Page 1

TMA

Thermomechanical

Analyzer

Revision D

Issued November 2006

TMA Q Series Getting Started Guide

Q Series

Getting Started Guide

1

Page 2

©2003, 2004 by TA Instruments—Waters LLC

109 Lukens Drive

New Castle, DE 19720

Notice

The material contained in this manual, and in the online help for the software used to support this instrument,

is believed adequate for the intended use of the instrument. If the instrument or procedures are used for purposes other than those specified herein, confirmation of their suitability must be obtained from TA Instruments.

Otherwise, TA Instruments does not guarantee any results and assumes no obligation or liability. TA Instruments also reserves the right to revise this document and to make changes without notice.

TA Instruments may have patents, patent applications, trademarks, copyrights, or other intellectual property

covering subject matter in this document. Except as expressly provided in written license agreement from TA

Instrument, the furnishing of this document does not give you any license to these patents, trademarks, copyrights, or other intellectual property.

TA Instruments Operating Software, as well as Module, Data Analysis, and Utility Software and their associated manuals and online help, are proprietary and copyrighted by TA Instruments. Purchasers are granted a

license to use these software programs on the module and controller with which they were purchased. These

programs may not be duplicated by the purchaser without the prior written consent of TA Instruments. Each

licensed program shall remain the exclusive property of TA Instruments, and no rights or licenses are granted to

the purchaser other than as specified above.

2

TMA Q Series Getting Started Guide

Page 3

Important: TA Instruments Manual Supplement

Please click on the links below to access important information supplemental to this

Getting Started Guide:

TA Instruments Trademarks

•

•

TA Instruments Patents

• Other Trademarks

• TA Instruments End-User License Agreement

• TA Instruments Offices

TMA Q Series Getting Started Guide

3

Page 4

Table of Contents

Important: TA Instruments Manual Supplement........................................................................................................ 3

Table of Contents ............................................................................................................................................................. 4

Notes, Cautions, and Warnings .................................................................................................................................... 6

Regulatory Compliance .................................................................................................................................................. 7

Safety Standards ...................................................................................................................................................... 7

Electromagnetic Compatibility Standards ............................................................................................................7

Safety ................................................................................................................................................................................. 8

Instrument Symbols ................................................................................................................................................. 8

Electrical Safety ........................................................................................................................................................ 8

Sample Decomposition ............................................................................................................................................ 9

Lifting the Instrument .............................................................................................................................................. 9

Handling Liquid Nitrogen ...................................................................................................................................... 9

Thermal Safety........................................................................................................................................................ 10

Cleaning the Instrument ........................................................................................................................................10

Chapter 1: Introducing the TMA ...............................................................................................................................11

Overview ........................................................................................................................................................................ 11

TMA System Components ............................................................................................................................................ 11

Standard Accessories ............................................................................................................................................ 12

Subambient Operation ...........................................................................................................................................12

TM

The QTMA Touch Screen with QNX/Platinum

..............................................................................................................................................................................

13

QNX/Platinum Primary Function Keys ............................................................................................................. 13

QNX/Platinum Control Menu ............................................................................................................................. 14

QNX/Platinum Display Touch Screen Options................................................................................................. 16

QNX/Platinum Calibration Options................................................................................................................... 17

The TMA Touch Screen (Original) ...............................................................................................................................18

Primary Function Keys .......................................................................................................................................... 18

TMA Control Menu Keys ....................................................................................................................................... 19

Display Menu Keys ................................................................................................................................................ 20

Options and Accessories .............................................................................................................................................. 21

Probes ...................................................................................................................................................................... 21

Mechanical Cooling Accessory ............................................................................................................................ 21

Instrument Specifications .............................................................................................................................................22

TMA Instrument Characteristics ................................................................................................................... 22

Chapter 2: Installing the TMA ................................................................................................................................... 23

Unpacking/Repacking the TMA ................................................................................................................................ 23

Installing the Instrument ..............................................................................................................................................23

Inspecting the System ............................................................................................................................................ 23

Choosing a Location .............................................................................................................................................. 24

Voltage Configuration Unit ................................................................................................................................... 25

4

TMA Q Series Getting Started Guide

Page 5

Connecting Cables and Lines ............................................................................................................................... 26

Ports .................................................................................................................................................................. 26

Purge Line ........................................................................................................................................................ 27

Connecting the Cooling Gas Line ................................................................................................................. 28

Installing the Stage................................................................................................................................................. 29

Installing the Expansion/Penetration Probes .................................................................................................... 30

Installing a Probe ............................................................................................................................................ 30

Removing a Probe ........................................................................................................................................... 30

Ethernet Switch Setup .................................................................................................................................... 31

Connecting the Instrument to the Switch .............................................................................................. 31

Connecting the Controller to the Switch ............................................................................................... 31

Connecting the Controller to a LAN ......................................................................................................32

Power Switch .......................................................................................................................................................... 33

Power Cable ............................................................................................................................................................ 33

Starting the TMA ........................................................................................................................................................... 34

Shutting Down the TMA .............................................................................................................................................. 34

Chapter 3: Use, Maintenance, & Diagnostics ..........................................................................................................

35

Using the TMA .............................................................................................................................................................. 35

Before You Begin .................................................................................................................................................... 35

Calibrating the TMA ..................................................................................................................................................... 36

Force Calibration .................................................................................................................................................... 36

Probe Calibration ................................................................................................................................................... 36

Temperature Calibration ....................................................................................................................................... 36

Cell Constant .......................................................................................................................................................... 37

Running a TMA Experiment ........................................................................................................................................ 38

Selecting a Probe .................................................................................................................................................... 38

Zeroing the Auto Measure System ....................................................................................................................... 39

Guidelines for Handling Samples ....................................................................................................................... 40

Sample Preparation ........................................................................................................................................40

Sample Loading .............................................................................................................................................. 40

Starting an Experiment ..........................................................................................................................................41

Stopping an Experiment ........................................................................................................................................41

Maintaining the Instrument .........................................................................................................................................42

Cleaning the Touch Screen.................................................................................................................................... 42

Cleaning the Probe Assembly ............................................................................................................................... 42

Cleaning the Stage ................................................................................................................................................. 43

Cleaning the Thermocouple ..................................................................................................................................44

Replacements .................................................................................................................................................................45

Replacing the Thermocouple ................................................................................................................................ 45

Removing the Existing Thermocouple ......................................................................................................... 45

Installing a New Thermocouple ................................................................................................................... 45

Replacing Fuses ..................................................................................................................................................... 47

Replacing the TMA Fuses .............................................................................................................................. 47

Replacement Parts......................................................................................................................................................... 48

Index............................................................................................................................................................................... 51

TMA Q Series Getting Started Guide

5

Page 6

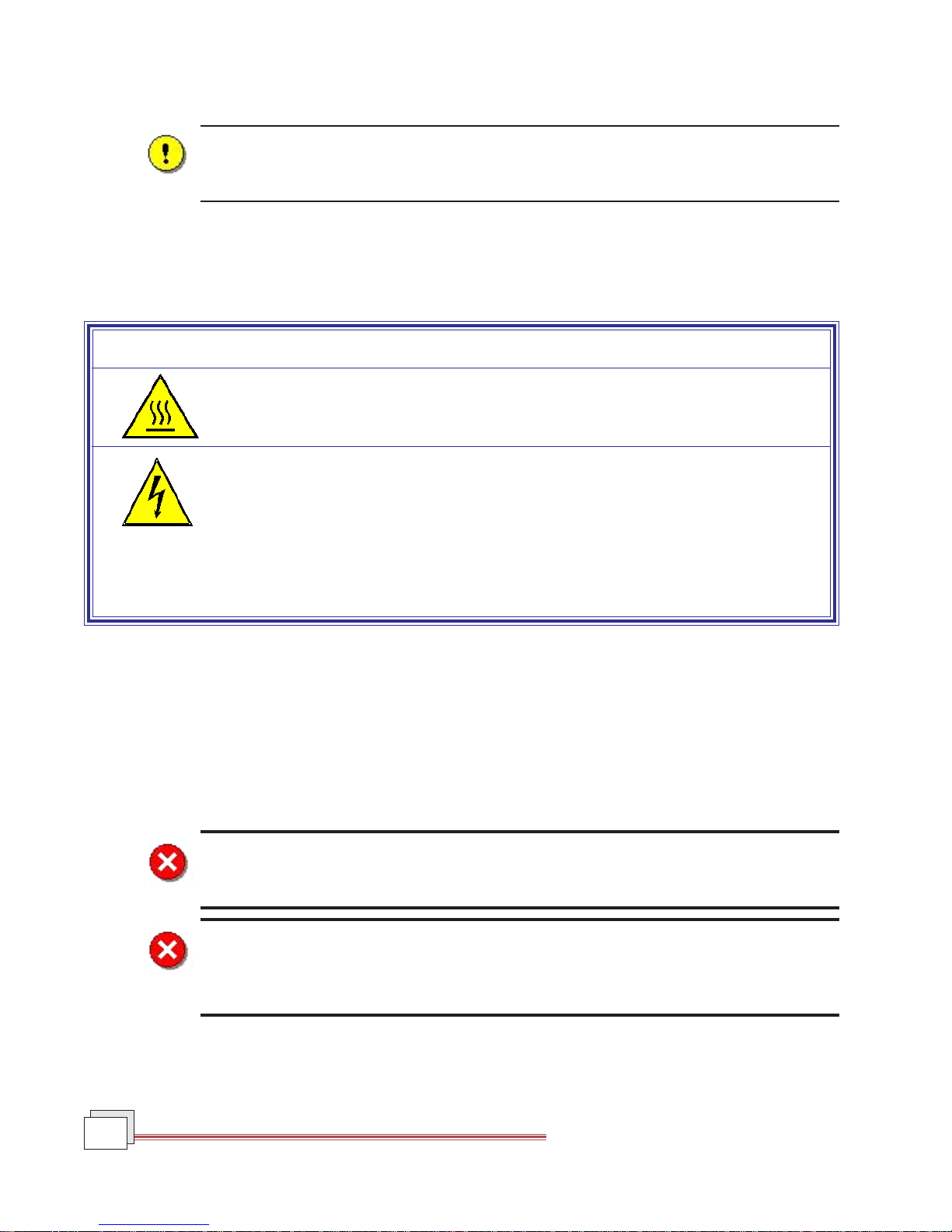

Notes, Cautions, and Warnings

This manual uses NOTES, CAUTIONS, and WARNINGS to emphasize important and critical instructions.

