Page 1

INSTALLATION AND MAINTENANCE INSTRUCTIONS

WARNING

DH400ACDCIHT Air Duct Smoke Detector

Before Installing

Please thoroughly read the System Sensor Guide for Proper

Use of Smoke Detectors in Duct Applications (A05-1004),

which provides detailed information on detector spacing,

placement, zoning, wiring, and special applications. Copies

of this manual are available online at www.systemsensor.com

or via System Sensor’s toll free fax-back service, Documents

on Demand at 800/736-7672. NFPA Standards 72 and 90A

should also be referenced for detailed information.

NOTICE: This manual should be left with the owner/user

of this equipment.

IMPORTANT: This detector must be tested and maintained

regularly following NFPA 72 requirements. The detector

should be cleaned at least once a year.

This detector is intended for use only with the 1451DHHT

detector head (supplied).

Table of Contents Page

[1] General Description 1

[2] Exploded View of Duct Detector Components 2

[3] Contents of the Duct Detector Kit 2

[4] Installation Sequence 2

[5] Duct Detector Maintenance and Test Procedures 8

[6] Detector Cleaning Procedures 9

[7] Specifications 10

[8] DH400 OE-1 Description and Installation 11

Warranty 12

List of Tables and Figures Page

Fig. 1: Duct Detector Exploded View 2

Fig. 2: Installation of Sampling Tube Gaskets 3

Fig. 3: Mounting Location of Speed Nuts 3

Table 1: Inlet Sampling Tube Selection 3

Fig. 4: Inlet Sampling Tube 4

Fig. 5: Sampling Tube Mounting Configurations 4

Fig. 6: Sampling Tube Filter Installation 5

Fig. 7: Wiring Diagram 6

Fig. 8: Wiring Diagram – No Control Panel 7

Fig. 9: Wiring Diagram – Accessories 8

Fig. 10: Testing Detector Alarm 9

Fig. 11: Detector Head Removal 9

Fig. 12: RTS451/RTS451KEY Test Coil Installation 10

Fig. 13: Ion Head Exploded View 10

[1] General Description

An HVAC system supplies conditioned air to virtually every

area of a building. Smoke introduced into this air duct system will be distributed to the entire building. Smoke detectors designed for use in air duct systems are used to sense

the presence of smoke in the duct.

Model DH400ACDCIHT Air Duct Smoke Detectors are supplied with the model 1451DHHT ionization detector head.

This smoke detection method is combined with an efficient

housing design that samples air passing through a duct

and allows detection of a developing hazardous condition.

When sufficient smoke is sensed, an alarm signal is initiated at the fire control panel monitoring the detector, and

appropriate action can be taken to shut off fans and blowers, change over air handling systems, etc. These actions

can facilitate the management of toxic smoke and fire gases

throughout the areas served by the duct system.

The DH400ACDCIHT air duct smoke detector is designed to

operate from 24 VDC, 24 VAC, 120 VAC, or 240 VAC. Alarm

and supervisory relay contacts are available for control

panel interface (alarm initiation), HVAC control, and other

auxiliary functions. This detector is not designed for 2-wire

applications.

For testing, the alarm can be enabled by a magnet activated

test switch or by the optional remote test station. The duct

smoke detectors latch into alarm state when alarm occurs.

LEDs on each detector illuminate to provide local alarm

indication, and optional accessories offer a variety of

annunciation capabilities.

The detector can be reset by a momentary power interruption, by the magnet activated reset switch, or by the

optional remote test station.

NOTICE: The DH400ACDCIHT can be installed outdoors

3825 Ohio Avenue, St. Charles, Illinois 60174

1-800-SENSOR2, FAX: 630-377-6495

www.systemsensor.com

using the optional accessory DH400 OE-1.

Please refer to section 9 for a description and

installation instructions.

