Page 1

INSTALLATION AND MAINTENANCE INSTRUCTIONS

FSB-200, FSB-200S

Single-ended Reflected Type

Projected Beam Smoke Detector

Specifications

General

Range: 16 to 230 Feet (5 to 70m)

230 to 328 Feet (70 to 100m) using optional accessory BEAMLRK

Sensitivity: 25% to 50% Total Obscuration in 6 levels

Level 1 = 25%

Level 2 = 30%

Level 3 = 40%

Level 4 = 50%

Level 5 = 30% to 50% (Acclimate)

Level 6 = 40% to 50% (Acclimate)

Spacing: 30 to 60 Feet (9.1 to 18.3m)

Response Time: Alarm: 20 seconds typical

Trouble: 30 seconds typical

Trouble Conditions: Beam Blockage (96% or More Obscuration)

Improper Initial Alignment

Self-compensation limit reached (service needed)

In Alignment mode

Test/Reset Features: Integral Sensitivity Test Filter (FSB-200S only, requires additional external power supply)

Sensitivity Filter (Incremental scale on reflector)

Local Alarm Test Switch

Local Alarm Reset Switch

Remote Test and Reset Switch Capability

(compatible with RTS451/RTS451KEY)

Indicators: Alarm: Remote Output, Local LED (red)

Trouble: Remote Output, Local LED (yellow)

Blink Pattern Indicates Trouble Diagnostics

Normal Operation: Local LED (flashing green with communication)

Alignment Aids: Optical Gunsight (coarse adjustment)

00 to 99 Digital Display (fine adjustment)

Sensitivity: Digital Display Readout in Percent Obscuration

Style 7 Operation: On-board isolators provide style 7 operation.

(may be disabled via shunts on circuit board)

12 Clintonville Rd.

Northford, CT 06472-1653

Phone: 203/484-7161

Environmental

Temperature: –22°F to 131°F (–30°C to 55°C)

Note: for applications below 32°F (0°C) see Special Applications section of this manual.

Humidity: 10% to 93% RH Noncondensing

Mechanical

Shipping Weight: 3.9 lbs. (1.77 kg)

Shipping Size: 15″ × 10.5″ × 6.5″ (381mm × 267mm × 165mm)

Mounting: Wall only without optional accessories

Wiring: Plug-in Terminal Blocks (12 to 22AWG)

Adjustment Angle: ±10° Horizontal and Vertical

Paintable Trim Ring: May be painted using enamel or acrylic type paints

N200-25-00 1 I56-2424-04R

Page 2

Specifications (continued)

Electrical

Voltage: 15 to 32 VDC

Standby Current: Avg. Standby: 2mA Max.

(1 communication every 5 sec., LED flashing, SLC @ 24 V)

Max. Alarm (LED on): 8.5mA Max.

Max. Trouble (LED on): 4.5mA Max.

Max. Alignment: 20mA Max.

External Supply

(FSB-200S only): Voltage: 15 to 32 VDC

Current: 0.5A Max.

Remote Output: Voltage: 15 to 32 VDC

(alarm) Note: Output voltage same as device input voltage.

Current: 15mA maximum

6mA minimum

Note: Output current is limited by 2.2Kohm resistor

General Description

Model FSB-200/FSB-200S is a long range projected beam

smoke detector designed to provide open area protection. It

is to be used with UL-listed compatible control panels only.

The detector consists of a transmitter/receiver unit and a

reflector. Smoke entering the area between the transmitter/

receiver and reflector causes a reduction in signal. When

the obscuration reaches alarm thresholds (chosen at the

transmitter/receiver unit), the detector generates an alarm

signal. Complete blockage of the beam causes a trouble

signal. Slow changes in obscuration due to a build up of

dirt or dust on the lens of the detector are compensated for

by a microcontroller that continuously monitors the signal

Special Applications

Due to the inherent capabilities of projected type beam

detectors they are often installed in locations where spottype detection is impractical. Projected type beam smoke

detectors are ideally suited for environmental conditions

that might include high ceilings, dusty and dirty environments, or environments that experience temperature

extremes. Often these conditions present special problems

for the installation of spot-type detectors and even greater

problems for their proper maintenance. Due to the inherent

flexibility of mounting locations and large coverage area of

projected type beam detectors often the conditions above

can be addressed or minimized.

strength and periodically updates the alarm and trouble

thresholds. When the self-compensation circuit reaches its

limit, the detector generates a trouble signal, indicating the

need for service.

Some examples of applications for beam detectors might

include freezers, aircraft hangars, cold storage warehouses,

shipping warehouses, enclosed parking facilities, sporting

arenas and stadiums, concert halls, barns, or stables. Some

Three LEDs on the detector indicate the current status: a

red LED for alarm, a yellow LED for trouble, and a blinking

green LED for standby operation. Note: The panel controls

the status of the red and green LEDs. The local reset but-

of these environments might be considered too hostile for

spot-type smoke detectors. If the environment is consid-

ered to be hostile then the colder alarm threshold settings

should be used.

ton is accessible by removing the outer paintable trim ring.

The yellow LED will blink in specific patterns to provide a

diagnostic aid when diagnosing the cause of a trouble signal. It will also blink the amount of drift compensation that

has been used at the conclusion of the local test. Trouble

signals automatically reset upon removing the cause of

trouble. Red and yellow LEDs can be remotely connected

to the remote Alarm and Trouble outputs. These outputs

mimic the functions of the detector’s red and yellow LEDs.

In addition to these indicators, there is a dual digital display

that reads 00 to 99. This display is used to indicate the signal strength of the beam in alignment mode and to indicate

the sensitivity setting of the detector in percent obscuration

when setting the sensitivity of the detector. No additional

equipment is needed for alignment of the beam.

