Page 1

INSTALLATION AND MAINTENANCE INSTRUCTIONS

PART NO.

A3008-00

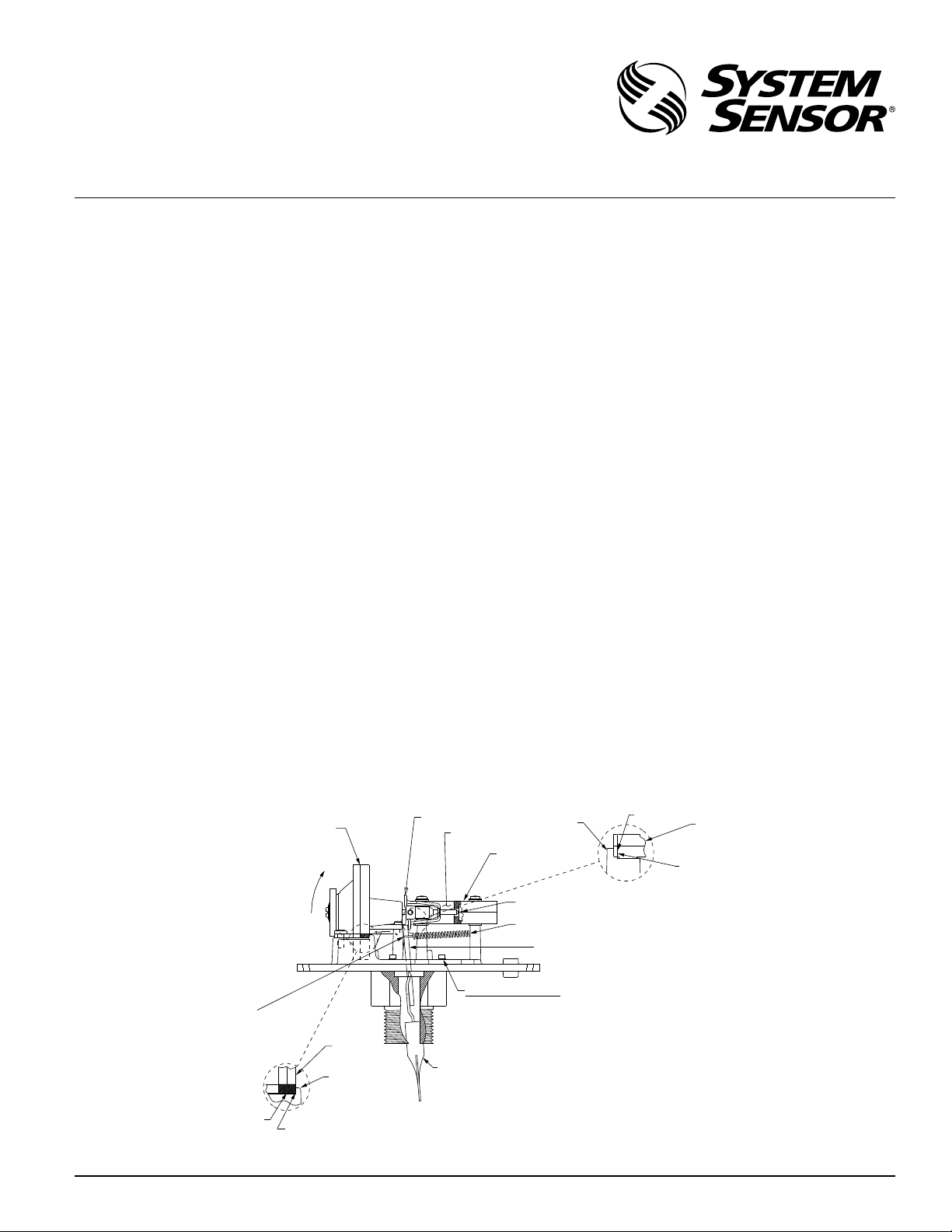

TILT 30∞ TO

REMOVE AND

RE-INSTALL

DELAY

MECHANISM.

TIMER STOP

CUTAWAY

VIEW

RAISED

BOSS

PART NO.

A77-01-02

STOP

SWITCH

ENCLOSURE

VERTICAL

ALIGNMENT

WALL

(BEHIND STOP)

SWITCH ENCLOSURE SLOT

SPRING

PADDLE LEVER ARM

DO NOT REMOVE!

MAIN PLATE

ATTACHMENT

SCREWS

WFDT - 3

WFDXX - 4

ACTUATOR

ASSEMBLY

DELAY

MECHANISM

MOUNTING

PLATE BOSS

DELAY

MECHANISM

STOP

VERTICAL

ALIGNMENT

WALL

SPRING

HOOK

Replacement Timer Delay Assembly

A3008-00 and Switch Assembly

A77-01-02 for WFD and WFDT

I56-0516-002

3825 Ohio Avenue, St. Charles, Illinois 60174

1-800-SENSOR2, FAX: 630-377-6495

www.systemsensor.com

NOTICE: This manual should be left with the owner/user

of this equipment.

