System Sensor WFD Series, WFD20, WFD25, WFD30, WFD35 Installation And Maintenance Instructions Manual

...Page 1

INSTALLATION AND MAINTENANCE INSTRUCTIONS

WFD Vane-type Waterflow

3825 Ohio Avenue, St. Charles, Illinois 60174

Detectors

Specifications

Contact Ratings: 10 A @ 125/250 VAC

2.5 A @ 24 VDC

Triggering Threshold Bandwidth (Flow Rate): 4 to 10 gpm

Static Pressure Rating: 250 PSI (Max) 2" – 8"

Dimensions, Installed: 3.5"H x 3.0"W x 6.7"D

Operating Temperature Range: 32°F to 120°F (0°C to 49°C)

Compatible Pipe: Steel water pipe, schedule 10 or 40.

Shipping Weight: 4 to 7 lb., according to size.

Enclosure Rating: NEMA 4, as tested by Underwriters Laboratories, Inc.

(requires optional Outdoor Cover Gasket Model WFDN4 and cover part #C58-164-01)

Important

Please Read Carefully And Save

This instruction manual contains important information

about the installation and operation of waterflow detectors.

Purchasers who install waterflow detectors for use by others must leave this manual or a copy of it with the user.

Read all instructions carefully before beginning. Follow

only those instructions that apply to the model you are installing.

Principles Of Operation

Vane-type waterflow detectors mount to water-filled pipes

in sprinkler systems. Waterflow in the pipe deflects a vane,

which produces a switched output–usually after a specified

delay. All waterflow detectors have a pneumatically controlled mechanical delay mechanism. Delays do NOT accumulate; they reset if the flow of water stops before the

entire delay has elapsed. All switches actuate when the water flow rate is 10 gallons per minute or greater, but will not

actuate if the flow rate is less than 4 gallons per minute.

1-800-SENSOR2, FAX: 630-377-6495

A Division of Pittway

CAUTION

Use vane-type waterflow detectors in wet-pipe systems

only. Do NOT use them in dry pipe, deluge, or preaction

systems. The sudden inrush of water in such systems may

break the vane or damage the mechanism.

Do not use in potentially explosive atmospheres. Do not allow unused wires to remain exposed.

This System Sensor installation manual covers the following waterflow detectors for sprinkler/fire alarm applications.

Models

WFD20 Waterflow detector, Schedule 10/40, 2"

WFD25 Waterflow detector, Schedule 10/40, 2-1/2"

WFD30 Waterflow detector, Schedule 10/40, 3"

WFD35 Waterflow detector, Schedule 10/40, 3-1/2"

WFD40 Waterflow detector. Schedule 10/40, 4"

WFD50 Waterflow detector, Schedule 10/40, 5"

WFD60 Waterflow detector, Schedule 10/40, 6"

WFD80 Waterflow detector, Schedule 10/40, 8"

D770-01-00 1 I56-459-07

Technical Manuals Online! - http://www.tech-man.com

Page 2

CAUTION

Do NOT use any of the WFD models on copper pipe. The

clamping forces of the mounting bolts may collapse the

pipe sufficiently to prevent the detector from functioning

properly.

Do NOT install steel or iron pipe sections in copper piping

for mounting a waterflow detector. Incompatibility between the dissimilar metals causes bimetallic corrosion.

Installation Guidelines

Before installing any waterflow alarm device, be thoroughly familiar with:

NFPA 72: National Fire Alarm Code

NFPA 13: Installation of Sprinkler Systems, Section 3.17

NFPA 25: Inspection, Testing and Maintenance of Sprin-

kler Systems

Other applicable NFPA standards, local codes, and the requirements of the authority having jurisdiction

Failure to follow these directions may prevent the device

from reporting the flow of water in the event the associated

sprinkler system is activated by a fire. System Sensor is not

responsible for devices that have been improperly installed,

tested, or maintained.

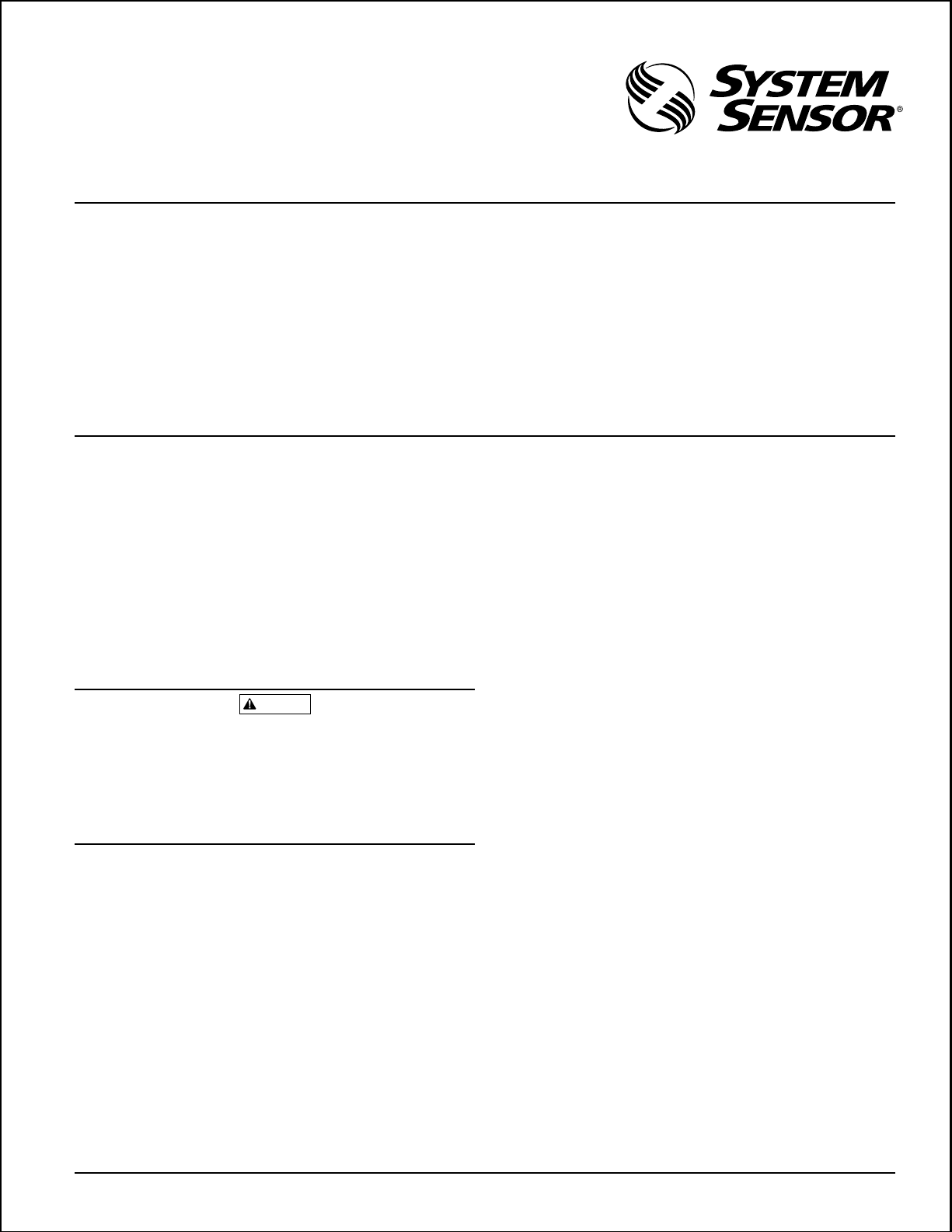

Figure 1. Mounting dimensions:

3-3/4"

3"

U-bolt nut

Pipe saddle

U-bolt

Overall width = pipe diameter + 3"

Pipe diameter

plus 5-1/4"

Pipe

Plastic vane

A78-1609-00

1. Mount the detector where there is adequate clearance for

installation and removal and a clear view of it for inspections. See Figure 1 for mounting dimensions.

2. Locate to protect from damage–6 to 7 feet above the

floor.

3. On horizontal runs, position the detector on the top or

side of the pipe. Do not mount it upside down because

condensation may collect in the housing and impair the

operation of the detector.

For vertical flow applications, mount the detector on

pipe through which water flows upward. Otherwise, the

unit may not operate properly.

4. Mount the detector at least 6 inches from a fitting that

changes the direction of water flow and no less than 24

inches from a valve or drain.

5. Be sure the direction-of-flow arrow matches the direction

of flow in the pipe.

Mounting Instructions

1. Drain the pipe.

2. Cut a hole at the desired location. Center the hole in the

pipe, as shown in Figure 2, and be sure the hole is perpendicular to the center of the pipe. Before drilling, use a

punch or scribe to mark the drill site to prevent the bit

from slipping. If the hole is off center, the vane will bind

against the inside wall of the pipe. Use a drill or hole

saw to cut a hole of the proper diameter. See Table 1 for

hole size.

