Page 1

Instruction Sheet

Constant

Room Temperature

Outdoor

Temperature

Drop

Heat

Loss

Increase

SUPERSEDES : 102-106, dated June 1, 2000

Plant ID# 9300-1059

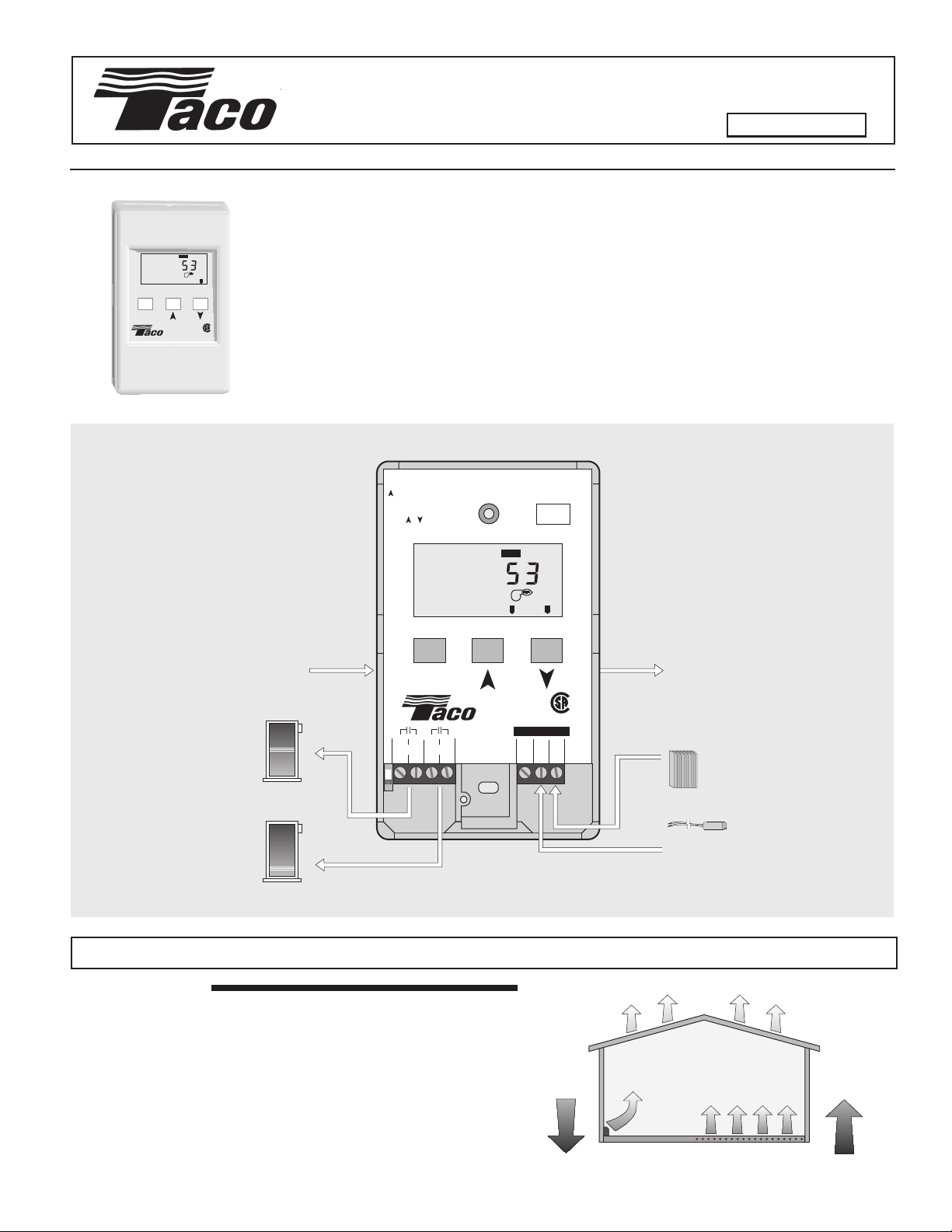

The PC702-1 is a microprocessor-based control designed to regulate the supply water temperature

from a two stage boiler system based on the outdoor temperature or DHW requirements. A wiring

harness is provided to be easily connected to the Taco Expandable (-EXP) Controls.

OUTDR

VIEW

°F

Interstage

1 2

DHW

Boiler

Delay

Demand

Demand

®

CUS

PC702

158033

Start

Item

The PC702-1 includes functions such as automatic reset ratio calculation, Warm Weather Shut Down

(WWSD), Minimum Boiler setting, adjustable interstage delay setting, optional boiler rotation, and an

optional automatic boiler differential. The control has a digital, liquid crystal display (LCD) that normally displays the Boiler Supply temperature, but can display other temperatures and settings.