Before installing the transmitter/receiver unit or reflector

in these types of applications special consideration should

be given to insure proper operation of the beam detector.

The beam detector should not be installed in environments

where there is no temperature control and condensation or

icing is likely. Condensation or icing of the reflector surface

or the outer surface of the transmitter/receiver unit will

obscure the light beam resulting in a false alarm. If elevated

humidity levels and rapidly changing temperatures can be

expected then condensation will likely form and the appli-

cation should not be considered acceptable for the beam

detector. The beam detector should not be installed in

locations where the transmitter/receiver unit, the reflector,

or the optical pathway between them may be exposed to

outdoor conditions such as rain, snow, sleet, or fog. These

N200-25-00 2 I56-2424-04R

Page 3

conditions will impair the proper operation of the detector

and must be avoided.

Approved Accessories

The following accessories can be purchased separately for

use with this beam detector.

BEAMLRK

The BEAMLRK allows System Sensor reflected beam detectors to be installed at separations between 230 and 328 feet

(70 to 100 meters). At these distances, four 8″×8″ reflectors

must be used to provide enough reflected infrared light.

This kit includes 3 additional reflectors with new test

scale legends. The reflector included with the transmitter/

receiver unit is the fourth reflector to be used. This kit is

not compatible with the multi-mount kit (BEAMMMK).

BEAMMMK

The BEAMMMK allows System Sensor reflected beam detectors and reflectors to be mounted to either a vertical wall or

the ceiling. The kit allows for additional alignment range in

cases where the detector and reflector cannot be mounted

within 10° of each other. The kit includes the hardware

necessary to mount either a single transmitter/receiver unit

or a single reflector. (To mount the transmitter/receiver the

surface mount kit, BEAMSMK, must also be used). If the

transmitter/receiver and the reflector require additional

alignment range two kits are required. The kit is not compatible with the long-range reflector kit (BEAMLRK).

BEAMSMK

The BEAMSMK allows System Sensor reflected beam detectors to be mounted when surface wiring is used. This kit

must be used when mounting the transmitter/receiver unit

with the multi-mount kit (BEAMMMK).

BEAMHK

The BEAMHK allows the transmitter/receiver unit to operate in environments prone to the formation of condensation. Condensation forming on the beam detector unit

may result in trouble or false alarm conditions. BEAMHK

will lessen the likelihood of condensation by maintaining

the unit at a temperature that is slightly higher than the

surrounding air. Please refer to the BEAMHK installation

manual for operation instructions.

BEAMHKR

The BEAMHKR allows the reflector to operate in environments prone to the formation of condensation. Condensation

forming on the reflector may result in trouble or false alarm

conditions. BEAMHKR will lessen the likelihood of condensation by maintaining the reflector at a temperature that is

slightly higher than surrounding air. The kit requires a 24V

power supply. When used with the long-range reflector kit

(BEAMLRK), it is necessary to purchase and install four

BEAMHKR kits. Please refer to the BEAMHKR installation

manual for operation instructions.

RTS451/KEY

The remote test accessory, RTS451/KEY allows for the

beam detector to be tested remotely. The test accessory

provides test and reset functions and green and red LED’s

that mimic the LED’s on the detector.

Parts List

Description Quantity

Transmitter/Receiver Unit . . . . . . . . . . . . . . . . . . . .1

Paintable Trim Ring . . . . . . . . . . . . . . . . . . . . . . . . .1

Reflector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Plug-in Terminal Blocks . . . . . . . . . . . . . . . . . . . . . .3

Isolator Shunts . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Instruction Manual . . . . . . . . . . . . . . . . . . . . . . . . .1

Orange Sticky Paper . . . . . . . . . . . . . . . . . . . . . . . . .1

Parts Diagram (not to scale)

Terminal Block

Isolator Shunt

Paintable

Trim Ring

C0306-00

Detector Placement

This section of the manual discusses the placement of projected beam detectors. Though this information is based

upon industry expertise, it is intended to be used only as

a technical guide. Always comply with the requirements of

applicable codes and standards such as, NFPA 72, National

Fire Alarm Code, as well as directives of the Authority

Having Jurisdiction (AHJ).

Projected beam detectors are usually located with their

beams parallel to the ceiling. However, they can be mounted vertically or at any angle to protect the area involved.

Since beam detectors sense the smoke buildup over a distance, they are ideal for locations with high ceilings. They

can also be mounted on a wall or ceiling below the level

of a spot type detector, reducing the effects of air stratification. Some typical locations would include large areas with

high ceilings such as atriums, warehouses, and factories.

NOTE: Projected beam smoke detectors should always

be mounted to stable mounting surfaces. See the

MOUNTING LOCATION section for details.

N200-25-00 3 I56-2424-04R

Page 4

Some fire codes specify spacing on a given center-to-center

1/2 S S

12-18 in.

(0.3-0.46m)

WALL

16 ft. (5m) Minimum

328 ft. (100m) Maximum

Tx/Rx Reflector

S

Tx/Rx Reflector

1/2 S Maximum

1/4 S

Max.

S

3 ft. (0.

9m

)

Max.

S

1/2 S MAX.

Tx/Rx

Reflector

distance between detectors under ideal conditions. This

spacing is based on rooms with smooth ceilings and no

physical obstructions between the contents being protected

and the detectors. Moreover, they are also based on a maximum ceiling height, and on the assumption that the value

and the combustible nature of the contents of the room

being protected do not warrant greater protection or closer

spacing.

In a room with a smooth ceiling, detectors should be

spaced between 30 and 60 feet (9.1 to 18.3m). One-half

that spacing between the beam and the sidewall may be

used as a guide. See Figure 1. The beam detector can be

mounted with the transmitter/receiver on one wall and the

reflector on the opposite wall, or both suspended from the

ceiling, or any wall/ceiling combination. In the case of the

ceiling mount, the distance from the end walls should not

exceed one-quarter of the selected spacing (7.5 ft. [2.3m]

maximum if the spacing is 30 ft. [9.1m]). See Figure 2.