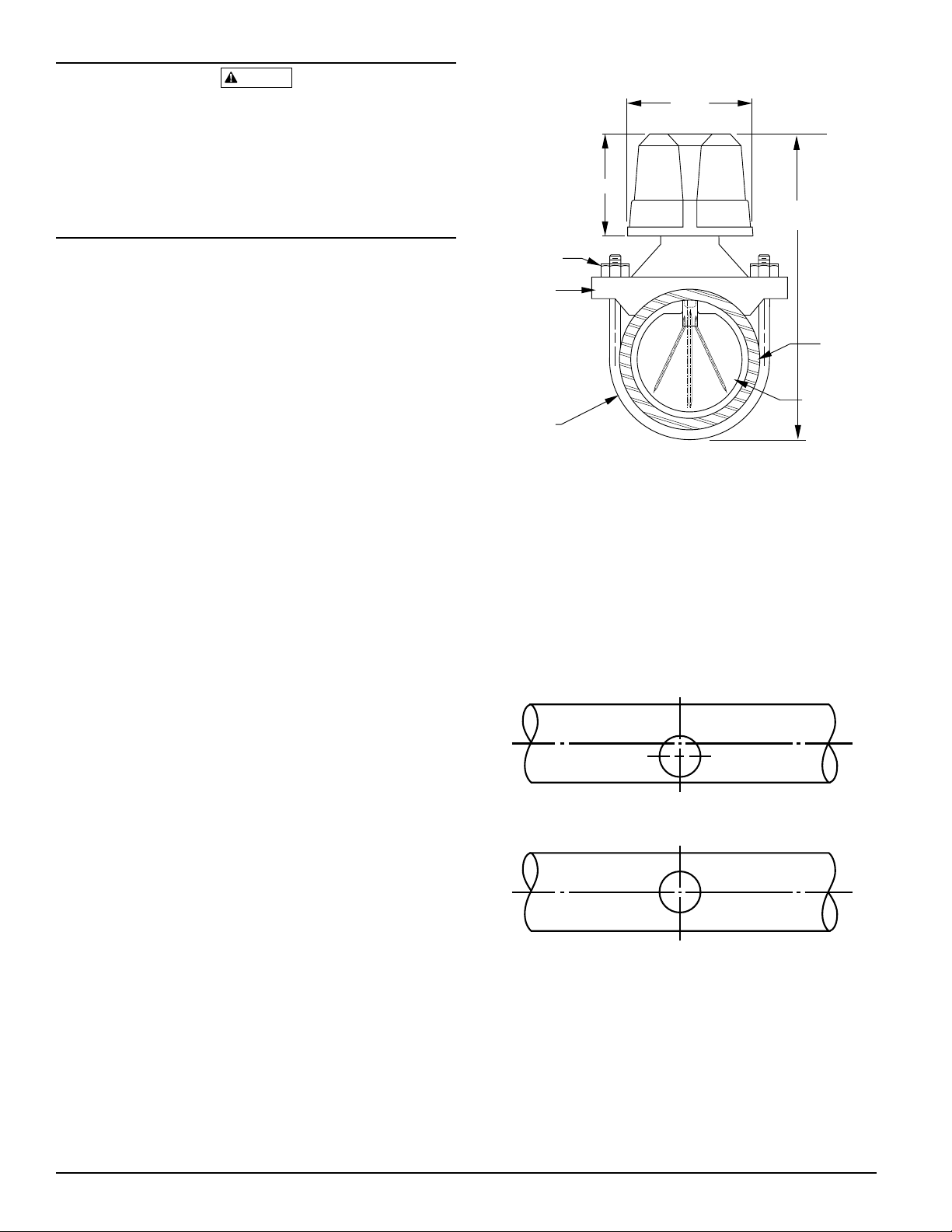

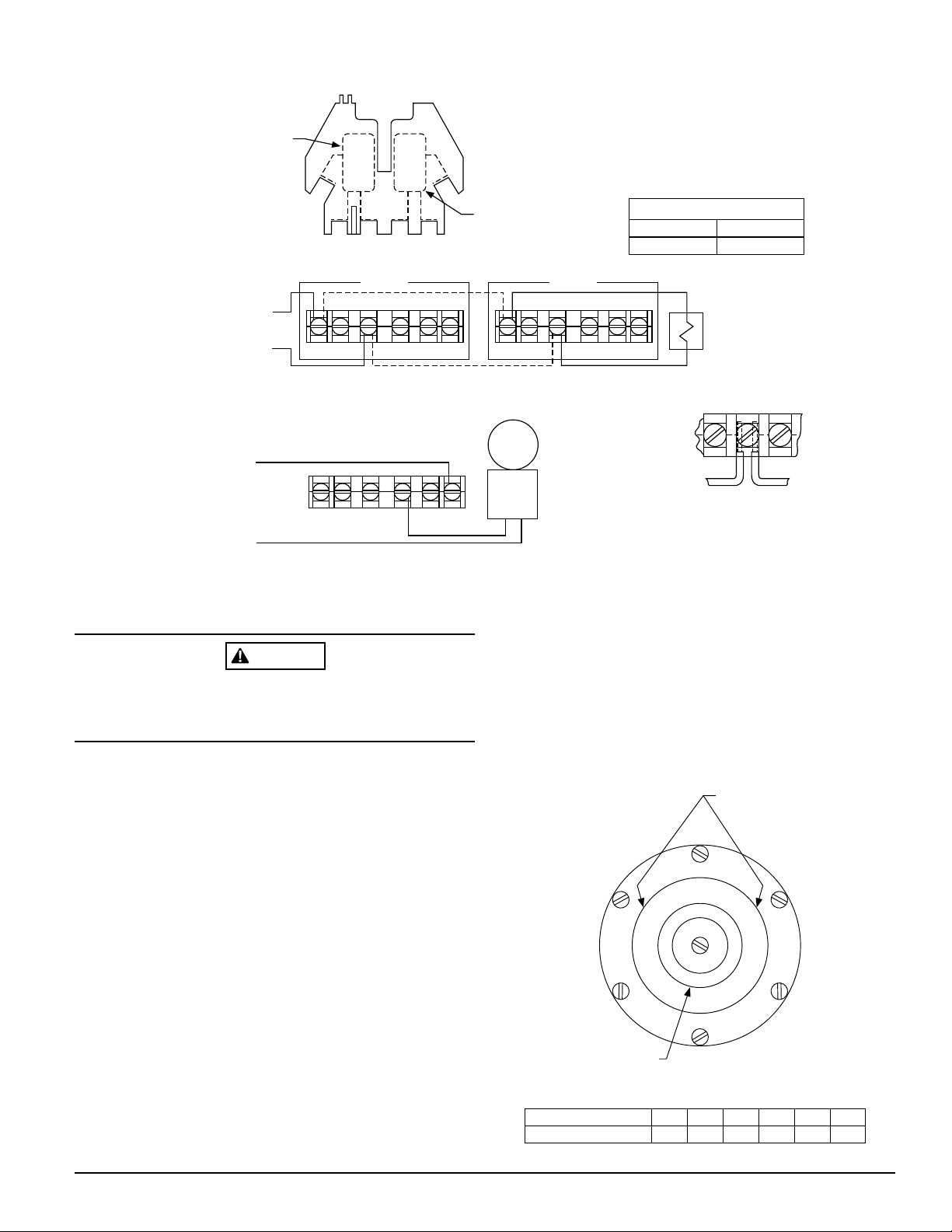

Figure 2. Mounting hole location:

Wrong

Right

Remove burrs from edge of hole. Clean out scale and foreign

matter for one pipe diameter on each side of hole.

A78-1496-01

D770-01-00 2 I56-459-07

Technical Manuals Online! - http://www.tech-man.com

Page 3

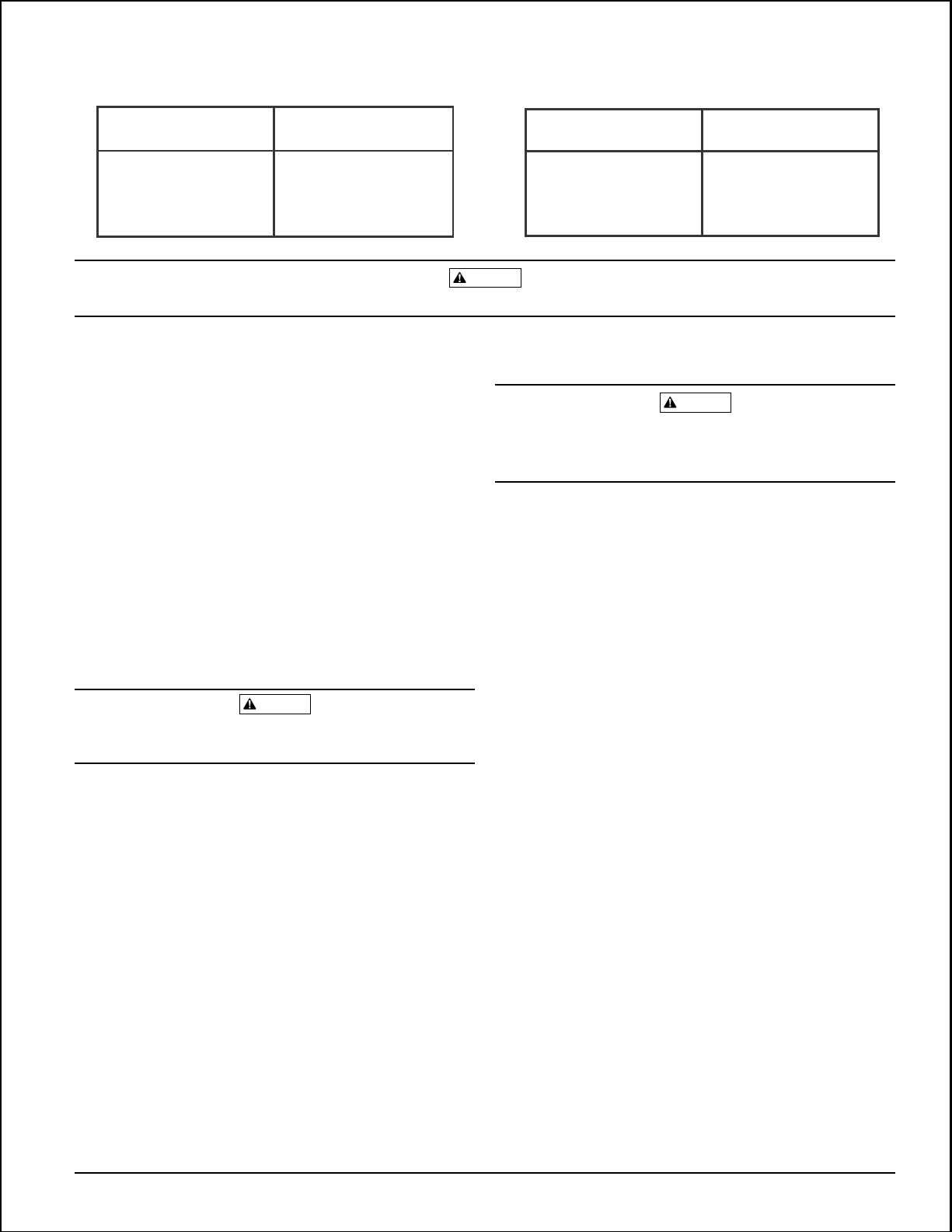

Table 2:Table 1:

WFD SIZE Hole Size

2" - 3-1/2

4" - 8

When drilling the hole with a hole saw, make certain that the center of the cut does not remain in the pipe.

3. Remove burrs and sharp edges from the hole. Clean and

remove all scale and foreign matter from the inside of

the pipe for one diameter on each side of the hole to ensure free movement of the vane. Clean the outside of the

pipe to remove dirt, metal chips, and cutting lubricant.

4. Seat the O-ring or gasket against the saddle and mount

the detector directly to the pipe. Carefully roll the vane

opposite the direction of flow and insert it through the

hole. Seat the saddle firmly against the pipe so that the

locating boss goes into the hole.

5. Install the U-bolt, tightening the nuts alternately to en-

sure a uniform seal. See Table 2 for torque values.

6. Remove the metal cover with the tamper-proof wrench

provided. Move the actuator lever back and forth to

check for binding. If the vane binds, remove the detector

and correct the cause before proceeding.

Be sure the direction-of-flow arrow points in the right direction or else water flow will go unreported. See Figure 3.

Preoperation Testing

1. Fill the sprinkler system and check for leaks around the

waterflow detector. If it leaks, first check for the proper

torque on the U-bolt nuts. If the leak persists, drain the

system and remove the detector (refer to Maintenance.

page 6). Check for dirt or foreign objects under the gasket, and make sure that the pipe surface is not dented.

Reinstall the detector and check again for leaks. Do not

proceed until all leaks have been stopped.

2. Connect an ohmmeter or continuity tester across the

COM and B switch terminals. The ohmmeter should indicate an open circuit.

3. Deflect the actuator lever and hold it until the pneumatic

delay shaft releases the switch buttons. The ohmmeter

or continuity tester should show a short circuit after the

delay has elapsed. If there is no delay, check the setting

of the delay adjustment dial.

"

"

CAUTION

1-1/4

2

"

"

CAUTION

Wiring

High Voltage. Electrocution Hazard. Do not handle live AC

wiring or work on a device to which AC power is applied.

Doing so may result in injury or death.

1. All models have two SPDT switches. Switch contacts

COM and B are closed when water is flowing and open

when it is not. Connect the switches, as shown in Figure

4 on page 5, depending on the application.

2. When connected to a listed sprinkler/fire alarm control

panel, the initiating circuit must be nonsilenceable.

3. A ground screw is provided with all waterflow detectors.

When grounding is required, clamp wire with screw in

hole located between conduit entrance holes. See Figure

5A, page 5.

4. If a second conduit entry is required, remove the knockout plug using a flat blade screwdriver as shown on Figure 5B, page 5. Strike sharply with a hammer to pierce

the wall of the knockout plug. Move to an adjacent wall

section and repeat until the plug falls out. Make sure

that the waterflow detector is supported adequately during this operation to avoid injury.

WFD SIZE Torque

2" - 3-1/2

4" - 8

"

"

WARNING

30 - 35 ft-lb

55 - 60 ft-lb

D770-01-00 3 I56-459-07

Technical Manuals Online! - http://www.tech-man.com

Page 4

Figure 3. Assembly diagram:

Cover

Tamper proof wrench

(P/N WFDW)

Switch enclosure

(Replacement P/N A77-01-02)

Delay mechanism

(Replacement

P/N A3008-00)

Mounting plate

Pipe saddle

Roll paddle opposite

of flow arrow

while inserting

Saddle gasket

Plastic vane

Conduit entrance

Direction-of-flow arrow

U-bolt nut

Pipe

Waterflow

WFD Size

"

– 3-1/2"

2

4

"

– 8

D770-01-00 4 I56-459-07

"

Hole Size

1-1/4"

2

"

U-bolt

Technical Manuals Online! - http://www.tech-man.com

A78-1914-00

Page 5

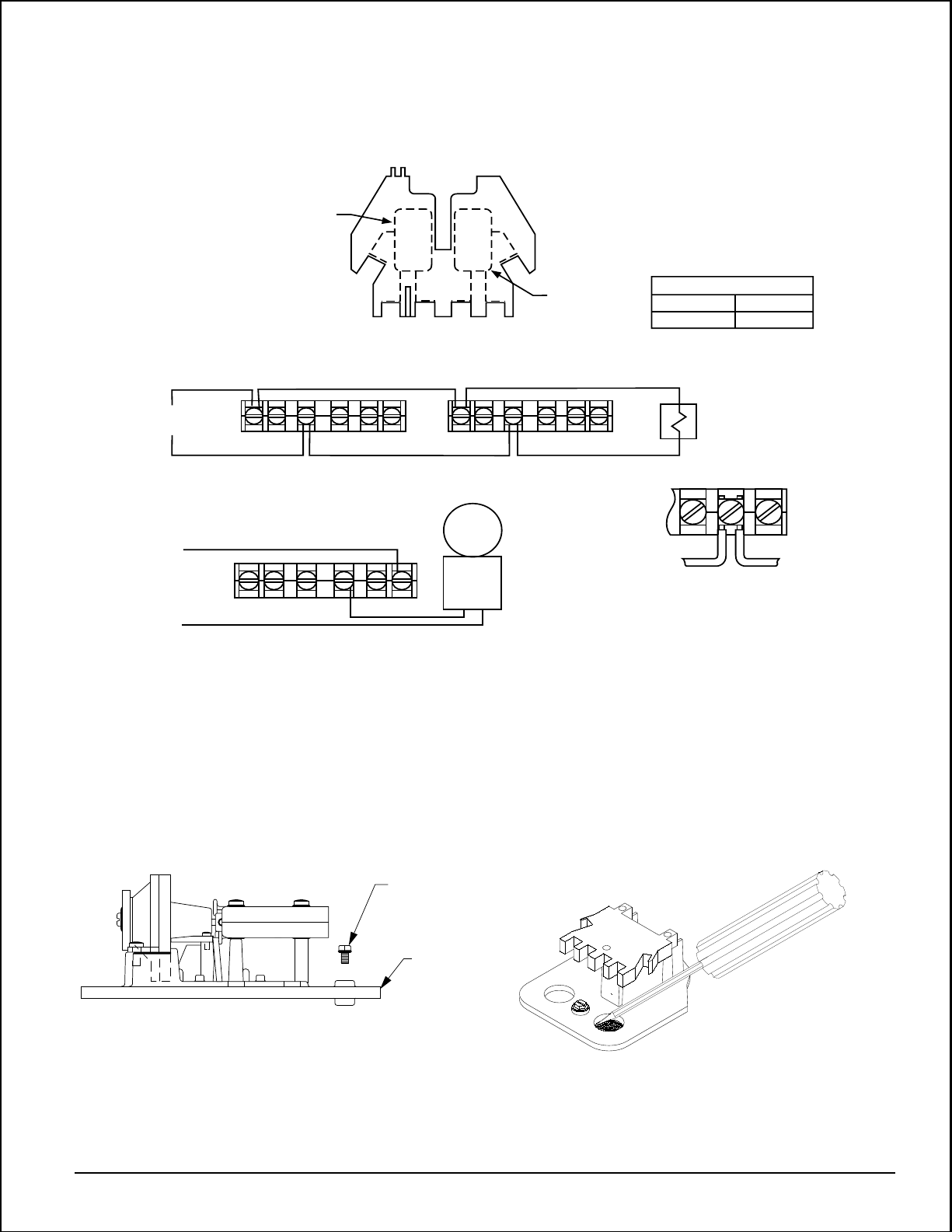

Figure 4. WFD wiring:

WFD Switch

Assembly

Top View

to nonsilenceable initiating

zone of listed FACP

to power source

compatible

with bell

Switch 1

COM

ABBA

WFD

B

B

COM

COM

Typical FACP Connection

(Multiple Detectors)

B

COM

Typical Local Bell Connection

COM

local

bell

COM

B

NOTE: Common and B connections will

close when vane is deflected, i.e.,

when water is flowing. Dual switches

permit applications to be combined

on a single detector.

