Page 1

OPERATOR INSTRUCTIONS

This tapping attachment can be used on all types of manually operated

The tap will return to a forward rotation as soon as it is with-drawn

FOR REVERSIBLE TAPPING ATTACHMENT MODEL: HR 3 & 4

machines with rotating non-reversing spindles.

INSTALLING MORSE TAPER ARBOR

Clean the matching taper. Then with a twisting motion, insert the arbor

into the attachment. Strike the tang end of the arbor with a plastic

hammer to lock it firmly. The hex nuts are provided to remove the

arbor.

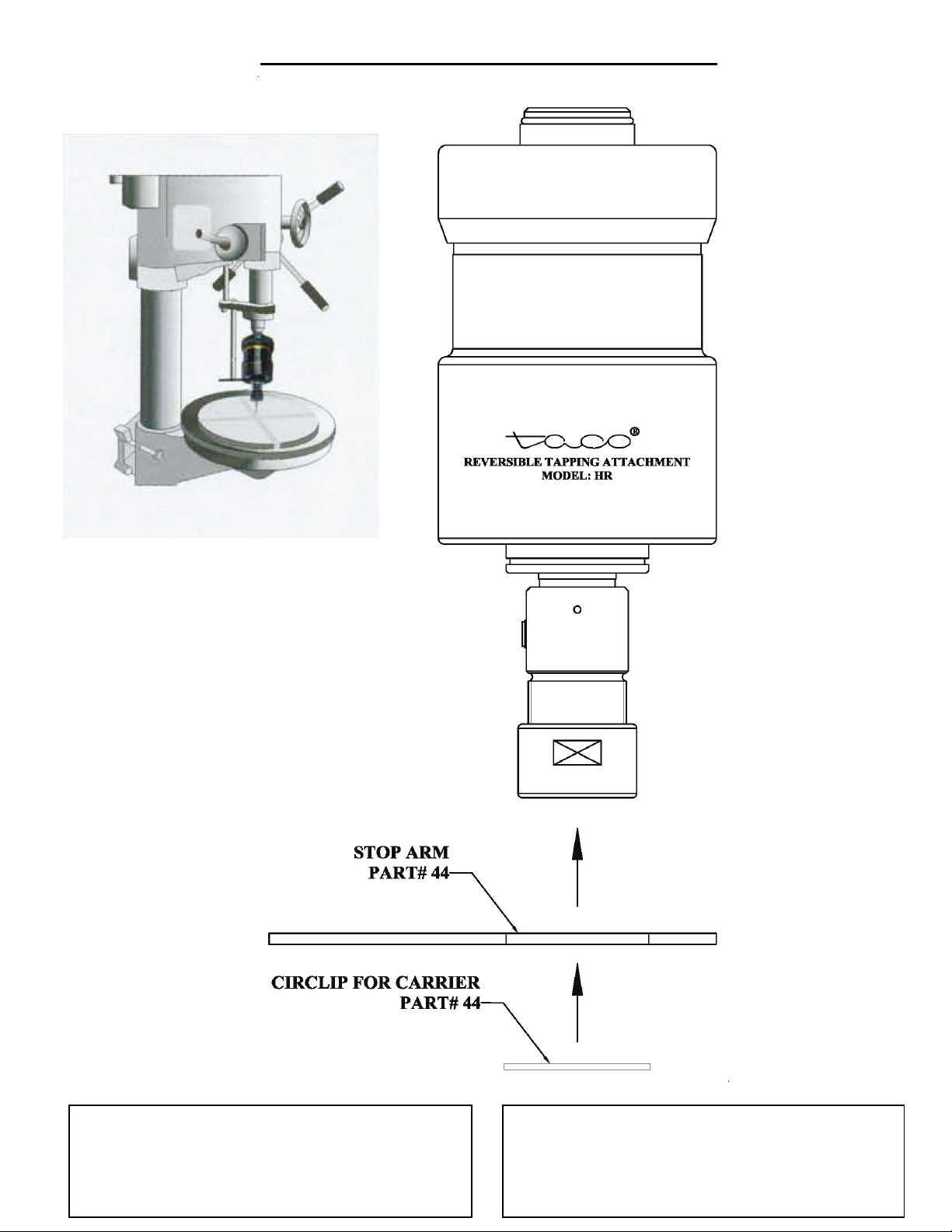

MOUNTING THE ATTACHMENT TO THE MACHINE

Mount the STOP ARM on the attachment. A circlip is provided to hold

the STOP ARM in place. Now mount the attachment on the machine

spindle. Ensuring that the taper is free of oil and grease. Extend strong

stop bar from machine spindle of machine table to engage short STOP

ARM. DO NOT HOLD STOP ARM BY HAND. DO NOT

LENGHTEN STOP ARM, DO NOT HOLD JOB BY HAND. Clamp

the job securely as full power of the machine is transmitted in reverse.