Control Strategy . . . . . . . . . . . . pg. 1 Control Adjustments . . . . pg. 6

Sequence of Operation . . . . . . . pg. 2 Troubleshooting . . . . . . . pg. 7

Installation . . . . . . . . . . . . . . . . . pg. 4 Error Messages. . . . . . . . . . . pg. 8

Settings . . . . . . . . . . . . . . . . . . . pg. 5 Technical Data . . . . . . . . . . . pg. 8

PC702–1 Two Stage Boiler

Reset & DHW Control

102-106

EFFECTIVE: March 1, 2004

DHW

Demand

Output

Boiler

Output

Boiler

Press & Hold:

Item,

to view settings

, to test

Press & Release:

Item +

+

to adjust menu

OUTDR

Start

Item

1

2

Rotation On / Off

Stage

1 1

Power : 24 V ±10% 50/60 Hz 3 VA

Relays: 120 V (ac) 5 A 1/6 hp pilot 240 VA

Demand: 20 to 260 V (ac) 2 VA

Delay

Interstage

PC702-1

Signal wiring

3

4

must be rated

Stage

at least 300V

2 2

VIEW

DHW

Demand

Do not apply power

5

Com

Jul 00

31000265

°F

1 2

Boiler

Demand

CUS

67

Sup

158033

Out

®

Made in

Canada

H1192A

To Taco

Zone

Control

Input

OutdoorSensor

Included

Input

Boiler Sensor

Included

Control Strategy

OUTDOOR RESET

In order to properly control a hot water heating system, the heat supplied

to the building must equal the heat lost by the building.

• The heat supplied to a building is proportional to the temperature of the

supply water and the surface area of the heating element. A small surface

area such as baseboard radiators requires a higher water temperature

than a larger surface area such as radiant floors.

• The heat lost from a building is dependent on the outdoor temperature,

as well as other factors. As the outdoor temperature drops, the building

heat loss increases.

Page 2

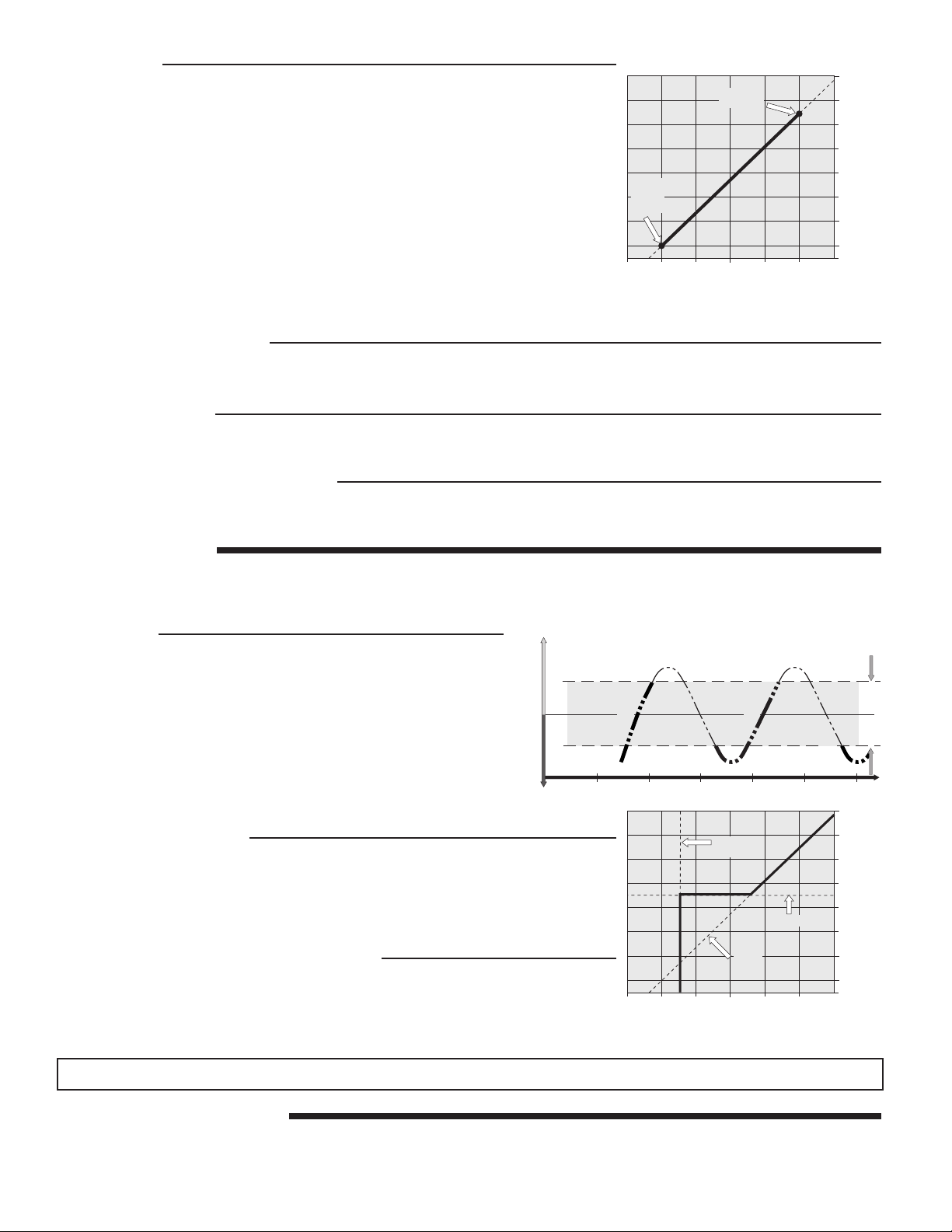

Reset Ratio

Supply Water Temperature

Time

Differential = 10°F (5°C)

