Page 1

505-010-2

Application Guide

VPU2 Air Control – Pressure Independent Multi-Zone

Self-Contained Interoperable Controller Model UCP-1

SUPERSEDES: January 16, 2013

Plant ID: 001-4026

Table of Contents

VPU2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Purpose of This Guide . . . . . . . . . . . . . . . . . . . . . . . . . 3

Representations and Warranties . . . . . . . . . . . . . . . . . 4

Applicable Documentation . . . . . . . . . . . . . . . . . . . . . . 4

Installation Instructions . . . . . . . . . . . . . . . . . . . . . . . . . 5

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Static Electricity . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

FCC Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Before Installing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

About this Document . . . . . . . . . . . . . . . . . . . . . . . . 5

Inspecting the Equipment . . . . . . . . . . . . . . . . . . . . 5

What is Not Included with this Equipment . . . . . . . . 6

Equipment Location . . . . . . . . . . . . . . . . . . . . . . . . .6

Selecting a Power Source . . . . . . . . . . . . . . . . . . . . 6

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Mounting the Device . . . . . . . . . . . . . . . . . . . . . . . .6

Routing Cabling to the Device . . . . . . . . . . . . . . . . . 7

Grounding the Device . . . . . . . . . . . . . . . . . . . . . . .7

Wiring Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Connecting Input Devices . . . . . . . . . . . . . . . . . . . 10

Connecting Output Devices . . . . . . . . . . . . . . . . . .11

Other Connections . . . . . . . . . . . . . . . . . . . . . . . . . 12

Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Mechanical. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Application Description . . . . . . . . . . . . . . . . . . . . . . . . 15

Sequence of Operation. . . . . . . . . . . . . . . . . . . . . . . . 17

Occupancy State . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Operational Mode . . . . . . . . . . . . . . . . . . . . . . . . . 18

Setpoint Calculations . . . . . . . . . . . . . . . . . . . . . . .20

Supply Air Setpoint Reset Curve . . . . . . . . . . . . . . 20

Outside Air Temperature Lockouts . . . . . . . . . . . .21

Heating Sequence . . . . . . . . . . . . . . . . . . . . . . . . . 22

EFFECTIVE: April 29, 2014

Cooling Sequence . . . . . . . . . . . . . . . . . . . . . . . . . 25

Economizer Operation. . . . . . . . . . . . . . . . . . . . . . 29

Dehumidification . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Fan Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Static Pressure Control . . . . . . . . . . . . . . . . . . . . . 30

Soft Start Ramping . . . . . . . . . . . . . . . . . . . . . . . . 31

Fan Proof. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

VPU2 and VAVI Communications . . . . . . . . . . . . . 31

Power On/Reset Delay . . . . . . . . . . . . . . . . . . . . . 32

Supply Air Temperature Monitoring . . . . . . . . . . . . 32

Smoke Detection . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Mixed Air Low Limit Detection . . . . . . . . . . . . . . . . 32

Filter Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Indoor Air Quality. . . . . . . . . . . . . . . . . . . . . . . . . . 33

Real Time Clock (RTC) . . . . . . . . . . . . . . . . . . . . . 33

Local Backup Schedule . . . . . . . . . . . . . . . . . . . . . 33

Runtime Accumulation. . . . . . . . . . . . . . . . . . . . . . 34

Alarms and Events. . . . . . . . . . . . . . . . . . . . . . . . . 34

Automatic Configuration . . . . . . . . . . . . . . . . . . . . 34

Controller Identification . . . . . . . . . . . . . . . . . . . . . . . 34

Inputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Diagnostic LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Troubleshooting Tips . . . . . . . . . . . . . . . . . . . . . . . 44

© 2014 Taco Electronic Solutions, Inc. 1

Page 2

iWorx® VPU2

THIS PAGE LEFT BLANK INTENTIONALLY

2 505-010-2, Effective: April 29, 2014

© 2014 Taco Electronic Solutions, Inc.

Page 3

iWorx® VPU2

VPU2

The VPU2 is a self-contained microprocessor-based controller for one Variable Air Volume (VAV) package unit. Applications include VAV package units with up to four stages of cooling, or a floating point control valve or a modulated output (valve or variable speed circulator) two stages of heating, or a floating point control valve or a modulated output

(valve or variable speed circulator) an economizer, and a variable speed fan. The VPU2 is designed for integrated networked operation with the iWorx® Local Control Interface (LCI) and up to 56 VAV terminal unit controllers.

Overview

Digital inputs are provided for fan status, mixed air low limit indication, smoke detector, and filter status. Analog inputs

are provided for mixed air temperature, return air humidity, supply air temperature and supply duct static pressure. An

indoor air quality (IAQ) input can be configured for analog or digital operation.

The VPU2 incorporates digital outputs in the form of triacs for fan start/stop, four cooling stages, two heating stages

and a two-position economizer. In addition, two analog outputs are provided to control a modulated economizer and

variable speed fan drive.

The controller is based on the LONWORKS® networking technology. The controller can be networked to a higher-level

control system for monitoring and control applications.

Features

• Four stages of cooling, or floating point valve control or a modulated output (valve or variable speed circulator)

• Two stages of heating, or floating-point valve control or a modulated output (valve or variable speed circulator)

• Dehumidification

• Modulated fan speed

• Digital or modulated economizer

• Economizer enabled based on enthalpy calculations or dry bulb

• Minimum cycle timers for stages

• Runtime accumulation for heating, cooling and fan

• Local backup schedule

• Maximum of 56 zones (VAV boxes)

• Supply air temperature safety limits

• Time proportioned control of the staged outputs to reduce cycling

• Proportional + Integral control of the modulated economizer, modulated heating, modulated cooling, and static

pressure

• Mixed air low limit protection, filter status, fan proof, freeze stat, and smoke detection inputs

• IAQ compensation based on IAQ alarm input or zone controller alarm

• Outside Air Temperature cutoffs

• Automatic morning warm-up sequence

•LONWORKS interface to building automation systems

• Automatic configuration with the LCI

• Alarm/Event reporting

PURPOSE OF THIS GUIDE

The iWorx® VPU2 Application Guide provides application information for the VPU2 Controller.

The reader should understand basic HVAC concepts, intelligent environmental control automation, and basic LON-

WORKS networking and communications. This Application Guide is written for:

• Users who engineer control logic

505-010-2, Effective: April 29, 2014 3

© 2014 Taco Electronic Solutions, Inc.

Page 4

iWorx® VPU2

• Users who set up hardware configuration

• Users who change hardware or control logic

• Technicians and field engineers of Taco Electronic Solutions, Inc.

REPRESENTATIONS AND WARRANTIES

This Document is subject to change from time to time at the sole discretion of Taco Electronic Solutions, Inc. All

updates to the Document are available at www.taco-hvac.com. When installing this product, it is the reader’s responsibility to ensure that the latest version of the Document is being used.

iWorx® products shall only be used for the applications identified in the product specifications and for no other purposes. For example, iWorx® products are not intended for use to support fire suppression systems, life support systems, critical care applications, commercial aviation, nuclear facilities or any other applications where product failure

could lead to injury to person, loss of life, or catastrophic property damage and should not be used for such purposes.

Taco Electronic Solutions, Inc. will not be responsible for any product or part not installed or operated in conformity with

the Document and instructions or which has been subject to accident, disaster, neglect, misuse, misapplication, inadequate operating environment, repair, attempted repair, modification or alteration, or other abuse. For further information, please refer to the last page of this Document for the company’s Limited Warranty Statement, which is also issued

with the product or available at www.taco-hvac.com.

APPLICABLE DOCUMENTATION

See the table below for additional documentation that may be applicable to this controller.

Description Audience Purpose

iWorx® VPU2 Application Guide,

Document No. 505-010 (this document)

iWorx® LCI Application Guide, Document No. 505-002

iWorx® VAV Application Guide, Document No. 505-011

http://www.iWorxWizard.com – Application Engineers

Additional

Documentation

– Application Engineers

– Installers

– Service Personnel

– Start-up Technicians

– End user

– Application Engineers

– Installers

– Service Personnel

– Start-up Technicians

– End user

– Application Engineers

– Installers

– Service Personnel

– Start-up Technicians

– End user

– Wholesalers

– Contractors

LonWorks FTT-10A Free Topology Transceiver User’s Guide, published by Echelon Corporation. It provides specifications and user instructions for the FTT-10A Free Topology Transceiver. See also: www.echelon.com/support/documentation/manuals/transceivers.

Provides instructions for setting up and using

the iWorx® VPU2 controller.

Provides instructions for setting up and using

the iWorx® Local Control Interface.

Provides instructions for setting up and using

the iWorx® VAV Series controller.

An on-line configuration and submittal package

generator based on user input. Automatically

generates bill of materials, sequence of operations, flow diagrams, wiring diagrams, points

and specifications.

4 505-010-2, Effective: April 29, 2014

© 2014 Taco Electronic Solutions, Inc.

Page 5

iWorx® VPU2

INSTALLATION INSTRUCTIONS

General

CAUTION: This symbol is intended to alert the user to the presence of important installation and mainte-

nance (servicing) instructions in the literature accompanying the equipment.

CAUTION: Risk of explosion if battery is replaced by an incorrect type. Contains lithium type battery; dispose of properly.

WARNING: Electrical shock hazard. Disconnect ALL power sources when installing or servicing this

equipment to prevent electrical shock or equipment damage.

Make all wiring connections in accordance with these instructions and in accordance with pertinent national and local

electrical codes. Use only copper conductors that are suitable for 167 °F (75 °C).

Static Electricity

Static charges produce voltages that can damage this equipment. Follow these static electricity precautions when handling this equipment.

• Work in a static free area.

• Touch a known, securely grounded object to discharge any charge you may have accumulated.

• Use a wrist strap when handling printed circuit boards. The strap must be secured to earth ground.