INSERTING THE TAP

A. MODEL : HR :

Insert the desire tap into the chuck of the attachment. The square

of the tap is fit and centered between adjustable square nuts &

further tighten Chuck Nut which forces the Collect to hold the tap

shank with a firm grip. Slacken adjustable square nut in order to

center the tap. Check that the adjustable square Nuts only grip the

square portion of the tap. Then firmly tighten the Adjustable

square nuts.

B. MODEL : HRF :

The Spindle of the attachment has a quick change device. Press

the bush of the adaptor (Model: QA) and insert the tap. Now

insert the adaptor with the tap into the spindle of the attachment.

To disengage the adaptor, push the bush of the adaptor again.

For each tap with varying shank dimension a different adaptor is

required.

TORQUE SETTING:

The torque adjustments are made by tightening or loosening the cup

nut (3) at the upper end of the attachment. When the desired torque

has been determined, the cup nut may be locked in place by a grub

screw (5). Proper procedure when beginning tapping operation in to

loosen the cup nut so that all the graduations on the body are visible.

Then tighten the cup nut progressively until the attachment will drive

a sharp tap. When the proper torque is determined for a specific job.

This reference point may be noted to save set up time in future. If later

during the operation the clutch slips it is evident that the tap is dull and

should be immediately exchanged for a sharp tap but the clutch should

not be tightened further.

THROUGH HOLE TAPPING:

Press the tap lightly against the mouth of the hole. The free axial float

is provided in the attachment which will automatically permit the tap

to follow its own lead. The operator merely moves the machine’s

spindle behind the lead of the tap until the desired, depth is reached.

To reduce the wear of the attachment it is recommended that a short,

quick upward movement of the machine spindle be made during

transition fro forward to reverse.

from the hole.

BOTTOM HOLE TAPPING

For accurate and efficient bottom hole tapping a machine feed stop

should be used to allow the attachment’s spindle to disengage in

neutral before the tap bottoms in the hole. To achieve this, set the

machine stop so that machine feed plus the attachment’s self feed

will equal the desired thread depth.

If clutch should slip before the tap reaches the desired depth,

check to see that the hole is of the correct size not packed with

chips, and that the tap is sharp and undamaged. The torque

control clutch is designed as a safety device to prevent tap

breakage in ease the tap accidentally hits to the bottom. We do

not recommend using the clutch for repetitive hole tapping unless

absolutely necessary.

TAPPING SPEED

The factors to be considered when trying to determine the best

tapping speed are :

* Material to be tapped.

* Pitch of the thread.

* Selection of tap :

● Length of chamfer on tap

● Rake Angle

● Standard, spiral or spiral point

* The percentage of full thread to be cut.

The tapping speed must be reduced as the Percentage

of full thread to be cut is increased.

* Drilled hole with respect to length of the hole to be tapped.

* Cutting fluid

* Straight or tapered thread to be tapped.

This tapping attachments have been designed to operate at max

800 R.P.M.

CUTTING FLUID :

The cutting fluid works two ways. Heat generated as the tap

proceeds into the hole both by the deformation of the material and

by friction. The fluid must discipate this heat. The fluid must also

lubricate so that the friction between the tap, the chips and the hold

is minimized.

Be sure to use large quantities of cutting fluid under pressure for

tapping. The higher the cutting speed, the deeper the hole and the

tougher the material, the more cutting fluid you will need.

LUBRICATION :

This attachment is prepacked at the factory and only needs periodic additions of grease to maintain proper lubrication. Approximately

every 600 Hrs partially disassemble the attachment and clean ball

bearing and gears. Add a small amount of grease and reassemble. Do

not over lubricate. Excess grease will create internal friction and overheating.

SERVICE OVERHAUL AND REPAIR

Since overhaul and repair are time consuming for someone not

familiar with the attachment, we recommend that they be sent to us.

We will be glad to get your tapping attachment operational again in

shortest possible time.