165°F(74°C)

B

o

i

l

e

r

o

f

f

B

o

i

l

e

r

o

n

155°F (68°C)

160°F (71°C)

B

o

i

l

e

r

o

f

f

B

o

i

l

e

r

o

n

Operation of a hot water heating system can generally be improved by modulating the

supply water temperature as the outdoor temperature changes. Using this approach, the

heat lost from the building is matched by the heat input to the building. The PC702-1 Boiler

Reset Control utilizes a reset ratio to set the relationship between outdoor temperature

and supply water temperature. The reset ratio determines the amount the supply water

temperature is raised for every 1° drop in outdoor air temperature, and it is determined

from the starting point and the system design conditions. In order for the control to

automatically determine the reset ratio, a starting point and design conditions must be

established. These two points are set by the following 4 adjustments:

• Boiler starting temperature

• Outdoor starting temperature

• Boiler design supply water temperature

• Outdoor Design Temperature

See Settings - Step Four for a complete description of each setting.

Reset

Starting

90

(32)

Ratio

Point

70

(21)

Design

Conditions

50

(10)30(-1)10(-12)

Outdoor air temperature

-10

(-23)

210

(99)

190

(88)

170

(77)

150

(65)

130

(54)

11 0

(43)

Supply water temperature

90

(32)

70

(21)

°

F

°C)

(

Reset Ratio Starting Point

The first point used to establish the reset ratio calculation is the starting point. It is a combination of an adjustable boiler starting water

temperature setting and an adjustable outdoor starting temperature setting.

Design Conditions

The second point to establish the reset ratio calculation is the design conditions. This point represents the required water temperature

during the coldest day of the year.

Warm Weather Shut Down (WWSD)

When the outdoor air temperature is warmer than the Warm Weather Shut Down setting, no additional heat is required in the building;

therefore, the heating system can be shut down. This setting has no effect on the reset ratio calculation.

BOILER OPERATION

The supply water temperature from the boiler(s) can be controlled by cycling the boiler(s) on and off. Modulation of the operating

temperature in hot water heating systems not only provides more comfort but also offers significant energy savings. The cooler the

boiler(s) runs, the more efficient it is due to less heat losses up the flue and reduced boiler jacket losses.

Differential

An on / off boiler must be operated with a differential in order to prevent

short cycling. When the supply water temperature drops below the

bottom rail of the differential, the boiler is turned on. The boiler is then

kept on until the supply water temperature rises above the top rail of

the differential. If the differential is too wide, there can be large supply

water temperature swings; however, if the differential is too narrow, the

boiler short cycles and operates inefficiently. This control can automatically calculate the boiler differential in order to achieve an appropriate balance between temperature swings and boiler efficiency. This

also permits the control to adapt to changing loads and conditions.

Minimum Boiler Supply

Most boilers require a minimum supply water temperature in order to prevent corrosion

from flue gas condensation. The control should therefore only modulate the boiler supply

water temperature down to the boiler manufacturer’s minimum recommended operating

temperature. Some boilers are designed to condense and should be operated at low

water temperatures as much as possible for maximum efficiency.

Domestic Hot Water (DHW) Boiler Supply

Most indirect DHW tanks require a relatively high supply water temperature in order to

produce adequate amounts of DHW. The control should therefore override the reset ratio

when there is a demand for DHW and raise the system supply temperature to a

temperature that is suitable for DHW generation.

70

90

(21)

(32)

WWSD

Temperature

Reset

Ratio

50

(10)30(-1)10(-12)

Outdoor air temperature

Minimum

-10

(-23)

°F

°C)

(

210

(99)

190

(88)

170

(77)

150

(65)

130

(54)

11 0

(43)

Supply water temperature

90

(32)

70

(21)

Sequence of Operation

POWERING UP THE CONTROL

After the PC702-1 is powered up, all the LCD segments are turned on for 2 seconds, followed by a software version number. The control

then displays the outdoor temperature.

2 of 8

Page 3

BOILER DEMAND

X

X

END

ZC

Zone 1 Zone 2 Zone 3 Zone 4

ZR

Zone 4Zone 3Zone 2Zone 1

The PC702-1 obtains a boiler demand through the Taco Zone Control when

a zone calls for heat. When the PC702-1 receives a boiler demand, the

Boiler Demand

pointer is displayed in the LCD.

DHW DEMAND

The PC702-1 obtains a DHW demand when a voltage between 24 and 240

V(ac) is applied across the two DHW demand wires (black wires) that come

out of the back of the control. When the PC702-1 receives a DHW demand,

DHW Demand

the

pointer is displayed in the LCD.

OUTDR

VIEW

°

F

1 2

Start

Interstage

DHW

Boiler

Delay

Demand

Demand

Item

®

CUS

PC702

158033

SWITCH

WARM WEATHER SHUT DOWN (WWSD)

When the outdoor temperature rises above the WWSD setting, the PC702-1 displays the WWSD segment in the LCD and turns off the

boiler(s). If the PC702-1 receives a boiler demand from the Taco Zone Control while in a WWSD, the boiler(s) remain off. If the

PC702-1 receives a DHW demand while in a WWSD, the boiler(s) are fired to satisfy the DHW demand.

