Page 1

INSTALLATION AND OPERATION INSTRUCTIONS

TACO ENERGY SAVING

ES2

ES2 ADAPT

ES2 SOLAR

ES2 PURE

EN

Page 2

Page 3

1 Declaration of conformity

We Taco Italia S.r.l. declare under our sole responsibility that the family of products ENERGY

SAVING to which this declaration relates are in conformity with the Council Directives on the

approximations of the laws of the EC Member State relating to:

• EMCD Directive (2014/30/EU)

Standard used: EN 61000-3-2:2014, EN 61000-3-3:2013, EN 55014-1:2006, EN 550142:1997 (including amendments)

• LVD Directive (2014/35/EU)

Standard used: EN 62233:2008, EN 60335-1:2012, EN 60335-2-51:2003 (including amendments)

• ErP Directive (2009/125/EC-2012/27/EU)

Commission Regulations n. 641/2009 and n. 622/2012

Applies only to circulators marked with the energy efciency index EEI. See the pump nameplate.

• RoHS II Directive (2011/65/EU)

This CE declaration of conformity is valid only when published as part of the Taco Italia installation and operating instructions.

Sandrigo, 31th May 2018

Luca Bolcati

General Manager and Managing Director

Person authorized to compile technical le and empowered to sign the EC declaration of

Conformity.

3Declaration of conformity

Page 4

ENERGY SAVING

2 Contents

1 Declaration of conformity 2

2 Contents 3

3 Indication of instructions 5

4 Important safety and installation instructions 6

5 Field of application 9

5.1 Types of system 9

5.2 Pumped liquids 9

6 Pumped liquids 10

6.1 Description of the product 10

6.2 Type key 10

6.3 Name plate 11

6.4 Components 11

6.5 Technical data 12

7 Installation at Site 14

7.1 Installation 14

7.2 Permissible installation positions 15

7.3 Motor housing regulation 15

7.4 Insulation of pump housing 16

8 Electric connection 17

9 Commissioning 18

9.1 Start-up of the circulator 18

9.2 Operating elements 18

9.3 Operating elements 19

9.4 Automatic detection of the presence of air - Vent system 20

10 Circulator setting 21

11 Performance curves 23

11.1 Performance curves - ES2 60 23

11.2 Performance curves - ES2 70 23

11.3 Performance curves - ES2 C 60 24

11.4 Performance curves - ES2 C 70 24

11.5 Performance curves - ES2 ADAPT 60 25

11.6 Performance curves - ES2 ADAPT 70 25

11.7 Performance curves - ES2 SOLAR 60 26

11.8 Performance curves - ES2 SOLAR 70 26

11.9 Performance curves - ES2 PURE C 40 27

4 Contents

Page 5

12 Maintenance 28

13 Faults, causes and remedies 28

13.1 Fault nding table 28

13.2 Unlocking procedure 29

14 Warranty 30

15 Disposal 30

5Contents

Page 6

ENERGY SAVING

These instructions include information necessary to assemble and use the product correctly.

Besides respecting the general safety regulations, it is necessary to observe all points specically and specially marked.

3 Indication of instructions

This manual contains information and prescriptions marked by the following symbols.

The inobservance of the safety provisions marked by the symbol “CAUTION”:

hazard” may endanger the safety of people.

The inobservance of the safety provisions marked by the symbol “CAUTION”:

electricity” may endanger the safety of people, as well as the integrity of

things.

The inobservance of the safety provisions marked by the word “CAUTION”

CAUTION

The Quick Guide contains following warning symbols.

may endanger the integrity and functionality of the equipment and of the

machines.

The circulators are not to be used to transfer ammable liquids such as

gasoline, oils, gas oil or similar liquids.

The circulators are not to be used to transfer aggressive liquids, such as acids

and sea water.

CAUTION

The removal of the screws can cause the output of hot uids under high pressure from heating system. Drain the system or close the isolating valves.

6 Indication of instructions

CAUTION

High temperature surface. Pay utmost care to prevent people from getting in

contact with the hot surfaces of the circulator.

Page 7

4 Important safety and installation instructions

Prior to installation, read these installation and operating instructions. The installation and

operation should also be in accordance with national regulations and accepted codes of good

practice.

This appliance can be used by children aged from 8 years and above and

persons with reduced physical, sensory or mental capabilities or lack of experience and knowledge, only if they have been given supervision or instruction

concerning use of the appliance in a safe way and understand the hazards

involved. Children shall not play with the appliance. Cleaning and user maintenance shall not be made by children without supervision.