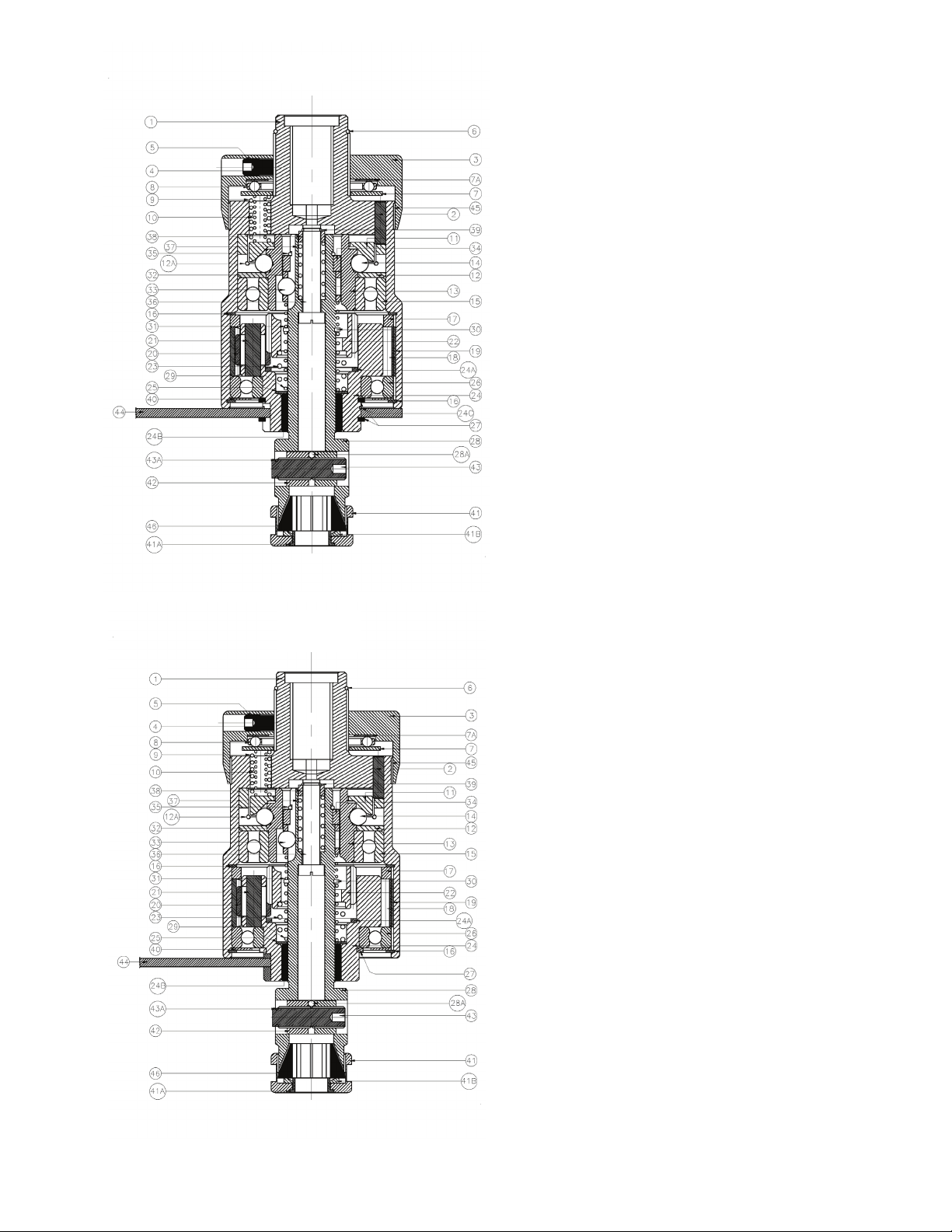

Page 2

HR 4

Page 3

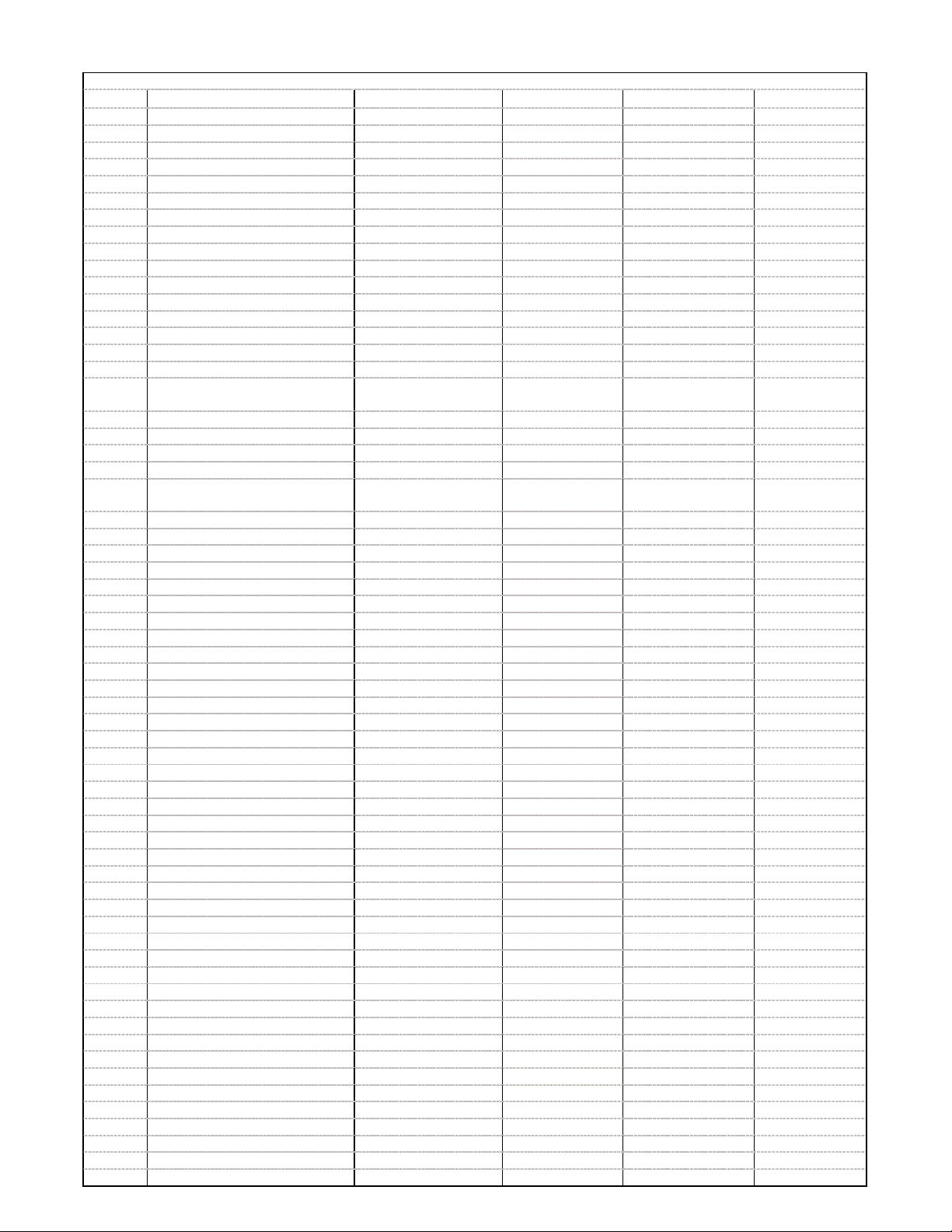

NOMENCLATURES

Ordering Numbers

Part No.

Part Name

HR3

HRF3

HR4

HRF4

1.

Body

1 HR3 (a)

1 HR3 (a)

1HR4(a)

1HR4(a)

2.

Pin for Body

2 HR3 (a)

2 HR3 (a)

2HR4(a)

2HR4(a)

3.

Cup Nut

3 HR3

3 HR3

3HR4

3HR4

4.

Pin for Cup Nut

4 HR3

4 HR3

4HR4

4HR4

5.

Grub Screw

5 HR3

5 HR3

5HR4

5HR4

6.

Lockring for Cup Nut

6 HR3

6 HR3

6HR4

6HR4

7.

Washer for Cup Nut

7 HR3

7 HR3

7HR4

7HR4

7A.

Washer for Cup Nut

7 AHR3

7 AHR3

7AHR4

7AHR4

8.

Thrust Bearing

8 HR3

8 HR3

8HR4

8HR4

9.

Pressure Spring Outer

9 HR3 (9 Nos.)

9 HR3 (9 Nos.)

9HR4(6Nos)

9HR4(6Nos)

10.