A NOTE highlights important information about equipment or procedures.

A CAUTION emphasizes a procedure that may damage equipment or cause loss of

data if not followed correctly.

A WARNING indicates a procedure that may be hazardous to the operator or to the

environment if not followed correctly.

6

TMA Q Series Getting Started Guide

Page 7

Regulatory Compliance

Safety St andards

For Canada:

CAN/CSA-22.2 No. 1010.1-92 Safety requirements for electrical equipment for measurement, control, and

laboratory use, Part 1: General Requirements + Amendments.

CAN/CSA-22.2 No. 1010.2.010-94 Particular requirements for laboratory equipment for the heating of materials

+ Amendments.

For the European Economic Area: (In accordance with Council Directive 73/23/EEC of 19 February 1973 on the

harmonization of the laws of Member States relating to electrical equipment designed for use within certain

voltage limits.)

EN61010-1: 1993 Safety requirements for electrical equipment for measurement, control, and laboratory use, Part

1: General Requirements + Amendments.

EN61010-2-010: 1994 Particular requirements for laboratory equipment for the heating of materials + Amendments.

For the United States:

UL61010A-1 Electrical Equipment for Laboratory Use; Part 1: General Requirements.

IEC 1010-2-010: 1992 Particular requirements for laboratory equipment for the heating of materials + Amendments.

Electromagnetic Compatibility Standards

For Australia and New Zealand:

AS/NZS 2064: 1997 Limits and methods of measurement of electronic disturbance characteristics of industrial,

scientific and medical (ISM) radiofrequency equipment.

For Canada:

ICES-001 Issue 3 March 7, 1998 Interference-Causing Equipment Standard: Industrial, Scientific, and Medical

Radio Frequency Generators.

For the European Economic Area: (In accordance with Council Directive 89/336/EEC of 3 May 1989 on the

approximation of the laws of the Member States relating to electromagnetic compatibility.)

EN61326-1: 1997 Electrical equipment for measurement, control, and

laboratory use-EMC requirements-Part 1: General Requirements + Amendments. Emissions: Meets Class A

requirements (Table 3). Immunity: Meets performance criteria B for non-continuous operation, minimum

requirements (Table 1).

For the United States:

CFR Title 47 Telecommunication Chapter I Federal Communications Commission, Part 15 Radio frequency

devices (FCC regulation pertaining to radiofrequency emissions).

TMA Q Series Getting Started Guide

7

Page 8

Safety

CAUTION: The operator of this instrument is advised that if the equipment is used in a

manner not specified in this manual, the protection provided by the equipment may

be impaired.

Instrument Symbols

The following labels are displayed on the TMA instrument for your protection:

Symbol Explanation

This symbol indicates that a hot surface may be present. Take care not to touch

these areas or allow any material that may melt or burn to come in contact with

these hot surfaces

This symbol on the rear access panel indicates that you must unplug the instrument before doing any maintenance or repair work; voltages exceeding 120/240

Vac are present in this system.

If you are not trained in electrical procedures, do not remove the cabinet covers

unless specifically instructed to do so in the manual. Maintenance and repair of

internal parts must be performed only by TA Instruments or other qualified

service personnel.

Please heed the warning labels and take the necessary precautions when dealing with those parts of the

instrument. The TMA Getting Started Guide contains cautions and warnings that must be followed for your own

safety.

Electrical Safety

You must unplug the instrument before doing any maintenance or repair work; voltages as high as 120/240 Vac

are present in this system.

WARNING: High voltages are present in this instrument. Maintenance and repair of

internal parts must be performed only by TA Instruments or other qualified service

personnel.

WARNING: After transport or storage in humid conditions, this equipment could fail to

meet certain aspects of the safety requirements of the safety standards indicated.

Refer to the CAUTION on page 24 for the method of drying out the equipment before

use.

8

TMA Q Series Getting Started Guide

Page 9

Sample Decomposition

The TMA is capable of heating samples to 1000°C. Many materials may decompose during the heating, which

can generate hazardous byproducts.

WARNING: If you are using samples that may emit harmful gases, vent the gases by

placing the instrument near an exhaust.

Samples should not be heated above their decomposition temperatures to prevent the relase of hazardous

materials or contamination of the TMA.

Lifting the Instrument

The TMA is a fairly heavy instrument. In order to avoid injury, particularly to the back, please follow this

advice:

WARNING: Close the furnace before moving the instrument, even for a short distance.

Use two people to lift and/or carry the instrument. The instrument is too heavy for one

person to handle safely.

Handling Liquid Nitrogen

The TMA can use the cryogenic (low-temperature) agent, liquid nitrogen, for cooling in subambient experiments.

Because of its low temperature [-195°C (-319°F)], liquid nitrogen will burn the skin. When you work with liquid

nitrogen, use the following precautions:

WARNING: Liquid nitrogen boils rapidly when exposed to room temperature. Be

certain that areas where liquid nitrogen is used are well ventilated to prevent displacement of oxygen in the air.

1. Wear goggles or a face shield, gloves large enough to be removed easily, and a rubber apron. For extra

protection, wear high-topped, sturdy shoes, and leave your pant legs outside the tops.

2. Transfer the liquid slowly to prevent thermal shock to the equipment. Use containers that have satisfactory

low-temperature properties. Ensure that closed containers have vents to relieve pressure.

3. The purity of liquid nitrogen decreases when exposed to air. If the liquid in a container has been open to the

atmosphere for a prolonged period, analyze the remaining liquid before using it for any purpose where high

oxygen content could be dangerous.

TMA Q Series Getting Started Guide

9

Page 10

WARNING:

Potential Asphyxiant

Liquid nitrogen can cause rapid suffocation without warning.

Store and use in an area with adequate ventilation.

Do not enter confined spaces where nitrogen gas may be present unless the

area is well ventilated.

The warning above applies to the use of liquid nitrogen. Oxygen depletion sensors are sometimes utilized

where liquid nitrogen is in use.

Thermal Safety

During an experiment, the furnace and sample can become very hot or very cold to the touch.

WARNING: Do not use your hands to manually move the furnace and do not put your

hands up inside the furnace. It may be hot enough to cause burns.

Cleaning the Instrument

See Chapter 3 for recommended cleaning and maintenance of the TMA instrument.

CAUTION: Before using any cleaning or decontamination method except those

recommended by TA Instruments, please check with TA Instruments to make sure that

the proposed method will not damage the equipment.

10

TMA Q Series Getting Started Guide

Page 11

Introducing the TMA

Overview

The Thermomechanical Analyzer (TMA) is an analytical instrument

used to test the physical properties of many different materials.

The TMA instrument works in conjunction with a controller and

associated software to make up a thermal analysis system.

Your controller is a computer that performs the following functions:

• Provides an interface between you and the analysis instruments

• Enables you to set up experiments and enter constants

• Stores experimental data

• Runs data analysis programs.

NOTE: For technical reference information, theory of

operation, and other information associated with the

TMA and not found in this manual, see the online help

associated with the instrument control software.

Chapter 1

TMA System Components

Your instrument consists of the following

components (see the figure here).

• The balance enclosure surrounds the TMA

balance mechanism, which exerts a

specified force on the sample.

• The probe assembly is inter-changeable for

making several different measurements on

various sample materials.

• The stage is an interchangeable component

that supports the sample during

measurement.

• The furnace assembly surrounds the stage to

heat the sample; it contains the integral

cooling container, the furnace monitor

thermocouple, and the sample purge line.

Furnace Assembly

Probe Assembly

Balance Enclosure

Weight Tray Door

Touch Screen

Stage

TMA Q Series Getting Started Guide

11

Page 12

• The weight tray, located behind the weight tray door, holds the weights to exert an additional known force

on the sample.

• The CHROMEL®*/ALUMEL®* sample thermocouple senses the temperature of the sample.

The TMA was developed by TA Instruments with the following features:

• Operates over a temperature range of –150 oC to 1000 oC using heating rates up to 200 oC/min

• Determines changes in sample properties resulting from changes in four experimental variables:

temperature, force, atmosphere, and time

• Uses samples that can be in solid, film, fiber, or powder form

• Employs interchangeable probes, allowing you to measure the melting point, softening point, tensile

modulus, compression modulus, glass transition, stress relaxation, creep, and expansion coefficient.

• Allows additional experiments in parallel plate rheometry, fiber tension, shrinkage force, flexure, and

dilatometry with the optional accessories that can be used with the instrument.

St andard Accessories

The accessory kit supplied with the TMA contains weights, a sample holder (stage), a hex wrench, tweezers,

samples for calibration, and standard probes.

The standard probes allow you to perform various basic analyses. These probes are as follows:

• The expansion probes are used to measure the thermal coefficient of expansion and glass transition. The

standard expansion probe is used for routine samples. The macro expansion probe covers a larger area of

the sample surface and is therefore able to give a more representative reading for samples such as

powders, materials with uneven surfaces, frozen liquids, and films.

• The penetration probe, which has a small tip that permits it to sink into the material as it is heated, is used

to measure softening and melting points.

• Optional probes are also available, see page 21.

Subambient Operation

The TMA can be used to run experiments on cooled samples with a cooling source such as liquid nitrogen

contained in the reservoir. In addition, a Mechanical Cooling Accessory is available, see page 21.