BOILER OPERATION

The boiler(s) operates around a differential that is either manually set or automatically controlled by the PC702-1. The control includes

a minimum on and off time for the heat source(s), in order to minimize short cycling. The automatic boiler differential increases system

efficiency by adjusting to changing loads.

POWER

INPUT120 VOLT CIRCULATORS

Boiler Demand

While the PC702-1 has a boiler demand, the system supply water temperature is controlled by turning the boiler(s) on and off. The

PC702-1 calculates the target supply water temperature based on the outdoor temperature, the reset ratio settings, and the boiler

minimum setting.

DHW Demand

While the PC702-1 has a DHW demand, the system supply water temperature is controlled by turning the boiler(s) on and off. The

PC702-1 targets a supply water temperature of at least 180°F (83°C).

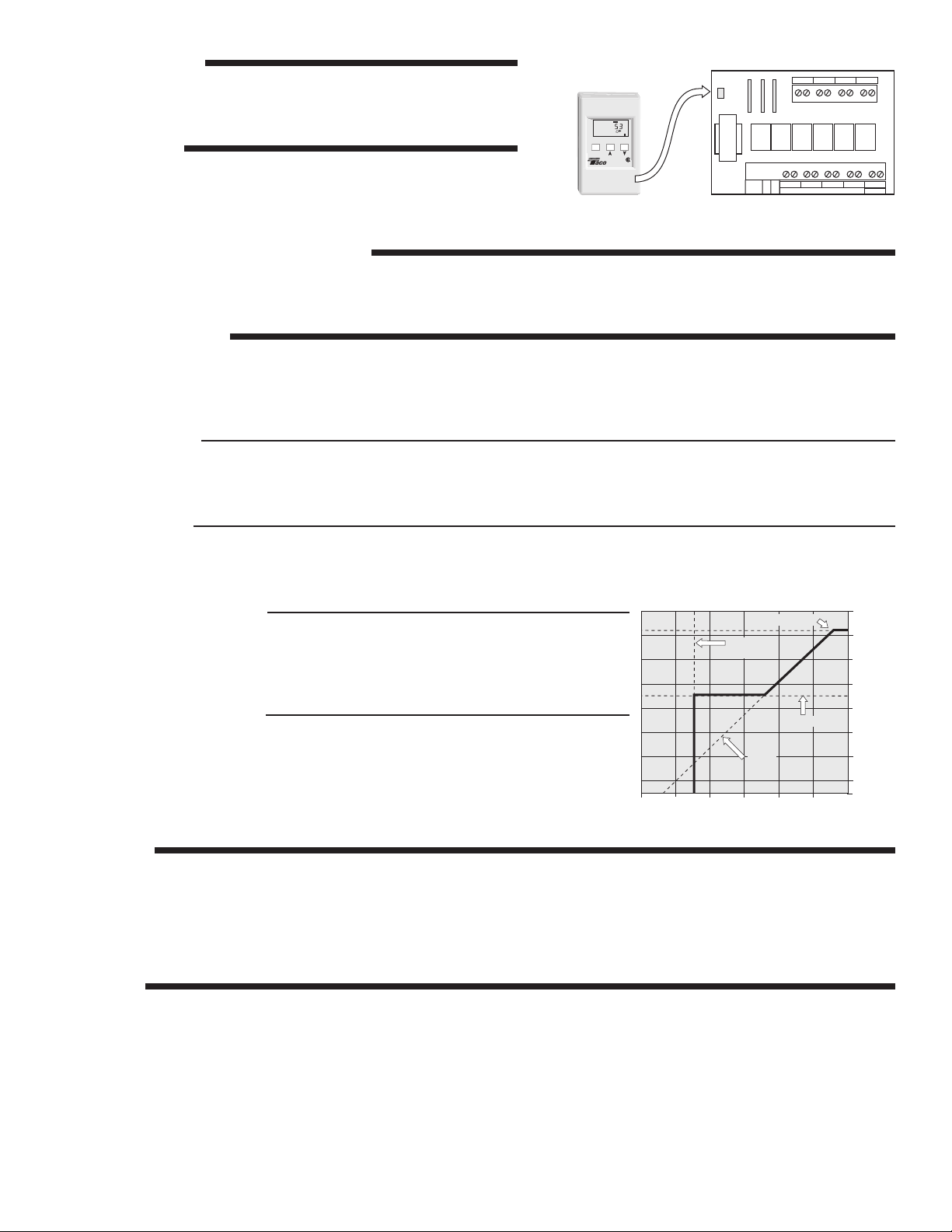

Maximum Boiler Supply

The PC702-1 does not allow the boiler target temperature to exceed the boiler design

temperature setting plus 10°F (6°C) to a maximum of 225°F (107°C). When operating at

Temperature

Maximum

WWSD

the maximum, the control displays the MAX segment in the LCD when either that boiler

supply or boiler target temperature are being viewed.

Minimum Boiler Supply

Minimum

The PC702-1 has a minimum boiler setting which selects a minimum boiler target

temperature in order to prevent corrosion from flue gas condensation. During mild

outdoor conditions, the boiler(s) cycles around the minimum boiler setting. This pro-

Reset

Ratio

grammed function has an OFF setting for condensing and electric boilers. When

operating at the minimum setting, the control displays the MIN segment in the LCD when

either that boiler supply or boiler target temperature are being viewed.

