Page 1

UVR 64

Version P5.3 EN

Manual Version 2

Four - Circuit Universal Controller

Operation

Installation instructions

en

Page 2

Page 3

Informations

The hydraulic diagrams of this manual are only diagrams in principle. They do not describe or

replace a professional system development. There is no guarantee for function if directly copied.

The settings of the menu functions ex works can be restored at any time using the yellow

key (“Eingabe” = entry) when plugging the unit in.

The settings of all the parameters and menu functions ex works can be restored at any

time using both blue keys (“ab/auf” = up/down) when plugging the unit in.

Page 4

4

Table of contents

Safety requirements ................................................................................................................. 5

Maintenance ............................................................................................................................ 5

Generally applicable rules ........................................................................................................ 6

Hydraulic diagrams ................................................................................................................ 7

Diagram 0: Solar power system with 2 consumers and 2 feed pumps ................................. 7

Diagram 16: Solar power system with 3 consumers and feed pump function ...................... 9

Diagram 32: Solar power system with 4 consumers ........................................................... 11

Diagram 48: Burner requirement, 2 feed pumps and simple solar power unit .................... 13

Diagram 64: Solar power system with two solar panels and two consumers ..................... 18

Diagram 80: Layering storage tank, feed pump and domestic hot water preparation ......... 21

Diagram 96: Solar power system with two consumers and two feed pump functions ....... 24

Diagram A0: Solar system with two consumers, feed pump, burner requirement ............. 26

Diagram B0: Solar power system, 2 feed pump functions, burner requirement ................. 28

Diagram C0 Solar power system with 3 consumers, bypass function ................................ 30

Diagram D0: Simple solar power system, 2 feed pumps, feed pump for domestic hot water

tank ..................................................................................................................................... 32

Installing instructions .......................................................................................................... 35

Installing the sensor(s) ....................................................................................................... 35

Installing the unit ................................................................................................................ 37

Electrical connection ........................................................................................................... 37

Data line (DL) ..................................................................................................................... 38

Selector switch ..................................................................................................................... 39

Assignment of time windows (F>A) .................................................................................... 41

Program selection (Progr.), Assignment of priority (Vorr.) .................................................. 42

Additional functions ............................................................................................................ 43

Programming procedure (Menü) ........................................................................................ 43

Sensor type ..................................................................................................................... 45

Function control .............................................................................................................. 46

Collector excess temperature limit .................................................................................. 47

Start function (ideal for tube collectors) ........................................................................... 48

Priority menu .................................................................................................................

.. 49

After-running time ........................................................................................................... 50

Hysteresen ...................................................................................................................... 50

Pump speed control ........................................................................................................ 51

Absolute value control A .............................................................................................. 51

Differential control F .................................................................................................... 52

Limiter function L ......................................................................................................... 52

Waveform .................................................................................................................... 52

Pump standstill ............................................................................................................ 53

Stability problems ........................................................................................................ 53

Pump speed processor ............................................................................................... 54

Auxiliary output A5 .......................................................................................................... 56

Instructions for troubleshooting ........................................................................................ 58

Table of settings ................................................................................................................. 59

Technical data ........................................................................................................................ 61

Page 5

5

Safety requirements:

All installation and wiring work on the controller must only be carried

out in a zero-volts state.

The opening, connection and commissioning of the device may only be

carried out by competent personnel. In so doing, all local security requirements must be adhered to.

The device corresponds to the latest state of the art and fulfills all necessary safety conditions. It may only be used or deployed in accordance with the technical data and the safety

conditions and rules listed below. When using the device, the legal and safety regulations

apposite to the particular use are also to be observed.

► The device must only be installed in a dry interior room.

► It must be possible to isolate the controller from the mains using an all-pole isolating de-

vice (plug/socket or double pole isolator).

► Before starting installation or wiring work, the controller must be completely isolated from

the mains voltage and protected against being switched back on. Never interchange the

safety extra-low voltage connections (sensor connections) with the 230V connections. Destructive and life-threatening voltages at the device and the connected sensors may occur.

► Solar thermal systems can become very hot. Consequently there is a risk of burns. Take

care when fitting temperature sensors!

► For safety reasons, the system should only be left in manual mode when testing. In this

operating mode, no maximum temperatures or sensor functions are monitored.

► Safe operation is no longer possible if the controller or connected equipment exhibits visu-

al damage, no longer functions or has been stored for a lengthy period of time under unsuitable conditions. If this is the case, place the controller and equipment out of service

and secure against unintentional use.

Maintenance:

The system does not require maintenance if handled and used properly. Use a cloth mois-

tened with soft alcohol (such as spirit) to clean. Do not use cleansers and/or solvents such as

trichlorethene.

As none of the components relevant to accuracy are under loads when used properly,

they have a long service life without much drift. The unit thus does not have any adjustment

options. No adjustments are needed.

The design characteristics of the unit must not be changed during repairs. Spare parts

must correspond to the original spare parts and be as good as new.

Page 6

6

Generally applicable rules for the proper use of this unit:

When used for floor and wall heaters: here, a safety thermostat must be used just as

with conventional heater controllers. It has to switch off the heating loop pump if there

is overheating regardless of the output from the controller to prevent indirect damage

from excess temperatures.

It is necessary to set all „Required settings“ mentioned in the hydraulic diagrams.

Relay output A4 can be made potential-free by resetting the jumpers.

All programs +1 (+2, +4, +8)" indicates that the selected program number can be in-

creased by the sum total of these numbers.

Example: Diagram 0, program 1 = pump-valve system

All programs +2: program also includes the boiler temperature T5

1+2 = 3 pump-valve system including the boiler temperature T5

Linking of outputs: Possibility to cancel out the numbered outputs listed in the pro-

gram diagram against each other (e.g. A1 with A2, A1 with A3 or A2 with A3, etc.). By

this means it is possible to assign the speed output at will. Addition of following numbers to the selected program number:

Linking of outputs A1 with A3 ..... +100 A1 with A4 ..... +200

A2 with A3 ..... +300 A2 with A4 ..... +400

A1 with A3 & A2 with A4 ..... +500 A3 with A4 ..... +600

Program selection

The following hydraulic diagrams are basic functions. Changes resp. additional functions are

described and defined by program numbers. The program number is the most important key

to correct function of the control system. Only by input of this number the controller knows,

which controlling business has to be done.

The program number is selected in the switch position Prog by the blue keys ab/auf

(=down/up).