To guard against injury, basic safety precautions should be observed, including the following:

1. Read and follow all safety instructions and all the important notices on the

appliance before installing, using and maintaining the circulator. failure to do so

may cause personal injury or damage to the circulator or installation.

2. Always disconnect electrical supply before putting on or taking off parts

and whilst the equipment is being installed, maintained or handled. Never

work with bare feet and/or with wet hands.

3. To avoid possible electric shock, special care should be taken since

water is used with electrical equipment. Carefully examine the circulator

before and after installation. Do not operate the circulator if it has a damaged

supply cord or enclosure, or if it is malfunctioning or it is dropped or damaged

in any manner. Inspect the circulator periodically. The circulator should not be

electrically supplied if there is water on parts not intended to be wet.

4. Risk of scalding.

To avoid injury before any servicing operation wait until the water has cooled

inside the circulator.

Do not touch the uid or the circulator when temperature is higher than 60°C.

7Important safety and installation instructions

Page 8

ENERGY SAVING

5. Improper use

This is a circulator to be used in heating plants and for the circulation of clean

water without abrasive particles. This is not a submersible pump. Do not use

this circulator:

• With liquids other than water (e.g. ammable liquids, etc.) (EN60335-2-51);

• For handling drinkable water or food related liquids;

• For the circulation of domestic water;

• In locations where special condition prevail, such as the presence of a corro-

sive or explosive atmosphere (dust, vapor or gas) (EN60335-2-51);

• For other than intended use.

Never run the circulator dry. The circulator must be always fully lled with

water when operating.

6. Installation

The circulator must be mounted in a stable/xed position in a dry, well

ventilated, frost-free, waterproof and protected place, with sufcient ventilation

around it. Assemble the circulator only after having ended all welding and

brazing works on the hosing. Before installing the circulator, make sure that

the internal part of the tubes is clean. Install the circulator in an accessible

place for future checks and disassembly procedures. Foresee enough space

for inspections and disassembling.

To avoid circulator overheating, do not place any object on the circulator itself.

7. Electric connection

IMPORTANT: Connection to the power supply must be effected by means of

a xed power cable which is tted with a plug-type connection or an all-pole

isolating switch with a minimum contact opening of 3 mm.

Electrical connection must be carried out only by a qualied electrician and in

accordance with local regulations and both data on the name-plate and the

appropriate diagram inside the terminal box cover.

Follow all safety standards.

Do not connect to mains supply unless circulator is fully and correctly

assembled.

8. Supply cord must be selected following the requirements of EN60335-2-51

Chapter 25. Supply cord must be protected against any kind of mechanical

damage (cuts, abrasion, etc.). It must not touch the pipe or the pump. (EN

60335-2-51). If the insulation of the Supply cord can come in contact with

parts having a temperature exceeding 70°C the supply cord insulation must

be protected, for example, by insulating sleeving having an appropriate

temperature rating. (EN60335-2-51).

9. Connect circulators only to a mains supply protected by a Residual Current

Device (RCD or Ground-Fault Circuit-Interrupter) with a rated residual operating current not exceeding 30mA.

8 Important safety and installation instructions

Page 9

10. Any modication to the equipment must be prior agreed upon with and au-

thorized by the manufacturer. Original spare parts and accessories authorized

by the manufacturer are integral part contributing to the safety of the equipment and of the machines. The use of not original components or accessories

may endanger the safety and causes the termination of the warranty. A safe

operation is assured only for the applications and conditions described in → 5

Field of application of this manual. Non-observance of the safety instructions

results in the loss of any claims to damages.

Non-observance of the safety instructions results in the loss of any claims to

damages.

The indicated limit values are binding and cannot be exceeded for any reason

whatsoever.

Keep these instructions for future reference.

9Important safety and installation instructions

Page 10

ENERGY SAVING

5 Field of application

5.1 Types of system

Models Uses

Circulation of water/liquids in hot water heating systems and in renewable

energy solar thermal systems:

ES2

ES2 C A

ES2 ADAPT

ES2 SOLAR

ES2 PURE

5.2 Pumped liquids

Clean liquids, not aggressive and not explosive, not containing solid particles, bers or mineral

oils.

In heating systems:

• Water for heating according to VDI 2035;

• Mixtures of water and glycol with glycol percentages not greater than 30%.

In domestic hot water circulation systems, max. 38°d water hardness.