D400-64-00 1 I56-991-08R

Page 2

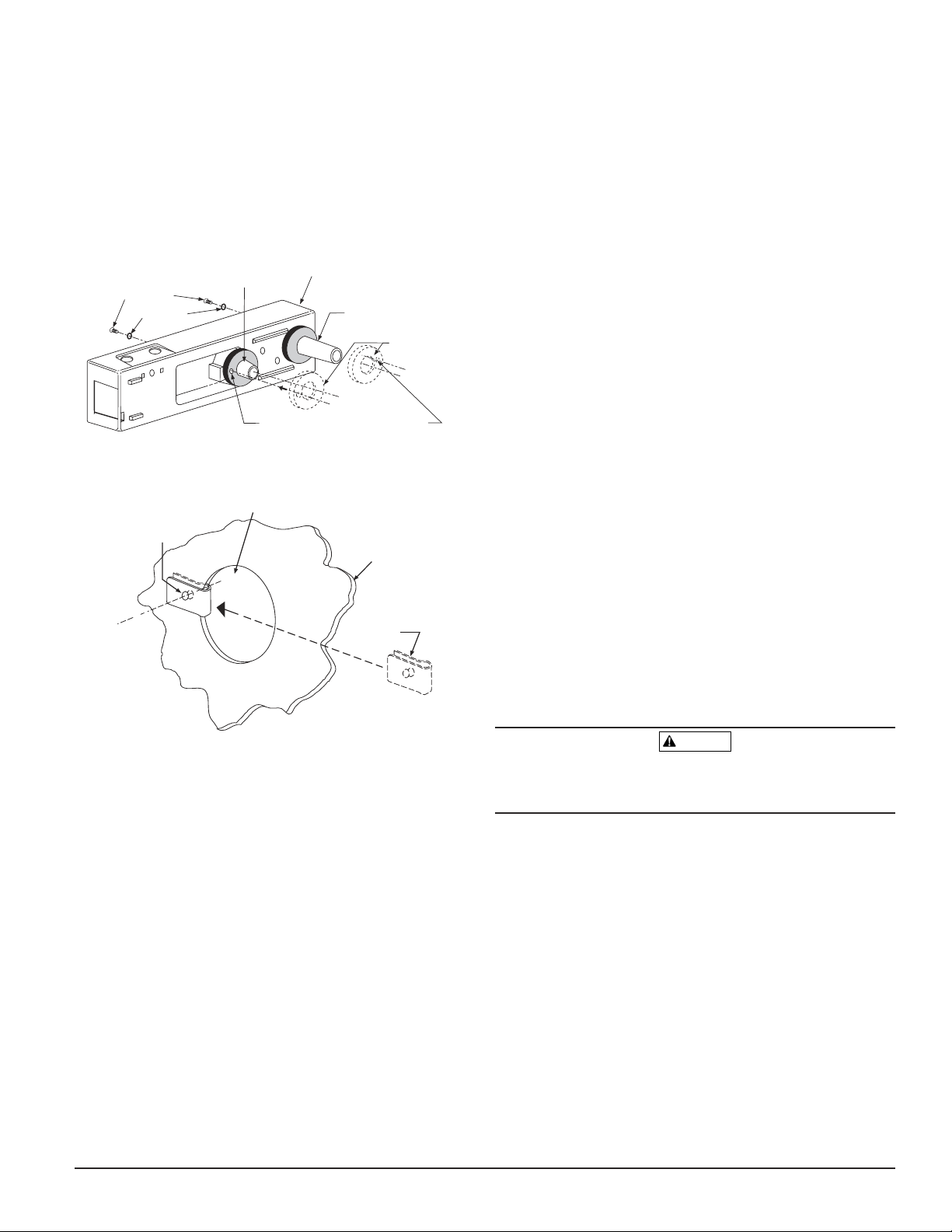

[2] Figure 1. Exploded View Of Duct Detector Components:

SAMPLING TUBE

FILTERS

CONDUIT HOLES

DUCT DETECTOR

HOUSIN

G

TERMINAL STRIP

PC BOARD

INSULATOR

DUCT DETECTOR

COVER

SAMPLING TUBE

MOUNTING

SCREWS

DETECTOR HEAD

EXHAUST

FILTER ADAPTER

DETECTOR BASE

INLET SAMPLING TUBE

(SUPPLIED SEPARATELY)

O-RINGS

FOAM

GASKETS

HOUSING

MOUNTING SCREWS

TEST MAGNET

TUBE

END

PLUG

H0237-00

[3] Contents Of The Duct Detector Kit

1. Complete housing base and cover assembly

2. Two #10 sheet metal mounting screws

3. Two sampling tube filters

4. One test magnet

5. Drilling template

6. Two 5/16 O-rings

7. Two rubber tube bushing seals

8. Four #6 self-tapping mounting screws for the sampling

and optional exhaust tube extension

9. One filter adapter

10. One inlet tube end plug

11. Two #10 speed nuts

12. One test coil and parts bag

NOTE: The inlet sampling tube must be ordered sepa-

rately. It must be the correct length for the width

of the duct where it will be installed. See Table 1

on page 4 to determine the inlet tube required for

different duct widths.

[4] Installation Sequence

Step Page

[4.1] Verify duct air flow direction and velocity 2

[4.2] Drill the mounting holes 3

[4.3] Secure the detector housing to the duct 3

[4.4] Install the sampling tube 3

[4.5] Complete the field wiring 5

[4.6] Install the filters and check pressure differential 5

[4.7] Perform detector check 5

[4.8] Install the cover 8

[4.1] Verify Duct Air Flow Direction And Velocity

Model DH400ACDCIHT detectors are designed to be used

in air handling systems having air velocities of 500 to 4000

feet per minute. Be sure to check engineering specifications

to ensure that the air velocity in the duct falls within these

parameters. If necessary, use a velocity meter to check the

air velocity in the duct.

[4.2] Drill The Mounting Holes

Remove the paper backing from the mounting template

supplied. Affix the template to the duct at the desired

mounting location. Make sure the template lies flat and

smooth on the duct. Center punch holes A and B. Drill the

holes as indicated on the template. Slide the two speed nuts

over the two small holes (hole A) next to the sampling tube

bushing holes (hole B) previously drilled in the duct. (See

Figure 3.)

D400-64-00 2 I56-991-08R

Page 3

[4.3] Secure The Detector Housing To The Duct

SCREW HOLES FOR ATTACHING

DETECTOR HOUSING TO DUCT

FOAM GASKETS

EXHAUST TUBE

(EXTENSION BUSHING)

DUCT DETECTOR

HOUSING

O-RINGS

MOUNTING

SCREWS

INLET SAMPLING

TUBE BUSHING

HOLE B

HOLE A

DUCT

WALL

SPEED

NUT

WARNING

Remove the duct housing cover. Slide the foam gaskets over

the tube bushings as shown in Figure 2. Make sure the two

small holes in the gaskets line up with the two base mounting holes. Put one 5/16-inch O-ring over each of the two

#10 sheet metal screws. Use the two sheet metal screws to

screw the detector housing to the duct. CAUTION: Do not

overtighten the screws.

Figure 2. Installation of foam gaskets over sampling

tube bushings:

H0238-00

Figure 3. Speed nut mounting location:

Mounting the detector housing in a vertical orientation

is acceptable, provided that the air flows directly into the

sampling tube holes as indicated in Figure 4.