FCC Compliance

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15 of

the FCC rules. These limits are designed to provide reasonable protection against harmful interference. This equipment can radiate radio frequency energy and, if not installed and used in accordance with the instructions, may cause

harmful interference to radio communications. However, there is no guarantee that interference will not occur in a particular installation. If this equipment does cause harmful interference to radio or television reception, which can be

determined by turning the equipment off and on, the user is encouraged to try to correct the interference by one or

more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and the receiver.

• Connect the equipment to a power source different from that to which the receiver is connected.

• Consult the equipment supplier or an experienced radio/TV technician for help.

You are cautioned that any changes or modifications to this equipment not expressly approved in these instructions

could void your authority to operate this equipment in the United States.

BEFORE INSTALLING

About this Document

The instructions in this manual are for the VPU2 controller, which supporst one Variable Air Volume package unit.

Inspecting the Equipment

Inspect the shipping carton for damage. If damaged, notify the carrier immediately. Inspect the equipment for damage.

Return damaged equipment to the supplier.

505-010-2, Effective: April 29, 2014 5

© 2014 Taco Electronic Solutions, Inc.

Page 6

iWorx® VPU2

What is Not Included with this Equipment

• A power source for the equipment electronics and peripheral devices.

• Tools necessary to install, troubleshoot and service the equipment.

• The screws or DIN rail needed to mount the device.

• Peripheral devices, such as sensors, actuators, etc.

• Cabling, cabling raceway, and fittings necessary to connect this equipment to the power source, FTT-10A network

and peripheral devices.

Equipment Location

Abide by all warnings regarding equipment location provided earlier in this document.

Optimally, the equipment should be installed within a secure enclosure.

If the equipment is to be installed outdoors, it must be contained within a protective enclosure. The enclosure must

maintain internal temperature and humidity within the ranges specified for this equipment.

The equipment must be installed within 500 feet of all input peripherals (smoke detectors, sensors, etc.) that are connected to the equipment.

Selecting a Power Source

This equipment requires a UL recognized Class 2 external power source (not supplied) to operate. The controller

power input requires a voltage of 24 Volts AC.

To calculate power source current requirements, add the power consumption of all peripheral devices to that of the

controller.

The controller and sensor power supplies can use the same power source. If both are using the same power source,

the loads must have EMF protection. This protection can be integral to the load, or installed in the 24 VAC wiring across

the load’s coil.

To provide necessary RFI and transient protection, the controller’s ground (GND) pin (T40) must be connected to earth

ground or the earth ground of the packaged unit’s enclosure ground. Failure to properly ground the controller may

cause it to exceed FCC limits. Excessive noise could also produce inaccurate sensor data. The power source must be

capable of operating with this connection to ground.

INSTALLATION

Warning: Electrical shock hazard. To prevent electrical shock or equipment damage, disconnect ALL

power sources to controllers and loads before installing or servicing this equipment or modifying any wiring.

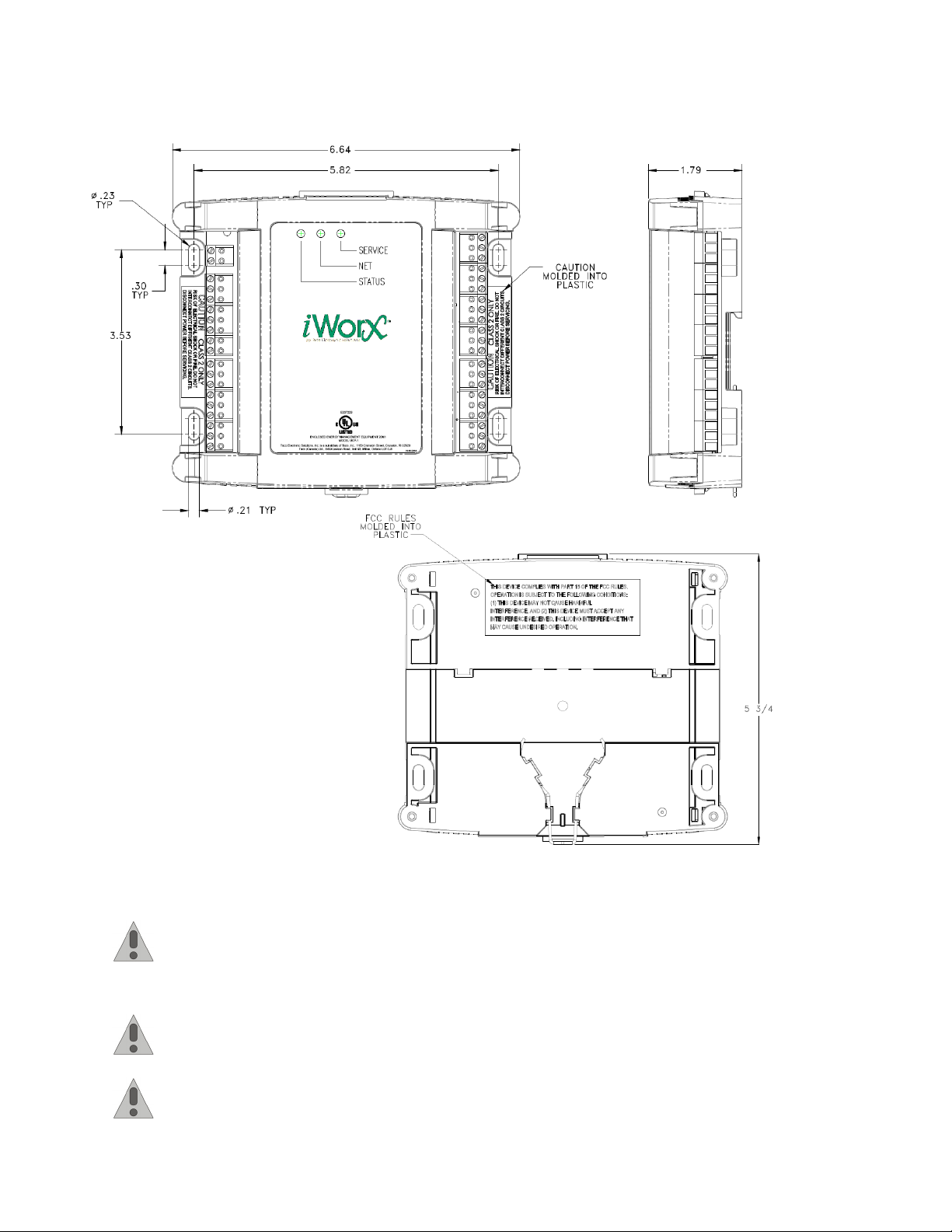

Mounting the Device

1.Select a mounting location. Enclosure mounting is recommended.

2.Hold the controller on the panel you wish to mount it on. With a marker or pencil mark the mounting locations on

the panel.

3.Using a small drill bit pre-drill the mounting holes.

4.Using two #6 pan head screws, mount the controller to the panel.

5.Wire the controller (See Routing Cabling to the Device).

6 505-010-2, Effective: April 29, 2014

© 2014 Taco Electronic Solutions, Inc.

Page 7

Figure 1: Mounting Dimensions

iWorx® VPU2

Routing Cabling to the Device

Cabling used to connect the power source and cabling used to connect the FTT-10A network must remain

separated within the control enclosure and wiring conduit.

Grounding the Device

The ground terminal (T40) must be securely connected to earth ground. Failure to properly ground this

equipment will result in improper operation. Improper grounding may also increase the risk of electrical

shock and may increase the possibility of interference with radio/TV reception.

For best performance, connect the power supply common terminal (T38) to the same external point as the

ground terminal (T40).

505-010-2, Effective: April 29, 2014 7

© 2014 Taco Electronic Solutions, Inc.

