Page 1

1

© System Sensor 2008 I56-2634-004ENPittway Tecnologica S.r.l, Via Caboto 19/3, 34147 Trieste, Italy

DEUTSCH

ENGLISH

INSTALLATION AND MAINTENANCE INSTRUCTIONS

A300 SERIES ASPIRATED SMOKE DETECTOR

should be monitored using a separate monitor module to

return the fault.

A300E Series smoke detectors are powered by an external

24Vdc power supply .

With the use of an exhaust pipe, the system is IP65 rated,

allowing its use in many harsh environments, and

applications where regular hosing is performed.

CA UTION!

The A300 Series has been independently tested and

certified to CEA4022 and must be installed in strict

compliance with these instructions if the certification

is to be maintained.

SPECIFICATIONS

Number of Sensors: A310E:1 or 2 sensors. A320E: 2 sensors

(order separately, recommended: 7251 sensor).

Internal Filtration: 2 stage dust particle filter

Flow Monitoring: Thermal device, high and low thresholds.

10 element bar graph indication.

Relay fault reporting

Supply Voltage: 24VDC (Nominal) 18-30VDC (12W min)

Supply Current: 120 mA - 500 mA depending on fan speed

setting and supply voltage. Maximum

current 350mA @24VDC with no aspirating

pipe (See table 4 for typical currents/fan

speeds)

Maximum Pipe Length: 1 Chan - 100 metres

2 Chan - 2 x 100 metres

Dependant on sensor type and application

IP rating: IP53 / IP65 optional with exhaust fitted

Operating Temperature: -10°C to 50°C

Operating Humidity: 10 to 95% RH (non-condensing)

Fuse Type/Rating: ‘T’ European sub-miniature (TR5)

1.25 A Anti-surge

INTRODUCTION

There are many instances where aspirated smoke

detectors are specified, but where the very high sensitivity

that is normally inherent in these devices is an

unnecessary expense. The A300E Series Aspirated Smoke

Detector provides the perfect solution.

A300E Series aspirating smoke detectors are available in

single or dual channel formats giving a large monitored area

using sampling holes in the place of point detectors.

The A310E single channel unit has a single detection pipe,

and may be used with one smoke sensor, or two sensors

which can be configured for alarm coincidence at the panel

to simulate a ‘Double Knock’ type operation. (Note: Not

included in VdS appro val).

The A320E unit is equipped with two detection pipe

channels and should be fitted with one sensor for each

channel and can thus cover a greater area than the A310E.

A high performance aspirator and flow monitoring circuit

ensure a constant, monitored flow level which can be

displayed on a 10 element bar graph with adjustments for

high and low flow thresholds.

The A300E Series units incorporate in-line air filters to

remove dust particles from the air samples.

A300E Series Aspirating smoke detectors provide closed

loop sampling whereby the exhausted air can be

completely returned to the sampled area making them

particularly suitable for prison cells.

A300E Series Aspirating smoke detectors use one or two

standard intelligent or conventional smoke sensors which

communicate their status directly with the control panel

(Recommended: 7251 Laser Sensor). The A300E monitors

its own systems and uses relay contacts to signal system

faults. If using an intelligent fire system, these contacts

Page 2

2D200-41-00

Pittway Tecnologica S.r.l, Via Caboto 19/3, 34147 Trieste, Italy

Pipe Specification

For full details of pipe installation please see the appendix

at the back of this manual.

Smoke tests should be performed before planning and

installing the pipe network.

Material

For CEA4022 compliance, the pipe should be red ABS to

EN 50086-1 (Crush 1, Impact 1, Temp 33).

Dimensions

Metric: 25.0mmOD - 21mmID;

Imperial: 3/4"BSP (26.7mmOD - 20mmID)

Note: Both metric and imperial sizes will fit into the unit.

Lengths may be cut as required, and joined by permanent

sockets, removable socket unions or solvent welded.

The A300 inlet port is tapered to allow a push fit of the

sampling pipe. The pipe should be cut squarely to ensure a

good, airtight seal. Solvent adhesive should not be used

for this joint.

Fixings

The means of fixing the pipe to the structure will depend on

site conditions. The normal methods are pipe clips, saddle

clamps or even tie wraps. Fixing centres are typically 1.5m

apart.