Switch 2

CONTACT RATINGS

125/250 VAC

24 VDC

WFD

B

end-of-line resistor

COM

Break wire as shown for

supervision of connection.

DO NOT allow stripped wire

leads to extend beyond

switch housing. Do NOT

loop wires.

10 AMPS

2.5 AMPS

Figure 5A. Ground screw location: Figure 5B. Knockout plug removal:

GROUND

SCREW

(GREEN)

MOUNTING

PLATE

A78-1586-00

A78-1914-03A78-2063-00

D770-01-00 5 I56-459-07

Technical Manuals Online! - http://www.tech-man.com

Page 6

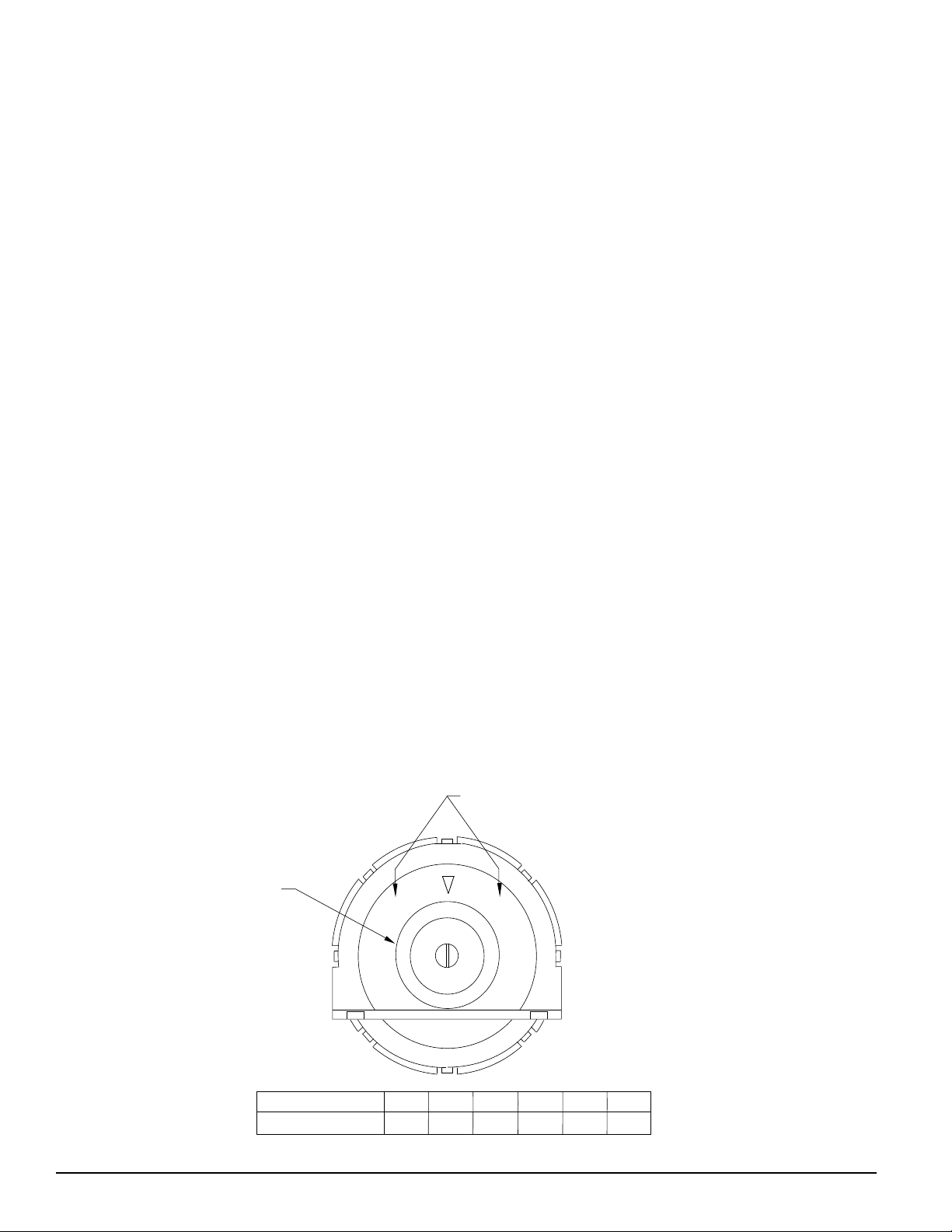

Mechanical Delay Adjustment

The pneumatic delay is preset at the factory to dial setting

2. To adjust the setting, turn the adjustment dial clockwise

to increase the delay, counterclockwise to decrease it. The

delay is adjustable from 0 to 70 seconds. See Figure 6.

NOTE: Set the delay to the minimum required to prevent

false alarms from flow surges.

Maintenance

To prevent accidental water damage, control valves

should be shut tight and the system completely drained

before waterflow detectors are removed or replaced.

Inspect detectors monthly for leaks and replace if a leak

occurs. Test detectors at least monthly, as described under

Operational Testing, to ensure proper operation. Test more

often if required by the authority having jurisdiction.

After extended service, parts of the detector may become

worn, reducing the delay time and causing false alarms. If

this happens, increase the delay. If the delay is already at

the maximum, replace the mechanical delay assembly. Refer to Maintenance for ordering replacement parts.

Operational Testing

Always notify a central station monitoring waterflow

alarms before repairing, maintaining, or testing waterflow

alarm devices.

1. Replace the cover and tighten the tamper proof screws

with the tamper proof wrench. Store the wrench in a secure place.

2. Open the inspector’s test valve and time how long it

takes for the detector to indicate a flow condition. The

detector should remain activated until the inspector’s

test valve is closed. Air pockets in the sprinkler system

may increase the apparent delay.

Under normal conditions, System Sensor waterflow detectors should provide years of trouble-free service. However,

if the delay mechanism or switch enclosure becomes

faulty, replace it. To replace the delay mechanism or

switch enclosure, use a phillips head screwdriver to remove the three screws that hold it in place. Either mechanism can be easily replaced without removing the

detector from the pipe or draining the pipe. Do not repair

or replace any other waterflow detector components. If

any other part of the detector does not perform properly,

replace the entire detector. Failure to to follow this instruction may result in failure of the detector to report the

flow of water. To replace the delay mechanism, request

Part No. A3008-00. For switch enclosure, request Part No.

A77-01-02.

Figure 6. Delay adjustment dial:

Table of dial settings

embossed here.

See below.

ON

ER

DIAL

MB

NU

2

3

Delay adjustment dial

0

APP

0

ROX

IMA

1

15

TE

1

2

30

TIME

4

45

55

DEL

0

5

AY

70

(SE

CON

DS)

5

4

3

Dial setting

Seconds (±50%)

D770-01-00 6 I56-459-07

0

0

15

1

23

30

45

55

5

4

70

Technical Manuals Online! - http://www.tech-man.com

A78-1496-05

Page 7

To remove a detector:

1. Drain the pipe.

2. Turn off electrical power to the detector and disconnect

the wiring.

3. Loosen the nuts and remove the U-bolts.

4. Gently lift the saddle far enough to get your fingers un-

der it. Then, roll the vane so it will fit through the hole

while continuing to lift the waterflow detector saddle.

5. Lift the detector clear of the pipe.

CAUTION

If a vane breaks in a pipe, find and remove it. If it is not removed, the vane may restrict the flow of water to all or part

of the sprinkler system.

D770-01-00 7 I56-459-07

Technical Manuals Online! - http://www.tech-man.com

Page 8

The Limitations of Waterflow Alarm Devices

1. Waterflow detectors may not work or operate properly if

sprinkler piping being monitored is plugged with pipe

scale, mud, stones or other foreign material. Sprinkler

systems should be checked regularly for such blocking

material, following the instructions in Chapter 5 of NFPA

Standard 13A.

2. Alarms generated by the activation of waterflow detectors may not be received by a central station if telephone

or other communication lines to the detector are out of

service, disabled, or open.

3. Vane-type waterflow detectors have a normal service life

Three-Year Limited Warranty

System Sensor warrants its enclosed waterflow detector to be free from defects in materials and workmanship under normal use and service for a

period of three years from date of manufacture. System Sensor makes no

other express warranty for this waterflow detector. No agent, representative, dealer, or employee of the Company has the authority to increase or

alter the obligations or limitations of this Warranty. The Company’s obligation of this Warranty shall be limited to the repair or replacement of any

part of the waterflow detector which is found to be defective in materials

or workmanship under normal use and service during the three year period commencing with the date of manufacture. After phoning System

Sensor’s toll free number 800-SENSOR2 (736-7672) for a Return Authorization number, send defective units postage prepaid to: System Sensor,

WARNING

of 10-15 years. Hard water systems, however, may reduce waterflow detector service life to 4 or 5 years.

4. Waterflow detectors are not a substitute for insurance.

Building owners should always insure property and lives

being protected by sprinkler systems.

5. If valves controlling the water supply to a sprinkler system are closed, vane-type waterflow detectors will not

work. All valves controlling a sprinkler water supply

should be sealed or locked in the normally open position. The normally open position should be monitored

by a sprinkler supervisory switch.

Repair Department, RA #__________, 3825 Ohio Avenue, St. Charles, IL

60174. Please include a note describing the malfunction and suspected

cause of failure. The Company shall not be obligated to repair or replace

units which are found to be defective because of damage, unreasonable

use, modifications, or alterations occurring after the date of manufacture.

In no case shall the Company be liable for any consequential or incidental

damages for breach of this or any other Warranty, expressed or implied

whatsoever, even if the loss or damage is caused by the Company’s negligence or fault. Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or exclusion may

not apply to you. This Warranty gives you specific legal rights, and you

may also have other rights which vary from state to state.

D770-01-00 8 I56-459-07

Technical Manuals Online! - http://www.tech-man.com

© System Sensor 1996

Page 9

INSTALLATION AND MAINTENANCE INSTRUCTIONS

WFDT/WFDTH Vane-type

Waterflow Detectors

3825 Ohio Avenue, St. Charles, Illinois 60174

1-800-SENSOR2, FAX: 630-377-6495

A Division of Pittway

Specifications

Contact Ratings: Two sets of SPDT (Form C)

10 A @ 125/250 VAC; 2.5 A @ 24 VDC

Triggering Threshold Bandwidth (Flow Rate): 4 - 10 GPM

Service Pressure Rating: 250 PSI (Max.)

Overall Dimensions, Installed: WFDT– 45/16

WFDTH– 45/16

″

H × 3

″

H × 3

3

/4

″

9

/16

W × 6

″

W × 6

3

/4″D

3

/4″D

Operating Temperature Ranges: 32°F - 120°F (0°C - 49°C)

Shipping Weight: 2.6 lbs.

The WFDT is U.L. listed for indoor and outdoor installations

The WFDTH is U.L. listed for indoor use only. The WFDTH can be installed between 2×4 stud wall construction.

Important

Please Read Carefully And Save

This instruction manual contains important information

about the installation and operation of waterflow detectors.

Purchasers who install waterflow detectors for use by

others must leave this manual or a copy of it with the user.

Read all instructions carefully before beginning.