Page 8

iWorx® VPU2

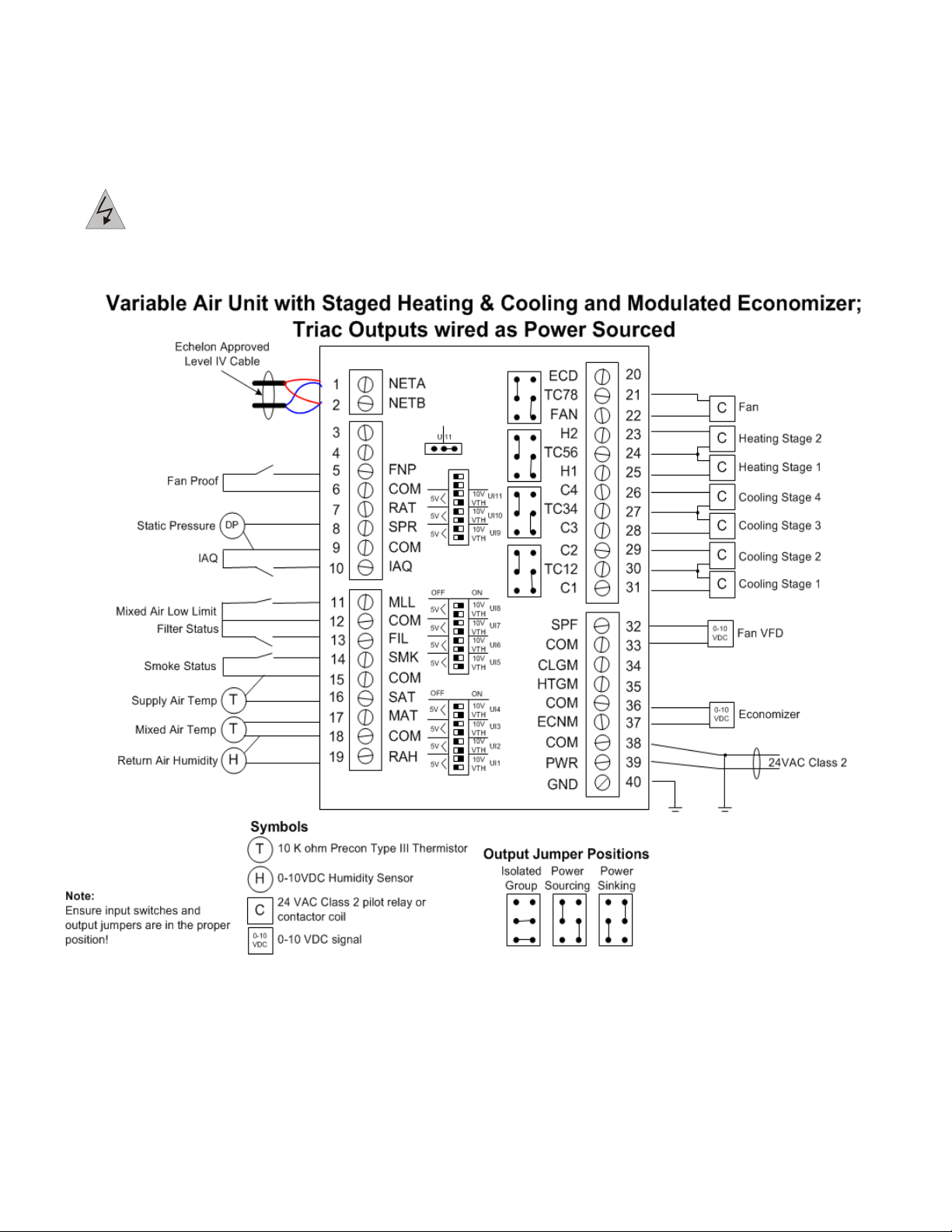

WIRING INFORMATION

WARNING: Terminals 6, 9, 12, 15, and 18 are connected internally on all VPU2 controllers. Disconnect

ALL power sources when installing or servicing this equipment to prevent electrical shock or equipment

damage.

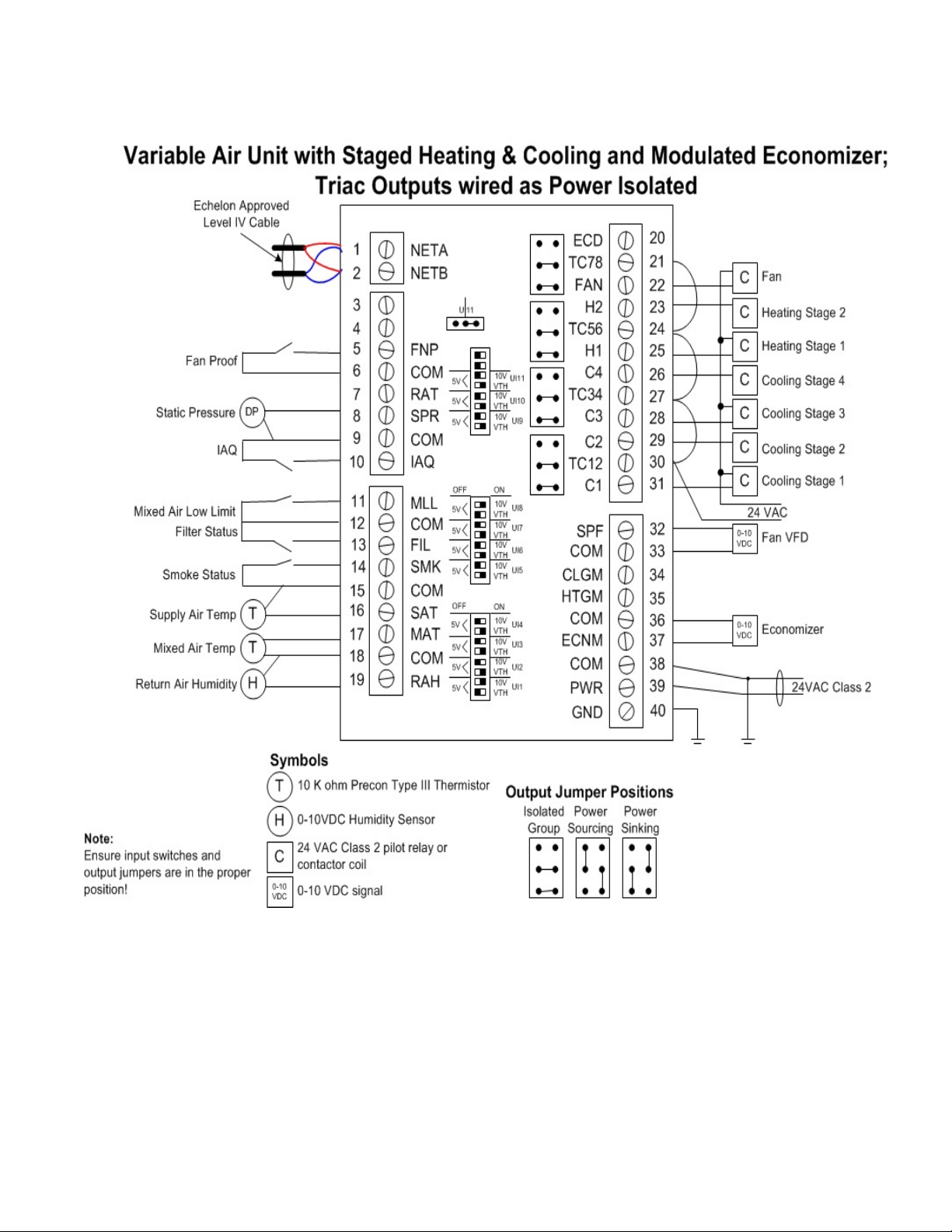

Figure 2: Typical VPU2 Wiring - Example A

8 505-010-2, Effective: April 29, 2014

© 2014 Taco Electronic Solutions, Inc.

Page 9

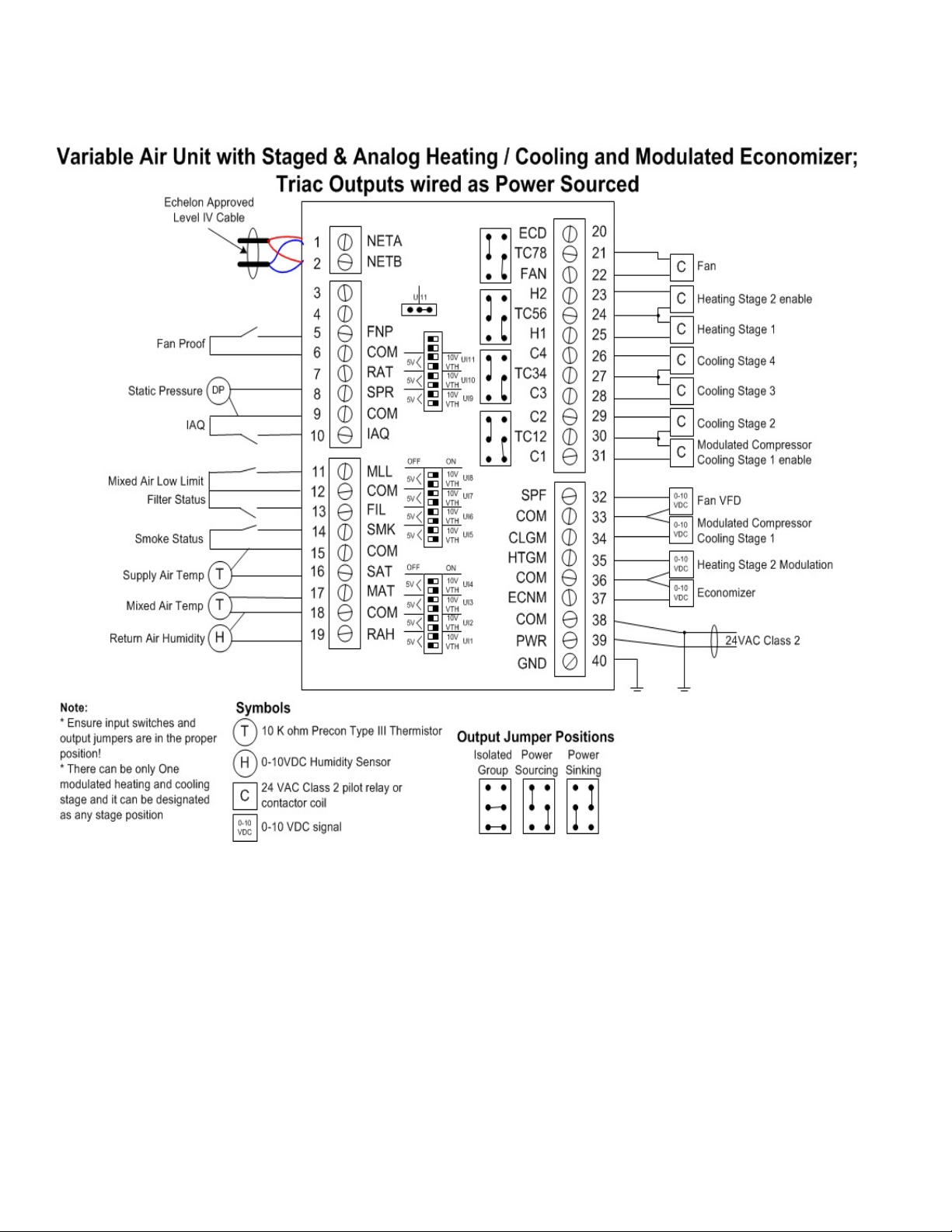

Figure 3: Typical VPU2 Wiring - Example B

iWorx® VPU2

505-010-2, Effective: April 29, 2014 9

© 2014 Taco Electronic Solutions, Inc.

Page 10

iWorx® VPU2

Figure 4: Typical VPU2 Wiring - Example C

Connecting Input Devices

Return Humidity (RAH)

To connect the Return Air Humidity sensor to the unit, connect the positive wire from the sensor to RAH (T19) and the

other wire to the adjacent common (T18). The sensor must be of the 0-10 Volt type.

