Page 1

102-557

Instruction Sheet

0018eTM ECM High-Efciency Circulator

Featuring Bluetooth® Communication

SUPERSEDES: NEW EFFECTIVE: March 22, 2019

Plant ID No. 001-5012

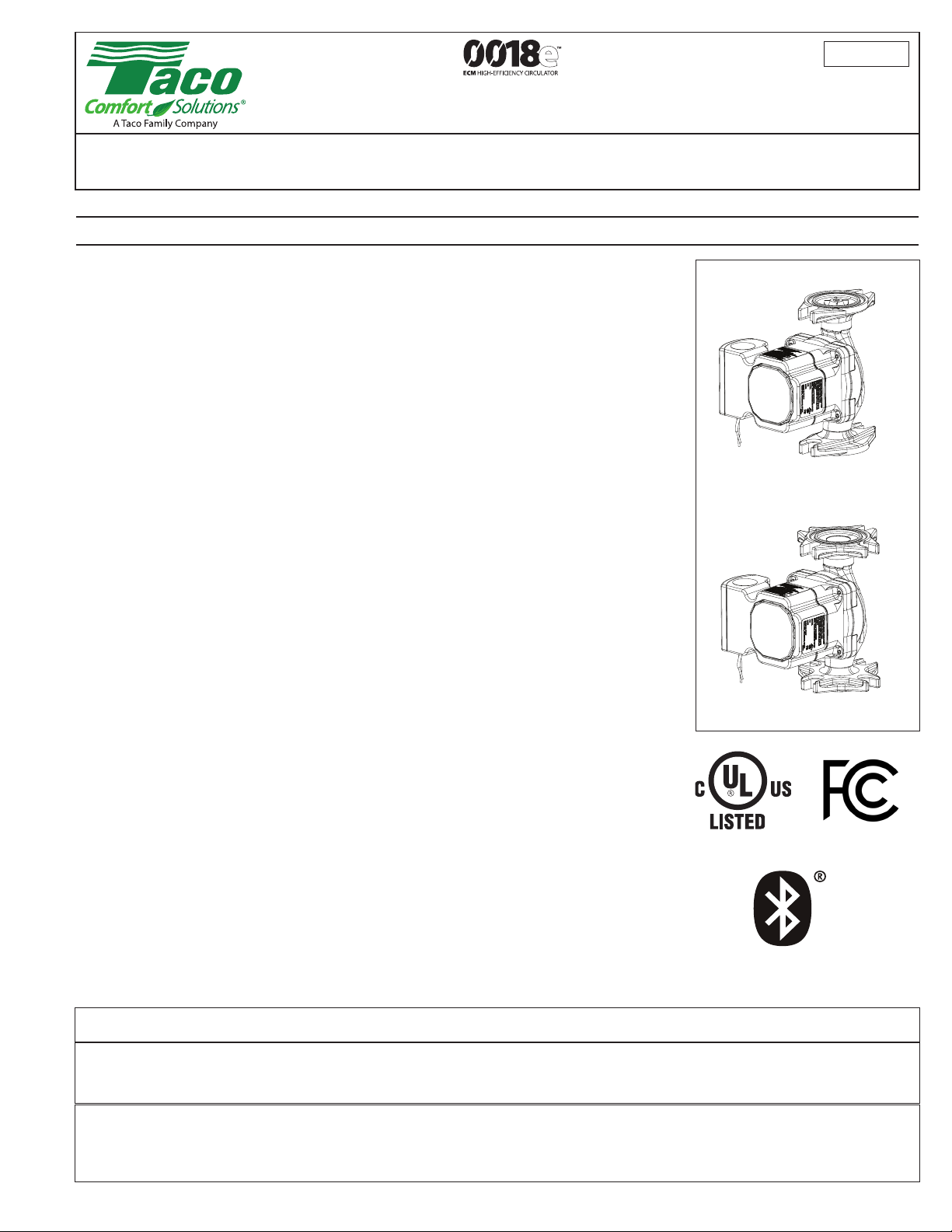

DESCRIPTION:

The 00e® series 0018eTM circulator is a variable speed wet rotor circulator with an ECM, permanent magnet

motor. Operating modes include innitely variable xed speed, constant pressure, proportional pressure,

and activeADAPT

0018eTM ECM Circulator Mobile App using Bluetooth® connectivity on your smartphone or tablet. The ECM

high-efciency motor reduces power consumption by up to 85% compared to equivalent AC permanent split

capacitor circulators.