General Information

This manual includes instructions for replacing either of

the assemblies listed above. Either of these may be replaced

without replacing the other.

The waterflow device need not be removed from the sprinkler system while the timing delay and/or switch assembly

is being replaced. Do not tamper with the main plate attachment screws since water leakage will occur. (See Figure 1.)

Do not replace any other component of the waterflow indicator in the field. If any other functional part of the detector

becomes faulty, remove and replace the entire detector. Not

doing so may result in the failure of the detector to indicate

a waterflow condition.

Delay Mechanism Removal

1. Turn the dial to zero (0) and remove the three screws

holding the delay mechanism in place.

2. Gently lift the front of the delay mechanism approximately 30 degrees to clear the paddle lever arm (see

Figure 1).

3. Pull forward and rock the delay mechanism back and

forth slightly to disengage the switch buttons from the

timer stop.

Delay Mechanism Replacement

1. Turn the replacement delay mechanism to zero (0).

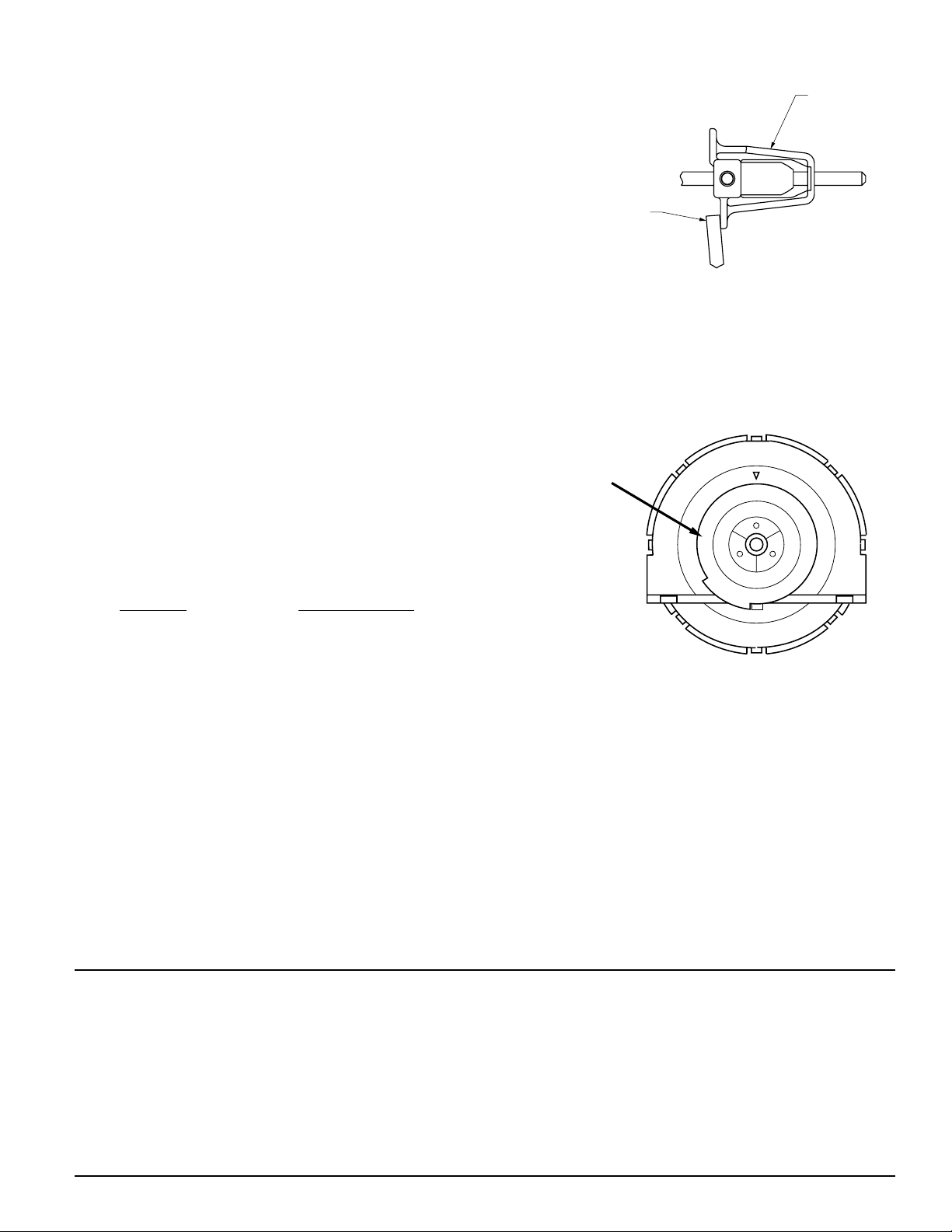

2. Orient the timer stop as depicted in Figure 2. Note the offset in the two vertical faces of the stop and their position.