Pressure Spring Inner

10 HR3 (9 Nos.)

10 HR3 (9 Nos.)

10HR4(6Nos)

10HR4(6Nos)

11.

Pressure Plate

11 HR3

11 HR3

11HR4

11HR4

12.

Clutch Driver

12 HR3

12 HR3

12HR4

12HR4

12.A

Lockring for Clutch Driver

12 AHR3

12 AHR3

12AHR4

12AHR4

13.

Forward Driver

13 HR3©

13 HR3©

13HR4©

13HR4©

14.

Balls for Forward Driver

14 HR3(6Nos)

14 HR3(6Nos)

14HR4(6Nos)

14HR4(6Nos)

Ball Bearing for Forward

16.

Circlip for Body

16 HR3(2Nos)

16 HR3(2Nos)

16HR4(2Nos)

16HR4(2Nos)

17.

Spacer

17 HR3

17 HR3

17HR4

17HR4

18.

Gear Ring

18 HR3

18 HR3

18HR4

18HR4

19.

Key for Gear Ring

19 HR3

19 HR3

19HR4

19HR4

20 HR3 (b) 3

Nos.

21.

Pin for Pinion

21 HR3 (b) 3 Nos.

21 HR3 (b) 3 Nos.

21HR4(b)3Nos

21HR4(b)3Nos

22.

Reverse Gear

22 HR3

22 HR3

22HR4

22HR4

23.

Spring for Reverse Gear

23 HR3

23 HR3

23HR4

23HR4

24.

Carrier

24 HR3 (b)

24 HR3 (b)

24HR4(b)

24HR4(b)

24 A

Ring for Carrier

24 AHR3 (b)

24 AHR3 (b)

24AHR4(b)

24AHR4(b)

24 B

Bush for Carrier

24 BHR3 (b)

24 BHR3 (b)

24BHR4(b)

24BHR4(b)

24 C

Spacer for Carrier

24 CHR3 (b)

24CHR3 (b)

-

-

25.

Washer for Carrier

25 HR3 (b)

25 HR3 (b)

25HR4 (b)

25HR4 (b)

26.

Ball Bearing for Carrier

26 HR3 (b)

26 HR3(b)

26HR4 (b)

26HR4 (b)

27.

Circlip for Carrier

27 HR3 (2 Nos.)

27 HR3 (2 Nos.)

27HR4

27HR4

28.

Spindle

28 HR3

-

28HR4

-

28.A

Pin for Spindle

28 AHR3

-

28AHR4

-

29.

Expansion Spring

29 HR3

29 HR3

29HR4

29HR4

30.

Lockring for Spindle

30 HR3

30 HR3

30HR4

30HR4

31.

Spring for Ball Carrier

31 HR3

31 HR3

31HR4

31HR4

32.

Ball Carrier

32 HR3

32 HR3

32HR4

32HR4

33.

Balls for Ball Carrier

33 HR3 (3Nos)

33 HR3(3Nos)

33HR4(3Nos)

33HR4(3Nos)

34.

Washer for Spindle

34 HR3

34 HR3

34HR4

34HR4

35.

Lockring for Washer

35 HR3

35 HR3

35HR4

35HR4

36.

Stud for Spindle

36 HR3

36 HR3

36HR4

36HR4

37.

Comp. Spring for Stud

37 HR3

37 HR3

37HR4

37HR4

38.

Washer for Stud

38 HR3

38 HR3

38HR4

38HR4

39.

Lockring for Stud

39 HR3

39 HR3

39HR4

39HR4

40.

Thrust Washer

40 HR3

40 HR3

40HR4

40HR4

41.

Chuck Nut

41HR3(d)

-

41HR4(d)

-

41A.

Bush for Chuck Nut

41AHR3 (d)

-

41AHR4(d)

-

41B.

Washer for Chuck Nut

41BHR3 (d)

-

41BHR4(d)

-

42

L–R Nuts

42 HR3

-

42HR4

-

43.

L–R Stud

43 HR3

-

43HR4

-

43A.

E–Type Circlip

43AHR3

-

43AHR4

-

44.

Stop Arm

44 HR3

44 HR3

44HR4

44HR4

45.

Torque Strip

45 HR3(a)

45 HR3(a)

45HR4(a)

45HR4(a)

46.

Collet

S413

-

S613

-

Collet

S453

-

S623

-

47.