90

(32)

50

70

(10)30(-1)10(-12)

(21)

Outdoor air temperature

-10

(-23)

°

F

°C)

(

ROTATION

The PC702-1 has an optional boiler rotation function that is selected using the DIP switch located next to terminal 1 in the wiring

chamber. The PC702-1’s boiler rotation function is fixed at 48 hours. The firing order of the boilers changes whenever one stage

accumulates 48 hours more running time than the other stage. After each rotation, the stage with the least running hours is the first to

fire, and the stage with the most running hours is the last to fire. This function ensures that both stages receive equal amounts of use.

When the

NOTE: If the boiler used is a lo-hi fire boiler, set the

Rotation On / Off

DIP switch is set to the

Off

position, Stage 1 is always the first stage to fire.

Rotation On / Off

DIP switch to the

Off

position.

210

(99)

190

(88)

170

(77)

150

(65)

130

(54)

11 0

(43)

Supply water temperature

90

(32)

70

(21)

STAGING

The PC702-1 controls up to two stages in order to supply the required target temperature. After the first stage is turned on in the firing

sequence, the control waits a minimum amount of time before turning on the next stage. This minimum amount of time is set using the

interstage delay setting. After the interstage delay has expired, the PC702-1 examines the current supply water temperature to

determine when the next stage is to fire. The control uses Proportional, Integral and Derivative (PID) logic.

Proportional - compares the actual supply temperature to the boiler target temperature. The colder the supply water temperature, the

sooner the next stage is turned on.

Integral - compares the actual supply temperature to the boiler target temperature over a period of time.

Derivative - determines how fast or slow the supply water temperature is changing. If the supply temperature is increasing slowly, the

next stage is turned on sooner. If the supply temperature is increasing quickly, the next stage is turned on later, if at all.

3 of 8

Page 4

INTERSTAGE DELAY

The PC702-1 has an adjustable interstage delay setting. This setting sets the minimum time delay between the firing of the first stage

and the firing of the second stage.

Each stage has a minimum on time, and a minimum off time of 30 seconds.

Installation

Caution

Improper installation and operation of this control could result in damage to the equipment and possibly even personal injury.

It is your responsibility to ensure that this control is safely installed according to all applicable codes and standards. This

electronic control is not intended for use as a primary limit control. Other controls that are intended and certified as safety

limits must be part of the control circuit.

STEP ONE

Check the contents of this package. If any of the contents listed are missing or damaged, please contact your sales representative for

assistance.

Type PC702-1 includes: • PC702-1 Boiler Reset Control • One Outdoor Sensor

• One Strap on Sensor • Instruction Sheet

Replacement sensors are available from Taco, Inc. Strap on Sensor – 9300-2044RP Outdoor Sensor – 9300-2052RP

Note

: Carefully read the details of the Sequence of Operation section in this brochure to ensure that you have chosen the proper control

for your application.

STEP TWO

Installing the Control

• Grasp the front cover by the fingertip grips on the top and bottom of the

enclosure and pull the front cover off. Remove the wiring cover screw.

• The enclosure is mounted onto a 2” x 4” electrical box near the Taco

Zone Control.

• The mounting holes in the enclosure accept #6 screws.

• Wiring to the control enters the wiring chamber through the back or

bottom of the enclosure.

• To reassemble the enclosure, first replace the wiring chamber cover and

then push the front cover onto the enclosure until it snaps into place.

Installing the Outdoor Sensor

Note

The temperature sensor (thermistor) is built into the enclosure.

• Take the sensor cover off by sliding it upward relative to the sensor base.

• Use one round or pan head screw to attach the base of the sensor to the wall.

• The sensor is wall mounted and the wiring enters through the bottom of the enclosure. The hole for the

cable entry must face downward in order to prevent water from entering and filling the enclosure.

• The sensor should be mounted on a wall which best represents the heat load on the building (i.e. a

northern wall for most buildings and a southern facing wall for buildings with large south facing glass

areas). The sensor should not be installed near heat sources such as ventilation or window openings.

• The sensor should be installed at an elevation above the ground that will prevent accidental damage

or tampering.

• Install the Outdoor Sensor and run the wiring back to the control mounting location.

Installing the Boiler Sensor

Note

This sensor is designed to mount on a pipe or in a temperature

immersion well.

• The sensor can be strapped directly to the pipe using the cable tie

provided. Insulation should be placed around the sensor to reduce the

effect of air currents on the sensor measurement.

• The Boiler Sensor should be placed downstream of a pump or after an

elbow or similar fitting. This is especially important if large diameter pipes

are used because the thermal stratification within the pipe can result in

erroneous sensor readings. Proper sensor location requires that the fluid

is thoroughly mixed within the pipe before it reaches the sensor.

4 of 8

Hole for

mounting screw

Cable Entry

Page 5

STEP THREE

Wiring to the Zone Control

Connect the PC702-1 cable to the Add-On interface on the Taco Zone Control. Ensure the

to

Reset

.

Wiring the Sensors

Do not apply power to these terminals as this will damage the control.

