Page 1

FAAST Fire Alarm Aspiration

Sensing Technology® Modbus

USER GUIDE

Page 2

User Guide: FAAST Fire Alarm Aspiration Sensing Technology® Modbus Protocol Schema 1

Table of Contents

Product Description .........................................................................................................................3

Communication Interface ................................................................................................................4

Client Interface .................................................................................................................................. 4

Accessible Registers .........................................................................................................................................................................4

Data Format ........................................................................................................................................................................................4

Device Sensor Status and Control Operations .............................................................................. 5

Device Read ........................................................................................................................................................................................5

Device Output and Operating Mode Control ...................................................................................................................................5

Device Conguration .........................................................................................................................................................................5

Device Time ........................................................................................................................................................................................6

Device Smoke Reference ..................................................................................................................................................................6

Modbus Administrator Password .....................................................................................................................................................6

Reading Logs .....................................................................................................................................................................................7

Event Log Read ..................................................................................................................................................................................7

Trend Log Read ..................................................................................................................................................................................7

Message Log Read ............................................................................................................................................................................7

Modbus Conguration .....................................................................................................................8

Input Registers..................................................................................................................................8

Holding Registers .............................................................................................................................9

Device Status .....................................................................................................................................................................................9

Sensor Status ................................................................................................................................................................................... 11

Device Logs ......................................................................................................................................................................................13

Factory Conguration ......................................................................................................................................................................14

Device Conguration .......................................................................................................................................................................15

Network Conguration ....................................................................................................................................................................17

Appendix A. Congurable options on FAAST .............................................................................. 18

A.1. Alarm Conguration Variables .................................................................................................................................................18

A.2. Device Conguration Variables ...............................................................................................................................................19

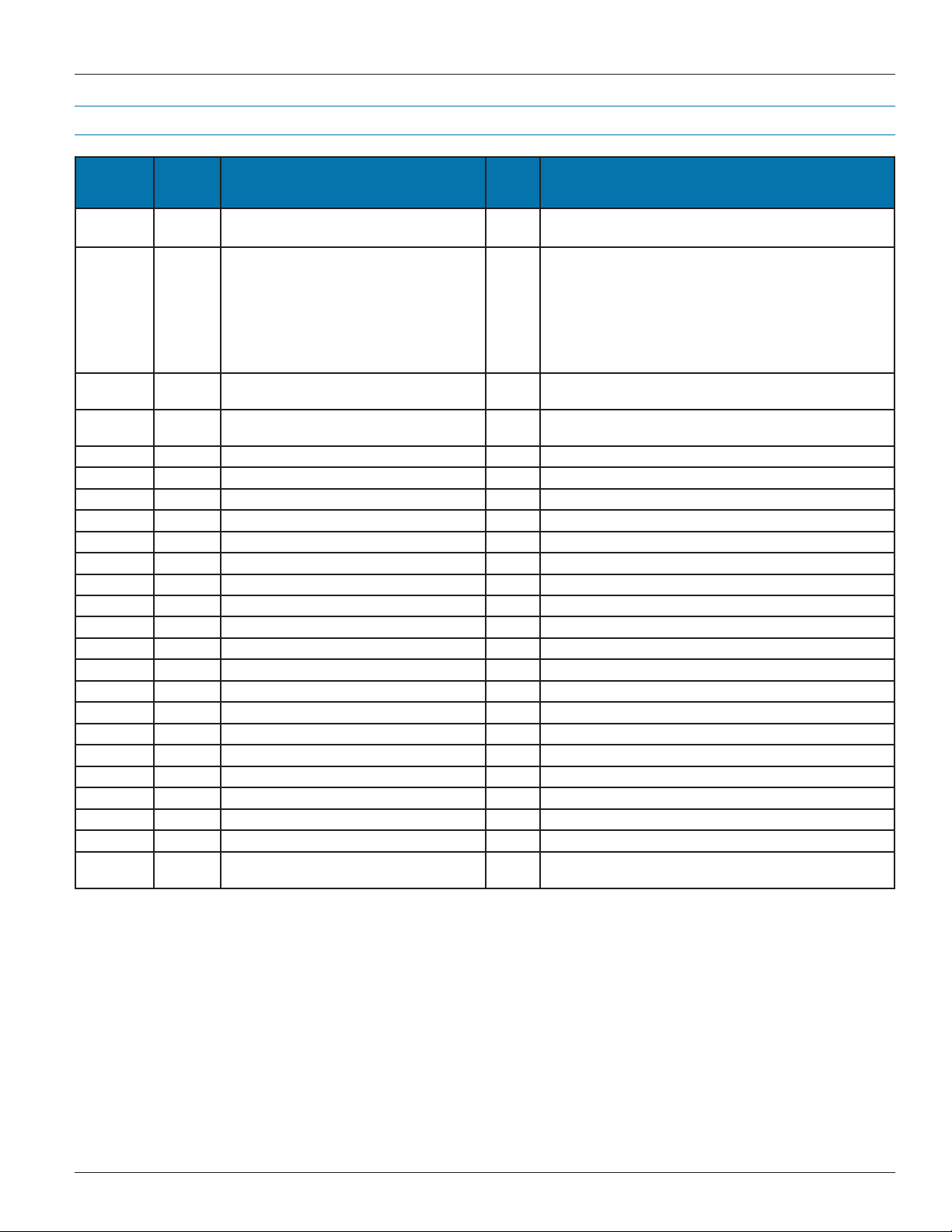

Revision Table

Revision Description of Change Author Date

A0 Initial Release for Review ZK 05/06/2013

22

Page 3

User Guide: FAAST Fire Alarm Aspiration Sensing Technology® Modbus Protocol Schema 1

Product Description

The FAAST - Fire Alarm Aspiration Sensing Technology® aspirating smoke detector is an advanced particulate detection system

designed for use in early warning and very early warning fire detection applications. FAAST draws air from the environment through

sampling holes in a pipe network and monitors for smoke particulates. FAAST includes a local display which provides a clear

indication of the devices status. Smoke particulate level, alarm level, air flow, and faults can all be discerned with a glance at the

user interface.

FAAST is also enabled by built-in Modbus communications capabilities. The Modbus Protocol utilizes the TCP server. They physical

connection is Ethernet.

Modbus is a communications protocol allowing for connectivity with several building management solutions. Using Modbus, a

FAAST device can be monitored remotely and various device configuration actions and device interactions are facilitated.

