Page 1

D770-32-00 1 I56-0053-003R

Zonecheck

Flow Switch Tester

INSTALLATION AND MAINTENANCE INSTRUCTIONS

3825 Ohio Avenue, St. Charles, Illinois 60174

1-800-SENSOR2, FAX: 630-377-6495

www.systemsensor.com

Important

Please Read Carefully And Save

This instruction manual contains important information about the installation and operation of a Zonecheck Flow Switch Tester. Purchasers who

install waterflow detectors for use by others must leave this manual or a

copy of it with the user.

Read all instructions carefully before beginning. Follow only those instructions that apply to the model you are installing.

Use Zonecheck Flow Switch Testers in wet-pipe systems only. Do NOT use

them in dry pipe, deluge, or preaction systems.

Do not use in potentially explosive atmospheres. Do not allow unused

wires to remain exposed.

Principles Of Operation

Retrofit Model

Zonecheck Flow Switch Tester shall mount on any clear steel pipe span of

the appropriate nominal size, either in a vertical upflow or horizontal run,

between 6″ and 12″ from the flow switch. Flow Switch Tester shall consist

of a recirculating pump, operating at nominal 110V or 220V as appropriate,

two (2) sets of valves and elbows to facilitate the circulation of the water,

a System Sensor vane-type waterflow detector, and a key switch to activate

the recirculating pump. When activated, the pump shall circulate the water

within the sprinkler riser around the waterflow detector vane to simulate

the flow of one sprinkler head in operation. The activating key switch shall

provide the means to be wired locally to one Flow Switch Tester, or interconnected with other key switches for group activation. Flow Switch Tester

shall be available for manifold and retrofit installation applications.

Manifold Model Specifications

Zonecheck Flow Switch Tester manifold models shall consist of a schedule 10 pipe assembly of the appropriate nominal size. Manifold assembly

CAUTION

Specifications

Static Pressure Rating: 175 PSI

Operating Temperature Range: 32°F–120°F (0°C–49°C)

Compatible Pipe

(Manifold Models): Schedule 10, 2″–4″ diameter

Compatible Pipe

(Retrofit Models): Schedule 10 and 40, 2″–8″ diameter

(50 mm through 200 mm)

Service Use: Inspection, Testing and

Maintenance of Water-Based

Fire Protection Systems: NFPA 25;

National Fire Alarm Code: NFPA 72

Manifold Assembly Length

(Manifold Models): 25.6″ (65 cm)

Component Connections:

Manifold Models: Retrofit Models:

2 ea. - 1″ NPT/25mm 2 ea. - 1″ NPT/25mm British Standard

British Standard Thread elbows

Thread elbows 2 ea. - 25mm British Standard

Thread elbows

Valves: Red: Standard valve

Green: Contains check valve

Warranty: 3 years

shall provide grooved ends for accepting the appropriate grooved connection fittings. Manifold assembly shall include no less than two drain ports

with the appropriate drain plugs. Manifold Zonecheck models shall come

with the pump, valves, elbows, pipe assembly, drain plugs, and System

Sensor waterflow detector pre-assembled.

Manifold Models

Domestic Models with 1

10 V Pump Canadian Models with 110 V Pump

ZC20, ZC25, ZC30, ZC40 ZC20A, ZC25A, ZC30A, ZC40A

Retrofit Models

Domestic Models Canadian Models International Models

with 110 V Pump with 110 V Pump with 220 V Pump

ZCR20 ZCR20A ZCR20E

ZCR25 ZCR25A ZCR25E

ZCR30 ZCR30A ZCR30E

ZCR40 ZCR40A ZCR40E

ZCR60 ZCR60A ZCR60E

ZCR80 ZCR80A ZCR80E

Replacement Parts

ZCK-1 Zonecheck 110V Keyswitch ZCK-1E Zonecheck 220V Keyswitch

ZCP-110 Zonecheck 110V Pump ZCP-220 Zonecheck 220V Pump

Do NOT install Zonecheck on copper piping.

