Page 1

INSTALLATION AND MAINTENANCE INSTRUCTIONS

Series

I56-2170-008R

Photoelectric Smoke Detector

2-Wire: 2WTR-B (Form C Relay), 2WTA-B (Sounder)

4-Wire: 4WTR-B (Form C Relay), 4WTA-B (Sounder)

4WTAR-B (Form C Relay, Sounder), 4WITAR-B (Isolated Thermal, Form C Relay, Sounder)

ELECTRICAL SPECIFICATIONS

2-wire 4-wire

System Voltage –Nominal: 12/24 12/24 V

(Non-polarized for 2WTR-B and 4WTR-B)

Min.: 8.5 10 V

Max.: 35 35 V

Max. Ripple Voltage: 30 30 % peak to peak of applied voltage

Avg. Standby Current: 50 50 µA average

Peak Standby Current: 100 — µA

Max. Alarm Current

4WTA-B, 4WTR-B: — 35 mA

4WTAR-B, 4WITAR-B: — 50 mA

2WTR-B: 130 — mA panel must limit current

2WTA-B: 130*

Alarm Contact Ratings: — 0.5 A @ 30 V AC/DC

Form C Contact Ratings: 2 2 A @ 30 V AC/DC

Audible Signal

(temp-3 tone): 85 85 dBA min. in alarm or supply polarity reversed (Sounder units only)

Remote Annunciator Output: 7 — mA maximum

EOL Relay: — 12/24 A77-716B

2-wire 4-wire

Reset Time (min): 0.3 0.3 seconds

Max. Start-up Capacitance: 0.1 — µF

Max. Initial Start-up Time: 45 15 seconds

AlarmVerification**

Start-up Time: 15 15 seconds

* Direct Power (Non-reverse Polarity): 130 mA limited by panel.

Reverse Polarity Power: 30 mA for the 2WTA-B in alarm; 12 mA for all other 2WTA-B units on the loop. Add 25 mA for the RRS-MOD reversing relay alarm current.

** Assumes the panel’s alarm verification reset time is 10 seconds or less. Should the alarm verification reset exceed 10 seconds, use the maximum initial start-up time.

PHYSICAL SPECIFICATIONS

Heat Sensor: 135°F (57.2°C)

Freeze Trouble: 41°F (5°C)

Operating Temperature Range: 32 to 100°F (0 to 37.8°C)

Operating Humidity Range: 0 to 95%

RH non-condensing

Storage Temperature Range: –4 to 158°F (–20 to 70°C)

Diameter (including base): 5.3 inches

Height (including base): 2.0 inches

Weight: 7.1 oz.

BEFORE INSTALLING

Please read thoroughly System Sensor Applications Guide for System Smoke

Detectors, which provides detailed information on detector spacing, place-

ment, zoning, wiring, and special applications. Copies are available on System

Sensor’s web site: www.systemsensor.com.

NOTICE: This manual shall be left with the owner/user of this equipment.

IMPORTANT: This detector must be tested and maintained regularly following National Fire Protection Association (NFPA) 72 National Fire Alarm Code

requirements. At a minimum, cleaning should be performed annually.

GENERAL DESCRIPTION

Models 2WTR-B and 2WTA-B are 2-wire photoelectric smoke detectors; models

4WTR-B, 4WTA-B, 4WTAR-B, and 4WITAR-B are 4-wire photoelectric smoke

detectors. All models incorporate a state-of-the-art optical sensing chamber

and an advanced microprocessor. The microprocessor allows the detector to

automatically adjust its sensitivity back to the factory setting when it becomes

more sensitive due to contaminants settling in its chamber. In order for this

feature to work properly, the chamber must never be opened while power is

applied to the smoke detector. This includes cleaning, maintenance or screen

replacement. All models also feature a restorable, built-in, fixed temperature

(135°F) thermal detector and are also capable of sensing a freeze condition if

the temperature is below 41°F.

Models 2WTA-B, 4WTA-B, 4WTAR-B, and 4WITAR-B contain a piezoelectric

horn which generates the ANSI S3.41 temporal pattern in an alarm condition.

All detectors on a zone will sound when the power supply to them is reversed.

The RRS-MOD can be used for the power supply reversal function. The RRSMOD also enables all the detectors’ sounders on a zone to be synchronized

and allows the zone to be silenced from the panel by entering the alarm silence key at the keypad.

The detector that initiated the alarm condition will have its red LED and Form

C relays (if applicable) latched until reset by panel.