Any other use is regarded as incorrect use. For the use with other uids, manufacturer’s

authorization is required.

• One-pipe systems

• Two-pipe systems

• Systems with constant or variable ows

• Underoor heating systems

• Boiler or primary circuit

• Storage tank circuit

Circulation of water/liquids in hot water heating systems and in renewable

energy solar thermal systems:

• Solar thermal systems

• One-pipe systems

• Two-pipe systems

• Systems with constant or variable ows

• Underoor heating systems

• Boiler or primary circuit

• Storage tank circuit

Domestic hot water circulation, drinking water circulation systems and similar

domestic and industrial circulation systems.

This circulator is suitable for drinking water only.

• The circulators are not to be used to transfer ammable liquids such as

gasoline, oils, gas oil or similar liquids.

• The circulators must never be used in refrigeration systems, air conditioning

systems and similar installations.

10 Field of application

Page 11

6 Product information

6.1 Description of the product

The ENERGY SAVING are a range of innovative wet rotor circulators with an integrated

frequency converter (INVERTER).

ENERGY SAVING circulators combine an advanced hydraulic system, a high efciency motor,

an intuitive electronic control and an operating software that allow to perfectly adapt to the

various operating conditions and the actual needs of the system.

The motor with electronic control module is mounted on the pump housing by four screws.

The criteria for differential pressure control depend on the set operating mode. In all operating

modes, the circulator adapts to the different loads of the system.

The ENERGY SAVING circulator range is available in the following versions:

ES2

ES2 ADAPT

ES2 SOLAR

ES2 PURE

6.2 Type key

Electronic circulator

Standard version

ADAPT: Version with activeADAPT

SOLAR: Solar thermal version

PURE: DHW version

MAXI: HVAC systems version

Cast-iron pump housing

C: Composite pump housing

B: Bronze pump housing

A: Pump housing with air separator

Nominal diameter (DN) of suction and discharge

ports (10 = G

Maximum head [dm]

Port-to-port length [mm]

F: Flanged circulator

D: Twin-head circulator

W: Circulator equipped with power cable

M: Circulator with Molex connector

3

/

4,

15 = G1, 25 = G1

Standard version with operating modes P, C and min-max.

Pump housing available in cast iron, plastic composite material (C) and plastic

composite material with air separator (C A)

Premium version with operating modes activeADAPT, P, C and min-max.

Pump housing available in cast iron.

Solar thermal systems version with operating modes P and min-max.

Pump housing available in cast iron.

Domestic hot water circulation systems with operating mode min-max.

Pump housing available in plastic composite material (C)

ADAPT 25 - 60 / 130Example

ES2

1

/

2

, 32 = G2) [mm]

11Field of application

Page 12

ENERGY SAVING

6.3 Name plate

Fig. 6.1: Name plate (example)

6.4 Components

Fig. 6.2: Exploded view

1 Type

2 Code

Input power P1[W] / Input curren I1[A] / System

3

pressure [MPa]

4 Voltage, frequency

5 Temperature class / Protection class

6 Energy Efciency Index (EEI)

7 CE mark / Appliance class / Quality mark

A Pump housing E Stator

B Impeller and bearing plate F Electronics

C Rotor G Motor housing

D Can H Front cover

12 Product information

Page 13

6.5 Technical data

Power supply 1x230 V -10%+6%, 50Hz

Adjustment of the rotation speed Manuale con selettore

Motor protection Non richiesta

Insulation class H

Protection class IP 44

Appliance class II

Ambient temperature da +2°C a +40°C

Liquid temperature

Maximum relative humidity ≤ 95%

Maximum operating pressure

Minimum pressure on the intake opening

Sound pressure level < 43 dB(A)

EMC (electromagnetic compatibility)

Specic EEI values

2

ES2

ES2 C

ES2 C A

ES2 PURE C

ES2 ADAPT

ES2 SOLAR

ES2

ES2 C

ES2 C A

ES2 ADAPT

ES2 SOLAR

ES2 PURE C

Minimum pressure Liquid temperature

0.03 MPa (0.3 bar) 50°C

1

0.10 MPa (1.0 bar) 95°C

0.15 MPa (1.5 bar) 110°C

EN 61000-3-2 / EN 61000-3-3

EN 55014-1 / EN55014-2

ES2 60

ES2 ADAPT 60

ES2 SOLAR 60

ES2 C 60

ES2 C 70

ES2 70

ES2 ADAPT 70

ES2 SOLAR 70

ES2 C A IEE ≤ 0,23 - Part 2

from +2°C to +95°C

from +2°C to +110°C

0,6 MPa (6 bar)

1,0 MPa (10 bar)

IEE ≤ 0,20 - Part 2

IEE ≤ 0,21 - Part 2

1

To avoid cavitation noise, minimum pressure values on the intake opening must be strictly respected.