General Installation Recommendations

Before installing any waterflow-related device, be thoroughly familiar

with: NFPA 72: National Fire Alarm Code

NFPA 13: Installation of Sprinkler Systems, Section 3.17

NFPA 25: Inspection, Testing and Maintenance of Sprinkler Systems

CAUTION

Electrical Specifications

Pump Operating Voltages: Domestic/Canadian models:

1.63A@110 V, 60 Hz

International models: .88A@220 V, 50Hz

Key Switch Operating Voltage: ZCK-1 110V, 60Hz; ZCK-1E: 220V, 50Hz

Key Switch Mounting Options: Includes back box for surface or flush

mounting. For pre-wiring, use a

411/16″ x 411/16″ back box

Key Switch Operation Modes: Self-test: Wired locally

Group test: Interconnected

Key Switch LED Operation: Ready state: No LED

Test Initiation: Green LED

Flow switch activation: Red LED

Page 2

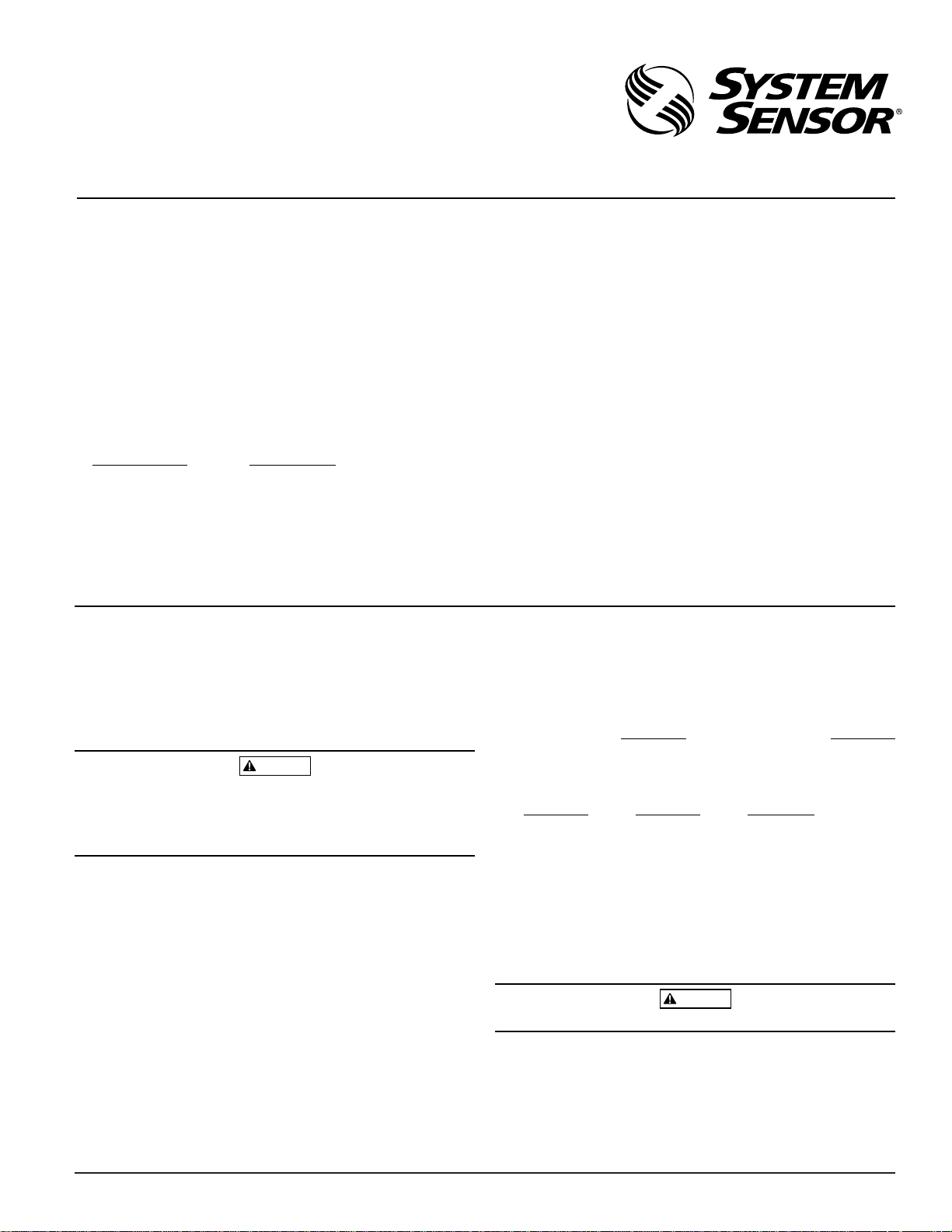

Zonecheck pump) on the other. IMPORTANT: There are two

Zonecheck valves enclosed with each Retrofit kit: 1.) A ‘Red’-handled

valve, which is a standard valve that serves as an inlet valve; and, 2.)