Table 1. Inlet tubes required for dif ferent duct

widths:

Outside Duct Width Inlet Tube Required

1 to 2 ft. ST-1.5

2 to 4 ft. ST-3

4 to 8 ft. ST-5

8 to 12 ft. ST-10

[4.4.1] Installation For Ducts Less Than 8 Feet Wide

1. If the tube is longer than the width of the air duct, drill

a 3/4-inch hole in the duct directly opposite the hole

already cut for the inlet tube. If the tube is shorter than

the width of the air duct, install the end plug into the

inlet tube as shown in Figure 4. Sampling tubes over 3

ft. long must be supported at the end opposite the duct

detector.

2. Slide the tube into the centermost housing bushing.

Position the tube so that the arrows point into the air

flow.

3. Secure the tube flange to the housing bushing with two

#6 self-tapping screws.

4. For tubes longer than the width of the air duct, the tube

should extend out of the opposite side of the duct. If

there are more than 2 holes in the section of the tube

extending out of the duct, select a different length using

Table 1. Otherwise, trim the end of the tube protruding

through the duct so that 1 to 2 inches of the tube extend

outside the duct. Plug this end with the end plug and

tape closed any holes in the protruding section of the

tube. Be sure to seal the duct when the tube protrudes.

H0116-00

[4.4] Install The Inlet

The inlet tube (shown in Figure 4) is identified by a series

of air inlet holes on the tube. This tube must be purchased

In no case should more than 2 air inlet holes be cut off the

tube. There must be a minimum of 10 holes in the tube

exposed to the air stream.

separately. Order the correct length, as specified in Table 1,

for width of the duct where it will be installed. The exhaust

tube is molded into the base of the duct housing, and the

A2440-00 Exhaust Tube Extension is available as an accessory in those cases where the molded exhaust port does not

extend at least 2 inches into the duct.

[4.4.2] Installation For Ducts More Than 8 Feet Wide

NOTE: To install inlet tubes in ducts more than 8 feet

wide, work must be performed inside the air

duct. Sampling of air in ducts wider than 8 feet

is accomplished by using the ST-10 inlet sampling

tube. If the tube is shorter than the width of the

The inlet tube is always installed in the centermost housing bushing, with air inlet holes facing into the air flow.

To assist proper installation, the tube’s mounting flange is

marked with arrows. Make sure the inlet tube is mounted

air duct, install the end plug into the inlet tube as

shown in Figure 4 and support the end opposite

the duct detector.

so that the arrows point into the air flow. Figure 5 shows

the various combinations of tube mounting configurations

with respect to air flow.

