Page 1

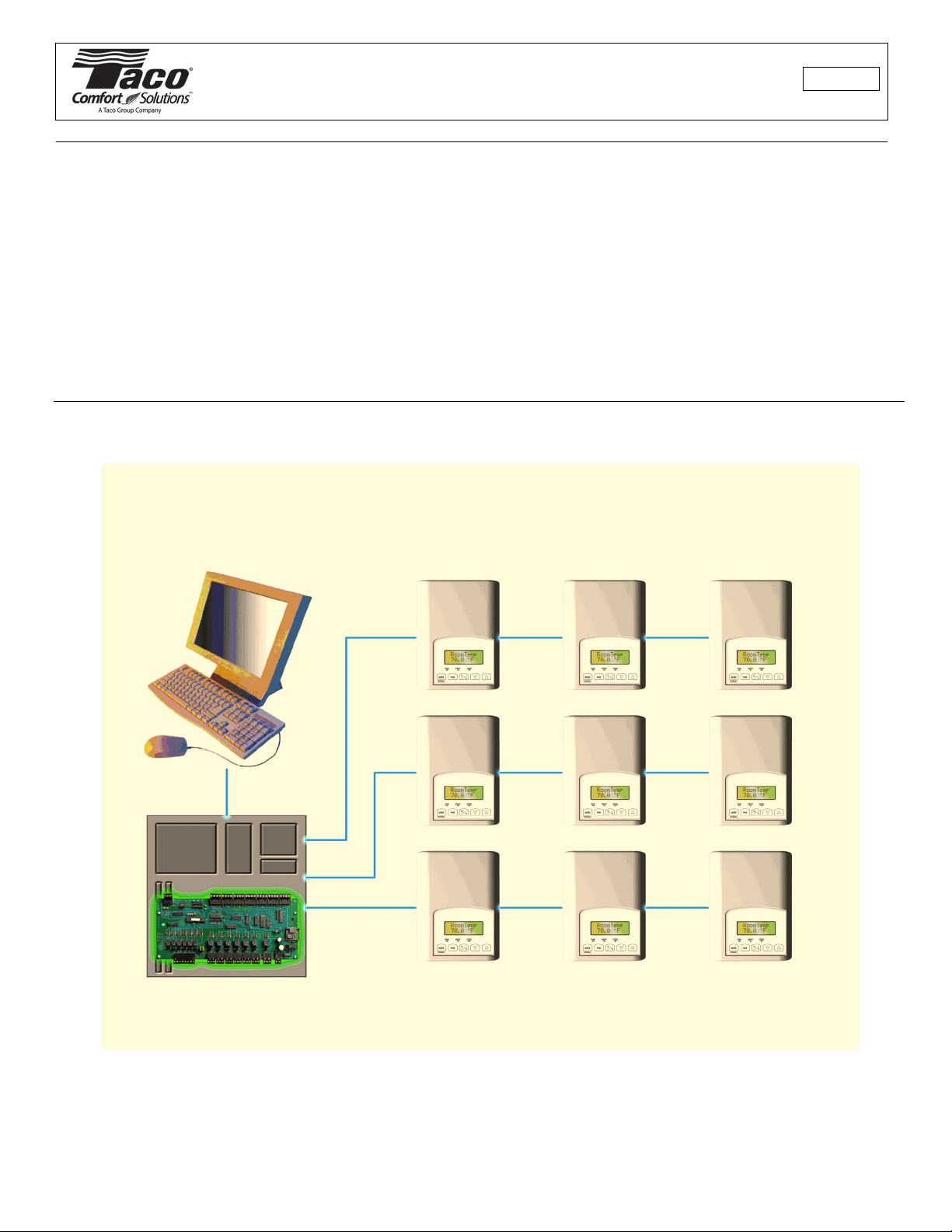

Integration Manual

VT7300 Series Thermostats

102-221

SUPERSEDES: New EFFECTIVE: November 1, 2008

LonWorks Integration Manual

PIR Ready VT7300 Series

24 Vac Low Voltage Fan Coil Thermostats

For Commercial and Lodging HVAC Applications

Page 2

Product Overview

The VT7300 PI thermostat family is specifically designed for fan coil control. The

product features a backlit LCD display with dedicated function menu buttons for simple

operation. Accurate temperature control is achieved due to the product’s PI

proportional control algorithm, which virtually eliminates temperature offset associated

with traditional, differential-based thermostats.

Models are available for On/Off, 3 point floating and analog 0 to 10 Vdc control.

All models contain can control three, two or single fan speed. 3 additional inputs are

also provided for monitoring and / or various advanced functions.

All models feature configurable System and Fan button functions to meet all possible

applications. They all contain an SPST auxiliary switch that can be used to control

lighting or auxiliary reheat.

The thermostats are also compatible with the new TACO PIR cover accessories. Thermostats equipped with a PIR cover

provide advanced active occupancy logic, which will automatically switch occupancy levels from Occupied to Stand-By

and Unoccupied as required by local activity being present or not. This advanced occupancy functionality provides

advantageous energy savings during occupied hours without sacrificing occupant comfort. All thermostats can be ordered

with or without a factory installed PIR cover (see notes below ).

The additional following documents are available at: www.taco-hvac.com

• PIR application information and examples, are available on document: PIR Application Guide 102-354

• PIR cover installation information is available on document: PIR Cover Install Guide 102-355

• Detailed information on the thermostat (VT73xxX5x21x), is available on document:102-220

Contents

• Thermostat Objects

• SNVTs and SCPTs Table Per Model

• Input Network Variables (nvi’s) Description

• Output Network Variables (nvo’s) Description

• Configuration Properties (nci’s) Description

• Integration - Global Commands

• Integration - Graphic User Interface (GUI) Objects

• Integration - Configuration Objects

• Wiring Guide

Overview

Network Configuration

Maximum Number Of Devices

Maximum Cable Length

EI-485 Repeaters

Terminators

• Network Adapter

• Software Files

• RoHS and Non-RoSH APB and NXE Files

• Device Identification

• Tips And Things You Need To Know

• Troubleshooting Section

• Document Control

2

Page 3

Thermostat Objects

VT7300 Space Comfort Controller

Object Type #8500

nviSpaceTemp

SNVT_temp_p

nviOutdoorTemp

SNVT_temp_p

nviSetpoint

SNVT_temp_p

nviSpaceRH

SNVT_lev_percent

nviFanSpeedCmd

SNVT_switch

nviAuxHeatEnable

SNVT_switch

nviOccManCmd

SNVT_occupancy

nviApplicMode

SNVT_hvac_mode

nviHeatCool

SNVT_hvac_mode

Mandatory

Network

Variables

Optional

Network

Variables

nvoSpaceTemp

SNVT_temp_p

nvoUnitStatus

SNVT_hvac_status

nvoDischAirTemp

SNVT_temp_p

nvoSpaceRH

SNVT_lev_percent

nvoEffectOccup

SNVT_occupancy

nvoTerminalLoad

SNVT_lev_percent

nviRemLockout

SNVT_count

nviDhumidLCK

SNVT_switch

nviAuxOut

SNVT_switch

Configuration Properties

Send Heartbeat (mandatory)

Temperature Setpoints (mandatory)

Minimum Send Time (optional)

Receive Heartbeat (optional)

Manufacturer

Network

Variables

Manufacturer Configuration Properties

Please see the manual for details.

Plug-In for configuration provided.