Figure 1. Spacing for smooth ceiling (side view):

Figure 2. Spacing for smooth ceiling (top view):

C0255-00

In the case of peaked or sloped ceilings, codes may specify

spacing of detectors by using horizontal spacing from the

peak of the roof or ceiling. Figures 3 and 4 show the spacing

for both the shed type and peaked type sloped ceilings.

On smooth ceilings, beam smoke detectors should gener-

ally be mounted between 12 and 18 inches (0.3 to 0.46m)

from the ceiling. In many cases, however, the location and

sensitivity of the detectors shall be the result of an engi-

neering evaluation that includes the following: structural

features, size and shape of the room and bays, occupancy

and uses of the area, ceiling height, ceiling shape, surface

and obstructions, ventilation, ambient environment, burn-

ing characteristics of the combustible materials present,

and the configuration of the contents in the area to be

protected.

Figure 3. Sloped ceiling (shed type):

C0254-00

C0256-00

N200-25-00 4 I56-2424-04R

Page 5

Figure 4. Sloped ceiling (peaked type):

1/2

S

S

S

1/2

S

3 ft. (0.9m)

Max.

3 ft. (0.9m

)

Max.

Mount Detector

Anywhere in This Area

Tx/Rx

Reflector

WA

L

L

REFLE

CTOR

Acceptable mounting

locations for reflector

10ϒ

10ϒ

C0257-00

Mounting Locations

Beam detectors require a stable mounting surface for

proper operation. A surface that moves, shifts, vibrates, or

warps over time will cause false alarm or trouble conditions. Initial selection of a proper mounting surface will

eliminate false alarms and nuisance trouble signals.

Mount the detector on a stable mounting surface, such as

brick, concrete, a sturdy load-bearing wall, support column, structural beam, or other surface that is not expected

to experience vibration or movement over time. DO NOT

MOUNT the beam detector on corrugated metal walls,

sheet metal walls, external building sheathing, external

siding, suspended ceilings, steel web trusses, rafters, nonstructural beam, joists, or other such surfaces.

the supplied drilling template (see Appendix II). The detector base has 4 primary mounting keyholes, one in each

corner of the base. All four hole locations should be used

to provide a secure mounting. The outer housing of the

beam detector is held to the base using four screws. In

order to mount the detector you must remove the outer

housing first.

The reflector can be mounted to the wall using the supplied drilling template (see Appendix III). The reflector

has 4 mounting holes, one in each corner. All four hole

locations should be used to provide a secure mounting.

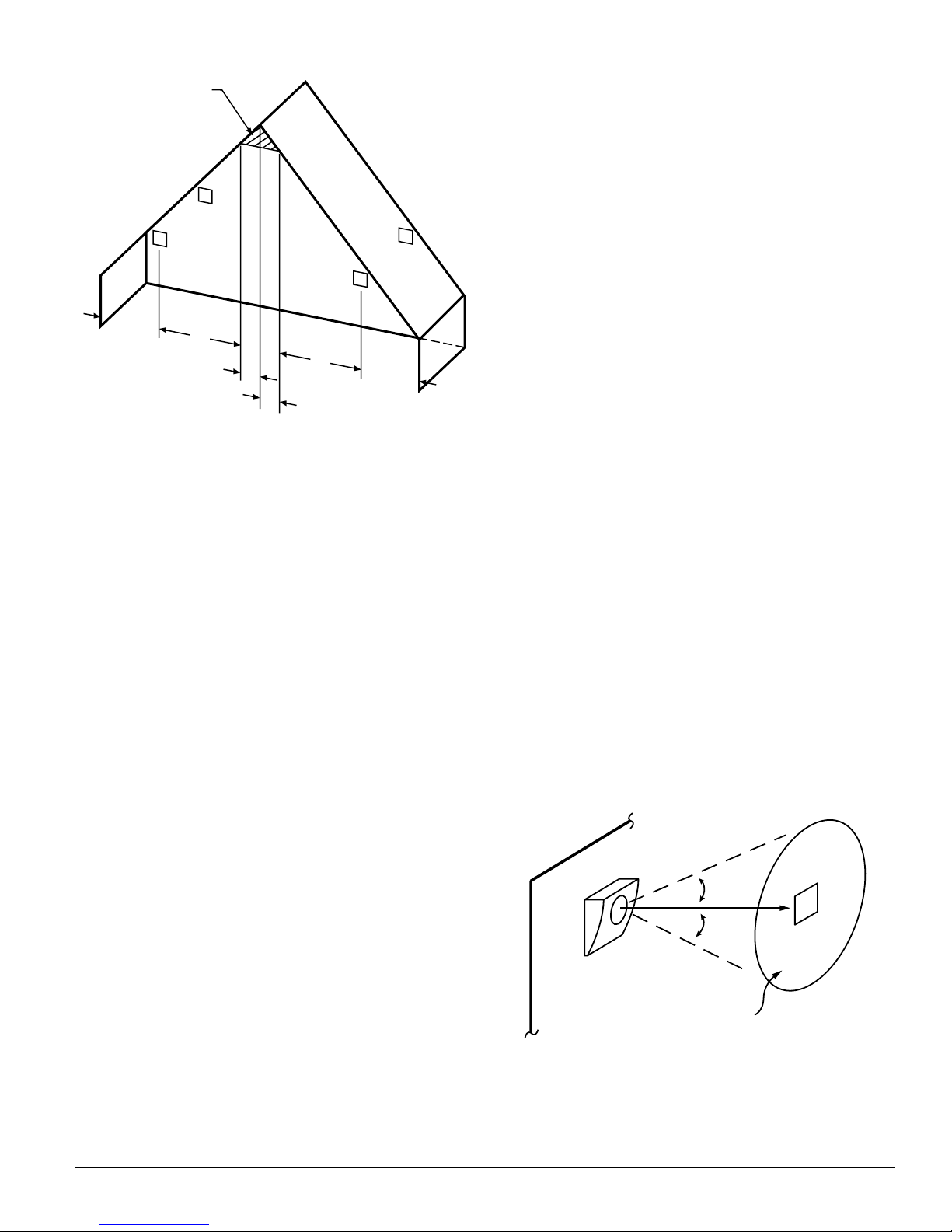

The reflector must be mounted such that it is within 10°

in both the X and Y planes of the transmitter/receiver unit.