Holes

The sampling pipe is perforated with sampling holes at

design spacing. These are typically 3mm and can either be

pre-drilled or drilled in situ. Care should be taken to avoid

swarf entering the pipe. It is always good practice to blow

compressed air through the pipe after drilling to clear any

debris before final connection to the equipment. In standard

configuration, with pipe hanging from ceiling, the holes will

be placed underneath, so the smoke can easily rise up into

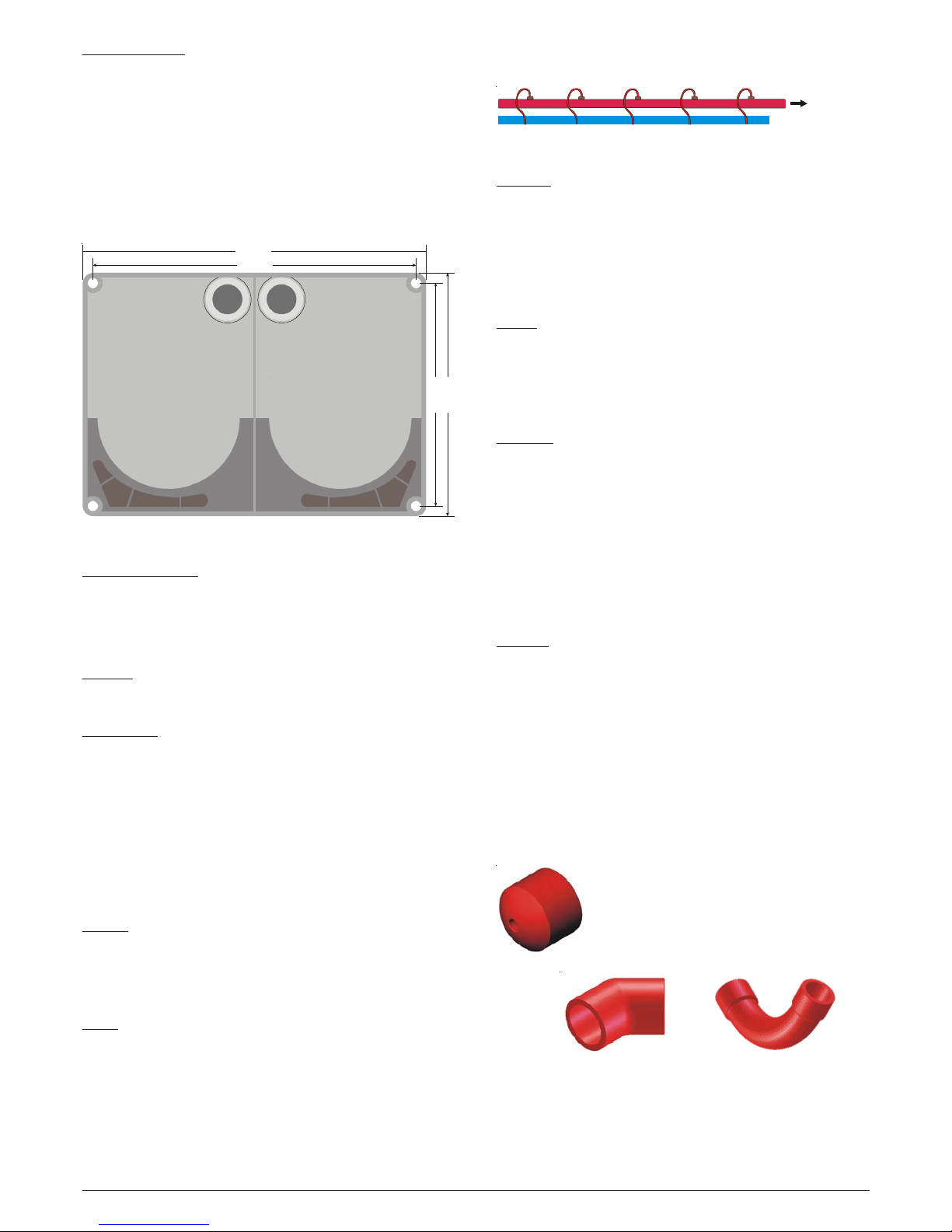

Figure 1: A300E Series Mounting Hole Centres

INSTALLATION

A300E Series Installation

The front cover of the A300 will need to be removed to

secure the unit permanently in place. This is done using

the special key that is supplied, which fits into the screw

hole in each corner of the unit. Please keep the key in a

safe place.

The A300E should be secured to a suitable surface through

the 4 corner fixing points as shown below using suitable

fasteners, for example no.6 wood screws.

Figure 2: Capillary Tube Sample Holes

End Cap

The end of the pipe should be terminated with an end cap,

having a central hole typically 6mm in diameter.

If the end cap is not used, then practically no air will be

drawn through the side holes.

Without a hole in the end cap the contributions from the

side holes will tend to be very unbalanced.

Bends

Bends are either 45 or 90 degrees. For the 90-degree bends

it is very important that slow radii are used and not a sharp

elbow , as this will introduce unacceptable pressure losses ,

and significantly increase the response times from holes

beyond the bend.

T Pieces

A T joint can be used on pipes to produce 2 branches. It is

recommended that the total number of holes in a resulting

pipe system is no more than the number of holes estimated

for a single pipe design. For example, if a single 100M pipe

can have up to 18 holes, 2 branches can have up to 9 holes

each. It is important that the branches have a balanced

design - that is, they should be approximately equal in

length and number/size of holes). For further information,

please see the maximum pipe length/hole size data in Table

6 and the T Piece e xample shown later in the manual.

Exhaust

In most installations the exhaust should be left open, but

there are some circumstances when it may be necessary

to connect a pipe to the exhaust port to divert the exhaust

away from the location of the unit; For example to reduce

noise, reduce risk of interference/deliberate obstruction,

improved environmental protection etc.

Pipe of the same specification as the sample runs should

be used and its length limited to a maximum of 10m to avoid

significant reduction in the airflow. Care should be taken to

position the new exhaust outlet where it cannot be

accidentally or deliberately blocked.

A320E Installation

Where the two pipe A320E unit is used, it is important that

the air flow through the two pipes is balanced otherwise the

responses of the two sensors may be affected.

Figure 3: Pipe Accessories

45° AND 90° PIPE BENDS

END CAP

242 mm

1

6

7

m

m

1

8

4

m

m

259 mm

To A300 E

Ceiling

the hole. Capillary tubes can also be used with the holes as

in figure 2.

Page 3

3

© System Sensor 2008 I56-2634-004ENPittway Tecnologica S.r.l, Via Caboto 19/3, 34147 Trieste, Italy

DEUTSCH

ENGLISH

A300E SERIES WIRING

Warning

Before working on the system, notify the proper

authorities that the system is undergoing maintenance

and will be temporarily out of service. Ensure that all

power is removed before opening the A300E unit.

Note: All wiring must be in accordance with local requirements

The A300E connections are accessed by removing the unit

cover using the supplied key, and then carefully lifting the

front display panel away from the A300E housing. The

ribbon cable that connects the front display PCB to the

main PCB may be unplugged if necessary .