nvoSCCstatus

SNVT_state_64

3

Page 4

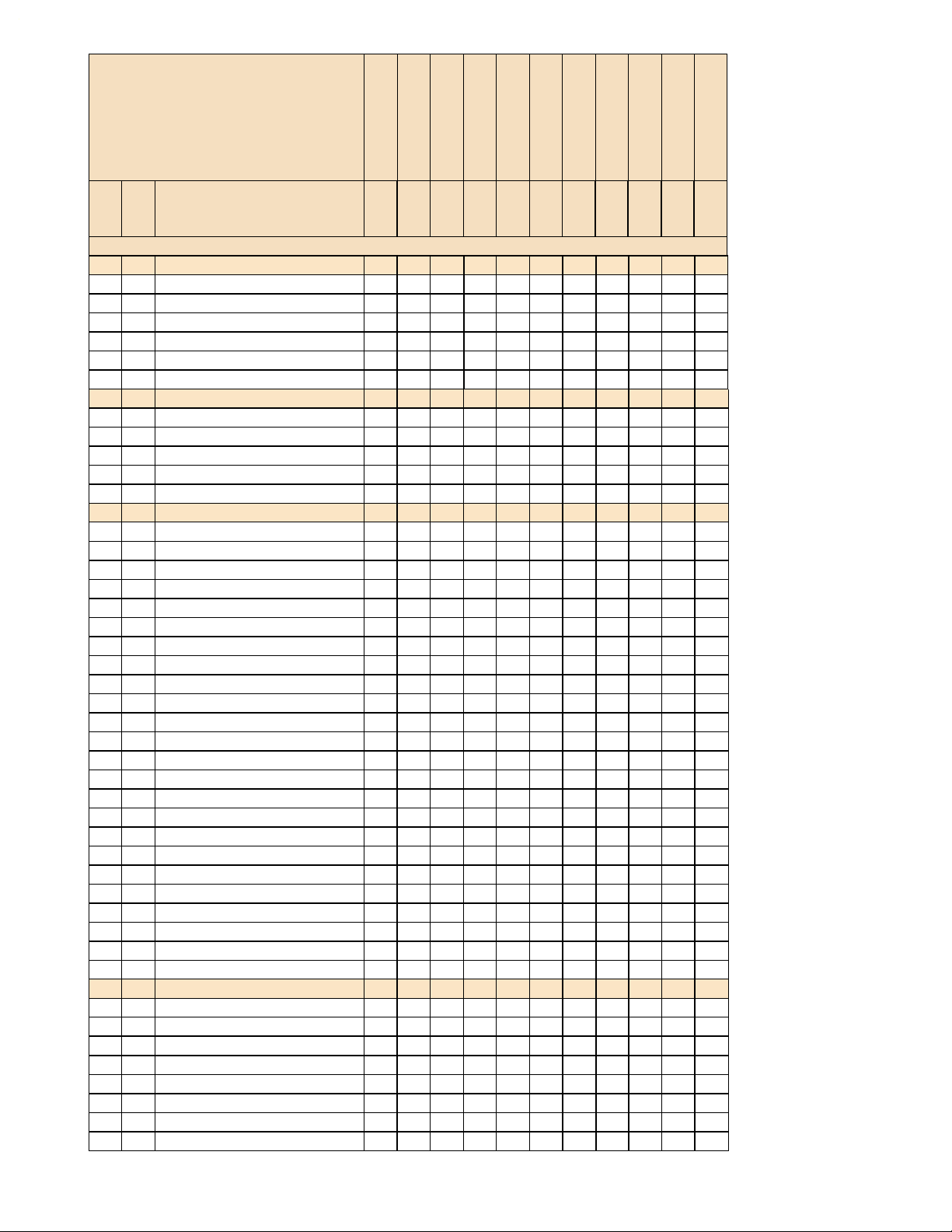

SNVTs

1

and SCPTs2 Table Per Model

Model Number

VT7300F5x21E

VT7300A5x21E

VT7300C5x21E

VT7350C5x21E

VT7305A5x21E

VT7305C5x21E

VT7355C5x21E

Point Name

No

Sub

N/A: Not applicable on this model

0 nviSpaceTemp XXXXXXXXXXX

1 nviOutdoorTemp XXXXXXXXXXX

2 nviSetpoint XXXXXXXXXXX

3 nviSpaceRH N/A N/A X N/A N/A X N/A X N/A X N/A

4 nviFanSpeedCmd XXXXXXXXXXX

5 nviAuxHeatEnable XXXXXXXXXXX

6 nviOccManCmd XXXXXXXXXXX

7 nviApplicMode XXXXXXXXXXX

8 nviHeatCool XXXXXXXXXXX

9 nviRemLockout XXXXXXXXXXX

10 nviDhumiLCK N/A N/A X N/A N/A X N/A X N/A X N/A

11 nviAuxOut XXXXXXXXXXX

12 nvoSpaceTemp XXXXXXXXXXX

13 nvoDischAirTemp XXXXXXXXXXX

14 nvoSpaceRH N/A N/A X N/A N/A X N/A X N/A X N/A

15 nvoEffectOccup XXXXXXXXXXX

16 nvoUnitStatus X X X X X X X X X X X

1 mode xxxxxxxxxxx

2 heat_output_primary x x xxxxxxxxx

4 cool_output x x xxxxxxxxx

6 fan_output x x xxxxxxxxx

7 in_alarm x x xxxxxxxxx

17 nvoSccStatus X X X X X X X X X X X

1 StateTerminal BO2 x x xxxxN/AN/AN/AN/AN/A

2 StateTerminal BO1 N/A x x N/A x x N/A N/A N/A N/A N/A

3 StateTerminal BO4 N/A x x N/A x x N/A N/A N/A N/A N/A

4 StateTerminal BO3 x x xxxxN/AN/AN/AN/AN/A

5 StateTerminal BO5 x x xxxxxxxxx

6 FanLow x x xxxxxxxxN/A

7 FanMed xxxxxxxxxxN/A

8 FanHigh x x xxxxxxxxx

9 UI 3 Status xxxxxxxxxxx

10 BI 2 Status xxxxxxxxxxx

11 BI1 Status xxxxxxxxxxx

12 Local PIR Motion xxxxxxxxxxx

13 Service Alarm xxxxxxxxxxx

14 Filter Alarm xxxxxxxxxxx

15 Window Opened x x xxxxxxxxx

16 Dehumidification Active N/A N/A x N/A N/A x N/A x N/A x N/A

18 nvoTerminalLoad X X X X X X X X X X X

1: SNVTs: Standard Network Variables Types

2: SCPTs: Standard Configuration Parameters Types

VT7350F5x21E

VT7305F5x21E

VT7355F5x21E

VT7300M5x21E

4

Page 5

Model Number

VT7300F5x21E

VT7350F5x21E

VT7305F5x21E

VT7300C5x21E

VT7300A5x21E

VT7305A5x21E

VT7350C5x21E

VT7305C5x21E

VT7355C5x21E

Point Name

No

Sub

N/A: Not applicable on this model

19 nciSetpoints X X X X X X X X X X X

1 occupied_cool xxxxxxxxxxx

2 standby_cool xxxxxxxxxxx

3 unoccupied_cool xxxxxxxxxxx

4 occupied_heat xxxxxxxxxxx

5 standby_heat xxxxxxxxxxx

6 unoccupied_heat xxxxxxxxxxx

20 nciRHmodel N/A N/A X N/A N/A X N/A X N/A X N/A

1 RHdisplay N/A N/A x N/A N/A x N/A x N/A x N/A

2 RHsetpoint N/A N/A x N/A N/A x N/A x N/A x N/A

3 DehumHyst N/A N/A x N/A N/A x N/A x N/A x N/A

4 DehumCool N/A N/A x N/A N/A x N/A x N/A x N/A

5 RHcalib N/A N/A x N/A N/A x N/A x N/A x N/A

21 nciGenOpt X X X X X X X X X X X

1 Control Type N/A x x N/A x x N/A N/A N/A N/A N/A

2 Drive Time xxxxxxN/AN/AN/AN/AN/A

3 Cycles Per Hour x x xxxxN/AN/AN/AN/AN/A

4 Reverse Acting Output N/A N/A N/A N/A N/A N/A x x x x x

5 BI1 xxxxxxxxxxx

6 BI2 xxxxxxxxxxx

7 UI3 xxxxxxxxxxx

8 Menu Scroll x x xxxxxxxxx

9 Auto Mode xxxxxxxxxxN/A

10 Temperature Scale xxxxxxxxxxx

11 Pipes # Main out config x x xxxxxxxxx

12 Sequence of Operation x x xxxxxxxxN/A

13 Fan Menu Sequence x x xxxxxxxxN/A

14 Heat Maximum setpoint x x xxxxxxxxx

15 Cool Minimum setpoint x x xxxxxxxxx

16 SetpointType x x xxxxxxxxx

17 Temporary Occ Time xxxxxxxxxxx

18 Deadband x x xxxxxxxxx

19 Calibration Room Sensor x x xxxxxxxxx

20 Auxiliary Contact Config x x xxxxxxxxx

21 Reheat Time Base x x xxxxxxxxx

22 Fan Mode xxxxxxxxxxx

23 PIR Stand-By Timer x x xxxxxxxxx

24 PIR Unoccupied Timer x x xxxxxxxxx

22 nciSccModel X X X X X X X X X X X

1 Thermostat Model x x xxxxxxxxx

2 Software Version xxxxxxxxxxx

23 nciHvacType XXXXXXXXXXX

24 nciSndHrtBt XXXXXXXXXXX

25 nciMinOuttM XXXXXXXXXXX

26 nciRcvHrtBt XXXXXXXXXXX

27 nciMajVer XXXXXXXXXXX

28 nciMinVer XXXXXXXXXXX

VT7355F5x21E

VT7300M5x21E

5

Page 6

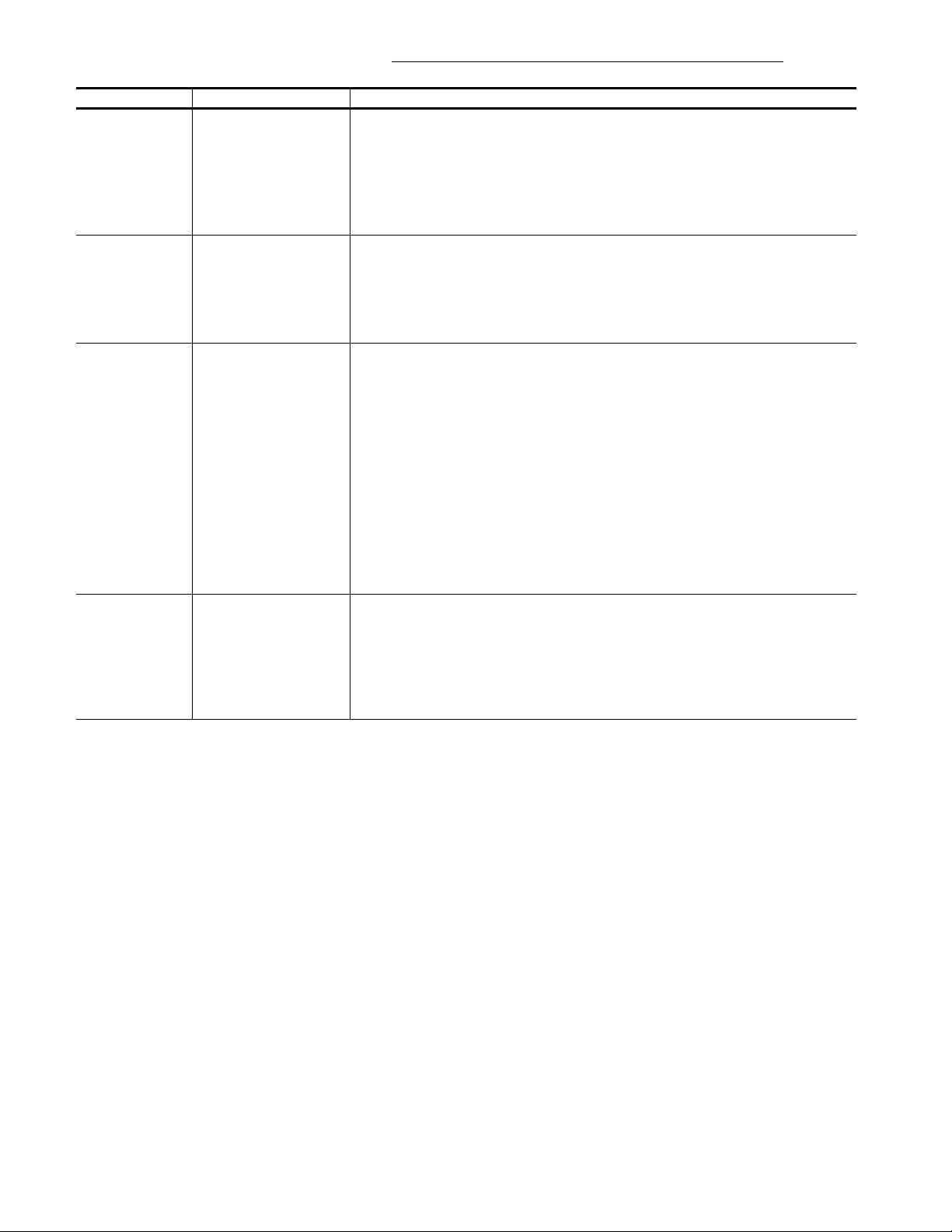

Input Network Variables (nvi’s) Description

Parameter Variable Name Function

Room

Temperature

network input

SNVT_temp_p

nviSpaceTemp

This input network variable provides a network remote temperature

value to the thermostat. When linked of written to, the internal

temperature reading (internal sensor) is no longer used.

Valid Range: 40 to 122°F (-40 to 50°C)

Default Null (release) Value: 621.81°F (327.67°C or 0x7FFF)

This network variable is subject to the Receive HeartBeat Time,

nviRcvHrtBt.

Outdoor Air

Temperature

network input

SNVT_temp_p

nviOutdoorTemp

This input network variable provides outdoor air temperature

information to the thermostat from a network value temperature

value. The device will automatically display the value on its display

when linked.

Valid Range: 40 to 122°F (-40 to 50°C)

Default Null (release) Value: 621.81°F (327.67°C or 0x7FFF)

Occupied

Cool & Heat

Setpoints

network Input

SNVT_temp_p

nviSetpoint

This input network variable is used to allow the occupied

temperature setpoints only to be changed via the network from a