The model 4WITAR-B photoelectronic smoke sensor is isolated from the fixedtemperature heat sensor, providing a self-resetting, local audible smoke alarm

that does not alarm at the panel. Only the fixed-temperature heat sensor will

cause the 4WITAR-B to initiate an alarm at the panel and the relay to change

its state.

NOTE: In order for all i3 sounder detectors on a loop to sound when the panel

alarms, the supply voltage polarity must be reversed. A reversing relay, System

Sensor model number RRS-MOD, must be used. The RRS-MOD is designed

to allow all i3 Series detectors in the same loop to sound when one of the

detectors goes into alarm. In addition, the RRS-MOD will synchronize all of

3825 Ohio Avenue, St. Charles, Illinois 60174

1-800-SENSOR2, FAX: 630-377-6495

www.systemsensor.com

D100-99-00 1 I56-2170-008R

Page 2

the i3 Series sounder smoke detectors on the loop. Some panels may require

SNAP OFF TAB FOR

the use of programmable outputs. Refer to System Sensor literature for further

information on the RRS-MOD.

All i3 Series detectors are designed to provide open area protection. Two-wire models

must be used with compatible UL Listed panels only.

When used with an “i3 Ready” control panel or the i3 Series 2W-MOD2 module (refer to installation manual), the 2WTR-B and 2WTA-B are capable of

generating a “maintenance needed” signal. The 2W-MOD2 can indicate a need

for cleaning, replacement, or a freeze trouble at the control panel or module.

WARNING

The 2W-MOD2 has replaced the previous model number 2W-MOD. To ensure

proper remote maintenance signaling capabilities, do not use the 2W-MOD

with i3 model numbers 2WTR-B and 2WTA-B.

Each i3 Series detector is supplied with a mounting base that can be ceiling- or

wall-mounted:

1. To a single gang box, or

2. To a 31⁄2-inch or 4-inch octagonal box, or

3. To a 4-inch square box with a plaster ring, or

4. Direct mount or to ceiling using drywall fasteners.

FIGURE 1: MOUNTING OF DETECTOR

S0121-00

Installation of the 2WTR-B, 2WTA-B, 4WTR-B, 4WTA-B, 4WTAR-B, and

4WITAR-B detectors is simplified by the use of a mounting base that may

be pre-wired to the system, allowing the detector to be easily installed or removed. The mounting base installation is further simplified by the incorporation of features compatible with drywall fasteners.

Two LEDs on the detector provide a local visual indication of the detector’s status:

TABLE 1: DETECTOR LED MODES

Green LED Red LED

Power-up Blink 10 sec Blink 10 sec

Normal (standby) Blink 5 sec —

Out of sensitivity — Blink 5 sec

Freeze Trouble — Blink 10 sec

Alarm — Solid

During an initial power-up delay, the red and green LEDs will blink synchronously once every ten seconds. It will take approximately 80 seconds for the

detector to finish the power-up cycle (see Table 2).

TABLE 2: POWER-UP SEQUENCE FOR LED STATUS INDICATION*

Condition Duration

Initial LED Status Indication 80 seconds

Initial LED Status Indication

4 minutes

(if excessive electrical noise is present)

* Refer to Electrical Specifications for start-up time in conjunction with panel

alarm verification.

NOTE: If, during power-up, the detector determines there is excessive electrical noise in the system such as those caused by improper grounding of the

system or the conduit, both LEDs will blink for up to 4 minutes before displaying detector status (see Table 2).

After power-up has completed and the detector is functioning normally within

its listed sensitivity range, the green LED blinks once every five seconds. If the

detector is in need of maintenance because its sensitivity has shifted outside

the listed limits, the red LED blinks once every five seconds. When the detector is in the alarm mode, the red LED latches on. The LED indication must not

be used in lieu of the tests specified under Testing. In a freeze trouble condition, the red LED will blink once every 10 seconds (refer to Table 1).

To measure the detector’s sensitivity, the i3 Series Model SENS-RDR Infrared

Sensitivity Reader tool (see Figure 4) should be used. Refer to instructions

manual D100-98-00 for the proper use of the SENS-RDR.

Models 2WTR-B and 2WTA-B also include an output that allows an optional

Model RA400Z/RA100Z Remote Annunciator to be connected.

MOUNTING

General spacing guidelines are 30˝×30˝, with each detector covering 900 ft2

under maximum conditions.