TM

self-adjusting proportional pressure. Adjust the operating mode with the dial or the Taco

Figure 1:

APPLICATION:

• Maximum operating pressure: 125 psi (8.6 bar)

• Maximum water temperature: 230°F (110ºC)

• Electrical specications:

Voltage: 110-120V, 50/60 Hz, single phase

Maximum operating power: 44W

Maximum amp rating: 0.54

• Equipped with a cast iron casing and should be used for closed loop systems only

• Not suitable for open loop potable water or chilled water systems

• Taco circulator pumps are for indoor use only – employer uniquement a l’interieur

• Acceptable for use with water or maximum of 50% water/glycol solution

Standard ange model: 0018e-F2

Part #: VR1816-HY2-FC2A01

FEATURES:

• 3 operating modes in dial activation:

- Proportional pressure ( TRV - Panel Radiator ), variable speed - 2 variable pressure

differential settings (Med or High)

- Constant pressure ( ZV - Zone Valve ), variable speed - 2 constant pressure

differential settings (Med or High)

- Fixed speed ( ZONE CIRC - zoning with circulators ) - innitely adjustable MIN/MAX settings

• 4 operating modes in 0018e

- Fixed Speed - innitely adjustable MIN/MAX settings

- Constant Pressure - variable speed - 9 constant pressure differential settings

- Proportional Pressure - variable speed - 9 variable pressure differential settings

- activeADAPTTM - Designed for constant circulation systems. Automatically adjusts

to system conditions

• Multi-color LED display showing operating mode and error code diagnostics

• Use with a Taco ZVC Zone Valve Control or SR Switching Relay for ON/OFF operation

• Nut capture feature on anges for easier t up

• Dual electrical knockouts and 6” stranded wire leads for easy wiring

• Double insulated - no ground-wire required

• Whisper quiet operation

• BIO Barrier® protects the pump from system contaminants

• SureStart® - automatic unblocking and air purging mode

• Optional 2-way ange model for easy t-up to any ange orientation

• Integral Flow Check (IFC®) included - Field installed

TM

Mobile App activation:

Optional 2-way ange model: 0018e-F4

Part #: VR1816-HY2-4C2A01

INSTALLATION:

WARNING: Do not use in swimming pool or spa areas. Pump has not been investigated for these applications.

AVERTISSEMENT: Ne pas utiliser dans une piscine ou un spa. La pompe n’a pas été étudiée pour ces applications.

CAUTION: The addition of petroleum based uids or certain chemical additives to systems using TACO equipment voids the warranty. Consult factory for uid

compatibility.

ATTENTION: L’ajout de liquides à base de pétrole ou de certains additifs chimiques à des systèmes utilisant un équipement TACO annule la garantie. Consultez

le fabricant pour connaître la compatibilité de liquides.

CAUTION: Installations at elevations over 5000 feet must have higher ll pressure of 20 psi minimum to prevent pump cavitation and ashing. Premature failure

may result. Adjust expansion tank pressure to equal ll pressure. A larger size expansion tank may be required.

ATTENTION: Des installations à des altitudes de plus de 1600 mètres doivent présenter une pression de remplissage plus élevée de 20 psi au minimum an

d’éviter toute cavitation ou ashing de la pompe. Une défaillance prématurée peut en résulter. Réglez la pression du réservoir d’expansion de façon qu’elle soit

égale à la pression de remplissage. Un réservoir d’expansion d’une taille supérieure peut être nécessaire.