2

The benchmark for most efcient circulators is EEI ≤ 0,20.

13Product information

Page 14

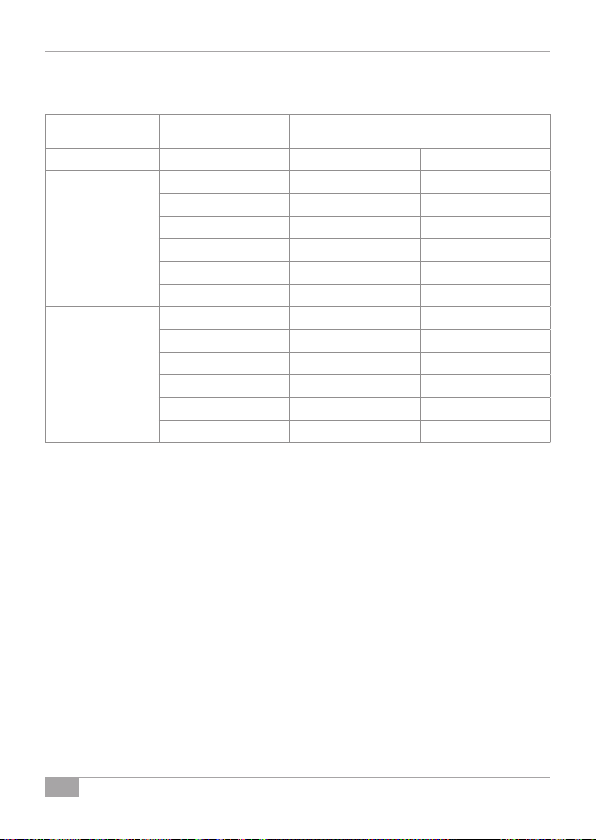

ENERGY SAVING

To avoid condensation in the motor and the electronics the temperature of the pumped

liquid must always be greater than the ambient temperature.

Ambient temperature Liquid temperature

[°C] Min. [°C] Max. [°C]

0 2 95

10 10 95

ES2

ES2 C

ES2 ADAPT

ES2 SOLAR

20 20 95

30 30 95

35 35 90

40 40 70

0 2 11 0

10 10 110

20 20 110

30 30 110

35 35 90

40 40 70

14 Product information

Page 15

7 Installation at Site

Installation and service by qualied personnel only!

7.1 Installation

The circulator must be mounted in a stable/xed position in a dry, well ventilated, frost-free,

waterproof and protected place, with sufcient ventilation around it.

Assemble the circulator only after having ended all welding and brazing works on the hosing.

Before installing the circulator, make sure that the internal part of the tubes is clean.

Install the circulator in an accessible place for future checks and disassembly procedures.

Foresee enough space for inspections and disassembling.

Foresee isolating valves at intake and output (before and after the circulator) to allow the

disassembly without emptying the plant.

The assembly of the interception organs must be carried out in such a way as to prevent

possible water leaks from involving the terminal board.

Perform the assembly without mechanical stresses acting on the circulator.

Avoid the installation in misaligned pipe work.

Fig. 7.1: Mounting procedure.

The direction of the water ow is indicated by the arrow on the pump housing, as shown in Fig.

7.1.

