the temperature at the sensor location using the digital thermometer. Next,

measure the resistance of the sensor using the testing meter. Ensure that the sensor is disconnected from the control at the time of testing. Using the reference chart below, determine the

sensor’s temperature. Compare the sensor’s temperature to that measured by the digital thermometer. The two temperature readings should be close.

If the sensors temperature is too high, this can indicate that there is a partial short in the sensor

wiring. If the sensor’s temperature is too low, this can indicate that there is a loose connection or

break in the sensor wiring. Isolate and repair the problem. If the problem is isolated to the sensor,

replace the sensor.

Com Boil Out Com Heat

Dem

OHM

Sys

Var

Pmp

Man

H

N

Temperature Resistance

F

-30

-20

-10

0

10

20

C

-34

-29

-23

-18

-12

-7

Ohms

234,000

165,000

118,000

85,500

62,500

46,000

Temperature Resistance

F

30

40

50

60

70

80

C

-1

4

10

16

21

27

Ohms

34,500

26,000

20,000

15,500

12,000

9,300

13 of 16

Temperature Resistance

F

90

100

110

120

130

140

C

32

38

43

49

54

60

Ohms

7,300

5,800

4,700

3,800

3,100

2,500

Temperature Resistance

F

150

160

170

180

190

200

C

66

71

77

82

88

93

Ohms

2,000

1,700

1,400

1,200

1,000

800

Page 14

Error Messages

EEPROM Read Error

The control was unable to read the installers settings from its memory. The

control was forced to load the factory

defaults for all settings. The control will

stop operation until all of the settings in

the Adjust menu have been checked.

Outdoor Sensor Short Circuit

A short circuit has been detected in the

outdoor sensor. The control assumes

an outdoor temperature of 32°F (0°C)

and continues operation. To clear this

error message, correct the short circuit

and press any button on the control.

Outdoor Sensor Open Circuit

An open circuit has been detected in the

outdoor sensor. The control assumes an

outdoor temperature of 32°F (0°C) and

continues operation. To clear this error

message, correct the open circuit and

press any button on the control.

Mixing Supply Sensor Short Circuit

A short circuit has been detected in the

mixing supply sensor. The control continues to operate the injection pump at

a low speed (17 - 18%) as long as a

demand is present. To clear this error

message, correct the short circuit and

press any button on the control.

Mixing Supply Sensor Open Circuit

An open circuit has been detected in

the mixing supply sensor. The control

continues to operate the injection pump

at a low speed (17 - 18%) as long as a

demand is present. To clear this error

message, correct the open circuit and

press any button on the control.

VIEW

VIEW

OUT

VIEW

OUT

VIEW

VIEW

Mixing Return Sensor Short Circuit

A short circuit has been detected in the

mixing return sensor. If the Maximum

VIEW

MIX

RET

Delta T setting is set to OFF, the control continues operation. If the Maximum Delta T setting is not set to OFF,

!

!

the control stops operation until the

fault is corrected. To clear this error

message, correct the short circuit and

press any button on the control.

Mixing Return Sensor Open Circuit

An open circuit has been detected in

the mixing return sensor. If the Maximum Delta T setting is set to OFF, the

!

control continues operation. If the Maximum Delta T setting is not set to OFF,

VIEW

MIX

RET

!

the control stops operation until the

fault is corrected. To clear this error

message, correct the open circuit and

press any button on the control.

Heat Source Sensor Short Circuit

A short circuit has been detected in the

!

heat source sensor. The boiler contact

VIEW

BOIL

is operated as if a heat source sensor

is not installed. The control provides a

heat source enable and does not pro-

SUP

MIX

vide heat source protection. To clear this

!

error message, correct the short circuit

and press any button on the control.

!

Heat Source Sensor Open Circuit

An open circuit has been detected in the

VIEW

BOIL

heat source sensor. The boiler contact

is operated as if a heat source sensor is

not installed. The control provides a heat

MIX

SUP

source enable and does not provide heat

!

source protection. To clear this error

message, correct the open circuit and

press any button on the control. If the

sensor was deliberately removed, power

!

down the control.