12

TMA Q Series Getting Started Guide

Page 13

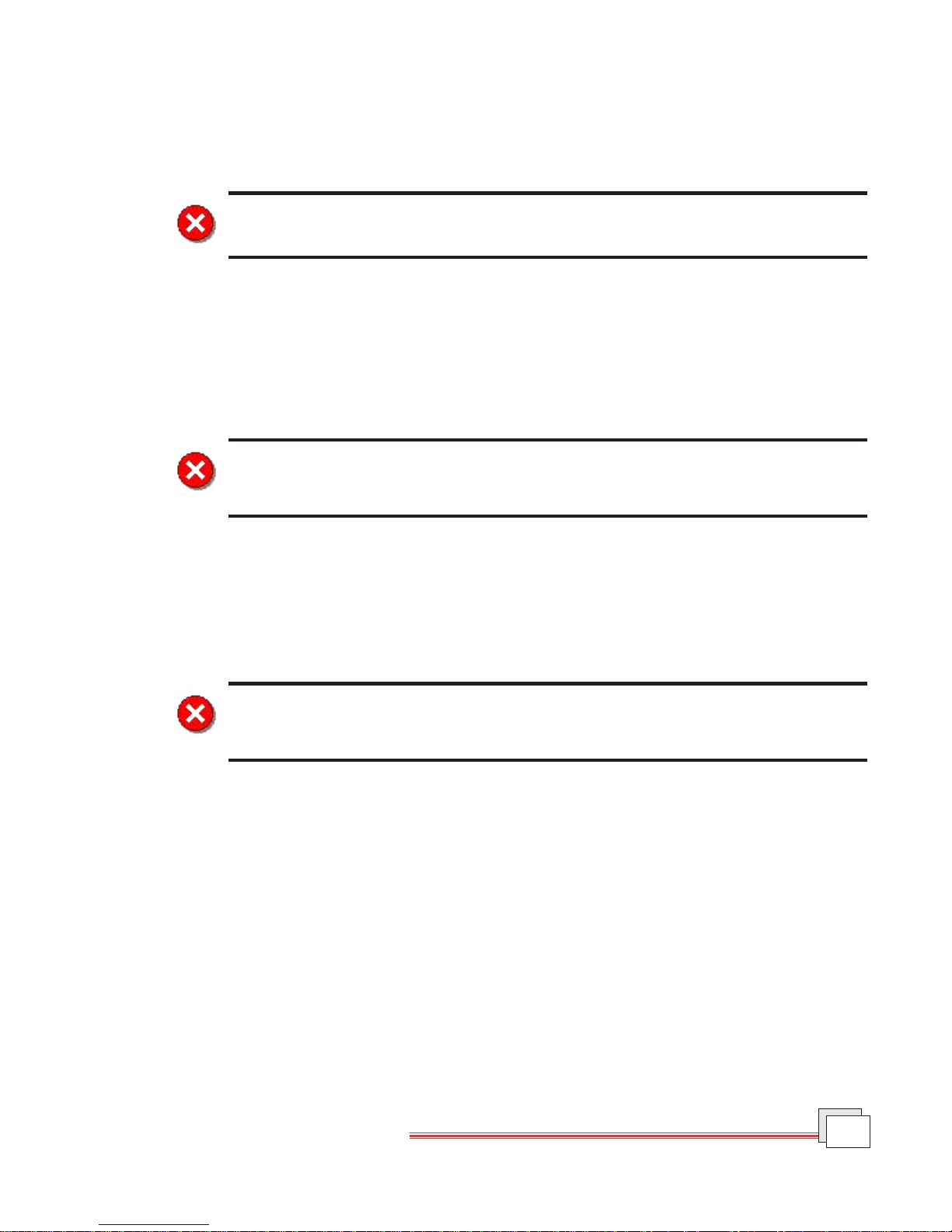

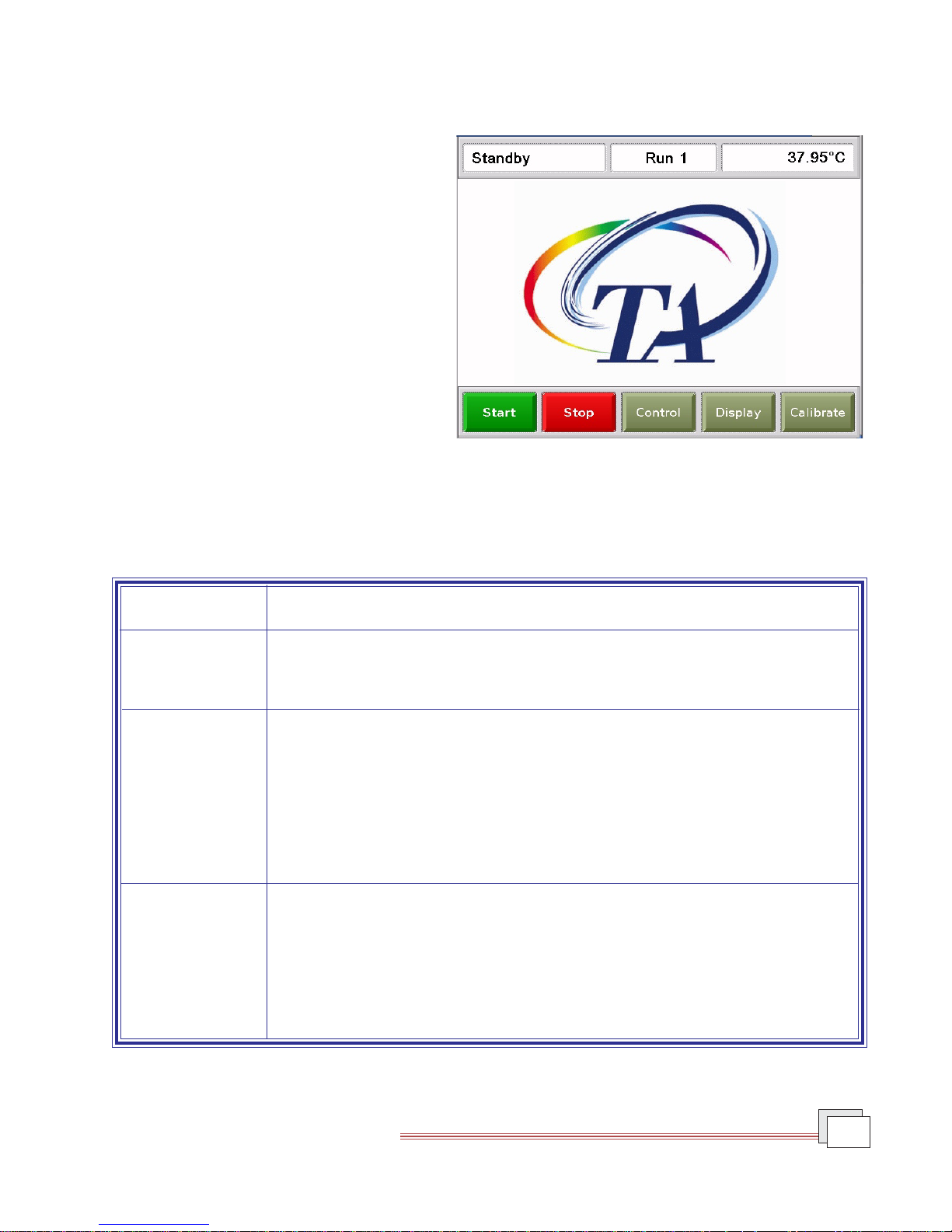

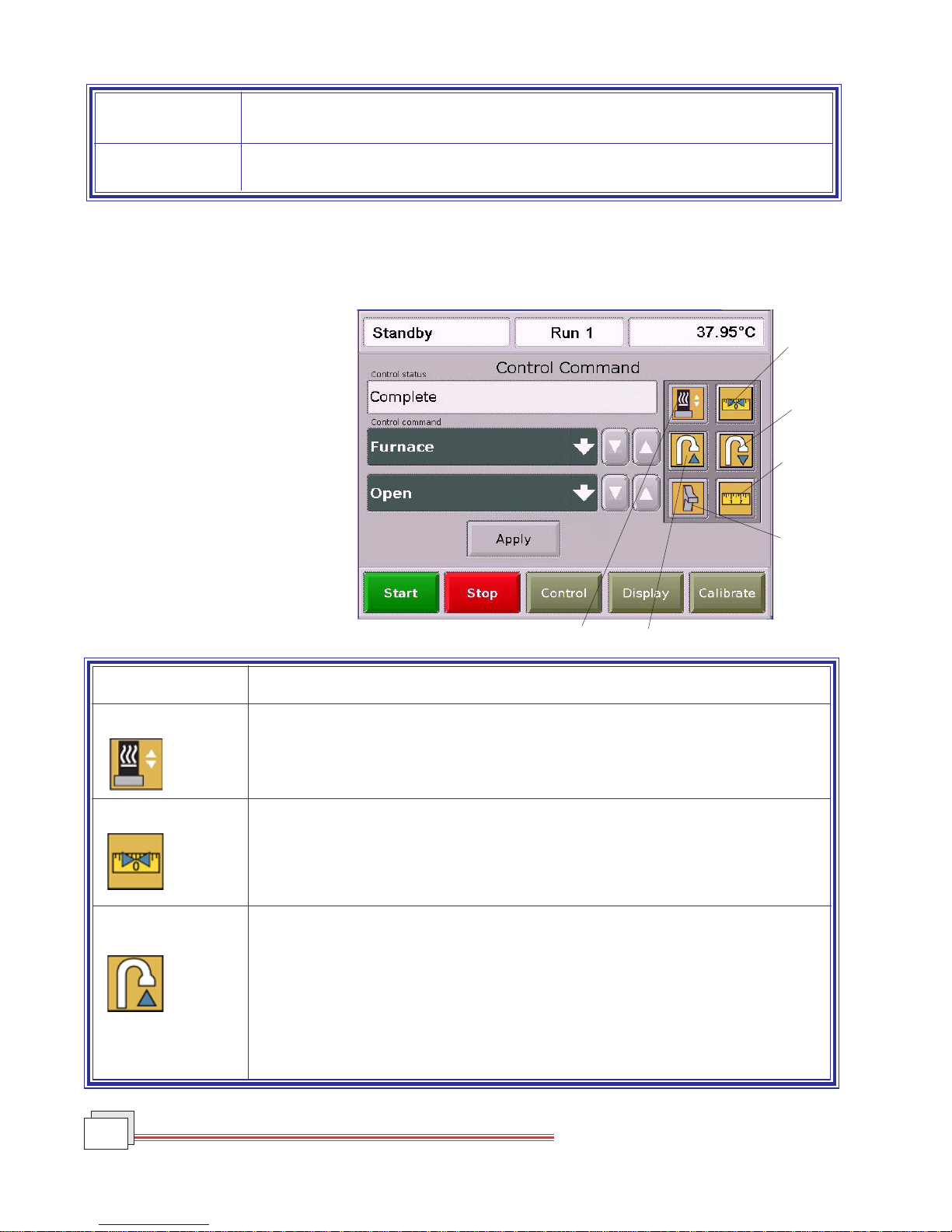

The QTMA Touch Screen with QNX/Platinum

The TMA Q400 instrument has a built-in

integrated display and keypad in the form of a

touch screen for local operator control. The

functions on the screen change depending upon

the menu you are using. This section briefly

describes the basic layout of these functions

when your instrument has QNX and Platinum

capabilities installed.