A ‘Green’-handled valve, which is an outlet valve that contains a check

valve. The valves must be oriented properly for Zonecheck to work

correctly. If mounting Zonecheck to a vertical riser, attach the Red

valve so that it will be above the pump, as the assembly would appear

after installion (See Figure 1 for illustration). If mounting Zonecheck

to a horizontal run of pipe, attach the red valve so that it will be downstream, in relation to the sprinkler system waterflow, from the

Zonecheck pump (See Figure 1 also). Attach the mechanical tees (supplied by others), ensuring that both tees are parallel to each other and

perpendicular to the Zonecheck assembly. Ensure that all joints are

tight and set the entire assembly aside.

3. Place the aluminum angle template on the pipe (leg ends contacting

pipe surface) locating one edge of the leg where the mechanical tee

holes will be drilled. Scribe or draw a pencil line on the

pipe the full length of the template. Note: Ensure

that both legs of the aluminum template

are in complete contact along their

entire length with the pipe surface to

ensure that the scribed line will run

along the center line of the pipe. Failure

to follow this step may cause damage to the Zonecheck product or

leakage.

4. Measure the center-to-center distance between the

mechanical tees and transfer that measured distance to the scribed line on the pipe surface. IMPORTANT: Ensure that the

markings on the pipe are located so

that the stripes on the Zonecheck pump

housing will be parallel to the floor

after installation (See Figure 1 for installation). Failure to follow this

step may result in pump seizure.

5. The Waterflow detector will typically mount to the pipe 90 degrees from

the location of the pump, as space permits. To determine

the location of the flow switch, scribe a second line

parallel to the line made in Step 3 and mark the

midpoint between the mechanical tees

This intersection line will locate the hole

for the waterflow device. Ensure that this

location will permit access to both the

detector and the Zonecheck assembly. If

located on horizontal pipe, ensure that the waterflow detector, once

mounted, will be located on the topside of the pipe. Ensure that the

intended location does not result in the detector being mounted upsidedown, as condensation may collect in the housing and impair the operation of the detector. See Figure 1 for illustration.

6. Refer to the suggested hole size requirements from the mechanical tee

manufacturer and the waterflow manufacturer and drill the three holes

where marked in Steps 4 & 5. IMPORTANT: Before drilling, verify that

the stripes on the Zonecheck pump housing will be parallel to the floor

after installation, as noted in Step 4 (See Figure 1 for illustration).

When drilling the holes with a hole saw, make certain that the center

of the cut does not remain in the pipe. Clean the outside of the pipe to

remove dirt, metal chips, and cutting lubricant.

7. Mount the completed Zonecheck assembly to the sprinkler pipe.

Secure the U-bolts of the mechanical tees and tighten to manufacturer’s recommended torque.

8. Remove the waterflow detector from the carton and install on pipe.

The direction-of-flow arrow shown on the saddle must match the

direction of the waterflow in the pipe. Refer to the manufacturer’s

instructions for mounting the waterflow detectors.

9. Refer to the wiring diagram (see Figure 2.) for proper electrical connections for stand-alone or multiple unit keyswitch installation.

Other applicable NFPA standards, local codes, and the requirements of the

authority having jurisdiction also apply.

Failure to follow these directions may prevent the device from reporting

the flow of water in the event the associated sprinkler system is activated

by a fire. System Sensor is not responsible for devices that have been

improperly installed, tested, or maintained.

1. Mount the Zonecheck Flow Switch Tester where there is adequate

clearance for installation and removal and a clear view of it for inspections.

2. When installing a manifold model, locate 6 to 7 feet above the floor to

protect from possible damage. When installing a retrofit model, mount

between 6″ and 12″ from the flow switch.