The main PCB (See figure 4) includes wiring terminal

blocks for connecting the 24V power supply to the A300E

unit, accessing the fault relay contacts for each channel

and the optional loop connections.

Power Connection

The A300E unit is designed to run from a nominal 24VDC

supply. The supply should be connected to the 2 way

connector on the main circuit board ensuring that the wires

are correctly orientated. It is recommended that the wires

should be a minimum size of 16 x 0.25mm (18AWG), or

larger if the supply is further than 5m from the system.

A ferrite core is provided for EMC compliance. This should

be fitted to the supply wiring as shown below.

The current drawn is dependent on the fan speed – see

Table 4 for details.

LOOP OR ZONE CONNECTIONS FROM FIRE

DETECTION CONTROL PANEL

Figure 4: A300E SERIES Terminal La yout

ASPIRATING SYSTEM

CHANNEL 2 FAULT

CONTACTS (A320E DUAL

CHANNEL UNIT ONLY )

NO

COM

NC

NO

COM

NC

EXTERNAL POWER SUPPLY

TO ASPIRATING SYSTEM

ASPIRATING SYSTEM CHANNEL 1 FAULT

CONTACTS (BOTH A310E AND A320E)

+24VDC

0VDC

FUSE

LOOP IN (+)

LOOP IN (-)

LOOP OUT (+)

LOOP OUT (-)

Sensor Connection

The loop terminals are linked via a ribbon cable to the +/terminals mounted on the front display PCB, which

facilitate connection to the sensor bases if required. The

necessary bases (standard base B501 type for 7251

sensors) should be mounted on the front display panel

using the M4 screws provided, with short wires connecting

to the +/- terminals if used.

Loop wiring connections are made to either the pluggable

terminal blocks or directly to sensor bases, both of which

will accept wire sizes from 1mm² to 2.5mm². For best

results, screened cable should be used. Refer to the

control panel instructions for cable type limitations.

Once wiring has been completed, the A300E unit should be

re-assembled in reverse order .

IMPORTANT

The glands on the top of the unit that provide entry for

the cabling must to be sealed to ensure that the only air

entering the unit is coming in through the sample

pipes. all wiring must pass through the cable seals

provided and no additional holes should be made. In

order to pass a cable through a seal it is necessary to

make a small hole in the centre of the seal with a

pointed implement (e.g. small screwdriver) and then

force the cable through the hole into the bo x. The small

hole will expand to accommodate any cable diameter

from 4 to 10mm and then provide an airtight seal.

Figure WF: Ho w to Fit the Ferrite

NO

COM

NC

NO

COM

NC

Page 4

4D200-41-00

Pittway Tecnologica S.r.l, Via Caboto 19/3, 34147 Trieste, Italy

T1 (-)

T1 (-)

T2 (+)

T2 (+)

B501

B501

T1 (-)

T1 (-)

T2 (+)

T2 (+)

B501

B501

(Wiring when

base #2

not fitted)