The status line along the top of the display

shows the current instrument status, run

selection, and temperature.

At the bottom of the screen is a set of keys that

are used for the primary instrument functions.

See the table below for a description of each key.

The functions in the middle of the touch screen will vary depending on the screen displayed.

TM

QNX/Platinum

Use the following keys for the main functions of the instrument.

Key Name Description

Start Begins the experiment. This is the same function as Start on the instrument

Stop If an experiment is running, this key ends the method normally, as though it had

Control Displays a list of the control command functions. These are used to

TM

Primary Function Keys

control software. Start automatically loads the sample pan and closes the

furnace, if necessary, before beginning the experiment.

run to completion; i.e., the method-end conditions go into effect and the data that

has been generated is saved. This is the same function as Stop on the instrument

control software.

If an experiment is not running (the instrument is in a standby or method-end

state), the Stop key will halt any activity (air cool, all mechanical motion, etc.).

control the instrument actions such as furnace movement, sample

loading/unloading, taring, etc. Items can be selected from the icons or from the

drop-down menu. Select Apply to initiate the command. See the next page for

more details on this screen.

(table continued)

TMA Q Series Getting Started Guide

13

Page 14

Display Accesses the display screen, which displays the signals from the instrument

such as signal display, real-time plot, instrument information, etc.

Calibrate Displays the calibration functions available for this instrument.

QNX/PlatinumTM Control Menu

The Control Menu (see the figure to

the right) is accessed by touching the

Control key at the bottom of the touch

screen. A brief description of each

control command is provided in the

table below.

NOTE: Most of the

commands shown

are not available

during an active

experiment.

Zero

Length

Zero

Length

Measure

Select the desired function either from

the drop-down list of Control Commands or by pressing the icon. Then

press Apply to initiate the action.

Furnace Probe Up

Control Command Description

FURNACE Toggles between the furnace closed (up) and furnace open (down) functions,

depending on where the furnace is when you press the key. This key can be

pressed while the furnace is moving, to reverse the direction of movement.

ZERO LENGTH Initializes the automeasure system. This operation should be performed before

a sample is loaded and any time the probe or stage is changed.

PROBE UP Used to “open” the probe, this key raises the probe 3 mm, the range of the LVDT,

when pressed one time. When the key is pressed a second time, mechanical

action occurs, moving the probe and LVDT coil to their maximum upward

position.

Shutdown

If the probe is moving down and PROBE UP is pushed, the probe will stop and

reverse its direction.

(table continued)

14

TMA Q Series Getting Started Guide

Page 15

Control Command Description

PROBE DOWN Used to “close” the probe, this key lowers the probe 3 mm, the range of the LVDT,

when pressed one time. When the key is pressed a second time, mechanical

action occurs, centering the LVDT coil.

If the probe is moving up and PROBE DOWN is pushed, the probe will stop and

reverse its direction.

SHUTDOWN Shuts down and resets the instrument.

MEASURE Measures your sample’s length automatically; use this key before beginning

the run. The measured length is transferred to the instrument control software

and the value is recorded in the Sample Size field.

NOTE: MEASURE is not used with the flexural probe.

AIR COOL Toggles the air cool function on or off. This is the same function as Air Cool on

the instrument control software.

RESET SAVED

PARAMETERS Resets the saved instrument parameters and resets the instrument.

TMA Q Series Getting Started Guide

15

Page 16

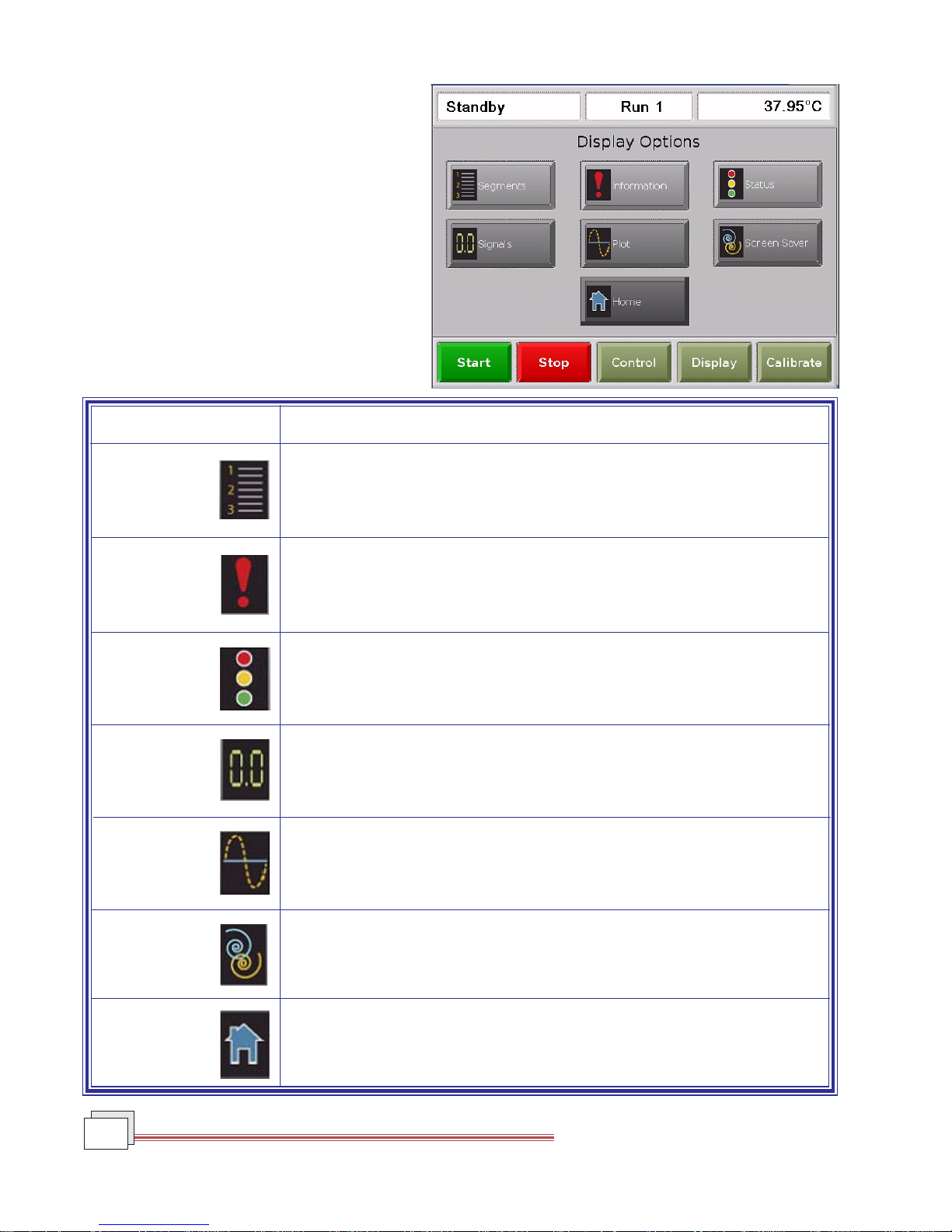

QNX/PlatinumTM Display

Touch Screen Options

The Display Options are accessed by touching

the Display key at the bottom of the touch

screen. The keys shown in the figure to the right

are displayed.

A brief description of the function of each key is

provided in the table below.

Key Name Description

SEGMENTS Accesses the experimental method that is currently being used for this experi-

ment.

INFORMATION Displays instrument information such as the software version, options, and

the IP address.

STATUS Displays the three main signals indicating the current status of the experiment.

SIGNALS Displays the real-time signal data that comes directly from the instrument. The

signals displayed here are customized through the instrument control software by accessing Tools/Instrument Preferences.

PLOT Displays a time-based plot of data as it is received from the instrument during

experiments.

SCREEN SAVER Allows you to choose a screen saver for the touch screen.

HOME Returns to the opening window.