If global indoor air humidity readings are being provided over the network, it is not necessary to attach a return air

humidity sensor directly to the VPU2.

Mixed Air (MAT)

To connect the Mixed Air thermistor to the unit, attach one wire from the thermistor to MAT (T17) and the other wire to

the adjacent common (T18). The thermistor used must be 10K Precon Type III.

10 505-010-2, Effective: April 29, 2014

© 2014 Taco Electronic Solutions, Inc.

Page 11

iWorx® VPU2

Supply Air (SAT)

To connect the Supply Air thermistor to the unit, attach one wire from the thermistor to SAT (T16) and the other wire to

the adjacent common (T15). The thermistor used must be 10K Precon Type III.

Smoke Detector (SMK)

To connect the smoke detector switch to the digital input, attach one wire of the contact to SMK (T14) and the other

wire to the adjacent common (T15). This must be a dry contact normally open switch. This input is for indication only. A

separate smoke detector should be wired into a fire alarm system if the generation of a fire alarm is required.

Filter Status (FIL)

To connect the filter switch to the digital input, attach one wire of the contact to FIL (T13) and the other wire to the adjacent common (T12).

Mixed Air Low Limit (MLL)

This must be a dry contact normally open switch. To connect the low limit indication switch to the digital input, attach

one wire of the contact to MLL (T11) and the other wire to the adjacent common (T12). This must be a dry contact normally open switch.

Indoor Air Quality (IAQ)

This must be a dry contact normally-open switch. To connect the digital CO2 level sensor to the unit, attach one wire

from the sensor to IAQ (T10) and the other wire to the adjacent common (T9). For a digital sensor, this must be a dry

contact, normally closed switch. For an analog sensor, it must be of the 0-10V type.

Static Pressure (SPR)

To connect the static pressure sensor to the analog input, attach the positive wire from the sensor to SPR (T8) and the

other wire to the adjacent common (T9). The sensor must be analog, 0 to 10 volt type.

Return Air Temperature (RAT)

To connect the return air temperature thermistor to the analog input, attach one wire of the sensor to RAT (T7) and the

other wire to the adjacent common (T6).

Fan Proof (FNP)

To connect the fan proof switch to the digital input, attach one wire of the contact to FNP (T5) and the other wire to the

adjacent common (T6). This must be a dry contact, normally closed switch. If you are not providing a fan proof input, T5

and T6 must be shorted (jumpered) together.

Connecting Output Devices

Modulated Economizer (ECNM)

The modulated economizer output can be set to 0-10 V max through the control logic. Connect the positive wire from

the damper actuator to ECNM (T37) and the other wire to the adjacent common (T36). See preceding figures for

details.

Modulated Heating (HTGM)

The modulated heating output can be set to 0-10 V max through the control logic. Connect the positive wire from the

heating output to HTGM (T35) and the other wire to COM (T36). See preceding figures for details.

Modulated Cooling (CLGM)

The modulated cooling output can be set to 0-10 V max through the control logic. Connect the positive wire from the

cooling output to CLGM (T34) and the other wire to COM (T33). See preceding figures for details.

505-010-2, Effective: April 29, 2014 11

© 2014 Taco Electronic Solutions, Inc.

Page 12

iWorx® VPU2

Modulated Static Pressure Fan (SPF)

The modulated static pressure fan output can be set to 0-10 V max through the control logic. Connect the positive wire

from the fan output to SPF (T32) and the other wire to COM (T33). See preceding figures for details.

Cooling Stage 1 or Cooling Floating Point Valve Open (C1)

The cooling stage output must be connected to a 24 VAC pilot relay if the load is greater than 1 Amp. See preceding

figures for details. If the load is less than 1 Amp, connect cooling stage 1 to C1 (T31) and TC12 (T30). For control of a

floating point valve, connect C1 as the valve open signal.

Cooling Stage 2 or Cooling Floating Point Valve Close (C2)

The cooling stage output must be connected to a 24 VAC pilot relay if the load is greater than 1 Amp. See preceding

figures for details. If the load is less than 1 Amp, connect cooling stage 2 to C2 (T29) and TC12 (T30). For control of a

floating point valve, connect C2 as the valve close signal.

Cooling Stage 3 (C3)

The cooling stage output must be connected to a 24 VAC pilot relay if the load is greater than 1 Amp. See preceding

figures for details. If the load is less than 1 Amp, connect to C3 (T28) and TC34 (T27).

Cooling Stage 4 (C4)

The cooling stage output must be connected to a 24 VAC pilot relay if the load is greater than 1 Amp. See preceding

figures for details. If the load is less than 1 Amp, connect to C4 (T26) and TC34 (T27).

Heating Stage 1 or Heating Floating Point Valve Open (H1)

The heating stage output must be connected to a 24 VAC pilot relay if the load is greater than 1 Amp. See preceding

figures for details. If the load is less than 1 Amp, connect heating stage 1 to H1 (T25) and TC56 (T24). For control of a

floating point heating valve, connect H1 (T25) as the valve open signal. TC56 (T24) is the common.

Heating Stage 2 or Heating Floating Point Valve Close (H2)

The heating stage output must be connected to a 24 VAC pilot relay if the load is greater than 1 Amp. See preceding

figures for details. If the load is less than 1 Amp, connect heating stage 2 to H2 (T23) and TC56 (T24). For control of a

floating point heating valve, connect H2 (T23) as the valve close signal. TC56 (T24) is the common.

Fan (FAN)

The fan output must be connected to a 24 VAC pilot relay if the load is greater than 1 Amp. See preceding figures for

details. If the load is less than 1 Amp, connect the fan to FAN (T22) and TC78 (T21).

Two Position Economizer (ECD)

The two-position economizer output must be connected to a 24 VAC pilot relay if the load is greater than 1 Amp. See

preceding figures for details. If the load is less than 1 Amp, connect the economizer to ECD (T20) and TC78 (T21).

Other Connections

Network (LON)

Network wiring must be twisted pair. One network wire must be connected to terminal NETA (T1) and the other network

wire must be connected to terminal NETB (T2). Polarity is not an issue since an FTT-10A network is used for communications.

Power (PWR)

Connect one output wire from a 24 VAC power supply to PWR (T39) and the other output wire from the power supply to

the adjacent common terminal (T38). T38 must be connected to earth ground.

12 505-010-2, Effective: April 29, 2014

© 2014 Taco Electronic Solutions, Inc.

Page 13

iWorx® VPU2

Ground (GND)

Terminal GND (T40) must be connected to earth ground. Failure to properly ground this equipment will

result in improper operation. Improper grounding may also increase the risk of electrical shock, and may

increase the possibility of interference with radio and TV reception.

Protocol

The VPU2 is based on the LONWORKS® networking technology and can be networked to a higher-level control system

for monitoring and control applications. For additional information on the Protocol reference the LonWorks FTT-10A

Free Topology Transceiver User's Guide, published by the Echelon Corporation.

SPECIFICATIONS

Electrical

Inputs

• Cabling: twisted shielded pair, 18 AWG recommended—500 feet max. (152 meters)

• Resolution: 10 bit

Mixed Low Limit, Filter Status, Smoke Detect, Local IAQ Alarm

• Dry Contact

• Normally Open

•5 Volts DC Max

Fan Proof

• Dry Contact

• Normally Closed

•5 Volts DC Max

Return Air Humidity, Static Pressure

• 0 - 10 Volts DC

Mixed Air Temperature, Supply Air Temperature, Return Air Temperature

• Precon Type III 10K thermistor

Outputs

Cooling Stages 1, 2, 3, & 4; Heating Stages 1 & 2; Fan Start/Stop; Two-position Economizer

•24 Volts AC

• 1A @ 50C, 0.5A @ 60C, limited by the Class 2 supply rating

Modulated Economizer, Modulated Static Pressure Fan

• 0-10 Volts DC

• 2K Ohm minimum load

• 8 bit resolution

Power

Power Requirements

• 24VAC (20VAC to 28VAC), requires an external Class 2 supply

Power Consumption

• 7.2W with no external loads, maximum limited by the Class 2 supply rating

505-010-2, Effective: April 29, 2014 13

© 2014 Taco Electronic Solutions, Inc.

Page 14

iWorx® VPU2

Recommended Sensor Wire

Cable Type Pairs Details Taco Catalog No.

18AWG 1 Stranded Twisted Shielded Pair, Plenum WIR-018

FTT-10A Network

• Speed: 78KBPS

• Cabling: Maximum node-to-node distance: 1312 feet (400 meters)

• Maximum total distance: 1640 feet (500 meters)

Cable Type Pairs Details Taco Catalog No.

Level 4 22AWG (0.65mm) 1 Unshielded, Plenum, U.L. Type CMP WIR-022

For detailed specifications, refer to the FTT-10A Free-Topology Transceiver User’s Guide published by Echelon Corporation (www.echelon.com/support/documentation/manuals/transceivers).

Mechanical

Housing

• Dimensions: 5.55” (141mm) high, 6.54” (166 mm) wide, 1.75” deep (44 mm)

• ABS

Weight

• Controller Weight: 0.70 pounds (0.32 kilograms)

• Shipping Weight: 1.0 pounds (0.46 kilograms)

Electronics

• Processor: 3150 Neuron 10 MHz

• Flash: 48 Kilobytes

• SRAM: 8 Kilobytes

• Termination: 0.197” (5.0 mm) Pluggable Terminal Blocks, 14-22 AWG

Environmental

• Temperature: 32 °F to 140 °F (0 °C to 60 °C)

• Humidity: 0 to 90%, non-condensing

Agency Listings

• UL Listed for US and Canada, Energy Management Equipment PAZX and PAZX7.

Agency Compliances

• FCC Part 15 Class A

14 505-010-2, Effective: April 29, 2014

© 2014 Taco Electronic Solutions, Inc.