1

Page 2

BOILER

FF

EXPANSION

TANK

ZONE 1ZONE 2

V1

PV4

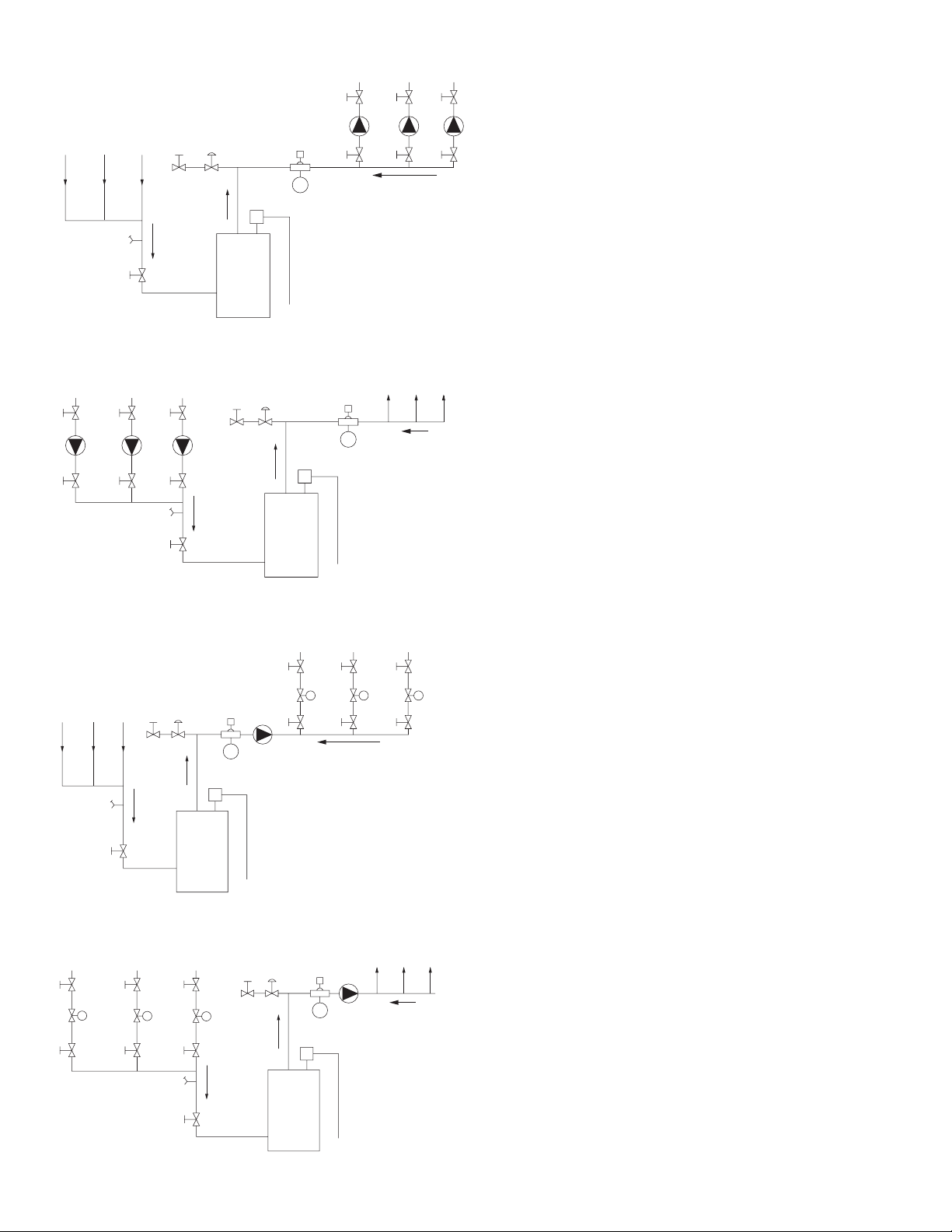

FIGURE 1:

MULTI-SPEED MODE

PREFERRED PIPING

FOR CIRCULATORS

ON BOILER SUPPLY

ZONE 1

V2

V3

P

ZONE 3

ZONE 2

V2

V3

P

ZONE 3

V2

V3

P

• AIR PURGING SEQUENCE

BY ZONE

LAST FIRST

FIGURE 1:

MULTI-SPEED MODE

Figure 2:

BOILER

FF

EXPANSION

TANK

ZONE 1ZONE 2

V1

PV4

FIGURE 2:

MULTI-SPEED OR VARIABLE SPEED MODES

PREFERRED PIPING

FOR ZONE VALVES

ON BOILER SUPPLY

ZONE 1

V2

V3

ZONE 3

ZONE 2

V2

V3

ZONE 3

V2

V3

• AIR PURGING SEQUENCE

BY ZONE

LAST FIRST

P

ZV1 ZV2 ZV3

M

M

M

FIGURE 2:

PREFERRED PIPING

FOR CIRCULATORS

ON BOILER SUPPLY

V3

ZONE 1

V3

ZONE 2

ZONE 3

V3

ZONE 3

PV4

ALTERNATE PIPING

FOR CIRCULATORS

ON BOILER RETURN

ZONE 3

V3

P

V2

ZONE 1ZONE 2

V1

ZONE 1ZONE 2

V3V3

PP

V2V2

PV4

V1

P

V2

FF

EXPANSION

TANK

P

P

V2

V2

LAST FIRST

• AIR PURGING SEQUENCE

BY ZONE

KEY:

VI, V2, V3 = SHUT-OFF ISOLATION VALVE

P = TACO CIRCULATOR WITH IFC

FF = FAST FILL BOILER FEED VALVE

PV4 = PURGE VALVE

RECOMMENDED PURGING STEPS:

BOILER

1. CLOSE V1, PV4, V2

2. OPEN V3

3. OPEN FF VALVE

4. OPEN V2, PV4, TO PURGE LAST ZONE

FIRST (ZONE 3)

5. CLOSE FF VALVE

6. CLOSE V2, PV4

ZONE1ZONE

ZONE

2

3

7. REPEAT STEPS 1 TO 6 FOR EACH

ADDITIONAL ZONE, PURGE ZONE 1 LAST

8. OPEN V1 WHEN ALL ZONES ARE PURGED

9. ADJUST SYSTEM TO DESIRED OPERATING

FILL PRESSURE IF REQUIRED

TANK

LAST FIRST

• AIR PURGING

SEQUENCE

BY ZONE

FF

EXPANSION

BOILER

Figure 3:

MULTI-SPEED OR VARIABLE SPEED MODES

PREFERRED PIPING

FOR ZONE VALVES

ON BOILER SUPPLY

ZONE 3

ALTERNATE PIPING

FOR ZONE VALVES

ON BOILER RETURN

ZONE 3

V3

ZV3 ZV2 ZV1

V2

ZONE 1ZONE 2

PV4

V1

M

M

FF

ZONE 1ZONE 2

V3V3

V2V2

BOILER

V3

V2

P

EXPANSION

TANK

M

FF

ZONE 1

ZV1 ZV2 ZV3

LAST FIRST

• AIR PURGING SEQUENCE

BY ZONE

EXPANSION

ZONE 2

M

ZONE1ZONE

LAST FIRST

P

V3

V2

• AIR PURGING

SEQUENCE

BY ZONE

V3

M

V2

TANK

ZONE 3

2

M

ZONE

KEY:

VI, V2, V3 = SHUT-OFF ISOLATION VALVE

P = TACO CIRCULATOR WITHOUT IFC INSTALLED

FF = FAST FILL BOILER FEED VALVE

PV4 = PURGE VALVE

ZV = ZONE VALVE

RECOMMENDED PURGING STEPS:

1. CLOSE V1, PV4, V2

2. OPEN V3 AND ZV3

3. OPEN FF VALVE

4. OPEN V2, PV4, TO PURGE LAST ZONE

FIRST (ZONE 3)

5. CLOSE FF VALVE

6. CLOSE V2, PV4

7. REPEAT STEPS 1 TO 6 FOR EACH

3

ADDITIONAL ZONE, PURGE ZONE 1 LAST

8. OPEN V1 WHEN ALL ZONES ARE PURGED

9. ADJUST SYSTEM TO DESIRED OPERATING

FILL PRESSURE IF REQUIRED

10. MOVE ALL ZV TO CLOSED/AUTOMATIC POSITION

PV4

BOILER

V1

2

Page 3

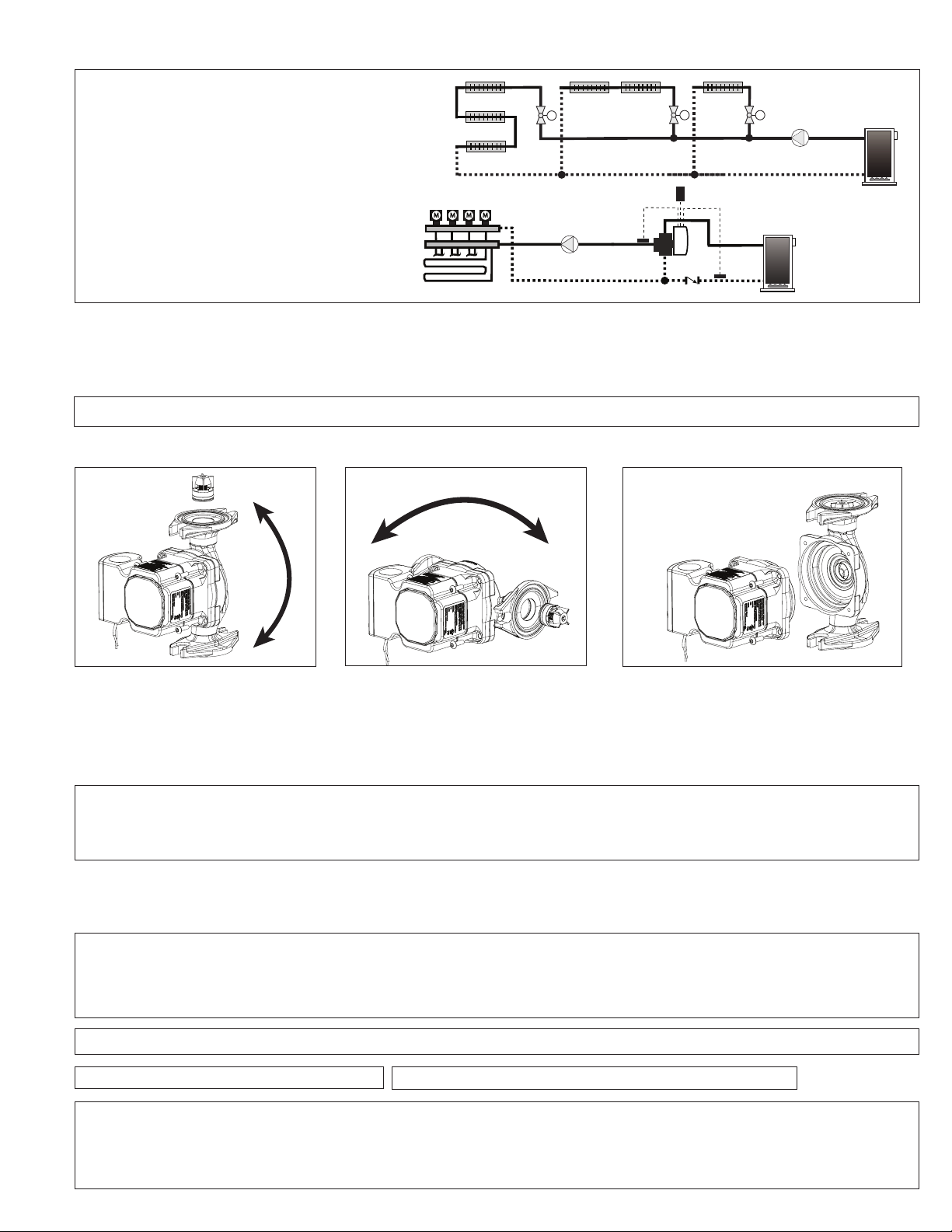

Typical Variable Speed Applications:

• Zone Valves

• Panel Radiation with

Thermostatic Valves

• Radiant Loops with

Actuators

Across a Series

Loop System Using

Zone Valves

M

M

M

- Varies speed to

maintain proportional

or constant pressure

differential (∆P)

M M M M

Across Multi-Zone

Radiant Manifolds

with Loop Actuators

Outdoor

Sensor

iSeries-R

B

B

C

C

A

A

Boiler

Sensor

1. Location: The circulator can be installed on the supply or return side of the boiler but for best system performance, it should

always pump away from the expansion tank. See piping diagrams in Figure 2 and Figure 3.

2. Mounting position: Circulator must be mounted with the motor in the horizontal position. See diagrams below for

acceptable motor mounting orientations.

CAUTION: Do not use at rubber gaskets. Only use O-ring gaskets provided or leaks may result. Warranty will be void.

Figure 4:

ACCEPTABLE MOTOR MOUNTING POSITIONS

Figure 5:

Spin casing

Spin

casing

to

change

ow

direction.

to change

ow direction.

Figure 6: Do not detach motor frame from pump

casing. Simply spin casing to the

proper ow direction.

CASING ROTATION

X

Always install with motor in horizontal orientation.

Position electrical junction box at 9 o’clock for best

viewing orientation. Pump casing may be rotated

to change ow direction. Locate the arrow on the

casing body to determine ow direction.

Integral Flow Check (IFC®) option - An IFC® is included in the carton. If required, press IFC into machined discharge port with plunger

and o-ring facing in, until it snaps into place. Before installing, press IFC plunger to be sure it moves freely. See diagram above.

CAUTION: To reduce the possibility of noise transmission, be sure to add vibration dampeners to piping when mounting circulator to wall

or oor joists.

ATTENTION: Pour réduire la possibilité de transmission de bruit, veillez à ajouter des amortisseurs de vibration à la tuyauterie lors du

montage du circulateur sur des chevêtres de mur ou de plancher.

3. Filling the system: Fill the system with tap water or a maximum of 50% propylene-glycol and water solution. The

system must be lled before operating the circulator. The bearings are water lubricated and should not be allowed to operate dry. Filling

the system will result in immediate lubrication of the bearings. It is always good practice to ush a new system of foreign matter before

startin the circulator.

WARNING: Risk of electric shock. To reduce the risk of electric shock, be certain that it is connected only to a properly grounded, grounding-type receptacle. Follow all local electrical and plumbing codes.

AVERTISSEMENT: Risque de choc électrique. Pour réduire le risque de choc électrique, veillez à ce qu’elle soit raccordée uniquement à un

réceptacle de type mise à la terre proprement mis à la terre. Respectez tous les codes de plomberie et électriques locaux.

WARNING: Use supply wires suitable for 90°C. AVERTISSEMENT: Employer des ls d’alimentation adeqauts pour 90°C.

WARNING: Disconnect power when servicing.

To rotate the pump casing, remove the 4 motor screws. When rotating pump casing position, DO NOT detach

motor housing from the casing. Damage to the casing O-ring and leakage may result. Simply spin casing to the

proper ow direction desired as shown in Figure 4 and Figure 5. Reattach the 4 screws (1⁄8” allens wrench required).

Be sure motor is positioned correctly and is seated evenly to prevent leakage or damage to O-ring. Tighten motor

screws evenly to 25-38 in-lbs torque.

CAUTION: Use exible conduit only. Not for use with rigid conduit.

WARNING: SERVICING OF DOUBLE-INSULATED APPLIANCES. A double-insulated appliance is marked with one or more of the following:

The words “DOUBLE INSULATION” or “DOUBLE INSULATED” or the double insulation symbol (square within a square). In a double-insulated appliance, two systems of insulation are provided instead of grounding. No grounding means is provided on a double-insulated

appliance, nor should a means for grounding be added. Servicing a double-insulated appliance requires extreme care and knowledge of

the system, and should be done by qualied service personnel. Replacement parts for a double-insulated appliance must be identical to

the parts they replace.

3

Page 4

4. Wiring the circulator: Disconnect AC power supply. Remove terminal box cover. Attach a wiring connector into knockout hole.

NEUTRAL

WIRING DIAGRAM

LN

No ground wire is required.