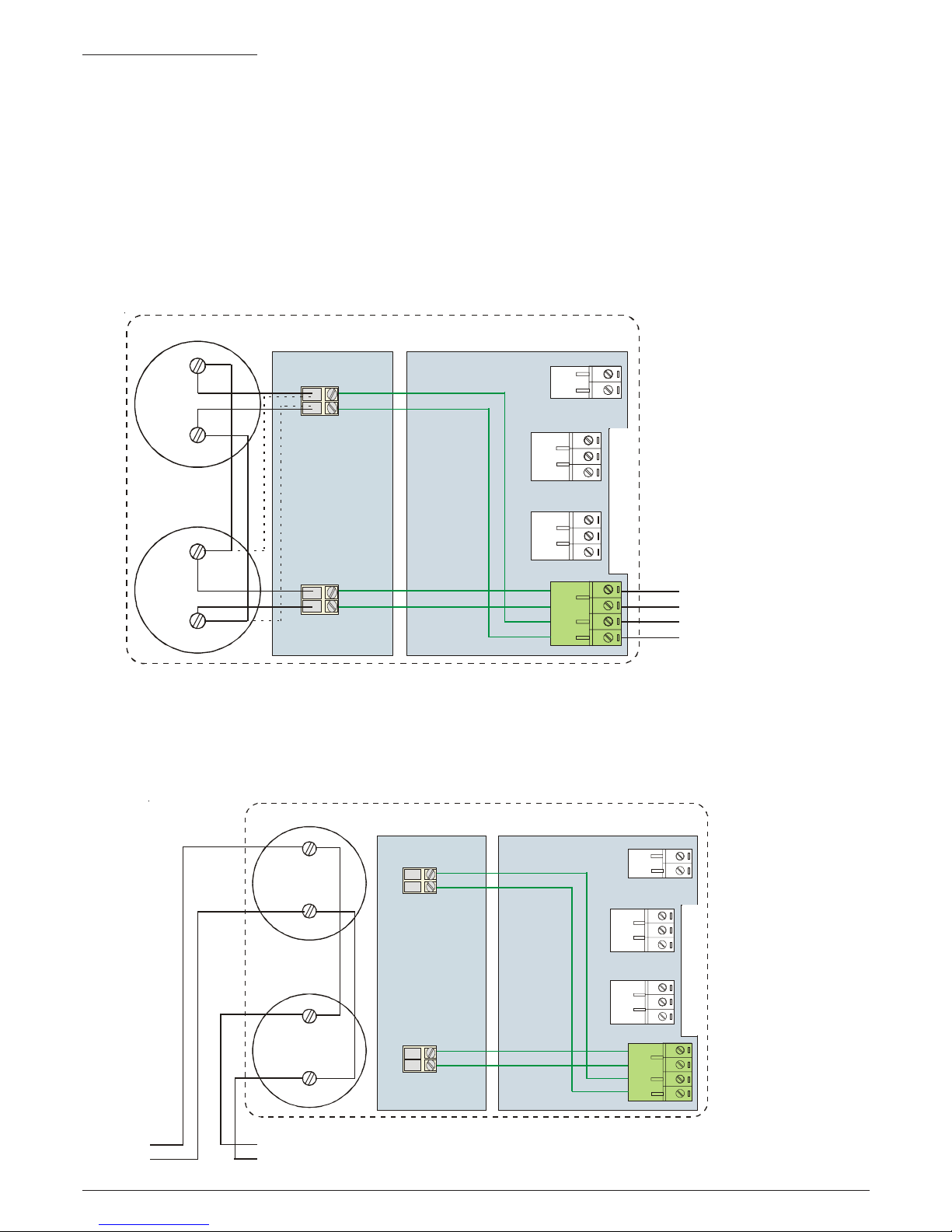

WIRING CONFIGURA TION

The A310E and A320E may be wired in several different configurations, dependant on the application and information

required. Typical configurations are shown below .

For the single channel A310E, either one or two sensors can be used (to simulate “double knock” type applications).

For the A320E dual channel system, sensor 1 monitors channel 1, and sensor 2 monitors channel 2.

See relevant sensor and module manuals for correct wiring to the device or base.

LOOP (+) IN

LOOP (-) IN

LOOP (+) OUT

LOOP (-) OUT

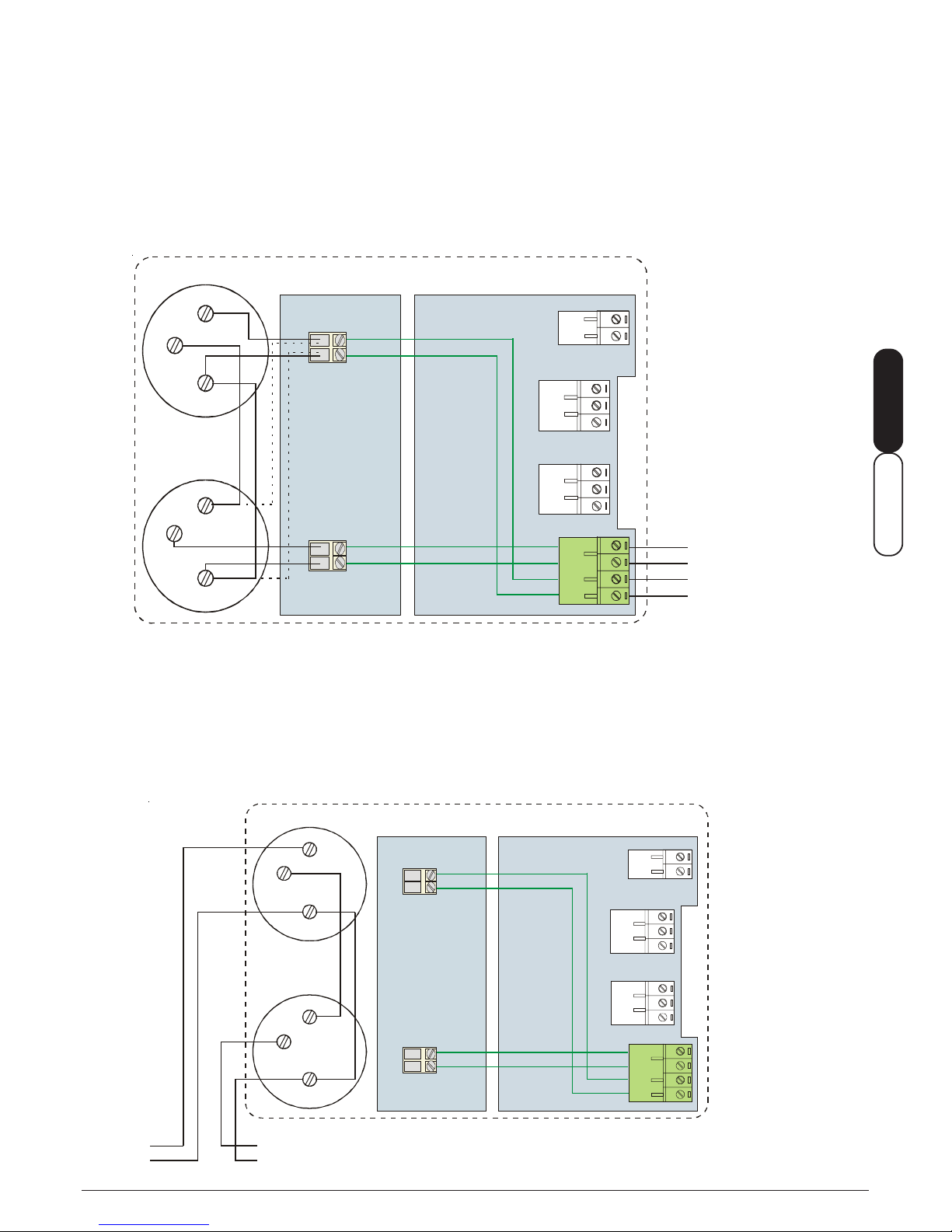

Sensor Arrangement 1.

See figure 5. Two analogue addressable sensors are wired through the aspirating unit. Loop connections are made to the

terminal block on the A300E main PCB.

Note: This configuration can increase the loop impedance by up to one Ohm. If this is lik ely to cause a problem, use Sensor

Arrangement 2 below .