3. On horizontal runs, orient the Zonecheck Flow Switch Tester on the

side of the pipe only. Failure to do so may impair the operation of the

Zonecheck pump (see Figure 1). For vertical flow applications, mount

the Zonecheck Flow Switch Tester on pipe through which water flows

upward. Otherwise, the unit may not operate properly.

4. Mount the Zonecheck Flow Switch Tester at least 6 inches from a fitting that changes the direction of water flow and no less than 24 inches from a valve or drain.

5. Be sure the direction-of-flow arrow shown on the saddle matches the

direction of the waterflow in the pipe.

Before installing a Zonecheck Flow Switch Tester:

1. Contact central monitoring station or appropriate fire safety personnel

before installing the Zonecheck Flow Switch Tester.

2. Identify and close tightly the sprinkler system’s zone valve.

3. Close both (Red & Green) Zonecheck valves.

4. Drain the sprinkler zone.

Installation Guidelines

Manifold Model

1. Remove the assembled manifold unit from the carton.

2. Prepare to install the manifold unit to the riser. If mounting the manifold unit to a vertical riser, orient the assembly with the red valve

above the Zonecheck pump. If mounting the manifold to a horizontal

waterflow pipe, orient the assembly with the red valve on the downstream end of the waterflow pipe (see Figure 1). Verify that the stripes

on the Zonecheck pump housing will be parallel to the floor after

installation. If Zonecheck will be located on a horizontal pipe, ensure

that the waterflow detector, once mounted, will be located on the topside of the pipe (see Figure 1 for illustration). Ensure that the intended location does not result in the detector being mounted upside

down, as water may collect in the housing and impair the operation of

the detector.

3. Mount the Schedule 10 pipe (to which the Zonecheck pump and

Waterflow Detector are mounted) to the riser using industry-accepted

practices in conjunction with applicable NFPA standards, local codes,

and the authority having jurisdiction.

4. Refer to the wiring schematic for proper electrical connections for

stand-alone or multiple unit keyswitch installation.

Retrofit Model

1. Remove contents from the carton.

2. Assemble the Zonecheck unit. If the mechanical tees used to attach the

Zonecheck unit to the sprinkler pipe have a British Standard Pipe

Thread (BSPT) outlet, select the elbows contained within the bag

marked ‘BSPT/BSPT’. If the mechanical tees have an NPT thread outlet, select the elbows contained within the bag marked ‘NPT/BSPT’

(Note: the embossed ‘A’ on the elbow designates the NPT thread).

Choose the appropriate elbows. Connect the BSPT threaded end of the

90-degree elbows to each of the Zonecheck valves, insert the gasket

into the valve, and connect each valve to the correct side of the

Zonecheck pump. Each valve has a female BSPT threaded end (connected to the elbow) on one side and a male union (connected to the