16

TMA Q Series Getting Started Guide

Page 17

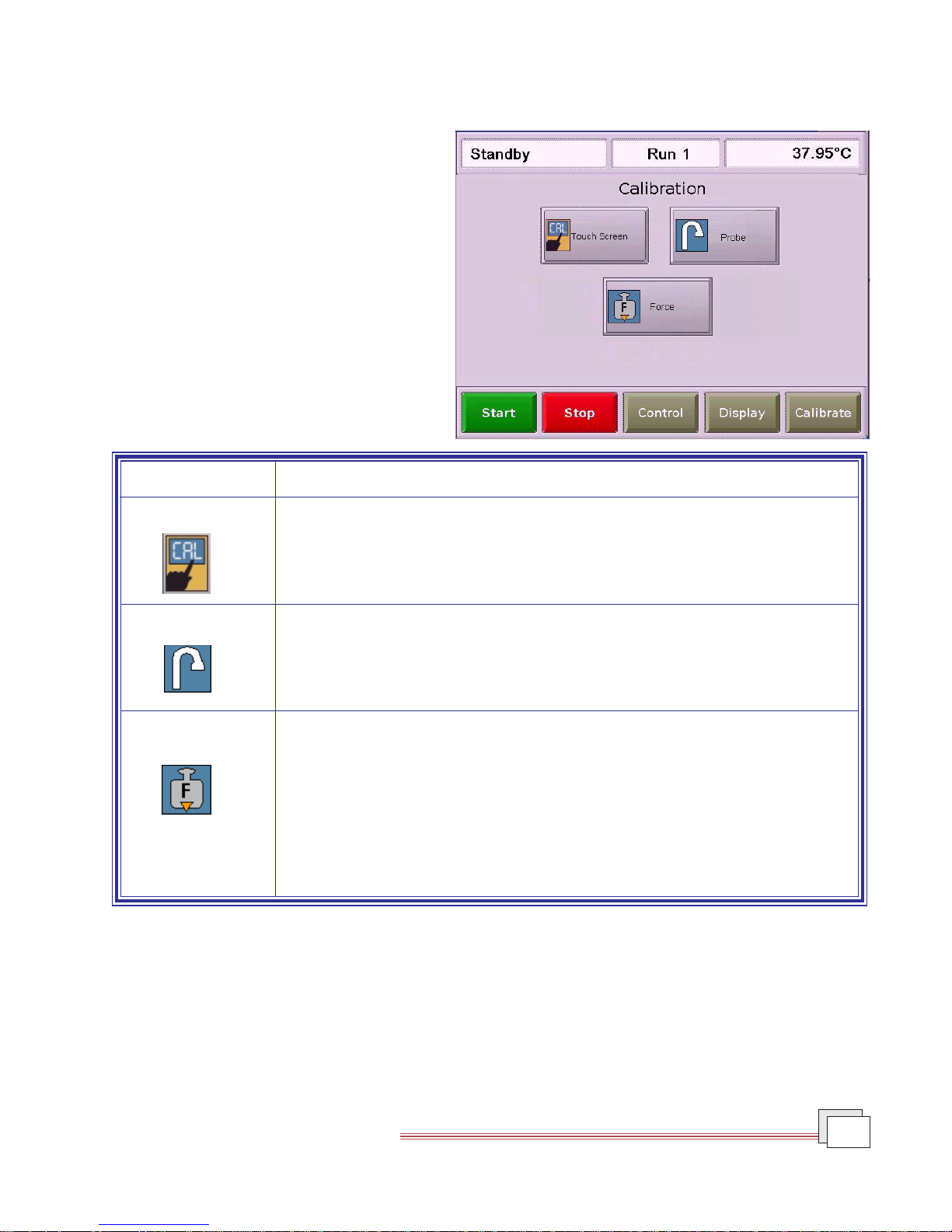

QNX/PlatinumTM Calibration Options

The Calibration Options are accessed by

touching the Calibrate key at the bottom of the

touch screen. The keys shown in the figure

below are displayed. A brief description of the

function of each key is provided in the table

below.

Key Name Description

TOUCH SCREEN Allows you to calibrate the touch screen display.

PROBE This procedure, sometimes called “initializing,” is used to calibrate zero force,

the LVDT, and the probe's compliance. It corrects for any difference in the

different probes used on the TMA and should be done every time you change a

probe on the TMA.

FORCE Force calibration calibrates the force exerted by the probe on the sample during

experiments using three different mass values (0, 50, and 100 grams) and can be

performed with any probe in place on the instrument. The first calibration point

is 0 grams. You may use weights other than the recommended 50 and 100 grams,

if desired (up to 100 grams is allowed). For example, you can use 10 grams for

force calibration if only low forces will be used in subsequent experiments.

This calibration should be performed periodically (approximately once a month).

TMA Q Series Getting Started Guide

17

Page 18

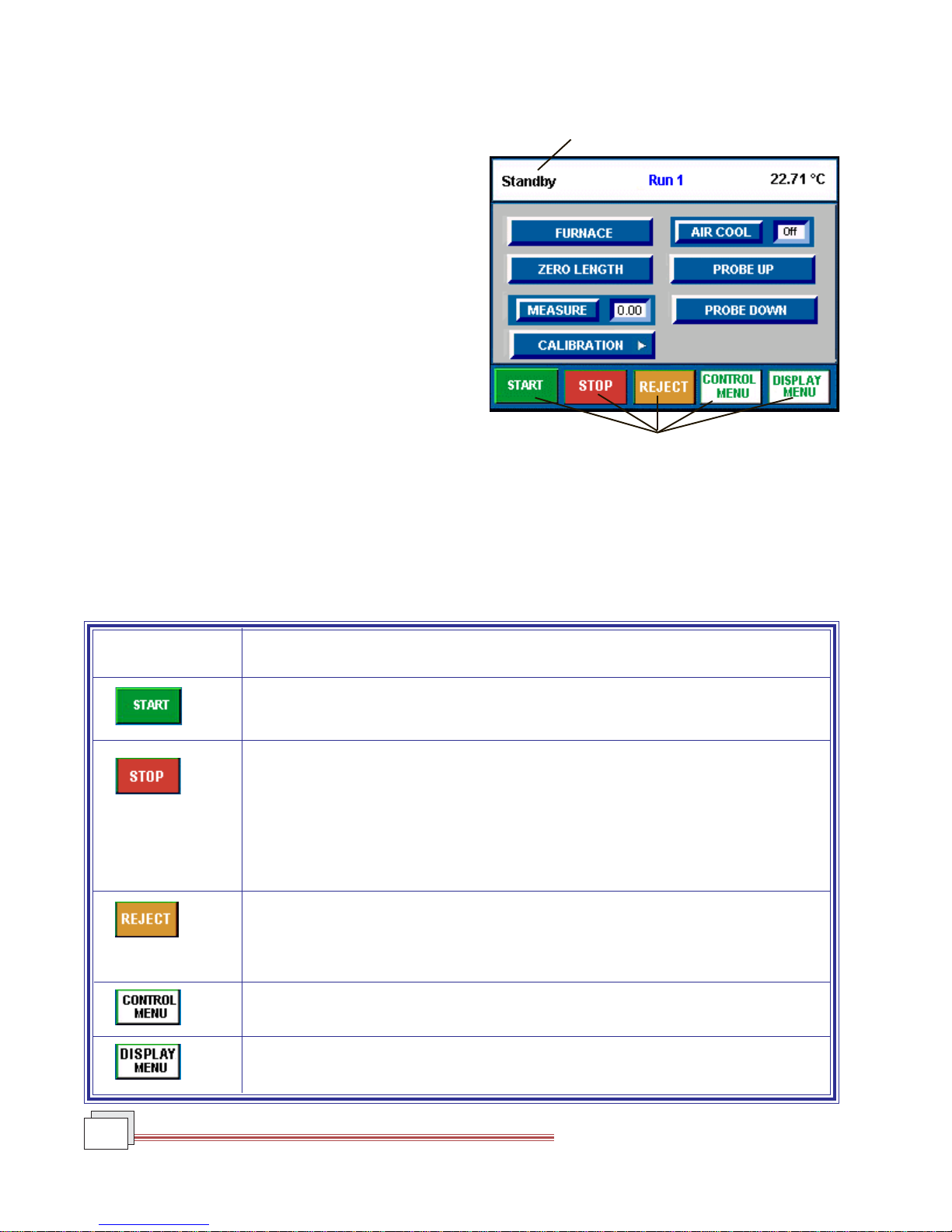

The TMA Touch Screen (Original)

The TMA Q400 instruments have a built-in integrated

display and keypad in the form of a touch screen for local

operator control. The functions shown on the screen

change depending upon the menu you are using. This

section briefly describes the functions of the keys shown

on the touch screen displays.

The status line along the top of the display (see the figure

to the right) shows the current instrument status, current

run number, and temperature.

At the bottom of the screen is a set of five keys that are

used for the primary instrument functions. These keys

are available to you regardless of the menu selected. See

the next section for an explanation of the primary function

keys.

NOTE: Experiment information and

instrument constants are entered from

the controller keyboard, not the instrument touch screen.

Status Line

Primary Function Keys

Primary Function Keys

This set of keys, found at the bottom of the touch screen, are used to perform the basic functions of the instrument and to access the two main screens. See the table below for details.

Key Name Description

Begins the experiment. This is the same function as Start on the instrument

control software.

If an experiment is running, this key ends the method normally, as though it had

run to completion; i.e., the method-end conditions go into effect and the data that

has been generated is saved. This is the same function as Stop on the instrument

control software.

If an experiment is not running (the instrument is in a standby or method-end

state), the Stop key will halt any activity (air cool, all mechanical motion, etc.).

If an experiment is running, REJECT ends the method. The the method-end

conditions go into effect just as if the method had run to completion. However,

the data that has been generated is discarded. This is the same function as Reject

on the instrument control software.

Displays the Control Menu touch screen keys. These are used to control certain

instrument actions.

Accesses the Display Menu screen, which is used to select the desired display

option.

18

TMA Q Series Getting Started Guide

Page 19

TMA Control Menu Keys

The Control Menu is accessed by touching the Control

Menu key at the bottom of the touch screen. The keys

shown in the figure here are displayed. A brief description of the function of each key is provided in the table

below. The available keys will vary based on the selected

coolers and installed accessories.

Key Name Description

Toggles between raising and lowering the furnace, depending on the state of the

furnace when you press the key.

Initializes the automeasure system. This operation should be performed before

a sample is loaded and any time the probe or stage is changed.

Measures your sample’s length automatically; use this key before beginning

the run. The measured length is transferred to the instrument control software

and the value is recorded in the Sample Size field.

Used to advance to the Calibration touch screen, which allows you to select from

either Probe Calibration or Force Calibration. Follow the instructions displayed

on the screen to perform these calibration procedures.

Toggles the air cool function on or off. This is the same function as Air Cool on

the instrument control software.

Used to “open” the probe, this key raises the probe 3 mm, the range of the LVDT,

when pressed one time. When the key is pressed a second time, mechanical

action occurs, moving the probe and LVDT coil to their maximum upward

position.

If the probe is moving down and PROBE UP is pushed, the probe will stop and

reverse its direction.

Used to “close” the probe, this key lowers the probe 3 mm, the range of the LVDT,

when pressed one time. When the key is pressed a second time, mechanical

action occurs, centering the LVDT coil.

If the probe is moving up and PROBE DOWN is pushed, the probe will stop and

reverse its direction.

TMA Q Series Getting Started Guide

19

Page 20

Display Menu Keys

The Display Menu is accessed by touching the DISPLAY

MENU key at the bottom of the touch screen. The menu

shown in the figure here will be displayed. A brief

description of the function of each key is provided in the

table below.