See Figure 5a. The reflector must also be mounted such

that plane of the reflector is perpendicular to the optical

line of sight to the transmitter/receiver unit. The maximum

tolerance for non-perpendicular mounting locations is 10°.

See Figure 5b. If the reflector cannot be mounted within

10° of the transmitter/receiver unit then the multi-mount

kit (BEAMMMK) may be used to provide greater angular

adjustment of the transmitter/receiver unit. If the perpendicular plane of the reflector cannot be mounted within 10°

of the optical line of sight then the multi-mount kit can be

used for the reflector. See BEAMMMK instructions.

To aid in locating the reflector in the alignment mirror

at long distances a bright orange sticky backed piece of

paper is provided. Remove the protective backing from

the orange sticker. Temporarily affix the orange paper next

to the reflector using the sticky backing of the paper. The

location of the sticky paper is not critical. It may be placed

anywhere near the reflector as long as it not covering the

reflective surface of the reflector. This sticky paper should

be removed once the installation is completed.

In cases where only one stable mounting surface as defined

above can be used, the transmitter/receiver unit should be

mounted to the stable surface and the reflector should

be mounted to the less stable surface. The reflector has

tions defined above.

a much greater tolerance for the unstable mounting loca-

Mounting Instructions

The transmitter/receiver unit may be mounted over a

recessed junction box. The cavity behind the detector is

then used for routing of the wiring from the junction box

to the terminal blocks on the detector. The transmitter/

receiver unit should be mounted to the wall such that unit

covers the recessed junction box in the wall completely.

If the junction box is not recessed then you may use the

surface mount kit (BEAMSMK). See the BEAMSMK installation instructions for surface mounting instructions. The

transmitter/receiver unit can be mounted to the wall using

N200-25-00 5 I56-2424-04R

Figure 5a. Reflector Mounting Guidelines

C0258-00

Page 6

Figure 5b. Reflector Mounting Guidelines

10ϒ maximum

optical line of sight

REFLECTOR

C0259-00

between the detector and the reflector, (A minimum of 10°

off perpendicular should be considered), and make certain

that the glass is smooth, clear and mounted securely. The

complete reflector blockage test can be used to determine if

the installation is acceptable. See Testing and Maintenance

Section of this manual.

Where high ceilings (in excess of 30 feet or 9.1 meters) are

present additional beams may be required to detect smoke

at lower levels.

Mounting Considerations for Single Ended Beam

Detectors

There must be a permanent clear line of vision between the

detector and the reflector. Reflective objects must not be

near the line of vision between the detector and reflector.

Reflective objects too near to the line of sight can reflect

the light beam from the transmitter to the receiver. If this

occurs, the detector will not be able to distinguish these

reflections from those of the reflector and the protected

space will be compromised. Reflective objects should be

Wiring Installation Guidelines

Always install all wiring in compliance with the National

Electrical Code, and/or the applicable local codes, and any

special requirements of the local authority having jurisdic-

tion. Proper wire gauges and suitable means for strain relief

should be used. The conductors used to connect beam

smoke detectors to control panels and accessory devices

should be color-coded to reduce the likelihood of wiring

errors. Improper connections can prevent a system from

responding properly in the event of a fire.

a minimum of 15 inches (38.1cm) from the line of sight

between the detector and reflector. In cases where reflective

objects cannot be avoided, the complete reflector blockage

test can be used to determine if the installation is acceptable. See Testing and Maintenance Section of this manual.

Installation wire used for the beam detector shall be no

smaller than 22 AWG (1.0 mm2). For best system perfor-

mance, all wiring should be twisted pair and installed in

separate grounded conduit. Do NOT mix fire system wiring

in the same conduit as any other electrical wiring. Shielded

Light sources of extreme intensity such as sunlight and halogen lamps, if directed at the receiver, can cause a dramatic

cable may be used to provide additional protection against

electrical interference.

signal change resulting in fault and alarm signals. To prevent

this problem direct sunlight into the transmitter/receiver

unit should be avoided. There should be a minimum of 10°

between the pathway of the light source and detector and

the line of sight between detector and reflector.

When installing the beam smoke detector in applications

where the head unit will be mounted to either a wall or

the ceiling using the multi-mount kit (BEAMMMK) flexible

conduit will be used. The surface mount kit (BEAMSMK)

and multi-mount kit (BEAMMMK) must be installed with

Operation of the detector through panes of glass should

be avoided. Since single ended beam detectors operate on

the cable before wiring the unit, according to the instruc-

tions supplied with the kit.

a reflection principle, a pane of glass perpendicular to the

line of sight between the detector and the reflector can

reflect the light beam from the transmitter to the receiver.

If this occurs, the detector will not be able to distinguish

these reflections from those of the reflector and the protected space will be compromised.