Outdoor Sensor

Connect the two wires from the Outdoor Sensor to the terminals

7). The Outdoor Sensor measures the outdoor air temperature.

Com — Out

(5 and

Boiler Sensor

Connect the two wires from the Boiler Sensor to the terminals

The Boiler Sensor measures the supply water temperature going from the boiler to the

system.

Wiring the Boilers

The Stage 1 and Stage 2 terminals (1 & 2 and 3 & 4) are isolated outputs in the PC702-1.

There is no power available on these terminals from the control. These terminals are to

be used as a switch to either make or break the boiler circuit. When the PC702-1 requires

the boiler(s) to fire, it closes the contact between terminals 1 and 2 and/or 3 and 4.

DHW Demand

To generate a DHW demand, a voltage between 24 and 240 V(ac) must be applied across

the two DHW demand wires (black wires) coming from the back of the control. This can

be achieved by wiring these two wires in parallel to the DHW (priority) zone on the Taco

Zone Control.

Com — Sup

(5 and 6).

Mode

switch on the Zone Control is set

6

7

Sup5Out

Com

5

6

7

Out

Sup

Com

Zone 3 Zone 4

Refer servicing to qualified

personnel. Opening voids

P

O

T

S

warranty.

Zone 3

Zone 2

Zone 4

POWER

INPUT120 VOLT CIRCULATORS

To DHW

Pump

Settings

Before adjusting the settings, read through the sequence of operation to ensure that you understand how the control operates. The

following page describes how to program these settings into the control once it has been powered up.

STEP FOUR

Boiler Starting Temperature (BOIL Start)

The

BOIL Start

setting is the starting supply water temperature of the reset ratio, and can be adjusted from 35 to 150°F (2 to 66°C).

This setting is typically set to the desired building temperature. In applications where fan coils are used, the

be set higher to prevent cold drafts during mild outdoor conditions. If the building feels cool during mild outdoor conditions, the BOIL

Start setting should be increased.

Outdoor Starting Temperature (OUTDR Start)

The OUTDR Start setting is the outdoor temperature at which the starting temperature is supplied. The adjustment range is from 35

to 85 °F (2 to 29°C). This setting is typically set to the desired building temperature.

Boiler Design Temperature (BOIL DSGN)

The BOIL DSGN setting is the water temperature required to satisfy the building heat loss during the coldest outdoor temperature.

This adjustment is typically dependent on the type of heating terminal used. The following are suggested settings for different terminal

units:

• Inslab Radiant ..................... 100 to 140°F (38 to 60°C) • Radiant Baseboard ................. 130 to 160°F (54 to 71°C)

• Staple-up Radiant .......... 130 to 160°F (54 to 71°C) • Convective Baseboard ....... 160 to 190°F (71 to 88°C)

• Radiators ............................ 140 to 160°F (60 to 71°C) • Fan Coil .............................. 180 to 200°F (82 to 93°C)

BOIL Start

may need to

Outdoor Design Temperature (OUTDR DSGN)

The OUTDR DSGN setting is the outdoor temperature used in the heat loss calculation. It is set to the typical coldest outdoor

temperature.

Boiler Minimum Supply Temperature (BOIL MIN)

Most boilers require a minimum operating temperature to prevent corrosion from flue gas condensation. The

Minimum Boiler

setting

should be programmed to the lowest supply water temperature at which the boiler can operate without causing the boiler flue gases

5 of 8

Page 6

to condense. Consult the boiler manufacturer for recommended minimum boiler supply temperatures. Some typical settings are as

follows:

• Steel fire tube boiler ….......... 140 to 160°F (60 to 71°C) • Condensing boiler ................. Off

• Cast iron boiler ….................. 135 to 160°F (57 to 71°C) • Electric boiler ........................ Off

• Copper tube boiler …............. 125 to 150°F (52 to 66°C)

Differential (DIFF)

The differential adjustment sets how far the actual boiler supply water temperature may deviate from the desired temperature before

the boiler is turned on or off, and it is determined by the flow rate through the system pump relative to the heat output by the boiler.

The differential can be adjusted to Ad (Auto differential) or from 2 to 42°F (1 to 23°C). The following formula can be used to calculate

the desired differential:

Differential = Example: = 10°F (6°C)

When the adjustment is set to

Btu/hr input 100,000 Btu/hr

System US GPM x 500 20 US GPM x 500

Ad (Auto Differential

), the differential is continuously calculated by the control, and varies as the heating

load changes.

Interstage Delay

The interstage delay setting is used to set the minimum time delay between the first stage firing and the second stage firing, and is

adjustable from 30 seconds to 4 minutes.

Warm Weather Shut Down (WWSD)

The WWSD can be adjusted from 35 to 100°F (2 to 38°C). The boiler will be shut down when the outdoor temperature is warmer than

this setting. If the WWSD is set to OFF, the control continues to provide a minimum boiler temperature even during warm outdoor

temperatures.

Control Adjustments

Boiler Start: ______________________________________ Boiler Minimum: _______________________________

Outdoor Start: ____________________________________ Differential: __________________________________

Boiler Design: ____________________________________ Interstage Delay: ______________________________

Outdoor Design: __________________________________ WWSD: ______________________________________

ADJUST MENU

To enter the adjustment mode, Press and Hold simultaneously, the

BOIL Start

Use the and

buttons to set the

desired boiler starting

tempeature.