PLEASE NOTE: WHILE Modbus CAN BE USED TO SET DEVICE CONFIGURATIONS, THE DESIGN OF ANY NEW FAAST

DEVICE MUST BE VERIFIED USING PipeIQ® TO ENSURE THAT SITE SPECIFIC REQUIREMENTS ARE MET. IF Modbus IS USED

TO MODIFY AN INSTALLED UNIT, ANY CHANGES TO SENSITIVITY SETTING SHOULD ALSO BE VERIFIED IN PipeIQ® TO

ENSURE CONTINUED SYSTEM PERFORMANCE.

3

Rev A0

Page 4

User Guide: FAAST Fire Alarm Aspiration Sensing Technology® Modbus Protocol Schema 1

Communication Interface

Modbus protocol stack is an application that runs over TCP. The device requires a 10 or 100Mbps Ethernet connection to an existing

IP network and a valid network configuration in order to enable Modbus Communications. The FAAST device’s TCP server will listen

for Modbus protocol packets on Port 502.

Separate TCP ports allow Modbus, e-mail, PipeIQ and web communications simultaneously. Finally, to transmit and receive data over

Modbus, the user requires a client that can generate Modbus packets over TCP.

Client Interface

When a client is connected through Port 502, the FAAST device will act as a Modbus/TCP “server”. This section defines the format of

data in Modbus/TCP registers. More information about Modbus/TCP can be obtained from www.Modbus.org.

The entire Modbus map is related to a single device, and the Slave ID parameter is unused by the FAAST device.

Accessible Registers

Input registers for registers listed in Table 1.

Holding registers in Tables 2 to 8.

Data Format

To properly transfer data to and from the Modbus registers, the following descriptions specify how data is organized when more than

one register is required to read or write a specific piece of data.

1. Long Integer, floating point:

Value = 0xaabbccdd

Holding Reg1 = 0xaabb

Holding Reg2 = 0xccdd

2. String:

Value = “test”

Holding Reg1 = “et”

Holding Reg2 = “ts”

3. IP Address:

Value = a.b.c.d

Holding Reg1 = dc

Holding Reg2 = ba

4. MAC Address:

Value = 0x (aa-bb-cc-dd-ee-ff)

Holding Reg1 = 0xbbaa

Holding Reg2 = 0xddcc

Holding Reg3 = 0xffee

4

Page 5

User Guide: FAAST Fire Alarm Aspiration Sensing Technology® Modbus Protocol Schema 1

Device Sensor Status and Control Operations

Device Read

The Modbus client is able to read the device status data directly via input and holding register reads.

Device Output and Operating Mode Control

The Modbus client is able to initiate different operating modes through the Sensor Input Holding Register.

1. Write the Administrator Password in the Administrator Password holding register (this is the same as the Button

Activation Passcode configured through PipeIQ).

2. Read the Sensor API status holding register and verify that the ADMIN_UNLOCK bit is set.

3. Write the value to the Sensor Input Holding Register (40035) that initiates the desired action or mode change:

a. 0x0001 to Isolate

b. 0x0002 to Disable

c. 0x0004 to initiate Test Mode

d. 0x0008 to Silence a Fault or Alarm (when equipped with an audible indicator)

e. 0x0010 to Reset the Device

f. 0x0020 to Reset the Airflow Baseline

g. 0x0040 to Clear the Event Log

h. 0x0080 to Clear the Trend Log

i. 0x0100 to Clear the Message Log

4. Write 0x0 to the Administrator Password in the Administrator Password holding register if no further changes

are desired.

Device Conguration

In order to write a new configuration, the following steps must be followed:

1. Write the Administrator Password in the Administrator Password holding register (this is the same as the Button

Activation Passcode configured through PipeIQ).

2. Read the Sensor API status holding register and verify that the ADMIN_UNLOCK bit is set. If it is set, the Sensor API

Command Register is enabled and will process commands issued.

3. The device must be placed in Disable Mode by setting disable bit in Sensor Input Holding register Holding register.

4. Read the Operating Mode holding register.

5. The Modbus client writes the new values for the respective configuration holding registers through Write Multiple

Register Command(s).

6. Write the Save Configuration Command value, 0xAA11 in the Modbus Specific configuration Command holding register

in order to save any configuration changes.

7. The device stores new configuration.

8. Read the Modbus Specific configuration Command holding register. The value will be 0x0000 when the Command

completes successfully.

9. Remove the device from Disable Mode by clearing the disable bit Sensor Input Holding register.

10. The device will reset and the new configuration will be applied.

5

Rev A0

Page 6

User Guide: FAAST Fire Alarm Aspiration Sensing Technology® Modbus Protocol Schema 1

Device Sensor Status and Control Operations (Cont’d)

Device Time

In order to set the time, the following steps must be followed:

1. Write the Administrator Password in the Administrator Password holding register.

2. Read the Sensor API status holding register and verify that the ADMIN_UNLOCK bit is set. If it is set, the Sensor API

Command Register is enabled and will process commands issued.

3. The Modbus client writes the new time value using Epoch/UNIX timestamp formate to the time holding registers through

Write Multiple Register Command(s).

4. Write the Save Time Command value, 0xEE22 in the Modbus Specific configuration Command holding register in order

to save the new time.

5. The device stores and applies the new device time.

6. Read the Modbus Specific configuration Command holding register. The value will be 0x0000 when the Command

completes successfully.

7. Write 0x0 to the Administrator Password in the Administrator Password holding register if no further changes are

desired.

Device Smoke Reference

The device may be programmed with a reference in order to compensate for a period of high particulate due to a change in ambient

environmental conditions. Use the following steps to modify the Device Reference:

1. Write the Administrator Password in the Administrator Password holding register.

2. Read the Sensor API status holding register and verify that the ADMIN_UNLOCK bit is set. If it is set, the Sensor API

Command Register is enabled and will process commands issued.

3. The Modbus client writes the new Reference Value in 32-bit Float format to the Smoke Reference Value register through

Write Multiple Register Command.

4. The device applies the new Reference.

5. Read the Sensor Smoke Reference Value to verify it stored correctly.

6. Write 0x0 to the Administrator Password in the Administrator Password holding register if no further changes are

desired.

Modbus Administrator Password

The Modbus Administrator Password grants the user the privilege of writing to the Holding Registers. This password is the same as

the User Interface Button Lockout Code. It is not readable through the Modbus Interface. It is set to ‘1111’ as the default. The values

may range from 1111 to 9999. The user may change the password by performing a Device Configuration Change as described

earlier.

A failure to gain administrator privileges due to a forgotten or lost password is a recoverable event by using the PipeIQ software,

connecting to the device and updating the device configuration with a known password.