D400-64-00 3 I56-991-08R

Page 4

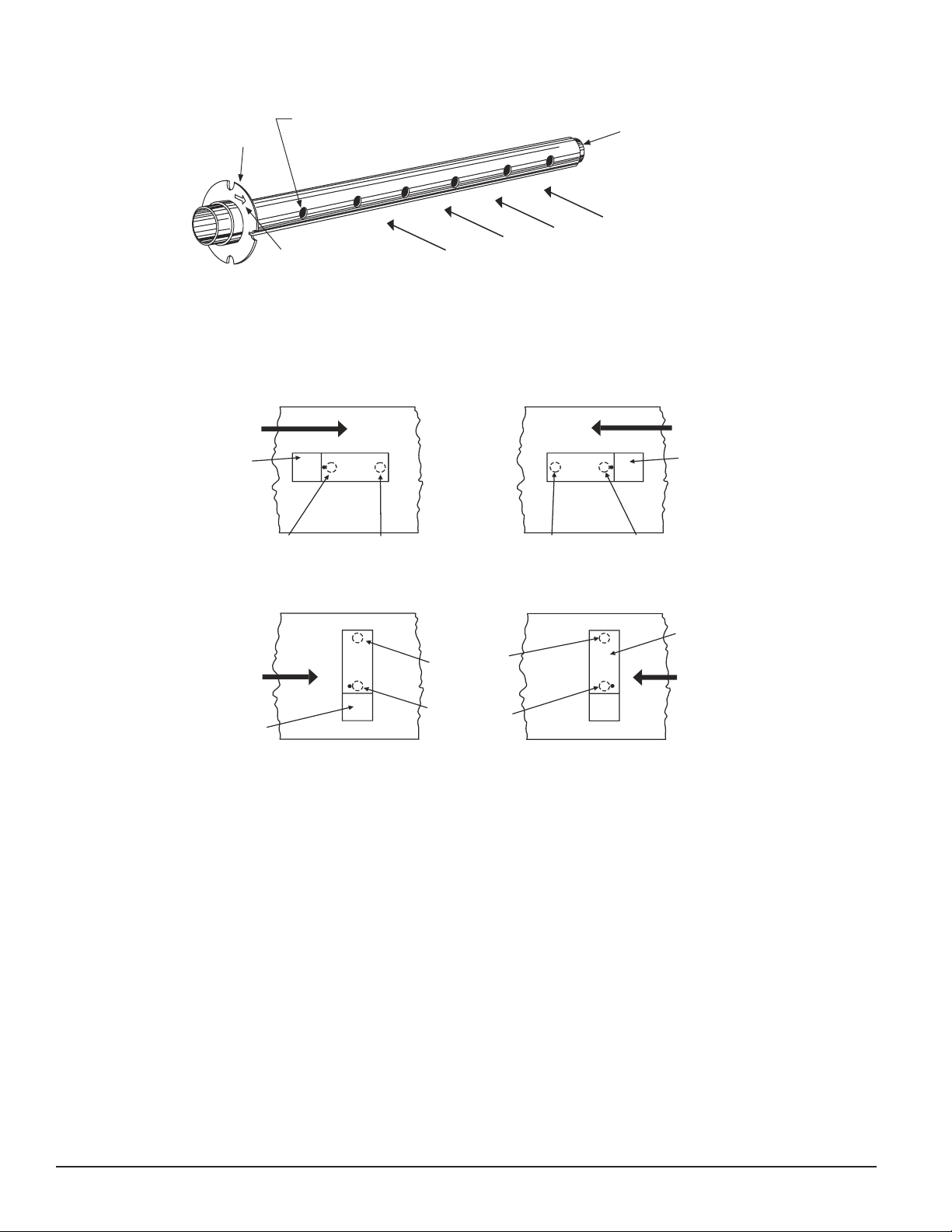

Figure 4. Air duct detector inlet sampling tube:

SAMPLING

TUBE

END CAP

AIR HOLES

ARROW

MUST

FACE

INTO AIR FLOW

AIR FLOW DIRECTION

FLANGE

AIR FLOW

DIRECTION

DETECTOR

HOUSING

DOTS INDICATE POSITION OF

SAMPLING TUBE HOLES

AIR FLOW

DIRECTION

DETECTOR

HOUSING

SAMPLING

TUBE

EXHAUST

TUBE

AIR FLOW

DIRECTION

EXHAUST

TUBE

SAMPLING

TUBE

SAMPLING

TUBE

EXHAUST

TUBE

DETECTOR

HOUSING

AIR FLOW

DIRECTION

DETECTOR

HOUSING

A.

B.

C.

D.

HORIZONTAL MOUNTING OF HOUSING

VERTICAL MOUNTING OF HOUSING

Figure 5. Tube mounting configurations with varying air flow direction:

H0108-02

Install the inlet tube as follows:

1. Drill a 3/4-inch hole in the duct directly opposite the

hole already drilled for the inlet tube.

2. Slide the inlet tube with the flange into the centermost

housing bushing. Position the tube so that the arrows

point into the air flow. Secure the tube flange to the

housing bushing with two #6 self-tapping screws.

3. From inside the duct, couple the other section of the

inlet tube to the section already installed using the 1/2inch conduit fitting supplied. Make sure that the holes

on both of the air inlet tubes are lined up and facing into

the air flow.

4. Trim the end of the tube protruding through the duct so

that 1 to 2 inches of the tube extend outside the duct.

Plug this end with the end plug and tape closed any

holes in the protruding section of the tube. Be sure to

seal the duct when the tube protrudes.

D400-64-00 4 I56-991-08R

NOTE: An alternate method to using the ST-10 is to use

Air currents inside the duct may cause excessive vibration,

especially when the longer sampling tubes are used. In

these cases a 3 inch floor flange (available at most plumbing supply stores) may be used to fasten the sampling tube

to the other side of the duct. When using the flange/connector mounting technique, drill a 1 inch to 1-1/4-inch hole

where the flange will be used.

two ST-5 inlet tubes. Remove the flange from

one of the tubes and install as described above.

After the installation, use electrical tape to close

off some of the sampling holes so that there is a

total of 10 to 12 holes spaced as evenly as possible

across the width of the duct.

H0109-01

Page 5

[5.4.3] Modifications Of Inlet Sampling Tubes

SAMPLING TUBE

FILTERS

SAMPLING TUBE

MOUNTING

SCREW

S

DETECTOR HEAD

EXHAUST

FILTER ADAPTER

DETECTOR BASE

INLET SAMPLING TUBE

FOAM GASKET

CAUTION

There may be applications where duct widths are not what

is specified for the installation. In such cases, it is permissible to modify an inlet sampling tube that is longer than

necessary to span the duct width.

[5.6] Install The Filters

To install the sampling tube filters, simply push the filter

adapter into the exhaust tube, and push the filter onto the

adapter tube on the left, as shown in Figure 9. Install the

other filter over the end of the inlet sampling tube.

Use a 0.193-inch diameter (#11) drill and add the appropriate number of holes so that the total number of holes

exposed to the air flow in the duct is 10 to 12. Space the

additional holes as evenly as possible over the length of

the tube.

[5.5] Field Wiring

Wiring Installation Guidelines

All wiring must be installed in compliance with the National

Electrical Code and the local codes having jurisdiction.

Proper wire gauges should be used. The conductors used

to connect smoke detectors to control panels and accessory

devices should be color-coded to reduce the likelihood of

wiring errors. Improper connections can prevent a system

from responding properly in the event of a fire.

For signal wiring, (the wiring between interconnected

detectors or from detectors to auxiliary devices), it is usually recommended that single-conductor wire be no smaller

than 18 gauge. The duct detector terminals accommodate

wire sizes up to 14 gauge. The last foot of conduit should

be flexible steel conduit (available in electrical supply

houses), which facilitates installation and puts less strain

on the conduit holes in the housing. Solid conduit connections may be used, if desired.

Figure 6. Sampling tube filter installation:

H0239-00

Filters require periodic cleaning or replacement, depending on the amount of dust and dirt accumulated. Visually

inspect the filters at least quarterly; inspect them more

often if the dust accumulation warrants it. See Section [6]

for more information. Replacement filters can be ordered

from System Sensor, 3825 Ohio Ave., St. Charles, IL 60174.

(Exhaust tube/intake tube filter P/N F36-05-00).