CAUTION

D770-32-00 2 I56-0053-003R

Page 3

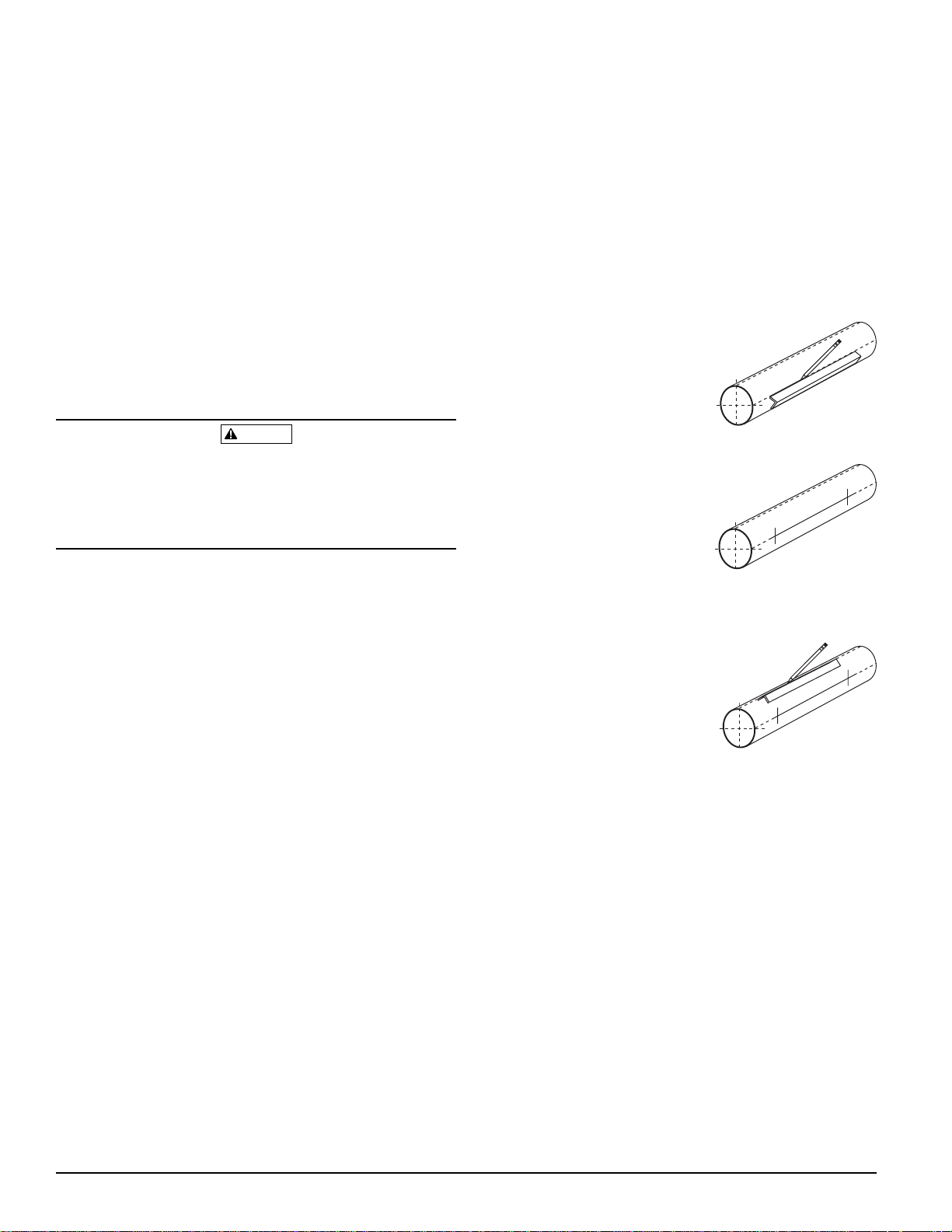

Figure 2. Wiring Diagrams

D770-32-00 3 I56-0053-003R

WIRING DIAGRAM FOR STAND ALONE APPLICATION

}

}

FOR INTERCONNECTING MULTIPLE ZONECHECK UNITS

}

}

}

}

AC POWER AND PUMP WIRING

MUST CONFORM TO NEC OR

YOUR LOCAL CODES.

OR OTHER MONITORING DEVICE.

WATERFLOW

DETECTOR

KEYSWITCH OPERATION IF WATERFLOW

DETECTOR IS CONNECTED TO PANEL

WF INPUT NOT REQUIRED FOR

NOTE:

AC GROUND

AC POWER

GND

JUNCTION BOX

AC

PUMP

PUMP

AC

WF INPUT

WATERFLOW

DETECTOR

INTER-CONNECT

PUMP

TO EARTH GND.

OR ATTACH TO

JUNCTION BOX

OR ATTACH TO

JUNCTION BOX

OR ATTACH TO

INTERCONNECT

SWITCH FOR

ZONECHECK

TO NEXT

AC GROUND

AC POWER

GND

AC

PUMP

PUMP

AC

TO EARTH GND.

PUMP

WF INPUT

INTER-CONNECT

PUMP

AC POWER

AC GROUND

TO EARTH GND.

PUMP

PUMP

AC

AC

GND

INTER-CONNECT

WF INPUT

WATERFLOW

DETECTOR

Figure 1. Zonecheck Installation

Correct Horizontal Installation

Correct Vertical Installation

Incorrect Horizontal Installation Incorrect Horizontal Installation

RED VALVE

WATERFLOW

DETECTOR

GREEN

VALV E

ZONECHECK

PUMP

RED VALVE

GREEN

VALV E

ZONECHECK

PUMP

WATERFLOW

DETECTOR

ZONECHECK

PUMP

ZONECHECK

PUMP

CORRECT

Pump stripes

(horizontal)

INCORRECT

Pump stripes

(vertical)