6

Page 7

User Guide: FAAST Fire Alarm Aspiration Sensing Technology® Modbus Protocol Schema 1

Reading Logs

In order to read the device logs, the following steps must be followed.

Event Log Read

1. Write the Administrator Password in the Administrator Password holding register.

2. Read the Sensor API status holding register and verify that the ADMIN_UNLOCK bit is set.

3. Write the Event log index value into corresponding holding register using Write Single Holding Register Command

(0x06). The default shall be 1 which reads the latest 40 events.

4. Read Event Logs.

Examples:

a. Total no. of events = 50, Index = 2, then the Event log read command will read last 10 events.

b. Total no. of events = 80, Index = 2, then the Event log read command will read last 40 events.

c. Total no. of events <= 80, Index = 3, then the client shall show Device read failure because there are no events present

in the memory corresponding to given Index value.

Trend Log Read

1. Write the Administrator Password in the Administrator Password holding register.

2. Read the Sensor API status holding register and verify that the ADMIN_UNLOCK bit is set.

3. Write the Trend log index value into corresponding holding register using Write Single Holding Register Command

(0x06). The default shall be 1 which reads the latest one trend log.

4. Read the Trend Log.

Examples:

a. Total no. of trends = 50, Index = 2, then the Trend log read command will read recent but one trend log.

b. Total no. of trends = 80, Index = 80, then the Trend log read command will read last trend log.

c. Total no. of trends = 30, Index >30, then the client shall show Device read failure because there are no trends present

in the memory corresponding to given Index value.

Message Log Read

1. Write the Administrator Password in the Administrator Password holding register.

2. Read the Sensor API status holding register and verify that the ADMIN_UNLOCK bit is set.

3. Write the Message log index value into corresponding holding register using Write Single Holding Register Command

(0x06). The default shall be 1 which reads the latest one message log.

4. Read the Message Log.

Examples:

a. Total no. of messages = 50, Index = 2, then the Message log read command will read recent but one message log.

b. Total no. of messages = 20, Index = 20, then the Message log read command will read last message log.

c. Total no. of messages = 30, Index >30, then the client shall show Device read failure because there are no messages

present in the memory corresponding to given Index value.

7

Rev A0

Page 8

User Guide: FAAST Fire Alarm Aspiration Sensing Technology® Modbus Protocol Schema 1

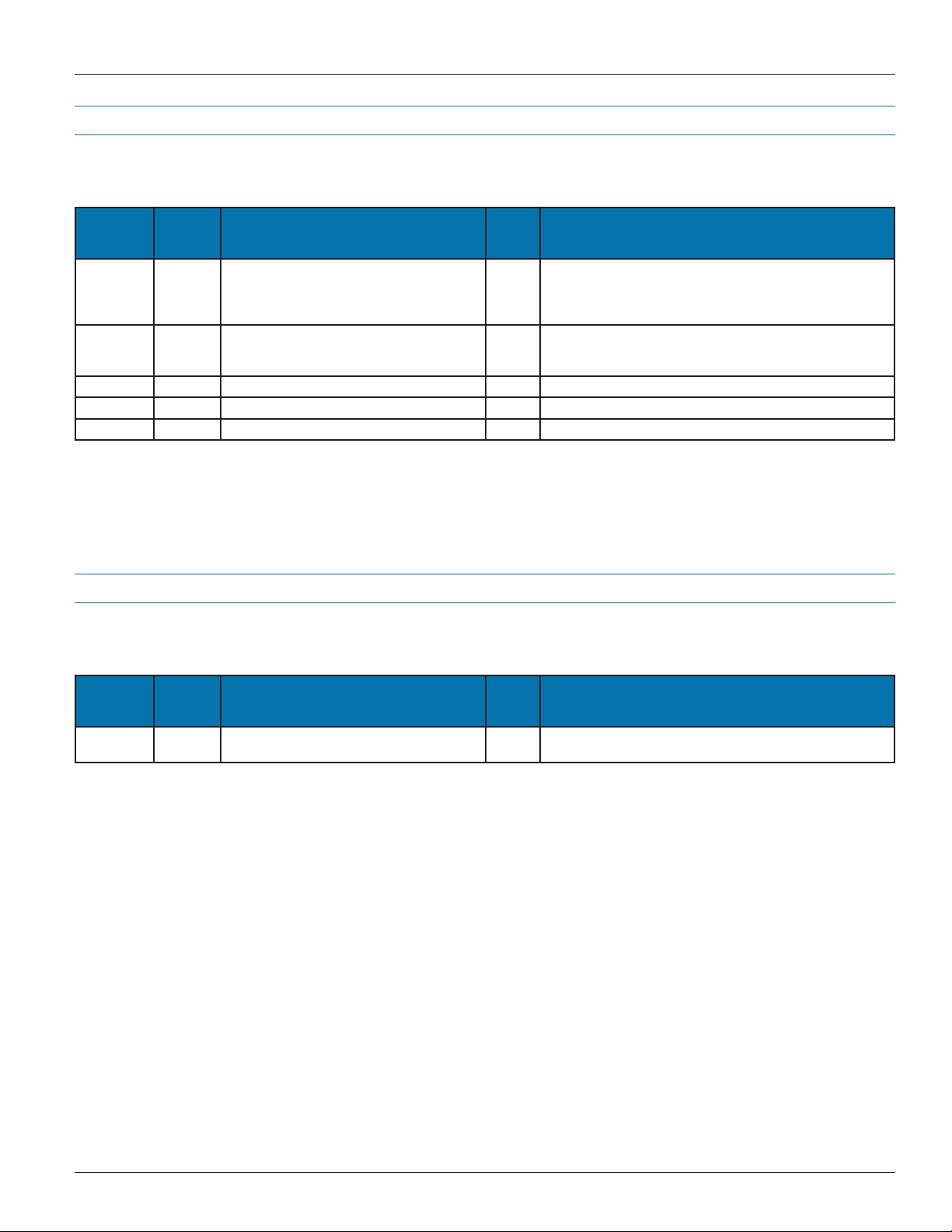

Modbus Conguration

The device’s Modbus Configuration Structure is READ/WRITE and mapped directly to a set of holding registers. The structure in the

Firmware is defined as follows:

Address Size

(16-bit

words)

40326 1 ∆ Administrator Password U16 Password to enable Commands through the Command

327 1 ∆ Sensor Command Register U16 Command Register:

328 1 ∆ Event Log Index U16 Starting Index of Event Log Entry which to read

329 1 ∆ Trend Log Index U16 Starting Index of Trend Log to read

330 1 ∆ Message Log Index U16 Starting Index of Message Log to read

Parameter Name Type Description

holding register.