Smoke detectors and alarm system control panels have

specifications for allowable loop resistance. Consult the

control panel manufacturer’s specifications for the total

loop resistance allowed for the particular model control

panel being used before wiring the detector loop.

Wiring Instructions

The DH400ACDCIHT duct detector is designed for easy

wiring. The housing provides a terminal strip with clamping plates. Wiring connections are made by stripping about

3/8-inch of insulation from the end of the wire, sliding the

bare end under the plate, and tightening the clamping plate

screw.

The detector may be wired for interconnection to UL listed

control panels, or for stand alone service per NFPA 90A.

Refer to the wiring diagrams of Figures 6, 7, and 8 to select

the appropriate circuit for your application.

[5.7] Perform Detector Check

1. Perform the STANDBY AND TROUBLE TEST per Section

[6.2.1].

2. Perform the MAGNET TEST per Section [6.2.2.1]. The

RTS451 test of Section [6.2.2.2] may substitute for this

requirement.

3. Perform the AIR FLOW TEST per Section [6.1.1].

4. Perform the SMOKE RESPONSE TEST per Section

[6.1.2].

5. Perform the SENSITIVITY TEST per Section [6.2.3].

6. Record all test results in the Detector Test Log at the end

of this manual.

[5.8] Install The Cover

Install the cover using the four screws that are fixed in the

housing cover. Be certain filters are installed as specified

in Section [5.6]. Make sure that the cover fits into the base

groove and that all gaskets are in their proper positions.

Tighten the four screws to 10 in-lbs.

D400-64-00 5 I56-991-08R

Page 6

24V

120

VAC

220/240

VAC

1

2 1

2

13 14

AVAILABLE POWER INPUTS

ALARM AUXILIARY CONTACTS

FOR FAN SHUTDOWN, ETC.

15

16

17

18

19 20

N.C.

C.N.O.

N.O.C.

N.C.

ALARM AUXILIARY CONTACTS SHOWN IN

STANDBY. CONTACTS TRANSFER DURING

ALARM AS INDICATED BY THE ARROWS.

TROUBLE CONTACTS

TROUBLE CONTACTS CLOSED IN ALARM AND STANDBY.

CONTACTS OPEN WHILE DETECTOR HEAD OR POWER IS

REMOVED, AND DURING RESET. OPEN CONTACTS

SIGNAL TROUBLE CONDITION TO PANEL.

24V

120

VAC

220/240

VAC

1 2

12

13

14

AVAILABLE POWER INPUTS

ALARM AUXILIARY CONTACTS

FOR FAN SHUTDOWN, ETC.

15 16

17

18

19

20

N.C.

C.

N.O.

N.O.

C.

N.C.

ALARM AUXILIARY CONTACTS SHOWN IN

STANDBY. CONTACTS TRANSFER DURING

ALARM AS INDICATED BY THE ARROWS.

TROUBLE CONTACTS

TROUBLE CONTACTS CLOSED IN ALARM AND STANDBY.

CONTACTS OPEN WHILE DETECTOR HEAD OR POWER IS

REMOVED, AND DURING RESET. OPEN CONTACT

S

SIGNAL TROUBLE CONDITION TO PANEL.

11

10

11

10

8

9

ALARM

INITIATION

CONTACTS

CONTACTS SHOWN

OPEN IN STANDBY.

CONTACTS CLOSE

IN ALARM.

8

9

ALARM

INITIATION

CONTACTS

CONTACTS SHOWN

OPEN IN STANDBY.

CONTACTS CLOSE

IN ALARM.

ALARM

INITIATION

LOOP

UL LISTED

CONTROL PANEL

FIRST DETECTOR IN THE LOOP

DH400ACDCIHT

LAST DETECTOR IN THE LOOP

DH400ACDCIHT

EOL RESISTOR

SPECIFIED BY

PANEL MANUFACTURER

CONNECT POWER SOURCE

TO APPROPRIATE TERMINALS

OF EACH DETECTOR. SEE

SPECIFICATIONS FOR

ADDITIONAL POWER SUPPLY

INFORMATION.

FOR WIRING OF AUXILIARY

DEVICES, REFER TO

MANUFACTURER'S

INSTALLATION INSTRUCTIONS

OR CONTACT MANUFACTURER.

POWER INPUTS ACCEPT

24 VDC, 24 VAC 50-60 HZ,

120 VAC 50-60 HZ, OR

220/240 VAC 50-60 HZ.

CONNECT POWER SOURCE

TO APPROPRIATE TERMINALS

OF EACH DETECTOR.

AUX. CONTACT RATINGS

10A @ 30 VDC RESISTIVE

10A @ 250 VAC

500mA MINIMUM @ 24 VDC

NOT INTENDED FOR

CONNECTION TO CONTROL

PANELS.

TROUBLE CONTACT RATING

0.3 A @ 32 VAC/DC

CAUTION

Figure 7. System wiring diagram for duct detectors using a UL listed control panel (see Figure 8 for wiring

of optional accessories):

Do not loop wire under terminals when wiring detectors. Break wire runs to provide system supervision of connections.

D400-64-00 6 I56-991-08R

H0240-00

Page 7

24V

120

VAC

220/240

VAC

1

2 1

2

13 14

AVAILABLE POWER INPUTS

ALARM AUXILIARY CONTACTS

FOR FAN SHUTDOWN, ETC.

15

16 17

18

19 20

N.C.

C.N.O.

N.O.C.

N.C.

ALARM AUXILIARY CONTACTS SHOWN IN

STANDBY. CONTACTS TRANSFER DURING

ALARM AS INDICATED BY THE ARROWS.