Page 15

iWorx® VPU2

APPLICATION DESCRIPTION

The VPU2 is a Variable Air Volume (VAV) package unit controller for controlling supply air temperature and supply air

duct static pressure. Figure 5 and Figure 6 illustrate typical VPU2 applications. The VPU2 operates in conjunction with

up to 56 VAVI zone controllers. Control is achieved by modulating the economizer position and sequencing the heating

and cooling stages based on the current supply air temperature requirements. In addition, the VPU2 controls the supply fan speed to maintain a supply duct static pressure setpoint.

Figure 5: VPU2 Application with Staged Heating & Cooling and Modulated Economizer

The VPU2 controls the starting and stopping of the supply air fan. During the occupied and warm-up periods, the fan

runs continuously. The fan cycles on during the unoccupied periods when a zone is in extended occupancy or when

there is a call for emergency heating. The fan speed control operates to maintain a configurable system static pressure

setpoint. Fan speed is calculated by a Proportional + Integral (P+I) control loop based on the measured static pressure

and setpoint. As the pressure increases above the pressure setpoint, the fan speed output is throttled back. As the

pressure decreases below the pressure setpoint, the output is increased.

The enthalpies of the outside and inside air are calculated periodically. A comparison is performed to determine if “free

cooling” is available. If “free cooling” is available, the economizer is enabled. Free cooling can also be enabled based

on a dry-bulb comparison of the outdoor air temperature and indoor temperature. The system can use either a twoposition or modulated economizer. If a two-position economizer is employed, it is energized when there is a call for

cooling. It is used as the first stage of cooling to take advantage of the energy savings. The two-position economizer

output is off when the modulating economizer feature is disabled.

505-010-2, Effective: April 29, 2014 15

© 2014 Taco Electronic Solutions, Inc.

Page 16

iWorx® VPU2

If a modulated economizer is employed and “free cooling” is available the modulated economizer position is calculated

by a Proportional + Integral (P+I) control loop. The control is based on the mixed air temperature and setpoint. As the

temperature increases above the mixed air setpoint the economizer is modulated open. The economizer is modulated

closed as the temperature decreases below the mixed air setpoint. The economizer is modulated to its minimum position when the economizer is disabled. The economizer can optionally be disabled during the unoccupied periods.

When free cooling is available, mechanical cooling will not be enabled until the economizer is fully open (100%) for

three minutes at which time mechanical cooling will be enabled. This will help in preventing low suction and icing of the

cooling coils.

Either type of economizer can be disabled during unoccupied periods.

The VPU2 operates in one of four states: morning warm-up/cool-down, occupied, unoccupied, or shutdown. A host

device on the network determines the active operating mode. An optional backup schedule is provided for cases when

the host device is not available. The operating state determines if the VPU2 is in heating mode or cooling mode.

Figure 6: VAV Zone Control System

Cooling is accomplished through control of up to four stages of cooling, or one floating point cooling valve or control of

one analog cooling output (valve or variable speed circulator).

When the operating mode is cooling (occupied and extended occupancy), the cooling stages are sequenced on and off

with a time-proportioned control algorithm to minimize excessive cycling. The sequencing is based on the supply air

temperature and cooling setpoint. The cooling stages are interlocked with the economizer control. If the economizer is

enabled, the cooling stages do not sequence on until the economizer has reached its open position.

If configured for modulated analog output the cooling output position is calculated by a P + I control loop based on the

supply temperature and the cooling setpoint. As the temperature increases above the cooling setpoint, the cooling output will be modulated open. The cooling output will be modulated closed as the temperature decreases below the cooling setpoint.

If configured for a floating point valve control the cooling valve is calculated by a P + I control loop based on the supply

temperature and cooling setpoint. As the temperature increases above the cooling setpoint, the valve will be modulated

open. The valve will be modulated closed as the temperature decreases below the cooling setpoint.

Heating is accomplished through control of up to two stages of electric heating, or control of one floating point heating

valve or control of one analog output.

When the operating mode is heating (morning warm-up), the heating stages are sequenced on and off with a time-proportioned control algorithm to minimize excessive cycling. The sequencing is based on the supply air temperature and

heating setpoint. Heating can also be controlled with a floating-point control of a valve.

The heating output position is calculated by a P +I control loop based on the supply temperature and the heating setpoint. As the temperature decreases below the heating setpoint, the heating output will be modulated open. The heating output will be modulated closed as the temperature increases above the heating setpoint.

16 505-010-2, Effective: April 29, 2014

© 2014 Taco Electronic Solutions, Inc.

Page 17

iWorx® VPU2

If configured for a floating point valve control the heating valve is calculated by a P + I control loop based on the supply

temperature and cooling setpoint. As the temperature decreases below the heating setpoint, the valve will be modulated open. The valve will be modulated closed as the temperature increases above the heating setpoint.

In both the heating and cooling modes the supply air temperature setpoint may be reset by the zone demand.

The VPU2 can also monitor the supply air temperature to determine if the heating and cooling are operating properly.

During the cooling mode, if the supply air temperature fails to drop below the cooling operational limit after a pre-determined time period, a cooling failed alarm is reported to the LCI.

During the heating mode, if the supply air temperature fails to rise above the heating operational limit after a pre-determined time period, a heating failed alarm is reported to the LCI.

As a safety device, the controller can optionally monitor the supply air temperature to determine if the heating stages

have failed on. If the supply air temperature rises above the heating high limit setpoint, the fan energizes. If the supply

air temperature does not drop below the setpoint after a pre-programmed time delay, the fan speed is overridden off. A

heating high limit exceeded alarm is reported to the LCI and all of the zone controllers.

An indoor air quality input is provided. If an indoor air quality alarm is detected, the supply air fan is energized and the

economizer is overridden to supply fresh air to the zones. In addition, an alarm condition can be signaled by one of the

zone controllers. When an alarm condition exists, the controller energizes the supply air fan and overrides the static

pressure setpoint to the IAQ alarm setpoint. The controller attempts to clear the IAQ condition by allowing the economizer to open more than usual. If the condition has not been cleared after a programmable delay, an alarm is sent to

the LCI.

The VPU2 monitors a digital input to determine the presence of smoke. When the input indicates smoke, the controller

immediately turns off the fan and all stages of heating and cooling. An alarm is reported to the LCI when this condition

exists. The VPU2 remains in the shutdown alarm state until it is reset.

A digital input is provided on the VPU2 to monitor the status of the air filter. An external pressure switch is wired to the

input to determine when the filter becomes dirty. An alarm is reported to the LCI when this condition exists.

Mixed air low limit protection is provided through a digital input. If a low limit condition exists, the VPU2 turns off all

stages of heating and cooling along with the supply air fan. If heating is controlled by a floating-point valve, the valve is

opened fully to prevent equipment damage. An alarm is reported to the LCI when this condition exists. The VPU2

remains in the shutdown alarm state until it is reset.

The VPU2 monitors an input to determine if the fan is operating properly. When the input indicates a fan failure, the

controller immediately turns off the fan and all stages of heating and cooling. An alarm is reported to the LCI when this

condition exists.

The VPU2 monitors the runtime of the cooling stages, heating stages and fan. When any one of the runtimes exceeds

a programmable limit, a maintenance alarm is reported to the LCI.

When the Return Air humidity rises above the humidity setpoint, dehumidification is enabled by enabling the cooling

stages, if modulated cooling is enabled; the cooling output goes to 100%. Dehumidification is disabled, when return air

humidity drops below the setpoint by 3%.

SEQUENCE OF OPERATION

This section describes the detailed sequence of operation for the VPU2 control algorithms.

Occupancy State

The VPU2 operates in one of three occupancy states: extended occupancy, occupied, or unoccupied. A host device on

the network determines the active operating mode. An optional backup schedule is provided for cases when the host

device is not available.

505-010-2, Effective: April 29, 2014 17

© 2014 Taco Electronic Solutions, Inc.

Page 18

iWorx® VPU2

In addition, the VPU2 polls each zone controller (VAVI) to determine if extended occupancy (bypass) has been

requested. During unoccupied periods when extended occupancy has been requested, the VPU2 enters the occupied

mode of operation. At least once every 5 seconds a different zone controller is polled.

Operational Mode

The VPU2 operates in one of three operating modes: primary heating, primary cooling, and primary off. The operating

mode determines whether warm or cool air is supplied to the zone controllers. The VPU2 determines the operating

mode based on its internal schedule state, which is determined based on the occupancy state and internal configuration variables. The VPU2 can be in one of the following operational states: morning warm-up, occupied, extended

occupancy, emergency heating, shutdown, and emergency.

Morning Warm-up

The purpose of morning warm-up is to heat up the unoccupied zones to a comfortable level before the zones are occupied. During morning warm-up, the VPU2 is in heating mode: the fan is energized, the static pressure is controlled, the

economizer is disabled, and the heating stages are controlled. The VPU2 enters the morning warm-up state from shutdown, bypass, or emergency heating states.

The VPU2 must be configured at the LCI to perform morning warm-up; a reference VAV zone must be selected, and

the optimum start time for heating must be configured. If the reference zone requires heating, and morning warm-up is

configured, the LCI advances the occupancy start time of the VPU2 and passes the number of minutes the occupancy

has been advanced. The VPU2 remains in morning warm-up until the reference zone temperature is within 1 °F of the

heating setpoint, or until the optimum start time has expired.

The VPU2 informs all of its associated VAVI controllers, regardless of their occupancy state, that morning warm-up is

being performed, to allow all associated VAVIs to take advantage of the heating mode. During morning warm-up, all

VAVI controllers control to their occupied setpoints, regardless of their occupancy state. After morning warm-up, the

VPU2 enters the occupied state and delays the staging of cooling for one stage time.

Morning Cool Down

Similarly to morning warm-up, the VPU2 can perform morning cool-down, cooling the soon-to-be occupied zones to a

comfortable level before occupancy. Morning cool-down is exactly like the occupied state, but the occupancy time has

been advanced.