When the detector has been mounted over a recessed junc-

tion box, all wiring should be routed out of the box and

behind the detector to the bottom of the detector where

the terminal blocks are located. When installing the wir-

ing in the junction box be sure to leave enough wire in the

box to connect to the terminal blocks. (Approximately 9″

Panes of glass will also absorb some of the light as it

passes through it. This absorption of light will reduce the

acceptable installed distance between the detector and the

reflector.

(23cm) of wire outside of the junction box will be required

for proper installation). All wiring to the detector is done

via pluggable terminal blocks. In order to properly make

electrical connections strip approximately 1/4″ (6mm) of

insulation from the end of the wire, sliding the bare end of

In cases where operation through panes of glass cannot

be avoided some specific installation practices can help to

minimize the effects of the glass. These practices include:

avoid penetration of multiple panes of glass, position the

glass so that it is not perpendicular to the line of sight

the wire under the clamping plate screw.

Figure 6 shows all the wiring connections to the transmitter/

receiver unit. Figure 7 shows the proper wiring diagram for

either class A or class B operation. Figure 8 shows the con-

nections that are necessary when using one of the optional

N200-25-00 6 I56-2424-04R

Page 7

remote test stations (RTS451 or RTS451KEY). Figure 9

SLC (–)

SLC (+)

SLC (–)

SLC (+)

RESET I NPUT

TEST INPUT

AUX (–)

REMOTE ALARM OUT

Not used

REMOTE TROUBLE OUT

TEST OPTION (–)

TEST OPTION (+)

T3 T2 T1

+ –

+ –

+

+

TO NEXT

DEVICE

FROM PANEL OR

PREVIOUS DEVICE

LISTED

REMOTE

POWER

SOURCE

* Only used for

FSB-200S. See

electrical ratings.

COMMUNICATION LINE

32 VDC MAX.

TWISTED PAIR IS

RECOMMENDED.

–

–

–

+

T3 T2 T1

RTS451/KEY

FSB-200/FSB-200S

Pin 1

Remote Alarm Out

T2-1

T2-2

T2-4

T2-3

AUX (–)

Power In +T1-1

T1-2

T1-3

T1-4Power In –

Power Out +

Power Out –

Reset Input

Test Input

T3-3

Remote Trouble Output

Optional Yellow LED

Pin 2

Pin 4

Pin 3

Pin 5

FSB-200S

Alarm

Signal

Circuit

(Note 1)

T2-1

T2-2

Note 1: See electrical ratings section of this

manual for circuit output ratings.

SLC (+)

SLC (–)

Red

shows the remote output for alarm indication.

WARNING: Disable the zone or system before applying

power to the beam detector to prevent unwanted alarms. When applying power to the beam

detector before the alignment procedure has

been completed the detector may enter alarm

or fault.

Figure 6. Wiring Connections at Detector

Figure 7. Wiring Diagram

C0335-00

Figure 8. Wiring Diagram (RTS451)

C0260-01

C0336-01

Figure 9. Wiring Diagram (RTS451)

N200-25-00 7 I56-2424-04R

C0326-00

Page 8

Installation / Alignment

Reference Figures 10 through 14 for installation, alignment,

brightly colored object on the wall near the reflector to

aide in seeing the reflector in the alignment mirror.

and maintenance.

3. Once the reflector has been located, begin to adjust both

The alignment of the FSB-200/FSB-200S is divided into four

steps: coarse alignment, fine adjustment, final gain adjustment, and final verification. It is necessary for all four

steps to be executed properly to ensure proper alignment

of the product. If the detector and reflector are mounted per

the horizontal and vertical alignment knobs so that the

reflector becomes centered in the alignment mirror. Take

care in this step. If the optics are incorrectly aligned in

this step, it will not be possible to proceed with the fine

adjustment step.

Mounting Locations and Mounting Instructions sections of

this manual and the alignment procedures are executed

properly, false alarms and nuisance trouble signals will be

Step 2. Fine Adjustment

Refer to Figures 10 through 12 for this step.

minimized.

In this step you will be fine-tuning the optics to the reflec-

Pre-Alignment Checklist

• Insure that both the detector and reflector are mounted

securely to stable surfaces.

• Insure that all wiring is correct.

• Insure that terminal blocks are fully seated into their

receptacles on the detector.

• Complete any wiring dressing to minimize movement

to the detector once the alignment procedure is completed.

• Insure that the appropriate number of reflectors are

used for the installed distance. Distances between 230

& 328 Feet (70 - 100m) require additional reflectors (4

total). The BEAMLRK accessory should be used in these

cases.

tor. To provide feedback of the signal level coming from the

reflector the dual digital display readout will be used. Due

to the large distance range that the detector can operate

over it is necessary that the detector operate with many different settings of “electronic amplifier gain”. The detector

is capable of determining the appropriate gain setting and

then setting it itself via on-board processing algorithms.

There are no external gain settings on the detector that

must be set by the operator. Periodically throughout the

fine adjustment step the detector will need to re-adjust its

“electronic amplifier gain” setting. When this occurs it will

be indicated by the dual digital readout as “- -”. When this

occurs, cease any further adjustment until the display again

reads a number value.

• Insure that the line of sight between the detector and

reflector is clear and that reflective objects are not too

near. See Mounting Instructions for more details.

1. Insure that neither you nor any other objects are in the

line of sight between the detector and the reflector.

• Insure that both the detector and reflector are mounted

within their operational parameters for off axis angles.

See Mounting Instructions for more details.

• Disable the zone or system to prevent unwanted alarms

before applying power.

• Insure power to the detector is “ON”.

• Insure that the appropriate address is set on the code

wheels.

2. Depress the Alignment switch once. Both the digital display and the yellow LED should turn on indicating that

alignment mode has been entered. The display should

begin reading “- -” signifying an electronic gain adjustment. After a few moments the display will indicate a

numeric value near 20. If the display reads “Lo” then

the detector is not receiving enough light from the reflector. Go back and repeat the course alignment step and

You are now ready to begin the alignment procedure.

verify that the proper number of reflectors is used for the

installed distance.