Green Terminal Plug

Spring Tabs

WIRE NUT

WHITE

BLACK

LINE

Use exible con-duit only. Connect Line/Hot power to the black lead, Neutral to the white lead. See wiring diagram.

Note: If pigtail leads provided are not used, be sure to trim eld wire to a strip length of .25” (+/- .025”) to prevent exposed wire causing

a short at the terminal plug. Connect line and neutral to green terminal plug as shown in diagram. Depress the spring tab with a small

screwdriver to insert wire into plug. Release tabs to complete connection. The 0018e is a double insulated circulator, no grounding wire

is necessary. Replace terminal box cover.

5. Start the circulator: When purging the system, it is recommended to run the circulator at manual full speed operation long enough to

remove remaining air from the bearing chamber. To do this, turn the dial clockwise to the ZONE CIRC - MAX position. This is especially

important when installing the circulator in the off-season.

Full Speed Operation:

To run the pump at full speed during the fast ll, start-up and purge process, rotate dial clockwise to MAX speed setting. To return to the

normal operating mode, turn dial to desired xed speed, constant pressure, or proportional pressure setting.

CAUTION: Never run the circulator dry or permanent damage may result.

ATTENTION: Ne laissez jamais le circulateur tourner à sec, des dommages permanents peuvent en résulter.

6. Programming your 0018e circulator:

a. Taco 0018e ECM Circulator Mobile App - www.TacoComfort.com/0018e_UserManual

1. Search for Taco 0018e ECM Circulator mobile app within the App Store or Google

Play on your mobile device.

2. Download the Taco 0018e ECM Circulator mobile app for free and install it on your mobile device.

3. Once complete, you are able to start using the app. Additional operating instructions can be found on the app itself.

Turn the selector dial counter-clockwise to the Bluetooth® setting icon for 2-way (read/write)

communication & control using the 0018e mobile app. This will enable wireless mode selection control,

performance diagnosis & reporting. In this dial postion, SureStart® capability is disabled. When the

selector dial is turned to any other position the 0018e mobile app can be used for 1-way (read only)

communication, providing performance diagnosis & reporting.

Minimum software requirements:

- iOS version 10 (BLE compatible)

- Android version 4.4 (BLE compatible)

b. Manual Dial

Note: The 0018e is factory-programmed for maximum speed operating mode. A Blue LED will appear when rst powered on.

If this is your desired operating mode, no programming changes are required.

The 0018eTM has 3 Operating Modes on the Selector Dial:

• Proportional Pressure ( TRV ) - Varies speed to maintain a proportional/variable pressure differential.

• Constant Pressure ( ZV ) - Varies speed to maintain a constant pressure differential.

• Fixed Speed ( ZONE CIRC ) - Innitely adjustable settings (MIN-MAX).

To change operating mode and settings:

Modify the performance of the circulator as needed by rotating the dial using a at screwdriver. When an operating mode is

changed, a blue, orange or green LED will illuminate when the circulator is powered on. The LED will ash each time mode is

changed. See diagrams below to determine best mode of operation for the system.The selection of the right functioning curve

depends on the characteristics of the heating system and the actual heat demand.

4

Page 5

0018e

Med

High

Q(gpm)

0 1 234 5 6 789 10 11 12 13 14 15 16

H (ft)

0

2

4

6

8

10

12

14

16

18

20

Q (l/s)

0.0 0.2 0.4 0.6 0.8 1.0 1.2

H (m)

0

1

2

3

4

5

6

Q (m

3

/h)

43210

Flow

Head in Feet

Green

LED

High

Med

Q(gpm)

0 1 234 5 6 789 10 11 12 13 14 15 16

H (ft)

0

2

4

6

8

10

12

14

16

18

20

Q (l/s)

0.0 0.2 0.4 0.6 0.8 1.0 1.2

H (m)

0

1

2

3

4

5

6

Q (m

3

/h)

43210

008

0015 – Med

007

0015 – Low

Flow

Head in Feet

Orange

LED

Min

Max

Q(gpm)

0 1 234 5 6 789 10 11 12 13 14 15 16

H (ft)

0

2

4

6

8

10

12

14

16

18

20

Q (l/s)

0.0 0.2 0.4 0.6 0.8 1.0 1.2

H (m)

0

1

2

3

4

5

6

Q (m3/h)

43210

0015 – Hi

008

0015 – Med

007

0015 – Low

Flow

Head in Feet

Blue

LED

min max

TM

PERFORMANCE CURVES

TRV - PANEL RADIATOR MODE

Variable Speed

ZV - ZONE VALVE SYSTEM MODE

Variable Speed

In TRV - Panel Radiator, Proportional

pressure mode, the circulator main

tains a proportional pressure differen

tial (∆p-v) as heating load increases

or decreases. Flow will change in

relationship to the change in pres

sure differential. Selection options

are Medium or High. If unsure on

proper setting, select

Medium

and

adjust as needed.