Page 7

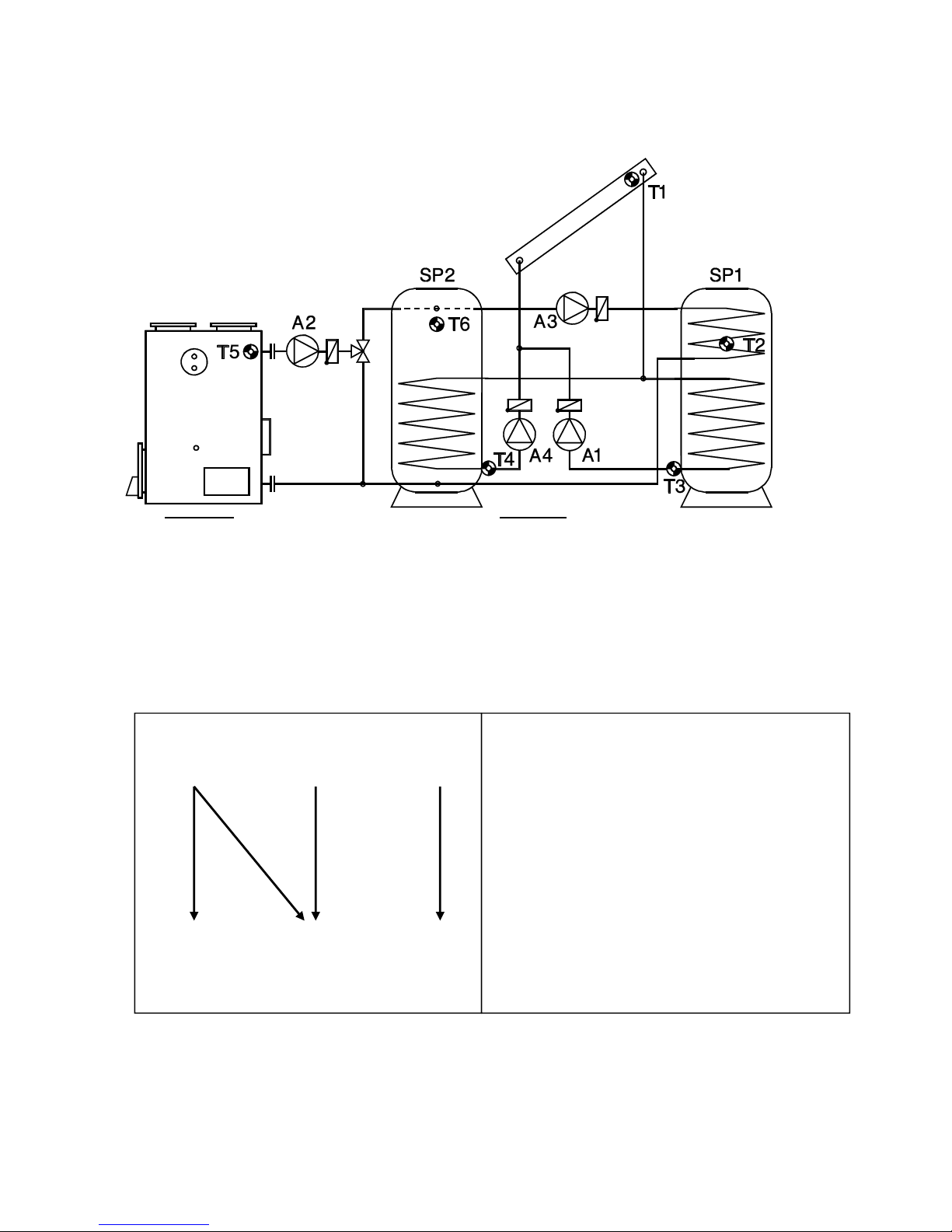

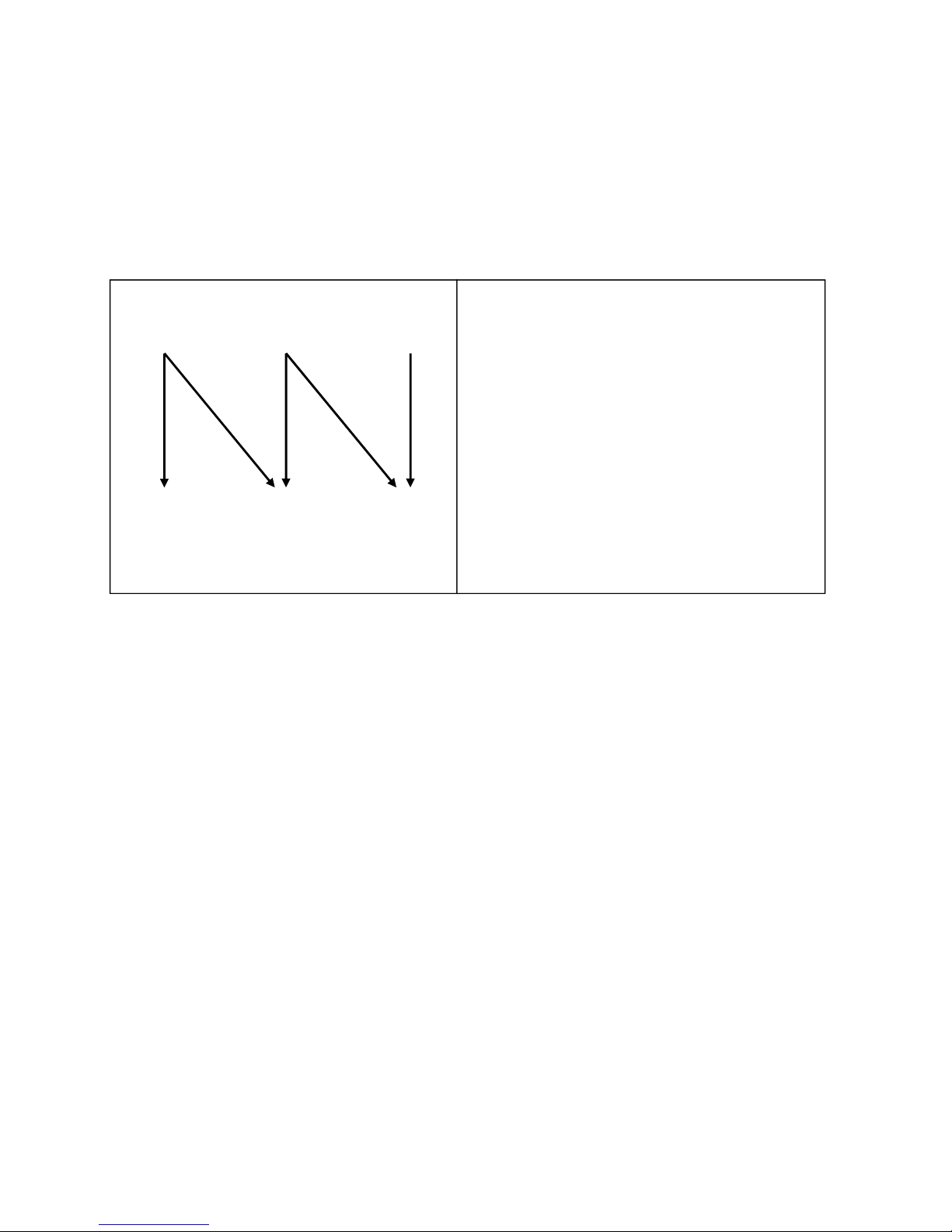

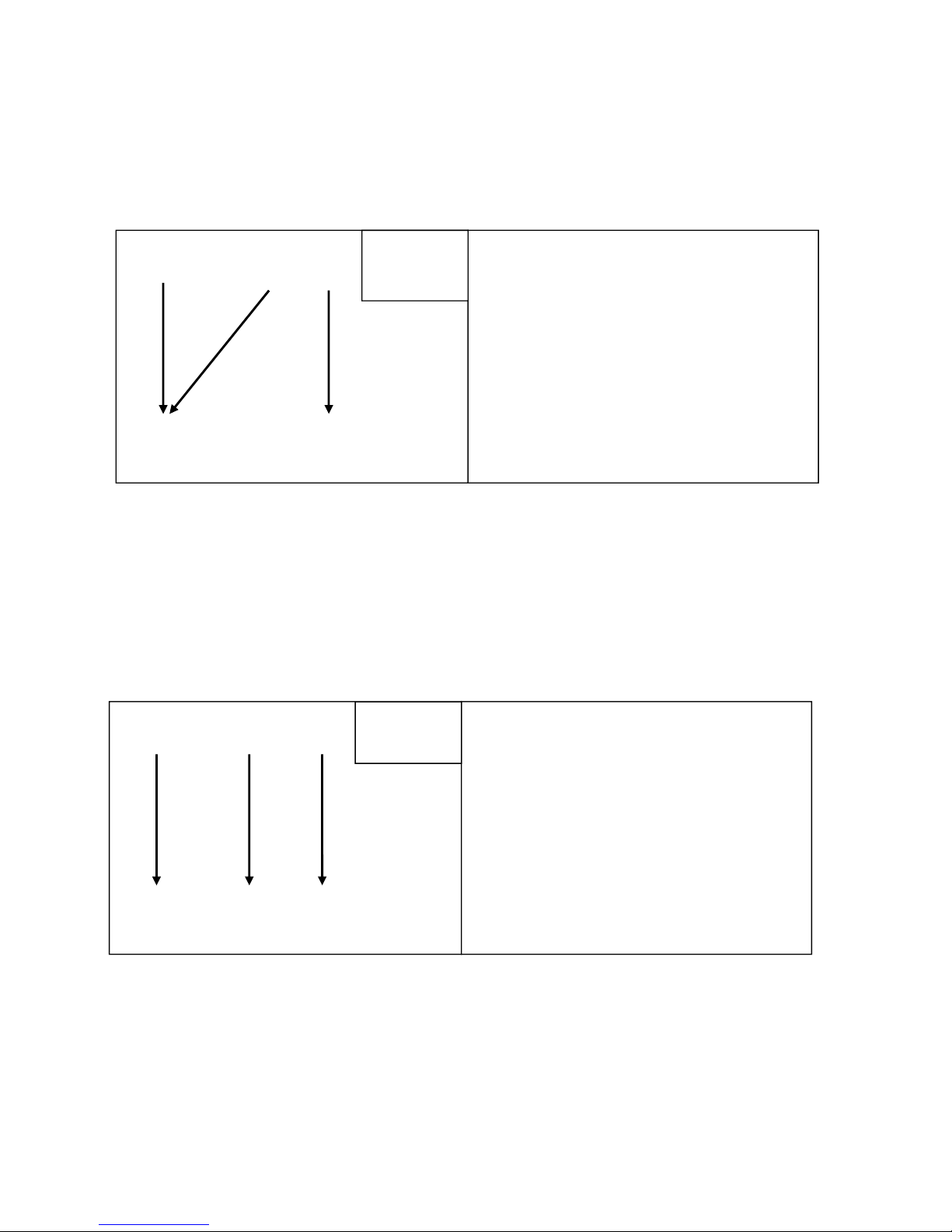

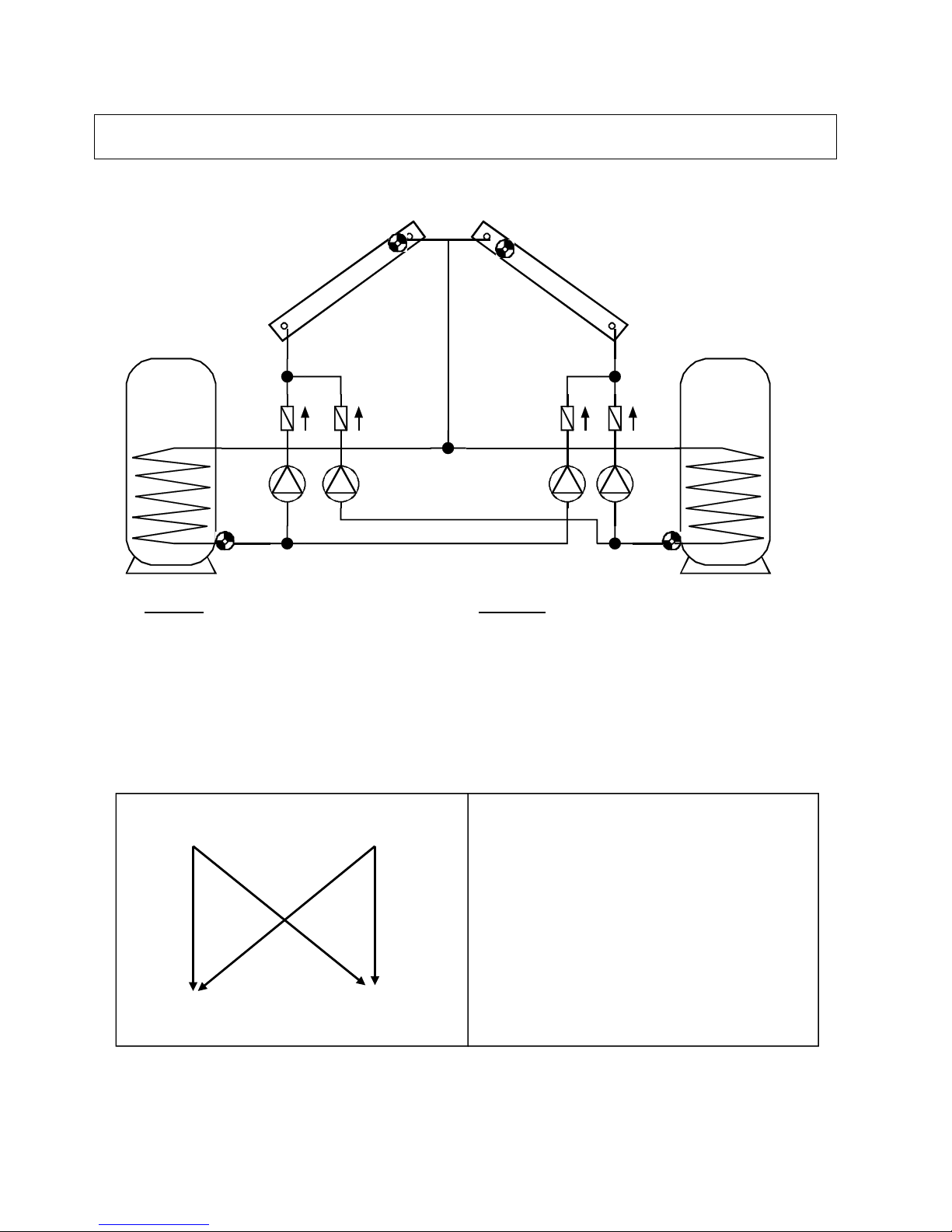

Diagram 0

7

Hydraulic diagrams

Diagram 0: Solar power system with 2 consumers and 2 feed pumps

Sensors Outputs

T1…. Collector A1…. Solar pump circuit 1

T2…. Tank 1 top A2…. Feed pump tank 2

T3…. Tank 1 bottom A3…. Feed pump tank 1

T4…. Tank 2 bottom A4…. Solar pump circuit 2

T5…. Boiler

T6…. Tank 2 top

Program 0: Function according to diagram

A1 = T1 > (T3 + diff1) & T3 < max1

A2 = T5 > (T4 + diff2) & T5 > min1 & T4 < max2

A3 = T6 > (T2 + diff3) & T6 > min2 & T2 < max3

A4 = T1 > (T4 + diff4) & T4 < max4

T1 T5 T6

min1 min2

diff1 diff4 diff2 diff3

A1 A4 A2 A3

T3 T4 T2

max1 max2 max3

max4

Required settings:

diff1 … coll. T1 – TK1 T3 A1

diff2 … boiler T5 – TK2 T4 A2

diff3 … TK2 T6 – TK1 T2 A3

diff4 … coll. T1 – TK2 T4 A4

min1 … switch-on temp. boiler T5 A2

min2 … switch-on temp. TK2 T6 A3

max1 … limit TK1 T3 A1

max2 … limit TK 2 T4 A2

max3 … limit TK 1 T2 A3

max4 … limit TK 2 T4 A4

Additional: Priority Vorr:

(typical: A11, A20, A30, A42)

TK2 TK1

Page 8

Diagram 0

8

Program 1: Instead of the two solar pumps, one pump and a three-way valve are used

(pump-valve system). The speed control (if activated) only operated when filling tank 1.

Without a priority allocation, tank 2 is filled by priority.

A1... common pump

A4... Valve (A4/S receives power when filling tank)

All programs +2: In program 0 the feed of tank TK1 by pump A3 is only controlled by differ-

ence TK2 T6 – TK1 T2. This program also includes the boiler temperature. When feeding

tank TK1 by pump A3 the difference boiler T5 – TK1 T2 will be considered additionally (same

setting diff3). Both min thresholds are active.

A1 = T1 > (T3 + diff1) & T3 < max1

A2 = T5 > (T4 + diff2) & T4 < max2 & T5 > min1

A3 = T6 > (T2 + diff3) & T2 < max3 & T6 > min2

or T5 > (T2 + diff3) & T2 < max3 & T5 > min1

A4 = T1 > (T4 + diff4) & T4 < max4

All programs +4: If both tanks have reached their maximum temperature due to the solar

power system, solar pump A1 and feed pump A3 are switched on (reverse cooling func-

tion). A3 ... or T3 > max1 & T6 < T3

All programs +8: If both tanks have reached their maximum temperature due to the solar

power system, solar pump A4 and feed pump A2 are switched on (reverse cooling function). A2 ... or T4 > max2 & T5 < T4

Note: If a solar pump is switched off manually, the controller works during reverse cooling

as the tank limit would be reached.

Program 12: The output A2 becomes available, if the feed function of tank TK2 is done by

the boiler controller. In this program A2 only switches with the thermostat function max2 at

T5 (e.g. burner requirement)

Program 13: Function like program 12, but with pump–valve system at the solar sector (see

program 1)

Program 14: Similar to Program 12. The burner requirement A2 switches on at min1 on T5.

Switch off appears when T2 has exceeded the threshold max2.

Program 15: Function like Program 14, but with pump–valve system in the solar system.

T1 T5 T6

min1 min2

diff2 diff3

diff1 A2 A3

A1 diff3

A3

diff4

A4

T3 T4 T2

max1 max2 max3

max4

Required settings:

diff1 …coll. T1 – TK1 T3 A1

diff2 …boiler T5 – TK2 T4 A2

diff3 …boiler T5 – TK1 T2 A3

TK2 T6 – TK1 T2 A3

diff4 …Coll. T1 – TK2 T4 A4

min1 …switch-on temp. boiler T5 A2,3

min2 …switch-on temp. TK2 T6 A3

max1 …limit TK1 T3 A1

max2 …limit TK2 T4 A2

max3 …limit TK1 T2 A3

max4 …limit TK2 T4 A4

Additional: Priority Vorr:

(typ

ical: A11, A20, A30, A42)