1. Check that both isolating valves are closed

2. Install the circulator with the motor shaft in horizontal position. Connect the piping without

3. Accurately insert the two gaskets supplied.

4. Establish a screwed connection between circulator and piping.

5. Tighten the screwed connection hand with an assembly tool (e.g. pipe wrench).

15Installation at Site

Page 16

ENERGY SAVING

Thread Pump housing material Tightening torque

G1 Composite PA 66 GF Max. 50 Nm

G1 Cast Iron EN-GJL-200 Max. 85 Nm

G1½ Cast Iron EN-GJL-200 Max. 125 Nm

G2 Cast Iron EN-GJL-200 Max. 165 Nm

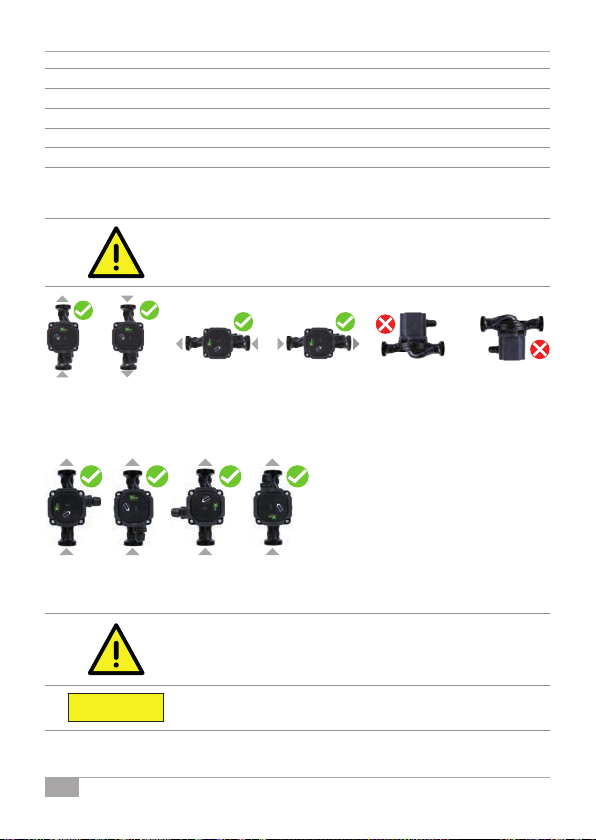

7.2 Permissible installation positions

Install the circulator with horizontal motor shaft axis (Fig. 7.2).

Fig. 7.2: Permissible installation positions

7.3 Motor housing positions

Fig. 7.3: Motor housing positions

The motor body can be rotated in the positions shown in Fig. 7.3.

Pay utmost care to prevent people from getting in contact with the hot

surfaces of the circulator.

Drain the system or close the isolating valves on either side of the pump

before the screws are removed. The pumped liquid may be scalding hot and

under high pressure.

CAUTION

16 Installation at Site

Pay attention not to damage the seal of the pump housing.

Page 17

Fig. 7.4: Changing the motor body position

Procedure (Fig. 7.4):

1. Slacken and remove the four screws M5 holding the motor.

2. Turn the motor to the desired position without extracting it from the pump housing.

3. Insert and tighten the pump housing screws (The tightening torque of the screws of the

pump housing must correspond to a value of 3.3 ± 0.5 Nm).

7.4 Insulation of pump housing

Fig. 7.5: Insulation of pump housing

Note: Limit heat loss from the pump housing and piping.

The heat loss from the pump and pipework can be reduced by insulating the pump housing

and the pipe with the thermal insulation shells supplied with the circulator (supplied as standard

only with model ES2 ADAPT) → Fig. 7.5.

CAUTION

Do not insulate the control box or cover the control panel.

17Installation at Site

Page 18

ENERGY SAVING

8 Electric connection

The electric connection has to be performed by a qualied electrician in

compliance with the national regulations. Follow the safety regulations and

installation regulations of your country.

Connection to the power supply must be carried out in compliance with the

standards via a xed power cable which is tted with a plug-type connection or

an all-pole isolating switch with a minimum contact opening of 3 mm.

The circulator belongs to class II and therefore grounding is not necessary. The circulator does

not require any external protection of the motor. Compare the frequency and the voltage of the

mains with the rating data. All electric information concerning the A1:G413 is on the signaling

plate. The connection cord must be laid in such a way as it cannot come in contact with the

hosing or the motor body. In case of use of the circulator with uids at a temperature higher

than 70 °C, use a connection cord resistant to high temperatures.

A B

HO5RN - F

2x0,50 mm²

Ø min 5 mm

Ø max 7 mm

Fig. 8.1: Electric connection

1. Connect the power supply conductors to the terminals according to the diagram given in

Fig. 8.1, from A to C. When using three-pole cables, remove the end of the grounding cable.

2. Insert the terminal board in the proper seat, connecting the blue wire (neutral) with letter N

and the black/brown wire (phase) with letter L. (Fig. 8.1.D).

3. Screw the two screws (Fig. 8.1.E - The tightening torque of the screws must correspond to a

maximum value of 0,3 Nm).

4. Tighten the sealing nuts to the fairlead (Fig. 8.1.F - The tightening torque must correspond to

a maximum value of 2 Nm).