The VPU2 must be configured at the LCI to perform morning cool-down: a reference VAV zone must be selected and

the optimum start time for cooling must be configured. If the reference zone requires cooling, the VPU2 enters the

occupied state.

Unlike morning warm-up, the VPU2 does not inform its associated zone controllers that it is in morning cool-down. Only

the VAVI controllers that are in the same group take advantage of the cooling and control to their occupied setpoints.

Occupied

A remote device on the network (such as an LCI) provides the current occupancy mode. There are two modes of occupancy; occupied and unoccupied. The VPU2 is in the occupied state if the VPU2 is scheduled for occupancy.

In addition, the current occupancy mode is periodically retrieved from each of the zone controllers. If at least one zone

controller is currently in occupancy or occupancy extension mode the occupancy mode is overridden to the occupied

state (See Extended Occupancy).

During the occupied state the controller is normally in the cooling mode. If the mixed air temperature is 7 °F colder than

the supply temperature (as can happen during cold winter weather), the controller enters the heating mode, and heats

the air to the cooling setpoint. Also, the fan is energized, the static pressure is controlled, and the economizer is

enabled. In heating mode, the controller compensates for the colder air being brought in by setting the economizer to

its minimum position.

The VPU2 enters the occupied state from shutdown, extended occupied, morning warm-up, and emergency heating

states. It remains in the occupied state until the VPU2 goes into the unoccupied state and no associated zone controllers are occupied.

18 505-010-2, Effective: April 29, 2014

© 2014 Taco Electronic Solutions, Inc.

Page 19

iWorx® VPU2

The current operational mode information is periodically transferred to the VAVI over the communications network. The

following information is transferred to the VAVI from the primary air source controller:

• Operational Mode (primary cool, primary heat, primary fan only, primary off)

• Alarm Conditions (IAQ Mode, Heat Failed On)

• Supply Air Temperature

Shutdown

When the space being controlled by the VPU2 is unoccupied, the controller operates in the shutdown state. The air

handler package unit is off, and there is no control of the static pressure or duct temperature.

The VPU2 is in the shutdown state when the occupancy status is “unoccupied,” and no associated controllers are occupied or in extended occupancy. The VPU2 enters the shutdown state from Occupied, Extended Occupancy and Emergency Heating Stages.

The controller can enter an unoccupied cooling state from shutdown when an associated VAVI zone controller's space

temperature is 1 °F warmer than its unoccupied cooling setpoint. During this cooling state, the controller is in cooling

mode; the fan is energized, the static pressure is controlled, the economizer is enabled provided it has been configured

to operate in the unoccupied mode, and the cooling stages are controlled. The controller remains in the cooling state

for thirty minutes or until no associated controllers are requiring cooling, after which the VPU2 reverts to the shutdown

state.

Extended Occupancy

When the VPU2 is in Shutdown state and a VAVI zone controller has indicated extended occupancy, the controller

enters the Extended Occupancy state (also known as Bypass). The Extended Occupancy state acts identically to the

Occupied State.

The VPU2 remains in the extended occupancy state until the VAVI's extended occupancy is over, the VPU2 enters

morning warm-up or cool-down, the VPU2 enters the occupied state, or the VPU2 enters the Shutdown state.

Emergency Heating

The VPU2 enters the emergency heating state from shutdown when an associated VAVI zone controller's space temperature is 10 °F colder than its unoccupied heating setpoint. During the emergency heating state, the VPU2 is in heating mode: the fan is energized, the static pressure is controlled, the economizer is disabled, and the heating stages are

controlled. The VPU2 remains in the emergency heating state for thirty minutes, after which the VPU2 reverts to the

shutdown state.

Emergency

The VPU2 enters the emergency state (from any state) when there is an emergency condition. Emergency conditions

are:

• Mixed air low limit

• Heat stuck on

• Fan failure

• Smoke alarm

During the emergency state, the air handler package unit is off and there is no control of the static pressure or duct

temperature. The VPU2 remains in the emergency state until the controller is reset.

505-010-2, Effective: April 29, 2014 19

© 2014 Taco Electronic Solutions, Inc.

Page 20

iWorx® VPU2

Setpoint Calculations

The supply air heating and cooling setpoints are programmable values. The effective setpoint is a calculated value

based on the current operating mode. The effective setpoint is set to the heating setpoint when the operational mode is

heating. It is set to the cooling setpoint when the operational mode is cooling.

Additionally the heating and cooling setpoints may be reset based on the greatest zone demand.

Supply Air Setpoint Reset Curve

If the Supply Temperature Setpoint Reset Curve is enabled, the VPU2 keeps track of the differential between each

zone's space temperature and its temperature setpoint. The VPU2 selects the zone with the greatest differential and

uses that Temperature Differential to adjust the Supply Temperature Setpoint.

If the Temperature Differential is less than the Temperature Differential Minimum, then the Supply Temperature Set-

point Low will be used. If the Temperature Differential is greater than the Temperature Differential Maximum, then the

Supply Temperature Setpoint High is used.

When the Temperature Differential lies between the Temperature Differential Maximum and Temperature Differential

Minimum, the Supply Temperature Setpoint is linearly interpolated between the Supply Setpoint High and Supply Setpoint Low.

20 505-010-2, Effective: April 29, 2014

© 2014 Taco Electronic Solutions, Inc.

Page 21

iWorx® VPU2

When the Temperature Differential Maximum is set to 0, the Supply Temperature Setpoint Reset Curve is disabled and

the VPU2 operates with the usual heating and cooling supply air temperature setpoints.

Figure 7: Supply Temp Reset Curves

Outside Air Temperature Lockouts

Heating can be disabled during warm weather by setting the outdoor air temperature heating lockout Max OAT Heat. If

the OAT is above the heating lockout temperature, the primary heating mode is disabled and the controller can only be

in the primary off or primary cooling modes. This feature requires a controller that broadcasts the OAT, such as an

ASM2 be installed on the network.

Cooling can be disabled during cold weather by setting the outdoor air temperature cooling lockout Min OAT Cool. If

the OAT is below the cooling lockout temperature, the primary cooling mode is disabled and the controller can only be

in the primary off or primary heating modes. This feature requires a controller that broadcasts the OAT, such as an

ASM2 be installed on the network.

505-010-2, Effective: April 29, 2014 21

© 2014 Taco Electronic Solutions, Inc.

Page 22

iWorx® VPU2

The economizer can be disabled during excessively warm or cool weather by setting the outdoor air temperature economizer lockouts Max OAT Econ and Min OAT Econ. If the OAT is above the Economizer Max OAT, or below the Econ-

omizer Min OAT, the economizer is disabled. During an IAQ emergency, the Economizer Min OAT is lowered by the

IAQ Settings Temperature Reset, while the Economizer Max OAT is raise by the same value. This feature requires a

controller that broadcasts the OAT, such as an ASM2, be installed on the network.

Heating Sequence

The controller provides support for either two stages of heating or one floating point or 0-10V modulating heating output

(valve or variable speed circulator). You can specify which type of heat you are using through configuration parameters.

Heating Stages

The heating sequence is initiated when the current operating mode calls for heat. The electric heating stages are

sequenced based on the supply air temperature, the heating setpoint and the control band. When the supply air temperature drops below the heating setpoint minus the control band, a stage is turned on. If the supply air temperature

remains below the control band for an additional time-period, the next available stage is turned on. If all zone temperature readings are within 0.5 °F of their setpoints, the next stage does not cycle on. This cycle continues until all available stages have been energized.

After the supply temperature has risen above the heating setpoint, the first available stage is turned off. If the supply air

temperature remains above the heating setpoint for an additional time-period, the next available stage is turned off.

This cycle continues until all available stages have been de-energized. If the supply air temperature rises above the

heating setpoint plus control band all of the stages immediately cycle off.

Figure 8: Staged Heating Sequence (Occupied)

T1 = Stage Cycle Time

T2 = Stage Cycle Time x 2

T1 T2T1T2

Stage 2 On

Stage 1 On

Temperature

Heating

Control

Band

Calculated

Heating Setpoint

Stage 2 Off

Stage 1 Off

Heating with Floating Point Control

The heating stage outputs can be configured for floating point control of a heating valve. Floating point control is

enabled when Heating Stages are set to zero and the Heating Valve Travel Time is non-zero. The H1 output is the

valve open signal and the H2 output is the valve close signal.

After a reset, the floating point valve is calibrated by closing the valve for a period of the travel time. This ensures that

the valve is fully closed. When the valve is at its calculated 0% or 100% position, the valve is overdriven for 30 seconds

to ensure that the valve is fully closed or open.

22 505-010-2, Effective: April 29, 2014

© 2014 Taco Electronic Solutions, Inc.

Page 23

iWorx® VPU2

The floating point control is similar to the heating modulated algorithm. If the space temperature is below the heating

setpoint, the valve is driven open. When the space temperature is above the heating setpoint, the valve is driven

closed. There is a +/- 1 °F (0.55 °C) deadband around the setpoint to prevent the valve from dithering. During mixed air

low limit alarms, the heating valve is driven to 100%.

Heating with Modulated Output (Valve or Variable Speed Circulator)

The calculated heating loop setpoint is derived from the heating setpoint and the loop proportional gain.

CalcHeatingLoopSp = CalcHeatingSp - ½(Kp)

The heating output is modulated by a P+I control loop based on the heating loop setpoint and the supply temperature.

The P+I control loop will modulate the output to maintain a constant supply temperature. As the temperature decreases

below the heating loop setpoint, the heating output will be modulated open. The heating output will be modulated

closed as the temperature increases above the heating loop setpoint.