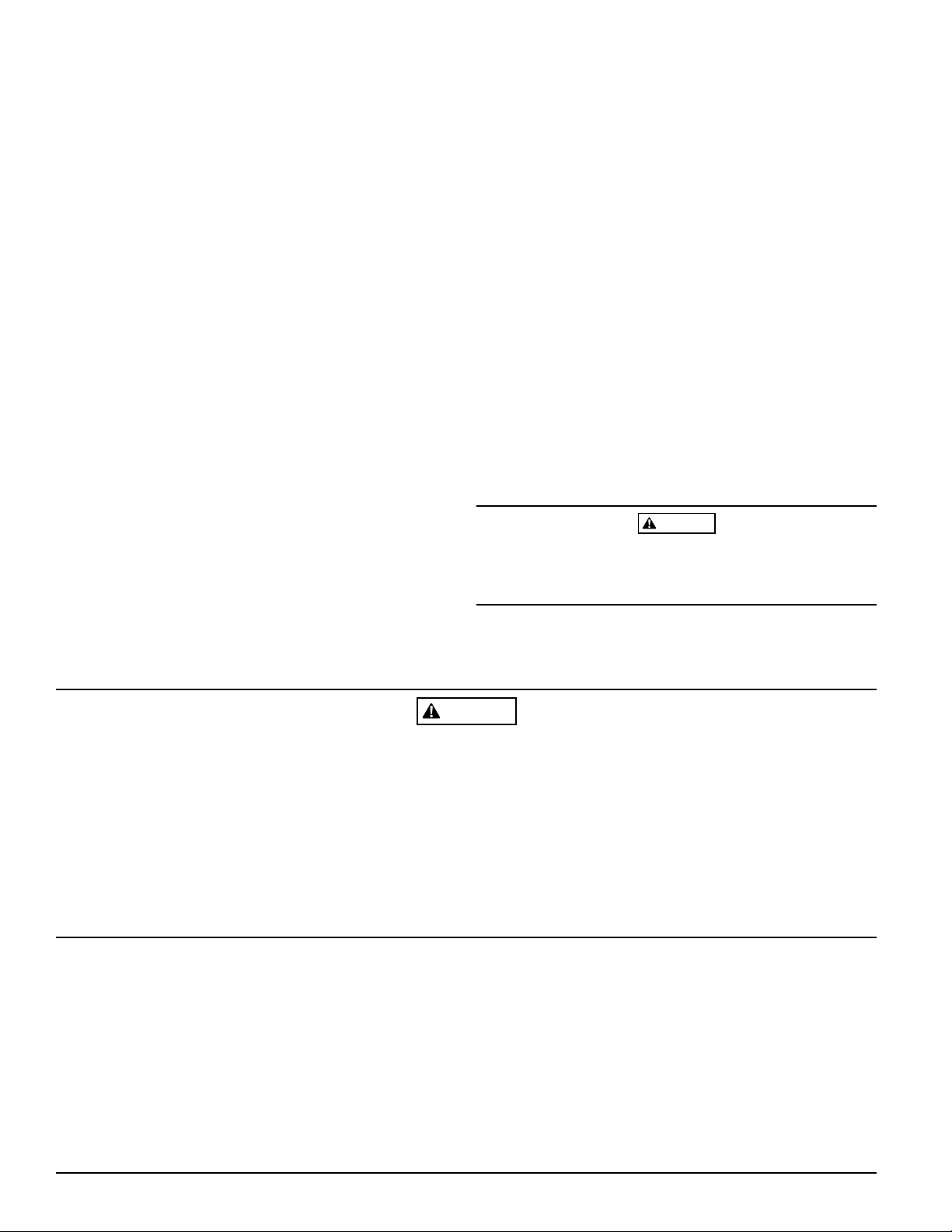

Tee Depth Threaded Sweat Poly B CPVC

1 × 1 × 1″

11/4 × 11/4 × 1″

11/2 × 11/2 × 1″

2 × 2 × 1"

Approximate Tee Depth Requirements

(See Figure 1)

21/8″

21/2″

23/4″

13/4″ N/A 21/4″

21/6″ N/A

21/4″

21/2″

N/A 23/4″

N/A

N/A

N/AN/A

CAUTION

Use vane-type waterflow detectors in wet-pipe systems

only. DO NOT USE IN DRY-PIPE, DELUGE, OR PRE-ACTION SYSTEMS. The sudden inrush of water in such systems may break the vane off or damage the mechanism. Do

not use in potentially explosive atmospheres. Do not leave

unused wires exposed.

Principles Of Operation

Vane-type waterflow detectors mount to water filled pipes

in sprinkler systems. Water flow in the pipe deflects a vane.

Deflection of the vane produces a switched output, usually

after a specified delay.

All WFDTs have a pneumatically controlled mechanical

delay mechanism. Delays are noncumulative; they reset if

the flow of water stops before the entire delay has elapsed.

All detectors will activate on a sustained flow of water

greater than 10 gallons per minute (gpm) but will not

activate if the flow rate is less than 4 gpm.

Compatible Pipe Tees

The WFDT and WFDTH fit 1″ to 11/2″ NPT threaded ferrous

and brass, 1″ to 2″ sweat brass, 11/2″ polybutylene plastic

and 1″ pvc plastic tees having a 1″ threaded NPT branch

(see Figure 1 and chart for recommended tee depths).

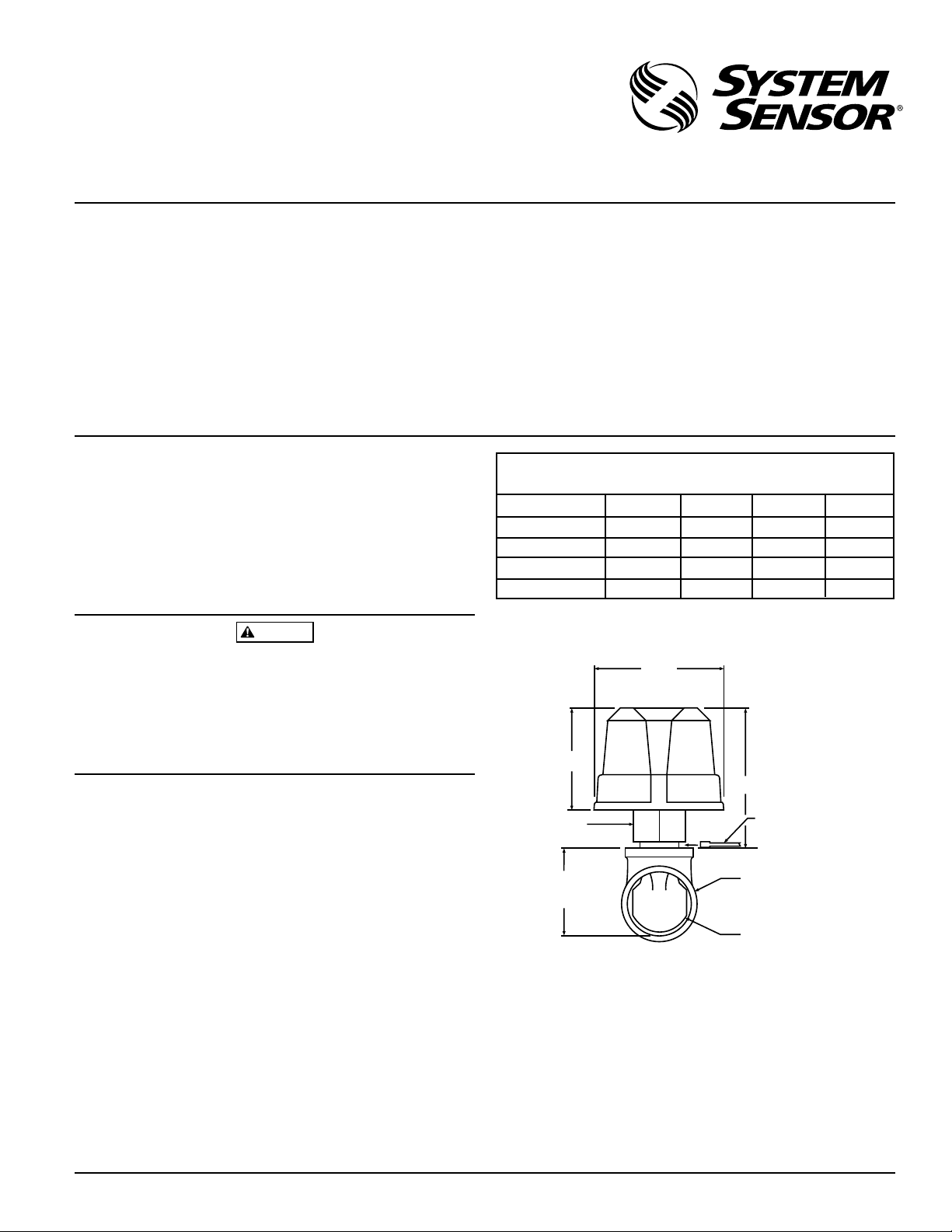

Figure 1. Mounting dimensions:

33/4″

(WFDT)

39/16″

(WFDTH)

3″

45/16″

Tee Adapter

Tee Depth

Refer to

Tee Depth

Table

Gage (End of Paddle Tree)

Must Fit Between Top of

Tee and Bottom of Flange

Tee Fitting

Plastic Vane

A78-1939-00

Installation Guidelines

Before installing any waterflow alarm device, be

thoroughly familiar with:

NFPA 72: National Fire Alarm Code

NFPA 13: Installation of Sprinkler Systems

NFPA 25: Inspection, Testing, and Maintenance of

Water-based Fire Protection Systems

NFPA 13D: Standard for 1 and 2 Family Dwellings and

Manufactured Homes

NFPA 13R: Standard for Multi-family Dwellings

N770-05-00 1 I56-480-03

Technical Manuals Online! - http://www.tech-man.com

Page 10

Figure 2. Assembly diagram:

COVER

TAMPER PROOF

WRENCH (P/N WFDW)

DELAY

MECHANISM

(REPLACEMENT

P/N A3008-00)

WATERFLOW

FLOW

FILLISTER

HEAD SCREW

1″ NPT THREAD

ACTUATOR

LEVER

SWITCH ENCLOSURE

(REPLACEMENT

P/N A77-01-02)

GROUND

SCREW

(GREEN)

MOUNTING

PLATE

PADDLE

(PADDLE

REPLACEMENT

KIT (P/N PRK9)

A78-2134-01

(Cover tamper option is available.)

Also, follow other applicable NFPA standards, local codes

and the requirements of the authority having jurisdiction.

Failure to follow these directions may result in failure of the

device to report a waterflow condition. System Sensor is

not responsible for devices that have been improperly

installed, tested or maintained.

1. Mount the detector where there is adequate clearance

for installation and removal and a clear view of it for inspection. See Figure 1 for mounting dimensions.

2. Locate to protect from damage, 6-7 feet above the floor.

3. On horizontal runs, position the detector on top of the

pipe or on the side of it. Do not mount it upside down

because condensation may collect in the housing and

impair the operation of the detector.

For vertical flow applications, mount detector on pipe

where upflow conditions exist. Failure to do so may prevent unit from operating properly.

4. Mount detector at least 6 inches from a fitting which

changes the direction of the water flow, or no closer than

24 inches from a valve or drain.

5. BE SURE DIRECTION-OF-FLOW ARROW MATCHES ACTUAL DIRECTION OF FLOW IN THE PIPE.

Mounting Instructions

1. The WFDT and WFDTH waterflow detectors are designed to fit only the appropriate tee fitting.

2. WFDT and WFDTH units are shipped without paddles

mounted to the actuator. Select the correct size paddle

for the type of tee being used. Align hole on stem of

paddle with hole on actuator lever. Fasten together using

a #4-40 x 1/4" fillister head screw supplied in bag assembly. See Figure 2. Use only the screw provided with

the unit. Drive screw head through hole in paddle until

it seats to actuator lever surface. No washer is required.

For paddle replacement refer to Maintenance section.

3. Carefully roll the vane opposite the direction of flow and

insert through tee. Thread detector onto tee fitting and

tighten with wrench. Use of thread sealant or tape is recommended. Use height gage (located at end of paddle

tee) to ensure proper depth of detector on tee fitting. See

Figure 1. Height gage must fit between top of tee fitting

and under side of hex tee adapter. A gap between gage

and tee adapter is acceptable. When correctly installed,

the detector must face in the proper direction of

waterflow and be aligned with the pipe.

4. Remove the metal cover. Move the actuator lever back

and forth to check for binding. If the vane binds, remove

the detector and correct the problem before proceeding.

CAUTION

Be sure the direction-of-flow arrow points in the right direction, otherwise a waterflow condition will go unreported.

See Figure 2.

Preoperation Testing

1. Fill the sprinkler system with water and check for leaks

around the WFDT or WFDTH. If there is a leak, check to

see that the fittings are tight. If leak persists, drain the

system and remove the detector (see removal instructions under Maintenance). Check for damaged threads

or cracked fitting. Reinstall the detector and check again

for leaks. Do not proceed until all leaks have been

stopped.

2. Connect an ohmmeter or continuity tester across (COM

and B) terminal switch contacts. The ohmmeter should

show an open circuit, no continuity.

3. Deflect the actuator lever and hold it until the pneumatic

delay shaft releases the switch buttons. The ohmmeter

or continuity tester should show a short circuit after the

delay has elapsed. If there is no delay, check the setting

of the delay adjustment dial.

NOTE: Leg of tee perpendicular to flow of water must

have a 1" NPT thread. Do not use a reducer to

achieve the correct thread size. Failure to follow

this instruction will result in failure of the detector

to report a waterflow condition.

N770-05-00 2 I56-480-03

Technical Manuals Online! - http://www.tech-man.com

Page 11

Figure 3. Field wiring:

Switch 1

COM

Top Vie w

NOTE: Common and B connections will

close when vane is deflected, i.e.,

when water is flowing. Dual switches

permit applications to be combined

on a single detector.