12 mm

5 mm

L

N

D E F G

C

1x230 V (-10%/+6%), 50 Hz

5. The LED light, if lighted, indicates that the power supply is present. (Fig. 8.1.G).

18 Electric connection

Page 19

min. Ø 7.0 mm

max. Ø 8.5 mm

9 Commissioning

9.1 Start-up of the circulator

For cables with outer

diameter of the sheath

between 7 mm and

8.5 mm: remove the

rubber retainer from

the cable gland. In this

case, the circulator

can only be installed

with the cable gland

down.

CAUTION

CAUTION

CAUTION

Absolutely avoid dry operation. Start the circulator only after having complete-

ly lled the plant.

Circulators with permanent magnets can not be driven in speed by means of

phase control of the supply voltage.

Circulators driven by an electronic frequency converter have a current peak at

each activation (inrush current) greater than traditional circulators (asynchronous). The activation stage of the circulator has to be size taking into account

this current peak. For further details contact the manufacturer.

Activation frequency: activations/deactivations through the mains voltage ≤ 20/24 h.

9.2 Operating elements

Selector

All settings are made using the selector on the

housing front.

The selector can be adjusted in a continuous

way with a rotation angle of 270 °.

The arrow on the selector indicates the operating

mode chosen.

LED light

The LED light on the front advises the commissioning/fault of the circulator.

Every operating mode is characterized by a xed

light of different colour.

After a change of operating mode, the LED

pulses 5 times. The pulse will be a change of

Fig. 9.1: Selector and LED light

brightness intensity of the LED light.

19Commissioning

Page 20

ENERGY SAVING

9.3 Mode of operation

A LED provides information about the operation status of the circulator.

LED COLOR DESCRIPTION

ActiveADAPT mode

The activeADAPT mode enables the circulator to actively

Violet

Green

Orange

Blu

Flashing white

Red

adapt its performance to the demands of the system during

short control intervals inside a dened control area.

• Improves the hydraulic balance of the system

• Ensures optimum performance during partial load periods

• Enables quick installation

P mode (∆p-v) – Proportional differential pressure

The circulator head is proportionally reduced with decreas-

ing of the heat demand from the heating system (ow rate

decrease) and is proportionally increased with increasing

demand of the heat demand from the heating system (ow

rate increase).

C Mode (∆p-c) - Constant differential pressure

The circulator maintains a constant pressure level (head)

irrespectively of the heat demand required from the heating

system (ow rate).

min-max mode – Fixed speed

The circulator maintains a xed speed irrespectively of the

heat demand from the heating system (ow rate).

The speed regulation is done by positioning the selector in

a gradual manner at any point between the Min and Max

positions.

Should this performance be insufcient, progressively increase the set value. Should this performance be excessive

or should noise arise due to the speed of the pumped uid,

progressively reduce the calibration.

Automatic detection of the presence of air - Vent system.

Proceed with the vent routine

Fault or malfunction

Faults, causes and remedies

20 Commissioning

Page 21

9.4 Automatic detection of the presence of air - Vent system

1a 1b

2 3

Fig. 9.2: Filling and venting of heating systems

Fill and bleed the system correctly. The circulator can be noisy at start due to the presence of

air. Such noise should stop after few minutes of operation. Usually the pump rotor chamber

normally bleeds automatically after a short time in operation.

The circulator is equipped with a special software system that detects the presence of excess

of air within the heating system. The LED shows the presence of air in the hydraulic circuit by

ashing and performing a rapid succession of WHITE colour.

10 min

Following the light signal, it’s possible to easily vent the heating system as follows:

1. Open the air vent valve in the hydraulic circuit above the circulator or open the cap of the air

separator in the pump housing, partially unscrewing it; when unscrewing the cap of the air

separator, beware of not losing the cap itself;

2. set the circulator to MAX position (maximum performance setting);

3. let the circulator run for a short period, according to the construction and the plant size;

4. once vented the system - the guide light (LED) stops blinking and the possible noise stops set the circulator as indicated in Par.10 Circulator setting

Repeat the procedure if necessary.

CAUTION

With solar thermal systems, ll the system with mixtures prepared for that application. The

circulator cannot be used to mix the uids in the system.

The plant cannot be drained by using the circulator.

Do not touch the uid or the circulator when the temperature is greater

than 60 °C. Hazard of scalding by simple contact.

21Commissioning

Page 22

ENERGY SAVING

10 Circulator setting

Modify the performance of the circulator (head) as needed by rotating the selector using a at

screwdriver, as given in the following table. The selection of the right functioning curve depends

on the characteristics of the heating system in question and the actual heat demand.