Replacing Cartridge Assembly

1. Disconnect the electrical supply.

2. Reduce system pressure to 0 psi and allow system to return to room temperature. Isolate the XPB by closing the service valves or

draining the system.

3. Remove screw holding the VSMC module to X – Pump Block. Unplug both pump Molex plugs, power cord and heat source & sensor

terminal blocks from VSMC. Set VSMC control aside in safe place, away from water damage.

4. Remove 4 screws holding plastic housing to pump castings.

5. Remove the body bolts and swing motor assembly away from the body.

6. Pull cartridge out of the motor housing.

7. Install replacement cartridge, making sure that the cover plate is between the cartridge flange and motor.

8. Make sure the replacement cartridge corresponds to the full circulator product number. A complete parts list is available from your

local plumbing supply wholesaler.

9. Reassemble the circulator using the new gasket and bolts supplied.

10. Reassemble plastic housing and VSMC control in reverse order.

11. Follow the “Installation” procedure to start up the circulator.

14 of 16

Page 15

Technical Data

PERFORMANCE DATA

Flow Range ................................................... 0 - 7.5 GPM

Head Range .................................................. 0 - 15.5 Feet

Minimum Fluid Temperature .......................... 32°F (0°C)

Maximum Fluid Temperature ......................... 180°F (85°C)

Maximum Working Pressure ......................... 125 psi

Connections .................................................. 3/4" NPT

C US UL Mark

FOR INDOOR USE ONLY

MATERIALS OF CONSTRUCTION

Casing (body) ................................................ Bronze

Stator Housing .............................................. Steel

Cartridge ....................................................... Stainless Steel

Impeller ......................................................... Non-Metallic

Shaft .............................................................. Ceramic

O-Ring & Gaskets ......................................... EPDM

Standard Heat Exchanger ............................. Stainless Steel

Single Wall Design

Optional Heat Exchanger .............................. Stainless Steel

Double Wall Design

DIMENSIONS & WEIGHT

Model: XPB-1 Ship Weight: 26.5 lbs (12.0 kg)

ELECTRICAL DATA CHART

Volts ....................................................... 120

Hz ........................................................... 60

Ph ........................................................... 1

Amps ...................................................... 2

RPM ....................................................... 3250

HP .......................................................... 2 @ 1/25

Motor Type ............................................. Permanent Split

Capacitor Impedance

Protected

CONTROL ADJUSTMENT MENU

Mixing Setpoint Temperature ........................ 60° to 185° F

Maximum Temperature Difference

Between Mixing Supply and Return .............. 10° to 70° F, Off

Design Outdoor Air Temperature ................... -60° to 32° F, Off

Design Heating System Supply Water

Temperature .................................................. 70° to 185° F

Maximum Mixing Target Supply .................... 80° to 185° F

Minimum Mixing Target Supply

Fluid Temperature ......................................... 35° to 150° F, Off

Minimum Heat Source Target Supply

Water Temperature ....................................... 80° to 180° F, Off

5

⁄8"

9

5

3

⁄8"

1

8

⁄4"

8"

1

⁄8"

4

18

5"

31⁄2"

3

16

⁄8"

3

⁄8"

12

3

⁄8"

1

⁄8"

4

1

⁄8"

4

3

⁄4"

6

CAUTION:

1. The addition of petroleum based fluids or certain chemical additives to systems utilizing TACO equipment voids the

warranty.

2. Use supply wires suitable for 90°C – ATTENTION: Employer des fils d´alimentation adequats pour 90°C.

WARNING:

1. To avoid electrical shock, disconnect the power supply to the circulator and the main electrical unit.

2. Do not use in swimming pool or spa areas; pump has not been investigated for this application

3

2

⁄4"

1

2

⁄2"

1

15

⁄8"

5

⁄8"

15 of 16

Page 16

Cleaning

The exterior of the control can be cleaned using a damp cloth. Do not use any solvents. Moisten the cloth and wring out any excess

water before cleaning the control.