ALARM INITIATION CONTACTS

TROUBLE CONTACTS CLOSED IN ALARM AND STANDBY.

CONTACTS OPEN WHILE DETECTOR HEAD OR POWER IS

REMOVED, AND DURING RESET. OPEN CONTACTS

SIGNAL TROUBLE CONDITION TO PANEL.

9

8

5

(+) ALARM SIGNAL

AUDIBLE PIEZO ALERT WITH ALARM AND

POWER (TROUBLE) LEDS. FOR STAND ALONE

APPLICATIONS ONLY. APA451 RECOMMENDED

FOR COMPLIANCE TO NFPA 90A. LOCATE IN

NORMALLY OCCUPIED AREA OF PREMISES.

DH400ACDCIHT

DUCT DETECTOR

SEE SPECIFICATIONS FOR

ADDITIONAL POWER

SUPPLY INFORMATION.

FOR WIRING OF AUXILIARY

DEVICES, REFER TO

MANUFACTURER’S

INSTALLATION INSTRUCTIONS

OR CONTACT MANUFACTURER.

TROUBLE CONTACT RATING

0.3A @ 32 VAC/DC

POWER INPUTS ACCEPT

24 VDC, 24 VAC 50-60 HZ,

120 VAC 50-60 HZ, OR

220/240 VAC 50-60 HZ

.

CONNECT POWER SOURCE

TO APPROPRIATE TERMINALS

OF EACH DETECTOR.

ALARM AUXILIARY CONTACT RATINGS

10A @ 30 VDC RESISTIV

E

10A @ 250 VA

C

500mA MINIMUM @ 24 VDC

NOT INTENDED FOR CONNECTION

TO CONTROL PANELS.

ALARM INITIATION CONTACT RATING

2.0A @ 30 VAC/DC (0.6 POWER FACTOR)

TROUBLE CONTACTS CLOSED IN STANDBY AND ALARM.

CONTACTS OPEN WHILE DETECTOR HEAD OR POWER

IS REMOVED, AND DURING RESET. OPEN CONTACTS

EXTINGUISH OPTIONAL APA451 GREEN “POWER” LED

TO INDICATE TROUBLE CONDITION.

(–) AUX POWER

(+) AUX POWER

TROUBLE

CONTACTS

APA451

N.O.

6

7

10

11

COMMON

FIELD

INSTALLED

JUMPER

POWER3

GRN.

RED

1

2 ALARM

Figure 8. Wiring diagram for duct detector systems equipped without a control panel (see Figure 8 for

wiring of additional optional accessories):

H0241-00

D400-64-00 7 I56-991-08R

Page 8

Figure 9. Wiring diagrams for optional accessories (see Figure 7 for APA451 wiring diagram):

ALARM SIGNAL (+)

AUX POWER (–)

5

6

(+)

(–)

DUCT DETECTOR

DH400ACDC

PA400 (OPTIONAL)

AUDIBLE ALERT

ALARM SIGNAL (+)

AUX POWER (–

)

5

6

(+)

(–)

DUCT DETECTOR

DH400ACDC

RA400Z (OPTIONAL)

REMOTE (LED)

ANNUNCIATOR

RED

ALARM SIGNAL (+)

AUX POWER (–

)

5

6

1

2

DUCT DETECTOR

DH400ACDC

RTS451/RTS451KEY

(OPTIONAL) REMOTE

TEST STATION

R

E

D

5

3

4

3

RESET

TEST

4

FIELD

INSTALLED

JUMPER

RESET (–)

TEST (–

)

H0242-00

[5] Duct Detector Maintenance And Test Procedures

Test and maintain duct detectors as recommended in NFPA

72. The tests contained in this manual were devised to

assist maintenance personnel in verification of proper

detector operation.

Before conducting these tests, notify the proper authorities

that the smoke detection system will be temporarily out of

service. Disable the zone or system under test to prevent

unwanted alarms.

After conducting these tests, record the appropriate information in the Detector Test Log at the end of this manual.

[5.1] Smoke Entry Tests

[5.1.1] Air Flow

To verify sufficient sampling of ducted air, use a manometer to measure the differential pressure created from air

flow across the sampling tubes. The pressure should measure no less than 0.01 inches of water and no greater than

1.20 inches of water.

[6.1.2] Smoke Response

To determine if smoke is capable of entering the sensing chamber, visually identify any obstructions. Plug the

exhaust and inlet tube holes to prevent ducted air from

carrying smoke away from the detector head, then blow

smoke such as cigarette, cotton wick, or punk directly at

the head to cause an alarm. REMOVE THE PLUGS AFTER

TESTING OR THE DETECTOR WILL NOT FUNCTION

PROPERLY.

[6.2] Standby, Alarm, And Sensitivity Tests

[6.2.1] Standby And Trouble

Standby- Check for the presence of the blinking red LEDs

(blinks about every 10 seconds) through the

housing cover. If the APA451 accessory is used,

its green Power LED should be illuminated continuously.

Trouble- If the detector LEDs do not blink or if the

APA451 Power LED is not illuminated, the detector lacks power (check wiring, panel, or power

supply), the head is missing (install), or the unit

is defective (return for repair).

Test- The trouble condition can be caused intention-

ally to verify correct operation of the system.

Remove power to the unit, remove the detector head (see Figure 11), or place the M02-0401 magnet into the Reset locator, as shown in

Figure 10. These actions should cause a trouble

condition locally and at the system control

panel.

[6.1.3] Filter Replacement

The filters do not substantially affect smoke behavior even

when they are up to 90% clogged. Quarterly visual inspection is usually often enough to determine if filters should

be replace because only a high percentage of contamination affects duct detector performance.