Step 1. Coarse Alignment

Refer to Figures 11 and 12 for this step.

NOTE: The display will continue to read “Lo” until the

detector receives enough light from the reflector to

1. Insure that both of the optics lock-down screws are loos-

continue with the fine adjustment step.

ened so that the optics will move freely.

NOTE: In alignment mode (indicated by the yellow LED

2. Looking through the alignment mirror at both the alignment sight and reflector simultaneously locate the posi-

and the numeric display) the sensitivity select and

test switches are disabled.

tion of the reflector in the optical sight. This step will

require some practice. It is necessary to train your eyes

to shift focus between the reflector and the mirror in

order to locate the reflector. If the distance between the

reflector and the detector is large it is helpful to place a

N200-25-00 8 I56-2424-04R

3. With the display reading a numeric value, begin adjusting the horizontal and vertical alignment knobs one at

a time in the direction that increases the numeric signal

level on the display. Continue adjusting each axis one

Page 9

at a time going back and forth between them until a

peak value is indicated. If a value of 90 is achieved, the

detector will re-adjust the electronic gain once again.

This will be indicated by a “- -” reading on the display.

When this happens halt any further adjustment until the

display again reads a numeric value. This process may

occur more than once during the fine adjustment step.

NOTE: Each time the display reads a value of 90 or greater

the detector will reduce the electronic gain. Each

time the display reads a value of 10 or less the

detector will increase the electronic gain.

4. Once satisfied that it is not possible to achieve a higher

reading on the display depress the alignment switch to

complete the fine adjustment step. The digital display

readout will turn “OFF” and the yellow LED will remain

“ON”.

NOTE: It may not be possible to achieve a value near 90

on the display during the last adjustment iteration.

The final value of the display will not likely be

near 90. This is normal. It is due to the detector

reducing its electronic gain each time a value of 90

is achieved. When this occurs the detector resumes

with less electronic gain than previously when 90

was achieved. Less gain makes it more difficult

to achieve higher values. Final values anywhere

between 20 and 90 are acceptable if no further

increase can be achieved.

NOTE: The housing contains a gasket seal that protects

the detector circuitry from corrosion and moisture

sources. To insure that the gasket seal performs

correctly it is necessary to fully tighten all four of

the screws that hold the outer housing in place.

3. Remove the protective film from the front surface of the

outer housing.

4. To initiate the final electronic gain adjustment, the reset

switch must be depressed. Once depressed the yellow

LED will begin to blink. This indicates that the detector

is adjusting the electronic gain setting. Once complete,

the yellow LED will stop blinking and the green LED will

begin blinking. This indicates that the gain adjustment

was successful.

NOTE: Use caution not to block the line of sight between

the detector and reflector in this step.

5. Install the outer aesthetic ring by snapping it onto the

outer housing.

NOTE: If the outer aesthetic ring has been painted insure

that the paint is completely dry before proceeding

with this step.

Step 4. Final Verification

This step is required to insure the detector has been setup correctly and will detect smoke at the proper sensitivity level.

NOTE: The alignment procedure is not complete yet.

At this time it is possible to set the sensitivity of the detector using the sensitivity switch and digital display. See the

Sensitivity Selection section of this manual for further details.

Step 3. Final Gain Adjustment

Refer to Figure 13 for this step.

In this step, the detector will electronically adjust its internal gain one final time. It is necessary to complete this

step with the outer housing installed since the housing will

change the amount of light received from the reflector.

1. Tighten the optics lock down screws so the optics are

secure.

2. Install the outer housing of the detector. The housing is

installed by tightening four screws, one in each corner

of the housing. The screws are captivated in the plastic

of the housing and cannot fall out during assembly.

1. With the detector functioning (indicated by the green

LED blinking), completely block the reflector with an

opaque material. (Due to the high optical efficiency of

the reflector the selection of the opaque material used

to block the reflector is not critical. Acceptable materials include, but aren’t limited to, this manual or the

cardboard packaging inserts.) See Figure 14. The detector should enter the fault condition (indicated by the

fault relay and the yellow LED (see Appendix I). If the

detector does not enter the trouble condition there is a

problem with the installation refer to the troubleshooting section in Appendix I for further assistance.

2. Complete a sensitivity test of the detector. Refer to the

Sensitivity Testing section of this manual for the appropriate procedure.

3. If the orange sticky paper was used to aid in the loca-

tion of the reflector in the alignment mirror it should be

removed now. It is no longer necessary.

Congratulations. You have completed the final installation

and alignment procedure.

N200-25-00 9 I56-2424-04R

Page 10

Figure 10. Switch Locations

ALIGNMENT

SENSITIVITY

TEST

RESET

STYLE 7 ISOLATOR SHUNTS

(SHOWN DISABLED)

CODE SWITCH

TENS

ONES

ALIGNMENT MIRROR

ALIGNMENT GUNSIGHT

DIGITAL SIGNAL

STRENGTH

READOUT

HORIZONTAL

ADJUSTMENT

VERTICAL

ADJUSTMENT

OPTICS

LOCK-DOWN

SCREWS

ALIGNMENT

POSITION

INDICATOR

EYE

REFLECTOR

SCREW

LOCATIONS

SCREW

LOCATIONS

RESET

SWITCH

Figure 11. Alignment Adjustment Locations

Figure 12. Coarse Alignment Procedure

C0265-00

Figure 13. Housing Screw Locations

C0263-00

N200-25-00 10 I56-2424-04R

C0264-00

C0266-00

Short Circuit Isolation

The detector includes an on-board circuit isolator that

allows for NFPA72 style 7 operation. In cases where style 7

operation is not desired the isolator can be disabled using

the two shunts on the circuit board. See Figure 10 for jumper locations. When the jumpers are present the isolator is

disabled. This is the default state.