Consult NFPA 72, the local Authority Having Jurisdiction (AHJ), and/or applicable codes for specific information regarding the spacing and placement

of smoke detectors.

The i3 Series heads and bases are keyed so that all heads will only fit into

their respective bases. One model 4-wire relay base will accept the 4WTR-B,

4WTAR-B and 4WITAR-B detector heads and no others. The 2WTR-B, 2WTA-B

and 4WTA-B will only fit into their respective mounting bases and no others.

The heads and bases are clearly identified as either 2-wire or 4-wire. When

mounting the i3 Series, ensure that the head is mounted to the correct base,

and the test switch is aligned with the tamper release tab.

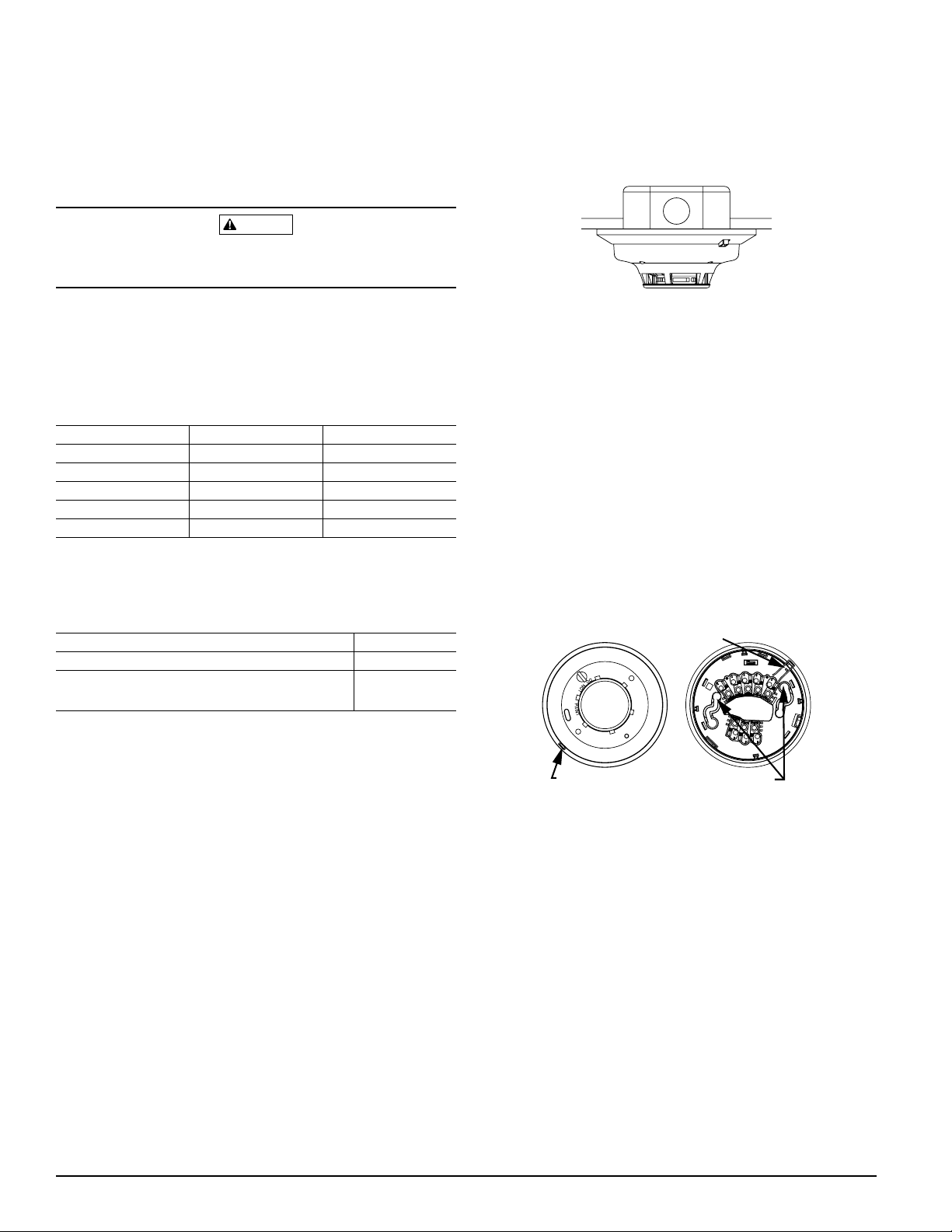

TAMPER-RESISTANT FEATURE

The i3 Series detectors include a tamper-resistant feature that prevents removal

from the mounting base without the use of a tool. To engage the tamper-resistant feature, cut the small plastic tab located on the mounting base (Figure

2), and then install the detector. To remove the detector from the base once it

has been made tamper resistant, use a small screwdriver to depress the square

tamper release tab, located on the skirt of the mounting base, and turn the

detector counterclockwise.