D400-64-00 8 I56-991-08R

Page 9

Figure 10. Testing detector alarm: Figure 11. Detector head removal:

TEST

LOCATOR

TEST

MAGNET

PAINTED SIDE

TOWARD HOUSING

DUCT

HOUSING

DETECTOR

HEAD

RESET

LOCATOR

TWIST

COUNTERCLOCKWISE

TO REMOVE

DUCT

HOUSING

TWIST

CLOCKWISE

TO

INSTALL

DETECTOR

HEAD

H0243-00 H0244-00

[5.2.2] Alarm Tests

[5.2.2.1] M02-04-01 Magnet Test

1. Place the painted surface of the magnet into the Test

locator molded into the side of the housing (see Figure

10).

2. The red alarm LEDs on the detector should latch on,

as should any accessories (PA400, RA400Z, RTS451,

APA451). Verify auxiliary functions (such as fan shutdown) and system control panel alarm status.

3. Place the painted surface of the magnet into the Reset

locator molded into the side of the housing (see Figure

10). This should clear the latched alarm condition at the

detector. If a system control panel is used, the panel may

also require resetting.

[5.2.2.2] RTS451/RTS451KEY Remote Test Station

The RTS451/RTS451KEY Remote Test Station facilitates test

of the alarm capability of the duct detector as indicated

in the RTS451/RTS451KEY manual. The DH400ACDCIHT

duct detector can be reset by the RTS451/RTS451KEY. If

a system control panel is used, the panel itself may also

require resetting.

To install the RTS451/RTS451KEY, connect the device as

shown in Figure 8; wire runs must be limited to 25 ohms or

less per interconnecting wire. Place the coil in the detector

housing with the arrow facing up and pointing toward the

detector as in Figure 12. Attach the coil leads to the housing terminals as shown; polarity is not important. Firmly

screw the bracket in place over the test coil.

[5.2.3] Sensitivity Tests

[5.2.3.1] MOD400R Sensitivity Test

After verification of alarm capability, use the MOD400R test

module with a voltmeter to check detector sensitivity as

described in the test module’s manual. The housing cover

must be removed to perform this test.

If test module readings indicate that the detector head is

outside of the acceptable range that is printed on the back

of the detector head, the detector head requires cleaning

per Section [7].

[6] Detector Cleaning Procedures

Notify the proper authorities that the smoke detector system is undergoing maintenance, and that the system will

be temporarily out of service. Disable the zone or system

undergoing maintenance to prevent unwanted alarms and

possible dispatch of the fire department.

[6.1] Air Filters

1. Turn off power to the system.

2. Remove and inspect the sampling tube filters.

3. If the filters are heavily coated with dirt, replace them

with new filters. If they are not heavily coated, use a

vacuum cleaner or compressed air nozzle to remove

dust, then reinstall the filters.

[6.2] Ion Heads

1. Remove the detector cover by depressing the three lock

prongs on the top of the cover and rotating the cover

counterclockwise to remove the cover and screen assembly (see Figure 14). The optional CRT400 Cover Removal

Tool makes cover removal easier.

2. Carefully pull the screen out of the cover.

D400-64-00 9 I56-991-08R

Page 10

DETECTOR

HEAD

TEST COIL

Figure 12. RTS451/RTS451KEY test coil installation:

LOCK PRONG

REMOVABLE SCREEN

(P/N RS14)

REMOVABLE

COVER

FOR

CLEANING

SENSING CHAMBER

H0245-00

3. Clean the screen thoroughly with a soft brush or vacuum. Replacement screens (RS14) are available.

4. Brush or vacuum the inside of the cover. The cover may

then be blown out with clean, compressed air.

5. Vacuum the sensing chamber before using clean,

compressed air to loosen and blow out any remaining

debris.

6. Press the screen back into the cover.

7. Replace the detector cover onto the sensing chamber.

Rotate it clockwise to lock it into place.

[7.3] Reinstallation

1. Reinstall the detector in its housing.

2. Restore system power.

3. Perform Detector Check, Section [5.7].

4. Notify the proper authorities testing has been completed

and the smoke detector system is back in operation.

Figure 13. Ion head exploded view:

H0246-00

[8] Model DH400ACDCIHT Air Duct Smoke Detector Specifications

Description

HVAC air duct mounted ionization smoke detector for separately powered systems or stand alone systems. Auxiliary

alarm relay contacts provide fan contactor shutdown to prevent HVAC circulation of smoke.

Environmental Limits

Operating Temperature: +32° to +158°F (0° to +70°C)

Storage Temperature: –22° to +158°F (–30° to +70°C)

Humidity: 10% to 93% R.H. non-condensing

Air Velocity: 500 to 4000 Ft/min.

1.5 to 20.3 m/sec.

Test Features

Magnetic test switch, magnetic reset switch, MOD400R test module (optional), RTS451 Remote Test Station (optional).

Mechanical Specifications

Length: 14.5 inches 37 cm

Width: 5 inches 13 cm

Depth (installed): 4 inches 10 cm

Weight: 4 pounds 1.8 kg

Terminals

Captive universal terminal screws with sems plates accept wire sizes of 14 gauge or smaller. The screws can withstand

10 in-lbs of tightening torque without damage.

