Page 1

Instruction Sheet

CX Expansion Tanks

SUPERSEDES: 402-015 dated April 1, 1990 EFFECTIVE: May 1, 2001

Plant ID No. 001-1017

402-015

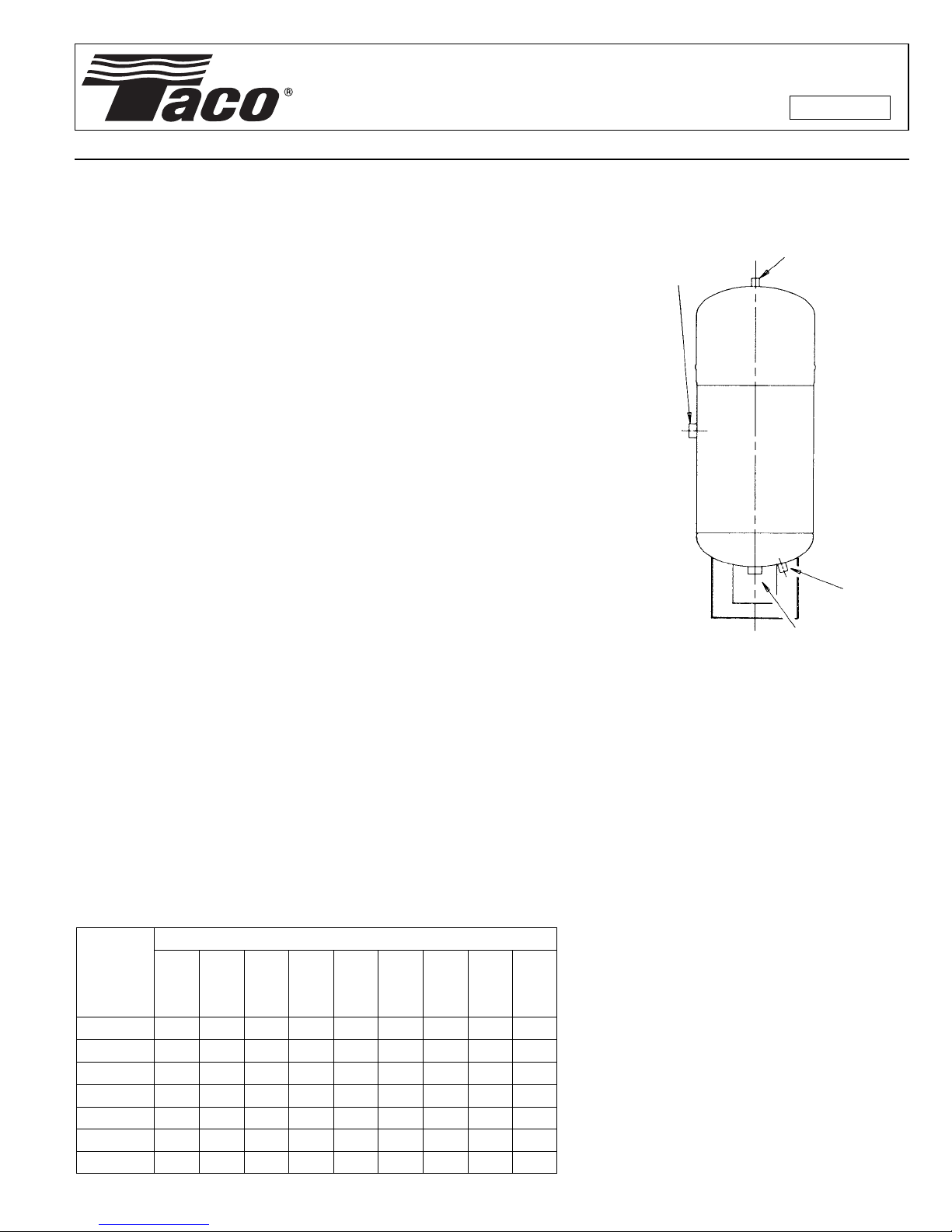

1. Note location on the tank of the system connection, charging valve and

the drain plug. Note labels on the tank or refer to Diagram 1 for location

of tank fittings.