MAIN PCB

DISPLAY PCB

Sensor Arrangement 2.

See Figure 6. The analogue sensors are connected directly to the fire control panel on the loop. The loop wiring is made

directly to the sensor bases.

SENSOR #2

SENSOR #1

A300E ASPIRATING SYSTEM ENCLOSURE

A300E ASPIRATING SYSTEM ENCLOSURE

MAIN PCB

DISPLAY

PCB

LOOP (+)

LOOP (-)

LOOP (+)

LOOP (-)

SENSOR#2

SENSOR#1

Figure 5: Wiring Configuration 1

Figure 6: Wiring Configuration 2

Page 5

5

© System Sensor 2008 I56-2634-004ENPittway Tecnologica S.r.l, Via Caboto 19/3, 34147 Trieste, Italy

DEUTSCH

ENGLISH

T1 (-)

T1 (-)

T5 (+)

T5 (+)

B524IEFT-1

(Wiring when

base #2

not fitted)

T6 (+)

T6 (+)

T1 (-)

T1 (-)

T6 (+)

T5 (+)

T5 (+)

B524IEFT-1

T6 (+)

Using Isolator Bases

The A310E and A320E may be fitted with isolator bases (B524IEFT-1) if required. The basic configurations used on the

previous page are amended below .

Sensor Arrangement 1 with Isolator Bases

See figure 30. Analogue addressable sensors are wired through the aspirating unit. Loop connections are made to the

terminal block on the A300E main PCB.

Figure 30: Wiring Configuration 1 with Isolator Bases

A300E ASPIRATING SYSTEM ENCLOSURE

DISPLAY PCB MAIN PCB

SENSOR#2

SENSOR#1

LOOP (+) IN

LOOP (-) IN

LOOP (+) OUT

LOOP (-) OUT

Sensor Arrangement 2 with Isolator Bases

See Figure 40. The analogue sensors are connected directly to the fire control panel on the loop. The loop wiring is made

directly to the sensor bases.

Figure 40: Wiring Configuration 2 with Isolator Bases

A300E ASPIRATING SYSTEM ENCLOSURE

DISPLAY PCB

MAIN PCB

SENSOR#2

SENSOR#1

LOOP (+)

LOOP (-)

LOOP (+)

LOOP (-)

Page 6

6D200-41-00

Pittway Tecnologica S.r.l, Via Caboto 19/3, 34147 Trieste, Italy

Fault Reporting

Fault monitoring of the A300E unit should be reported back to the panel using one of the suggested input module

arrangements:

For the A310E, a single input M210E module can be used (see Figure 50).

For the A320E, a dual input M220E can be used if separate fault reporting for each channel is required (see Figure 50).

Alternatively, an M210E module can be used if common fault reporting from both channels of the A320E is sufficient within

the system (see Figure 60).

If the wiring and module must remain within the aspirating unit, an M503ME micro module can be used in place of the M210E.

47K R

47K R

4

7

K

R

Figure 50: Suggested Wiring for A310E / A320E Using M210E / M220E Module

A300E ASPIRATING SYSTEM ENCLOSURE

DISPLAY

PCB

MAIN PCB

SENSOR #2

SENSOR #1

EXTERNAL PSU +24V

EXTERNAL PSU 0V

M210E OR

M220E

INPUT

MODULE

(A320E AND

M220E ONLY )

LOOP (+)

LOOP (-)

LOOP (+)

LOOP (-)

Figure 60: Suggested Wiring f or A320E Using M210E Module (Common F ault Reporting)

A300E ASPIRATING SYSTEM ENCLOSURE

MAIN PCB

DISPLAY

PCB

EXTERNAL PSU +24V

EXTERNAL PSU 0V

SENSOR #2

SENSOR #1

LOOP (+)

LOOP (-)

M210E INPUT

MODULE

LOOP (+)

LOOP (-)

Page 7

7

© System Sensor 2008 I56-2634-004ENPittway Tecnologica S.r.l, Via Caboto 19/3, 34147 Trieste, Italy

DEUTSCH

ENGLISH

OK

HI LOOK

HI LO

CODE

0 1 2 3 4 5 6 7 8 9

0 1 2 3 4 5 6 7 8 9

OK HI LO

CODE

0 1 2 3 4 5 6 7 8 9

A310E ASPIRA TING SYSTEM LAYOUT

Figure 7a: Display Functions A310E

POWER ON

(IF FLASHING - VOLTAGE LOW)

GENERAL FAULT

AIRWAY INLET

NOT USED

NOT USED

CODE ENTRY

AIRFLOW SPEED

BAR GRAPH

POSITION FOR

SECOND SENSOR

IF REQURIED

AIRFLOW INDICATOR:

OK, HIGH. LOW

FAN FAULT

A320E ASPIRA TING SYSTEM LAYOUT

Figure 7b: Displa y Functions - Dual Channel V ersion:

POWER, GENERAL FAULT, AND CODE ENTRY INDICATORS ARE COMMON TO BOTH CHANNELS.

UNLOCK

INSTALL

SENSOR

HERE

INSTALL SECOND

SENSOR HERE

AIRFLOW INDICATORS AND AIRFLOW

SPEED BARGRAPH REFER TO THE

CHANNEL IN WHICH THEY ARE LOCATED.

AIRFLOW INDICATOR:

OK, HIGH. LOW

UNLOCK

INSTALL FIRST

SENSOR HERE

GENERAL FAULT

NOT USED

NOT USED

POWER ON

(IF FLASHING -

VOLTAGE LOW)

AIRWAY INLETS

CODE ENTRY

FAN FAULT

Page 8

8D200-41-00

Pittway Tecnologica S.r.l, Via Caboto 19/3, 34147 Trieste, Italy

ASPIRATING SYSTEM SET UP

Refer to figures 7a and 7b to identify LED indicators; figure

8 shows the position of the buttons.