Enter as an Unsigned Decimal number.

0xAA11 – Save Configuration

0xEE22 – Save Time

Table 1. Modbus Specific configuration Holding Registers

∆ Information - Registers 326-330 can be configured by using Function code 6(single write) or Function 16 (multiple write).

Input Registers

The Modbus Holding Register addresses are indexed for a Honeywell Building Solutions Enterprise Building IntegratorTM client. Other

clients may need to subtract 1 from each address in order to access the desired register.

Address Size

(16-bit

words)

30001 1 Schema U16 Modbus Firmware Schema for client to determine version of

Parameter Name Type Description

register mapping.

Table 2. Modbus Input Registers

8

Page 9

User Guide: FAAST Fire Alarm Aspiration Sensing Technology® Modbus Protocol Schema 1

Holding Registers

Note: The Modbus Holding Register addresses are indexed for a Honeywell Building Solutions Enterprise Building IntegratorTM client.

Other clients may need to subtract 1 from each address in order to access the desired register.

Device Status

The device’s Device Status Structure is READ ONLY and mapped directly to a set of holding registers. The structure in the Firmware

is defined as follows:

Address Size

(16-bit

words)

40001-2 2 Universal Time Stamp U32 Read Only - Universal Time Stamp corresponding to the

3 1 Startup Flags U16 Startup flags

4 1 System Faults U16 System Faults.

5 1 Minor Faults U16 Minor Faults.

6 1 Urgent Faults U16 Urgent Faults.

7 1 Operating Mode U16 Device Operating Mode Enumeration:

Parameter Name Type Description

real-time clock value in UNIX seconds epoch format

For internal use only.

Bit 0: Low Voltage

Bit 1: Low Flow

Bit 2: Configuration

Bit 3: Sensor

Bit 4: External Monitor

Bit 5: Time

Bit 6: Communication

Bit 7: Aspirator

Bit 8: Filter

Bit 9: Isolation

Bit 10: High Flow

Bits 11-15 unused

Bit 0: Low Flow

Bit 1: Configuration

Bit 2: External Monitor Open

Bit 3: External Monitor Short

Bit 4: Time

Bit 5: Filter

Bit 6: High Flow

Bits 7-15 unused

Bit 0: Low Flow

Bit 1: Configuration

Bit 2: Communication

Bit 3: Sensor

Bit 4: Aspirator

Bit 5: Filter

Bit 6: High Flow

Bit 7: Low Voltage

Bits 8-15 unused

CONFIGURATION_MODE 0,

INITIALIZATION_MODE 1,

TEST_MODE 2,

NORMAL_MODE 3,

DISABLE_MODE 4,

RESET_MODE 5,

FACTORY_MODE 6,

SERVICE_MODE 7,

ISOLATE_NEW_MODE 8,

RESET_NETWORK_MODE 9

9

Rev A0

Page 10

User Guide: FAAST Fire Alarm Aspiration Sensing Technology® Modbus Protocol Schema 1

Holding Registers (Cont’d)

Device Status

Address Size

(16-bit

words)

8 ½ Relay Status U8 Relay Status.

9 1 Internal Error Flags – HW Comm U16 Internal Comm Error.

10 1 Internal Error Flags – HW U16 Internal HW Error.

11 1 Internal Error Flags – SW U16 Internal SW Error.

12 1 Fan Speed in RPMs U16 Speed of fan in RPMs

13 ½ Alarm Level U8 Alarm Status.

14 1 Lifetime Count in Days U16 Days of operation during lifetime

15 ½ Filter Cover State U8 Filter Cover State.

16 1 Factory Configuration Status U16 Factory Configuration State.

17 1 Device Configuration Status U16 Device Configuration State.

18 1 Network Configuration Status U16 Network Configuration State.

19-30 12 Password Recovery Code U16 Code for recovering the device PipeIQ password.

Parameter Name Type Description

Bit 0: Alert

Bit 1: Action1

Bit 2: Action2

Bit 3: Fire1

Bit 4: Fire2

Bit 5: Minor (if equipped)

Bit 6: Urgent/Fault

Bit7: Isolate (if equipped)

Bits 8-15 unused

For internal use only.

For internal use only.

For internal use only.

Bit 0: Alert

Bit 1: Action1

Bit 2: Action2

Bit 3: Fire1

Bit 4: Fire2

Bits 5-15 unused.

Not zero = open

0 = closed

CONFIG_STATE_PRIMARY 0,

CONFIG_STATE_BACKUP 1,

CONFIG_STATE_UNCONFIGURED 2

See Factory Configuration State.

See Factory Configuration State.

Uses the format to store a string.

Table 3. Device Status Modbus Holding Registers

10

Page 11

User Guide: FAAST Fire Alarm Aspiration Sensing Technology® Modbus Protocol Schema 1

Sensor Status

The device’s Sensor Status Structure is READ ONLY with the exception of the Smoke Reference Value and mapped directly to a set

of holding registers. The structure in the Firmware is defined as follows:

Address Size

(16-bit

words)

40031-32 2 System Time U32 Device Time in UNIX seconds epoch format, use Universal

33-34 2 ∆ Smoke Reference Value F32 Smoke reference value used to increase noise floor of

35 1 ∆ Sensor Action Inputs U16 All bits are self-clearing and will read ‘0’ after bit has been

36 ½ Ch 1 Air Temperature S8 Real-time sampled air temperature in Channel 1

37 ½ Ch 1 Air Velocity Change S8 Percentage change from baseline air velocity in Channel 1

38-39 2 Ch 1 Air Velocity Baseline F32 Average velocity during baselining in Channel 1

40-41 2 Ch 1 Air Velocity Daily Min F32 Daily minimum air velocity realized on Channel 1

42-43 2 Ch 1 Air Velocity Daily Max F32 Daily maximum air velocity realized on Channel 1

44 ½ Ch 2 Air Temperature S8 Real-time sampled air temperature in Channel 2

45 ½ Ch 2 Air Velocity Change S8 Percentage change from baseline air velocity in Channel 2

46-47 2 Ch 2 Air Velocity Baseline F32 Average velocity during baselining in Channel 2

48-49 2 Ch 2 Air Velocity Daily Min F32 Daily minimum air velocity realized on Channel 2

50-51 2 Ch 2 Air Velocity Daily Max F32 Daily maximum air velocity realized on Channel 2

Parameter Name Type Description

Time Stamp instead.

detector.