INSTALLATION GUIDELINES

The i3 Series detectors represent an advancement over the previous sounder

and Form C relay models and are designed to be used with the 2W-MOD2 and

RRS-MOD only. Do not mix detector models on a zone.

FIGURE 2: TAMPER-RESISTANT FEATURE

TAMPER LOCK

TAMPER RELEASE TAB

DIRECT MOUNT HOLES

S0109-00

WIRING INSTALLATION GUIDELINES

All wiring must be installed in compliance with the NFPA 70, National Electrical Code, applicable state and local codes, and any special requirements of the

local Authority Having Jurisdiction.

Proper wire gauges should be used. The conductors used to connect smoke

detectors to the alarm control panel and accessory devices should be colorcoded to reduce the likelihood of wiring errors. Improper connections can

prevent a system from responding properly in the event of a fire.

The screw terminals in the mounting base will accept 14–22 gauge wire. For

best system performance, all wiring should be installed in separate grounded

conduit; do not mix fire alarm system wiring in the same conduit as any other

electrical wiring. Twisted pair may be used to provide additional protection

against extraneous electrical interference.

Wire connections are made by stripping approximately 1⁄4-inch of insulation

from the end of the feed wire, inserting it into the proper base terminal, and

tightening the screw to secure the wire in place. Do not put wires more than 2

gauge apart under the same clamping plate.

TWO-WIRE COMPATIBILITY

System Sensor two-wire smoke detectors are marked with a compatibility

identifier located on the label on the back of the product. For two-wire models 2WTR-B and 2WTA-B, connect detectors only to compatible alarm control

panels as identified by System Sensor’s two-wire compatibility chart, available

at www.systemsensor.com.

D100-99-00 2 I56-2170-008R

Page 3

NOTE: Models 2WTR-B and 2WTA-B are not to be installed on initiating cir-

POSITION SENS-RDR AT AN ANGLE ON

THE OVAL AREA OR AT THE CHAMBER

OPENING BY THE WORD “PAINT”

PUSH RECESSED

SWITCH WITH A

0.18″ MAX.

DIAMETER TOOL

RECESSED

TEST SWITCH

LED

cuits containing other makes/models of smoke detectors.

NOTE: Style D initiating circuits require the use of a 2W-MOD2 for models

2WTR-B and 2WTA-B.

WIRING DIAGRAMS

FIGURE 3A: WIRING DIAGRAM, 2WTR-B AND 2WTA-B

EOL

–

+

RESISTOR

RA400Z

(5)

RA –

(4)

RA +

(3)

– IN/OUT

(2)

+ OUT

(1)

+ IN

(6) NC

OPTIONAL

(7) C

RELEASING

(8) NO

DEVICE

NOT INCLUDED ON

2WTA-B MODEL

2-WIRE

ZONE

2-WIRE

CONTROL

PANEL

S0122-00

NOTE: FOR ALL COMPATIBLE ADEMCO PANELS,

DO NOT EXCEED 30 OHMS LINE IMPEDANCE.

NOTE: ONLY ONE 2WTR-B DETECTOR PER ZONE CAN BE USED.

NOTE: Only one 2WTA-B detector shall be installed on a zone, unless the

panel switches the zone to a reverse polarity, non-current limited power supply. For panels that do not provide this feature, a reversing relay, System Sensor model RRS-MOD, may be used. When utilized with the 2WTA-B, it allows

for more than one detector to be utilized on a loop. Some panels may require

the use of programmable outputs. Refer to System Sensor literature for further

information on the RRS-MOD. The 2WTA-B detector shall not be mixed with

other 2-wire detectors on the same zone.

CAUTION

Any 2-wire i3 smoke detector (2W-B, 2WT-B, 2WTA-B, or 2WTR-B) wired

in the Style D initiating device circuit (IDC) configuration requires the use

of a 2W-MOD2 module. This is because fire alarm control panels vary by

manufacturer on the implementation of Style D circuits. Therefore, the only

way to insure proper operation of 2-wire i3 smoke detectors (2W-B, 2WT-B,

2WTA-B, or 2WTR-B) on Style D IDC’s is to use a 2W-MOD2 module. Refer to

the 2W-MOD2 installation manual, document D500-46-00, for Style D wiring

diagrams. The 2W-MOD2 installation manual may be downloaded from the

System Sensor web site at www.systemsensor.com.