To enter the detector set-up mode, press and hold the

<SELECT> and <CHANGE> keys simultaneously on the

right hand side of the A300E housing until the Code Entry

LED starts flashing.

Access Code

To access the set-up functions, an access code needs to

be entered into the A300E.

T o enter the code , press the <CHANGE> button repeatedly

- the LEDs on the channel 2 (Right Side) Smoke Level /

Airflow Speed bar graph will illuminate in turn. Once the

desired number LED is illuminated, press <SELECT>.

Repeat for each figure in the code.

• The access code is 510

Warning: Ensure that this code is kept secure as it

permits access to the operation functions of the

detector.

Once the third number has been entered, the unlock LED

will illuminate, and will remain illuminated whilst the

aspirating system is in its set-up mode. The system will go

straight into its set up mode, starting from SET FAN

SPEED.

SELECT BUTTON

CHANGE BUTTON

Figure 8: User Functions

T able 1: A310E: Set-Up Pr ocedure.

At each stage, use the <CHANGE KEY> to select the

desired setting. Once the correct value is set press the

<SELECT> key momentarily to accept the setting and step

to the next function. Note that after the final step,

momentarily pressing <SELECT> will wrap back to step one.

A

S

D

Step Mode Indication Function

1. Set Fan Speed “Power On” LED Flashes Sets aspirating system fan speed.

Press <CHANGE> to cycle through fan speed settings for 0 to 9 indicated on LED bar graphs.

Fan speed will change as the settings cycle though.

Press <SELECT> once desired speed is selected to set speed and cycle to next mode

2. Set Bar Graph

Sensitivity

“OK” LED Flashes Press <CHANGE> to set air flow sensitivity as indicated on bar graph.

Press <SELECT> once desired sensitivity is selected to accept and cycle to next mode

3. Set High air flow

limit

“Hi” LED flashes Press <CHANGE> to set upper air flow limit as indicated on bar graph.

Press <SELECT> once desired high air flow limit is selected to accept and cycle to next mode

4. Set Low air flow

limit

“Lo” LED flashes Press <CHANGE> to set lower air flow limit as indicated on bar graph.

Press <SELECT> once desired low air flow limit is selected to accept and cycle to next mode

5. Set Flow Delay ‘Hi/Lo Flow’ LED’s both

flash

Press <CHANGE> to set required delay on Bar Graph (see Table 7)

Press <SELECT> once the desired Flow Delay is selected to accept and cycle to next mode

6. Calibrate Flow

Sensors

Fan Fault LED flashes

then

Power On and Fan Fault

Flash

Once the Fan Fault LED is illuminated, press and hold the <CHANGE> key until all LEDs are

extinguished and the fan stops. After a few seconds, the “Power On”, “Fan Fault” and

“Unlock” LEDs start flashing. The fan remains off to calibrate zero flow. After a few seconds,

the fan turns on to calibrate normal flow. On completion of calibration, the unit exits the setup

mode, and the airflow is displayed.

Note: Should any change be made to the pipework, or any

fan adjustment made, then it is necessary to re-calibrate

the fan sensors as in step 5 of table 1, or step 8 of table 2,

as relevant.

Bar Graph Displays

Once the set-up mode has been exited, the current airflow

levels are displayed on the cumulative bar graph display;

the High and Low flow limits are also shown.

SET-UP NOTES

The Fan Speed, Flow Limits and Flow Sensitivity need to

be set for each installation prior to Flow Calibration and

testing. It is not possible to provide the settings for all

possible installations but the following guidelines should

assist in the commissioning of the unit.

The current stage in the set-up is indicated by LED

indicators on the detector fascia as described in table 1.

To exit from setup at any point, press and hold the

<SELECT> key. If no button is pressed f or one minute, the

detector will automatically exit the setup mode.

Setup functions are displayed sequentially as in tables 1

and 2.

Page 9

9

© System Sensor 2008 I56-2634-004ENPittway Tecnologica S.r.l, Via Caboto 19/3, 34147 Trieste, Italy

DEUTSCH

ENGLISH

Fan Speed

The Fan Speed should be set as high as possibleto achie ve

the fastest transport time from the sampling point to the

sensors, this is especially important for longer pipe lengths

and for installations that must conform to the requirements

of CEA4022. There is, however, a balance to be achieved

between performance and the unit’s power requirements,

and reference should be made to the current consumption

figures in the specifications prior to setting this value. F an

speeds of 3 and below should not be used for standard

configurations.

Flow Sensitivity

This setting determines the responsiveness of the system

in reporting blocked sampling points or broken pipes . The

number of sampling points and fan speed are the main

factors to consider for this setting.

T able 2: A320E: Set-Up Pr ocedure.

Table 3 shows typical settings for a variety of standard fan

speed/hole quantity combinations. Other speed/hole

combinations should be verified by testing during

commissioning.

Flow Delay

An increase/decrease in flow above/below the FLOW

HIGH/FLOW LOW limits will result in a FLOW FAULT after

a delay of approximately 15s. Once the flow is returned to a

normal level, the fault condition will be cleared within about

2s. These are the factory set default values.

In environments where the sampled airflow may be

affected by sudden temperature/pressure changes or there

is a risk of physical interference with the sampling point

(e.g. prison cell applications), it may be necessary to

increase the delay between the flow going out of limits and

signalling a FLOW F AUL T condition. Delay values of up to

270s before signalling a fault are available when setting up

the detector.