Page 9

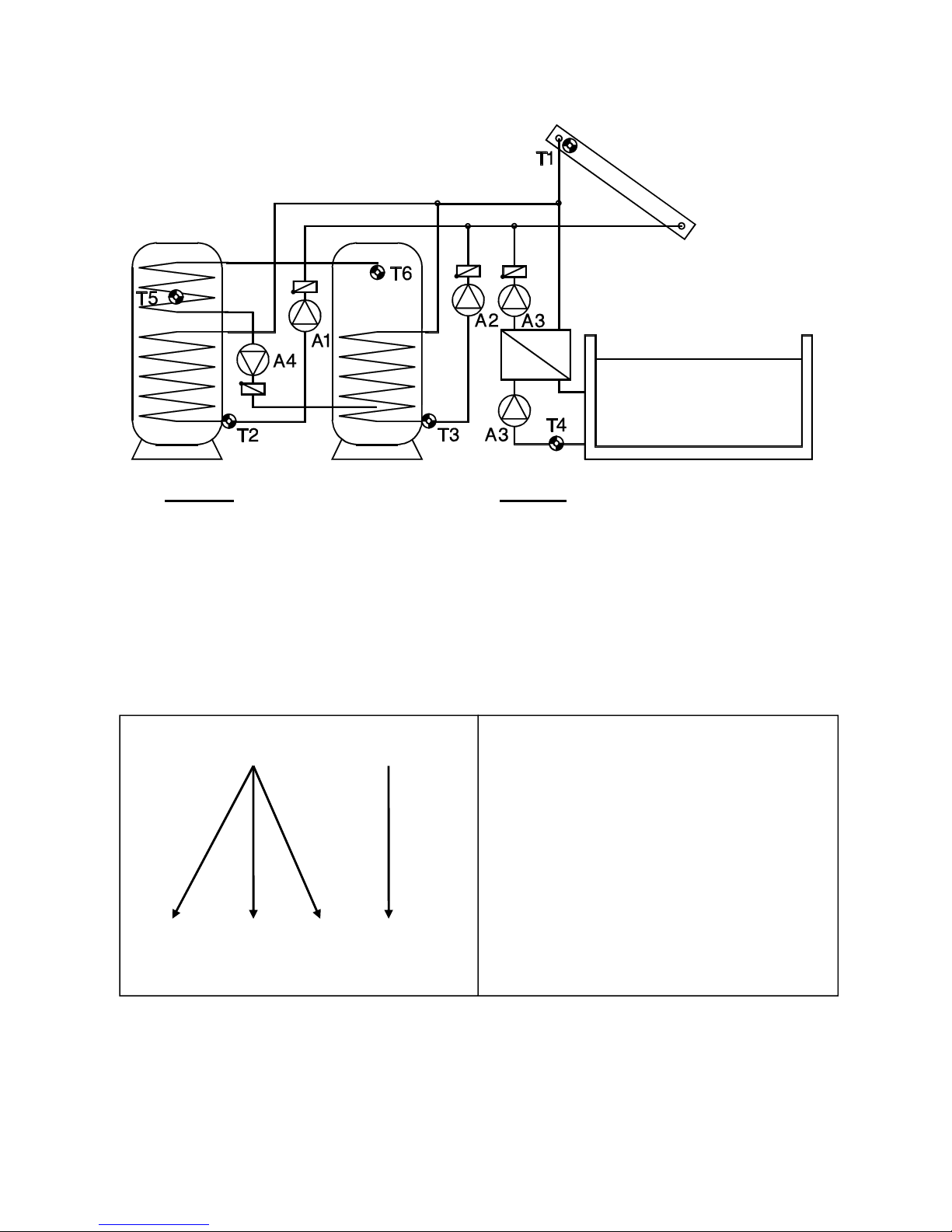

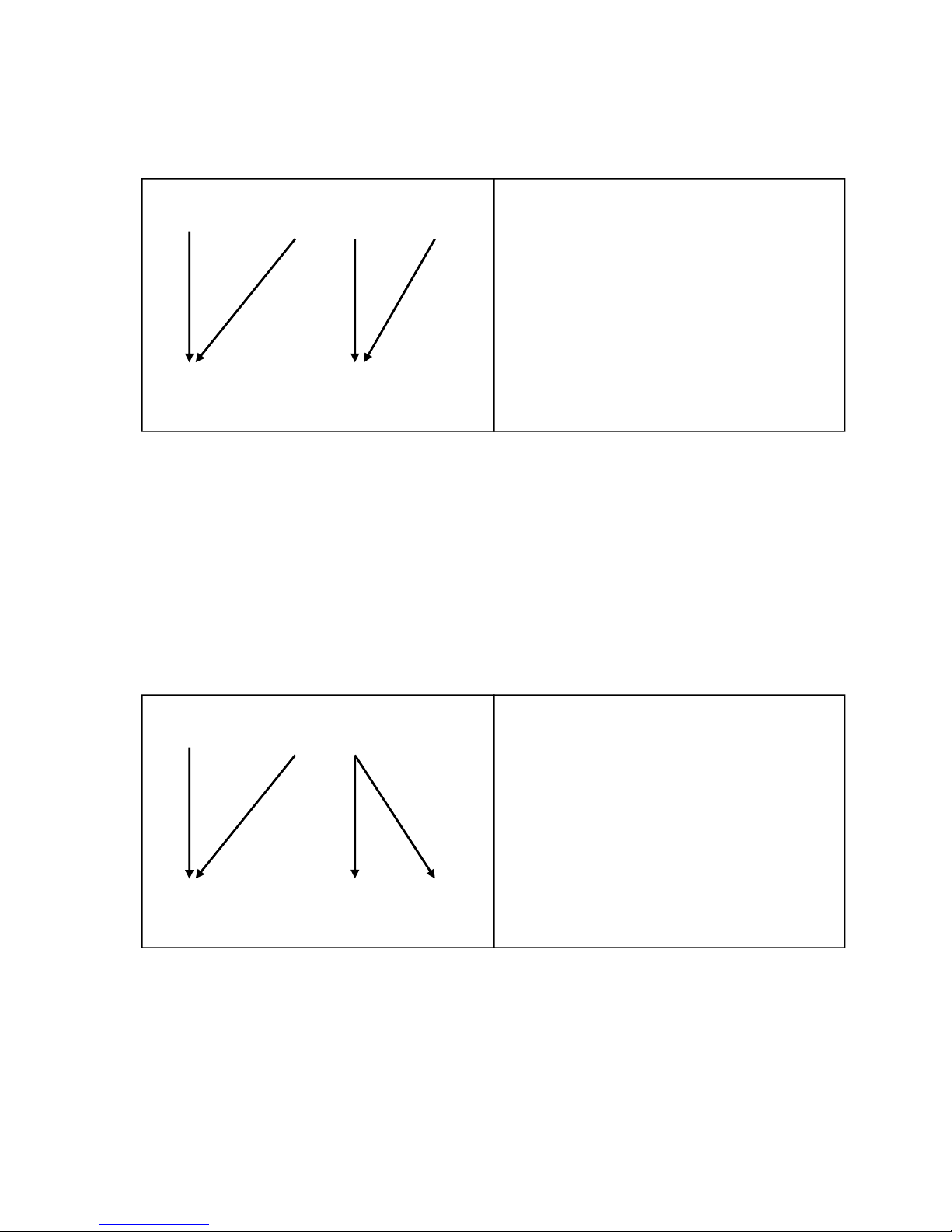

Diagram 16

9

Diagram 16: Solar power system with 3 consumers and feed pump function.

Sensors Outputs

T1…. Collector A1…. Solar pump tank TK1

T2…. Tank 1 bottom A2…. Solar pump buffer TK2

T3…. Tank 2 bottom A3…. Solar pump pool TK3

T4…. Tank 3 (pool) A4…. Feed pump

T5…. Tank 1 top

T6…. Tank 2 bottom

Program 16: Function according to diagram

A1 = T1 > (T2 + diff1) & T1 > min1 & T2 < max1

A2 = T1 > (T3 + diff2) & T1 > min1 & T3 < max2

A3 = T1 > (T4 + diff3) & T1 > min1 & T4 < max3

A4 = T6 > (T5 + diff4) & T6 > min2 & T5 < max4

T1 T6

min1 min2

diff1 diff3 diff4

A1 A3 A4

diff2

A2

T2 T3 T4 T5

max1 max2 max3 max4

Required settings:

diff1 …coll. T1 – TK1 T2 A1

diff2 …coll. T1 – TK2 T3 A2

diff3 …coll. T1 – TK3 T4 A3

diff4 …TK2 T6 – TK1 T5 A4

min1 switch-on temp. coll. T1 A1,A2,A3

min2 …switch-on temp. TK2 T6 A4

max1 …limit TK1 T2 A1

max2 …limit TK2 T3 A2

max3 …limit TK3 T4 A3

max4 …limit TK1 T5 A4

Additional: Priority Vorr:

(typical: A11, A22, A33, A40)

TK1

TK2

TK3

Page 10

Diagram 16

10

Program 17: Pump-valve system between TK1 und TK2. TK1 and TK2 are fed by a common pump A1 and a three-way valve A2. The speed control (if activated) only operated when

filling tank 1.

A1... common pump

A2... valve (A2/S receives power when filling tank TK2)

Program 18: Pump-valve system between TK1 und TK3.

A1... common pump

A3... valve (A3/S receives power when filling tank TK3)

Program 19: A common pump feeds all three tanks. Valve A3 switches between TK2 and

TK3 and – in series – valve A2 between TK1 and TK2. I.e. if both valves are free from ten-

sion, TK1 will be fed. The speed control (if activated) only operated when filling tank 1.

A1... common pump

A2... valve (A2/S receives power when filling tank TK2)

A3... valve (A3/S receives power when filling tank TK3)

If there is an active priority allocation, the two valves A2 and A3 are never switched on

simultaneously: when filling into tank 2, only pump A1 and valve A2 are switched on, when

filling into tank 3, only pump A1 and valve A3 are switched on.

All programs +4: A4 is only a signal contact which shows, that all tanks have reached their

max-thresholds.

All programs +8: If all tanks have reached their maximum temperature due to the solar

power system, tank TK2 will be fed regardless of max2.

Page 11

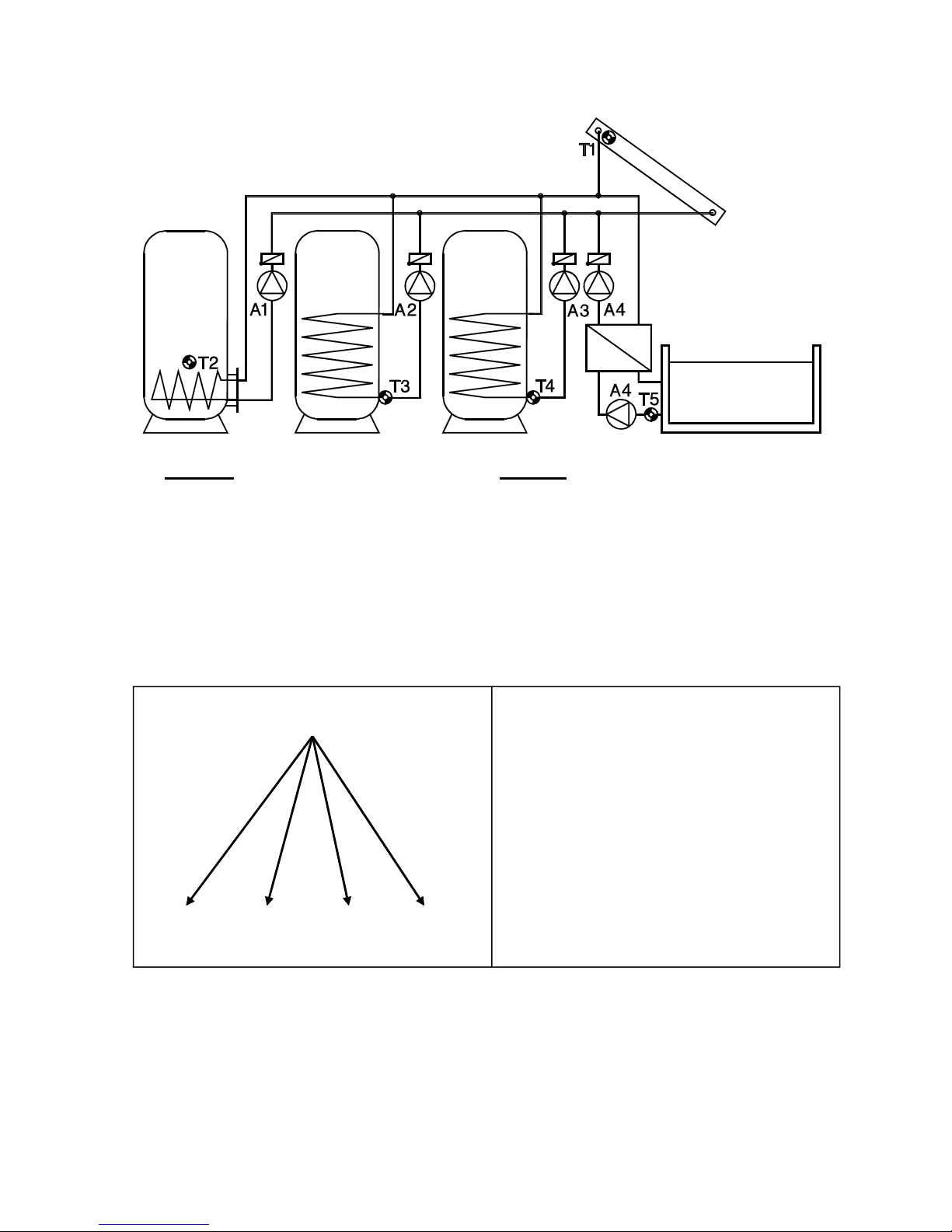

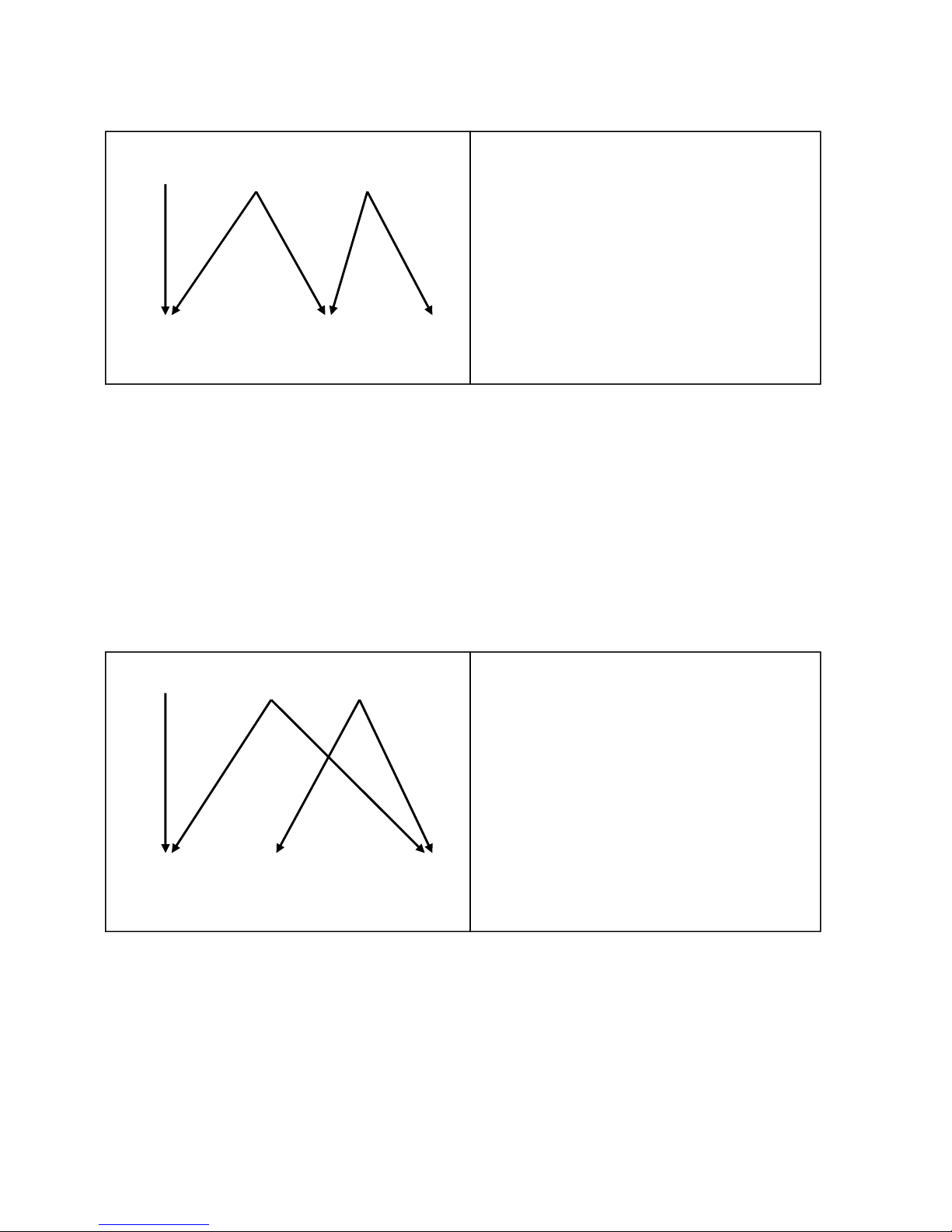

Diagram 32

11

Diagram 32: Solar power system with 4 consumers

Sensors Outputs

T1…. Collector A1…. Solar pump TK1

T2…. Tank 1 (TK1) A2…. Solar pump buffer TK2

T3…. Tank 2 (TK2) A3…. Solar pump buffer TK3

T4…. Tank 3 (TK3) A4…. Solar pump pool TK4

T5…. Tank 4 (pool TK4)

T6…. Freely usable

Program 32: Function according to diagram

A1 = T1 > (T2 + diff1) & T1 > min1 & T2 < max1

A2 = T1 > (T3 + diff2) & T1 > min1 & T3 < max2

A3 = T1 > (T4 + diff3) & T1 > min1 & T4 < max3

A4 = T1 > (T5 + diff4) & T1 > min1 & T5 < max4

T1

min1

diff1 diff4

A1 A4

diff2 diff3

A2 A3

T2 T3 T4 T5

max1 max2 max3 max4

Required settings:

diff1 …coll. T1 – TK1 T2 A1

diff2 …coll. T1 – TK 2 T3 A2

diff3 …coll. T1 – TK 3 T4 A3

diff4 …coll. T1 – TK 4 T5 A4

min1 …switch-on temp. coll. T1 A1,

A2, A3, A4

max1 …limit TK 1 T2 A1

max2 …limit TK 2 T3 A2

max3 …limit TK 3 T4 A3

max4 …limit TK 4 T5 A4

Additional: Priority Vorr:

(typical: A11, A22, A33, A44)

TK1 TK2 TK3

TK4

Page 12

Diagram 32

12

Program 33: Pump-valve system between TK1 und TK2. TK1 and TK2 are fed by a common pump A1 and a three-way valve A2. The speed control (if activated) only operated when

filling tank 1.