Key Name Description

Accesses the experimental procedure that is currently being used and highlights

the active segment.

Displays the three main signals indicating the current status of the experiment.

Displays instrument information such as the software version, options, and the

IP (Internet Protocol) address.

Displays the real-time signal data that comes directly from the instrument. The

signals displayed here are customized through the instrument control software.

Ensures proper shutdown of the instrument before turning off the power.

Beeps the controller that is connected to the instrument.

Returns to the opening window.

20

TMA Q Series Getting Started Guide

Page 21

Options and Accessories

Several optional probes and a cooling accessory are available from TA Instruments to be used with the TMA. A

brief description of each one follows. For more information refer to the online documentation.

Probes

• Film/Fiber Probe: The TMA film/fiber accessory can be used to measure the physical properties of fibers or

films as a function of force, temperature, or time.

• Flexure Accessory: The Flexure Accessory can be used on the TMA for three-point bending studies to

measure the flexibility and strength of a variety of materials, such as composites, plastics, and PC boards.

It employs a knife-edged probe and either of two types of fixtures, quartz or low-friction aluminum,

depending upon the type of experiment desired.

• Dilatometer Accessory: The dilatometer accessory kit can be used to determine the volume coefficient of

expansion.

• Parallel Plate Rheometer Accessory: The parallel plate rheometer accessory can be used to obtain

viscosity-temperature or viscosity-time data on substances at low shear rates, over the range of 10 to 10

Pa-sec (1 to 106 Poise).

• Hemispherical Probe: The hemispherical probe is used with the standard quartz stage to obtain softening

point data on substances. It is installed, operated, and calibrated using the same procedures as for the

standard expansion and penetration probes.

7

Mechanical Cooling Accessory

The Mechanical Cooling Accessory (MCA) is designed to provide

you with a source of continuous cooling for the TMA, while eliminating the need for liquid nitrogen or dry ice. It is a portable,

freestanding refrigeration system that can be placed on the floor

under a lab bench to conserve counter space. The MCA has a twostage compressor system that operates in a cascade fashion (first one

compressor turns on, then the other compressor joins in). Refrigerant is carried from the unit through an insulated coaxial hose to the

cooling head.

When using the MCA it is important to select Tools/Instrument

Preferences/TMA Page and check the box "MCA attached" to avoid

damage to the system.

TMA Q Series Getting Started Guide

21

Page 22

Instrument Specifications

The tables found on the following pages contain the technical specifications for the TMA.

TMA Instrument Characteristics

Dimensions Depth 55.9 cm (22 in.)

Width 45.5 cm (18 in.)

Furnace Open Height 64.8 cm (25.5 in.)

Furnace Closed Height 61 cm (24 in.)

Weight (approx.) 31.4 kg (69 lb)

Weight with Transformer 39.5 kg (87 lbs)

Power 120 Vac, 47–63 Hz, 1.44 kVA standard

230 Vac, 47–63 Hz, 1.44 kVA if configured with a step-down

transformer

Accessory Outlets Power: 120 V, 47–63 Hz, 400 VA each (used with TA accessories

only)

Operating Environment Temperature: 15–30 °C

Conditions Relative Humidity: 5–80 % (non-condensing)

Installation Category II

Pollution Degree 2

Maximum Altitude: 2000 m

Temperature Range –150 to 1000

Sample Height 25 mm (1 inch) maximum

Sample Thickness for Film/Fiber 0.5 mm maximum

Sample Diameter 10 mm (0.39 in) maximum

Sensitivity 15 nanometers

Displacement Range +2.5 mm (+0.10 inch)

Linearity +0.5 %

Loading 0.001 to 1.0 Newtons (102 g)

Purge gases Calibrated for: air, argon, helium, nitrogen, or oxygen

Typical purge flow rate 100 ml/min (-100 °C and above) or 200 ml/min (-150 °C and

above).

Programmed Heating Rate 0.01 to 200 oC/min

Temperature Reproducibility +2 oC

o

C

22

TMA Q Series Getting Started Guide

Page 23

Chapter 2

Installing the TMA

Unpacking/Repacking the TMA

The instructions needed to unpack and repack the instrument are found as separate unpacking instructions in

the shipping box and in the online documentation associated with the instrument control software. You may

wish to retain all of the shipping hardware, the plywood, and boxes from the instrument in the event you wish

to repack and ship your instrument.

WARNING: Have an assistant help you unpack this unit. Do not attempt to do this

alone.

Installing the Instrument

Before shipment, the TMA instrument is inspected both electrically and mechanically so that it is ready for

operation upon proper installation. Only limited instructions are given in this manual, consult the online

documentation for additional information. Installation involves the following procedures:

• Inspecting the system for shipping damage and missing parts

• Installing a voltage configuration unit.

• Connecting the TMA to the TA Instruments controller

• Connecting cables and gas lines.

It is recommended that you have your TMA installed by a TA Instruments Service Representative, call for an

installation appointment when you receive your instrument.

CAUTION: To avoid mistakes, read this entire chapter before you begin installation.

NOTE: If you plan to ship your TMA by commercial carrier, you will need to remove the voltage

configuration unit first. Please refer to the online help accessed through the Help menu for

detailed instructions on transporting the TMA.

Inspecting the System

When you receive your TMA, look over the instrument and shipping container carefully for signs of shipping

damage, and check the parts received against the enclosed shipping list.

• If the instrument is damaged, notify the carrier and TA Instruments immediately.

• If the instrument is intact but parts are missing, contact TA Instruments.

TMA Q Series Getting Started Guide

23

Page 24

Choosing a Location

Because of the sensitivity of TMA experiments, it is important to choose a location for the instrument using the

following guidelines. The TMA should be:

In ... a temperature-controlled area.

... a clean, vibration-free environment.

... an area with ample working and ventilation space.

On ... a stable work surface.

NOTE: Placing the TMA on a stable, vibration-free work surface is very important to instrument

performance.

Near ... a power outlet (120 Vac, 50 or 60 Hz, 15 amps, or 230 Vac, 50 or 60 Hz, 10 amps if configured with

a step down transformer).

...your TA Instruments thermal analysis controller.

...sources of compressed lab air and purge gas supplies with suitable regulators.

CAUTION: Your air source must be clean, dry, and oil-free to ensure proper operation

of the TMA.

Away

from ... any flammable materials.

... dusty environments.

... exposure to direct sunlight.

... direct air drafts (fans, room air ducts).

... poorly ventilated areas.

... noisy or mechanical vibrations.

CAUTION: Drying out the instrument may be needed, if it has been exposed to humid

conditions. Certain ceramic materials used in this equipment may absorb moisture,

causing leakage currents to exceed those specified in the applicable standards until

moisture is eliminated. It is important to be certain that the instrument ground is

adequately connected to the facilities ground for safe operation.

Run the following method to dry out the TMA:

1 Ramp at 10°C/min to 400°C

2 Isothermal for 30 min.

24

TMA Q Series Getting Started Guide

Page 25

Voltage Configuration Unit

A voltage configuration/safety isolation unit is required for 230 Vac or 120 Vac. It is shipped in a separate

container from the instrument. Obtain the unit and follow these steps to install it in the Power Control Unit

(PCU):

WARNING: High voltages are present in this instrument as indicated by the

label.

Be sure to unplug the instrument before performing these instructions. See the

WARNING on page 8.

WARNING: Use of the voltage configuration/safety isolation unit is required to protect

against hazardous leakage current from the furnace assembly.

1. Disconnect the A10J10 connector from A10P10 located inside the PCU. Now connect the A10J10 connector

on the voltage configuration unit to A10P10 located inside the PCU.

2.

Connect A10J10 located inside the PCU to A38J1 on the anti-surge

subassembly. See the diagram to the right.

3. Install the subassembly into the PCU and tighten the four (4) captive

fasteners to secure it.

Original

Power Control Unit

Voltage Configuration Unit

4. For 230 Vac only: Remove the fuse holder from the power entry

module and replace the 10 amp fuses with 6.3 amp fuses, which are

supplied in the voltage configuration kit. Discard the 10 amp fuses.

Final

See the figure below.

Power Control Unit

Power

Entry

Module

Fuse

Fuse Holder

Fuse

Captive Fasteners

Replace Fuses for 230 Vac Only

TMA Q Series Getting Started Guide

Voltage Configuration Unit

25

Page 26

Connecting Cables and Lines

To connect the cables and gas lines, you will need access to the TMA instrument’s rear panel. All directional

descriptions are written on the assumption that you are facing the back of the instrument.

NOTE: Connect all cables before connecting the power cords to outlets. Tighten the thumbscrews on all computer cables.

CAUTION: Whenever plugging or unplugging power cords, handle them by the plugs,

not by the cords.

WARNING: Protect power and communications cable paths. Do not create tripping

hazards by laying the cables across accessways.

WARNING: DO NOT position the instrument so that it is

difficult to turn off the power switch or to unplug the power cord.

Ports

The TMA has nine ports that are located on the back of the instrument. The following table provides a description of function of each port. Refer to this list when connecting cables and lines.

Ethernet

COM 1

COM 2

Event

24 VDC Output

Five Ports on Left Rear of TMA

Port Function

Ethernet Provides communication capabilities.

Com 1 Diagnostic port (factory use only).

Com 2 Accessory port.

Event Capable of the following functions: general purpose relay contact closure, or

general purpose input 4 – 24 Vdc for external syncing. This port is not used for

standard operation.

24 VDC output This port is not used with the TMA.

(table continued)

26

TMA Q Series Getting Started Guide

Page 27

Port Function

Base Purge This port is not used with the TMA.

Gas 1 Gas inlet port controlled by the Mass Flow Controller. Used for the sample purge

gas.

Gas 2 This port is not used with the TMA.

Cooling Gas Provides the furnace with air for cooling (830 kPa gauge [120 psig] maximum

pressure).

Cooling Gas

Gas 1

Ports on the Back of the TMA Q400

Purge Line

You can control the sample atmosphere during experiments by connecting a purge gas to the system. The TMA

is equipped with a mass flow controller (MFC) to control the flow rate of the gas. Follow these instructions to

connect the purge line. Refer to the figure below to locate the purge lines.