-

-

-

ZONE CIRC - FIXED SPEED MODE

Innitely Adjustable (MIN-MAX)

In Zone Valve - Constant pressure

mode, the circulator maintains a

constant pressure differential (∆pc) in the system as heating load

increases or decreases. Selection

options are Medium or High. See

chart to left for equivalent 00 model

at each setting.

ZONE CIRC - Fixed speed mode

Shaded area represents

full operating range.

allows the installer to ne tune the

circulator ow rate to precisely match

design load conditions. It is innitely

variable between MIN/MAX settings.

See chart to left for equivalent 00

model at each variable speed setting.

5

Page 6

CAUTION: Do not attempt to remove LED panel from circulator. Serious damage to circulator electronics may result.

ATTENTION: N’essayez pas de retirer le panneau de LED du circulateur. Des dommages sérieux à l’électronique du circulateur peuvent

en résulter.

7. Troubleshooting the error codes: Listed below are potential diagnostic error codes which will appear on the LED display in case

of a malfunction.

FAULTS

The circulator is

noisy

Loud noises of

water circulation

Circulator is not

running although

the electrical

power supply is

switched on

CONTROL

PANEL

LED on

LED on

Flashing white

LED

CAUSES REMEDIES

Suction pressure is

insufficient - cavitation

Presence of foreign bodies

in the impeller

Air in the system

Increase the system suction

pressure within the

permissible range.

Disassemble the motor and

clean the impeller.

Vent the system. Repeat

fill and purge steps.

LED on The flow is too high Reduce the pump speed.

Verify voltage value of the

Lack of power supply

electric plant.

Verify the connection of the

motor.

LED off

One fuse in the installation

is blown

The circulator is defectiveReplace the pump.

Verify the fuses of the pump.

Let the pump cool down for

some minutes. Then try to re-

Overheating

start it. Verify that the water

and ambient temperature are

within the indicated

temperature ranges.

Disassemble the motor and

LED red The rotor is blocked

clean the impeller. See

unblocking procedure below.

Building does not

get warm.

6

LED on

Insufficient supply voltage

The circulator

performance is too low

Verify that the power supply

matches the data on the name

plate.

Increase the suction head.

Increase speed or ∆P setting.

Page 7

Unblocking Procedure:

A red light in the LED indicates the circulator rotor is blocked or sticking. Turn the selector to the position MAX, disconnect

and connect power supply to start the automatic release process. The circulator makes 100 attempts to restart (process lasts

approximately 15 minutes). Every restart is signalled by a short ash of white LED light. If the blocking is not removed through

the automatic release process after 100 attempts to restart, the circulator goes into standby and the LED remains solid red.

Perform the manual unblocking steps described below.

1. Disconnect power supply - the warning light switches off.

2. Close both isolating valves and allow cooling. If there are no shut-off devices, drain the system so that the uid level is

beneath that of the circulator.

3. Loosen 4 motor bolts. Remove motor from casing. Carefully pull the rotor/impeller from the motor.

4. Remove impurities and deposits from the impeller and casing.

5. Reinsert the rotor/impeller into the motor.

6. Set the dial to the MAX position.

7. Connect power supply. Check for impeller rotation.

8. If the circulator still doesn’t run it will need to be replaced.

Replacement Parts List

198-213 RP Casing O-ring

198-214 RP Wiring plug connector (green)

198-215 RP Terminal box cover (black)

198-217 RP Terminal box cover screws (5 per bag)

0010-025 RP Integral Flow Check (IFC®)

007-007 RP Flange gasket set

0018e Pump Cross Reference (Fixed Speed Mode):

SPEED TACO GRUNDFOS WILO B & G/XYLEM ARMSTRONG

Minimum

Medium

Maximum 0015 (Hi)

003

006

007

008

0015 (Low)

0015 (Med)

0018e Pump Cross Reference (Variable Speed Mode):

Alpha 15-55 (Low)

UP-15-42

UPS-15-58 (Low

UPS-15-58 (Med)

Alpha 15-55 (Med)

UPS-15-58 (Hi)

Alpha 15-55 (Hi)

-

-

Star S-21 (1)

Star S-21 (2)

Star S-21 (3)

Eco-Vario (Low)

Eco-Vario (Med)

-

NRF-25 (1)

NRF-25 (2)

NRF-25 (3)

Eco-Vario (Hi)

Compass (1)

Astro 230 (1)

Astro 230 (2)

Compass (2)

Astro 230 (3)

Compass (3)

TACO GRUNDFOS WILO B & G/XYLEM ARMSTRONG

VR1816

0015e3

007e

Alpha 15-55 Stratos Eco Eco-Auto Compass 20-20

7

Page 8

CAUTION

This equipment has been tested and found to comply with the limits for

a Class B digital device, pursuant to part 15 of the FCC Rules. These

limits are designed to provide reasonable protection against harmful

interference in a residential installation. This equipment generates, uses

and can radiate radio frequency energy and, if not installed and used in

accordance with the instructions, may cause harmful interference to radio

communications. However, there is no guarantee that interference will

not occur in a particular installation. If this equipment does cause harmful

interference to radio or television reception, which can be determined by

turning the equipment off and on, the user is encouraged to try to correct

the interference by one or more of the following measures:

Reorient or relocate the receiving antenna.