US Standard Units Max: 0.10 (%/ft)

Metric Units Max: 0.328 (%/m)

read and processed

Bit 0: 1 Isolate – Toggles Isolate Mode

Bit1: 1 Disable – Toggles Disable Mode

Bit2: 1 Test – Place the device in Test Mode

Bit3: 1 Silence Sounder (if enabled / equipped)

Note: Sounder Silence is effective for a single alarm or fault

occurrence. If an alarm recurs, another alarm is initiated or

another fault occurs, the sounder will re-energize.

Bit4: Reset Device

Bit5: Reset Airflow Baselines

Current baseline cleared, and device will set a new

baseline. New baseline established within 15 minutes.

Bit6: Clear Event Log Note: Allow this action up to 10

seconds to complete. Erases all Event Log entries

Bit7: Clear Trend Log Note: Allow this action up to 5

seconds to complete. Erases all Trend Log entries

Bit8: Clear Message Log Note: Allow this action up to 5

seconds to complete. Erases all Message Log entries

Bit9-15: Unused

(multichannel device only)

(multichannel device only)

(multichannel device only)

(multichannel device only)

(multichannel device only)

11

Rev A0

Page 12

User Guide: FAAST Fire Alarm Aspiration Sensing Technology® Modbus Protocol Schema 1

Sensor Status (Cont’d)

Address Size

(16-bit

words)

52 ½ Ch 3 Air Temperature S8 Real-time sampled air temperature in Channel 3

53 ½ Ch 3 Air Velocity Change S8 Percentage change from baseline air velocity in Channel 3

54-55 2 Ch 3 Air Velocity Baseline F32 Average velocity during baselining in Channel 3

56-57 2 Ch 3 Air Velocity Daily Min F32 Daily minimum air velocity realized on Channel 3

58-59 2 Ch 3 Air Velocity Daily Max F32 Daily maximum air velocity realized on Channel 3

60 ½ Ch 4 Air Temperature S8 Real-time sampled air temperature in Channel 4

61 ½ Ch 4 Air Velocity Change S8 Percentage change from baseline air velocity in Channel 4

62-63 2 Ch 4 Air Velocity Baseline F32 Average velocity during baselining in Channel 4

64-65 2 Ch 4 Air Velocity Daily Min F32 Daily minimum air velocity realized on Channel 4

66-67 2 Ch 4 Air Velocity Daily Max F32 Daily maximum air velocity realized on Channel 4

68 ½ Smoke Particulate Display U8 Front panel particulate level (0-10)

69-70 2 Smoke Current Obs F32 Current Obscuration Level the Smoke Sensor is Detecting

71-72 2 Smoke Daily Max Obs F32 Maximum Obscuration Level the Smoke Sensor Detected

73-74 2 Smoke Daily Min Obs F32 Minimum Obscuration Level the Smoke Sensor Detected

75-76 2 Alert Threshold F32 Current Active Alert Threshold ( %/ft if US Standard or %/m

77-78 2 Action1 Threshold F32 Current Active Action1 Threshold ( %/ft if US Standard or

79-80 2 Action2 Threshold F32 Current Active Action2 Threshold ( %/ft if US Standard or

81-82 2 Fire1 Threshold F32 Current Active Fire1 Threshold ( %/ft if US Standard or %/m

83-84 2 Fire2 Threshold F32 Current Active Fire2 Threshold ( %/ft if US Standard or %/m

85 1 Sensor Status U16 Bit 0 – Admin Unlock

Parameter Name Type Description

(multichannel device only)

(multichannel device only)

(multichannel device only)

(multichannel device only)

(multichannel device only)

(multichannel device only)

(multichannel device only)

(multichannel device only)

(multichannel device only)

(multichannel device only)

since 12am

since 12am

if metric)

%/m if metric)

%/m if metric)

if metric)

if metric)

1 = Unlocked, 0 = Locked

Bit 1 –Baselining

1 = set (configured from sensor action inputs)

Table 4. Sensor Status Modbus Holding Registers

∆ Information - Registers 35 can be configured by using Function code 6(single write) or Function 16 (multiple write).

∆ Warning!! Device threshold configuration variables should be set by the user to values scaled based on the Units configuration

setting. The detector will interpret the value differently for different Units settings. E.g. The device will interpret a 0.01 threshold

setting as 0.01 %/ft when Units setting is US Standard. The device will interpret a 0.01 threshold setting as 0.01 %/m when Units

setting is Metric.

12

Page 13

User Guide: FAAST Fire Alarm Aspiration Sensing Technology® Modbus Protocol Schema 1

Device Logs

The device’s Log Structure is READ ONLY and mapped directly to a set of holding registers. The structure in the Firmware is defined

as follows:

Address Size

(16-bit

words)

40086 1 Event Log Entries U16 Number of Event Log Entries

87 1 Trend Log Entries U16 Number of Trend Log Entries

88 1 Message Log Entries U16 Number of Message Log Entries

89-208 3 x 40 Read Event Log U32

209-232 24 Read Trend Log U32

233-298 66 Message Log U32

Parameter Name Type Description

U16

F32 [11]

U16 [64]

Reads 40 log entries starting with the entry in the Index register.

Each entry contains a 32-bit Epoch time stamp and 16-bit Event number

The events numbers represent the following events:

Test 0

Normal 1

Isolate 2

POR 3

Reset 4

UI Passcode Entry Failure 5

UI Passcode Entry Success 6

UI Button Autolock 7

Filter Cover Open 8

Filter Cover Closed 9

Configuration Change Success 10

User Login 11

User Logout 12

Flow Fault High 13

Flow Fault Low 14

Configuration Fault 15

Configuration Fault Urgent 16

Sensor Fault 17

External Device Fault 18

External Device Fault Clear 19

Communication Fault 20

Aspiration Fault 21

Aspiration Fault Urgent 22

Filter Fault 23

Filter Fault Urgent 24

Time Fault 25

Low Voltage Fault 26

Low Voltage Fault Clear 27

Alarm Alert 28

Alarm Action1 29

Alarm Action2 30

Alarm Fire1 31

Alarm Fire2 32

Operating Mode Disable 33

Reads log entry specified by the Index register.