CAUTION: Do not use any liquid in the purge lines. Use of corrosive gases will shorten

the life of the instrument.

WARNING: Use of an explosive gas as a purge gas is dangerous and is not recommended for the TMA instrument. See Chapter 1 for a list of recommended purge

gases.

1. Locate the Gas 1 port; this port is used to purge the sample area.

2. Connect the primary gas line to the Gas 1 port using 1/8-inch O.D.

tubing. Teflon® TFE tubing is recommended and is supplied in the

instrument shipping accessory kit. The flow rate is controlled

through the Mass Flow Controller settings chosen using the

instrument control software.

Gas 1

Port Not Used

TMA Q Series Getting Started Guide

27

Page 28

The purge gas flows through the instrument and is channeled

internally to the sample purge line shown in the figure to the left.

3. Make sure that the pressure of your purge gas source is

regulated between 100 and 140 kPa gauge (15 and 20 psig).

Air Cool

Line

Sample

Purge

Line

Connecting the Cooling Gas Line

Air cooling is used to cool the TMA furnace to room temperature.

Follow the procedure below to install the

cooling gas line for air cool:

1. Locate the Cooling Gas fitting, a 1/4-inch

Legris fitting on the right side of the TMA

cabinet back, marked with an 830 kPa

gauge (120 psig) maximum warning label

(see the figure to the right).

2. Make sure your compressed air source is

dry, filtered, and regulated to between 170

and 830 kPa gauge (25 and 120 psig).

3. Connect the compressed air line to the

Cooling Gas fitting.

Cooling Gas Fitting

28

TMA Q Series Getting Started Guide

Page 29

Installing the Stage

To install the stage on the TMA, check to make sure the

furnace is raised and off to the side. Then follow these steps

(refer to the figure here for illustration of the parts):

1. Remove the stage shield by lifting it straight up. (This is a

friction fit.)

2. Turn the large stage nut counterclockwise to remove it.

Stage

Shield

Stage

Nut

3. Twist the stage retainer ring (with key slots) counter-

clockwise, and pull it up off the three posts.

4. Remove the stage from the accessory kit.

Stage

Retainer

Ring

Wave

Washer

5. Slide the wave washer (washer with rippled edges)

down over the top of the stage so that it fits on the flange.

Stage

6. Slide the stage retainer ring down over the top of the

stage so that it rests on top of the wave washer.

7. Insert the whole assembly (stage, wave washer, and

retainer ring) into the stage opening, aligning the key

slots in the retainer ring with the posts.

Stage

8. Press down and turn the retainer ring clockwise to lock

Opening

the assembly in position.

9. Replace the large stage nut, turning it clockwise to install it.

10. Attach the thermocouple to the stage as follows:

a. Position the tip of the thermocouple so that it bends at a 90° angle and lies flat against the platform. It

should be close to, but not touching the sample.

Keyways

Flange

Posts

b. Hold the thermocouple against the stage assembly,

and put on the spring clip to keep the thermocouple in

place (see the figure below).

Springclip

TMA Q Series Getting Started Guide

11. Place the stage shield on

the stage, aligning the slot

in the bottom over the

thermocouple (see the figure

to the right).

12. Install one of the probes

as directed in the next

section. (Refer to Chapter 3

for guidelines to use when

selecting a probe.)

13. Rotate the furnace into

position over the stage.

Probe

Stage

Stage Shield

Thermocouple

29

Page 30

Installing the Expansion/Penetration Probes

When you first receive the TMA, you will need to install a probe. Later, if a different sample form is used, you

can change to the appropriate probe for the experiment. (Refer to Chapter 3 for details on probe selection.) The

procedures that follow explain the installation and removal of the expansion, macro expansion, penetration,

flexure, dilatometer, and hemispherical probes.

Installing a Probe

1. Raise the furnace and rotate it clockwise to move it off to the side.

2. Insert the core end of the probe carefully into the opening in the TMA stage.

3. Loosen the probe-locking lever, which is the knurled post found behind the weight tray door, by turning it

counterclockwise. Hold the probe-locking lever in the up position and continue lowering the probe into the

stage until you can feel it seat in the locking mechanism.

4. Tighten the probe-locking lever by turning it clockwise.

5. Calibrate the newly installed probe as directed in the online help found in the instrument control software.

Removing a Probe

1. Raise the furnace, and rotate it clockwise to move it off to the side.

2. Grasp the top of the probe with one hand. Using the other hand, locate and hold the probe-locking lever,

found behind the door that covers the weight tray.

3. Unscrew the locking lever by turning it counterclockwise approximately one turn.

4. Raise the probe gently and twist slightly to aid its removal from the stage opening.

30

TMA Q Series Getting Started Guide

Page 31

Ethernet Switch Setup

In order to connect the instrument to a network, you will need to make the necessary cable connections as

described below. The instrument and controller will be connected to an Ethernet switch. In addition, there are

instructions for connecting the controller to a LAN.

Connecting the Instrument to the Switch

1. Locate the Ethernet port on the left rear of the instrument (shown in

the figure to the right).

2. Connect one end of the Ethernet cable into the instrument's Ethernet

port.

3. Connect the other end of the Ethernet cable to one of the network ports

on the Ethernet switch (shown in the figure below).

Ethernet Switch

4. Check the configuration switches, located on the back panel. They must

be set to off, or the up position, for the controller to communicate to the

instruments.

Yellow Light

Ethernet Connection

Green Light

5. Check the Ethernet port on the rear of the instrument. If communica-

Configuration Switches

tion between the instrument and the switch has been properly established, a solid green light and flashing yellow light will appear at the port.

6. Follow the directions in the next section to connect the controller to the Ethernet switch.

Connecting the Controller to the Switch

1. Locate the Ethernet port on the back of the computer.

2. Plug one end of the Ethernet cable into the computer's Ethernet port (shown in the

figure to the right).

3. Connect the other end of the cable to one of the network ports on the switch.

4. Check the Ethernet port on the rear of the computer. If communication between the

computer and the switch has been properly established, a solid green light and

flashing yellow light will appear at the port.

5. Follow the directions in the next section to connect the controller to a LAN for net-

working capabilities.

TMA Q Series Getting Started Guide

Computer

Ethernet Port

31

Page 32

Connecting the Controller to a LAN

Before you can connect the controller to a LAN, you will need to have

already installed a network interface card into the computer.

1. Locate the second Ethernet port on the back of the computer.

2. Plug one end of the Ethernet cable into the computer's Ethernet port.

3. Plug the other end into the LAN.

4. Check the Ethernet port on the rear of the computer. If communication

between the computer and the LAN has been properly established, a

solid green light and flashing yellow light will appear at the port.

Yellow Light

Ethernet Connection

Green Light

32

TMA Q Series Getting Started Guide

Page 33

Power Switch

The power switch is located at the rear of the instrument. It is part of the

assembly called the power entry module, which also contains the power

cable connection and fuses. The power switch is used to turn the

instrument on and off.

Power Cable

Power Entry Module

NOTE: A <HAR>-marked (harmonized) power cable

meeting the standards of the country of installation is

required for the European Economic Area.

Install the power cable as follows:

1. Make sure the TMA POWER switch is in the Off (0) position.

2. Plug the power cable into the TMA power entry module.

CAUTION: Before plugging the TMA power cable into the wall outlet, make sure the

instrument is compatible with the line voltage. Check the label on the voltage configuration unit panel to verify the voltage.

3. Plug the power cable into the wall outlet.

Reset Button

TMA Q Series Getting Started Guide

33

Page 34

Starting the TMA

1. Check all connections between the TMA and the controller. Make sure each component is plugged into the

correct connector.

2. Set the instrument power switch to the ON (1) position.

After the proper power up sequence, the TA Instruments logo will be displayed on the touch screen, this indicates that the instrument is ready for use.

NOTE: Allow the TMA to warm up for at least 30 minutes before performing an experiment.

Shutting Down the TMA

Before you decide to power down your instrument, consider the following:

• All of the components of your thermal analysis system are designed to be powered on for long periods.

• The electronics of the TMA and the controller perform more reliably if power fluctuations caused by

turning units on and off are minimized.

For these reasons, turning the system and its components on and off frequently is discouraged. Therefore, when

you finish running an experiment on your instrument and wish to use the thermal analysis system for some

other task, it is recommended that you leave the instrument on.

To ensure proper shutdown of the instrument, it is recommended that you initiate the "Shutdown Instrument"

function before turning off or resetting your instrument. This function is available on the instrument touch

screen or through the Instrument Control software.

To power down your instrument set the power switch to the OFF (0) position.

34

TMA Q Series Getting Started Guide

Page 35

Chapter 3

Use, Maintenance, & Diagnostics

Using the TMA

All of your TMA experiments will have the following general outline. In some cases, not all of these steps

will be performed. The majority of these steps are performed using the instrument control software. The

instructions needed to perform these actions can be found in the online help in the instrument control program; therefore, they will not all be covered in detail here.

• Calibrating the instrument

• Selecting, calibrating, and zeroing the probe

• Selecting the desired mode (standard or calibration) through the TA instrument control software

• Preparing and loading the sample

• Adjusting the thermocouple position and closing the furnace

• Creating or choosing the test procedure and entering sample and instrument information through the

TA instrument control software

• Setting the purge gas flow rate

• Adding coolant to the furnace reservoir for subambient operation, if applicable

• Starting the experiment.

To obtain accurate results, follow procedures carefully.

Before You Begin

Before you set up an experiment, ensure that the TMA and the controller have been installed properly. Make

sure you have:

• Made all necessary cable connections from the TMA to the computer

• Connected all gas lines

• Powered up the unit

• Connected any desired accessories

• Connected the instrument with the controller

• Become familiar with controller operations

• Calibrated the TMA, if necessary.

TMA Q Series Getting Started Guide

35

Page 36

Calibrating the TMA

To obtain accurate experimental results, calibrate the TMA when you first install it. To keep your TMA

working to the highest level of performance possible, you should calibrate periodically thereafter. A brief

description of each calibration is outlined below. For details on how to perform that calibration, refer to the

online help documentation accessed through the instrument control software.