FIGURE 3B: WIRING DIAGRAM, 4WTR-B, 4WTA-B, 4WTAR-B, AND

4WITAR-B

AUX OR

SMOKE

POWER

IDC

4-WIRE

CONTROL

PANEL

+

–

–

+

(

(

(

(

(

1

)

+ IN

2

)

+ OUT

4

3

)

)

A

– IN/OUT

5

)

A

(

1

)

+ IN

(

2

)

+ OUT

(

3

)

– IN/OUT

EOL

RELAY

(

)

A77-716B

EOL

RESISTOR

(

(

5

4

)

)

A

A

NOTE: To install units so that corresponding LEDs are lined up, refer to the

“Green LED” indicator on the base.

1. Wire the mounting base screw terminals per Figure 3a or Figure 3b, as

applicable.

2. Place detector on the base and rotate clockwise. The detector will drop

into the base and lock into place with a “click”.

3. After all detectors have been installed, apply power to the alarm control unit.

4. Test each detector as described in Testing.

5. Reset all the detectors at the alarm control unit.

6. Notify the proper authorities that the system is in operation.

CAUTION

Dust covers are an effective way to limit the entry of dust into the smoke

detector sensing chamber during construction. However, they may not completely prevent airborne dust particles from entering the detector. Therefore,

System Sensor recommends the removal of detectors before beginning construction or other dust producing activity. When returning the system to service, be sure to remove the dust covers from any detectors that were left in

place during construction.

CAUTION

Smoke detectors are not to be used with detector guards unless the combination has been evaluated and found suitable for that purpose.

CAUTION

When using the RRS-MOD with model 2WTA-B, do not mix the 2WTA-B with

other model smoke detectors and dry contact closure devices, including mechanical heat detectors, manual pull stations and waterflow switches. Such

mixing can cause a direct short on the auxiliary power terminals, damaging

the control panel’s internal circuitry and/or damage devices connected to the

initiating device circuit.

TESTING

Detectors must be tested after installation and following maintenance.

NOTE: Before testing, notify the proper authorities that maintenance is being

performed and the system will be temporarily out of service. Disable the zone

or system undergoing maintenance to prevent any unwanted alarms.

Ensure proper wiring and power is applied. After power up, allow 80 seconds

for the detector to stabilize before testing.

Test i3 Series detectors as follows:

A. TEST SWITCH

1. An opening for the recessed test switch is located on the detector housing (See Figure 4).

2. Insert a small screwdriver or allen wrench (0.18˝ max.) into the test

switch opening; push and hold.

3. If the detector is within the listed sensitivity limits, the detector’s red

LED should light within one second.

FIGURE 4: RECESSED TEST SWITCH OPENING AND SENS-RDR POSITION

(6) NC

(7) C

NOT INCLUDED ON

4WTA-B MODEL

(7) C

(8) NO

OPTIONAL

RELEASING

DEVICE

(6) NC

(8) NO

OPTIONAL

RELEASING

DEVICE

NOT INCLUDED ON

4WTA-B MODEL

S0123-00

INSTALLATION

WARNING

Remove power from alarm control unit or initiating device circuits before installing detectors.

B. SMOKE ENTRY TEST

Hold a smoldering punk stick or cotton wick at the side of the detector and

S0110-00

gently blow the smoke through the detector until it alarms.

D100-99-00 3 I56-2170-008R

Page 4

C. DIRECT HEAT METHOD

Using a 1000-1500 watt hair dryer, direct the heat toward either of the thermistors. Hold the heat source about 12 inches from the detector to avoid damage

to the plastic.

NOTE: For the above tests, the detector will reset only after the power source

has been momentarily interrupted. It is not necessary to reset the model

4WITAR-B, when smoke is used to initiate the alarm.

When testing the 4WITAR-B model, pressing the test switch will result in a

non-latching local alarm that does not alarm at the control panel. Once the

test button is released, the unit will return to its standby condition. Only the

fixed-temperature heat sensor will cause the 4WITAR-B to initiate an alarm at

the panel.

If a detector fails any of the above test methods, its wiring should be checked

and it should be cleaned as outlined in the Maintenance section. If the detector still fails, it should be replaced.