Sensitivity Selection

The detector has six sensitivity selections. Each of these

selections is only acceptable over a specific distance separation between the detector and the reflector per UL268.

The chart below is used to determine which selections are

Page 11

acceptable for your installed distance. The sensitivity of

2.0

1.5

1.0

0.5

0.0

0

25% Setting

30% Setting

40% Setting

50% Setting

50 100 150 200 250 300 350

Sensitivity in %/Ft. vs. Distance

(assumes uniform smoke distribution)

Distance in Feet

Obscuration (%/Ft.)

the detector can be set only when the housing is removed

and the detector is not in the fine adjustment step of the

alignment mode, indicated by the illumination of the dual

digital display. To set the sensitivity depress the sensitivity

button one time. See Figure 10. Once the switch is pressed

the digital display will illuminate and read the current

sensitivity setting in percent obscuration. To change the

sensitivity continue to depress the sensitivity switch until

the desired setting is achieved. The digital display will turn

off automatically if no further switch presses occur.

Sensitivity

Setting% Obscuration

Level 1 25 25 16.4 to 120 5.0 to 36.6

Level 2 30 30 25 to 150 7.6 to 45.7

Level 3 40 40 60 to 220 18.3 to 67

Level 4 50 50 80 to 328 24.4 to 100

Acclimate

Level 1

Acclimate

Level 2

30 to 50 A1 80 to 150 24.4 to 45.7

40 to 50 A2 80 to 220 24.4 to 67

Display

Reading

Acceptable

Distance

Between

Detector

and

Reflector

(Feet)

Acceptable

Distance

Between

Detector

and

Reflector

(meters)

Sensitivity Testing

NOTE: Before testing, notify the proper authorities that the

smoke detector system is undergoing maintenance,

and therefore the system will be temporarily out

of service. Disable the zone or system undergoing

maintenance to prevent unwanted alarms.

Detectors must be tested after installation and following

periodic maintenance. The sensitivity of the FSB-200/FSB200S may be tested as follows:

NOTE: Before testing the detector, check for the presence

of the flashing green LED at the receiver, making

sure not to disturb or block the beam. If it does not

flash and the detector is not in trouble or alarm,

power has been lost to the detector (check the wiring).

A. Calibrated Test Filter

The sensitivity of the detector can be tested using an

opaque material to cover the reflector by an amount indicated by the graduated scale on the reflector. (Due to the

high optical efficiency of the reflector the selection of the

opaque material used to block the reflector is not critical.

Acceptable materials include, but aren’t limited to, this

manual or the cardboard packaging inserts.)

In addition to the four standard sensitivity selections the

detector has two Acclimate settings. When either of these

settings is chosen the detector will automatically adjust its

sensitivity using advanced software algorithms to select the

optimum sensitivity for the environment. The sensitivity

will be continuously adjusted within the ranges specified

in the chart above.

Sensitivity

Total obscuration can be converted to percent per foot,

assuming uniform smoke density for the entire length of

the beam. The charts below converts total obscuration to

percent per foot for all acceptable sensitivity settings.

N200-25-00 11 I56-2424-04R

Refer to Figure 14 for this procedure.

1. Verify the sensitivity setting of the detector in % obscuration. See the Sensitivity Selection section of this manual

for sensitivity determination if sensitivity is unknown.

2. Place the blocking material over the reflector, lining it

up with the graduated marks that are 10 less than the

detector’s setting in % obscuration. The detector should

not alarm or fault. Keep the material in place for a minimum of 1 minute.

3. Place the blocking material over the reflector lining it

up with the graduated marks that are 10 more than the

detectors setting in % obscuration. The detector should

enter alarm within 1 minute.

C0268-00

Page 12

Figure 14. Reflector Test Card Procedure

LINE UP EDGE OF

TEST CARD WITH

APPROPRIATE

OBSCURATION LEVEL

MOVE TEST CARD

TO DESIRED AMOUNT

OF OBSCURATION

B. Test Switch

The detector can be tested using the local test switch on

the transmitter/receiver unit or remotely using the remote

test station.

The remote test station, RTS451 or RTS451KEY, can be used

with the FSB-200/FSB-200S beam smoke detector. Follow

instructions included with the test station for proper use.

See Figure 8 (Remote Test Station) for wiring diagram.

The FSB-200S is equipped with an integral sensitivity test

feature that consists of a calibrated test filter attached to

a servo motor inside the detector optics. When a test is

initiated using the remote test station or local test switch

the test filter is moved in the pathway of the light beam.

The on-board microprocessor then determines if the proper

level of signal reduction is received at the receiver. If the

proper level of signal reduction is received the detector will

enter alarm. If the proper level of signal reduction was not

achieved, indicating that the sensitivity of the detector is

out of tolerance, the detector will enter the trouble condition.

C0267-00

4. The detector can be reset with the reset switch on the

detector unit or remote reset.

5. Notify the proper authorities that the system is back on

line.

If the detector fails this test several steps should be taken

to determine if the detector is faulty or simply needs to be

re-adjusted before returning the unit. These steps include:

1. Verify all wiring connections and appropriate power is

applied to the detector.

2. Verify that the optical line of sight is free from obstructions and reflective objects.

3. Apply the maintenance procedure in this manual.

Repeat the test procedure. If the detector still fails the

test procedure proceed with step 4.

4. Repeat the alignment procedure in this manual. If the

alignment procedure is successful repeat the test procedure. If the detector still fails the test it should be

returned.

Always perform a complete reflector blockage test as in step

4 of the Installation/Alignment procedure to insure that the

pathway between the detector and reflector is clear.