Force Calibration

Force calibration calibrates the force exerted by the probe on the sample during experiments using three

different mass values (0, 50, and 100 grams) and can be performed with any probe in place on the instrument.

The first calibration point is 0 grams. You may use weights other than the recommended 50 and 100 grams, if

desired (up to 100 grams is allowed). For example, you can use 10 grams for force calibration if only low

forces will be used in subsequent experiments.

This calibration should be performed periodically (approximately once a month) and can be performed from

the TA instrument control program or the instrument's touch screen.

NOTE: A force calibration performs the functions of a probe calibration (see the next section). Therefore, it is not necessary to perform a probe calibration immediately following a

force calibration.

Probe Calibration

This procedure, sometimes called “initializing,” is used to calibrate zero force, the LVDT, and the probe's

compliance. It corrects for any difference in the different probes used on the TMA and should be done every

time you change a probe on the TMA. This calibration can be performed from the TA instrument control

program or the instrument's touch screen.

Temperature Calibration

Temperature calibration is based on a run, conducted in the calibration mode, in which a temperature standard (e.g., indium) is heated through its melting point. The recorded melting point of this standard is compared to the known melting point, and the difference is calculated for temperature calibration.

In addition, you can use up to four other standards to calibrate temperature. If you use one pair of known

and observed points, the entire curve is offset, or shifted, to the actual melting point. If you use multiple

standards, the temperature is corrected by a cubic spline fit between the points with fixed offset values

beyond the calibration window. This can create a small discontinuity in the heating rate. The multiple-point

temperature calibration is more accurate than the one-point calibration.

For all probe types except the film/fiber accessory, small flattened pieces of standard metals are placed on

the stage. To protect the stage from amalgamation with the metal, it is recommended that aluminum or

platinum be placed between the stage and the metal standard. The end of the probe can also be wrapped with

foil for added protection.

For the film/fiber probe, metal wires can be crimped into the aluminum balls and used for calibration.

36

TMA Q Series Getting Started Guide

Page 37

When to Calibrate:

The sample thermocouple should be calibrated in the following situations:

• When the TMA is first installed

• When the sample thermocouple is changed

• When the TMA is serviced or repaired

• Periodically (approximately once a month)

• If you are changing the temperature range of interest

• If the run data obtained seems to be inaccurate

• When the purge gas is changed.

Cell Constant

Cell constant calibration is based on a run conducted in the calibration mode in which a known standard (e.g.,

aluminum or copper) is heated through its transition temperature and data is gathered for analysis. The cell

constant is calculated by dividing the actual coefficient of expansion of the standard by the measured coefficient of expansion. The cell constant is then entered in the instrument control software for calibration of the

instrument.

Using the default cell constant value of 1.000 is usually adequate; however, for greatest accuracy, calibration

should be performed.

It is recommended that you follow the procedures of ASTM Standard Test Method E831 to perform the cell

constant calibration.

TMA Q Series Getting Started Guide

37

Page 38

Running a TMA Experiment

CAUTION: Drying out the instrument may be needed, if it has been exposed to humid

conditions. Certain ceramic materials used in this equipment may absorb moisture,

causing leakage currents to exceed those specified in the applicable standards until

moisture is eliminated. It is important to be certain that the instrument ground is

adequately connected to the facilities ground for safe operation.

Run the following method to dry out the TMA:

1 Ramp at 10°C/min to 400°C

2 Isothermal for 30 min.

All of your TMA experiments will follow the same general outline (see page 35). In some cases, not all of these

steps will be performed. The following sections provide more information on these steps. See the instrument

control software online help for anything not covered in this manual.

Selecting a Probe

The type of probe that you use is dependent upon the kind of testing information desired. The table below

lists the probes available, their specifications, and the type of testing yielded.

When choosing a probe to use for an experiment, follow these steps:

1. Select and install the appropriate probe for the analysis desired. See the table on the next page for a brief

description of the various probes available.

2. Perform a Probe Calibration for a newly installed probe or “zero” an already installed probe. (The

zeroing instructions are found in the next section.)

TMA Probe Types

Probe Type Contact Diameter Pressure Exerted by Types of Tests Yielded

mm (in.) 0.01 N Load

Penetration 0.89 (0.035) 16 kPa Softening point

Melting point

Expansion 2.54 (0.100) 1.9 kPa Expansion coefficient

Compression modulus

Tensile modulus

Glass transition

Macro Expansion 6.07 (0.239) 0.34 kPa Expansion coefficient

Compression modulus

Tensile modulus

Glass transition

Film/Fiber Not applicable Not applicable Tensile stress

38

(table continued)

TMA Q Series Getting Started Guide

Page 39

Probe Type Contact Diameter Pressure Exerted by Types of Tests Yielded

mm (in.) 0.01 N Load

Flexure 5.08 (0.2) 0.49 kPa Deflection temperature

Flexibility

Dilatometer 6.07 (0.239) 0.34 kPa Expansion coefficient

Parallel Plate 9.52 (0.375) 0.14 kPa Viscosity-temperature

Viscosity-time

Wall shear rate

Hemispherical ~2.54 (0.1) ~1.9 kPa Softening point

NOTE: Refer to online help for details regarding the probes.

Zeroing the Auto Measure System

This procedure is used to initialize the auto-length measure system. It should be performed before each

experiment to ensure accurate sample length measurements. To zero the TMA auto measure system, simply

press the ZERO LENGTH key on the touch screen.

TMA Q Series Getting Started Guide

39

Page 40

Guidelines for Handling Samples

Sample Preparation

Sample preparation will vary based on the selected probe type. Guidelines for samples used for penetration

and expansion

• They should be as flat as possible, with parallel ends, to ensure stable placement on the stage.

• Samples should be long enough (5 to 10 mm for most materials) for adequate resolution, keeping in

mind that large samples may experience temperature gradients during high heating rates.

• Thermoplastic samples can be heated and formed into suitable specimens and then cooled; however,

this process may change important thermal history.

• If you plan to run samples that may melt and adhere to the stage, it is best to use the quartz protective

wafers under the sample. See the next section for information.

Sample Loading

After your sample has been prepared, follow these steps to load it on the TMA:

1. Raise the furnace and rotate it clockwise to move it off to the side.

2. Remove any previously run samples from the stage and ensure that no residue remains.

studies are detailed below:

NOTE: It is recommended that you place a quartz wafer or a piece of thin aluminum foil

between the stage and any thermoplastic samples to prevent damage to the stage. See step

3.

3. For samples that may melt and adhere to the stage: Place the protective quartz wafer onto the stage and

center it.

4. Access the Control Menu on the touch screen. Press ZERO

LENGTH on the touch screen to provide a zero reference point.

5. Open (raise) the probe. (Press PROBE UP on the touch screen).

6. Place the sample on the stage under the probe tip (see the figure

to the right).

7. Adjust the sample thermocouple, if needed. Regardless of the

size or shape of the sample that you are running on the TMA,

position the tip of the thermocouple so that it bends at a gentle

90° angle and lies flat against the platform. It should be close to,

but not touching the sample (as shown here). Note that a sharp

bend could damage the thermocouple.

8. Measure the sample length as follows: Before you begin the

experiment, it is important to take an initial measurement of the

sample. To do this, simply press the MEASURE key on the

instrument touch screen. This automatically applies the preload

force that you have specified through the instrument control

program, then measures and stores the sample length.

40

TMA Q Series Getting Started Guide

Page 41

Starting an Experiment

Before you start the experiment, ensure that the TMA is connected with the controller, the sample is loaded,

the furnace is closed, and you have entered all necessary information through the instrument control software.

NOTE: Once the experiment is started, operations are best performed at the computer

keyboard. The TMA is very sensitive to motion and might pick up the vibration caused by

touching a key on the instrument touch screen.

Stopping an Experiment

If for some reason you need to discontinue the experiment, you can stop it at any point by selecting Stop

through the instrument control software or by pressing the STOP key on the touch screen.

Another function that stops the experiment is REJECT. However, the Reject function discards all of the data

from the experiment while the Stop function saves any data collected up to the point at which the experiment

was stopped.

TMA Q Series Getting Started Guide

41

Page 42

Maintaining the Instrument

The primary maintenance procedures described in this section are the customer’s responsibility. Any further

maintenance should be performed by a representative of TA Instruments or other qualified service personnel.

Consult the online documentation installed with the instrument control software for further information.

WARNING: Because of the high voltages in this instrument, untrained personnel must

not attempt to test or repair any electrical circuits.

CAUTION: Before using any cleaning or decontamination method except those

recommended by TA Instruments in this chapter, please check with TA Instruments to

make sure that the proposed method will not damage the equipment.

Cleaning the Touch Screen

You can clean the TMA touch screen as often as you like. The touch screen should be cleaned with a household liquid glass cleaner and soft cloth. Wet the cloth, not the touch screen with the glass cleaner, and then

wipe off the touch screen and surrounding surfaces.

WARNING: Do not use harsh chemicals, abrasive cleansers, steel wool, or any rough

materials to clean the touch screen as you may scratch the surface and degrade its

properties.

Cleaning the Probe Assembly

After each experiment, check the probe assembly. If the probe is dirty, remove it using the procedures found

in Chapter 2 and the online help, then clean the probe as follows:

1. Use contact cleaner or acetone applied with a soft brush or cloth to clean the LVDT core and the upper

probe.

2. Heat the end of the quartz probe with a Bunsen burner until the residue evaporates and the probe is

clean. Heat the probe very slowly if the sample contains a large amount of glass or mineral filler.

NOTE: Probes may also be cleaned in a nitric acid solution.

42

TMA Q Series Getting Started Guide

Page 43

Cleaning the St age

Dirt or sample residue left on the top of the stage may interfere with the next sample placed on the stage. To

maintain proper experimental conditions, clean the stage as follows:

For small amounts of residue:

1. Use industrial cleaner or acetone on a soft cloth to wipe the top of the stage.

For thorough cleaning:

Refer to the figure to the right when needed.

1. Raise the furnace, and rotate it clockwise to move it off

to the side.