Page 1

Instruction Sheet

Industrial Flow Switch

SUPERCEDES: 102-122 DATED January 1, 2002

# 5401110-REV E

(IFS01 &

IFS02 ONLY)

GENERAL

The Model IFS is a flow switch used in liquid

flow lines carrying water or any fluid not harmful

to brass, stainless steel, EPDM or fluorosilicone,

and not classified as a hazardous fluid.

This switch can serve as a way to start and stop

electrically operated equipment when a flow or no

flow condition occurs in a variety of applications.

This device is designed for use only as an operating control. Where an operating control failure

would result in personal injury and/or loss of property, it is the responsibility of the installer to add

devices (safety, limit controls) that protect against,

or systems (alarm, supervisory systems) that warn

of control failure.

102-022

EFFECTIVE: March 17, 2004

Listings/Approvals:

• UL Guide (NKPZ) for industrial control

equipment per UL Standard 508 Industrial

Control Equipment

• UL Guide (MFHX) for heating/cooling appliance switch per UL Standard 353 Limit

Controls

• CSA Class (321106) for industrial control

equipment per CSA Standard C22.2 No.

14-M Industrial Control Equipment

Maximum Service Pressure: 250 PSI

Enclosure:

NEMA Type 1 (For indoor use only)

Formed sheet metal with powdercoat finish.

Not for use in hazardous locations.

Contacts:

IFS01: One SPDT (Form C) switch

IFS02: Two sets of SPDT (Form C) switches

to provide versatility in wiring two separate

circuits.

15 Amps at 125/250VAC

.5 Amps at 125VDC

.25 Amps at 250VDC

Motor Ratings : 120VAC 240VAC

Horsepower : 1/8 1/4

AC F.L.A. : 3.8 2.9

AC L.R.A. : 22.8 17.4

Pilot Duty Rating : 125 VA 120/240 VAC

IFSH1/2 Contacts:

IFSH1: One SPDT (Form C) switch

IFSH2: Two sets of SPDT (Form C) switches

to provide versatility in wiring two separate

circuits.

22 Amps at 125/250VAC

Motor Ratings : 120VAC 240VAC

Horsepower : 1/2 1

AC F.L.A. : 9.8 8.0

AC L.R.A. : 58.8 48.0

Pilot Duty Rating : 125 VA 120/240 VAC

Ambient Temperature Range:

32°F/176°F (0°C/80°C)

Media Temperature Range:

32°F/250°F (0°C/121°C)

Pipe Connections:

1" NPT Brass on models IFSxxB

1" NPT 316 Stainless Steel on models

IFSxxS

Conduit Entrance: Two openings for 1/2" conduit

Usage: For pipe sizes 1" - 8"

Caution: This device is not intended for applica-

tions in explosive environments.

Note: IFSW Series available with NEMA 4 enclo-

sure for outdoor use. (See bulletins

#102-026 & #102-027 or Catalog 100-8.2).

Page 2

MOUNTING AND INSTALLATION

The Model IFS may be mounted in a horizontal

pipe line or a vertical pipe line with upward liquid

flow. It is not recommended for installations

where flow is downward. When mounted in a

horizontal pipe line the switch will trip at a lower

flow rate than shown in Fig. 7.

Mount the device in a section of pipe where there

is a straight run of at least 5 pipe diameters on

each side of the flow switch. Do not locate adjacent to valves, elbows or orifices. The switch

should be mounted so the terminals or wire leads

are easily accessible for wiring.

IFS models with flexible paddles are furnished

with 4 paddles. Rigid paddle models are furnished with 2 paddles. For pipe sizes 1", 2", 3" or

6", use the paddles provided. Intermediate sizes

may be trimmed from the appropriate paddle

using the paddle template in Fig. 5. The paddle

must not touch the inside of the pipe or bind in

any way. Paddles smaller than the actual pipe

size should be used for added support and higher

sensitivity, see Fig. 3. The paddles must be properly attached and the screw that holds the paddle

must be securely tightened.