Accessories

MOD400R Sensitivity Test Module

RA400Z Remote Annunciator

RTS451/RTS451KEY Remote Test Station, test & reset switch with alarm LED

PA400 Piezo Sounder

APA451 Annunciator with piezo, alarm & power LEDs

CRT400 Cover Removal Tool

D400-64-00 10 I56-991-08R

Page 11

F36-05-00 Replacement Air Filter (two per package)

M02-04-01 Replacement Test Magnet

P48-21-00 Replacement End Plug for inlet sampling tube

RS14 Replacement Screen, Ion

A2650-01 Replacement Installation Kit (mounting hardware)

DH400 OE-1 Enclosure for outdoor applications

Sampling (Inlet) Tubes

TUBE OUTSIDE DUCT WIDTH

ST-1.5 1 to 2 feet (0.3 to 0.6 m)

ST-3 2 to 4 feet (0.6 to 1.2 m)

ST-5 4 to 8 feet (1.2 to 2.4 m)

ST-10 8 to 12 feet (2.4 to 3.7 m)

Exhaust Tube Extension

A2440-00 5.75 in. (14.6 cm.) additional

Electrical Specifications

Power supply voltage: 20-29 VDC 24 VAC 50-60-Hz 120 VAC 50-60 Hz 220/240 VAC 50-60 Hz

Input capacitance: 270 µF max. 270 µF max. N/A N/A

Reset voltage: 3.0 VDC or less 2.0 VAC or less 10 VAC or less 20 VAC or less

Reset time (by power down): 0.6 sec. max. 0.6 sec. max. 0.6 sec. max. 0.6 sec. max.

Power up time: 34 sec.max. 34 sec. max. 34 sec. max. 34 sec. max.

Alarm response time: 2 to 17 sec. 2 to 17 sec. 2 to 17 sec. 2 to 17 sec.

Electrical Ratings

Power Supply Voltage 20-29 VDC 24VAC 50-60 Hz 120 VAC 50-60 Hz 220/240 VAC 50-60 Hz

CURRENT REQUIREMENTS (USING NO ACCESSORIES)*

Max. standby current 25 mA 35 mA AC avg. 20mA AC avg. 20mA AC avg.

Max. alarm current 95 mA 55 mA AC avg. 55 mA AC avg. 30 mA AC avg.

*NOTE: Accessories require extra current. Refer to accessory device manual.

CONTACT RATINGS

Alarm initiation contacts (SPST) 2.0A @ 30 VAC/DC (0.6 power factor)

Alarm auxiliary contacts (DPDT) 10A @ 30 VDC Resistive

10A @ 250 VAC

NOTE: Alarm auxiliary contacts must switch 500 mA minimum at 24 VDC. Alarm auxiliary contacts shall not be

connected to initiating circuits of control panels. Use the alarm initiation contact for this purpose.

Trouble contacts (SPST) 0.3A @ 32 VDC (resistive)

[8] DH400 OE-1 Optional Accessory

General Description

The DH400 OE-1 all-weather enclosure is specifically

Preparation

Locate the two adhesive backed gaskets packaged with the

enclosure.

designed to house and protect the System Sensor model

DH400ACDCIHT high temperature duct detector from the

elements. This enclosure provides protection in outdoor

installations against rain, sleet, and snow or in indoor

NOTE: In order to provide effective sealing, these gaskets

must be placed on the outside of the enclosure

around the two large openings.

installations against dripping water.

Remove the protective paper. Place the gaskets around the

NOTE: The DH400 OE-1 is designed solely for the use

with System Sensor model DH400ACDCIHT high

temperature duct smoke detector.

large openings, aligning the screw holes of the gaskets with

the screw holes of the enclosure. Press firmly to insure

complete adhesion.

D400-64-00 11 I56-991-08R

Page 12

Mounting

Remove the front cover of the enclosure and place it against

the duct at the desired mounting location. Make sure the

four mounting holes on the enclosure rest squarely on the

duct work.

Using the enclosure as a template, mark the location of all

eight openings (the four corner holes, the two sampling

tube openings, and the two duct mounting holes) on the

duct using a pencil or a permanent marker.

Cut the two sampling tube openings using a 1-3/8″ hole

saw or hole punch. Drill the remaining six holes (0.17″

diameter) using a #21 drill bit. Using the screws provided,

secure the enclosure at the four corners.

Please refer to insert for the Limitations of Fire Alarm Systems

Three-Year Limited Warranty

System Sensor warrants its enclosed air duct smoke detector to be free

from defects in materials and workmanship under normal use and service

for a period of three years from date of manufacture. System Sensor makes

no other express warranty for this air duct smoke detector. No agent, representative, dealer, or employee of the Company has the authority to increase

or alter the obligations or limitations of this Warranty. The Company’s

obligation of this Warranty shall be limited to the repair or replacement

of any part of the air duct smoke detector which is found to be defective in materials or workmanship under normal use and service during

the three year period commencing with the date of manufacture. After

phoning System Sensor’s toll free number 800-SENSOR2 (736-7672) for

a Return Authorization number, send defective units postage prepaid to:

D400-64-00 12 I56-991-08R

© 2003 System Sensor

System Sensor, Repair Department, RA #__________, 3825 Ohio Avenue,

St. Charles, IL 60174. Please include a note describing the malfunction and

suspected cause of failure. The Company shall not be obligated to repair

or replace units which are found to be defective because of damage, unreasonable use, modifications, or alterations occurring after the date of manufacture. In no case shall the Company be liable for any consequential or

incidental damages for breach of this or any other Warranty, expressed or

implied whatsoever, even if the loss or damage is caused by the Company’s

negligence or fault. Some states do not allow the exclusion or limitation of

incidental or consequential damages, so the above limitation or exclusion

may not apply to you. This Warranty gives you specific legal rights, and

you may also have other rights which vary from state to state.

Loading...

Loading...