To prevent the integral component from becoming too large, there is anti-wind up reset protection. This protection

clamps the integral value when all of the components add up to more than 100% or less than 0%. The following equations are used for P+I control:

Kp = Proportional Gain

Ki = Integral Gain

Error = HeatingLoopSp - SpaceTemp

I = I+(Ki x Error)

HeatPosition = (Kp x Error) + I

Temperature control only occurs when the operational mode is heating or morning warm-up, or when heating is

required to heat the mixed air temperature to reach the supply air setpoint. During unoccupied and cooling periods, the

heating valve is driven to 0%. During mixed air low limit alarms, the heating valve is driven to 100%.

The floating point control is similar to the heating staging algorithm. If the supply air temperature is below the supply air

setpoint, the valve is driven open. When the supply air temperature is above the supply air setpoint, the valve is driven

closed. There is a +/- 2 °F deadband around the setpoint to prevent the valve from dithering.

Heating with Stages and Modulation

The controller can combine its staged and modulated modes. In the combined mode of operation, the modulated output is considered to be one of the stages. The stage to be associated with modulation is selected in the Staged Heating

configuration page.

Modulation starts when the selected stage would normally start (i.e., if stage 2 is selected as the modulating stage, it

starts if stage 1 has been active for the staging interval and the temperature is still below the heating control band).

If the modulating stage is not the last stage, subsequent stages are activated once the Stage Threshold percentage

has been met by the modulating output and has remained there for the duration of the Staging Interval.

In order to maintain a smooth total heating output, the modulating output responds to subsequent stages activating or

deactivating. It does so by clearing its interval output when a subsequent stage is activated:

I =0

Modulating Output = K_p × Error

It forces its interval output to the Staging Interval whenever a subsequent stage is deactivated. This feature prevents

large jumps in overall heating output.

I = Staging Threshold

Modulating Output =(K_p × Error) + I

505-010-2, Effective: April 29, 2014 23

© 2014 Taco Electronic Solutions, Inc.

Page 24

iWorx® VPU2

Figure 9: Modulated Staging with 2 Stages; 2nd Stage Modulating

24 505-010-2, Effective: April 29, 2014

© 2014 Taco Electronic Solutions, Inc.

Page 25

Figure 10: Modulated Staging with 2 Stages; 1st Stage Modulating

iWorx® VPU2

Cooling Sequence

The controller provides support for either four compressor stages of cooling or one floating point or 0-10V modulating

cooling output (valve or variable speed circulator). You can specify which type of cooling you are using through configuration parameters.

Cooling Stages

The cooling sequence is initiated when the current operating mode calls for cool. The cooling compressor stages are

sequenced based on the supply temperature, the cooling setpoint and the control band. When the supply air temperature rises above the cooling setpoint plus the control band, a stage is turned on. If the supply air temperature remains

above the control band for an additional time-period, the next available stage is turned on. If all zone temperature readings are within 0.5 °F of their setpoints, the next stage does not cycle on. This cycle continues until all available stages

have been energized.

505-010-2, Effective: April 29, 2014 25

© 2014 Taco Electronic Solutions, Inc.

Page 26

iWorx® VPU2

After the supply temperature has dropped below the cooling setpoint, the first available stage is turned off. If the supply

air temperature remains below the cooling setpoint for an additional time-period, the next available stage is turned off.

This cycle continues until all available stages have been de-energized. If the supply air temperature drops below the

cooling setpoint plus control band all of the stages immediately cycle off.

Figure 11: Staged Cooling Sequence (Occupied)

Stage 4 Off

Stage 3 Off

Stage 2 Off

Stage 1 Off

Temperature

Space

Setpoint

T3T4

Cooling

Control

Band

Calculated

Cooling

Setpoint

T1 T2T1T2 T3 T4

Stage 4 On

Stage 3 On

Stage 2 On

Stage 1 On

T1 = Stage Cycle Time

T2 = Stage Cycle Time x 2

T3 = Stage Cycle Time x 3

T4 = Stage Cycle Time x 4

Cooling with Floating Point Control

The cooling outputs can be configured for floating point control of a cooling valve. Floating point control is enabled

when Cooling Stages is set to zero and the Cooling Valve Travel Time is non-zero. The C1 output is the valve open signal and the C2 output is the valve close signal.

After a reset, the floating point valve is calibrated by closing the valve for a period of the travel time. This ensures that

the valve is fully closed. When the valve is at its calculated 0% or 100% position, the valve is overdriven for 30 seconds

to ensure that the valve is fully closed or open.

The floating point control is similar to the cooling modulated algorithm. If the space temperature is above the cooling

setpoint, the valve is driven open. When the space temperature is below the cooling setpoint, the valve is driven

closed. There is a +/- 1 °F (0.55 °C) deadband around the setpoint to prevent the valve from dithering. During mixed air

low limit alarms, the cooling valve is driven to 100%.

Cooling with Modulated Output (Valve or Variable Speed Circulator)

The calculated cooling loop setpoint is derived from the cooling setpoint and the loop proportional gain.

CalcCoolingLoopSp = CalcCoolingSp - ½(Kp)

The cooling output is modulated by a P+I control loop based on the cooling loop setpoint and the space temperature.

The P+I control loop will modulate the output to maintain a constant space temperature. As the temperature increases

above the cooling loop setpoint, the cooling valve will be modulated open. The cooling output will be modulated closed

as the temperature decreases below the cooling loop setpoint. When unoccupied mode is entered, the cooling loop

setpoint is set up through a separate unoccupied cooling setpoint.

26 505-010-2, Effective: April 29, 2014

© 2014 Taco Electronic Solutions, Inc.

Page 27

iWorx® VPU2

To prevent the integral component from becoming too large, there is anti-wind up reset protection. This protection

clamps the integral value when all of the components add up to more than 100% or less than 0%. The following equations are used for P+I control:

Kp = Proportional Gain

Ki = Integral Gain

Error = CoolingLoopSp - SpaceTemp

I = I+(Ki x Error)

CoolPosition = (Kp x Error) + I

Supply Air Temperature Lockout

To eliminate cooling stages coming on when the economizer has satisfied the SAT, the VPU2 monitors the Supply Air

Temperature (SAT) and compares it to the SAT Cooling Limit. Should the SAT fall below the SAT Cooling Limit, additional cooling will not be enabled. If the SAT rises above the SAT Cooling Limit, additional cooling will be enabled as

needed.

Cooling with Stages and Modulation

The controller can combine its staged and modulated modes. In the combined mode of operation, the modulated output is considered to be one of the stages. The stage to be associated with modulation is selected in the Staged Cooling

configuration page.

Modulation starts when the selected stage would normally start (i.e., if stage 2 is selected as the modulating stage, it

starts if stage 1 has been active for the Staging Interval and the temperature is still above the cooling control band).

If the modulating stage is not the last stage, subsequent stages are activated once the Stage Threshold percentage

has been met by the modulating output and has remained there for the duration of the Staging Interval.

In order to maintain a smooth total cooling output, the modulating output responds to subsequent stages activating or

deactivating. It does so by clearing its interval output when a subsequent stage is activated:

I= 0

Modulating Output = K_p × Error

It forces its interval output to the Staging Interval whenever a subsequent stage is deactivated. This feature prevents

large jumps in overall cooling output.

I = Staging Threshold

Modulating Output= (K_p × Error) + I

505-010-2, Effective: April 29, 2014 27

© 2014 Taco Electronic Solutions, Inc.

Page 28

iWorx® VPU2

Figure 12: Modulated Staging with 2 Stages; 2nd Stage Modulating

Figure 13: Modulated Staging with 2 Stages; 1st Stage Modulating

28 505-010-2, Effective: April 29, 2014

© 2014 Taco Electronic Solutions, Inc.

Page 29

iWorx® VPU2

Economizer Operation

The VPU2 provides support for either two-position or modulated economizer types. You can specify which type of

economizer you are using through a configuration parameter. Both economizer types are enabled based on availability

of “free cooling” from the outdoor air. Free cooling can be determined by dry bulb or enthalpy comparisons. In order to

provide maximum energy savings, the cooling stages are interlocked with the economizer.

Dry Bulb Comparison

Free cooling can be determined based on a comparison of outdoor air temperature and indoor air temperature. When

the outdoor air temperature is a programmable amount below the indoor air temperature (reference zone VAVI's zone

temperature), free cooling is enabled. When the outdoor air temperature rises above the indoor temperature (reference

zone VAVI's zone temperature) free cooling is disabled.

Enthalpy Calculation

An enthalpy calculation is performed periodically to determine if “free cooling” is available. The outside enthalpy is calculated based on the outside air temperature and humidity. The outside temperature and humidity are measured by an

external device (such as an ASM Series) on the network and sent to the controller. The same calculation is performed

on the inside air based on the space temperature (reference zone VAVI’s zone temperature) and return air humidity.

The inside enthalpy minus the outside enthalpy must be greater than the Free Cooling Setpoint in order for the economizer to be used for free cooling.

Optionally, an external device can measure the indoor air humidity globally. In this case, the return air humidity sensor

would not be required at each VPU2.

Two-position Economizer

If present, the two-position economizer is enabled when there is “free cooling” available as determined by the enthalpy

calculations. When the economizer is enabled, the economizer triac output is energized. When the economizer is disabled, the economizer output is de-energized. A configuration parameter is available to optionally disable the economizer during unoccupied periods.

Modulated Economizer

When configured, the modulated economizer is enabled when there is “Free Cooling” available as determined by the

enthalpy or dry bulb calculations.

Figure 14: Economizer Control

When the economizer is enabled, the economizer triac output is energized. When the economizer is disabled, the

economizer output is de-energized. A configuration parameter is available to optionally disable the economizer during

unoccupied periods.

When the economizer is enabled, a P+I control loop modulates the economizer output. The P+I control loop modulates

the economizer position to maintain a constant mixed air temperature.

505-010-2, Effective: April 29, 2014 29

© 2014 Taco Electronic Solutions, Inc.