single analog value. (Note: the Stand-By and Unoccupied setpoints

are not changed). The corresponding heating and cooling values

are derived from the minimum deadband configuration value

Default Null Value: 621.81°F (327.67°C or 0x7FFF)

Ex. If the minimum deadband configuration value = 2 °F and

nviSetpoint = 70°F.

• The resulting Occupied heating setpoint will equal 69 °F which is

derived from 70 °F minus _ the minimum deadband configuration

value of 2 °F

• The resulting Occupied cooling setpoint will equal 71 °F which is

derived from 70 °F plus _ the minimum deadband configuration

value of 2 °F

Room

Humidity

network input

SNVT_lev_percent

nviSpaceRH

This input network variable is the measured room humidity in

percent monitored by the thermostat.

Valid Range: 5 to 90%

Default Null Value: +163.835 (0x7FFF)

This network variable is subject to the Receive HeartBeat Time,

nviRcvHrtBt

6

Page 7

Parameter Variable Name Function

Fan Mode network input

SNVT_switch

nviFanSpeedCmd

This input network variable is used to connect an external fan

speed switch to the node or to allow any supervisory device to

override the fan speed controlled by the node’s control algorithm.

This input is used in conjunction with FanMenu bit in nciGenOpts.

Default Null Value: AUTO (state = 0xFF)

Valid Range:

Fan

Menu

Value

State Value Equivalent

Percent

Requested Speed

Sequence of

Operation

network input

SNVT_switch

nviAuxHeatEnable

0

0

1

1

1

1

1

N/A N/A Off - Not Used

0 0% Off - Not Used

1 to 66 0.5 to 33% Low

67 to 133 33.5 to 66.5% Medium

134 to 200 67 to 100% High

201 to 255 100% 3 – Not Used

0xFF N/A N/A Auto – Not Used

1

0 n/ N/A Off – Not Used

1 0 0% Off – Not Used

1 0 to 100 0.5 to 50% Low

1 101 to 200 50.5 to 100% High

1 201 to 255 100% 2 – Not Used

0xFF N/A N/A Auto – Not Used

2

0 N/A N/A Off - Not Used

1 0 0% Off - Not Used

1 1 to 66 0.5 to 33% Low

1 67 to 133 33.5 to 66.5% Medium

1 134 to 200 67 to 100% High

1 201 to 255 100% 3 – Not Used

0xFF N/A N/A Auto

3

0 n/ N/A Off – Not Used

1 0 0% Off – Not Used

1 0 to 100 0.5 to 50% Low

1 101 to 200 50.5 to 100% High

1 201 to 255 100% 2 – Not Used

0xFF N/A N/A Auto

4

0 n/ N/A Off – Not Used

1 0 0% Off – Not Used

1 1 to 200 0.5 to 100% On (High)

1 201 to 255 100% On – Not Used

0xFF N/A N/A Auto

This input network variable is used to enable or disable the

1

auxiliary heat stage.

This input is used in conjunction with nviHeatCool and SeqOper.

Default Null Value: AUTO (state = 0xFF)

Set value to 100% for both On & Off state

Valid Range:

See note 1 below

State Value Auxiliary Heat Operation

0 N/A Disabled – Not Used

1 0 % Disabled

1 1 to 99% Partially Enabled – Not Used

1 100% Enabled

0xFF N/A Enabled (invalid)

7

Page 8

Parameter Variable Name Function

Occupancy network input

SNVT_occupancy

nviOccManCmd

This input network variable is used to command the Space

Comfort Controller into different occupancy modes. It is typically

set by a supervisory node to remotely control the occupancy

modes to override the local occupancy routines of the thermostat.

Default Null Value: OC_NUL = 0xFF

Valid Range:

System Mode network input

SNVT_hvac_mode

nviApplicMode

This network variable input is used to coordinate the Space

Comfort Controller with any node that may need to control the

heat/cool changeover of the unit.

This input is used in conjunction with nviHeatCool and SeqOper.

Default Null Value: HVAC_AUTO.

This network variable is subject to the receive heartbeat time,

nciRcvHrtBt

Valid Range:

0 = OC_OCCUPIED *

1 = OC_UNOCCUPIED )

2 = OC_BYPASS – Not Used

3 = OC_STANDY – Not Used

0xFF = OC_NUL (Release to internal occupancy)**

* OC_OCCUPIED and OC_UNOCCUPIED commands will

always have full authority over the local occupancy routines

of the thermostat may they be a local input or a PIR cover.

** OC_NUL command will release the thermostat to use its

own internal occupancy routine driven from one of the digital

input or a PIR cover installed on board.

0 = HVAC_AUTO

1 = HVAC_HEAT

2 = HVAC_MRNG_WRMUP – Not Used

3 = HVAC_COOL

4 = HVAC_NIGHT_PURGE – Not Used

5 = HVAC_PRE_COOL – Not Used

6 = HVAC_OFF

7 = HVAC_TEST – Not Used

8 = HVAC_EMERG_HEAT – Not Used

9 = HVAC_FAN_ONLY – Not Used

12 = HVAC_MAX_HEAT – Not Used

13 = HVAC_ECONOMY – Not Used

14 = HVAC_DEHUMID – Not Used)

15 = HVAC_CALIBRATE – Not Used)

0xFF = HVAC_NUL – Not Used

8

Page 9

Parameter Variable Name Function

Sequence of

operation

network input

SNVT_hvac_mode

nviHeatCool

1

This network variable input is used to coordinate the Space

Comfort Controller with any node that may need to control the

heat/cool changeover of the unit. This input is overridden by

nviApplicMode, unless nviApplicMode is HVAC_AUTO. If

nviApplicMode is HVAC_AUTO, then nviHeatCool determines the

effective mode of the unit.