Step Mode Indication Function

1. Set Fan Speed “Power On” LED Flashes Sets aspirating system fan speed.

Press <CHANGE> to cycle through fan speed settings for 0 to 9 indicated on LED bar graphs.

Fan speed will change as the settings cycle though.

Press <SELECT> once desired speed is selected to set speed and cycle to next mode

2. Set Channel 1 Bar

Graph Sensitivity

Channel 1 “OK” LED

Flashes

Press <CHANGE> to set air flow sensitivity as indicated on Channel 1 bar graph.

Press <SELECT> once desired sensitivity is selected to accept and cycle to next mode

3. Set Channel 2 Bar

Graph Sensitivity

Channel 2 “OK” LED

Flashes

Press <CHANGE> to set air flow sensitivity as indicated on Channel 2 bar graph.

Press <SELECT> once desired sensitivity is selected to accept and cycle to next mode

4. Set Channel 1

High air flow limit

Channel 1 “Hi” LED flashes Press <CHANGE> to set upper air flow limit as indicated on Channel 1 bar graph.

Press <SELECT> once desired high air flow limit is selected to accept and cycle to next mode

5. Set Channel 1

Low air flow limit

Channel 1 “Lo” LED

flashes

Press <CHANGE> to set lower air flow limit as indicated on Channel 1 bar graph.

Press <SELECT> once desired low air flow limit is selected to accept and cycle to next mode

6. Set Channel 2

High air flow limit

Channel 2 “Hi” LED flashes Press <CHANGE> to set upper air flow limit as indicated on Channel 2 bar graph.

Press <SELECT> once desired high air flow limit is selected to accept and cycle to next mode

7. Set Channel 2

Low air flow limit

Channel 2 “Lo” LED

flashes

Press <CHANGE> to set lower air flow limit as indicated on Channel 2 bar graph.

Press <SELECT> once desired low air flow limit is selected to accept and cycle to next mode

8. Set Flow Delay ‘Hi/Lo Flow’ LED’s both

flash

Press <CHANGE> to set required delay on Bar Graph (see Table 7). Note that both

channels will have the same setting.

Press <SELECT> once the desired Flow Delay is selected to accept and cycle to next mode

9. Calibrate Flow

Sensors

Fan Fault LED flashes

then

Power On and Fan Fault

Flash

Once the Fan Fault LED is illuminated, press and hold the <CHANGE> key until all LEDs are

extinguished and the fan stops. After a few seconds, the “Power On”, “Fan Fault” and

“Unlock” LEDs start flashing. The fan remains off to calibrate zero flow. After a few seconds,

the fan turns on to calibrate normal flow. On completion of calibration, the unit exits the setup

mode, and the airflow is displayed.

Tab le 7: Flow Delay Settings

BARGRAPH LED FLOW INTO FAULT DELAY FLOW OUT OF FAULT DELAY

(Seconds) (Seconds)

0* 15 2

130 18

260 18

390 18

4 120 18

5 150 18

6 180 18

7 210 18

8 240 18

9 270 18

*Factory default setting Note: all timings are approximate

Page 10

10D200-41-00

Pittway Tecnologica S.r.l, Via Caboto 19/3, 34147 Trieste, Italy

TESTING

Testing should only be carried out by qualified

personnel. Before undertaking any testing ensure that

the proper authorities have been informed, and if

necessary, that the unit has been isolated from the fire

control panel to prevent unwanted alarms.

Sensor Testing

With the unit powered up and the top cover removed

the sensors can be tested for functionality using methods

described by the manufacturer (for example aerosol spray

or magnet test).

System Testing

Alarm: The installed system must be checked with the top

cover securely fitted. As a minimum, smoke should be

introduced to the furthest sampling point from the A300E

unit on each branch of the pipe. The choice of smoke

source is dependant on the installation but in all cases the

smoke must be present for the duration of the test –

aerosol sprays for point detectors DO NOT work on

aspirated systems.

If it is possible to get close to the sampling point then a

basic, functional check can be carried out with smoke

matches or lighted taper etc. But for measurable

performance tests then refer to Appendix A of the FIA Code

of Practice for Aspirating Systems to select the

appropriate test for the installation.

Fault: Simulate a fault on the A300E unit (for example,

remove the power) and check that a fault is signalled at the

fire panel.

MAINTAINANCE

With normal use, the filter elements will eventually become

contaminated with dust particles, impeding airflow. It is

recommended that it be changed every six months.

To change the filter :

1. Unscrew the top cover

2. Lift out the foam filter elements from its housing

3. Fit a new filter kit so that it lies flush with the top of its

housing

4. Replace the top cover

5. Test the unit as described above.

IMPORTANT

To ensure maximum efficiency and longevity of the filter,

when fitting the replacement filter element kit, the Coarse

filter needs to be fitted first into the pipe.

ACCESSORIES

The following accessories are available to order:

Model Number Product

02-FL50 Replacement Filter Element Kit

20-LA0015 Replacement Key to Open Detector

Table 5: Problem Solving

T able 4: A300E Current Consumption

Fan Speed Current mA

Bargraph Value

0110

1 120

2 130

3 150

4 170

5 190

6 220

7 235

8 265

9 300

T able 3: Typical Flow Sensitivity Settings

PIPE SETUP RECOMMENDED FLOW

(all 50m lengths unless otherwise stated) FAN SPEEDS SENSITIVITY

13 x 3mm Sampling Holes, 1 x 6mm End Hole 9 9

8 x 3mm Sampling Holes, 1 x 6mm End Hole 6-9 9

4 x 3mm Sampling Holes, 1 x 6mm End Hole 6-9 7

1 x 5mm Sampling Hole, 1 x 5mm End Hole 6-9 5

1 x 8mm End Hole 5-9 2

1 x 8mm End Hole (10m Pipe) 3-9 1

Problem Possible Solutions

Power light flashing. Ensure supply to external power

connector within limits.