Notify the proper authorities when the system is back in service.

LOOP VERIFICATION (MODELS 2WTR-B AND 2WTA-B ONLY)

Loop verification is provided by the EZ Walk loop test feature. This feature

is for use with i3 Series compatible control panels or the i3 Series 2W-MOD2

module only. The EZ Walk loop test verifies the initiating loop wiring and

provides visual status indication at each detector. Refer to System Sensor literature for further information on the 2W-MOD2.

WARNING

The 2W-MOD2 has replaced the previous model number 2W-MOD. To ensure

proper EZ Walk Test capabilities, do not use the 2W-MOD with i3 model numbers 2WTR-B and 2WTA-B.

TABLE 3: EZ WALK TEST DETECTOR MODES

MAINTENANCE

NOTE: Before performing maintenance on the detector, notify the proper authorities that maintenance is being performed and the system will be temporarily out of service. Disable the zone or system undergoing maintenance

to prevent any unwanted alarms. Power must be removed from the detector

before performing maintenance of any kind.

1. Remove the detector cover by turning counterclockwise. (See Figure 5.)

2. Vacuum the cover or use canned air to remove any dust or debris.

3. Remove the top half of the screen/sensing chamber by lifting straight up

(Figure 5).

4. Vacuum or use canned air to remove any dust or particles that are present on both chamber halves.

5. Replace the top half of the screen/sensing chamber by aligning the arrow

on the screen/sensing chamber with the arrow on the housing. Press

down firmly until the screen/sensing chamber is fully seated.

6. Replace the detector cover by placing it over the screen/sensing chamber

and turning it clockwise until it snaps into place.

7. Reinstall the detector and test. (See the Testing section.)

8. Notify the proper authorities when the system is back in service.

Figure 5: Removing Screen/Sensing Chamber

REMOVABLE

DETECTOR

COVER

SCREEN/SENSING

CHAMBER

(TOP HALF)

DETECTOR HOUSING

S0111-00

Green LED Red LED

Proper Operation Double blink 5 sec —

Out of Sensitivity — Double Blink 5 sec

Freeze Condition — Double Blink 10 sec

NOTE: The EZ Walk loop test must not be used instead of alarm testing.

Please refer to insert for the Limitations of Fire Alarm Systems

System Sensor warrants its enclosed product to be free from defects in materials and

workmanship under normal use and service for a period of three years from date of

manufacture. System Sensor makes no other express warranty for the enclosed product.

No agent, representative, dealer, or employee of the Company has the authority to increase or alter the obligations or limitations of this Warranty. The Company’s obligation

of this Warranty shall be limited to the replacement of any part of the product which

is found to be defective in materials or workmanship under normal use and service

during the three year period commencing with the date of manufacture. After phoning

System Sensor’s toll free number 800-SENSOR2 (736-7672) for a Return Authorization

number, send defective units postage prepaid to: System Sensor, Returns Department, RA

This device complies with part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) This device may not cause harmful interference, and (2) this device must

accept any interference received, including interference that may cause undesired operation.

NOTE: This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference in a residential installation. This equipment generates, uses and can radiate radio frequency energy and, if not installed and used

in accordance with the instructions, may cause harmful interference to radio communications. However, there is no guarantee that interference will not occur in a particular installation. If this equipment does cause harmful interference to radio or television reception, which can be determined by turning the equipment off and on, the user is encouraged to try

to correct the interference by one or more of the following measures:

– Reorient or relocate the receiving antenna.

– Increase the separation between the equipment and receiver.

– Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

– Consult the dealer or an experienced radio/TV technician for help.

D100-99-00 4 I56-2170-008R

©2009 System Sensor

THREE-YEAR LIMITED WARRANTY

#__________, 3825 Ohio Avenue, St. Charles, IL 60174. Please include a note describing

the malfunction and suspected cause of failure. The Company shall not be obligated to

replace units which are found to be defective because of damage, unreasonable use,

modifications, or alterations occurring after the date of manufacture. In no case shall the

Company be liable for any consequential or incidental damages for breach of this or any

other Warranty, expressed or implied whatsoever, even if the loss or damage is caused by

the Company’s negligence or fault. Some states do not allow the exclusion or limitation of

incidental or consequential damages, so the above limitation or exclusion may not apply

to you. This Warranty gives you specific legal rights, and you may also have other rights

which vary from state to state.

FCC STATEMENT

Loading...

Loading...