2. Carefully remove the protective cover in the system connection coupling

OPTIONAL

BULLSEYE

SIGHTGLASS

3

⁄4" NPTF

SYSTEM

CONNECTION

located at the top center of the tank. There should not be much, if any,

air pressure under this plug.

CAUTION: DO NOT REMOVE THE PIPE PLUGS LOCATED ON THE

SIDE AND BOTTOM OF THE TANK (TANK DRAINS). THESE PLUGS

SHOULD NEVER BE REMOVED UNLESS NECESSARY AND THEN

ONLY AFTER THE AIR PRESSURE IN THE TANK HAS BEEN BLED

OFF TO ZERO GAUGE PRESSURE. BEFORE BLEEDING OFF ANY OF

THE AIR CHARGE, ALWAYS ISOLATE THE TANK FROM THE SYSTEM

WITH A SHUT-OFF VALVE.

3. Before making any connections to the tank, check the tank air charge.

Use an accurate automotive or similar type gauge on the air valve located under the tank skirt. The air charge pressure must be equal to the

pre-charge pressure specified for the system. Refer to the label on

the tank for the specified tank pre-charge pressure. In most cases

the specified tank pre-charge pressure is equal to the system fill

pressure at the tank location. Use Diagram 2 – Air Charge Check Chart

to correct the value read on the pressure gauge for the ambient temper-

CHARGING

VALVE

ature at the tank location.

4. After making sure that the air charge is correct, the pipe connection to the

DO NOT REMOVE.