A1... common pump

A2... valve (A2/S receives power when filling tank TK2)

All programs +2: Pump-valve system between TK1 und TK3.

A1... common pump

A3... valve (A3/S receives power when filling tank TK3)

All programs +4: Pump-valve system between TK1 und TK4.

A1... common pump

A4... valve (A4/S receives power when filling tank TK4)

All programs +8: If all tanks have reached their maximum temperature due to the solar

power system, tank TK2 will be fed regardless of max2.

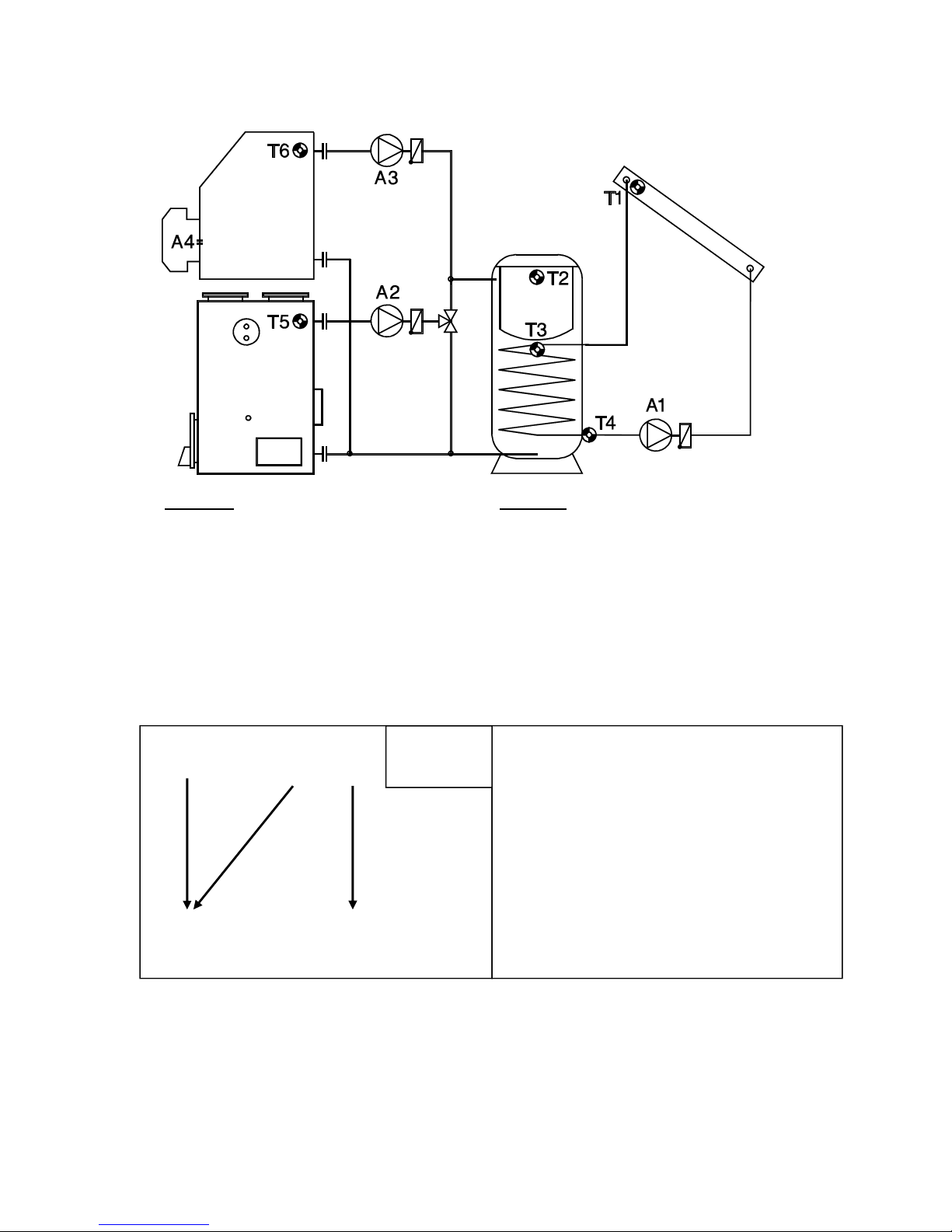

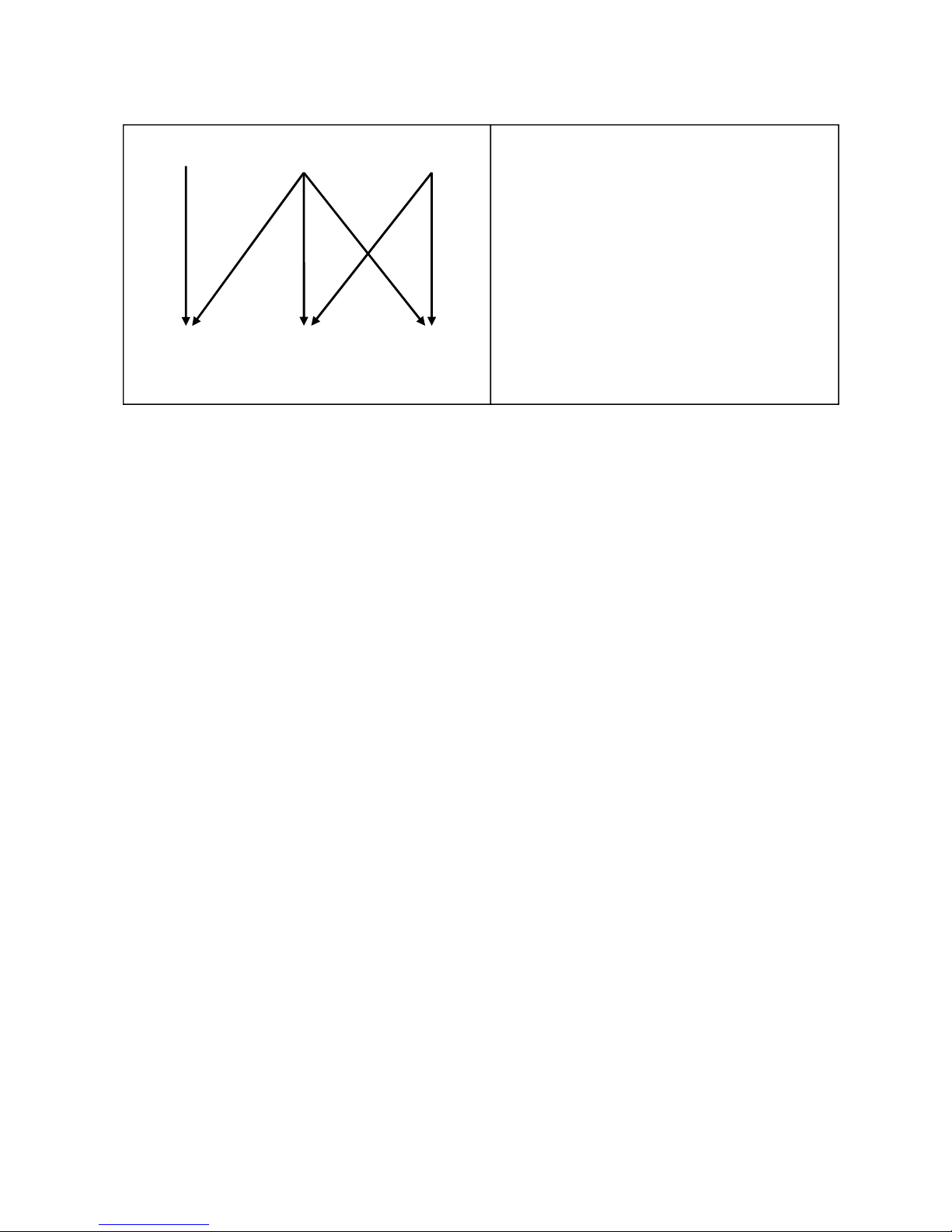

Page 13

Diagram 48

13

Diagram 48: Burner requirement, 2 feed pumps and simple solar power unit

Sensors Outputs

T1…. Collector A1…. Solar pump

T2…. Tank top A2…. Feed pump solid fuel boiler

T3…. Tank center A3…. Feed pump oil/gas boiler

T4…. Tank bottom A4…. Burner requirement

T5…. Solid fuel boiler (“sfb”)

T6…. Oil/gas boiler (“ogb”)

Program 48: Function according to diagram

A1 = T1 > (T4 + diff1) & T4 < max1

A2 = T5 > (T4 + diff2) & T5 > min1 & T4 < max2

A3 = T6 > (T3 + diff3) & T6 > min2 & T3 < max3

A4 (on) = T2 < max4 – hysteresis

A4 (off) = T2 > max4

T1 T5 T6

min1 min2

diff1

A1 diff2 diff3

A2 A3

T4 T3

max1 max3

max2

Required settings:

diff1 …coll. T1 – TK T4 A1

diff2 …sf-boiler T5 – TK T4 A2

diff3 …oil boiler T6 – TK T3 A3

diff4 …see all programs +8

min1 …switch-on temp. sfb T5 A2

min2 …switch-on temp. ogb T6 A3

max1 …limit TK T4 A1

max2 …limit TK T4 A2

max3 …limit TK T3 A3

max4 …burner requirement TK T2 A4

Burner A4

T2 max4

Burner

requirement

Page 14

Diagram 48

14

Program 49: If the tank has reached its maximum temperature due to the solar power system, solar pump A1 and feed pump A2 are switched on (reverse cooling function).

A2 ... or T4 > max1 & T5 < T4

All Programs +2: Output A4 (burner requirement) switches on when T2 falls below threshold

max4 and switches off when T3 exceeds max3. Max3 is no longer the tank limit for the

oil/gas boiler feed pump.

A1 = T1 > (T4 + diff1) & T4 < max1

A2 = T5 > (T4 + diff2) & T5 > min1 & T4 < max2

A3 = T6 > (T3 + diff3) & T6 > min2

A4 (on) = T2 < max4 – hysteresis

A4 (off) = T3 > max3

All Programs +4: Three independent differential loops. The tank feeding A2 from the solid

fuel boiler is controlled by the difference diff2 between boiler sensor T5 and the sensor T2

(tank top)

A1 = T1 > (T4 + diff1) & T4 < max1

A2 = T5 > (T2 + diff2) & T5 > min1 & T2 < max2

A3 = T6 > (T3 + diff3) & T6 > min2 & T3 < max3

A4 (on) = T2 < max4 – hysteresis

A4 (off) = T2 > max4

T1 T5 T6

min1 min2

diff1

A1 diff2 diff3

A2 A3

T4 T3

max1

max2

Required settings:

diff1 …coll. T1 – TK T4 A1

diff2 …sf-boiler T5 – TK T4 A2

diff3 …oil boiler T6 – TK T3 A3

min1 …switch-on temp. sfb T5 A2

min2 …switch-on temp. ogb T6 A3

max1 …limit TK T4 A1

max2 …limit TK T4 A2

max3 …burner requ. OFF TK T3 A4

max4 …burner requ. ON TK T2 A4

Burner A4

T2 max4

T3 max3

T1 T5 T6

min1 min2

diff1 diff2 diff3

A1 A2 A3

T4 T2 T3

max1 max2 max3

Required settings:

diff1 …coll. T1 – TK T4 A1

diff2 …sf-boiler T5 – TK T2 A2

diff3 …oil boiler T6 – TK T3 A3

min1 …switch-on temp. sfb T5 A2

min2 …switch-on temp. ogb T6 A3

max1 …limit TK T4 A1

max2 …limit TK T2 A2

max3 …limit TK T3 A3

max4 …burner requirement TK T2 A4

Burner A4

T2 max4

Page 15

Diagram 48

15

All Programs +8: This program enables controlling of two generators to each one consumer.

Output A4 is switched with the difference diff4 between T2 and T3 instead of burner requirement. T2 is available for an additional forth generator. In this case threshold max4 operates at T3.

A1 = T1 > (T4 + diff1) & T4 < max1

A2 = T5 > (T4 + diff2) & T5 > min1 & T4 < max2

A3 = T6 > (T3 + diff3) & T6 > min2 & T3 < max3

A4 = T2 > (T3 + diff4) & T3 < max4

Program 60: The whole function offers switching of two generators to one consumer and one

generator to two consumers. Output A4 gets an additional difference function instead of

burner requirement. A4 switches, if sensor T6 is increasing min2 and is greater than T2 by

diff4 and T2 has not exceeded max4.