OUTDR Start

Press and release

the Item button. Use

and buttons

the

to set the desired

outdoor starting

tempeature.

BOIL DSGN

Press and release

the Item button. Use

the

and buttons

to set the boiler

design tempeature.

BOIL

Start Interstage

Delay

OUTDR

Start Interstage

Delay

DSGN

BOIL

Start Interstage

Delay

DHW

Demand

DHW

Demand

DHW

Demand

ADJUST

ADJUST

ADJUST

OUTDR DSGN

Press and release

°F

the Item button. Use

the

to set the outdoor

design tempeature.

Boiler

Demand

BOIL MIN

Press and release

°F

the Item button. Use

the

to set the boiler

minimum

Boiler

tempeature.

Demand

DIFF

°F

Press and release

the Item button. Use

the

to set the boiler

differential

Boiler

tempeature.

Demand

OUTDR

and buttons

BOIL

and buttons

and buttons

The control automatically goes back to viewing when the buttons are left alone for 20 seconds

All settings will be saved even during power down of the control

Item

, and Buttons. The ADJUST element will turn on.

DSGN

Start Interstage

Delay

MIN

Start Interstage

Delay

Start Interstage

Delay

DIFF

DHW

Demand

DHW

Demand

DHW

Demand

ADJUST

Demand

ADJUST

Demand

ADJUST

Demand

Interstage Delay

Press and release

°F

the Item button. Use

the

to set the desired

interstage delay time.

Boiler

WWSD

Press and release

°F

the Item button. Use

the

to set the desired

WWSD tempeature.

Boiler

Units

Press and release

the Item button. Use

the

to select between °F

and °C

Boiler

and buttons

and buttons

and buttons

Start Interstage

Delay

WWSD

Start Interstage

Delay

Start Interstage

Delay

DHW

Demand

DHW

Demand

DHW

Demand

ADJUST

min

Boiler

Demand

ADJUST

°F

Boiler

Demand

ADJUST

°F

Boiler

Demand

6 of 8

Page 7

POWER UP

VIEW MENU

On power up, the

control displays all

segments for 2

seconds and the

control version

number.

The control then

automatically goes

to operating mode,

and displays the

outdoor

temperature.

OUTDR

DSGN

BOIL

TARGET

MAXMIN

WWSD

Start Interstage

Delay

OUTDR

Start Interstage

Delay

DIFF

ADJUST

DHW

Demand

VIEW VIEW

DHW

Demand

Outdoor

°F

Temperature

°C

The OUTDR element

1 2

is turned on. The

outdoor temperature

is displayed

Boiler

Demand

Boiler

°F

Temperature

Press and release

1 2

the Item button. The

boiler supply

temperature is

Boiler

displayed.

Demand

OUTDR

Start Interstage

Delay

BOIL

Start Interstage

Delay

VIEWVIEW

DHW

Demand

DHW

Demand

°F

Boiler

Demand

°F

1 2

Boiler

Demand

Boiler Target

BOIL

Temperature

Press and release

the Item button. The

boiler target

temperature is

displayed.

To view all control settings, the

may be pressed and held while in the View

Menu. The control will then scroll through all

the adjustable items.

TARGET

Start Interstage

Delay

Item

VIEW

DHW

Demand

button

Troubleshooting

STEP FIVE

As in any troubleshooting procedure, it is important to isolate a problem as much as possible before proceeding. The error messages

greatly simplify troubleshooting of the PC702-1. When the control displays an error message, identify the fault from the look-up table

on page 8 and follow standard testing procedures to confirm the problem. If you suspect a wiring fault, return to step three and carefully

check all external wiring and wiring connections.

Sensor and Internal Faults

• If an outdoor sensor fault occurs, the PC702-1 will assume a fixed outdoor temperature of 32°F (0°C) and will target the appropriate

supply water temperature. An error message is displayed.

• If a supply sensor fault occurs, the PC702-1 turns the boiler off and displays an error message.

• If an EEPROM fault occurs, the PC702-1 turns the boilers off until

all the settings are checked.

°F

1 2

Boiler

Demand

Adjustment of Settings

• If the outdoor temperature is cold and the rooms are cold, increase the BOIL DSGN setting by 5°F (3°C) per day.

• If the outdoor temperature is near the WWSD temperature and the rooms are cold, increase the BOILStart setting.

• If the boiler is cycling too often, increase the Differential setting or set control to Ad (Auto Differential). If the second stage is coming

on too soon, increase the Interstage Delay setting.

Testing the Sensors

A good quality test meter capable of measuring up to 5,000 kΩ (1 kΩ = 1000 Ω) is required

to measure the sensor resistance. In addition to this, the actual temperature must be

measured with either a good quality digital thermometer, or, if a thermometer is not

available, a second sensor can be placed alongside the one to be tested and the readings

compared.