Default Null Value: HVAC_AUTO.

This network variable is subject to the receive heartbeat time,

nciRcvHrtBt

Valid Range:

See note 1 below

Lockout network input

UNVT_nvi/nvo

nviRemLockout

This network variable input is used to enable or disable user

access to thermostat

Default Null Value: Level 0.

Valid Range:

Level Occupied

0 Yes access Yes access Yes access Yes access

1 Yes access Yes access Yes access No access

2 Yes access No access No access Yes access

3 Yes access No access No access No access

4 No access No access No access Yes access

5 No access No access No access No access

DhumiLCK network input

UNVT_nvi/nvo

nviDhumiLCK

This network variable input is used to enable or disable

dehumidification

Default Null Value: Dehumidification not allowed

Set value to 100% for both On & Off state

Valid Range:

Aux contact network input

UNVT_nvi/nvo

nviAuxOut

This network variable input is used remotely command the

Auxiliary Output (BO5).

NOTE Auxiliary Contact configuration NEEDS to be set to 5 for this

function to operate ( 5 = Output to follow secondary network

occupancy command )

Set value to 100% for both On & Off state

Default Null Value: Auxiliary contact Off

Valid Range:

0 = HVAC_AUTO

1 = HVAC_HEAT

2 = HVAC_MRNG_WRMUP – Not Used

3 = HVAC_COOL

4 = HVAC_NIGHT_PURGE – Not Used

5 = HVAC_PRE_COOL – Not Used

6 = HVAC_OFF

7 = HVAC_TEST – Not Used

8 = HVAC_EMERG_HEAT – Not Used

9 = HVAC_FAN_ONLY – Not Used

12 = HVAC_MAX_HEAT – Not Used

0xFF = HVAC_NUL – Not Used

Temperature

Setpoints

System

Mode

Settings

Fan Mode

Settings

Unoccupied

Override

State =0 = Dehumidification not allowed (Thermostat’s default

value)

State = 1 = Dehumidification allowed

State = 0 = Auxiliary contact Off (Thermostat’s default value)

State = 1 = Auxiliary contact On

9

Page 10

Output Network Variables (nvo’s) Description

All output network variables will be updated no faster than the Minimum Send Time (nciMinOutTm) configuration value.

An output network variable will be transmitted immediately when its value has changed significantly (manufacturer’s

defined). Additionally, this variable will also be transmitted as a heartbeat output on a regular basis as dictated by the

Maximum Send Time (nciSndHrtBt) configuration value.

Parameter Variable Name Function

Room

Temperature

network output

SNVT_temp_p

nvoSpaceTemp

This output network variable is used to monitor the effective space

temperature sensor that the Space Comfort Controller is using for

control. This output echoes the value of the input.

Valid Range: 14 to 122°F (-10 to 50°C)

The value 621.07°F (327.67°C or 0x7FFF) will be sent as an

invalid value in case of a sensor failure.

Supply

Temperature

network output

SNVT_temp_p

nvoDischAirTemp

This output network variable is used to monitor the temperature of

the air that leaves the Space Comfort Controller

NOTE: UI3 needs to be configured to (SS) Supply air sensor

monitoring

Valid Range: -40 to 122°F (-40 to 50°C)

The value 621.81°F (327.67°C or 0x7FFF)will be sent as an invalid

value in case of a sensor failure.

Room

Humidity

network output

SNVT_lev_percent

nvoSpaceRH

This output network variable indicates the space humidity in

percent.

Valid Range: 0 to 100%.

The value 0x7FFF = +163.835% will be set as an invalid value to

indicate a humidity sensor failure.

Occupancy network output

SNVT_occupancy

nvoEffectOccup

This output network variable is used to indicate the actual

occupancy mode of the unit. This information is typically reported

to a supervisory controller or provided to another Space Comfort

Controller to coordinate the operation of multiple units

Valid Range:

0 = OC_OCCUPIED

1 = OC_UNOCCUPIED

2 = OC_BYPASS

1

3 = OC_STANDBY

Unit Status

network

output

SNVT_hvac_status

nvoUnitStatus

Note 1: OC_BYPASS can be initiated by either nviOccManCmd or a

local input. NvoEffectOccup will only be in OC_BYPASS for the

duration of the ToccTime (nciGenOpts), until reinitiated by either a

transition of the local input or an update to nviOccManCmd.

This output network variable is available to report the Space

Comfort Controller status. It combines the operating mode, the

capacity of heating and cooling used and an indication if any

alarms are present in the object.

Sub Name Valid Value

01 mode HVAC_AUTO

HVAC_HEAT

HVAC_MRNG_WRMUP – Not Used

HVAC_COOL

HVAC_NIGHT_PURGE – Not Used

HVAC_PRE_COOL – Not Used

HVAC_HVAC_OFF

HVAC_HVAC_TEST – Not Used

HVAC_HVAC_EMERG_HEAT – Not Used

10

Page 11

Parameter Variable Name Function

Unit Status

network

SNVT_hvac_status

nvoUnitStatus

Sub Name Valid Value

output

02: heat_output

_primary

03 heat_output

_secondary

04 cool_output: 0-100%, 0x7FFF (Invalid)

05 econ_output Not Used

06 fan_output 0-100%, 0x7FFF (Invalid)

07 In_alarm 0 (No alarms)

Thermostat’s

I/O status

network output

UNVT_fc_thermo_

state

nvoSccStatus

This network variable output is used to report the Space Comfort

Controller inputs’ and outputs’ status.

Sub Name Valid value Default Value

01 StateTerminal BO2 0 = Off

02 StateTerminal BO1 0 = Off

03 StateTerminal BO4 0 = Off

04 StateTerminal BO3 0 = Off

05 StateTerminal BO5 0 = Off

06 FanLow 0 = Off

07 FanMed 0 = Off

08 FanHigh 0 = Off

09 UI3 Status -40 to 122 °F

10 BI2 Status 0 = activated

11 BI1 Status 0 = activated

12 Local PIR Motion 0 = No motion

13 Service Alarm 0 = No alarm

14 Filter Alarm 0 = No alarm

15 Window Opened 0 = No alarm

16 Dehumidification

Active

Heating/

Cooling

demand

network output

SNVT_lev_percent

nvoTerminalLoad

This output indicates the current heat/cool energy demand of the

unit. Positive values indicate that cooling energy is in use by the

space comfort controller, while negative values indicate that

heating energy is in use by the space comfort controller.

Valid Range: -100% to 100%

HVAC_FAN_ONLY – Not Used

HVAC_MAX_HEAT – Not Used

0-100%, 0x7FFF (Invalid)

Not Used

1 (Alarm On)

0x7FF (Alarming disabled) – Not Used

0 = Off

1 = On

0 = Off

1 = On

0 = Off

1 = On

0 = Off

1 = On

0 = Off

1 = On

0 = Off

1 = On

0 = Off

1 = On

0 = Off

1 = On

N/A

(-40 to 50°C)