Technical Data

VSMC - Variable Speed Mixing Control

Control - Microprocessor PID control: This is not a safety (limit)

control

Ambient Conditions - Indoor use only, 32 to 185°F (0 to 85°C), <90% RH non-

condensing

Power Supply - 120 V (ac) +/- 10% 50/60 Hz 720 VA

Var. Pump - 120 V (ac) 1 A 1/12 hp, fuse T1 A 250 V

Sys / Pmp Relay - 120 V (ac) 5 A 1/4 hp, pilot duty 240 VA

Boiler Relay - 120 V (ac) 5 A 1/4 hp, pilot duty 240 VA

Demand - 24 V (ac) 0.1 VA or Dry contact

Sensors - NTC thermistor, 10 kohm @ 77°F (25°C +/- 0.2°C) B=3892

Included - Taco Outdoor Sensor and 2 Taco Strap-on Sensors

PATENT PENDING

VIEW

%

1

ITEM

MENU

X - PUMP BLOCK

MIX SUP

F

DEM

TM

XPB-1

U

L

R

US

C

The installer must ensure that this control and its wiring are isolated and/or shielded from strong sources of electromagnetic noise.

Conversely, this Class B digital apparatus complies with Part 15 of the FCC Rules and meets all requirements of the Canadian Interference-Causing Equipment Regulations. However, if this control does cause harmful interference to radio or television reception, which

can be determined by turning the control off and on, the user is encouraged to try to correct the interference by reorienting or relocating

the receiving antenna, relocating the receiver with respect to this control, and/or connecting the control to a different circuit from that to

which the receiver is connected.

Limited Warranty Statement

Taco, Inc. will repair or replace without charge (at the

company’s option) any product or part which is proven

defective under normal use within one (1) year from the

date of startup or one (1) year and six (6) months from the

date of shipment (whichever occurs first). Taco, Inc. will

repair or replace without charge (at the company’s option)

any Taco “00” Series circulator cartridge that is proven

defective under normal use within three (3) years from the

date of manufacture.

In order to obtain service under this warranty, it is the

responsibility of the purchaser to promptly notify the local

Taco stocking distributor or Taco in writing and promptly

deliver the subject product or part, delivery prepaid, to the

stocking distributor. For assistance on warranty returns, the

purchaser may either contact the local Taco stocking

distributor or Taco. If the subject product or part contains no

defect as covered in this warranty, the purchaser will be

billed for parts and labor charges in effect at time of factory

examination and repair.

Any Taco product or part not installed or operated in

conformity with Taco instructions or which has been subject

to misuse, misapplication, the addition of petroleum-based

fluids or certain chemical additives to the systems, or other

abuse, will not be covered by this warranty.

If in doubt as to whether a particular substance is suitable

for use with a Taco product or part, or for any application

restrictions, consult the applicable Taco instruction sheets

or contact Taco at (401-942-8000).

Taco reserves the right to provide replacement products and

parts which are substantially similar in design and

functionally equivalent to the defective product or part. Taco

reserves the right to make changes in details of design,

construction, or arrangement of materials of its products

without notification.

TACO OFFERS THIS WARRANTY IN LIEU OF ALL

OTHER EXPRESS WARRANTIES. ANY WARRANTY

IMPLIED BY LAW INCLUDING WARRANTIES OF

MERCHANTABILITY OR FITNESS IS IN EFFECT ONLY

FOR THE DURATION OF THE EXPRESS WARRANTY

SET FORTH IN THE FIRST PARAGRAPH ABOVE.

THE ABOVE WARRANTIES ARE IN LIEU OF ALL OTHER

WARRANTIES, EXPRESS OR STATUTORY, OR ANY

OTHER WARRANTY OBLIGATION ON THE PART OF

TACO.

TACO WILL NOT BE LIABLE FOR ANY SPECIAL,

INCIDENTAL, INDIRECT OR CONSEQUENTIAL

DAMAGES RESULTING FROM THE USE OF ITS

PRODUCTS OR ANY INCIDENTAL COSTS OF

REMOVING OR REPLACING DEFECTIVE PRODUCTS.

This warranty gives the purchaser specific rights, and the

purchaser may have other rights which vary from state to

state. Some states do not allow limitations on how long an

implied warranty lasts or on the exclusion of incidental or

consequential damages, so these limitations or exclusions

may not apply to you.

16 of 16

Loading...

Loading...