Spanner Set

47 HR3

-

47HR4

-

48.

Allen Key

48 HR3

48 HR3

48HR4

48HR4

49.

Arbor

(a)M20x2.50/MT2

49(a)HR3

49(a)HR3

-

-

(b) M20 x 2.50/MT3

49(b) HR3

49(b) HR3

49(b)HR4

49(b)HR4

(c) M20x2.50/MT4

49© HR3

49© HR3

49b©HR4

49©HR4

15.

20. Pinion 20 HR3 (b) 3 Nos.

Driver

15 HR3© 15 HR3© 15HR4© 15HR4©

20HR4(b)3Nos 20HR4(b)3Nos

Page 4

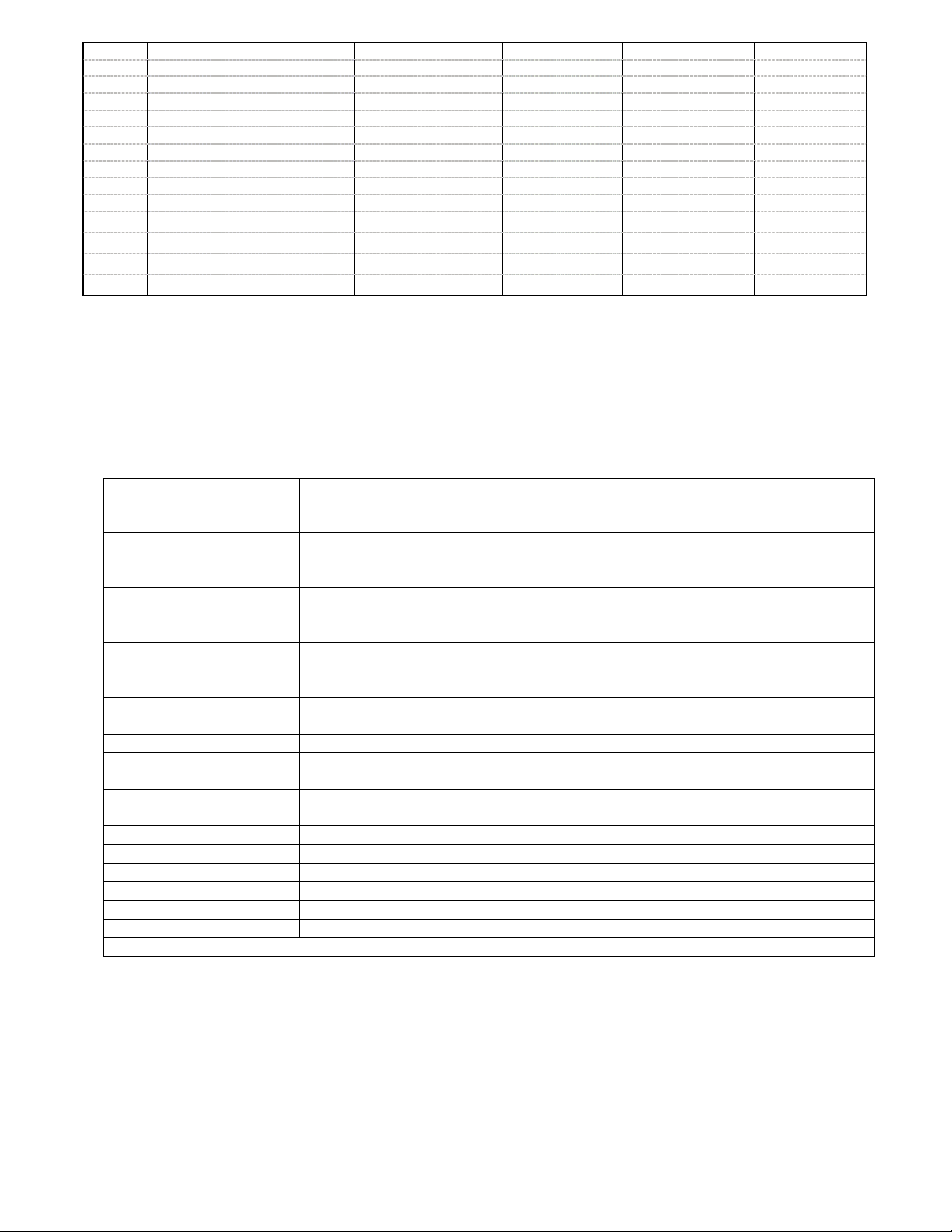

Cutting Speed

Type Tap. - HSS

Steel carbon

0.50 – 1.10 %C

20 – 40

Or Sulphur-base oil

Steel-Chromium Nickel

10˚ - 15˚

10 – 30

Heavy Sulphur-base oil

Steel-Chromium-

Heavy Chloride base oil

Sulphur-base oil

Monel Metal

10˚ - 15˚

10 – 23

Heavy Chloride base oil

Soluble oil or Sulphur-

Iron-cast

3˚ - 7˚

30 – 80

Dry or Soluble oil

Soluble oil or light base

oil

Soluble oil or light base

oil

Bronze

5˚ - 10˚

35 – 60

Dry

Aluminum Drawn

20˚ – 30˚

60 – 100

Kerosene or Soluble oil

Aluminum Cast

10˚ – 15˚

60 – 100

Kerosene or Soluble oil

Duralumin

10˚ – 20˚

60 – 100

Dry

Bakelite

0˚ – 5˚