For a 1" pipe application mount in a standard 1" x

1" x 1" tee. Use a reducing tee for larger sizes of

pipe to keep flow switch close to pipe and provide

adequate paddle length in the flow stream.

Example: Use a 2" x 2" x 1" tee for 2" pipe. A

weldolet may also be used. Screw the device into

the tee fitting as shown in Fig. 4. The flat of the

paddle must be at a right angle to the flow. The

arrow on the side of the bushing must point in the

direction of flow, see Fig. 1.

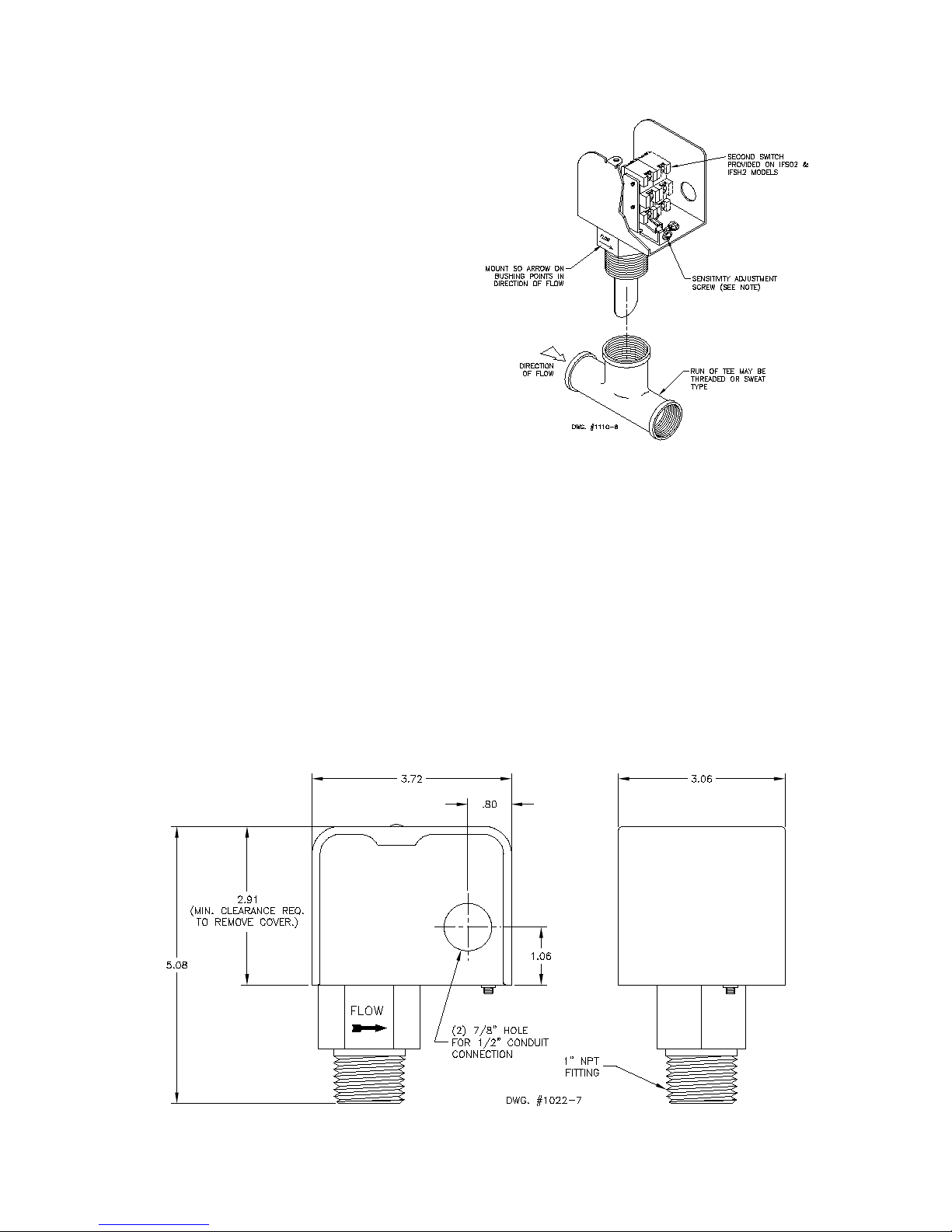

FIG. 2

FIG. 1

Sensitivity Adjustment Note:

Turn screw clockwise to increase the flow rate

required to activate the switch.

Turn screw counter-clockwise to decrease the

flow rate required to activate the switch.

Page 3

FIG. 3

FIG. 5

Typical paddle arrangement

for 6" to 8" pipe, using smaller

flexible paddles for added

support and higher sensitivity.

Use the drawing at

right as a template

and trim at the dotted arc when trimming the appropriate paddle for intermediate pipe

sizes.

CAUTION:

The paddle must

not touch the inside of the pipe or

bind in any way.

NOTE:

When installing

rigid paddles, do

not stack paddles.

Only install ONE

paddle that best

fits the pipe.

FIG. 4

CAUTION:

Screw the device into the TEE fitting as shown.

Care must be taken to properly orient the device for

the direction of the flow. Do not tighten by grasping

the switch enclosure. Use the wrenching flats on the

bushing only. Turning radius required for mounting

the IFS is 3".

Page 4

WIRING

Use properly rated temperature supply wire for

the anticipated service temperature.

Make all electrical connections in accordance

with the National Electrical Code and local regulations.

See Figs. 6A and 6B for diagrams illustrating

switch action.

ADJUSTMENT

Remove switch cover and turn the sensitivity

adjusting screw clockwise to increase the flow

rate required to actuate the switch. Turn the

sensitivity adjusting screw counter-clockwise to

decrease the flow rate required to actuate the

switch. (See Fig. 1.) Be sure to replace the

cover upon completion of the installation and

adjustment.

CAUTION: Check the installation for "no-flow"

switch operation. Make appropriate adjustments

to the sensitivity adjustment screw to be sure the

switch restores fully at the desired flow rate.

FIG. 6A

FIG. 7

muminiM

tnemtsujdA

mumixaM

tnemtsujdA

IFS01 / IFS02

SWITCH INFORMATION

SNOITACIFICEPS

hctiwSetautcAotderiuqeRMPG-setaRwolFlacipyT

)snoitallatsniepiplacitrevroF(

)sehcni(eziSepiP14/112/1122/12345*68*

wolF

5.45.465.75.3181530507012

esaercnI

wolF

5.35.355.55.931520406091

esaerceD

wolF

5.9015.3102920507021081014

esaercnI

wolF

75.85.015.81625456501061083

esaerceD

IFSH1 / IFSH2

SWITCH INFORMATION

FIG. 6B

NOTES:

1. Typical flow rates for 1" to 1 1/2" pipe sizes

are averages which may vary approximately

±1 GPM with the use of a bronze reducing

tee.

2. Typical flow rates for 2" to 8" pipe sizes are

averages which may vary ±10% with the use

of a 1" weldolet.

(*) Flow rates for these sizes are calculated.

Do it Once. Do it Right.

TACO, INC., 1160 Cranston Street, Cranston, RI 02920 Telephone: (401) 942-8000 FAX: (401) 942-2360.

TACO (Canada), Ltd., 6180 Ordan Drive, Mississauga, Ontario L5T 2B3. Telephone: 905/564-9422. FAX: 905/564-9436.

Manufactured by POTTER ELECTRIC SIGNAL CO., St. Louis, MO

Visit our web site at: http://www.taco-hvac.com

Printed in USA

Copyright 2002

TACO, Inc.

Loading...

Loading...