NOTE: For the FSB-200 this test does not satisfy the

requirements of NFPA72 for periodic maintenance

and sensitivity verification of beam type detectors.

For the FSB-200S this test in conjunction with the

complete reflector blockage test (see step 4 of the

Installation/Alignment procedure in this manual)

does satisfy the requirements of NFPA72 for periodic maintenance and sensitivity verification of

beam type detectors.

If the detector fails this test several steps should be taken

to determine if the detector is faulty or simply needs to be

re-adjusted before returning the unit. These steps include:

1. Verify all wiring connections and appropriate power is

applied to the detector.

2. Verify that the optical line of sight is free from obstructions and reflective objects.

3. Apply the maintenance procedure in this manual.

Repeat the test procedure. If the detector still fails the

test procedure proceed with step 4.

NOTE: For the FSB-200S the external power supply must

be connected for the test switch to work.

N200-25-00 12 I56-2424-04R

4. Repeat the alignment procedure in this manual. If the

alignment procedure is successful repeat the test pro-

Page 13

cedure. If the detector still fails the test it should be

returned for repair.

NOTE: For the FSB-200S, the external power supply must

be connected for the test switch to work.

Maintenance

NOTE: Before cleaning the detector, notify the proper

authorities that the smoke detector system is undergoing

maintenance, and therefore the system will be temporarily out of service. Disable the zone or system undergoing

maintenance to prevent unwanted alarms.

1. Carefully clean the outer housing lens face. A damp soft

cloth with a mild soap may be used. Avoid products with

solvents or ammonia.

2. Carefully clean the reflector. A damp soft cloth with a

mild soap may be used. Avoid products with solvents or

ammonia.

3. Notify the proper authorities that the system is back on

line.

Painting

The outer aesthetic ring may be painted using a spray or

brush type paint of appropriate type. See specification section of this manual for paint types.

NOTE: Never paint the flat lens surface of the outer

housing.

Special Note Regarding Smoke Detector Guards

Smoke detectors are not to be used with detector guards

unless the combination has been evaluated and found suitable for that purpose.

N200-25-00 13 I56-2424-04R

Page 14

Appendix I. Operation Modes and Troubleshooting Guide

• Sunlight into detector or reflector.

• Re-Align detector.

initialization or detector reset

Alignment Switch

Test Stations

Out of Range

• Clean detector and reflector.

Out of Range

reflector for reflective objects in the pathway.

• Faulty unit.

• Faulty unit.

discharged state.

Remains in fault until reset or time-out

after alignment

Blinks output by Yellow

LED and Remote Trouble

Output once the device

has passed a local

remote test:

Percent the

detector has

drifted

Remains in fault until reset or time-out

<100% 9

input

input

Number

of blinks

output

<10% None

<20% 1

<30% 2

<40% 3

<50% 4

<60% 5

<70% 6

<80% 7

<90% 8

Dual Digital Display Initiating means Comments & Troubleshooting Tips

Output

Remote Alarm

*Green

See Note Below

Trouble Output

Yellow and Remote

Below

See Note

0-99, or – if automatic gain

resetting, or Lo if signal is

too low

Off 3 Quick Blinks Blink Blink Off Long Term Drift Reference

Off 2 Quick Blinks Blink Blink Off Long Term Drift Reference

Off On Off Panel or RTS451/KEY Remains in alarm until reset or time-out

drift used

Off 2 Quick Blinks Blink Blink Off Increase of Reflected Signal • Inspect line of sight between detector and

Off 4 Quick Blinks Blink Blink Off Beam Blockage • Remove blockage.

On 4 Quick Blinks Blink On Off Beam Blockage • Remove blockage.

Off Blink until complete Blink Blink Off Apply Power from

Off Blink until complete Blink Blink Off Depressing RESET switch

On Blinks out amount of

Blink Blink Off Panel or RTS451/KEY test

Blink Blink Off Panel or RTS451/KEY test

time-out

time-out

Off On until reset or

Off On until reset or

Off On Off Panel or RTS451/KEY Remains in alarm until reset or time-out

drift used

On Blinks out amount of

Modes *Red

Normal Off Off Blink Blink Off Successful completion of

Alignment Off On Blink Blink On, Relative amount of signal

Alarm On Off Off On Off Smoke, Test Filter, RTS451

Trouble-Drift Comp

Elevated Signal

Trouble-Drift Comp

Reduced Signal

N200-25-00 14 I56-2424-04R

Trouble-Signal

Over Range

Trouble-Beam

Blockage Initial

Response

Trouble-Beam

Blockage Long

Term Response

Initialization-

Power on

Initialization-

alignment exit

Local Test

(FSB-200S)

Pass Result

Local Test

(FSB-200S)

Fail Result

Local Test

(FSB-200)

Fail

Local Test

(FSB-200)

Pass Result

Note: Green and Red LEDs are controlled by the control panel.

Page 15

Appendix II. Detector Drilling Template

4.345″

6.190″

Scale = 1:1

N200-25-00 15 I56-2424-04R

Page 16

N200-25-00 16 I56-2424-04R

Page 17

5.512″

(140mm)

8.465″

(215mm)

Appendix III. Reflector Drilling Template

Scale = 1:1

N200-25-00 17 I56-2424-04R

Page 18

Please refer to insert for the Limitations of Fire Alarm Systems

This projected beam smoke detector has been tested and found to comply

with the limits for a Class B digital device, pursuant to part 15 of the FCC

Rules. These limits are designed to provide reasonable protection against

harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio

N200-25-00 18 I56-2424-04R

FCC Statement

frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a residential area is likely to cause

harmful interference in which case the user will be required to correct the

interference at his own expense.

©2004 System Sensor

Loading...

Loading...