30 – 65

Dry

Plastics, Soft

20˚ - 30˚

60 – 70

Dry

The above information are subject to Tapping Speed instructions

(d) M20x2.50/MT5

-

-

49(d)HR4

49(d)HR4

(e) JT3/MT3

49(e) HR3

49(e) HR3

-

-

(f) JT3/MT4

49(f) HR3

49(f) HR3

-

-

(g) JT4/MT4

-

-

49(g)HR4

49(g)HR4

(h) JT4/MT5

-

-

49(h)HR4

49(h)HR4

50

Nut for Arbor

50HR3

50HR3

50HR4

50HR4

51.

Spindle

--

51 HRF3

-

51HRF4

52.

Pressure Block

--

52 HRF3

-

52HRF4

53.

Spring for Pressure Block

--

53 HRF3

-

53HRF4

54.

Lockring for Pressure Block

--

54 HRF3

-

54HRF4

55. Balls -- 55HRF3(3Nos) - 55HRF4(3Nos)

56. Knurling Sleeve -- 56 HRF3 - 56HRF4

57. Spring for Kn. Sleeve -- 57 HRF3 - 57HRF4

58. Lockring for Kn. Sleeve -- 58 HRF3 - 58HRF4

Note: - Following parts are only available as an assembly.

(a) Body (1) with Part No. (2) and (45).

(b) Carrier (24) with Part No. (20), (21), (24A), (24B), (24C), (25) and bearing (26).

(c) Bearing (15) with Part No. (13).

(d) Chuck Nut (41) with Part No. (41A) and (41B).