40°F = Open

122°F = Close

1 = not activated

1 = not activated

1 = not activated

1 = not activated

0 = No motion

1 = Motion

0 = No alarm

1 = Alarm on

0 = No alarm

1 = Alarm on

0 = No alarm

1 = Alarm on

0 = Off

0 = Off

1 = On

11

Page 12

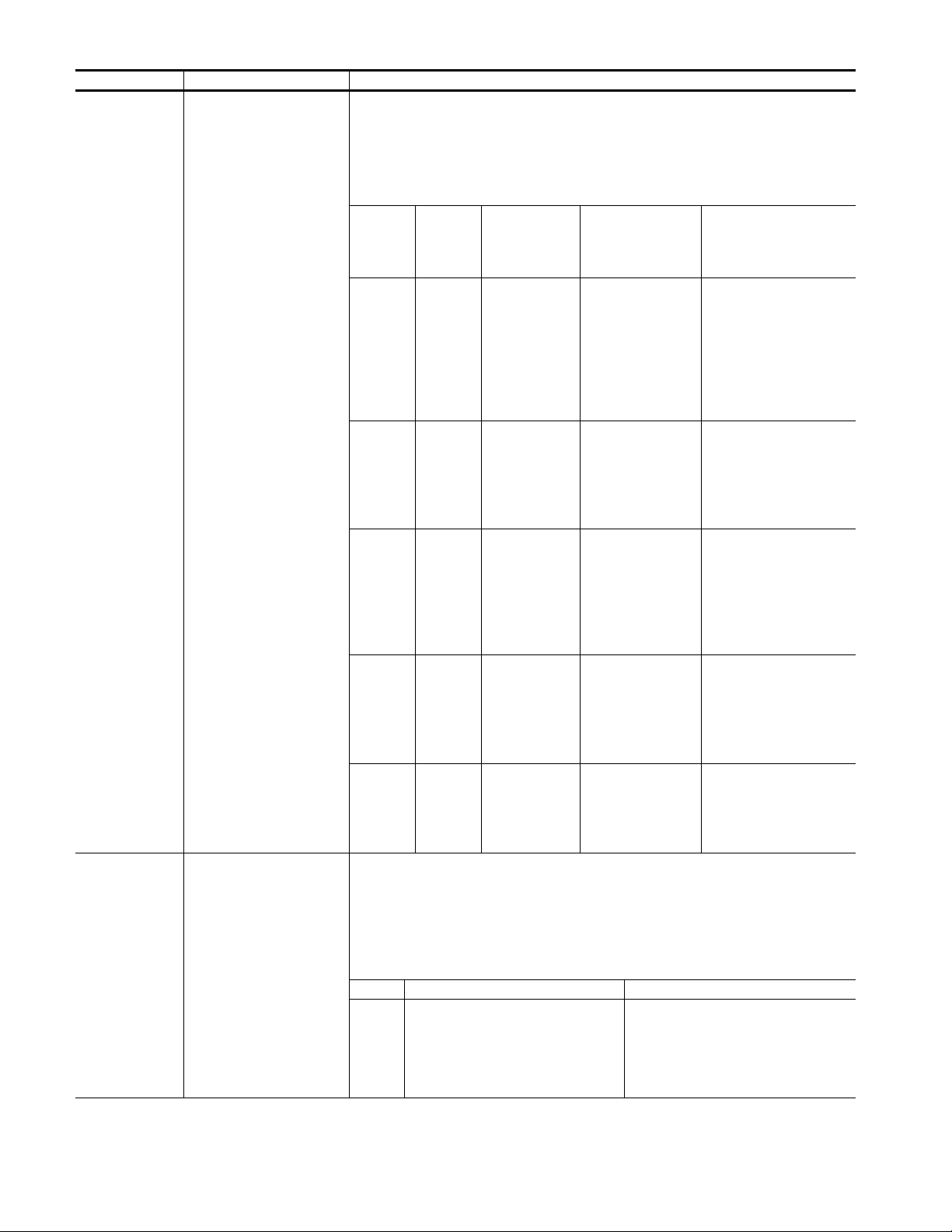

Configuration Properties (nci’s) Description

Parameter Variable Name Function

Temperature

Setpoints

network input config

SNVT_temp_setpt

nciSetPts

This configuration property defines the space temperature

Valid Range and Default values:

Sub Name Valid Range Default value

01 occupied_cool 54 to 100°F

02 standby_cool 54 to 100°F

03 unoccupied_cool 54 to 100°F

04 occupied_heat 40 to 90°F

05 standby_heat 40 to 90°F

06 unoccupied_heat 40 to 90°F

RH options network input config

This configuration property defines the space humidity parameters

UNVT_gen_opts

nciRHmodel

Valid Range and Default values:

Sub Name Valid Range Default value

01 RHdisplay 0 = Not active

02 RHsetpoint 30 to 100% RH 50% RH

03 DehumHyst 2 to 20% RH 5% RH

04 DehumCool 20 to 100% RH 100% RH

05 RHcalib -15 to +15% RH 0% RH

Thermostat’s

common

configuration

parameters

network input

UNVT_fc_gen_opts

nciGenOpts

This configuration property defines the thermostat’s common

Valid Range and Default values:

Sub Name Valid Range Default value

01 Control Type 0 = On/Off Control

config

02 Drive Time 0.5 to 9 minutes (0.5

03 Cycles Per Hour 3, 4, 5, 6, 7 and 8 CPH 4 CPH

04 ReverseActing

05 BI1 0 = None

06 BI2 0 = None

07 UI3 0 = None

08 Menu Scroll 0 = No Scroll

setpoints for various heat, cool and occupancy modes.

75°F (24.0°C)

(12 to 37.5°C)

78°F (25.5°C)

(12 to 37.5°C)

80°F (26.5°C)

(12 to 37.5°C)

72°F (22.0°C)

(4.5 to 32°C)

69°F (20.5°C)

(4.5 to 32°C)

62°F (16.5°C)

(4.5 to 32°C)

and their settings.

0

1 = Active

configuration parameters and their settings.

0

1 = Floating Control

3 minutes

increments)

Output

0 = Direct Acting (DA)

1 = Reverse Acting (RA)

0

0

1 = Rem NSB

2 = Motion NO

3 = Motion NC

4 = Window

0

1 = Door Dry

2 = Override

3 = Filter

4 = Service

0

1 = COC/NH

2 = COC/NC

3 = COS

4 = SS

1

1 = Scroll Active

12

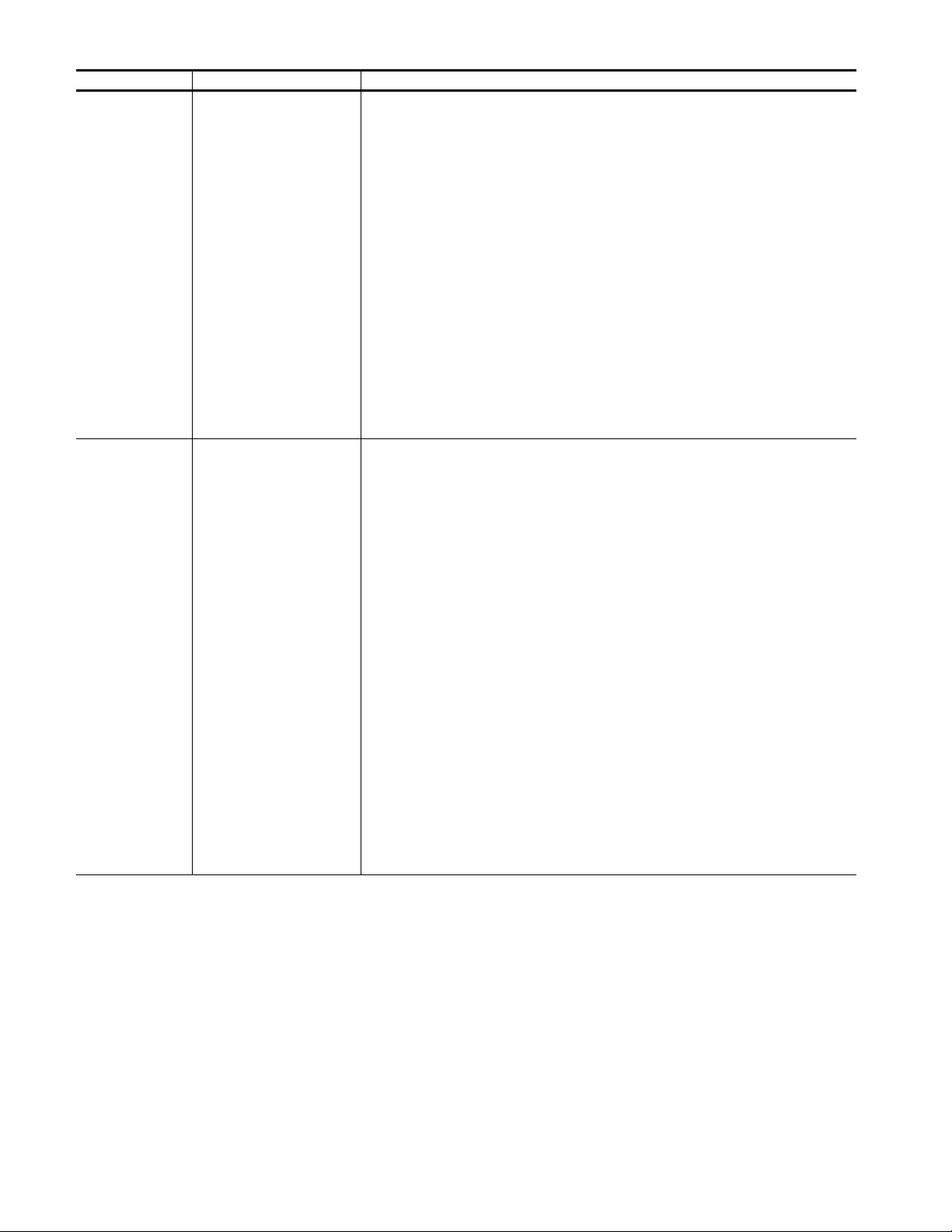

Page 13

Parameter Variable Name Function

Thermostat’s

common

UNVT_fc_gen_opts

nciGenOpts

Sub Name Valid Range Default value

09 Auto Mode 0 = Not Active

configuration

parameters

network input

config

10 Temperature

Scale

11 Pipes # Main

out config

12 Sequence of

Operation

13 Fan Menu 0 = Low-Med-High

14 Heat

Maximum

Setpoint

15 Cool Minimum

Setpoint

16 Setpoint Type 0 = Permanent

17 Temporary

Occ Time

18 Deadband 2, 3, 4 or 5 °F

19 Calibration

Room Sensor

20 Auxiliary

Contact Config

21 Reheat Time

Base

22 Fan Mode 0 = Low

23 PIR Stand-By

Timer

24 PIR

Unoccupied

Timer

0

1 = Active

0 = °C

°F

1 = °F

2 = 2 pipe

4 pipe

4 = 4 pipe

0 = Cooling Only

1 = Heating Only

1 = Heating

Only

2 = Cooling & Reheat

3 = Heating & Reheat

4 = Cooling/Heating 4 pipes

5 = Cooling /Heating 4 pipes

& Reheat

4 = On-Auto

1 = Low-High

2 = Low-Med-High-Auto

3 = Low-High-Auto

4 = On-Auto

40 to 90°F

90°F (32°C)