LED

ES2 ADAPT ES2 ES2 SOLAR ES2 PURE

activeADAPT *

MODEL

- - -

Lowest proportional curve

Intermediate proportional curve

Highest proportional curve

Intermediate constant curve

* Factory setting

22 Circulator setting

P1

P2

P3

Lowest constant curve

CI

CII

Highest constant curve

CIII

Fixed speed curves

min - max

Lowest proportional curve

P1 *

Highest proportional curve

P2

- -

Lowest constant curve

CI

Highest constant curve

CII

-

Fixed speed curves

min - max

Proportional curve

P

- -

Fixed speed curves

min - max*

--

Fixed speed curves

min - max*

Page 23

11 Performance curves

11.1 Performance curves - ES2 60

0

H [m]

max

6

5

CII

CII

4

CI

CI

3

P2

P2

2

P1

P1

1

min

0

0.5 1.0 1.5 2.0 2.5 3.0 3.50.0

0.0 0.2

11.2 Performance curves - ES2 70

1050 15 Q [US.gpm]

0.4 0.6 0.8 1.0

Q [IMS.gpm]105

H [ft]

20

15

10

5

0

3

Q [m

/h]

Q [l/s]

min - max

H [m]

7

6

5

4

3

2

1

0

0

0

max

CII

CII

CI

CI

P2

P2

P1

P1

min

0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.00.0

0.0 0.2

105 15 Q [US.gpm]

0.4 0.6 0.8 1.0

Q [IMS.gpm]105

H [ft]

20

15

10

5

0

3

Q [m

/h]

Q [l/s]

min - max

23Circulator setting

Page 24

ENERGY SAVING

11.3 Performance curves - ES2 C 60

0

H [m]

6

5

4

3

2

1

0

0.0 0.2

max

CII

CII

CI

CI

P2

P2

P1

P1

min

0.5 1.0 1.5 2.0 2.5 3.0 3.50.0

1050 15 Q [US.gpm]

0.4 0.6 0.8 1.0

11.4 Performance curves - ES2 C 70

H [m]

7

6

5

4

3

2

1

0

0

0

max

CII

CII

CI

CI

P2

P2

P1

P1

min

0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.00.0

0.0 0.2

105 15 Q [US.gpm]

0.4 0.6 0.8 1.0

Q [IMS.gpm]105

H [ft]

20

15

10

5

0

3

Q [m

/h]

Q [l/s]

Q [IMS.gpm]105

H [ft]

20

15

10

5

0

3

Q [m

/h]

Q [l/s]

min - max

min - max

24 Performance curves

Page 25

11.5 Performance curves - ES2 ADAPT 60

1050 15 Q [US.gpm]

P2

P2

P2

P1

P1

P1

0.4 0.6 0.8 1.0

H [m]

6

5

4

3

2

1

0

0.0 0.2

0

max

CIII

CIII

CIII

CII

CII

CII

CICI

CI

min

P3

P3

P3

0.5 1.0 1.5 2.0 2.5 3.0 3.50.0

11.6 Performance curves - ES2 ADAPT 70

H [m]

7

6

5

4

3

2

1

0

0

0

max

CIII

CIII

CII

CII

CI

CI

min

0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.00.0

0.0 0.2

105 15 Q [US.gpm]

P3

P3

P2

P2

P1

P1

0.4 0.6 0.8 1.0

Q [IMS.gpm]105

activeADAPT

Q [IMS.gpm]105

activeADAPT

H [ft]

20

min

15

10

5

0

3

Q [m

/h]

Q [l/s]

H [ft]

20

15

10

5

0

3

Q [m

/h]

Q [l/s]

min

activeADAPT

min - max

activeADAPT

activeADAPT

min - max

activeADAPT

25Performance curves

Page 26

ENERGY SAVING

11.7 Performance curves - ES2 SOLAR 60

1050 15 Q [US.gpm]

0.4 0.6 0.8 1.0

H [m]

6

5

4

3

2

1

0

0.0 0.2

0

max

PP

min

0.5 1.0 1.5 2.0 2.5 3.0 3.50.0

11.8 Performance curves - ES2 SOLAR 70

H [m]

0

max

7

6

5

4

3

PP

2

1

min

0

0.0 0.2

0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.00.0

1050 15 Q [US.gpm]

0.4 0.6 0.8 1.0

Q [IMS.gpm]105

H [ft]