Recommended Cutting Speed

Material Rake Angle

0.10 – 0.50 % C

Molybdenum

10˚ - 15˚

10˚ - 15˚ 10 – 30 Heavy Sulphur-base oil

Speed feet/min

20 – 50

Steel-stainless 10˚ - 15˚ 10 – 23

Steel-cast 10˚ - 15˚ 15 – 50

Brass Drawn 10˚ - 15˚ 60 – 100

Brass Cast 0˚ - 5˚ 60 – 100

Cutting Fluid

Oil emulsion

base oil

Page 5

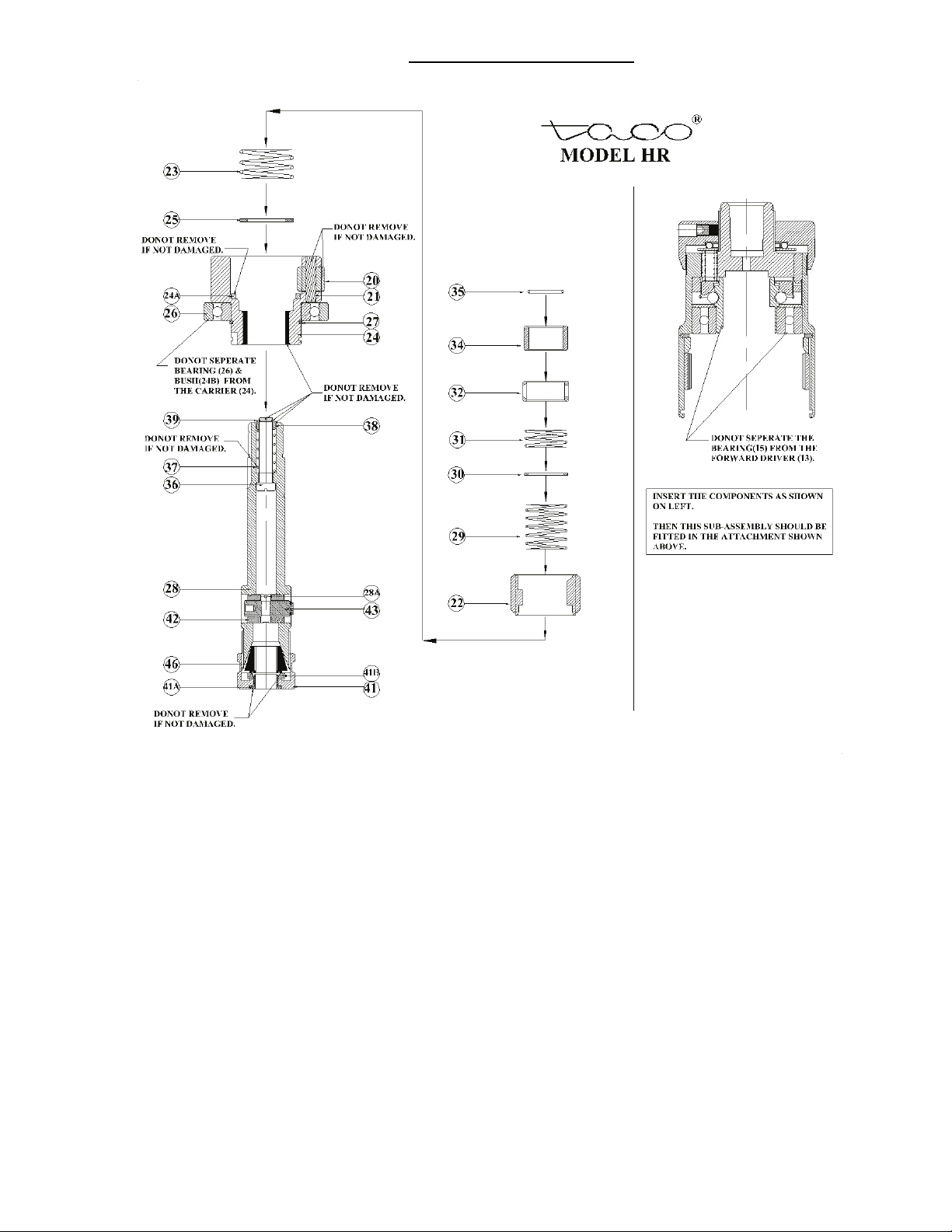

ASSEMBLY PROCEDURE

INSTRUCTIONS FOR DISASSEMBLY

1. Remove Lockring (6) and unscrew cup nut (3).

2. Hold unit in vertical position and remove thrust bearing (8), Washer (7) & Washer (7A).

3. Carefully invert unit over a clean receptable, pressure springs (9 & 10) will drop out.

4. From the lower end remove Chuck Nut (41),Collet (46) if necessary then remove E-Type Circlip (43A) and Loosen L-R stud (43) to remove Nuts(42)

(For Model HR).

5. Remove Circlip (27), Stop Arm (44), Circlip (16) and Bearing Cover (40).Do not remove Circlip (27) which holds bearing.

6. Lift out complete gear – carrier sub-assembly with spindle unit.

7. Remove Gear Ring (18), key (19) and Spacer (17).

8. Remove Lockring (35), Washer (34), Ball Carrier (32), Balls (33) and Spring (31).

9. Lift out Reverse Gear (22) and Spring (23).

10. Remove Lockring (30), Expansion Spring (29) and Washer (25) for relieving spindle unit from Carrier sub-assembly.

11. Remove Circlip (16) for disassembling clutch sub-assembly. Invert the Body over a clean receptable. Lift off pressure plate (11), Balls (14),

Clutch Driver (12). For reassembly pack grease in clutch sub-assembly, so Pressure Plate (11) will stay in place while reassembling Clutch

Bearing assembly.

12. Do not disassemble Ball bearings (15 & 26).

13. Do not disassemble pinion (20) – Carrier (24) sub assembly.

INSRTUCTIONS FOR ASSEMBLY

1. Clean and lubricate all parts requiring lubrication thoroughly.

2. Reverse procedure for assembly.

Page 6

PROCEDURE FOR MOUNTING THE STOP-ARM

Loading...

Loading...