First measure the temperature using the thermometer and then measure the resistance

Ω

Ω

of the sensor at the control. The wires from the sensor must not be connected to the

control while the test is performed. Using the chart below, estimate the temperature

measured by the sensor. The sensor and thermometer readings should be close. If the

test meter reads a very high resistance, there may be a broken wire, a poor wiring

connection or a defective sensor. If the resistance is very low, the wiring may be shorted,

there may be moisture in the sensor or the sensor may be defective. To test for a defective

sensor, measure the resistance directly at the sensor location.

Do not apply voltage to a sensor at any time as damage to the sensor may result.

Temperature Resistance Temperature Resistance Temperature Resistance Temperature Resistance

°F °C Ω °F °C Ω °F °C Ω °F °C Ω

-30

-20

-10

0

10

20

-34

-29

-23

-18

-12

-7

234,196

165,180

118,018

85,362

62,465

46,218

30

40

50

60

70

80

-1

4

10

16

21

27

34,558

26,099

19,900

15,311

11,883

9,299

90

100

110

120

130

140

32

38

43

49

54

60

7,334

5,828

4,665

3,760

3,050

2,490

150

160

170

180

190

200

66

71

77

82

88

93

2,045

1,689

1,403

1,172

983

829

7 of 8

Page 8

STEP SIX

• Install the wiring cover over the wiring chamber and secure it with the screw provided.

• Place the front cover on the control and snap it into place.

• It is important to explain the operation of this control within the system to the end user, and to anyone else who may be operating

the system.

Error Messages

Whenever a fault is detected, an error message will be displayed to indicate the location of the problem.

EEPROM

Read Error

Outdoor

Sensor Open

OUTDR

Circuit

Outdoor

Sensor Short

Circuit

OUTDR

Boiler

Sensor Short

Circuit

BOIL

Technical Data

PC702-1 Two Stage Boiler Reset & DHW Control

Control — Microprocessor PI control; This is not a safety (limit) control.

Packaged weight — 1.5 lb. (670 g)

Dimensions — 4-3/4” H x 2-7/8” W x 7/8” D (120 x 74 x 22 mm)

Approvals — CSA NRTL /C; Meets ICES & FCC regulations for EMI/RFI.

Ambient conditions — Indoor use only, 32 to 105°F (0 to 40°C), < 90% RH non-

Power supply — Class 2, 24 V ±10% 50/60 Hz 3 VA (Powered by Taco -Exp

Relays — 24 V (ac) 5 A 1/6 hp, pilot duty 240 VA

DHW Demand — 20 t o 260 V (ac) 2 VA

Sensors — NTC thermistor, 10 kΩ @ 77°F (25°C ±0.2°C) ß=3892

included: Outdoor Sensor M 2036 and Universal Sensor 071.

Boiler Start

Outdoor Start

Boiler Design

Outdoor Design

Boiler Minimum

Differential

Interstage Delay

WWSD

Units

— 35 to 150°F (2 to 66°C) 70°F (21°C)

— O f f, 80 to 180°F (Off, 27 to 82°C) 140°F (60°C)

— Auto, 2 to 42°F (Auto, 1 to 24°C) Auto

— 0:30 to 4:00 minutes 2:00 min.

— 35 to 100°F, Off (2 to 38°C, Off) 70°F (21°C)

— °F, °C °F

condensing.

Control)

Factory

—

35 to 85°F (2 to 29°C) 70°F (21°C)

—

70 to 220°F (21 to 104°C) 190°F (88°C)

—

-60 to 32°F (-51 to 0°C) 10°F (-12°C)

Boiler

BOIL

Sensor Open

Circuit

Refer to the troubleshooting section

for operation details.

Press & Hold:

Item,

, to test

Press & Release:

Item +

Rotation On / Off

to view settings

+ to adjust menu

1

Stage

1 1

OUTDR

Item

2

Start

Delay

Signal wiring

3

4

must be rated

Stage

at least 300V

2 2

Power: 24 V ±10% 50/60 Hz 3 VA

Relays: 120 V (ac) 5 A 1/6 hp pilot 240 VA

Demand: 20 to 260 V (ac) 2 VA

Jul 00

31000265

VIEW

°F

1 2

Boiler

DHW

Interstage

Demand

Demand

CUS

PC702-1

158033

Do not apply power

5 67

Com

Out

Sup

®

Made in

Canada

H1192A

The installer must ensure that this control and its wiring are isolated and/or shielded from strong sources of electromagnetic noise.

Conversely, this Class B digital apparatus complies with Part 15 of the FCC Rules and meets all requirements of the Canadian

Interference-Causing Equipment Regulations. However, if this control does cause harmful interference to radio or television reception,

which can be determined by turning the control off and on, the user is encouraged to try to correct the interference by reorienting or

relocating the receiving antenna, relocating the receiver with respect to this control, and/or connecting the control to a different circuit

from that to which the receiver is connected.

Do It Once. Do It Right.™

TACO, INC., 1160 Cranston Street, Cranston, RI 02920 Telephone: (401) 942-8000 FAX: (401) 942-2360.

TACO (Canada), Ltd., 6180 Ordan Drive, Mississauga, Ontario L5T 2B3. Telephone: 905/564-9436.

Visit our web site at: http://www.taco-hvac.com

8 of 8

Copyright 2004 TACO, Inc.

Portions Copyright 2000

tekmar Control Systems Ltd.

tekmar Control Systems Inc.

Loading...

Loading...