FACTORY USE ONLY

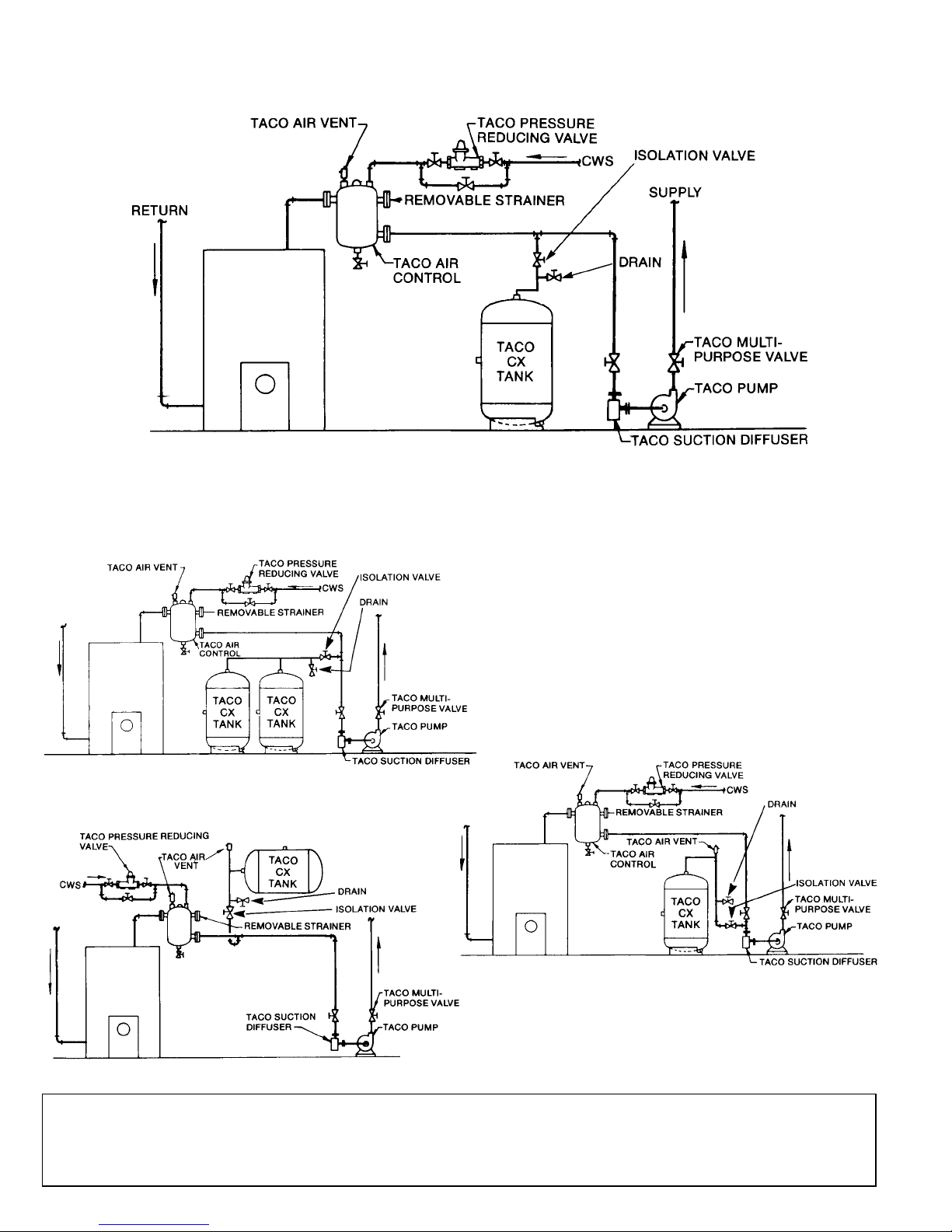

system may now be made. The piping requirements for captive air tanks

are different from those of plain steel expansion tanks. Note the Captive Air

Tank Piping Diagrams. Piping and air elimination devices should be

Diagram 1 – Location of Tank Fittings

arranged so that air will not be trapped in the tank, above the tank or in the

nozzle. Pitch the piping connection up away from the tank and use automatic air vents where necessary. Note the piping diagram.

5. Locate the CX tank connection as close as possible to the suction side

of the pump. This ensures that the pressures realized from the pump

head will be additive in the system. A combination shut-off and drain

valve should be located in the connection piping to provide for tank isolation during the initial hydrostatic test.

Diagram 2 – Air Charge Check Chart

Specified

Pre Charge

Pressure

P.S.I.

(at 68ºF)

12

20

30

40

50

60

70

36

Ambient Temperature (ºF)

39.238.237.536.7

30.0

40.0

How to Use the Chart

1. Determine ambient air temperature where the

tank is being checked.

2. Locate the specified pre-charge pressure in the

92847668605244

100

13.613.212.812.412.011.611.210.810.4

22.121.621.120.520.019.518.918.417.9

32.732.031.430.729.328.628.027.3

43.342.541.640.8

53.952.952.051.050.049.048.047.146.1

64.563.462.361.160.058.957.756.655.5

75.173.972.671.370.068.767.466.164.9

left hand column.

3. Follow across horizontally to the number under

the ambient air temperature.

4. The number found under Step No. 3 is the temperature corrected air charge pressure in p.s.i.

and should agree with the gauge reading

observed at the tank.

5. If the temperature corrected air charge pressure differs by more than 1 p.s.i. from the precharge pressure specified for the system, then

correct it by bleeding pressure through the air

charge valve or by adding pressure with an air

compressor.

Page 2

Captive Air Tank Piping Diagrams – Recommended Location

Captive Air Tank Piping Diagrams – Alternate Locations

Do it Once. Do it Right.

TACO, INC., 1160 Cranston Street, Cranston, RI 02920 Telephone: (401) 942-8000 FAX: (401) 942-2360.

TACO (Canada), Ltd., 6180 Ordan Drive, Mississauga, Ontario L5T 2B3. Telephone: 905/564-9422. FAX: 905/564-9436.

Visit our web site at: http://www.taco-hvac.com

Printed in USA

Copyright 2001

TACO, Inc.

Loading...

Loading...