Increase the separation between the equipment and receiver.

Connect the equipment into an outlet on a circuit different from that to

which the receiver is connected.

Consult the dealer or an experienced radio/TV technician for help.

This device complies with Industry Canada license exempt RSS

standard(s). Operation is subject to the following two conditions:

(1) This device may not cause interference, and

(2) This device must accept any interference, including interference that

may cause undesired operation of the device.

Le présent appareil est conforme aux CNR d’Industrie Canada

applicables aux appareils radio exempts de licence. L’exploitation est

autorisée aux deux conditions suivantes:

(1) l’appareil ne doit pas produire de brouillage, et

(2) l’utilisateur de l’appareil doit accepter tout brouillage radioélectrique

subi, même si le brouillage est susceptible d’en compromettre le

fonctionnement.

Under Industry Canada regulations, this radio transmitter may only

operate using an antenna of a type and maximum (or lesser) gain

approved for the transmitter by Industry Canada. To reduce potential

radio interference to other users, the antenna type and its gain should

be so chosen that the equivalent isotropically radiated power (e.i.r.p.) is

not more than that necessary for successful communication.

Conformément à la réglementation d’Industrie Canada, le présent

émetteur radio peut fonctionner avec une antenne d’un type et d’un gain

maximal (ou inférieur) approuvé pour l’émetteur par Industrie Canada.

Dans le but de réduire les risques de brouillage radioélectrique à

l’intention des autres utilisateurs, il faut choisir le type d’antenne et son

gain de sorte que la puissance isotrope rayonnée équivalente (p.i.r.e.)

ne dépasse pas l’intensité nécessaire à l’établisse-ment d’une

communication satisfaisante.

To comply with FCC and Industry Canada RF radiation exposure limits

for general population, the antenna(s) used for this transmitter must be

installed such that a minimum separation distance of 20cm is maintained

between the radiator (antenna) and all persons at all times and must not

be co-located or operating in conjunction with any other antenna or

transmitter.

LIMITED WARRANTY STATEMENT

Taco, Inc. will repair or replace without charge (at

the company’s option) any Taco High Efciency

circulator or circulator part which is proven defec-

tive under normal use within three (3) years from

the date code.

In order to obtain service under this warranty, it

is the responsibility of the purchaser to promptly notify the local Taco stocking distributor or

Taco in writing and promptly deliver the subject

product or part, delivery prepaid, to the stocking

distributor. For assistance on warranty returns,

the purchaser may either contact the local Taco

stocking distributor or Taco. If the subject prod-

uct or part contains no defect as covered in this

warranty, the purchaser will be billed for parts

and labor charges in effect at time of factory

examination and repair.

Any Taco product or part not installed or operated

in conformity with Taco instructions or which has

been subject to misuse, misapplication, the addi-

tion of petroleum-based uids or certain chemical additives to the systems, or other abuse, will

not be covered by this warranty.

If in doubt as to whether a particular substance

is suitable for use with a Taco product or part, or

for any application restrictions, consult the applicable Taco instruction sheets or contact Taco at

(401-942-8000).

Taco reserves the right to provide replacement

products and parts which are substantially similar in design and functionally equivalent to the

defective product or part. Taco reserves the right

to make changes in details of design, construction, or arrangement of materials of its products

without notication.

TACO OFFERS THIS WARRANTY IN LIEU OF

ALL OTHER EXPRESS WARRANTIES. ANY

WARRANTY IMPLIED BY LAW INCLUDING

WARRANTIES OF MERCHANTABILITY OR

FITNESS IS IN EFFECT ONLY FOR THE

A Taco Family Company

2019

DURATION OF THE EXPRESS WARRANTY

SET FORTH IN THE FIRST PARAGRAPH

ABOVE.

THE ABOVE WARRANTIES ARE IN LIEU OF

ALL OTHER WARRANTIES, EXPRESS OR

STATUTORY, OR ANY OTHER WARRANTY

OBLIGATION ON THE PART OF TACO.

TACO WILL NOT BE LIABLE FOR ANY

SPECIAL, INCIDENTAL, INDIRECT OR

CONSEQUENTIAL DAMAGES RESULTING

FROM THE USE OF ITS PRODUCTS OR ANY

INCIDENTAL COSTS OF REMOVING OR

REPLACING DEFECTIVE PRODUCTS.

This warranty gives the purchaser specic rights,

and the purchaser may have other rights which

vary from state to state. Some states do not

allow limitations on how long an implied war-

ranty lasts or on the exclusion of incidental or

consequential damages, so these limitations or

exclusions may not apply to you.

8

Loading...

Loading...