(4.5 to 32°C)

54 to 100°F

54°F (12°C)

(12 to 37.5°C)

0

1 = Temporary

0, 1, 2, 3, up to 24 hours 2 hours

2°F (1°C)

(1 to 2.5°C)

± 5°F (±2.5°C) 0°C

0 = Aux Contact used for

0

reheat

1 = Aux NO with occupancy

2 = Aux NC with occupancy

3 = Aux NO with occupancy

& Fan On

4 = Aux NC with occupancy

& Fan On

5 = Remote control

nviAucOut

0 = 15 minutes

0

1 = 10 seconds

Depending on

1 = Med

2 = High

Fan Menu

Selected

3 = Auto

4 = On

0.5 to 24.0 Hours 0.5 Hours

0.0 to 24.0 Hours 0.0 Hours

13

Page 14

Parameter Variable Name Function

Thermostat’s

model number

network input config

UNVT_model_number

nciSccModel

This configuration property defines model number and software

version of the thermostat

Valid Range and Default values:

Sub Name Valid Range Default value

01 Thermostat

Model

02 Software

Version

HVAC UnitType Identifier

network input config

SNVT_hvac_type

nciHvacType

This configuration property helps the user identify the type of

equipment being monitored.

Valid Range:

Sub Identifier Name

HVT_GENERIC – Not Used

0

HVT_FAN_COIL

1

HVT_VAV – Not Used

2

HVT_HEAT_PUMP– Not Used

3

HVT_ROOFTOP – Not Used

4

HVT_UNIT_VENT – Not Used

5

HVT_CHIL_CEIL – Not Used

6

HVT_RADIATOR – Not Used

7

HVT_AHU – Not Used

8

HVT_SLF_CONT – Not Used

9

Maximum

Send Time

network input config

SNVT_time_sec

nciSendHrtBt

This configuration property defines the maximum period of that

expires before the specified network variable outputs will

automatically be updated

Valid Range: 0 sec. to 6553.4 sec.. Setting nciSendHrtBt to 0

disables the Send Heartbeat mechanism.

Default Null Value : 0.0 sec (no automatic update)

Minimum

Send Time

network input config

SNVT_time_sec

nciMinOutTm

This configuration property defines the minimum period of time

between automatic network variable outputs transmissions.

Valid Range: 0 sec. to 6553.4 sec.. Setting nciRcvHrtBt to 0

disables the Minimum Send Time mechanism.

Default Null Value : 0.0 sec (no minimum send time)

Minimum

Receive Time

network input config

SNVT_time_sec

nciRcvHrtBt

This configuration property is used to control the maximum time

that elapses after the last update to a specified network variable

input before the Space Comfort Controller starts to use its default

values.

Valid Range: 0 sec. to 6553.4 sec.. Setting nciRcvHrtBt to 0

disables the Receive Heartbeat mechanism.

Default Null Value : 0.0 sec (no failure detected)

Hardware or

Software

revisions

Hardware or

Software

revisions

network input config

SCPT_maj_ver

nciMajVer

network input config

SCPT_min_ver

nciMinVer

This configuration property defines the major module hardware

and software revisions.

Valid Range: 0 to 255

This configuration property defines the minor module hardware

and software revisions.

Valid Range: 0 to 255

41 = VT7300A1000E

42 = VT7305A1000E

Depend on model

being used

43 = VT7350C1000E

44 = VT7300C1000E

45 = VT7355C1000E

46 = VT7305C1000E

47 = VT7350F1000E

48 = VT7300F1000E

49 = VT7355F1000E

50 = VT7305F1000E

51 = VT7350M1000E

00

Generic

Fan Coil

Variable Air Volume Terminal

Heat Pump

Rooftop Unit

Unit Ventilator

Chilled Ceiling

Radiator

Air Handling Unit

Self-Contained Unit

14

Page 15

Note 1:

How to use nviHeatCool, nviAuxHeatEnable and SeqOpera (Sequence of Operation) variables:

Current

nviHeatCool

3 = HVAC_COOL X 0 = Cooling Only 1= HVAC_HEAT 1 = Heating Only

3 = HVAC_COOL X 2 = Cooling & Reheat 1= HVAC_HEAT 3 = Heating & Reheat

1 = HVAC_HEAT X 1 = Heating Only 3= HVAC_COOL 1 = Cooling Only

1 = HVAC_HEAT X 3 = Heating & Reheat 3= HVAC_COOL 2 = Cooling & Reheat

3 = HVAC_COOL X 0 = Cooling Only

3 = HVAC_COOL X 2 = Cooling & Reheat

1 = HVAC_HEAT X 1 = Heating Only

1 = HVAC_HEAT X 3 = Heating & Reheat

0 = HVAC_AUTO X 4 = Cool/Heat 4 Pipes

0 = HVAC_AUTO X

NviAuxHeat

Enable =

Enabled

NviAuxHeat

Enable =

Disabled

Current SeqOpera If nviHeatCool

changed to:

2 Pipe Application

4 Pipe Application

0= HVAC_AUTO

1= HVAC_HEAT

0= HVAC_AUTO

1= HVAC_HEAT

0= HVAC_AUTO

3= HVAC_COOL

0= HVAC_AUTO

3= HVAC_COOL

1= HVAC_HEAT

3= HVAC_COOL

5 = Cool/Heat 4P &

Reheat

1= HVAC_HEAT

3= HVAC_COOL

New SeqOpera

4 = Cool/Heat 4 Pipes

1 = Heating Only

5 = Cool/Heat 4P & Reheat

3 = Heating & Reheat

4 = Cool/Heat 4 pipes

1 = Cooling Only

5 = Cool/Heat 4P & Reheat

2 = Cooling & Reheat

1 = Heating Only

0 = Cooling Only

3 = Heating & Reheat

2 = Cooling & Reheat

15

Page 16

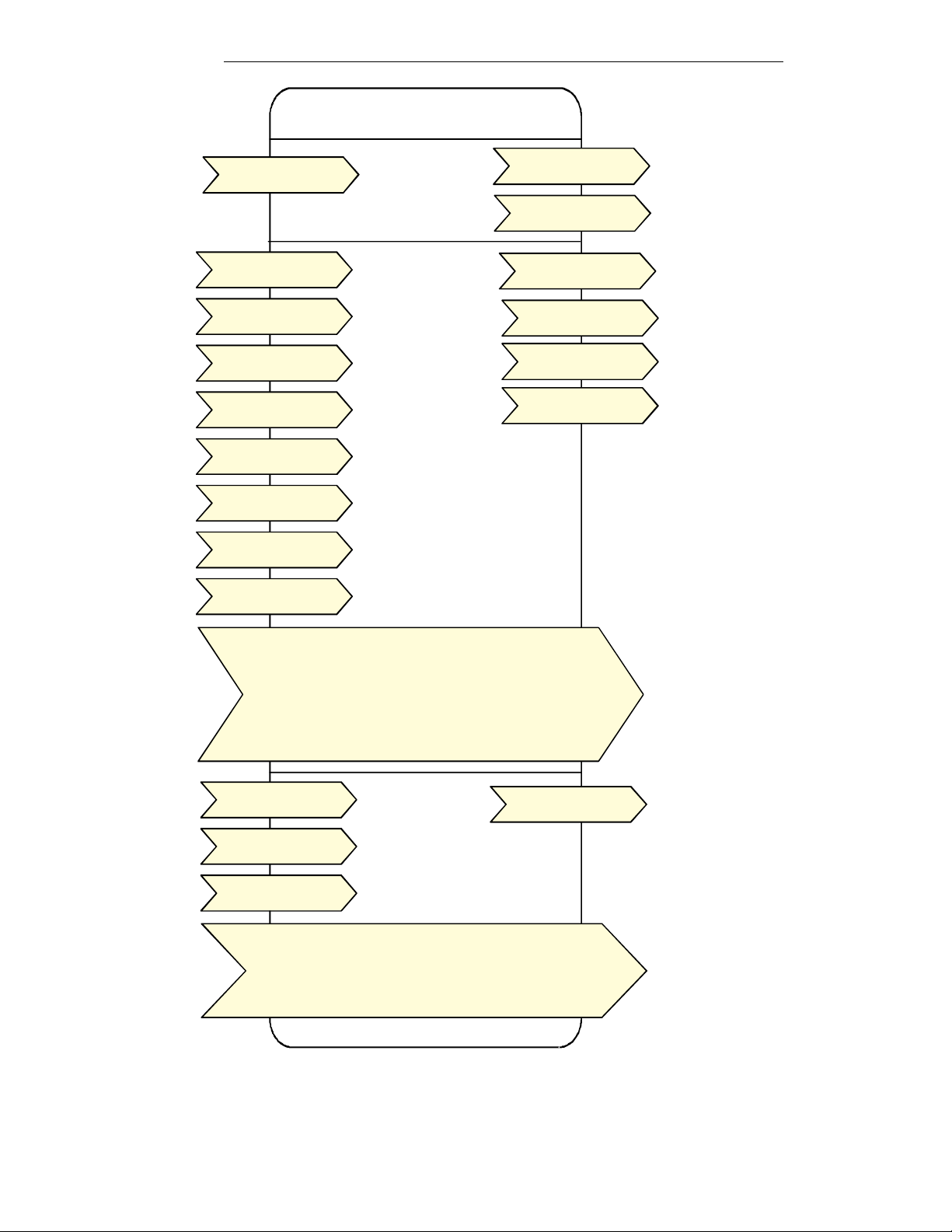

Integration – Global Commands

The following figure shows, which objects from the thermostat, can be monitored and commanded from the BAS frontend.