Each entry contains a 32-bit time stamp and daily air velocity and smoke

detection logs including:

Float : Daily Alert Threshold

Float : Daily Action1 Threshold

Float : Daily Action2 Threshold

Float : Daily Fire1 Threshold

Float : Daily Fire2 Threshold

Float : Trend Max

Float : Trend Min

Float : Trend Avg

Float : Air Velocity Max

Float : Air Velocity Min

Float : Air Velocity Avg

Reads the log entry specified by the Index register.

Each entry contains a 32-bit time stamp and a UTF-16 64 character string.

Table 5. Device Log Modbus Holding Registers

13

Rev A0

Page 14

User Guide: FAAST Fire Alarm Aspiration Sensing Technology® Modbus Protocol Schema 1

Factory Conguration

Address Size

(16-bit

words)

40299 ½ SLC Interface Present bool Designates the presence of an SLC interface

300 1 SLC_PROTOCOL_TYPE U16 Defines the supported SLC protocol.

301 1 OEMID_TYPE U16 Defines Device OEM.

302-304 3 MAC Addr U8[6] Device’s MAC Address

305 ½ Sensor Type U8 Smoke 1

306 ½ Firmware Main Board Rev U8 Main Board Microcontroller Firmware Image Revision

307 ½ Firmware Photo 1 Rev U8 Chamber Microcontroller Firmware Image Revision

308 ½ Firmware Photo 2 Rev U8 Not used, set to zero

309 ½ Hardware Main Board Rev U8 Revision of Main Board Hardware

310 ½ Hardware Photo1 Rev U8 Revision of Photodetector Hardware

311 ½ Hardware Photo 2 Rev U8 Not used, set to zero

312 ½ Hardware Blue Rev U8 Revision of Blue LED Driver Hardware

313 ½ Hardware Laser Rev U8 Revision of Laser Driver Hardware

314 ½ Hardware UI Rev U8 Revision of User Interface Hardware

315 ½ Hardware Ultrasonics Rev U8 Revision of Ultrasonics Board Hardware

316 ½ Hardware SLC Rev U8 Revision of SLC Interface Hardware

317 ½ Photo Cal1 U8 For internal use only.

318 ½ Photo Cal2 U8 For internal use only.

319 ½ Photo Cal3 U8 For internal use only.

320 1 Blue Cal U16 For internal use only.

321 1 IR Cal U16 For internal use only.

322 ½ Airflow Boundary U8 For internal use only.

323 ½ Airflow Timer U8 For internal use only.

324-325 2 Mfg Time Stamp U32 Manufacturing Time Stamp – UNIX seconds since epoch

Parameter Name Type Description

(ie Eclipse, Flashscan, etc)

CONVENTIONAL 0

CLIP 1

FLASHSCAN 2

ECLIPSE 3

ADVANCED 4

PROTOCOL_OTHER 5

For internal use only.

Stored in the format described for MAC address storage.

format

Table 6. Factory Configuration Modbus Holding Registers

14

Page 15

User Guide: FAAST Fire Alarm Aspiration Sensing Technology® Modbus Protocol Schema 1

Device Conguration

Address Size

(16-bit

words)

40331 1 Device Config Counter U16 Configuration Counter

332-333 2 Config Timestamp U32 Time of last configuration

334 1 Units U16 Units of Measure for Alarm Threshold Obscuration Values

335 ½ Relays Latching U8 Set latching behavior of minor fault and alarms.

336 ½ Alert Delay U8 Alert Alarm Delay in Seconds

337 ½ Action1 Delay U8 Action1 Alarm Delay in Seconds

338 ½ Action2 Delay U8 Action2 Alarm Delay in Seconds

339 ½ Fire1 Delay U8 Fire1 Alarm Delay in Seconds

340 ½ Fire2 Delay U8 Fire2 Alarm Delay in Seconds

341 ½ Acclimate Enable U8 Enable Acclimate Mode (use Acclimate Alarm Thresholds)

Parameter Name Type Description

Metric 0

US Standard 1

Non-latching 0

Latching 1

Bit 0: Alert

Bit1: Action1

Bit2: Action2

Bit3: Fire1

Bit4: Fire2

Bit5: Minor

Disable 0

Enable Not Zero

342-343 2 Day Time Start U32 Epoch Local Time Stamp to mark the time in which to use

344-345 2 Night Time Start U32 Epoch Local Time Stamp to mark the time in which to use

346-347 2 ∆ Alert Day Threshold F32 Alert Alarm Day Obscuration Threshold

348-349 2 ∆ Alert Night Threshold F32 Alert Alarm Night Obscuration Threshold

350-351 2 ∆ Alert Weekend Threshold F32 Alert Alarm Weekend Obscuration Threshold

352-353 2 ∆ Action1 Day Threshold F32 Action1 Alarm Day Obscuration Threshold

354-355 2 ∆ Action1 Night Threshold F32 Action1 Alarm Night Obscuration Threshold

356-357 2 ∆ Action1 Weekend Threshold F32 Action1 Alarm Weekend Obscuration Threshold

358-359 2 ∆ Action2 Day Threshold F32 Action2 Alarm Day Obscuration Threshold

360-361 2 ∆ Action2 Night Threshold F32 Action2 Alarm Night Obscuration Threshold

362-363 2 ∆ Action2 Weekend Threshold F32 Action2 Alarm Weekend Obscuration Threshold

364-365 2 ∆ Fire1 Day Threshold F32 Fire1 Alarm Day Obscuration Threshold

366-367 2 ∆ Fire1 Night Threshold F32 Fire1 Alarm Night Obscuration Threshold

368-369 2 ∆ Fire1 Weekend Threshold F32 Fire1 Alarm Weekend Obscuration Threshold

370-371 2 ∆ Fire2 Day Threshold F32 Fire2 Alarm Day Obscuration Threshold

the day alarm thresholds.

the night alarm thresholds.