COM

ABBA

WFDTH

WFDT

BB

to nonsilenceable initiating

zone of listed FACP

to power source

compatible

with bell

COM COM

Typical FACP Connection

B

COM

Typical Local Bell Connection

Field Wiring

WARNING

High Voltage. Electrocution Hazard. Do not handle live AC

wiring or work on a device to which AC power is applied.

Doing so may result in severe injury or death.

Switch 2

WFDTH

WFDT

BB

COM COM

local

bell

WFDT and WFDTH

switch assembly

CONTACT RATINGS

125/250 VA C

24 VDC

Break wire as shown for

supervision of connection.

DO NOT allow stripped wire

leads to extend beyond

switch housing. DO NOT

loop wires.

10 AMPS

2.5 AMPS

end-of-line resistor

A78-1992-00

After extended service, parts of the detector may become

worn reducing the delay time and causing false alarms. If

this happens, increase the delay. If the delay is already at

maximum, replace the mechanical delay assembly. Refer to

Maintenance section for ordering replacement parts.

1. The WFDT and WFDTH have two SPDT switches. Switch

contacts (COM and B) are closed when water is flowing

and open when water is not flowing. Connect the switches

as shown in Figure 3 depending on the application.

2. When connected to a listed sprinkler/fire alarm control

panel, the initiating circuit must be non-silenceable.

3. A ground screw is provided with all units. When grounding is required, clamp wire with screw in hole located

between conduit entrance holes. See Figure 2.

Mechanical Delay Adjustment

The pneumatic delay is preset at dial setting 2 at the

factory. To adjust the delay, turn the adjustment dial on the

delay mechanism. Turn clockwise to increase the delay,

counterclockwise to decrease the delay. Delay can be

adjusted over a range from 0-70 seconds. See Figure 4.

NOTE: Set the delay to the minimum required to prevent

false alarms due to flow surges.

N770-05-00 3 I56-480-03

Technical Manuals Online! - http://www.tech-man.com

Figure 4. Delay adjustment dial:

Table of dial settings

3

2

45

1

30

0

15

0

1

0

2

3

Delay adjustment dial

Dial setting

Seconds (±50%)

001152303454555

embossed here.

See below.

4

55

5

70

5

4

70

A78-1596-05

Page 12

Operational Testing

Always notify a central station monitoring waterflow

alarms before repairing, maintaining or testing waterflow

alarm devices.

1. Replace the cover and tighten the security screws with

the tamper proof wrench. Store the wrench in a secure

place.

2. Open the inspector’s test valve and time how long it

takes for the detector to indicate a flow condition. The

detector should remain activated until the inspector’s

test valve is closed. Air pockets in the sprinkler system

may increase the apparent time delay.

Maintenance

To prevent accidental water damage, control valves should

be shut tightly and the system completely drained before

waterflow detectors are removed or replaced.

Inspect detectors monthly for leaks. Test detectors at least

monthly as described under Operational Testing above to

insure proper operation. This device is not designed for use

on “dry pipe” systems. Test more often if required by the

authority having jurisdiction.

replacement kits are available. To replace the delay

mechanism, request Part No. A3008-00; for switch

enclosure, request Part No. A77-01-02. Complete

instructions are enclosed with each. Either mechanism can

be easily replaced without removing the detector from the

pipe or draining the pipe. If damage occurs to paddle, order

replacement kit PRK9. Refer to procedure below for

removal of detector on pipe. Do not repair or replace any

other waterflow detector components in the field. If any

other part of the detector does not perform properly,

replace the entire detector. Failure to follow this

instruction may result in failure of the detector to report

a waterflow condition.

Proceed as follows to remove a detector.

1. Drain the pipe.

2. Turn off electrical power to the detector, and then disconnect wiring.

3. Unscrew WFDT or WFDTH from tee fitting.

4. Lift detector clear of pipe.

CAUTION

Under normal conditions System Sensor waterflow

detectors should provide years of trouble-free service. If,

however, the delay mechanism becomes faulty,

WARNING

The Limitations of Waterflow Alarm Devices

1. Waterflow detectors may not work or operate properly if

sprinkler piping being monitored is plugged with pipe

scale, mud, stones or other foreign material. Sprinkler

systems should be checked regularly for such blocking

material, following the instructions in NFPA Standard 25.

2. Alarms generated by the activation of waterflow detectors may not be received by a central station if telephone

or other communication lines to the detector are out of

service, disabled, or open.

Three-Year Limited Warranty

System Sensor warrants its enclosed waterflow detector to be free from defects in materials and workmanship under normal use and service for a

period of three years from date of manufacture. System Sensor makes no

other express warranty for this waterflow detector. No agent, representative, dealer, or employee of the Company has the authority to increase or

alter the obligations or limitations of this Warranty. The Company’s obligation of this Warranty shall be limited to the repair or replacement of any

part of the waterflow detector which is found to be defective in materials

or workmanship under normal use and service during the three year period commencing with the date of manufacture. After phoning System

Sensor’s toll free number 800-SENSOR2 (736-7672) for a Return Authorization number, send defective units postage prepaid to: System Sensor,

If a vane breaks off in a pipe, find and remove it. Failure to

do so may restrict the proper flow of water to part of the

sprinkler system.

3. Vane-type waterflow detectors have a normal service life

of 10-15 years. Hard water systems, however, may reduce waterflow detector service life to 4 or 5 years.

4. If valves controlling the water supply to a sprinkler system are closed, vane-type waterflow detectors will not

work. All valves controlling a sprinkler water supply

should be sealed or locked in the normally open position. The normally open position should be monitored

by a sprinkler supervisory switch.

Repair Department, RA #__________, 3825 Ohio Avenue, St. Charles, IL

60174. Please include a note describing the malfunction and suspected

cause of failure. The Company shall not be obligated to repair or replace

units which are found to be defective because of damage, unreasonable

use, modifications, or alterations occurring after the date of manufacture.

In no case shall the Company be liable for any consequential or incidental

damages for breach of this or any other Warranty, expressed or implied

whatsoever, even if the loss or damage is caused by the Company’s negligence or fault. Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or exclusion may

not apply to you. This Warranty gives you specific legal rights, and you

may also have other rights which vary from state to state.

N770-05-00 4 I56-480-03

Technical Manuals Online! - http://www.tech-man.com

© System Sensor 1996

Page 13

INSTALLATION AND MAINTENANCE INSTRUCTIONS

WFDTNR Vane-type

Waterflow Detector

Specifications

Contact Ratings: 10 A @ 125/250 VAC

2.5 A @ 24 VDC

Triggering Threshold Bandwidth (Flow Rate): 4 - 10 GPM

Static Pressure Rating: 250 PSI (Max.)

Overall Dimensions, Installed: 3.25" x 4.25" cover dia.

3.25" above pipe tee

Operating Temperature Range: 32°F - 120°F (0°C - 49°C)

Shipping Weight: 1.5 lbs.

Important

Please Read Carefully And Save

This instruction manual contains important information

about the installation and operation of waterflow detectors.

Purchasers who install waterflow detectors for use by others must leave this manual or a copy of it with the user.

Read all instructions carefully before beginning.

CAUTION

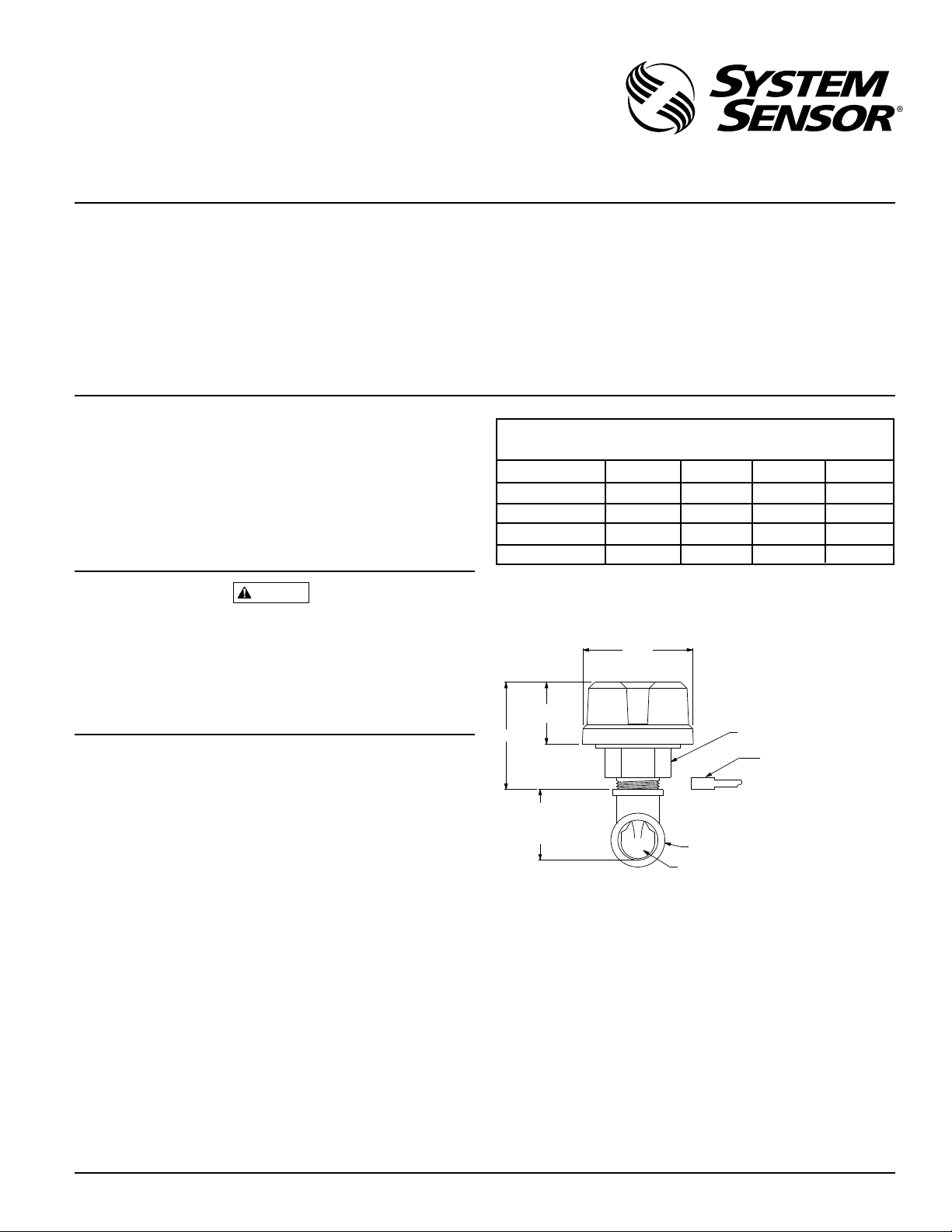

Tee Depth Threaded Sweat Poly B CPVC

1 × 1 × 1″

11/4 × 11/4 × 1″

11/2 × 11/2 × 1″

2 × 2 × 1"

A Division of Pittway

3825 Ohio Avenue, St. Charles, Illinois 60174

1-800-SENSOR2, FAX: 630-377-6495

Approximate Tee Depth Requirements

(See Figure 1)

21/8″

21/2″

23/4″

13/4″ N/A 21/4″

21/6″ N/A

21/4″

21/2″

N/A 23/4″

N/A

N/A

N/AN/A

Use vane-type waterflow detectors in wet-pipe systems

only. DO NOT USE IN DRY-PIPE, DELUGE, OR PRE-ACTION SYSTEMS. The sudden inrush of water in such systems may break the vane off or damage the mechanism. Do

not use in potentially explosive atmospheres. Do not leave

unused wires exposed.

Principles Of Operation

Vane-type waterflow detectors mount to wet-pipe systems

only. Water flow in the pipe deflects a vane. Deflection of

the vane produces a switched output. All detectors will activate on a sustained flow of water greater than 10 gallons

per minute (gpm) but will not activate if the flow rate is

less than 4 gpm.

Compatible Pipe Tees

Model WFDTNR fits 1"–11/2" NPT threaded ferrous and

brass, 1" - 2" sweat brass, 11/2" polybutylene plastic and 1"

pvc plastic tees having a 1" threaded NPT branch (see Figure 1 and chart for recommended tee depths).

Installation Guidelines

Before installing any waterflow alarm device, be thoroughly familiar with:

NFPA 72: Installation, Maintenance and Use of Local

Protective Signalling Systems

Figure 1. Mounting dimensions:

3 1/4"

1 3/4"

3 1/4"

"TEE DEPTH"

REFER TO

TEE DEPTH

TABLE

PIPE TEE FITTING

PLASTIC VANE

HEX TEE ADAPTOR

INSTALLATION GAGE

(END OF PADDLE TREE)

MUST FIT BETWEEN TOP

OF TEE AND BOTTOM OF

HEX TEE ADAPTOR FLANGE.

A78-2110-00

NFPA 13: Installation of Sprinkler Systems, specifically

Section 3.17

NFPA 25: Inspection, Testing and Maintenance of Sprin-

kler Systems, specifically Chapters 4 and 5

NFPA 13D: Standard for Residential Dwellings

NFPA 13R: Standard for Multifamily Dwellings

Other applicable NFPA standards, local codes and the requirements of the authority having jurisdiction.