Page 4

D770-32-00 4 I56-0053-003R

©

2000 System Sensor

Three-Year Limited Warranty

System Sensor warrants its enclosed Zonecheck Flow Switch Tester to be

free from defects in materials and workmanship under normal use and

service for a period of three years from date of manufacture. System Sensor

makes no other express warranty for this Flow Switch Tester. No agent, representative, dealer, or employee of the Company has the authority to

increase or alter the obligations or limitations of this Warranty. The

Company’s obligation of this Warranty shall be limited to the repair or

replacement of any part of the Flow Switch Tester which is found to be

defective in materials or workmanship under normal use and service during the three year period commencing with the date of manufacture. After

phoning System Sensor’s toll free number 800-SENSOR2 (736-7672) for a

Return Authorization number, send defective units postage prepaid to:

System Sensor, Repair Department, RA #__________, 3825 Ohio Avenue,

St. Charles, IL 60174. Please include a note describing the malfunction and

suspected cause of failure. The Company shall not be obligated to repair or

replace units which are found to be defective because of damage, unreasonable use, modifications, or alterations occurring after the date of manufacture. In no case shall the Company be liable for any consequential or

incidental damages for breach of this or any other Warranty, expressed or

implied whatsoever, even if the loss or damage is caused by the Company’s

negligence or fault. Some states do not allow the exclusion or limitation of

incidental or consequential damages, so the above limitation or exclusion

may not apply to you. This Warranty gives you specific legal rights, and

you may also have other rights which vary from state to state.

1. Zonecheck Flow Switch Testers may not work or operate properly if

sprinkler piping being monitored is plugged with pipe scale, mud,

stones or other foreign material. Sprinkler systems should be checked

regularly for such blocking material, following the instructions in

Chapter 5 of NFPA Standard 13A.

The Limitations of Zonecheck Flow Switch Tester

WARNING

2. All valves controlling a sprinkler water supply should be sealed or

locked in the normally open position. The normally open position

should be monitored by a sprinkler supervisory switch.

Please refer to insert for the Limitations of Fire Alarm Systems

Pre-Operation Guidelines

Contact central monitoring station or appropriate fire safety personnel

prior to testing Zonecheck.

Zonecheck Testing: Self-Test Mode

To activate the Zonecheck wired locally to the ZCK-1 key switch (refer to

stand-alone wiring diagram), insert key and turn to the right. The green

LED on the ZCK-1 will illuminate to show that the pump has been activated. The red LED on the ZCK-1 will illuminate once the waterflow detector has been activated. The red and green LEDs will remain illuminated

until the key is switched to the standby position. NOTE: The red LED will

not illuminate if the waterflow detector is not wired to the ZCK-1 key

switch. When testing has been completed, turn the key back to the standby position.

Only activate the Zonecheck ZCK-1 key switch when the valves are

opened and the sprinkler system is full.

WARNING

Zonecheck Testing: Group-Test Mode

All Zonecheck systems whose ZCK-1 key switches are interconnected

(refer to interconnecting wiring diagram), may be activated from any ZCK1 key switch. To initiate the group test, insert key and turn to the left.

The LEDs on the key switch from where the group test was initiated only

indicate the activity for the Zonecheck connected directly to that key

switch. The red and green LEDs will remain illuminated until the key is

switched to the standby position.

When testing has been completed, turn the key back to the standby

position.

Trouble Shooting Recommendations for Zonecheck Flow Switch

Tester

The unit fails to activate the remote alarm signal

1. Is there power to the circulator, i.e. Zonecheck pump?

2. Is the impeller spindle turning? If not, switch off at the key switch.

Turn the spindle manually with a screwdriver for several turns then

switch on the keyswitch.

3. Is the circulator fitted correctly for the flow of water to move the paddle?

4. Is the green handled valve fitted on the delivery side of the circulator?

5. Are the Zonecheck valves in the “open” position?

6. Is the signal wiring operating correctly? Check the wiring.

After installing a Zonecheck Automatic Flow Switch Tester:

1. Backfill and hydraulically test the system.

2. Contact central monitoring station or appropriate fire safety personnel.

3. Open the main isolation valve slowly until fully opened.

4. Open both Zonecheck valves fully.

CAUTION

Loading...

Loading...