A1 = T1 > (T4 + diff1) & T4 < max1

A2 = T5 > (T4 + diff2) & T5 > min1 & T4 < max2

A3 = T6 > (T3 + diff3) & T6 > min2 & T3 < max3

A4 = T6 > (T2 + diff4) & T6 > min2 & T2 < max4

T1 T5 T6 T2

min1 min2

diff1

A1 diff2 diff3 diff4

A2 A3 A4

T4 T3

max1 max3

max2 max4

Required settings:

diff1 …coll. T1 – TK T4 A1

diff2 …sf-boiler T5 – TK T4 A2

diff3 …oil boiler T6 – TK T3 A3

diff4 …generator T2 – TK T3 A4

min1 …switch-on temp. sfb T5 A2

min2 …switch-on temp. ogb T6 A3

max1 …limit TK T4 A1

max2 …limit TK T4 A2

max3 …limit TK T3 A3

max4 …limit TK T3 A4

T1 T5 T6

min1 min2

diff1

A1 diff2 diff3 diff4

A2 A3 A4

T4 T3 T2

max1 max3 max4

max2

Required settings:

diff1 …coll. T1 – TK T4 A1

diff2 …sf-boiler T5 – TK T4 A2

diff3 …oil boiler T6 – TK T3 A3

diff4 …oil boiler T6 – TK T2 A4

min1 …switch-on temp. sfb T5 A2

min2 …switch-on temp. ogb T6 A3,4

max1 …limit TK T4 A1

max2 …limit TK T4 A2

max3 …limit TK T3 A3

max4 …limit TK T2 A4

Page 16

Diagram 48

16

Program 61: Function similar to Program 60, but output A3 does not only switch by the origin

function, but additionally, if T5 is increasing min1 and is greater than T3 by diff3

A1 = T1 > (T4 + diff1) & T4 < max1

A2 = T5 > (T4 + diff2) & T5 > min1 & T4 < max2

A3 = T6 > (T3 + diff3) & T6 > min2 & T3 < max3

or T5 > (T3 + diff3) & T5 > min1 & T3 < max3

A4 = T6 > (T2 + diff4) & T6 > min2 & T2 < max4

Program 62: Additionally to program 60 output A4 switches, if T5 is increasing min1 and is

greater than T2 by diff4.

A1 = T1 > (T4 + diff1) & T4 < max1

A2 = T5 > (T4 + diff2) & T5 > min1 & T4 < max2

A3 = T6 > (T3 + diff3) & T6 > min2 & T3 < max3

A4 = T6 > (T2 + diff4) & T6 > min2 & T2 < max4

or T5 > (T2 + diff4) & T5 > min1 & T2 < max4

T1 T5 T6

min1 min2

diff1

A1 diff2 diff4

A2 A4

diff3 diff3

A3 A3

T4 T3 T2

max1 max3 max4

max2

Required settings:

diff1 …coll. T1 – TK T4 A1

diff2 …sf-boiler T5 – TK T4 A2

diff3 …oil boiler T6 – TK T3 A3

diff3 …sf-boiler T5 – TK T3 A3

diff4 …oil boiler T6 – TK T2 A4

min1 …switch-on temp. sfb T5 A2,3

min2 …switch-on temp. ogb T6 A3,4

max1 …limit solar TK T4 A1

max2 …limit TK T4 A2

max3 …limit TK T3 A3

max4 …limit TK T2 A4

T1 T5 T6

min1 min2

diff1

A1 diff2 diff4

A2 A4

diff3

A3 diff4

A4

T4 T3 T2

max1 max3 max4

max2

Required settings:

diff1 …coll. T1 – TK T4 A1

diff2 …sf-boiler T5 – TK T4 A2

diff3 …oil boiler T6 – TK T3 A3

diff4 …oil boiler T5 – TK T2 A4

sf-boiler T6 – TK T2 A4

min1 …switch-on temp. sfb T5 A2,4

min2 …switch-on temp. ogb T6 A3,4

max1 …limit TK T4 A1

max2 …limit TK T4 A2

max3 …limit TK T3 A3

max4 …limit TK T2 A4

Page 17

Diagram 48

17

Program 63: Output A3 switches as described in program 61 and A4 as per program 62.

A1 = T1 > (T4 + diff1) & T4 < max1

A2 = T5 > (T4 + diff2) & T5 > min1 & T4 < max2

A3 = T5 > (T3 + diff3) & T5 > min1 & T3 < max3

or T6 > (T3 + diff3) & T6 > min2 & T3 < max3

A4 = T5 > (T2 + diff4) & T5 > min1 & T2 < max4

or T6 > (T2 + diff4) & T6 > min2 & T2 < max4

T1 T5 T6

min1 min2

diff4

diff1 A4

A1 diff2

A2 diff4

diff3 A4

A3

diff3

A3

T4 T3 T2

max1 max3 max4

max2

Required settings:

diff1 …col. T1 – TK T4 A1

diff2 …boiler T5 – TK T4 A2

diff3 …boiler T5 – TK T3 A3

…boiler T6 – TK T3 A3

diff4 …boiler T5 – TK T2 A4

…boiler T6 – TK T2 A4

min1 …switch-on temp. T5 A2,3,4

min2 …switch-on temp. T6 A3,4

max1 …limit TK T4 A1

max2 …limit TK T4 A2

max3 …limit TK T3 A3

max4 …limit TK T2 A4

Page 18

Diagram 64

18

T1 T2

SP 2

A4 A3

SP 1

A2 A1

T4 T3

Diagram 64: Solar power system with two solar panels and two consumers

Note: Setting the time switch, the definition of the output corresponds to the actual output,

but setting the priority it corresponds to the basic function of program 64.

Program 64: Each tank is fed from each solar panel by 4 separate pumps. No feed pump

function!

Sensor Outputs

T1…. Collector 1 A1…. Pump collector 1 – TK1

T2…. Collector 2 A2…. Pump collector 1 – TK2

T3…. Tank 1 bottom A3…. Pump collector 2 – TK1

T4…. Tank 2 bottom A4…. Pump collector 2 – TK2

T5…. Freely usable

T6…. Freely usable

Program 64: Function according to diagram

A1 = T1 > (T3 + diff1) & T3 < max1

A2 = T1 > (T4 + diff2) & T4 < max2

A3 = T2 > (T3 + diff1) & T3 < max1

A4 = T2 > (T4 + diff2) & T4 < max2

T1 T2

diff1 diff2 diff2

A1 A2 A4

diff1

A3

T3 T4

max1 max2

Required settings:

diff1 …coll. T1 – TK1 T3 A1

coll. T2 – TK1 T3 A3

diff2 …coll. T1 – TK2 T4 A2

coll. T2 – TK2 T4 A4

diff3 …see all programs +1

max1 …limit TK1 T3 A1,3

max2 …limit TK2 T4 A2,4

Additional: Priority Vorr:

(typical: A11, A22, A31, A42)

TK 2 TK 1

Page 19

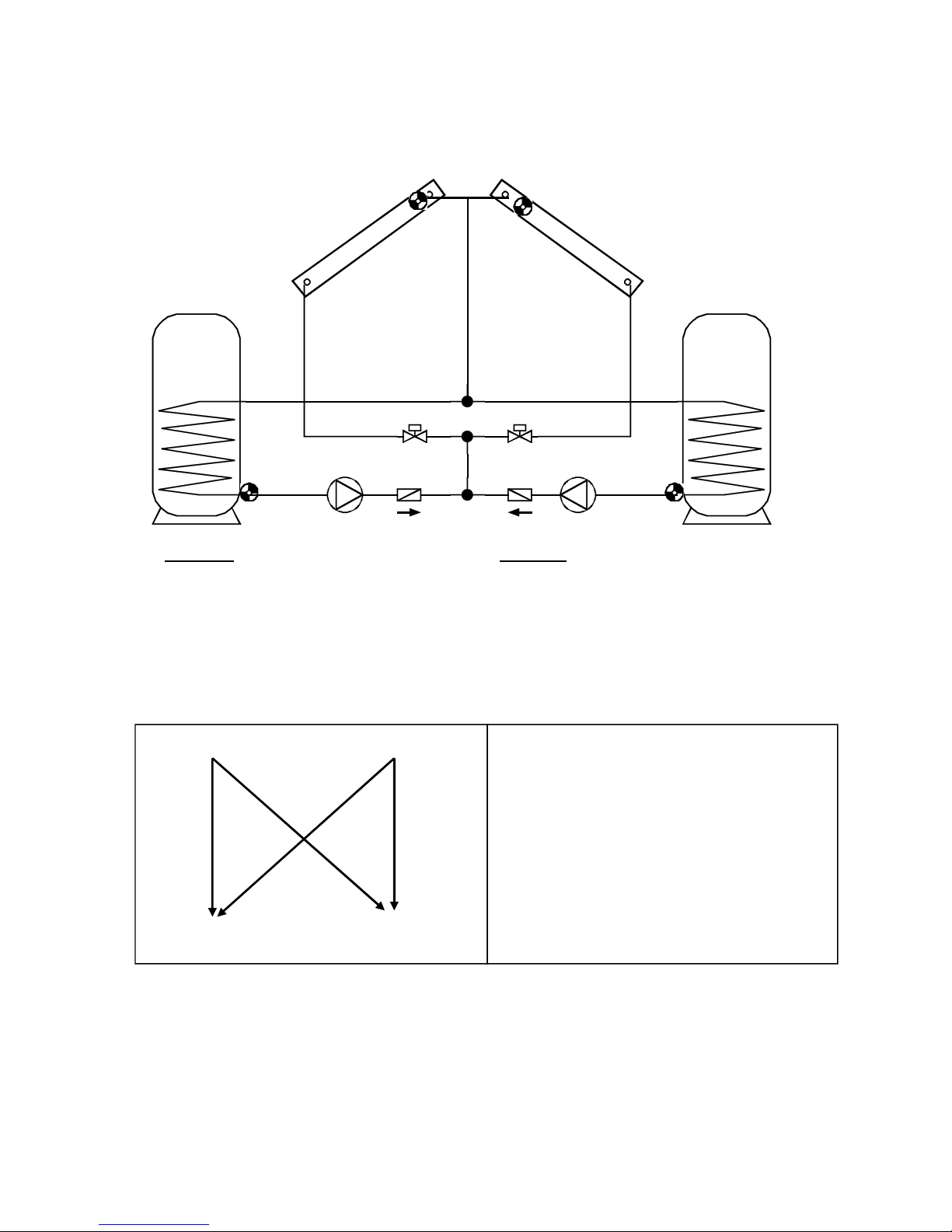

Diagram 64

19

T1 T2

SP 2

SP 1

T4 T3

A3 A4

A2 A1

Program 66: 2 stop valves and 2 pumps instead of the 4 pumps in program 64. No feed

pump function!

Attention! If both valves are closed, both pumps will be switched off.

Sensors Outputs

T1…. Collector 1 A1…. Pump TK1

T2…. Collector 2 A2…. Pump TK2

T3…. Tank 1 bottom A3…. Valve Collector panel 1

T4…. Tank 2 bottom A4…. Valve Collector panel 2

T5…. Freely usable

T6…. Freely usable

A1 & A3 = T1 > (T3 + diff1) & T3 < max1

A1 & A4 = T2 > (T3 + diff1) & T3 < max1

A2 & A3 = T1 > (T4 + diff2) & T4 < max2

A2 & A4 = T2 > (T4 + diff2) & T4 < max2

A system of one pump and a three-way valve instead of two pumps can be realized by us-

ing the auxiliary output A5: Pump = A1, three-way valve = A2; the auxiliary output A5 switches simultaneously with A2 the pump A1 (setting: A2o).

T1 T2

diff1 diff2 diff2

A1,A3 A2,A3 A2,A4

diff1

A1,A4

T3 T4

Required settings:

diff1 …coll. T1 – TK1 T3 A1,3

coll. T2 – TK1 T3 A1,4

diff2 …coll. T1 – TK2 T4 A2,3

coll. T2 – TK2 T4 A2,4

diff3 …see all programs +1

max1 …limit TK1 T3 A1,3,4

max2 …limit TK2 T4 A2,3,4

Additional: Priority Vorr:

(typical: A11, A22, A31, A42)

TK 2 TK 1

Page 20

Diagram 64

20

Program 68: Function according to diagram.

The three-way valve A3 receives power when filling tank TK2.

Sensors Outputs

T1…. Collector 1 A1…. Solar pump collector panel 1

T2…. Collector 2 A2…. Solar pump collector panel 2

T3…. Tank 1 bottom A3…. Three-way valve (feeding tanks)

T4…. Tank 2 bottom A4…. Feed pump

T5…. Tank 1 top

T6…. Tank 2 top

A1 = T1 > (T3 + diff1) & T3 < max1

A1 & A3 = T1 > (T4 + diff2) & T4 < max2

A2 = T2 > (T3 + diff1) & T3 < max1

A2 & A3 = T2 > (T4 + diff2) & T4 < max2

A4 = T6 > (T5 + diff4) & T6 > min2 & T5 < max4

All Programs +1: If the difference between collector sensors T1 and T2 exceeds the difference diff3, the colder collector is switched off. This prevents heat from being lost in the colder collector when temperatures are mixed.

T1 T2 T6

min2

diff1 diff2 diff2 diff4

A1 A1,3 A2,3 A4

diff1

A2

T3 T4 T5

max1 max2 max4

Required settings:

diff1 …coll. T1 – TK1 T3 A1

coll. T2 – TK1 T3 A2

diff2 …coll. T1 – TK2 T4 A1,3

coll. T2 – TK2 T4 A2,3

diff3 …see all programs +1

diff4 …TK2 T6 – TK1 T5 A4

min2 …switch-on temp. T6 A4

max1 …limit TK1 T3 A1,2

max2 …limit TK2 T4 A1,2,3

max4 …limit TK1 T5 A4

Additional: Priority Vorr:

(typical: A11, A22, A31, A42)

TK 2 TK 1

Page 21

Diagram 80

21

Diagram 80: Layering storage tank, feed pump and domestic hot water preparation

Sensors Outputs

T1…. Collector A1…. Solar pumps

T2…. Tank top A2…. Heat exchanger pump (hot water)

T3…. Tank bottom A3…. Three-way valve layering storage

T4…. Hot water (ultra-fast sensor) A4…. Feed pump

T5…. Boiler

T6…. Solar flow

Program 80: Function according to diagram

A1 = T1 > (T3 + diff1) & T3 < max1

A2 = T2 > (T4 + diff2) & T4 < max2

A3 = (T6 > min2 or T6 > (T2 + diff3)) & T2 < max3

A4 = T5 > (T3 + diff4) & T5 > min1 & T3 < max4

T1 T5 T6 T6

min1 min2

diff1 diff4 diff3

A1 A4 A3 A3

T3 T2

max1 max3

max4

diff2

A2

T4

max2

Required settings:

diff1 …coll. T1 – TK T3 A1

diff2 …tank T2 – WW T4 A2

diff3 …flow T6 – TK T2 A3

diff4 …boiler T5 – TK T3 A4

min1 …switch-on temp. boiler T5 A4

min2 …switch-on temp. flow T6 A3

max1 …limit TK T3 A1

max2 …limit WW T4 A2

max3 …threshold TK T2 A3

max4 …limit feed pump TK T3 A4

Additional: Both speed controls Pd1,

Pd2

CW

Page 22

Diagram 80

22

Program 80: Function according to diagram

Both solar pumps are switched on by the difference diff1. The three-way valve A3 switches

to the tank top, when T6 is increasing min2 or is greater than T2 by diff3, but T2 has not exceeded the threshold max3.