Failure to follow these directions may result in failure of the

device to report a waterflow condition. System Sensor is

N770-06-00 1 I56-509-01

Technical Manuals Online! - http://www.tech-man.com

Page 14

Figure 2. Assembly diagram:

COVER

TAMPER PROOF

WRENCH (P/N WFDW)

PADDLE

A78-2111-00

ACTUATOR

LEVER

FLOW

ACTUATOR

ASSEMBLY

HEAD SCREW

WATER FLOW

FILLISTER

1" NPT THREAD

GROUND

SCREW

(GREEN)

MOUNTING

PLATE

not responsible for devices that have been improperly installed, tested or maintained.

1. Mount the detector where there is adequate clearance

for installation and removal and a clear view of it for inspection. See Figure 1 for mounting dimensions.

2. Locate to protect from damage, 6-7 feet above the floor.

3. On horizontal runs, position the detector on top of the

pipe or on the side. Do not mount it upside down.

4. Mount detector at least 6 inches from a fitting which

changes the direction of the water flow.

5. BE SURE DIRECTION-OF-FLOW ARROW MATCHES ACTUAL DIRECTION OF FLOW IN THE PIPE.

Mounting Instructions

1. This WFDTNR waterflow detector is designed to fit only

the appropriate tee fitting.

NOTE: Leg of tee perpendicular to flow of water must

have a 1" NPT thread. Do not use a reducer to

achieve the correct thread size. Failure to follow

this instruction will result in failure of the detector

to report a waterflow condition.

2. WFDT units are shipped without the paddles mounted to

the actuator. Select the correct size paddle for the tee being used the appropriate nominal pipe diameter size is

molded on the surface of the paddles). Align hole on

stem of paddle with hole on actuator lever. Fasten together using a #4-40 x 1/4" fillister head screw supplied

in bag assembly. See Figure 2. Use only the screw provided with the WFDTNR. Drive screw head through hole

in paddle until it seats firmly to actuator lever surface.

No washer is required. For paddle replacement refer to

Maintenance section.

3. Thread detector onto tee fitting and tighten with

wrench. Use of thread sealant or tape is recommended.

Use height gage (located at end of paddle tee) to ensure

proper depth of detector on tee fitting. See Figure 1.

Height gage must fit between top of tee fitting and under

side of hex tee adapter. A gap between gage and tee

adapter is acceptable. When correctly installed, the detector must face in the proper direction of waterflow and

be aligned with the pipe.

4. Remove the plastic cover with the tamper proof wrench

provided. Move the actuator lever back and forth to

check for binding. If the vane binds, remove the detector

and correct the problem before proceeding.

CAUTION

Be sure the direction-of-flow arrow points in the correct direction, otherwise a waterflow condition will go unreported. See Figure 2.

Operational Testing

Always notify a central station monitoring waterflow

alarms before repairing, maintaining, or testing waterflow

alarm devices.

1. Fill the sprinkler and check for leaks around the

WFDTNR. If it leaks, check to see that the fittings are

tight. If leak persists, drain the system and remove the

detector (see removal instructions under Maintenance).

Check for damaged threads or cracked fitting. Reinstall

detector and check again for leaks. Do not proceed until

all leaks have been stopped.

2. With cover removed, connect an ohmmeter or continuity tester across (COM and B) terminal switch contacts.

The ohmmeter should show an open circuit, no continuity (when the red switch buttons are depressed).

3. Deflect the actuator lever to release the switch buttons.

The ohmmeter or continuity tester should show a short

circuit when the switch buttons are released.

4. Open the inspector's test valve to allow the detector to

indicate a flow condition. The detector should remain

activated until the inspector's test valve is closed. Air

pockets in the sprinkler system may prevent the detector

from firing immediately.

5. Replace the cover and tighten the security screws with

the tamper proof wrench. Store wrench is a secure place.

Field Wiring

1. The WFDT has two SPDT switches. Switch contacts

(COM and B) are closed when water is flowing and open

when water is not flowing. Connect the switches as

shown in Figure 3 depending on the application.

2. When connected to a listed sprinkler/fire alarm control

panel, the initiating circuit must be non-silenceable.

N770-06-00 2 I56-509-01

Technical Manuals Online! - http://www.tech-man.com

Page 15

Figure 3. Field wiring:

Switch 1

COM

COM

NOTE: Common and B connections will

close when vane is deflected, i.e.,

when water is flowing. Dual switches

permit applications to be combined

on a single detector.

Strip Gauge

to nonsilenceable initiating

zone of listed FACP

to power source

compatible

with bell

ABBA

WFDTNR

BB

COM COM

Typical FACP Connection

B

Typical Local Bell Connection

Switch 2

COM

3. A ground screw is provided with all WFDT units. When

grounding is required, clamp wire with screw in hole located between conduit entrance holes. See Figure 2.

WARNING

High Voltage. Electrocution Hazard. Do not handle live AC

wiring or work on a device to which AC power is applied.

Doing so may result in severe injury or death.

Maintenance

To prevent accidental water damage, control valves should

be shut tightly and the system completely drained before

waterflow detectors are removed or replaced.

Inspect detectors monthly for leaks. Test detectors at least

monthly as described under Operational Testing to insure

proper operation. This device is not designed for use on

“dry pipe” systems. Test more often if required by the authority having jurisdiction.

CONTACT RATINGS

WFDTNR

BB

COM COM

local

bell

125/250 VAC

24 VDC

Break wire as shown for

supervision of connection.

DO NOT allow stripped wire

leads to extend beyond

switch housing. DO NOT

loop wires.

10 AMPS

2.5 AMPS

end-of-line resistor

Under normal conditions System Sensor waterflow detectors should provide years of trouble-free service. If, however, the switch enclosure becomes faulty, request Part No.

A77-01-08. If damage occurs to paddle, order replacement

kit PRK9. Refer to procedure below for removal of detector

on pipe. Do not repair or replace any other waterflow detector components in the field. If any other part of the detector does not perform properly, replace the entire

detector. Failure to follow this instruction may result in

failure of the detector to report a waterflow condition.

Proceed as follows to remove a detector:

1. Drain the pipe

2. Turn off electrical power to the detector, and then disconnect wiring

3. Unscrew WFDTNR from tee fitting

N770-06-00 3 I56-509-01

Technical Manuals Online! - http://www.tech-man.com

Page 16

WARNING

The Limitations of Waterflow Alarm Devices

1. Waterflow detectors may not work or operate properly if

sprinkler piping being monitored is plugged with pipe

scale, mud, stones or other foreign material. Sprinkler

systems should be checked regularly for such blocking

material, following the instructions in Chapter 5 of NFPA

Standard 13A.

2. Alarms generated by the activation of waterflow detectors may not be received by a central station if telephone

or other communication lines to the detector are out of

service, disabled, or open.

3. Vane-type waterflow detectors have a normal service life

Three-Year Limited Warranty

System Sensor warrants its enclosed waterflow detector to be free from defects in materials and workmanship under normal use and service for a

period of three years from date of manufacture. System Sensor makes no

other express warranty for this waterflow detector. No agent, representative, dealer, or employee of the Company has the authority to increase or

alter the obligations or limitations of this Warranty. The Company’s obligation of this Warranty shall be limited to the repair or replacement of any

part of the waterflow detector which is found to be defective in materials

or workmanship under normal use and service during the three year period commencing with the date of manufacture. After phoning System

Sensor’s toll free number 800-SENSOR2 (736-7672) for a Return Authorization number, send defective units postage prepaid to: System Sensor,

of 10-15 years. Hard water systems, however, may reduce waterflow detector service life to 4 or 5 years.

4. Waterflow detectors are not a substitute for insurance.

Building owners should always insure property and lives

being protected by sprinkler systems.

5. If valves controlling the water supply to a sprinkler system are closed, vane-type waterflow detectors will not

work. All valves controlling a sprinkler water supply

should be sealed or locked in the normally open position. The normally open position should be monitored

by a sprinkler supervisory switch.

Repair Department, RA #__________, 3825 Ohio Avenue, St. Charles, IL

60174. Please include a note describing the malfunction and suspected

cause of failure. The Company shall not be obligated to repair or replace

units which are found to be defective because of damage, unreasonable

use, modifications, or alterations occurring after the date of manufacture.

In no case shall the Company be liable for any consequential or incidental

damages for breach of this or any other Warranty, expressed or implied

whatsoever, even if the loss or damage is caused by the Company’s negligence or fault. Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or exclusion may

not apply to you. This Warranty gives you specific legal rights, and you

may also have other rights which vary from state to state.

N770-06-00 4 I56-509-01

Technical Manuals Online! - http://www.tech-man.com

© System Sensor 1996

Page 17

INSTALLATION AND MAINTENANCE INSTRUCTIONS

OSY2 Gate Valve

Supervisory Switch

Specifications

Contact Ratings: 10 A @ 125/250 VAC

2.5 A @ 24 VDC

Dimensions: 53/4"H X 31/2"W X 31/4"L

Maximum Stem Extension: 25/8"

Minimum Stem Extension:

Bracket Span: 63/4"

Operating Temperature Range: 32° - 120°F (0° - 49°C)

Shipping Weight: 23/4 lb.

Important

Please Read Carefully And Save

This manual contains important information about the installation and operation of supervisory switches. These instructions apply to System Sensor switches for outside

screw and yoke valves only. Read all instructions carefully

before beginning installation.

WARNING

Do NOT use this switch in explosive or potentially explosive atmospheres.

Do NOT leave unused wires exposed.

5

/8"

A Division of Pittway

3825 Ohio Avenue, St. Charles, Illinois 60174

1-800-SENSOR2, FAX: 630-377-6495

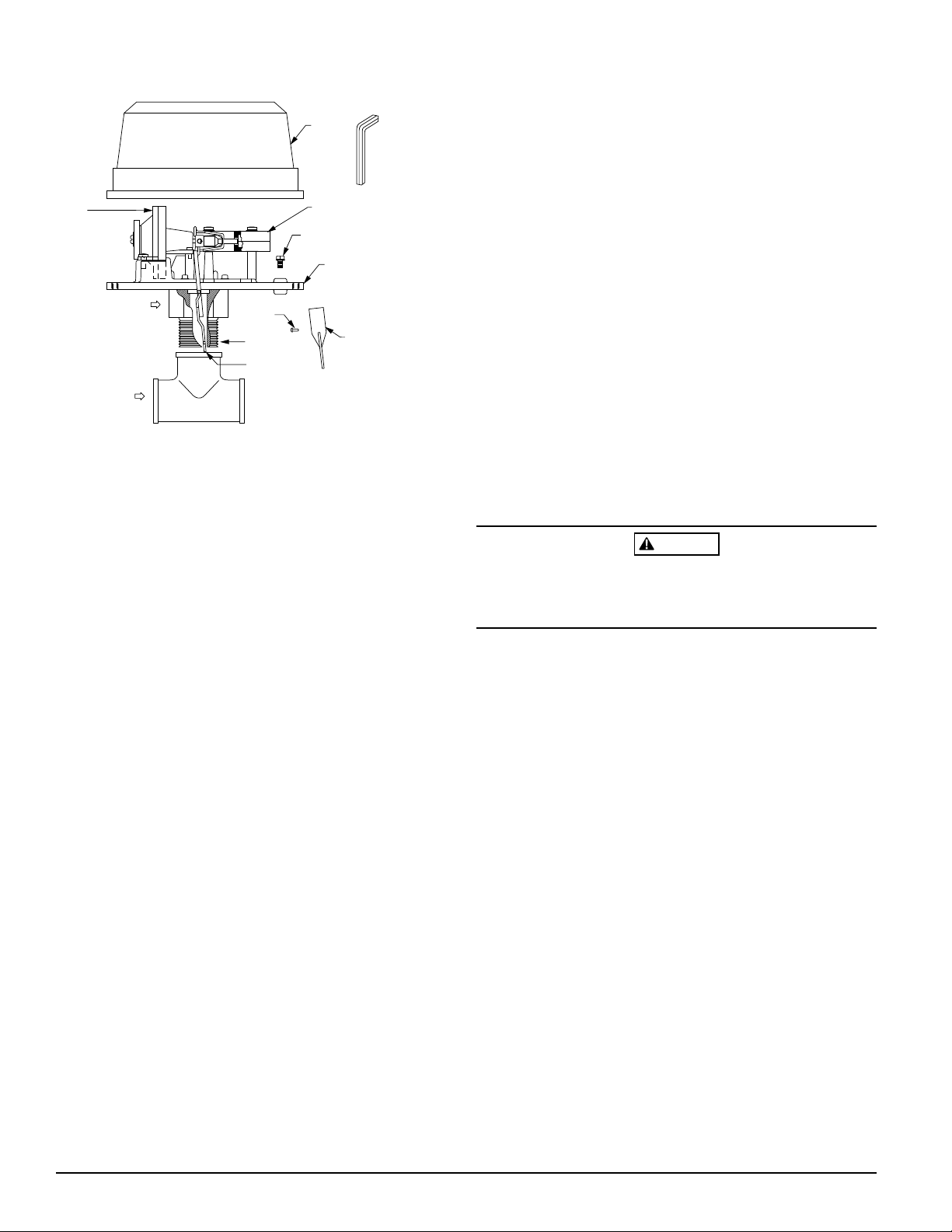

Figure 1:

ACTUATOR

VERTICAL (DOWN)

ACTUATOR

HORIZONTAL

ment. If this is the case, the bolts can be positioned on the

outside of the yoke.