Figure 1: Global commands from a BAS front-end to a VT7300 series tstat

Integration – Graphic User Interface (GUI) Objects

The following objects should be typically used in a GUI:

nvoSpaceTemp

occupied_heat (nciSetpts);

unoccupied_heat (nciSetpts);

occupied_cool (nciSetpts);

unoccupied_cool (nciSetpts);

nvoSpaceRH

RHsetpoint (nciRHmodel);

nvoOutdoorTemp

nvoDischAirTemp

nviOccManCmd

nvoEffectOccup

heat_output_primary (nvoUnitStatus)

cool_output (nvoUnitStatus)

ServiceAlarm (nvoSccStatus)

FilterAlarm (nvoSccStatus)

WindowOpened (nvoSccStatus)

16

Page 17

Figure 2: Graphical User Interface (GUI) example of a Fan-Coil system

17

Page 18

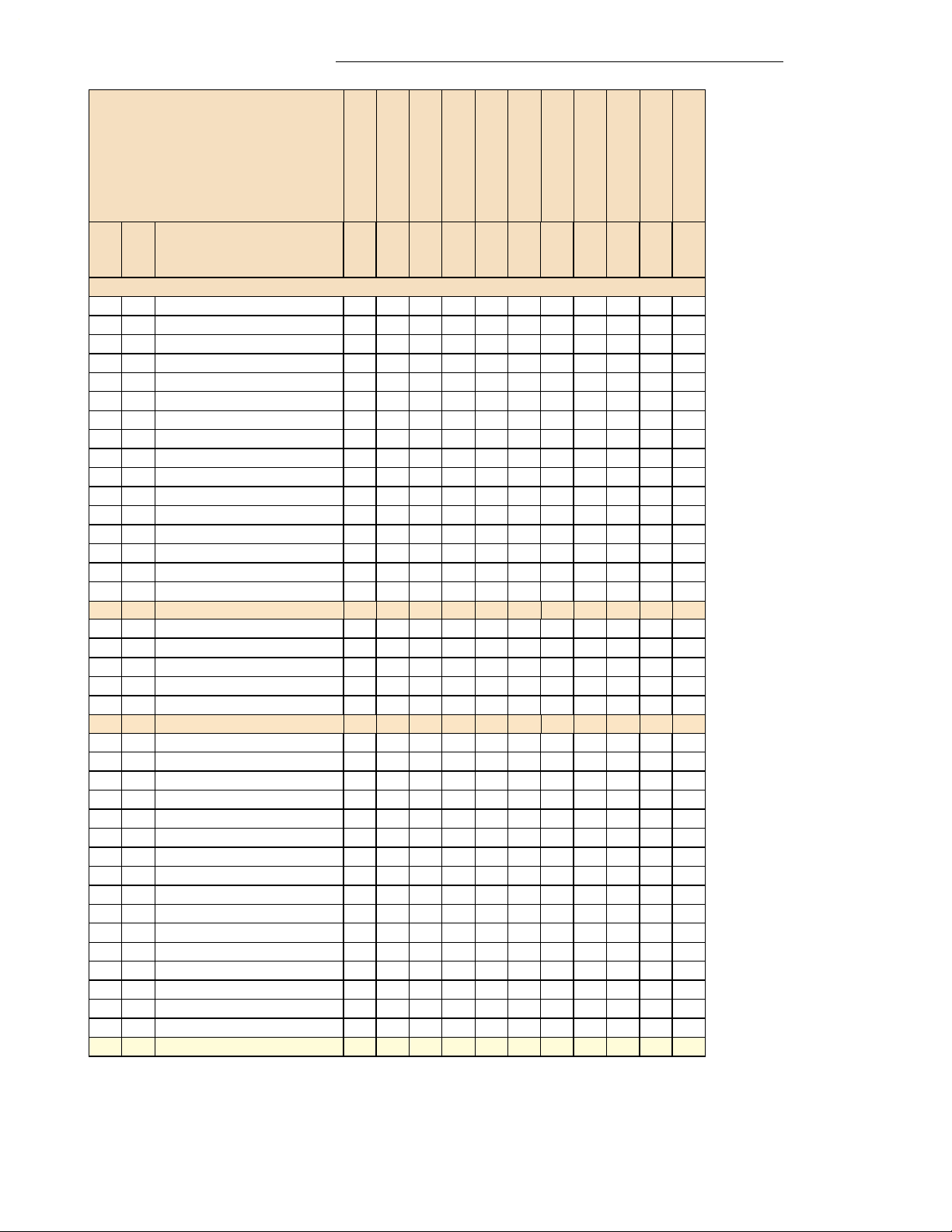

Configuration Objects

The following SNVT and UNVT should be typically used for configuration purposes:

nciGenOpts;

nciRHmodel;

nciSetpoints;

Wiring Guide

Overview

For clarity we will use the term “Device” to represent any product with an active Echelon network connection, including

TACO and non-TACO controllers.

Summary Specifications:

Parameter Details

Network Wiring 24 to 16AWG, twisted pair

Maximum total wire length

1

1600 feet (500 meters) in free topology

Maximum device-to-device distance 1600 feet (500 meters) in free topology

Polarity Polarity insensitive

Multi-drop Free Topology

Termination for Free Topology Network Segment

Termination for Doubly Terminated Bus Network

One RC network with Ra = 52.3Ω±1%, 1/8W

Two RC network with Ra = 105Ω±1%, 1/8W

Segment

Number of transceivers per segment Up to 64

Baud rate 78000 bits per second

1

Network segment length varies depending on wire type.

Table 1: Summary of Specifications for a TACO ’ LON Network

Network Configuration

The Echelon network is designed to support free topology wiring and will accommodate bus, star, loop or any of these

topologies. Echelon devices can be located at any point along the network wiring.

Figures 3.1 to 3.5 present five different network topologies. The actual termination circuit will vary by application.

18

Page 19

Maximum Number Of Devices

Up to 64 transceivers are allowed per network segment. If your network requires more than 64 transceivers a repeater is

then required to extend your network

19

Page 20

Maximum Cable Length

The maximum length of a chain is related to its transmission speed. The longer the chain, the slower the speed.

Using proper cable, Echelon supports a baud rate of 78 kilobits per second for distances up to 1600-ft (500 m) in free

topology and 8800 ft (2700 m) in bus topology with double terminations.

If you require a maximum network length of more than 1600-ft (500 m) or 8800 ft (2700 m), then a repeater is

required to extend the network.

Repeater

In the event that the limits on the number of transceivers or total wire distance are exceeded, a physical layer

repeater can be added to interconnect two or more network segments. A repeater will double the overall channel

capability, including node count and network extent, but not bandwidth. Note that only one physical layer repeater

should be placed in series between any two nodes on a channel. If additional cabling or network bandwidth is

required, then a LonWorks Router should be used in place of a repeater.

Terminators

Echelon network segments requires termination for proper data transmission performance. The type of terminator varies

depending on whether shielded or unshielded cable is used. Free topology and Bus networks also differ in their

termination requirements. The following sections describe the various terminators and terminations procedure.

Free Topology Network Segment

In a free topology segment, only one termination is required and may be placed anywhere on the free topology

segment. There are two choices for the termination:

1. RC network with Ra = 52Ω±1%, 1/8W

2. LPI-10 Link Power Interface, with jumper at “1 CPLR” setting.

Doubly Terminated Network Segment

In a doubly terminated bus topology, two terminations are required, one at each end of the bus. There are two

choices for each termination:

1. RC network with Ra = 105Ω±1%, 1/8W

2. LPI-10 Link Power Interface, with jumper at “2 CPLR” setting.

Only one LPI-10 interface is supported per segment. The other terminator must be an RC-type.

Grounding Shielded Twisted Pair Cable

When using Shielded Twisted Pair, terminate the twisted pair as listed in the previous section and ground the

cable shield by using a capacitor, to tie the shield to earth ground, and a large-value resistor to bleed off any

static charge on the shield. Tying the shield to earth ground through a capacitor will avoid DC and 50/60Hz

ground paths from being formed through the shield. Typical values for resistor and capacitor are as follows:

Capacitor = 0.1μF, 10%, Metalized Polyester, ≥ 100V

Resistor = 470kΩ, 1/4W, ±5%

The cable shield should be grounded at least once per segment, and preferably at each node. Grounding the

shield at every node will assist in suppressing 50/60Hz standing waves.