The speed controlled output A2 is used for domestic hot water preparation. The detection of

a flow is possible by using a volume flow switch, electrically switched in series to sensor T4.

Sensor T4 is kept constant by the speed control (absolute value control). When T2 decreases, the controller keeps the difference between T2 and T4 constant (setting of the value d in

menu speed control) for avoiding the mixing inside the tank because of too high pump speed

(differential control). The slower of the two speeds “wins out”.

Program 81: If T2 has reached max3, the quick warm-up phase has been completed, and

the speed control for A1 is thus blocked optimal efficiency.

Program 82: The speed control for A1 is blocked, when the three-way valve switches to the

bottom (A3 = off). In this case the priority control is active for the possibility of switching back

to the top tank area at high enough solar radiation.

All Programs +4: The domestic hot water preparation is not applicable. A2 is the secondary

pump in the solar loop. T4 should be mounted in the primary solar loop. A2 switches, when

A1 is already active and T4 is greater than T3 by diff2.

A1 = T1 > (T3 + diff1) & T3 < max1

A2 = T4 > (T3 + diff2) & (A1 = on)

A3 = (T6 > min2 or T6 > (T2 + diff3)) & T2 < max3

A4 = T5 > (T3 + diff4) & T5 > min1 & T3 < max4

T4 T1 T5 T6 T6

min1 min2

diff2 diff1 diff4 diff3

A2 A1 A4 A3 A3

& A1 ein

T3 T2

max1 max3

max4

Required settings:

diff1 …coll. T1 – TK T3 A1

diff2 …solar flow T4 – TK T3 A2

diff3 …flow T6 – TK T2 A3

diff4 …boiler T5 – TK T3 A4

min1 …switch-on temp. boiler T5 A4

min2 …switch-on temp. flow T6 A3

max1 …limit TK T3 A1

max3 …threshold. TK T2 A3

max4 …limit. feed pump TK T3 A4

Additional: Both speed controls Pd1,

Pd2

Page 23

Diagram 80

23

Program 88: A1 gets additionally the threshold min1 at T1. The solid fuel boiler is not appli-

cable. The domestic hot water preparation by A2 is also switching, if T4 is greater than T5 by

diff2. T5 could be a volume flow switch. A4 is used for burner requirement. A4 switches

when T2 has not exceeded max4.

A1 = T1 > min1 & T1 > (T3 + diff1) & T3 < max1

A2 = T4 > (T5 + diff2) or (T2 > 50°C & T4 < max2)

A3 = (T6 > min2 or T6 > (T2 + diff3)) & T2 < max3

A4 (on) = T2 < max4 – hysteresis

A4 (off) = T2 > max4

Program 89: according to program 88, but: If T4 has reached max3, the quick warm-up

phase has been completed, and the speed control of A1 is thus blocked optimal efficiency.

Program 92: according to program 88, but: the changing between tank center and top is

done by a thermic valve. Therefore A3 is free for an additional feed pump function. A3

switches when T6 is increasing min2 and is greater than T3 by diff3 and T3 has not exceeded max3.

A1 = T1 > min1 & T1 > (T3 + diff1) & T3 < max1

A2 = T4 > (T5 + diff2) or (T2 > 50°C & T4 < max2)

A3 = T6 > min2 & T6 > (T3 + diff3) & T3 < max3

A4 (on) = T2 < max4 – hysteresis

A4 (off) = T2 > max4

Program 94: according to program 92, but: the sensor T2 in the tank top is used for the feed

pump function A3. Therefore this function is better suitable for oil or gas boilers.

A1 = T1 > min1 & T1 > (T3 + diff1) & T3 < max1

A2 = T4 > (T5 + diff2) or (T2 > 50°C & T4 < max2)

A3 = T6 > min2 & T6> (T2 + diff3) & T2 < max3.

A4 (on) = T2 < max4 – hysteresis

A4 (off) = T2 > max4

T1 T6 T6 T4 A2 off

min1 min2 T2 < 50°C

diff1 diff3 diff2

A1 A3 A2 A2 on

A3

T3 T2 T5 A2 on

max1 max3 T4 > max2

Required settings:

diff1 …coll. T1 – TK T3 A1

diff2 …sensor T4 – sensor T5 A2

diff3 …flow T6 – TK T2 A3

min1 …switch-on temp. coll. T1 A2

min2 …switch-on temp. flow T6 A3

max1 …limit TK T3 A1

max2 …limit WW T4 A2

max3 …threshold TK T2 A3

max4 …burner requirement T2 A4

Additional: Both speed controls Pd1,

Pd2

Burner A4

T2 max4

Page 24

Diagram 96

24

Diagram 96: Solar power system with two consumers and two feed pump functions

Sensors Outputs

T1…. Collector A1…. Solar pump loop 1

T2…. Tank TK1 top A2…. Feed pump TK2

T3…. Tank TK1 center A3…. Feed pump TK3

T4…. Tank TK1 bottom A4…. Solar pump loop 2

T5…. Tank TK2 bottom

T6…. Tank TK3 bottom

Program 96: Function according to diagram.

A1 = T1 > (T3 + diff1) & T1 > min1 & T3 < max1

A2 = T2 > (T5 + diff2) & T2 > min2 & T5 < max2

A3 = T2 > (T6 + diff3) & T2 > min2 & T6 < max3

A4 = T1 > (T4 + diff4) & T1 > min1 & T4 < max4

T1 T2

min1 min2

diff1 diff2 diff3

A1 A2 A3

diff4

A4

T3 T4 T5 T6

max1 max4 max2 max3

Required settings:

diff1 …coll. T1 – TK1 T3 A1

diff2 …TK 1 T2 – TK 2 T5 A2

diff3 …TK 1 T2 – TK 3 T6 A3

diff4 …Coll. T1 – TK 1 T4 A4

min1 …switch-on temp. coll. T1 A1,4

min2 …switch-on temp. TK 1 T2 A2,3

max1 …limit TK1 T3 A1

max2 …limit TK2 T5 A2

max3 …limit TK3 T6 A3

max4 …limit TK1 T4 A4

Additional: Priority Vorr:

(typical: A11, A20, A30, A42)

TK1

TK2 TK3

Page 25

Diagram 96

25

Program 97: Instead of the two solar pumps, one pump and a three-way valve are used

(pump-valve system). The speed control (if activated) only operated when filling loop 1 (T3).

A1... common pump

A4... Valve (A4/S receives power when filling tank TK1 bottom)

All Programs +2: Instead of the two feed pumps, one pump and a three-way valve are used

(pump-valve system). The speed control (if activated) only operated when filling loop TK2

(T5).

A2... common pump

A3... Valve (A3/S receives power when filling tank TK3)

Page 26

Diagram A0

26

Diagram A0: Solar system with two consumers, feed pump, burner requirement

Sensors Outputs

T1…. Collector A1…. Solar pump loop 1

T2…. Tank TK1 top A2…. Solar pump loop 2

T3…. Tank TK1 bottom A3…. Feed pump TK1

T4…. Tank TK2 bottom A4…. Feed pump TK2

T5…. Boiler

T6…. Tank TK2 top

Program A0: Function according to diagram.

A1 = T1 > (T3 + diff1) & T3 < max1

A2 = T1 > (T4 + diff2) & T4 < max2

A3 = T6 > (T2 + diff3) & T6 > min2 & T2 < max3

A4 = T5 > (T6 + diff4) & T5 > min1 & T6 < max4

T1 T5

min1

diff1 diff2 diff4

A1 A2 A4

T6

T3 T4 max4

max1 max2 min2

diff3

A3

T2

max3

Required settings:

diff1 …coll. T1 – TK1 T3 A1

diff2 …coll. T1 – TK2 T4 A2

diff3 …TK2 T6 – TK1 T2 A3

diff4 …boiler T5 – TK2 T6 A4

min1 …switch-on temp. boiler T5 A4

min2 …switch-on temp. TK2 T6 A3

max1 …limit TK1 T3 A1

max2 …limit TK2 T4 A2

max3 …limit TK1 T2 A3

max4 …limit TK2 T6 A4

Additional: Priority Vorr:

(typical: A11, A22, A30, A40)

TK2 TK1

Page 27

Diagram A0

27

All Programs +1: Instead of the two solar pumps, one pump and a three-way valve are used

(pump-valve system). The speed control (if activated) only operated when filling TK 1 (T3).

A1... common pump

A2... Valve (A2/S receives power when filling tank TK2)

All Programs +2: Output A4 is used for burner requirement with separated on and off

thresholds instead of feed pump function.

A1 = T1 > (T3 + diff1) & T3 < max1

A2 = T1 > (T4 + diff2) & T4 < max2

A3 = T6 > (T2 + diff3) & T6 > min2 & T2 < max3

A4 (on) = T6 < min1 A4 (off) = T5 > max4

Program A4: The feed pump function of output A4 is active between boiler T5 and tank 1 T2.

A1 = T1 > (T3 + diff1) & T3 < max1

A2 = T1 > (T4 + diff2) & T4 < max2

A3 = T6 > (T2 + diff3) & T6 > min2 & T2 < max3

A4 = T5 > (T2 & diff4) & T5 > min1 & T2 < max4

Program A6: Burner requirement A4 (on), when T5 < min1

Burner requirement A4 (off), when T2 > max4

A1 = T1 > (T3 + diff1) & T3 < max1

A2 = T1 > (T4 + diff2) & T4 < max2

A3 = T6 > (T2 + diff3) & T6 > min2 & T2 < max3

A4 (on) = T5 < min1 A4 (off) = T2 > max4

T1 T6

min2

diff1 diff2 diff3

A1 A2 A3

T3 T4 T2

max1 max2 max3

Required settings:

diff1 …coll. T1 – TK1 T3 A1

diff2 …coll. T1 – TK2 T4 A2

diff3 …TK2 T6 – TK1 T2 A3

min1 …burner requ. ON T6 A4

min2 …switch-on temp. TK2 T6 A3

max1 …limit TK1 T3 A1

max2 …limit TK2 T4 A2

max3 …limit TK1 T2 A3

max4 …burner requ. OFF T5 A4

Additional: Priority Vorr:

(typical: A11, A22, A30, A40)

Burner A4

T6 min1

T5 max4

Page 28

Diagram B0

28

Diagram B0: Solar power system, 2 feed pump functions, burner requirement

Sensors Outputs

T1…. Collector A1…. Solar pump

T2…. Tank TK2 bottom A2…. Feed pump TK2

T3…. Tank TK1 center A3…. Feed pump TK1

T4…. Tank TK1 bottom A4…. Burner requirement

T5…. Tank TK1 top

T6…. Boiler

Program B0: Function according to diagram.

A1 = T1 > (T4 + diff1) & T4 < max1

A2 = T5 > (T2 + diff2) & T5 > min1 & T2 < max2

A3 = T6 > (T3 + diff3) & T6 > min2 & T3 < max3

A4 (on) = T5 < max4 – hysteresis

A4 (off) = T5 > max4

T1 T5 T6

min1 min2

diff1 diff2 diff3

A1 A2 A3

T4 T2 T3

max1 max2 max3

Required settings:

diff1 …coll. T1 – TP1 T4 A1

diff2 …TK1 top T5 – TK2 T2 A2

diff3 …boiler T6 – TK1 T3 A3

diff4 …see all programs +1

min1 …switch-on temp. TK1 T5 A2

min2 …switch-on temp. boiler T6 A3

max1 …limit TK1 T4 A1

max2 …limit TK2 T2 A2

max3 …limit TK1 T3 A3

max4 …burner requirement T5 A4

Burner A4

T5 max4

Burner

requirement

TK1 TK2

Page 29

Diagram B0

29

All Programs +1: The feeding of the hot water tank is normally done by the difference buffer

T5 – hot water tank T2. This program considers also the boiler temperature T6.

A1 = T1 > (T4 + diff1) & T4 < max1

A2 = T5 > (T2 + diff2) & T2 < max2 & T5 > min1

or T6 > (T2 + diff4) & T2 < max2 & T6 > min2

A3 = T6 > (T3 + diff3) & T3 < max3 & T6 > min2

A4 (on) = T5 < max4 – hysteresis

A4 (off) = T5 > max4

All Programs +2: Separated on and off thresholds for the burner requirement

A3 = T6 > (T3 + diff3) & T6 > min2

A4 (on) = T5 < max3

A4 (off) = T3 > max4

All Programs +4: Diagram with solid fuel boiler instead of a solar power system. The threshold min1 affects not at T5 but at T1.

T1 T5 T6

min1 min2

diff1 diff2 diff4 diff3

A1 A2 A2 A3

T4 T2 T3

max1 max2 max3

Required settings:

diff1 …coll. T1 – TP1 T4 A1

diff2 …TK1 top T5 – TK2 T2 A2

diff3 …boiler T6 – TK1 T3 A3

diff4 …boiler T6 – TK2 T2 A2

min1 …switch-on temp. TK1 T5 A2

min2 …switch-on temp. boiler T6 A2, 3

max1 …limit TK1 T4 A1

max2 …limit TK2 T2 A2

max3 …limit TK1 T3 A3

max4 …burner requirement T5 A4

Burner A4

T5 max4

Page 30

Diagram C0

30

Diagram C0: Solar power system with 3 consumers, bypass function

Sensors Outputs

T1…. Flow solar loop A1…. Primary solar pump

T2…. Tank TK1 A2…. Solar pump TK1

T3…. Tank TK2 A3…. Solar pump TK2

T4…. Tank Tk3 A4…. Solar pump TK3

T5…. Freely usable

T6…. Collector

Program C0: Function according to diagram. The primary and the secondary side are sepa-

rated hydraulically. The secondary pumps are switched separated from the primary pumps.