All supervisory switch installations must comply with local

codes and ordinances and the requirements of the authority

having jurisdiction. Additional information is available in

National Fire Protection Association standards NFPA 13,

13D, 13R, 71, and 72.

General Installation Considerations

The OSY2 Supervisory Switch can be mounted on open

yoke valves between 1/2" and 12" in diameter in the positions shown in Figure 1 only. If the switch is installed with

the actuator pointing upward, water may leak into the interior of the switch. Therefore, do NOT install the OSY2

with its actuating lever pointing upward.

All OSY2 models are equipped with a ground screw inside

the switch housing near the conduit exit hole for those applications where grounding is required.

Narrow Yoke Valves

As Figure 2 suggests, installing the valve with mounting

bolts inside the yoke is recommended. However, some

valves may have yokes that are too narrow for this arrange-

Limited Clearance Valves

The OSY2 mounting bracket fits most of the open yoke

valves used in fire protection systems. However, some of

these valves, especially those less than 11/2" in diameter,

have irregularly shaped yokes or such limited clearances

that the clamping bar cannot be installed properly and/or it

causes the valve to bind. If this is the case, the use of the

supplied J-bolts is required to attach the OSY2 to the valve

(see J-Bolt Detail, Figure 2).

Installation Procedure

See Figures 2 and 3, as required, while performing the procedure that follows.

Perform step 1 on valves 11/2" in diameter and smaller

only. Proceed directly to step 2 if the switch is being installed on a valve larger than 11/2" in diameter.

1. Remove and discard the two C-clips and roller from the

actuating lever.

2. Set the valve to its fully open position. Remove the OSY2

Supervisory Switch from the carton and adjust the position of the retaining washers to provide sufficient bolt

length for the yoke thickness of the valve.

N770-04-00 1 I56-393-05

Technical Manuals Online! - http://www.tech-man.com

Page 18

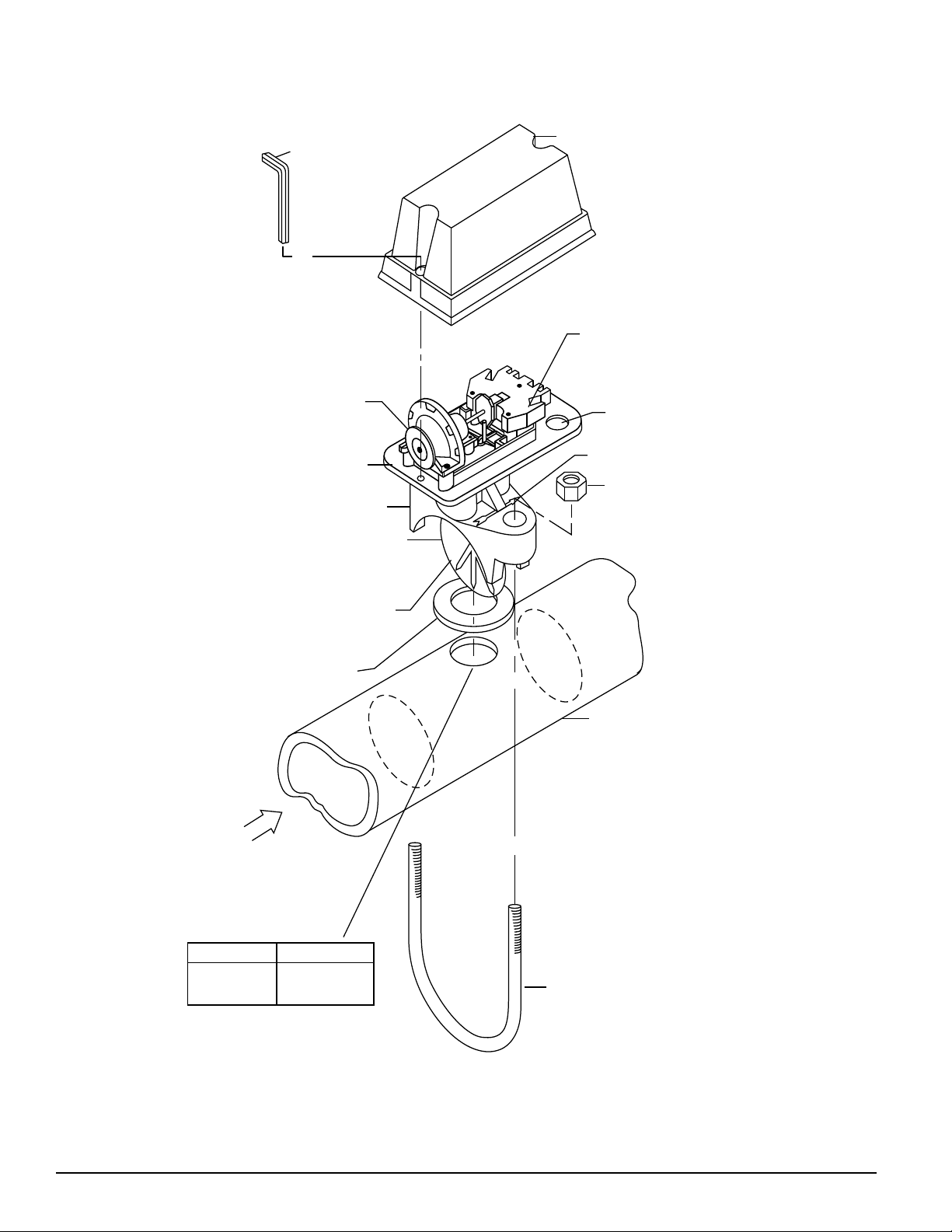

Figure 2:

Actuating Cam

Actuating lever

set screw

Wrench for

tamper-resistant

screws

(P/N WFDW)

Cover

Spring

Mounting screws

Terminal block

Tamper-resistant

screws

Seal

Base housing

Mounting Bracket

"C" clip

Actuating lever roller

(2 thru 12"only)

Valve Stem

Carriage Bolt

Yoke

Clamping Bar

J-Bolt Detail

Hex wrench

(P/N HEXW)

SLIDE CLAMPING

BAR TO REMOVE

OR INSTALL.

NOTE:

LARGER GATE VALVE SHOWN (2" THRU 12"). WHEN INSTALLING

SUPERVISORY SWITCH TO SMALLER GATE VALVES (1/2" THRU 1 1/2")

CARRIAGE BOLTS ARE TO BE LOCATED ON OUTBOARD SIDE OF YOKE.

ON SMALL VALVES WITH LIMITED CLEARANCE THE USE OF J-BOLTS

MAY BE REQUIRED.

Retaining Washer

Nut

N770-04-00 2 I56-393-05

Technical Manuals Online! - http://www.tech-man.com

Page 19

Figure 3: the valve, slide the open end of the clamping bar onto

the bolts and under the retaining washers, as indicated

in Figure 2.

7. Ensure that the actuating lever does not hit the inside

of the cover or the clamping bar at any point in its

travel. If it does, adjust the length of the lever by loosening the set screw, sliding the lever in or out, as

needed, and retightening the set screw.

8. Adjust the supervisory switch position on the valve so

that both switches are depressed (COM to B circuit

VALVE

STEM

GLAND

THREADED VALVE

STEM HEX

YOKE

CLAMPING BAR NOT SHOWN

GROOVE

GLAND HEX NUT

OR BOLT

open) when the actuating lever is in the groove with

the valve in the full open position. The COM to B

circuit should close when the valve is closed 1/5 of its

Position the switch on the valve with the bolts on the inside

(preferably) or outside of the yoke, depending on clearances. Adjust the position of the OSY2 as far as possible

from the valve gland and in a location where the actuating lever contacts the unthreaded section of the valve

stem (if the valve stem is already grooved, proceed directly to step 6).

3. When the switch is in position on the valve, slide the

open end of the clamping bar onto the bolts and under

the retaining washers. If necessary, adjust the length of

the actuating lever by loosening the set screw on the

cam, sliding the lever in or out, as appropriate, and retightening the set screw. The lever is properly adjusted

when it clears the clamping bar. Tighten the nuts by

hand and slide the OSY2 until the second switch trip

points are found as the lever rests on the valve stem.

This approximates the final position of the OSY2 after

the valve stem is grooved. Carefully check all clearances

travel or 2 full turns of the handle, whichever is less.

The switch produces an audible “click” when it closes.

The switch closure can also be tested electrically by

using an ohmmeter to test for continuity between its

terminals.

9. Tighten the nuts securely with a wrench and check the

operation of the OSY2 as in step 8. If necessary, reposition the OSY2 and test it again.

10. Wire the supervisory switch as shown in Figure 4.

11. Replace the OSY2 cover and tighten the tamper-resistant

cover screws with the special wrench provided. Store

this wrench in a secure location.

12. Test the operation of the OSY2 by closing the valve the

1

/5 of its travel distance or two full turns, whichever is

less. The circuit between COM and B should indicate a

closure during this procedure. If it does not, readjust

the supervisory switch and actuator positions until the

switch closes when the valve is operated.

of the bolts, actuator, mounting bracket, clamping bar,

and OSY2 cover. Adjust the position as necessary. If

clearance is a problem, refer to the Limited Clearance

Valves (page 1) section of this manual.

4. Mark the point on the valve stem where the actuating le-

Testing

Test the operation of all supervisory switches before they

are placed into service and at least semiannually, or as required by the authority having jurisdiction.

ver contacts the valve stem.

5. Remove the OSY2 by loosening the nuts and sliding the

clamping bar from beneath the retaining washers. Remove the OSY2 from the valve and set it aside.

(a) Valves 11/2" in diameter and smaller only.

Use a 1/4" untapered round file to file a groove 3/32"

NOTE: Notify the proper authorities that the supervisory

switch(es) is (are) undergoing maintenance and,

therefore, will be temporarily out of service. Disable the system or zone undergoing testing to pre-

vent unwanted alarms.

deep in the valve stem at the mark that was made in

step 4. Be sure to remove any burrs resulting from the

filing to avoid damaging the valve stem packing

gland.

(b) Valves larger than 11/2" inches in diameter only.

Use a 3/8" untapered round file to file a groove 1/8"

Test the operation of the OSY2 by closing the valve the 1/5

of its total travel distance or two full turns, whichever is

less. A contact closure must occur during this procedure. If

it does not, readjust the supervisory switch and actuator

positions until the switch closes when the valve operated.

deep in the valve stem at the mark that was made in

step 4. Be sure to remove any burrs resulting from the

filing to avoid damaging the valve stem packing

gland.

6. Mount the switch loosely with the actuating lever centered in the groove. When the switch is in position on

N770-04-00 3 I56-393-05

Technical Manuals Online! - http://www.tech-man.com

Page 20

Figure 4. Supervisory switch wiring diagram:

Top View

Switch 1

Strip Gage

to nonsilenceable initiating

zone of listed FACP

to power source

compatible

with bell

COM

ABBA

COM

Sup. Switch

BB

COM COM

Typical FACP Connection

B

COM

Typical Local Bell Connection

Switch 2

Sup. Switch

BB

COM COM

local

bell

CONTACT RATINGS

125/250 VAC

24 VDC

10 AMPS

2.5 AMPS

end-of-line resistor

Break wire as shown for supervision

of connection. DO NOT allow stripped

wire leads to extend beyond switch

housing. DO NOT loop wires.

WARNING

The Limitations of Supervisory Switch Alarm Devices

1. Alarms generated by the actuation of the activating lever

may not be received by a central station if telephone or

other communication lines to the detector are out of service, disabled, or open.

2. Supervisory switch alarm devices have a normal service

life of 10-15 years.

Three-Year Limited Warranty

System Sensor warrants its enclosed supervisory switch to be free from

defects in materials and workmanship under normal use and service for a

period of three years from date of manufacture. System Sensor makes no

other express warranty for this supervisory switch. No agent, representative, dealer, or employee of the Company has the authority to increase or

alter the obligations or limitations of this Warranty. The Company’s obligation of this Warranty shall be limited to the repair or replacement of any

part of the supervisory switch which is found to be defective in materials

or workmanship under normal use and service during the three year period commencing with the date of manufacture. After phoning System

Sensor’s toll free number 800-SENSOR2 (736-7672) for a Return Authorization number, send defective units postage prepaid to: System Sensor,

A78-1639-00

3. Supervisory switches are not a substitute for insurance.

Building owners should always insure property and lives

being protected.

Repair Department, RA #__________, 3825 Ohio Avenue, St. Charles, IL

60174. Please include a note describing the malfunction and suspected

cause of failure. The Company shall not be obligated to repair or replace

units which are found to be defective because of damage, unreasonable

use, modifications, or alterations occurring after the date of manufacture.

In no case shall the Company be liable for any consequential or incidental

damages for breach of this or any other Warranty, expressed or implied

whatsoever, even if the loss or damage is caused by the Company’s negligence or fault. Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or exclusion may

not apply to you. This Warranty gives you specific legal rights, and you

may also have other rights which vary from state to state.