15

Rev A0

Page 16

User Guide: FAAST Fire Alarm Aspiration Sensing Technology® Modbus Protocol Schema 1

Device Conguration (Cont’d)

Address Size

(16-bit

words)

372-373 2 ∆ Fire2 Night Threshold F32 Fire2 Alarm Night Obscuration Threshold

374-375 2 ∆ Fire2 Weekend Threshold F32 Fire2 Alarm Weekend Obscuration Threshold

376-377 2 ∆ Alert Acclimate Threshold Max F32 Maximum Alert Alarm Threshold when operating in

378-379 2 ∆ Alert Acclimate Threshold Min F32 Minimum Alert Alarm Threshold when operating in

380-381 2 ∆ Action1 Acclimate Threshold Max F32 Maximum Action1 Alarm Threshold when operating in

382-383 2 ∆ Action1 Acclimate Threshold Min F32 Minimum Action1 Alarm Threshold when operating in

384-385 2 ∆ Action2 Acclimate Threshold Max F32 Maximum Action2 Alarm Threshold when operating in

386-387 2 ∆ Action2 Acclimate Threshold Min F32 Minimum Action2 Alarm Threshold when operating in

388-389 2 ∆ Fire1 Acclimate Threshold Max F32 Maximum Fire1 Alarm Threshold when operating in

390-391 2 ∆ Fire1 Acclimate Threshold Min F32 Minimum Fire1 Alarm Threshold when operating in

392-393 2 ∆ Fire2 Acclimate Threshold Max F32 Maximum Fire2 Alarm Threshold when operating in

394-395 2 ∆ Fire2 Acclimate Threshold Min F32 Minimum Fire2 Alarm Threshold when operating in

Parameter Name Type Description

Acclimate® Mode

Acclimate Mode

Acclimate Mode

Acclimate Mode

Acclimate Mode

Acclimate Mode

Acclimate Mode

Acclimate Mode

Acclimate Mode

Acclimate Mode

396 ½ ID Number U8 Can be used for the SLC address or an identification

397-428 32 Contact U8[64] UTF-16 Contact Name string buffer

431-460 32 Facility U8[64] UTF-16 Facility Name string buffer

461-492 32 Facility Location U8[64] UTF-16 Facility Location string buffer

493-524 32 Device Location U8[64] UTF-16 Device Location string buffer

525-527 3 Button Lock U8[3] User Interface Lockout

528-529 2 Passcode U32 Passcode for unlocking the buttons from the front panel.

number on a loop

Flashscan 1-Address: 1-159

Flashscan 5-Address: 1-155

CLIP: 1-99

Unlocked 0

Locked 1

Bit 0: Isolate

Bit 1: Reset/Mode

Bit 2: Test

Unsigned Long Value: 1111-9999

Table 7. Device Configuration Modbus Holding Registers

∆ Warning!! Device threshold configuration variables should be set by the user to values scaled based on the Units configuration

setting. The detector will interpret the value differently for different Units settings. E.g. The device will interpret a 0.01 threshold

setting as 0.01 %/ft when Units setting is US Standard. The device will interpret a 0.01 threshold setting as 0.01 %/m when Units

setting is Metric.

16

Page 17

User Guide: FAAST Fire Alarm Aspiration Sensing Technology® Modbus Protocol Schema 1

Network Conguration

Address Size

(16-bit

words)

40530 1 Network Config Counter U16 Configuration Counter

531-546 16 Password U8

547-570 24 E-mail Sender U8

571-594 24 E-mail Server U8

595-618 24 E-mail Recipient #1 U8

619 ½ E-mail Recipient #1 Notifications U8 Enables for notifications based on type of event. See

620-643 24 E-mail Recipient #2 U8

644 ½ E-mail Recipient #2 Notifications U8 Enables for notifications based on type of event

645-668 24 E-mail Recipient #3 U8

669 ½ E-mail Recipient #3 Notifications U8 Enables for notifications based on type of event

670-693 24 E-mail Recipient #4 U8

694 ½ E-mail Recipient #4 Notifications U8 Enables for notifications based on type of event

695-718 24 E-mail Recipient #5 U8

719 ½ E-mail Recipient #5 Notifications U8 Enables for notifications based on type of event

720-743 24 E-mail Recipient #6 U8

744 ½ E-mail Recipient #6 Notifications U8 Enables for notifications based on type of event

745 ½ Static IP Enable U8 Enable/Disable for Static IP. Disabled state enables

746-747 2 Static IP Address U8

748-749 2 Static IP Subnet U8[

Parameter Name Type Description

[32]

UTF-8 E-mail sender account name string buffer

[48]

UTF-8 E-mail outgoing SMTP server name string buffer

[48]

UTF-8 E-mail address of recipient #1

48]

NET_CONFIG_STR for bit definitions

UTF-8 E-mail address of recipient #2

[48]

UTF-8 E-mail address of recipient #3

[48]

UTF-8 E-mail address of recipient #4

[48]

UTF-8 E-mail address of recipient #5

[48]

UTF-8 E-mail address of recipient #6

[48]

DHCP-based IP address assignment. 0 =Disabled,

Not zero = Enabled

Static IP Address

[4]

Static IP Subnet Mask

750-751 2 Static IP Gateway U8

752-753 2 Static IP Pref DNS U8

754-755 2 Static IP Alt DNS U8

Table 8. Network Configuration Modbus Holding Registers

17

4]

Static IP Gateway

[4]

Static IP Preferred DNS Address

[4]

Static IP Alternate DNS Address

[4]

Rev A0

Page 18

User Guide: FAAST Fire Alarm Aspiration Sensing Technology® Modbus Protocol Schema 1

Appendix A. Congurable options on FAAST

A.1. Alarm Conguration Variables

Name Description Range Default Value Units

AlertThresholdDay The sensitivity where the Alert Alarm will occur during the daytime. 0.00046 – 6.25

Action1ThresholdDay The sensitivity where the Action1 Alarm will occur during the

daytime.

Action2ThresholdDay The sensitivity where the Action2 Alarm will occur during the

daytime.

Fire1ThresholdDay The sensitivity where the Fire1 Alarm will occur during the daytime. 0.00046 – 6.25

Fire2ThrehsoldDay The sensitivity where the Fire2 Alarm will occur during the daytime. 0.00046 – 6.25

AlertThresholdNight The sensitivity where the Alert Alarm will occur during the nighttime. 0.00046 – 6.25

Action1ThresholdNight The sensitivity where the Action1 Alarm will occur during the

nighttime.

Action2ThresholdNight The sensitivity where the Action2 Alarm will occur during the

nighttime.

Fire1ThresholdNight The sensitivity where the Fire1 Alarm will occur during the

nighttime.

Fire2ThrehsoldNight The sensitivity where the Fire2 Alarm will occur during the

nighttime.