A1 = (T6 > (T2 + diff1) or T6 > (T3 + diff1) or T6 > (T4 + diff1))

& T6 > min2 & (T2 < max2 or T3 < max3 or T4 < max4)

A2 = T1 > (T2 + diff2) & T1 > min1 & T2 < max2

A3 = T1 > (T3 + diff3) & T1 > min1 & T3 < max3

A4 = T1 > (T4 + diff4) & T1 > min1 & T4 < max4

T6 T1

min2 min1

diff1 diff1 diff2 diff4

A1 A1 A2 A4

diff1 diff3

A1 A3

T2 T3 T4

max2 max3 max4

Required settings:

diff1 …coll. T6 – TK T2, T3, T4 A1

diff2 …flow T1 – TK1 T2 A2

diff3 …flow T1 – TK2 T3 A3

diff4 …flow T1 – TK3 T4 A4

min1 switch-on temp. flow T1 A2,A3,A4

min2 …switch-on temp. coll. T6 A1

max2 …limit TK1 T2 A1,2

max3 …limit TK2 T3 A1,3

max4 …limit TK3 T4 A1,4

Additional: Priority Vorr:

(typical: A10, A21, A32, A43)

TK3 TK2 TK1

Page 31

Diagram C0

31

All Programs +1:

Instead of both pumps A2 and A3 one pump A2 and a three-way valve A3 are deployed.

(pump-valve system between TK1 and TK2).

A2... common pump or bypass valve

A3... Valve (A3/S receives power when filling tank TK2 (T3))

All Programs +2:

Instead of both pumps A2 and A4 one pump A2 and a three-way valve A4 are deployed.

(pump-valve system between TK1 and TK3).

A2... common pump or bypass valve

A4... Valve (A4/S receives power when filling tank TK3 (T4))

All Programs +4: If all of the tanks have reached their maximum temperature, loading to

TK2 (T3) continues regardless of max3.

Page 32

Diagram D0

32

T1 T2 T3 T6

min1 min2

diff1 diff2 diff3 diff4

A1 A2 A3 A4

T4 T5

max1 max4

max2

max3

Required settings:

diff1 …coll. T1 – SP1 T4 A1

diff2 …heat source T2 – TK1 T4 A2

diff3 …boiler T3 – TK1 T4 A3

diff4 …TK1 T6 – TK2 T5 A4

min1 …heat source T2 A2

min2 …boiler T3 A3

max1 …limit TK1 T4 A1

max2 …limit TK1 T4 A2

max3 …limit TK1 T4 A3

max4 …limit TK2 T5 A4

Diagram D0: Simple solar power system, 2 feed pumps, feed pump for domestic hot

water tank

Sensors Outputs

T1…. Collector A1…. Solar pump

T2…. Heat source A2…. Feed pump TK1

T3…. Boiler A3…. Feed pump TK1

T4…. Tank TK1 bottom A4…. Feed pump TK2

T5…. Tank TK2 bottom

T6…. Tank TK1 top

Program D0: Function according to diagram.

A1 = T1 > (T4 + diff1) & T4 < max1

A2 = T2 > (T4 + diff2) & T2 > min1 & T4 < max2

A3 = T3 > (T4 + diff3) & T3 > min2 & T4 < max3

A4 = T6 > (T5 + diff4) & T5 < max4

E.g. heat recovery

TK1

TK2

Page 33

Diagram D0

33

Program D1: Threshold min2 is active at sensor T6 and switches output A4.

Program D2: instead of the independent temperature difference between T6 and T5 the dif-

ference between T6 and T4 applies. Hence it is possible to heat one consumer from four

generators.

A4 = T6 > (T4 + diff4) & T4 < max4

Program D4: Sensor T3 will be compared with T5 additionally to sensor T4. Hence the boiler

can feed tank TK1 (T4) as well as tank TK2 (T5).

A1 = T1 > (T4 + diff1) & T4 < max1

A2 = T2 > (T4 + diff2) & T2 > min1 & T4 < max2

A3 = T3 > (T4 + diff3) & T3 > min2 & T4 < max3

A4 = T6 > (T5 + diff4) & T5 < max4

or T3 > (T5 + diff4) & T3 > min2 & T5 < max4

T1 T2 T3 T6

min1 min2

diff1 diff2 diff3 diff4

A1 A2 A3 A4

T4

max1

max2

max3

max4

Required settings:

diff1 …coll. T1 – TK T4 A1

diff2 …heat source T2 – TK T4 A2

diff3 …boiler T3 – TK T4 A3

diff4 …heat sourceT6 – TK T4 A4

min1 …heat source T2 A2

min2 …boiler T3 A3

max1 …limit TK1 T4 A1

max2 …limit TK1 T4 A2

max3 …limit TK1 T4 A3

max4 …limit TK1 T4 A4

T1 T2 T3 T6

min1 min2

diff1 diff2 diff3 diff4 diff4

A1 A2 A3 A4 A4

T4 T5

max1 max4

max2

max3

Required settings:

diff1 …coll. T1 – TK1 T4 A1

diff2 …heat source T2 – TK1 T4 A2

diff3 …boiler T3 – TK1 T4 A3

diff4 …TK1 T6 – TK2 T5 A4

boiler T3 – TK2 T5 A4

min1 …heat source T2 A2

min2 …boiler T3 A3, A4

max1 …limit TK1 T4 A1

max2 …limit TK1 T4 A2

max3 …limit TK1 T4 A3

max4 …limit TK2 T5 A4

Page 34

Diagram D0

34

Program D5: Instead of the independent temperature difference T6 – T5 the controller compares the sensors T6 and T3.

A1 = T1 > (T4 + diff1) & T4 < max1

A2 = T2 > (T4 + diff2) & T2 > min1 & T4 < max2

A3 = T3 > (T4 + diff3) & T4 < max3

A4 = T6 > (T3 + diff4) & T6 > min2 & T3 < max4

Program D6: Output A4 switches only because of the following function.

A1 = T1 > (T4 + diff1) & T4 < max1

A2 = T2 > (T4 + diff2) & T2 > min1 & T4 < max2

A3 = T3 > (T4 + diff3) & T3 > min2 & T4 < max3

A4 = T4 > (T5 + diff4) & T5 < max4

Program D7: Outputs A3 and A4 switch only because of the following function.

A3 = T3 > (T4 + diff3) & T4 < max3

A4 = T4 > (T5 + diff4) & T4 > min2 & T5 < max4

T1 T2 T3

min1 min2

diff1 diff2 diff3

A1 A2 A3

T4

max1

max2

max3

diff4 / A4

T5

max4

Required settings:

diff1 …coll. T1 – TK1 T4 A1

diff2 …heat source T2 – TK1 T4 A2

diff3 …boiler T3 – TK1 T4 A3

diff4 …TK1 T4 – TK2 T5 A4

min1 …heat source T2 A2

min2 …boiler T3 A3

max1 …limit TK1 T4 A1

max2 …limit TK1 T4 A2

max3 …limit TK1 T4 A3

max4 …limit TK2 T5 A4

T6

min2

diff4

A4

T1 T2 T3

min1 max4

diff1 diff2 diff3

A1 A2 A3

T4

max1

max2

max3

Required settings:

diff1 …coll. T1 – TK1 T4 A1

diff2 …heat source. T2 – TK1 T4 A2

diff3 …sensor T3 – TK1 T4 A3

diff4 …sensor T6 – sensor T3 A4

min1 …heat source T2 A2

min2 …Sensor T6 A4

max1 …limit TK1 T4 A1

max2 …limit TK1 T4 A2

max3 …limit TK1 T4 A3

max4 …limit sensor T3 A4

Page 35

Installing instructions

35

Installing instructions

Installing the sensor(s):

The sensors must be arranged and installed properly for the system to function correctly.

To this end, make sure that they are completely inserted in the immersion sleeves. The

threaded cable connections provided can be used to provide strain relief. The clip-on sensors

must be insulated to protect them from being influenced by the ambient temperature. Water

must be kept out of the immersion sleeves when used outdoors (damage from freezing).

In general, the sensors may not be exposed to moisture (such as condensation water),

which might enter the cast resin and damage the sensor. If this happens, heating the sensor

to 90°C for an hour might help. When using immersion sleeves in NIRO tanks (inoxydable) or

pools, pay attention to their non-corrosion properties.

Collector sensor (red or black cable with connection box): Insert either in the tube

directly soldered or riveted to the absorber and sticking out of the collector’s frame or

in a t-shaped connector on the outer collector’s supply line collector tube. Screw an

immersion sleeve with an MS (brass) threaded cable connection (= to protect from

moisture) into this T-shaped connector and insert the sensor. To protect from lightening, the connection box has parallel overvoltage protection between the sensor and

the extension cable.

Boiler sensor (boiler supply line): This sensor is either screwed into the boiler with

an immersion sleeve or attached to the boiler’s supply line at a slight distance.

Tank sensor: The sensor that the solar power system needs should be used with an

immersion sleeve for fin coil heat exchangers just above the exchanger or, if integrated bare-tube heat exchangers are used, on the lower third of the exchanger or the exchanger’s return line so that the immersion sleeve is inside the exchanger’s tube. The

sensor that monitors the heating of the tank from the boiler is installed at the level of

the desired amount of hot water during the heating season. The plastic threaded cable

connections provided can be used to provide strain relief. They must not be installed

below the register / exchanger.

Buffer sensor: The sensor that the solar power system needs is installed on the bot-

tom of the tank just below the solar heat exchanger using the immersion sleeve provided. The plastic threaded cable connections provided can be used to provide strain

relief. It is recommended that the sensor be used between the middle and the upper

third of the buffer tank using the immersion sleeve as a reference sensor for the heat-

er’s hydraulics or - flush with the tank’s wall - under the insulation.

Pool sensor (swimming pool): Put a T-shaped connector on the suction line imme-

diately on the line leading from the pool and screw the sensor in with an immersion

sleeve. In the process, make sure that the material used is non-corroding. Another option is to put the sensor on the same spot using hose clamps or adhesive tape and to

provide thermal insulation for ambient influences.

Clip-on sensor: Use pipe clamps, hose clamps, and the like must be attached to the

respective line. Make sure that suitable material is used (corrosion and temperature

resistance, etc.). Then, the sensor has to be well insulated so that the tube temperature can be taken exactly and influences from the ambient temperature can be ruled

out.

Page 36

Installing instructions

36

Hot water sensor: When the control system is used in hot water systems with an ex-

ternal heat exchanger and variable-speed pump, changes in the amount of tempera-

ture have to be reacted to quickly. Hence, the hot water sensor has to be put directly

on the heat exchanger’s outlet. A t-shaped connector should be used to insert the ultrafast sensor (special accessory) in the outlet using an O-ring along the NIRO tube

(inoxydable). The heat exchanger has to be installed upright with the hot water outlet

on top.

Radiation sensor: To get a measurement according to the collector’s position, it

should be parallel to the collector. It should thus be screwed onto the metal sheet or

next to the collector along an extension of the assembly rail. To this end, the sensor case has a blind hole that can be opened at any time.

Line extension

All of the sensor cables with a cross-section of 0.75mm2 can be extended up to 30m. Beyond

30m they can be extended by use of a suitably larger cross section. The sensor and the

probe can be connected by putting the heat-shrinkable sleeve truncated to 4 cm over a wire

and twisting the bare ends. Then the heat-shrinkable sleeve is put over the bare, twisted

ends and carefully heated (such as with a lighter) until it has wrapped the connection tightly.

Cable laying

In order to obtain interference-free signal transmission (to avoid measurement fluctuations)

the sensor lines must not be subject to interference factors. With the generally accepted use

of unshielded cables sensor lines are to be laid in their own cable channel at least 20 cm

away from mains cables.

Page 37

Installing instructions

37

Installing the unit

CAUTION! ALWAYS PULL THE MAINS PLUG BEFORE OPENING THE CASE!

Unscrew the 4 screws at the edges of the case. The controlling electronic is situated in the

cover plate and is connected by a ribbon cable to the mains module, which is set in the basin

of the case. The basin of the case can be screwed on through the two holes to the wall using

the fastening screws provided (with the cable bushings downwards). For easier handling

the mains module can be token out of the case.

Electrical connection:

Warning: The electrical connection should only be made by a professional electrician in

accordance with the relevant local guidelines. The sensor lines may not be fed through the

same cable channel as the supply voltage.

Attention: Only work on the control system when it is dead. Assembling the device should

always be done without tension.

All sensors and pumps resp. valves must be connected to the controller according to the

numbering of the chosen diagram.

Sensors 1 - 6 and data line DL

The relay output A4 can be made potential-free by setting the jumpers J1-J2-J3. For this

purpose the jumper J2 must be set in the center instead of jumpers J1 and J3 (standard).

All sensor ground wires are internally looped and can be exchanged as need be.

Page 38

Installing instructions

38

W..... root C

S...... make contact NO

Ö...... break contact NC

Note: The system has to be grounded properly to protect it from damage due to lightening.

Sensor failures due to storms and static electricity are usually the result of improper ground-

ing.

Data line (DL)

The data line was specially developed for the UVR series and is only compatible with the

products of Technische Alternative. It is only made for generating outputs and is suitable as

interface to the PC for transferring the measured temperatures and output states.

Any cable with a cross section of 0.75 mm² can be used for the data link (e.g. twin-strand)

having a max. length of 30 m. For longer cables, we recommend the use of shielded cable.

Interface to PC: The data is cached via the data converter D-LOGG or boot loader

BL-NET and transferred to the PC on request. An individual power pack (CAN-NT) is necessary for supplying power to the BL-NET!

sensor

sensor

sensor

sensor

sensor

sensor

data line

Page 39

Selector switch

39

Selector switch

The selector switch has 16 different positions. Each position has two functions (e.g. switch

position diff2 / T2). The value, which is nearer to the selector switch, will be displayed without

pressing of the yellow key “Eingabe” (e.g. T2). By pressing the yellow key “Eingabe” (= input) the second value will be displayed (e.g. diff2). The blue keys “ab” (= down) resp. “auf”

(= up) change the settings. Holding the key pressed increases resp. decreases constantly the

value, short taps cause a change of 1.

The interior legend (e.g. T5 = displayed temperature of sensor 5) has no direct connection

to the outside legend (e.g. min1 = temperature limit of the tank). E.g. in diagram 0 the sensor

T5 has connection with min1, but T3 corresponds with max1.

T1 - T6

Actual temperature of the sensors

A1 - A4

State of the outputs („Ein“ = ON, „Aut“ = automatic mode, „Aus“ = OFF)

The changing occurs by pressing the blue keys ab/auf (down/up).

diff1 - 4

Difference temperatures, setting range: 0 to 99 K

min1, 2

Minimal thresholds, setting range: 0 to 150 °C

max1 - 4

Limit of storage temperature, setting range: 0 to 150 °C

F1e - F3e

Switch-on time of time windows 1 to 3

F1a - F3a

Switch-off time of time windows 1 to 3

Uhr

Time (resolution: 10 minutes), setting by the blue keys ab/auf (down/up).