Page 30

iWorx® VPU2

I

The P+I control loop is based on the mixed air temperature setpoint and economizer setpoint. As the temperature

increases above the economizer setpoint, the economizer is modulated open. The economizer is modulated closed as

the temperature decreases below the economizer setpoint.

To prevent the integral component from becoming too large, there is anti-wind up reset protection. This protection

clamps the integral value when all of the components add up to more than 100% or less than 0%. The following equations are used for P+I control:

= Proportional Gain

K

p

Ki = Integral Gain

Error EconSp MixedAirTemp–=

IKiError+=

EconPosition = (K

x Error) + I

p

When the economizer is disabled, it modulates to the minimum position. A configuration parameter is available to

optionally disable the economizer during unoccupied periods.

Dehumidification

The VPU2 can be configured to keep humidity below a given setpoint. If the Setpoint is set to zero, dehumidification is

disabled. When the humidity is above the Setpoint dehumidification begins and stops when the humidity drops below

Setpoint minus 3%.

Dehumidification stops when the reference zones (VAVI) space temperature drops below the heating setpoint minus

the control band offset. Dehumidification is also disabled when the unit is in heating.

During dehumidification, the operating mode will be displayed as “Dehumid,’ the cooling outputs will stage on and the

stage timer is enforced, or modulating output or floating point valve will be set to 100%.

Fan Operation

During Morning Warm-up, Occupied, Extended Occupancy, and Emergency Heating states, the fan runs continuously.

During the shutdown state, the fan is off.

The fan can be overridden from the LCI or another host controller. When the fan is overridden, the static pressure P+I

loop control is disabled and the integral sum is cleared to prevent anti-windup reset. The fan's modulated output can be

overridden between 0 and 100%. If the desired speed is greater than the current speed, the speed is ramped up to the

desired speed based on the Soft Start Ramp setting.

Static Pressure Control

Static pressure control is achieved by modulating a variable speed drive based on the measured static pressure in the

supply duct. The static pressure sensor input has maximum range of 5.000" W.C. with a minimum resolution of

0.005" W.C.

The fan speed output is modulated by a P+I control loop based on the static pressure loop setpoint and the supply

static pressure measurement. The P+I control loop modulates the output to maintain a constant static pressure within

the supply air duct. As the supply static pressure decreases 0.025" W.C. below the static pressure loop setpoint, the

output is modulated towards its maximum value. The output is modulated towards its minimum value as the supply

static pressure increases to 0.025" W.C. above the static pressure loop setpoint. When the static pressure is within

±0.025” W.C. of the static pressure setpoint, the damper output remains at its current level.

30 505-010-2, Effective: April 29, 2014

© 2014 Taco Electronic Solutions, Inc.

Page 31

iWorx® VPU2

I

B

To prevent the integral component from becoming too large, there is anti-wind up reset protection. This protection

clamps the integral value when all of the components add up to more than 100% or less than 0%. The following equations are used for P+I control:

Kp = Proportional Gain

Ki = Integral Gain

Error SupplyStaticPressure LoopSetpoint–=

IKiError+=

ypassPosition KpError I+50.00%+=

A separate static pressure setpoint is provided to increase the supply static pressure when an IAQ alarm condition

exists. The fan speed control maintains the IAQ alarm pressure setpoint as long as an IAQ alarm condition exists.

Programmable minimum and maximum outputs are provided for the fan speed. These settings can be reversed for

reverse air movement. Overrides are provided to assist in system air balancing during commissioning.

Soft Start Ramping

The VPU2 can be configured to soft start ramp to prevent damage to the ducts and equipment when the fan is first

energized. Setting the soft start ramp rate to 0% per second or 100% per second disables soft start ramping. The soft

start ramping clamps the P+I output to the current ramp rate. Soft start ramping ends when the static pressure is within

the deadband, greater than the pressure setpoint, or when the soft start ramp reaches 100%. Once soft start ramping

ends, the P+I loop’s integral sum is backwards calculated to create a smooth transition to the static pressure P+I loop

control.

Fan Proof

A fan status input is provided for monitoring the operation of the fan. When the fan is initially turned on, there is a 30

second delay before the fan status is checked. If at any time after the delay, the fan status indicates the fan is not running, a fan failure condition is generated. The heating and cooling stages are interlocked with the fan. When a fan failure condition exists, the heating stages, cooling stages and the fan immediately turn off. The controller must be reset to

clear this condition.

NOTE: If not providing a fan proof switch, the dipswitch for the fan proof input must be configured with the

(0-10V) switch set to “on” and “Vth” set to “off.” After a fan failure, the controller's status LED changes from

green to solid red. To return the controller to normal operation after the failure condition is resolved, you

must reset the controller by removing and reapplying power or by using the controller reset feature on the

LCI.

VPU2 and VAVI Communications

The VPU2 polls an associated VAVI controller every 5 seconds to transfer information necessary for control.

The following information is transferred from the VPU2 to the VAVI controller:

• Operational Mode: primary cool, primary heat, and primary off

• Occupancy Mode: occupied, unoccupied, and bypass (denotes morning warm-up)

• Alarm Conditions: IAQ Mode and Heat Failed On

The following information is transferred from the VAVI to the VPU2 controller:

• Zone temperature

• Calculated Heating Setpoint

• Calculated Cooling Setpoint

• IAQ Sensor Status (safe, alarm)

505-010-2, Effective: April 29, 2014 31

© 2014 Taco Electronic Solutions, Inc.

Page 32

iWorx® VPU2

• Local Alarm (VAVI shutdown)

• Occupancy Mode: occupied, unoccupied, and occupied extension)

• Supplemental heat status: on, off

Associating VAVIs

In order for the VPU2 and VAVIs to share information the controllers need to be associated. To associate the VAVIs to

the VPU2 you first need to select the VPU2 from the LCI's list of controllers. Once the VPU2 has been selected

depress the HVAC Setup button then the Zone Members button. There is a list of all VAVIs on the network that will be

displayed along with the designation “Included” or “Excluded.” To include a VAVI, simply depress the desired VAVI in

the list and it will show “Included” and the color will change to Red. After all the desired associations are complete

depress the Save button so the information will be sent to all associated controllers.

Associating the Reference Zone; VAVI

In order for the VPU2 and reference VAVI to share information the controllers need to be associated. To associate the

reference VAVI to the VPU2 you first need to select the VPU2 from the LCI's list of controllers. Once the VPU2 has

been selected depress the HVAC Setup button then the Reference Zone button. There you will see a list of all VAVIs on

the network along with the designation “Included” or “Excluded” for each. To include the reference VAVI, simply

depress the desired VAVI in the list and it will show “Included” and the color will change to Red. After all the desired

associations are complete, depress the Save button so the information will be sent to all associated controllers. The

VPU2 may have only one (1) reference zone.

Power On/Reset Delay

The VPU2 imposes a thirty second delay after being powered on or after a reset. No control takes place until after the

thirty second delay has expired.

Supply Air Temperature Monitoring

The VPU2 monitors the supply air temperature to determine if the heating and cooling stages are operating properly.

During heating mode, if the supply air temperature does not rise above the heat mode alarm setpoint after a 10-minute

delay a heat mode alarm is generated. During cooling mode, if the supply air temperature does not drop below the cool

mode alarm setpoint after a 10-minute delay, a cool mode alarm is generated.

The VPU2 has provisions for detecting a gas valve that has been become stuck in the open position. The stuck gas

valve sequence helps to prevent overheating the HVAC unit.

During periods when the operational mode is primary off or primary fan only, if the supply air temperature rises above

175 °F the system fan is started. If the supply air temperature does not drop below 150 °F after 5 minutes, the fan

speed decreases to 0% and an alarm is sent to the zone controllers and LCI. The zone controllers react to the alarm by

positioning their dampers to the maximum position.

During periods when the operational mode is primary cooling, if the supply air temperature does not drop below 100 °F

after 15 minutes, the cooling mode is terminated and the controller enters the primary off operational mode. The primary off logic then checks for the stuck gas valve condition.

Smoke Detection

A smoke detector input is provided. If the smoke detector indicates smoke is present then all of the stages and the fan

turn off. Once the situation has been corrected, reset the controller to clear this condition.

Mixed Air Low Limit Detection

An input is provided for a mixed air low limit detection device. If a low limit condition is detected, all of the stages and

the fan turn off. Once the low limit is corrected, reset the controller to clear this condition.

32 505-010-2, Effective: April 29, 2014

© 2014 Taco Electronic Solutions, Inc.

Page 33

iWorx® VPU2

Filter Status

The filter status input is monitored to determine if the filter is operating properly. The input is used to indicate that maintenance is required on the filter. The unit is not shut down due to a filter alarm.

Indoor Air Quality

An indoor air quality input is provided. If an indoor air quality alarm is indicated while the space is occupied, the supply

air fan is energized and the economizer is overridden to supply fresh air to the space. The source of an indoor air quality signal can be a digital sensor providing an on/off signal or a configurable analog sensor.

Setup of the analog sensor requires the IAQ sensor settings to be populated. A Min, Max, Setpoint, and Offset can be

specified.

When an indoor air condition is sensed by the controller, the economizer is opened to 100%. If the mixed air temperature drops too low, the economizer modulates in an attempt to maintain the IAQ MAT setpoint while still allowing fresh

air into the system.

The controller has a temperature reset function for IAQ alarm operation. The temperature reset function allows the

space temperature to rise above or drop below the calculated control setpoints by a configurable amount. During IAQ

Alarm operation, if the space temperature rises above or drops below the temperature reset limit, the controller

resumes normal economizer control to maintain a comfort space temperature. Once the space temperature is brought

within the calculated setpoints and an IAQ Alarm condition still exists, the controller resumes the IAQ mode of operation.

The controller has a configurable alarm delay function. This function allows the controller to attempt to clear the IAQ

condition with the economizer before triggering an alarm. If the IAQ condition is still present after the IAQ Alarm Delay,

the alarm message is sent to the LCI.

Return Air IAQ