N770-04-00 4 I56-393-05

Technical Manuals Online! - http://www.tech-man.com

© System Sensor 1996

Page 21

INSTALLATION AND MAINTENANCE INSTRUCTIONS

Cover

Tamper screws

Tamper proof

wrench

(P/N WFDW)

Actuating cam

Actuating lever

set screw

Nipple set screws

Threaded nipple

Base housing

Actuating lever

Retaining nut

Switch Enclosure

Mounting screws

Spring

Hex wrench

(P/N HEXW)

4-1/4" H

(Assembled)

3-1/4" D

3-1/2" W

PIBV2 Post Indicator and

Butterfly Valve Supervisory Switch

Specifications

Contact Ratings: 10A @ 125/250 VAC

2.5 A @ 24 VDC

Overall Dimensions: 81/4 H X 31/2 W X 31/4" D

Operating Temperature Range: 32°F to 120°F (0°C to 49°C)

Maximum Stem Extension: 2 5/32"

Shipping Weight 2 lbs.

Important

Please Read Carefully and Save

This instruction manual contains important information on

the installation and operation of supervisory switches.

Purchasers who install supervisory switches for use by others must leave this manual or a copy of it with the user.

These instructions apply to System Sensor switches for post

indicator and butterfly type valves. Read all instructions

carefully before beginning. Follow only those instructions

that apply to the model being installed.

Figure 1:

A Division of Pittway

3825 Ohio Avenue, St. Charles, Illinois 60174

1-800-SENSOR2, FAX: 630-377-6495

CAUTION

Do NOT use in potentially explosive atmospheres.

Do NOT leave unused wires exposed.

Before installing any supervisory switches in sprinkler systems, be thoroughly familiar with:

NFPA 72: Installation, Maintenance and Use of Local

Protective Signalling Systems

NFPA 13: Installation of Sprinkler Systems, specifi

cally, Section 3.17

NFPA 25: Inspection, Testing and Maintenance of

Sprinkler Systems, specifically Chapters 4

and 5

General Information for Post Indicator Valves and

Butterfly Valves

1. Model PIBV2 is designed for installation in a 1/2" NPT

tapped hole and located so that the actuating lever of the

switch engages the target or flag of the valve . The

switch actuating lever is spring loaded against the flag or

target of the valve and is released when the valve moves

toward the closed position from the fully open position.

The switch is factory set to indicate an alarm condition

Technical Manuals Online! - http://www.tech-man.com

when the target and lever move in the direction toward

the conduit entry hole when the valve closes, but can be

reversed if the installation demands (refer to Section 4).

2. Model PIBV2 is equipped with a removable 1/2" NPT

N770-03-00 1 I56-394-05

A78-1587-00

pipe nipple which is locked in place with two set screws.

These models also include an adjustable length actuating lever which eliminates any need for alteration of the

length of the lever. A hex key is furnished for both of

these features.

3. The cover is secured with two tamper resistant screws

which require a special key to remove. One key is included with each supervisory switch. Replacement and

additional keys are available (Part No. WFDW).

Page 22

Figures 2A and 2B:

Rising Flag

A78-1629-00 A78-1630-00

Falling flag

HEAD

TARGET

Section 1

Installation Instructions For Post Indicator Valves

1. There are two types of post indicator valves - rising flag

and falling flag. In a rising flag installation, the PIBV2

mounts below the target assembly, as shown in Figure

2A. Closing the valve raises the target assembly and releases the actuating lever on the PIBV2. In a falling flag

installation, the PIBV2 mounts above the target assembly (Figure 2B). Closing the valve lowers the target assembly and releases the actuating lever on the PIBV2.

The PIBV2 is set for falling flag installation. If a rising flag operation is desired, it is necessary to reverse the action of the switch (See Section 4).

2. If the post indicator valve is predrilled with 1/2" NPT

mounting hole, remove the plug and go to step 6. If the

post indicator valve is NOT equipped with a 1/2" NPT

mounting hole, it will be necessary to drill and tap the

hole.

3. Position the valve in the fully open position ("OPEN"

should appear in the window) and remove the head

and target assembly. In doing so, ensure that the assembly can be reinstalled with its original adjustment.

4. (a)In a falling flag installation (flag lowers as valve is

closed), measure the distance from the bottom of the

head to the upper surface of the target that will contact the actuating lever of the PIBV2. Add 3/32" to this

measurement and mark the outside of the housing at

that location. Drill with a 23/32" drill bit and tap a 1/2"

NPT thread.

(b)In a rising flag installation (flag rises as valve is

closed), measure the distance from the bottom of the

head to the lower surface of the target that will contact the actuating lever. Subtract 3/32" to this measurement and mark the outside of the housing at that

location. Drill with a 23/32" drill bit and tap a 1/2" NPT

thread.

5. Replace the head and target assembly.

6. Screw the locknut onto the threaded nipple which is

supplied with the PIBV2.

7. Screw the nipple hand tight into the 1/2" hole in the

valve and tighten the locknut against the housing to secure the nipple in position.

8. Insert a probe into the hole through the nipple to measure the distance from the open end of the nipple to the

to the desired position on the target assembly. Subtract

5

/8" from the distance and set the length of the actuating lever of the PIBV2 from the end of the enclosure to

this distance. Tighten the set screw which holds the actuating lever.

9. Close the valve 3 to 4 revolutions.

10. Install the PIBV2 onto the nipple and orient the conduit

entry down (See Figure 4). Apply pressure to the PIBV2

and lock the set screws to secure the nipple to the

PIBV2.

11. Slowly open the valve to its fully open position. The

switch should trip as the valve opens, but not force the

actuating lever against the nipple when fully open. To

check for this condition, open the valve fully and depress the top of the actuating cam to stretch the actuating spring further. There should be some additional

movement available. If no movement is available, damage may occur to the PIBV2 actuator lever. It will be

necessary to adjust the flag location by removing the

head and turning the handle while the valve stem is

disengaged (refer to the valve manufacturer.)

12. After checking the fully open position to ensure adequate clearance, close the valve slowly until the

PIBV2 contacts trip. The switches must trip within 1/5

of the full travel distance of the valve.

13. If the PIBV2 does not change states within 1/5 of the

length of travel, it may be necessary to adjust the flag

up or down by removing the head and turning the

handle (refer to the valve manufacturer.)

Section 2

Installation Instructions For Butterfly Valves

(See Figure 3)

1. Remove the 1/2" NPT plug from the gear housing.

2. Loosen 2 set screws that hold the nipple on the PIBV2

and remove the nipple.

3. Screw the locknut onto the nipple.

4. Screw the nipple into the 1/2" NPT hole and hand

tighten. Tighten the locknut firmly to the housing to secure the nipple.

5. Open the valve fully and close the valve approximately 3

revolutions, noting which direction the target moves.

6. Retract the actuating arm and install PIBV2 onto the

N770-03-00 2 I56-394-05

Technical Manuals Online! - http://www.tech-man.com

Page 23

Figure 3:

Conduit Entry

Phillips

Screw

Spring

in final

position

Actuating Lever

Switch Enclosure

Spring

in initial

position

Slide in

this direction

CLOSE

A78-1633-00

N

E

P

O

O

T

CLOSE

nipple, orienting the PIBV2 to trip the switch as the

valve closes. If the conduit entry is on the wrong side, it

will be necessary to reverse the action of the switch (see

Section 4). Apply pressure to PIBV2 and tighten set

screws to secure the assembly.

7. Slide the actuating arm into the valve until it bottoms on

the flag, but do not tighten set screw.

8. Open the valve to the full open position and tighten set

screw to hold actuating arm in position. (Actuating arm

length will adjust slightly as valve is opened.) Check to

ensure that in the full open position the actuating arm is

not resting on the nipple. Do this by depressing the actuating cam to further stretch the spring, ensuring that

more travel is available when the valve is open. If there

is no travel, damage may occur to PIBV2 actuating arm.

Some slight alteration of the valve stop setting may be

necessary to ensure that no damage occurs.

9. Carefully close valve and note the number of handle

revolutions until the switch trips. The switch must trip

within 1/5 of the total travel range of the valve.

Actuator Vertical (Pointing Up)

2. Ground Screw — A ground screw is provided with all

supervisory switch models. When grounding is required,

clamp wire with the screw in hole located near conduit

entrance.

3. Wiring — See Figure 6, Page 4.

Section 4

Reversing The Action Of Pibv2

1. Loosen the 3 phillips screws on the top of the black

switch enclosure so that the switch enclosure is loose

and free to move (see Figure 5).

2. Slide the switch enclosure away from the conduit entry

toward the actuating pivot arm as far as possible and

tighten the 3 screws to secure the enclosure. (Ensure

that switch enclosure remains oriented away from the

conduit entry as screws are tightened.)

3. Grasp the spring at the center and lift it over the actuating cam so that it seats on the opposite side of the actuator (see Figure 5).

Figure 5:

Section 3

General Installation Instructions

1. Installation Positions

Figure 4:

The following are examples of acceptable mounting

positions:

Actuator Vertical (Down) Actuator Horizontal

The following mounting position is not acceptable:

N770-03-00 3 I56-394-05

Technical Manuals Online! - http://www.tech-man.com

A78-1631-00

Page 24

Figure 6:

Switch 1

Top View

NOTE: Common and B connections will

close when valve moves 1/5 of its

total travel distance.

Strip Gage

to nonsilenceable initiating

zone of listed FACP

to power source

compatible

with bell

COM

ABBA

COM

Sup. Switch

BB

COM COM

Typical FACP Connection

B

COM

Typical Local Bell Connection

Switch 2

Sup. Switch

BB

COM COM

local

bell

CONTACT RATINGS

125/250 VAC

24 VDC

10 AMPS

2.5 AMPS

end-of-line resistor

Break wire as shown for supervision

of connection. DO NOT allow stripped

wire leads to extend beyond switch

housing. DO NOT loop wires.

The Limitations of Supervisory Switch Alarm Devices

1. Alarms generated by the activation of the actuating lever

may not be received by a central station if telephone or

other communication lines to the alarm device are out of

service, disabled, or open.

2. Supervisory switch alarm devices have a normal service life

of 10-15 years.

Three-Year Limited Warranty

System Sensor warrants its enclosed supervisory switch to be free from

defects in materials and workmanship under normal use and service for a

period of three years from date of manufacture. System Sensor makes no

other express warranty for this supervisory switch. No agent, representative, dealer, or employee of the Company has the authority to increase or

alter the obligations or limitations of this Warranty. The Company’s obligation of this Warranty shall be limited to the repair or replacement of any

part of the supervisory switch which is found to be defective in materials

or workmanship under normal use and service during the three year period commencing with the date of manufacture. After phoning System

Sensor’s toll free number 800-SENSOR2 (736-7672) for a Return Authorization number, send defective units postage prepaid to: System Sensor,

A78-1639-00

WARNING

3. Supervisory switches are not a substitute for insurance.

Building owners should always insure property and lives

being protected.

Repair Department, RA #__________, 3825 Ohio Avenue, St. Charles, IL

60174. Please include a note describing the malfunction and suspected

cause of failure. The Company shall not be obligated to repair or replace

units which are found to be defective because of damage, unreasonable

use, modifications, or alterations occurring after the date of manufacture.

In no case shall the Company be liable for any consequential or incidental

damages for breach of this or any other Warranty, expressed or implied

whatsoever, even if the loss or damage is caused by the Company’s negligence or fault. Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or exclusion may

not apply to you. This Warranty gives you specific legal rights, and you

may also have other rights which vary from state to state.

N770-03-00 4 I56-394-05

Technical Manuals Online! - http://www.tech-man.com

© System Sensor 1996

Page 25

INSTALLATION AND MAINTENANCE INSTRUCTIONS

Cover Tamper Switch

Specifications

Contact Ratings: 5.0A @ 125/250 VAC

2.5A @ 24 VDC

Overall Dimensions: 11/4˝H x 2˝W x 3/4˝D

Operating Temperature Range: 32° to 120°F (0° to 49°C)

Shipping Weight: 0.025 lb.

A Division of Pittway

3825 Ohio Avenue, St. Charles, Illinois 60174

1-800-SENSOR2, FAX: 630-377-6495

NOTICE: This manual should be left with the owner/user

of this equipment.

CAUTION

Do not leave unused wires exposed. Do not use in potentially explosive atmospheres.

General Information

This cover tamper switch mounts to all System Sensor

WFD, WFDT, OSY2 and PIBV2 terminal block units. Cover

removal produces a switch output. The unit will reset when

the product cover is reinstalled.

Installation Guidelines

Before installing any cover tamper switch, be thoroughly

familiar with:

Figure 1. Assembly Diagram:

NFPA 72: National Fire Alarm Code

NFPA 13: Installation of Sprinkler Systems, specifically

section 3.17.

NFPA 25: Inspection, Testing and Maintenance of Sprin-

kler Systems, specifically chapters 4 and 5.

Other applicable NFPA standards, local codes and the requirements of the authority having jurisdiction.

Failure to follow these directions may result in failure of the

device to report an alarm or trouble condition. System Sensor is not responsible for devices that have been improperly

installed, tested or maintained.

Mounting Instructions

1. Install switch mounting bracket onto terminal block us-

ing the 2 screws provided, shown in Figure 1.

2. Snap the switch onto the switch mounting bracket in po-

sition shown in Figure 1.

D770-05-00 1 I56-403-03

Technical Manuals Online! - http://www.tech-man.com

A78-1661-00

Page 26

WARNING

High voltage. Electrocution hazard. Do not handle live AC

wiring or work on a device to which AC power is applied.

Doing so may result in severe injury of death.

Field Wiring

1) Wire as required per wiring diagram (Figure 2), placing

the stripped wire lead under the correct terminal plate.

Extra wire lead should be clipped and terminated with a

wire nut to avoid shorting to housing.