20

15

10

5

0

3

Q [m

/h]

Q [l/s]

Q [IMS.gpm]105

H [ft]

20

15

10

5

0

3

Q [m

/h]

Q [l/s]

max

min

min

min - max

max

min - max

26 Performance curves

Page 27

11.9 Performance curves - ES2 PURE C 40

0 5 10 Q [US.gpm]

H [m]

4

max

3

2

1

min

0

0.0 0.2 0.4 0.6 0.8

Q [IMS.gpm]108642

H [ft]

15

10

5

0

3

/h]

3.02.52.01.51.00.5

Q [m

Q [l/s]

min - max

27Performance curves

Page 28

ENERGY SAVING

12 Maintenance

The circulator does not require any special maintenance during operation.

Motor bearings are lubricated by the pumped liquid.

Before each maintenance intervention, disconnect power supply and

wait for the circulator to cool.

13 Faults, causes and remedies

13.1 Fault nding table

FAULTS CONTROL PANEL CAUSES REMEDIES

Increase the system suction

pressure within the permissible range.

Disassemble the motor and

clean the impeller

Vent the system (→ 9.4

Automatic detection of

the presence of air - Vent

system.)

Reduce the rotation speed

(→ 10 Circulator setting)

Verify voltage value of the

electric plant.

Verify the connection of

the motor

Verify the fuses of the plant

Let the pump cool down for

some minutes. Then try to

re-start it.

Verify that the water and

ambient temperature are

within the indicated temperature ranges.

The circulator is noisy

Loud noises of water

circulation

Circulator is not

running although the

electrical power supply

is switched on

LED on

LED on

Flashing white LED Air in the system

LED on The ow is too high

LED off

Suction pressure is insufcient - cavitation

Presence of foreign bodies

in the impeller

Insufcient supply voltage

One fuse in the installation

is blown

The circulator is defective Replace the pump

Overheating

28 Maintenance, warranty and disposal

Page 29

FAULTS CONTROL PANEL CAUSES REMEDIES

Disassemble the motor and

clean the impeller if the

Circulator is not

running although the

electrical power supply

is switched on

Building does not get

warm

Should you fail to eliminate the cause of the malfunction, refer to the Distributor or nearest

Service Center.

LED red

LED on

The rotor is blocked

Insufcient supply voltage

The circulator performance

is too low

Should you fail to eliminate

the cause of the malfunction,

refer to the Distributor or

nearest Service Center.

doesn’t succeed (→ 13.2)

Verify that the power supply

matches the data on the

name plate.

Increase the suction head

(→10 Circulator setting)

13.2 Unlocking procedure

A red light in the LED indicates a locking.

Turn the selector to the position max, disconnect and connect power supply to start the

automatic release process.The circulator operates 100 attempts to restart (process lasts

approximately 15 minutes).

Every restart is signalled by a short ash of LED light. If the locking is not removed through the

automatic release process after 100 attempts to restart the circulator, it goes into standby and

the LED remains red. In this case follow the manual procedure described in the next steps:

1. Disconnect power supply - the warning light switches off.

2. Close both isolating valves and allow cooling. If there are no shut-off devices, drain the

system so that the uid level is beneath that of the circulator.

3. Carefully pull the rotor/impeller

4. Remove impurities and deposits with appropriate agents.

5. Reinsert the rotor/impeller

6. Set the selector on the wished position.

7. Connect power supply.

If the circulator doesn’t run → .

With high uid temperatures and pressures there is the risk of burnings.

Hazard of scalding by simple contact.

29Maintenance, warranty and disposal

Page 30

ENERGY SAVING

14 Warranty

The warranty covers manufacturing and processing defects. It does not cover damages

deriving from incorrect installation or design defects of the system, damages which occur

during transport, or seizure due to residues within the system. Proof of purchase is required to

administer warranty claims.

15 Disposal

The correct disposal and recycling of this product will prevent damage to the environment and

risks to human health.

1. Use public or private disposal organisations when disposing of all or part of the product.

2. For information about proper disposal, it is necessary to ask to the city administration, the

authorized ofce or the retailers of the product.

Reserved right of modication

30 Maintenance, warranty and disposal

Page 31

Page 32

Taco Italia S.r.l. - Via G. Galilei, 89-91 - 36066 Sandrigo (VI) - ITALY

www.tacoitalia.com

MKTG-TRA-MAN-0.A-05/2018-ENG

Loading...

Loading...