F>A

Assignment menu (which time window interacts with which output)

Setting: see chapter „Assignment of the time windows”

Prog Selection of the program number according to the chosen diagram. The pro-

gram number defines the basic function of the controller and is the most im-

portant input. Setting by the blue keys ab/auf (down/up)

Vorr Priority menu. Assignment of priority 0 to 4 to the outputs: 0 = no priority, 1 =

highest, 4 = lowest priority; setting: see chapter “Assignment of priority”

Vers

Actual software version (important for enquiry calls); it cannot be changed.

Menü

Main menu for access to the sub menus of the controller

Page 40

Selector switch

40

diff: The output will be released, when the temperature difference between two set sensors

exceeds this value. diff is the basic function (differential control) of this unit for most

programs. Recommendation: In solar applications, diff should be set to 7 - 10K.

Somewhat lower values suffice for the feed pump program. The hysteresis has an increasing effect, i.e. reaching the temperature difference plus hysteresis the output will

switch on, falling below the difference it will switch off. (ex works = 5,0K)

min: The minimal threshold min generally prevents boilers from being clogged with soot.

Recommended value in this case: 60 to 70°C. The hysteresis has an increasing effect,

i.e. reaching the threshold plus hysteresis the output will switch on, falling below the

threshold it will switch off. (ex works = 0°C)

max: The maximum function limits the storage of tanks. The hysteresis has a decreasing ef-

fect, i.e. reaching the threshold the output will switch off, falling below the threshold

minus hysteresis it will switch on again. (ex works = 90 °C)

Schematic representation of setting values:

F1e: Switch-on time (e) of first time window (F1). The time window function allows blocking

or enabling an output additionally to the conditions of a program. A total of three time

windows stands by.

F1a: Switch-off time (a) of first time window (F1).

Page 41

Selector switch

41

Uhr: Setting of the actual time, important for correct function of time windows. The controller

has a power reserve of approx. 24 hours, i.e. when blackout longer than 24 hours occurs, time must be set again.

F>A: Menu for assignment of each time window to one of the 4 outputs.

Assignment of time windows (F>A)

Position of selector switch: Uhr / F>A

Pressing the yellow „Eingabe“ key for 2 seconds causes entry or exit

to/from the sub menu

normal (short) pressing switches from one position to the next

The value can be changed with the blue keys ab/auf (down/up).

ew

ex works = original setting by the factory

14.5 – actual time = 2:50 pm. Setting by pressing the blue keys ab/auf.

Pressing the yellow „Eingabe“ key for 2 seconds causes entry to the

sub menu F>A

F14 – Assignment of time window 1 to output A4. In the time window

(F1e – F1a) the respective program determines the status of the selected output (A4). Outside the time window it is switched off.

ew = F10 (time window 1 inactive)

F23 - Assignment of time window 2 to output A3. In the time window

(F2e – F2a) the respective program determines the status of the selected output (A3). Outside the time window it is switched off.

ew = F20 (time window 2 inactive)

F30 – Time window F3e – F3a is not assigned to an output. Therefore it

is inactive.

ew = F30 (time window 3 inactive)

F14 – Pressing the yellow „Eingabe“ key at the end of the menu, the run

starts again. Going back to normal operation happens by pressing the

yellow key „Eingabe“ for 2 seconds, turning the selector switch or auto-

matically after one minute.

Page 42

Selector switch

42

Program selection (Progr.), assignment of priority (Vorr.)

Position of selector switch: Prog. / Vorr.

Pressing the yellow „Eingabe“ key for 2 seconds causes entry or exit

to/from the sub menu

normal (short) pressing switches from one position to the next

The value can be changed with the blue keys ab/auf (down/up).

ew

ex works = original setting by the factory

P16 – Actual used program : 16

Setting by pressing the blue keys ab/auf.

Pressing the yellow „Eingabe” key for 2 seconds causes entry to the

sub menu Vorr. (= priority)

A12 – Assignment of second priority to the output A1. I.e. the output

will be enabled, when all superior outputs with priority 1 are switched

off.

ew = A10 (output A1 switches independently)

A21 – Output A2 has the highest priority 1.

ew = A20 (output A2 switches independently)

A31 – Output A3 has the same (highest) priority 1 as A2.

ew = A30 (output A3 switches independently)

A40 – Output A4 has assigned no priority. It can switch independently

from all other outputs.

ew = A40 (output A4 switches independently)

A12 – Pressing the yellow „Eingabe” key at the end of the menu, the

run starts again. Going back to normal operation happens by pressing

the yellow „Eingabe” key for 2 seconds, turning the selector switch or

automatically after one minute.

Vers: In this switch position the software version of the computer is displayed (e.g. E5.2). It

shows the “intelligence” of the controller and must be advertised to the manufacturer

for enquiry calls. It cannot be changed.

Menü: „Menü“ (= menu) allows the setting of about 50 different parameters, which are set ex

works to standard settings. Sometimes it is necessary to change them. A change of

these values should only be done, if the user has knowledge of all functions as these

settings can change the basic features of the controller. Different parameters are

stored in sub menus.

Page 43

Additional functions

43

Additional functions

Programming procedure („Menü“)

Position of selector switch: Vers. / Menü

Pressing the yellow „Eingabe“ key for 2 seconds causes entry or exit

to/from the sub menu

normal (short) pressing switches from one position to the next

The value can be changed with the blue keys ab/auf (down/up).

ew

ex works = original setting by the factory

E5.0 – software version of controller: It shows the „intelligence“ of the

device and cannot be changed.

Pressing the yellow „Eingabe“ key for 2 seconds causes entry to the

sub menu section

SEn – sensor type: Selection of sensor type KTY (=semi-conductor)

or Pt1000 (=platinum)

ew = all sensors Pt1000

Entry to sub menu „sensor type“

FCo – function control: Activating of the detection function (sensor

failure, circulation problems). Error messages are displayed, if a failure

occurs.

ew = function control deactivated

Entry to sub menu „function control“

Utb – collector excess temperature limit – switch-off function when

too high collector temperature occurs.

ew = collector excess temperature limit function active

Entry to sub menu „collector excess temperature limit“

StF – start function: settings for start-up of pumps in time for solar

power systems (ideal for tube collectors)

ew = start function deactivated

Entry to sub menu “start function”

Pri – solar priority: settings for priority conditions

ew = all values are set to „standard system“

Entry to sub menu „solar priority“

PnL – after-running time: Settings for each output

ew = no after-running times

Page 44

Additional functions

44

Entry to sub menu „ after-running time “

HSt – hystereses: Setting of the hystereses for exact balancing of the

system

ew = all hystereses at 3K per 64°C

Entry to sub menu „ hystereses “

Pd1 – pump speed control for output A1: Sub menu for the speed

processor for activation and alignment of speed control for output A1

ew = pump speed control function deactivated

Entry to sub menu „pump speed control output 1“

Pd2 - pump speed control for output A2: Sub menu for the speed

processor for activation and alignment of speed control for output A2

ew = pump speed control function deactivated

Entry to sub menu „pump speed control output 2“

Hau – auxiliary output A5: Linking of the auxiliary output A5 to the

outputs A1 – A4 and the time windows F1 – f3

ew = AUS (=off) (auxiliary output switched off)

Entry to sub menu „ auxiliary output A5 “

End – end of the passage: the passage can be repeated. Exit from

each display to normal operation happens by pressing the yellow

„Eingabe“ key for 2 seconds, turning the selector switch or automati-

cally after one minute.

Page 45

Additional functions

45

Sensor type

Solar collectors reach standstill temperatures of 200 to 300°C. No value above 200°C is

expected due to the sensor installation point and physical properties (dry steam does not

conduct heat well, for instance). The standard Pt1000 series sensors can be permanently

exposed to 250°C and briefly to 300°C. KTY10 sensors are designed for brief use at 200°C.

The Sensor type menu enables changing over of the individual sensor inputs between

Pt1000 and KTY types.

As default factory setting all inputs are set to Pt1000 type.

F1P – Sensor 1 is set to Pt1000 (standard). Changing to KTY by

pressing the blue “ab/auf” keys (down/up). A short tap at the yellow key

“Eingabe” switches to the next sensor.

ew = F1P

F2H – Sensor 2 is set to KTY .

ew = F2P

F3H - Sensor 3 is set to KTY.

ew = F3P

ew = F4P

ew = F5P

F6H – Sensor 6 is set to KTY. A short tap at the yellow key “Eingabe”

switches back to the first sensor. The passage can be repeated.

ew = F6P

The radiation sensor GBS can be connected to each sensor input (sensor type KTY) and

assigned to the start or the priority function.

Page 46

Additional functions

46

Function control

Function control allows detection of sensor interruption or short circuit (error code FF1 –

FF6), missing circulation caused by too high temperatures (>40K) between solar panel and

consumer after 10 minutes pump-run (error code FF7) and circulation error (error code FF8)

of the solar power system.

For detection of circulation error a temperature sensor gets a threshold temperature. Circulation error applies, if the sensor exceeds the set threshold temperature between 00:00 to 5:00

am.

If an error occurs the display shows alternating to the usual display an error code in

one-second-intervals.

FF1...... FF6......Short circuit or interruption T1 to T6

FF7...... Temperature difference between solar collector and tank is more than 40K after

10 minutes pump run. Probably no circulation!

FF8...... Circulation error. The sensor selected under Fc has exceeded the temperature

threshold L in the period 00:00 to 05:00 am.

F1J – Function control – sensor T1 „J(a)“ (=Yes): Sensor T1 is monitored for

interruption and short circuit. If an error occurs the message “FF1” (=function

error at sensor T1) will be displayed during normal operation

ew = F1n

F2n – Function control – sensor T2 “no”: Sensor T2 is not monitored. Never-

theless during normal operation an interruption (= 999°C) or a short circuit

(= -99°C) will be displayed at the sensor temperatures.

ew = F2n

ew = F3n

ew = F4n

ew = F5n

F6n – Function control – sensor T6 “no”

ew = F6n

FdJ – Function control – difference temperature “J(a)” (=Yes): If in the just ac-

tive solar circuit after more than 10 minutes pump run the temperature difference is still more than 40K, an error code FF7 is displayed.

ew = Fdn

Fc4 – Function control – circulation error at sensor T4. If sensor T4 exceeds

between 00:00 and 05:00 am the value “L”, error code FF8 is displayed during

normal operation.

ew = Fc0 (off)

L35 – Increases the temperature at sensor „Fc“ between 00:00 and 05:00 am

over 35°C the error code FF8 is displayed. “L” will not be displayed, if function

control for circulation error is not activated.

ew = 70

Page 47

Additional functions

47

Collector excess temperature limit

Steam builds up when the system is not circulating. When it automatically switches on

again, the pump does not have the pressure to lift the fluid level above the highest point in

the system (collector feed line). If there is no circulation, the load on the pump is enormous.

This function allows the pump to be blocked above a set collector temperature threshold until

a second set threshold is fallen short of.

Temperature above which the output is to be blocked (as long as the

output is set to „automatic“)

ew = 140

Temperature threshold releasing the output.

ew = 100

The higher temperature is the switch-off temperature; the lower is the temperature, at

which the solar pump will be switched on again.

Switch-off temperature can be set up to 199°C. Setting over this value „AUS“ is displayed

(=off). That means that the function is deactivated.

Page 48

Additional functions

48

Start function (ideal for tube collectors)

In the morning, solar power systems sometimes do not “start” quickly

enough because the warm heat transfer medium does not reach the collector sensor. Flat

collector panels and forced-circulation vacuum tubes generally lack sufficient gravitational

force.

The start function tries to release a rising interval while the collector temperature is constantly monitored. The computer first determines the weather conditions based on the constant measurements of the collector temperatures. It thus determines the right time for a

short rinsing interval to maintain the actual temperature for normal operation.

When the radiation sensor is used, the solar radiation is used for the calculation of the start

function (radiation sensor GBS 01 - non-standard accessory).

The start function is deactivated ex works.

A 1 – Activation of start function. A 1 means start function active, A 0 =

start function deactivated

ew = A 0

F 3 – Connection of a radiation sensor to sensor input T3. F 0 means,

that the average temperature (long-term mean regardless of the weather)

is calculated instead of the radiation sensor value.

ew = F 0

c20 – radiation threshold 200W/m², above which rinsing is allowed.

Without a radiation sensor, the computer calculates the necessary temperature increase for the long-term mean that launches rinsing from this

value.

ew = 15

r15 – Pump runtime (rinsing time) in seconds. During this time, the

pump should have pumped roughly half of the content of the collector’s

heat transfer medium past the collector sensor.

ew = 15

i35 – Maximum allowable interval between two rinses in minutes (exam-

ple: 35 minutes). This time is automatically reduced according to the

temperature increase after rinsing.

ew = 20

n 4 – Number of start attempts (= counter). The system is automatically

reset for a start attempt if the last start attempt was more than four hours

ago.

Page 49

Additional functions

49

Priority menu

When the consumers with lower priority are being filled, the unit monitors

the irradiation at the radiation sensor or the collector temperature. If a radiation threshold C is

reached or the collector temperature is exceeded by a value calculated from the threshold for

the low-priority consumer, the priority timer is activated. The pump then switches off for a set

waiting time of 60 sec (waiting time 1)

After the rinsing time (1, 3), the computer calculates the increase in collector temperature.

It detects whether the set waiting time tA has been reached to heat the collector to the priority

temperature. In the second case, the unit waits until the priority has been reached to switch.

If the computer detects that the increase will not suffice within the tA time (4, 5), it discontin-

ues the process and reactivates the time again after tL. At tL=0, the low-priority is only al-

lowed when the maximum threshold for the priority is reached (=absolute priority).

F 4 – Sensor T4 is a radiation sensor starting the priority timer. If the ra-

diation sensor exceeds the radiation threshold “c”, the priority timer is

launched. Without the radiation sensor, the launch is based on the collector temperature. Setting range: F0 (= no radiation sensor) to F4

ew = F 0

c20 – radiation threshold in W/m² (e.g. 200 W/m²) above which rinsing

is allowed. Without a radiation sensor (F 0), the computer calculates the

necessary temperature increase for the long-term mean that launches

rinsing from this value. Setting range: c 0 to 99

ew = 30

tA5 – Waiting time of low priority (5 minutes). This is the time in which

the collector should reach the temperature necessary for priority operation. Setting range: 0 to 9 minutes (tA0 to tA9)

ew = 5

tL3 – Pump run-time of low-priority (e.g. 30 minutes). If the solar radia-