NightTimeEnter Time at which to switch to nighttime thresholds. 10:00pm Time

NightTimeExit Time at which to switch to daytime thresholds. 5:00am Time

AlertHigh Sensitive limit for Alert when acclimate mode is active 0.00046 – 6.25

Action1High Sensitive limit for Action1 when acclimate mode is active 0.00046 – 6.25

Action2High Sensitive limit for Action2 when acclimate mode is active 0.00046 – 6.25

Fire1High Sensitive limit for Fire1 when acclimate mode is active 0.00046 – 6.25

Fire2High Sensitive limit for Fire2 when acclimate mode is active 0.00046 – 6.25

AlertLow Insensitive limit for Alert when acclimate mode is active 0.00046 – 6.25

Action1Low Insensitive limit for Action1 when acclimate mode is active 0.00046 – 6.25

Action2Low Insensitive limit for Action2 when acclimate mode is active 0.00046 – 6.25

Fire1Low Insensitive limit for Fire1 when acclimate mode is active 0.00046 – 6.25

Fire2Low Insensitive limit for Fire2 when acclimate mode is active 0.00046 – 6.25

AcclimateAlertLevel Current Sensitivity for Alert Alarm when in acclimate mode. AlertHigh –

AcclimateAction1Level Current Sensitivity for Action1 Alarm when in acclimate mode. Action1High –

AcclimateAction2Level Current Sensitivity for Action2 Alarm when in acclimate mode. Action2High –

AcclimateFire1Level Current Sensitivity for Fire1 Alarm when in acclimate mode. Fire1High – Fire-

AcclimateFire2Level Current Sensitivity for Fire2 Alarm when in acclimate mode. Fire2High – Fire-

0.0015 – 20.5

0.00046 – 6.25

0.0015 – 20.5

0.00046 – 6.25

0.0015 – 20.5

0.0015 – 20.5

0.0015 – 20.5

0.0015 – 20.5

0.00046 – 6.25

0.0015 – 20.5

0.00046 – 6.25

0.0015 – 20.5

0.00046 – 6.25

0.0015 – 20.5

0.00046 – 6.25

0.0015 – 20.5

0.0015 – 20.5

0.0015 – 20.5

0.0015 – 20.5

0.0015 – 20.5

0.0015 – 20.5

0.0015 – 20.5

0.0015 – 20.5

0.0015 – 20.5

0.0015 – 20.5

0.0015 – 20.5

AlertLow

Action1Low

Action2Low

1Low

2Low

Table 9. Alarm Configuration Variable Ranges

18

0.012

0.0396

0.05

0.165

0.1

0.33

0.25

0.825

0.5

1.65

0.012

0.0396

0.05

0.165

0.1

0.33

0.25

0.825

0.5

1.65

0.00138

0.00455

0.0028

0.00924

0.0075

0.02475

0.01

0.033

0.1

0.33

0.012

0.0396

0.05

.165

0.1

0.33

0.25

0.825

0.5

1.65

AlertLow %/ft %/m

Action1Low %/ft %/m

Action2Low %/f %/m

Fire1Low %/ft %/m

Fire2Low %/ft %/m

%/ft %/m

%/ft %/m

%/ft %/m

%/ft %/m

%/ft %/m

%/ft %/m

%/ft %/m

%/ft %/m

%/ft %/m

%/ft %/m

%/ft %/m

%/ft %/m

%/ft %/m

%/ft %/m

%/ft %/m

%/ft %/m

%/ft %/m

%/ft %/m

%/ft %/m

%/ft %/m

Page 19

User Guide: FAAST Fire Alarm Aspiration Sensing Technology® Modbus Protocol Schema 1

A.2. Device Conguration Variables

Name Description Range Default Value

Acclimate Mode Enable Set to activate acclimate mode operation Enable / Disable Disabled

Alert Alarm Latch Set to latch Alert alarm. Requires a RESET to clear

alarm. This setting is only valid for conventional

product.

Action1 Alarm Latch Set to latch Action1 alarm. Requires a RESET to

clear alarm. This setting is only valid for conventional

product.

Action2 Alarm Latch Set to latch Action2 alarm. Requires a RESET to

clear alarm. This setting is only valid for conventional

product.

Fire1 Alarm Latch Set to latch Fire1 alarm. Requires a RESET to clear

alarm. This setting is only valid for conventional

product.

Fire2 Alarm Latch Set to latch Fire2 alarm. Requires a RESET to clear

alarm. This setting is only valid for conventional

product.

Alert Delay Programmable delay before activating Alert Alarm.

This setting is only valid for conventional product.

Action1 Delay Programmable delay before activating Action1

Alarm. This setting is only valid for conventional

product.

Action2 Delay Programmable delay before activating Action2

Alarm. This setting is only valid for conventional

product.

Fire1 Delay Programmable delay before activating Fire1 Alarm.

This setting is only valid for conventional product.

Fire2 Delay Programmable delay before activating Fire2 Alarm.

This setting is only valid for conventional product.

PassCodeButtonLockout Allows lockout feature of buttons. 0000 - 9999 1111

TEST Lockout Setting for locking and unlocking of TEST button.

This setting is only valid for conventional product.

RESET Lockout Setting for locking and unlocking of RESET button.

This setting is only valid for conventional product.

DISABLE Lockout Setting for locking and unlocking of DISABLE button.

This setting is only valid for conventional product.

IP Address IP address of the device 192.168.1.10

Subnet Mask 255.255.255.0

Gateway 192.168.1.1

Address Device local address range

CLIP enabled product

Flashscan enabled product

Eclipse enabled product

Time Real time clock time in hours/minutes/seconds Midnight

Date Real time clock date Current date

Year Real time clock year Current year

Log Setting Configures the method of Event logging for either

FIFO (first in first out) or LIFO (last in first out) setting

Password User Password for Web Access User entry Monitor

Latching/Non-Latching Latching

Latching/Non-Latching Latching

Latching/Non-Latching Latching

Latching/Non-Latching Latching

Latching/Non-Latching Latching

0 - 60 seconds 0

0 - 60 seconds 0

0 - 60 seconds 0

0 - 60 seconds 0

0 - 60 seconds 0

Locked / Unlocked For the lock

function to work the passcode

must be any value other than

0000

0-255

1-99

1-159

1-255

FIFO / LIFO FIFO

Locked

Locked

Locked

1

Table 10. Device Configuration Variable Ranges.

19

Rev A0

Page 20

User Guide: FAAST Fire Alarm Aspiration Sensing Technology® Modbus Protocol Schema 1

Technical Support

System Sensor strives to provide our customers with outstanding support for the FAAST Fire Alarm Aspiration Sensing Technology®

and all our products. For more information, contact us using one of the methods below:

Web: E-mail: Phone:

systemsensor.com/faast systemsensor.com/contact 800.736.7672 (press 2) Mon-Fri, 7:30 a.m. – 5:00 p.m. CST

User Guide: FAAST Fire Alarm Aspiration Sensing Technology® with Modbus

©2013 System Sensor. ASUG27801 • 7/13

Loading...

Loading...