20

Page 21

Network adapter

Although network connections are polarity insensitive, it is good practice to keep polarity consistent throughout the entire

site. Figure 4 shows a network connection example and the location of the Status LED. This Status LED may help to

troubleshoot network problems.

Figure 4: Network connections and location of the Status LED on a LON module

Table 2 shows the different possibilities with the Status LED behaviour of the LON module.

Condition of the Status LED Explanation

Continuously ON The device has no application loaded in its memory and is

Un-configured

Flashing at a rate of 1/2Hz The device has an application loaded in its memory but is

Un-configured. When a device is in the un-configured state, it

does not know which devices to communicate with. A

network management tool is used to logically bind the node

to another in a LonWorks network.

Continuously OFF The device has an application loaded into its memory and is

bound onto a LonWorks network.

Table 2: Status LED condition

Software Files

XIF: When binding a node onto the network, an XIF file is needed. The XIF file has information that is used by the network

management tool to help ease the installation and maintenance process of a node. It is also used for offline configuration

of the node.

APB and NXE: When running an application program associated with a XIF file, an APB or NXE file is needed. Please

note that the thermostats have the APB file already flashed from the factory.

Device Resource File (DRF): When a LON network management tool is used; a DRF file must be installed. DRF files are

needed to display special manufacturer defined variables or configurations correctly.

• Please note that all release notes for the XIF, APB & NXE software files will be included under the

following folder name on your hard drive: C:\LonWorks\Import\Viconics. The name of the file is:

VT7xxxReadme.txt

Plug-Ins File: Plug-Ins simplify start-up, maintenance, configuration and reduce the installation effort.

• Please note that all release notes for Plug-Ins files will be included under the following folder name on

your hard drive: C:\LonWorks\Plug-Ins\Viconics\VT7xxx. The name of the file is: Readme.txt.

• All the latest software files can be downloaded from VICONICS’ web site at

www.viconics.com.com

21

Page 22

RoHS & Non-RoHS APB and NXE Files

In July of 2006, new APB and NXE files where introduced to support new RoHS compliant components from Echelon

Corporation. Those APB and NXE software revisions are not backward compatible and some care and attention

must be taken to assure you are utilizing the correct revision during the commissioning procedure. Please note that the

thermostats already have the proper file flashed from the factory.

In order to differentiate non-RoHS and RoHS software, a new PID has been issued for each new RoHS software as

shown in Figure 5.

Your LNS systems already have a built in protection against firmware mismatch and will refuse any upload from nonRoHS software to a RoHS device or vice-versa. The PID change has been instituted in order to prompt an

“incompatibility” message from your Niagara based system.

Figure 5: RoHS and Non-RoHS Marking and Program IDs

XIF, APB and NXE File Names and Corresponding PIDs

Used on thermostat XIF file names APB / NXE file

names

Non-RoHS VT7200 / VT7300 Series T7X-FC.XIF T7X-FC.APB 80:00:C5:55:00:04:04:0B

RoHS VT7200 / VT7300 Series T7X-FCr.XIF T7X-FCr.APB 80:00:C5:55:00:04:04:1B

RoHS PIR VT7200 / VT7300 Series ** T7X-FC-PIR.XIF T7X-FC-PIR.APB 80:00:C5:55:00:04:04:1D

** Please note that all new PIR ready thermostat series of the VT7200 / VT7300 thermostat family will use the latest

released files to properly use all the new advanced occupancy functions associated with a local PIR accessory cover

installed on the thermostat.

Associated PID

22

Page 23

Device Identification

An Echelon device has a unique mechanism to identify itself, the Neuron ID, which is obtained during commissioning.

There are two ways of getting the Neuron ID: with a Service Pin or manually.

Service PIN

The service pin is used to identify the device at commissioning. By pressing simultaneously the “Up” button and the

“Down” button located on the keypad interface of a VT7300 device, the program ID and the Neuron ID (LonWorks Unique

ID) contained in the device are transmitted to the commissioning or service tool. The Status LED will blink when the

device accepts the Service Pin command.

Figures 6 and 7 show an example of a Service PIN request made through a commissioning tool

Figure 6: Service Pin request through a commissioning tool

Figure 7: Service Pin request through a commissioning tool

23

Page 24

Manual Identification

Neuron ID of a device can also be entered manually through a commissioning or service tool. Neuron ID should be

located on the Echelon chip of the device being commissioned.

Figure 8 shows an example of a Manual Neuron ID request made through a commissioning tool.

Figure 8: Manual Neuron ID request

Tips And Things You Need To Know

In order to operate nviAuxOut (auxiliary output) from the network, Aux contact configuration (Auxcont nciGenOpt)

needs to be set as “Network Controlled”;

If the heartbeat is lost, the module will release the network sensor value for the Room Temperature (nviSpaceTemp)

and the Outdoor Temperature (nviOutdoorTemp);

The SeqOpera value (Sequence of Operation) depends on the nviHeatCool value and nviAuxHeatEnable value. See

note 1 on page 15 for all the details;

Troubleshooting Section

Error / Trouble

Possible Cause Solution

Condition

Thermostat does not

come online

The LON network has too many

devices.

Do not exceed the maximum number of

devices and maximum length allowed

by the EIA-485 specifications.

Too many devices were installed

without any repeaters.

Repeaters need to be installed as

specified in this document.

The LON cable runs are broken Locate the break and correct wiring

The thermostat does not have power Apply power to the thermostat

Document Control

Document Name: ITG-VT7300-PIR-LON E06

Document Filename: ITG-VT7300-PIR-LON E06.pdf

Revision Date Changes

01 January 4, 2006 Created to coincide with release of the VT7300 as a LonMark certified product.

02 April 5, 2006 Updated the DRF files section and removed any application guide reference

03 July 11, 2006 Modified the Software Files section and added the RoHS / Non-RoHS section

04 Aug 15, 2006 Modified Note 1 on page 15

05 Nov 21, 2007 Added modifications required for PIR support to the new VT73xxX5xxxE release

06 Jan 21, 2008 Added additional modifications required for PIR support

24

Page 25

Do it Once. Do it Right.

®

LIMITED WARRANTY STATEMENT

A

y

Taco, Inc. will repair or replace without charge (at the company’s option) any product or part which is proven defective under normal use within three

(3) years from the date of start-up or three (3) years and six (6) months from date of shipment (whichever occurs first).

In order to obtain service under this warranty, it is the responsibility of the purchaser to promptly notify the local Taco stocking distributor or Taco in

writing and promptly deliver the subject product or part, delivery prepaid, to the stocking distributor. For assistance on warranty returns, the

purchaser may either contact the local Taco stocking distributor or Taco. If the subject product or part contains no defect as covered in this warranty,

the purchaser will be billed for parts and labor charges in effect at time of factory examination and repair.

ny Taco product or part not installed or operated in conformity with Taco instructions or which has been subject to misuse, misapplication, the

addition of petroleum-based fluids or certain chemical additives to the systems, or other abuse, will not be covered by this warranty.

If in doubt as to whether a particular substance is suitable for use with a Taco product or part, or for any application restrictions, consult the

applicable Taco instruction sheets or contact Taco at [401-942-8000].

Taco reserves the right to provide replacement products and parts which are substantially similar in design and functionally equivalent to the

defective product or part. Taco reserves the right to make changes in details of design, construction, or arrangement of materials of its products

without notification.

TACO OFFERS THIS WARRANTY IN LIEU OF ALL OTHER EXPRESS WARRANTIES. ANY WARRANTY IMPLIED BY LAW INCLUDING

WARRANTIES OF MERCHANTABILITY OR FITNESS IS IN EFFECT ONLY FOR THE DURATION OF THE EXPRESS WARRANTY SET FORTH

IN THE FIRST PARAGRAPH ABOVE.

THE ABOVE WARRANTIES ARE IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR STATUTORY, OR ANY OTHER WARRANTY

OBLIGATION ON THE PART OF TACO.

TACO WILL NOT BE LIABLE FOR ANY SPECIAL, INCIDENTAL, INDIRECT OR CONSEQUENTIAL DAMAGES RESULTING FROM THE USE OF

ITS PRODUCTS OR ANY INCIDENTAL COSTS OF REMOVING OR REPLACING DEFECTIVE PRODUCTS.

This warranty gives the purchaser specific rights, and the purchaser may have other rights which vary from state to state. Some states do not allow

limitations on how long an implied warranty lasts or on the exclusion of incidental or consequential damages, so these limitations or exclusions ma

not apply to you.

TACO INC., 1160 Cranston Street, Cranston, RI 02920 Telephone: (401) 942-8000 FAX: (401) 942-2360.

Taco (Canada), Ltd., 6180 Ordan Drive, Mississauga, Ontario L5T 2B3. Telephone: 905/564-9422 FAX: 905/564-9436.

Visit our web site at: http://www.taco-hvac.com

Printed in USA

Copyright 2008

TACO, Inc.

25

Loading...

Loading...