3. Placing the mechanism on a slight angle to the waterflow device as shown in Figure 1, slide the rear of the

timer shaft between the switch buttons until the timer

stop is encountered. Rock the delay mechanism back

and forth to retract the switch buttons and continue to

seat the delay mechanism into position on the plate.

4. Check the following before replacing the retaining

screws (refer to Figures 1 and 2).

a. Insert the end of the shaft into the rear slot of the

switch enclosure (see Figure 1).

b. Rest the paddle lever arm on the front face of the

timer stop (see Figure 2).

c. Center the delay mechanism on the plate, making

sure the slots in the plastic are aligned with the holes

in the metal mounting plate.

d. Make sure the leading edge of the mounting plate

boss is in contact with the stops on the delay mechanism (see Figure 1).

e. Firmly seat the delay mechanism on the three sup-

port posts.

f. Seat the spring hook in the groove in the paddle le-

ver arm.

Figure 1. Delay Assembly (WFDT shown, WFDXX lower unit configuration is different):

N770-07-00 1 I56-0516-002

W0204-00

Page 2

Switch Enclosure Replacement

TOP

TIMER STOP

PADDLE LEVER ARM

WHEN INSTALLING REPLACEMENT

DELAY MECHANISM, TIMER STOP

AND PADDLE LEVER ARM MUST BE

POSITIONED AS SHOWN.

Delay

adjustment

dial

NOTE: Retard time may exceed 90 seconds.

55

70

0

15

45

30

T

I

M

E

D

E

L

A

Y

I

N

S

E

C

O

N

D

S

N

U

M

B

E

R

O

N

D

I

A

L

I

S

A

P

P

R

O

X

I

M

A

T

E

1. Remove the three screws holding the switch enclosure.

2. Pull gently on the switch enclosure and rock slightly to

disengage the switch buttons from the timer stop.

3. Install the replacement switch enclosure using a similar

rocking action to depress the switch buttons. Do not

turn the timer stop or shaft more than 15 degrees while

replacing the switch enclosure. Check the position of

the timer stop per Figure 2.

4. Slide the switch enclosure toward the delay mechanism

until the vertical alignment boss on the plate seats into

the alignment groove one corner of the switch enclosure. (Only one will engage.) Exert pressure on the

switch enclosure holding it seated flat and pushed toward the delay mechanism while replacing the three

retaining screws. Seat firmly using approximately 6 inlbs. of torque.

System Check

1. With the dial set on zero, actuate the lever arm forward

and back checking for smooth operation of the switch

mechanism. The lever arm should operate freely with no

obstruction. The switches should activate when the arm

is moved forward and reset when the arm is released.

2. With a continuity meter installed between the (COM)

and (B) terminals on one of the switches, the following

conditions should occur:

Condition COM to B Circuit

Normal or non-flow Open circuit

Lever actuated or water flow in pipe (10 gpm) Closed circuit

3. Turn the dial to the desired delay setting and time the

response of the system to waterflow conditions as normally done on routine system tests.

4. Insure that the system returns to the non-alarm condition after the flow in the system is discontinued.

5. Replace the cover with the two security screws and

wrench (not supplied).

Figure 2.

W0205-00

Figure 3.

W0139-00

System Sensor warrants its enclosed product to be free from defects in

materials and workmanship under normal use and service for a period

of three years from date of manufacture. System Sensor makes no other

express warranty for the enclosed product. No agent, representative,

dealer, or employee of the Company has the authority to increase or alter

the obligations or limitations of this Warranty. The Company’s obligation of this Warranty shall be limited to the replacement of any part of

the product which is found to be defective in materials or workmanship under normal use and service during the three year period commencing with the date of manufacture. After phoning System Sensor’s

toll free number 800-SENSOR2 (736-7672) for a Return Authorization

number, send defective units postage prepaid to: System Sensor, Returns

N770-07-00 2 I56-0516-002

©2006 System Sensor

Three-Year Limited Warranty

Department, RA #__________, 3825 Ohio Avenue, St. Charles, IL 60174.

Please include a note describing the malfunction and suspected cause

of failure. The Company shall not be obligated to replace units which

are found to be defective because of damage, unreasonable use, modifications, or alterations occurring after the date of manufacture. In no

case shall the Company be liable for any consequential or incidental

damages for breach of this or any other Warranty, expressed or implied

whatsoever, even if the loss or damage is caused by the Company’s

negligence or fault. Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or

exclusion may not apply to you. This Warranty gives you specific legal

rights, and you may also have other rights which vary from state to state.

Loading...

Loading...