No lights on display. Ensure supply leads correctly

Fan not running orientated. Ensure that FUSE

correctly seated in socket and fuse

not blown.

No lights on display. Ensure ribbon cable fully seated into

Fan running OK. main & display boards.

Flow HI/LO light on Ensure sampling pipes correctly

installed, lid fitted and box fully sealed.

Ensure filters not blocked.

Ensure flow calibration procedure has

been carried out

Flow reading on Bargraph Decrease Flow sensitivity setting

display moves erratically. and re-calibrate air flows

Flow reading on Increase Flow sensitivity setting

Bargraph unresponsive and re-calibrate air flows

to broken/blocked pipes

Sensor(s) unresponsive Ensure sampling pipe installed correctly

to smoke tests and undamaged. Ensure that holes

and pipe length do not exceed limits

for detector. Ensure that

recommended test method is used.

Page 11

11

© System Sensor 2008 I56-2634-004ENPittway Tecnologica S.r.l, Via Caboto 19/3, 34147 Trieste, Italy

DEUTSCH

ENGLISH

Example 2: With Bends :

All pipes are Metric 25mm or Imperial 3/4” (27.6mm). All sample

holes are 3mm, with 6mm end hole.

* Estimated Values

ASPIRATING SYSTEM CONFIGURATION

Set out below are some examples of maximum length pipe

configurations that can be used with an A300 unit fitted with

the 7251 sensor. It should be possible to adapt these

examples for shorter pipe run systems; however some

specific applications will have specific considerations that

must be taken into account, and local standards may also

apply.

The default size for sample holes is 3mm, and the end hole

is 6mm. Ensure that no hole is less than 100mm from a

bend or ‘T’ piece

Table 6 shows the maximum allowable pipe lengths for

CEA 4022 compliance. In the examples shown below,

which fulfill the requirements of this table, the fire alarm

threshold, set at the control panel, should be at the 7251

laser sensor sensitivity level 1 (most sensitive).

For short to mid range application, it is recommended that

the fan speed for the A300E is kept at a default setting of 5

(this will be suitable in many circumstances). The primary

effect of changing the fan speed will be to increase or

decrease the transport time.

Default settings are programmed into the detector for the

high and low flow limits. It should not normally be

necessary to change these settings.

NOTE

If using a sensor other than the 7251 Laser, see section 3.1

Sensors Certified for use with the A300 in the

Appendices.

Tab le 6: A300E Series Pipe Installation Limits

The following figures apply to System Sensor A310E / A320E

detectors fitted with 7251 sensors

A310E Single Channel System

Example 1:

Aspirating

Smoke

Detector

25mm Pipe Diameter with 3mm Sampling Holes

Heigh t From

Ground 1.5 m

Riser Height

1.0 m

Ceiling Height

2.5 m

Pipe Lengt h

(Incl uding Riser

and Bends)

100 m

First Hole 4.0 m from Riser

6mm End Hole

46.5m

42.5m

10m

Top View

(9 Holes)

(8 Holes)

Aspirating

Smoke

Detector

25mm Pipe Diameter with 3mm Sampling Holes

Height Fro m

Ground 1.5 m

6mm

End Hole

Riser Height

1.0 m

Ceiling Height

2.5 m

Pipe Length

(Including Riser)

100 m

First Hole 4.0 m from Riser

DETECTOR A310E A320E

SENSITIVITY ALARM LEVEL 1 1

(set at the panel)

FAN SPEED 9 9

SINGLE PIPE PER INLET -

Length (Per Pipe/Inlet) Metres 1 0 0 10 0

Max Number of Holes (Per Pipe) 18 1 8

SINGLE ‘T’ (2 PIPES) PER INLET Max Length (Per Pipe) Metres 1 0 0 50*

Max Number of Holes (Per Pipe) 9 6*

Pipe No. Hole Fan Alarm

Length of 3mm Spacing Speed Level

(m) Holes (m)

100 18 5.3 9 1

Pipe No. Hole Fan Alarm

Length of 3mm Spacing Speed Level

(m) Holes (m)

100 17 5.25 9 1

Page 12

12D200-41-00

Pittway Tecnologica S.r.l, Via Caboto 19/3, 34147 Trieste, Italy

A320E Dual Channel System

Example 1:

Example 2: With Bends :

Using T Pieces

Note 1: It is important that the airflow through the 2 branches is balanced,

so each branch will need to be of a similar length and number of holes.

Note 2: Using more than one T piece on each channel has not been

tested and therefore cannot be recommended.

Example 1: 1 Channel

Aspirating

Smoke

Detector

Pipe Length (Including Riser and Bends) 2 x 100 m

Ceiling Height

2.5 m

Height From

Ground 1 .5 m

Riser Height

1.0 m

25mm Pipe Diameter with 3mm Sampling Holes

6mm End Hole

Top V i e w

5 m

5 m

4 m

First Hole 9 m from Riser

Pipe Length to

Bend 94 m

Example 2: 2 Channel

Aspiratin

g

Smoke

Detector

6mm

End Hole

Pipe Len

g

th

(Includin

g

Riser)

2 x 100 m

Ceiling Height

2.5 m

Height From

Ground 1. 5 m

Riser Height

1.0 m

25mm Pipe Diameter with 3mm Sampling Holes

First Hole 4.0 m from Riser

Pipe No. Hole Fan Alarm

Length of 3mm Spacing Speed Level

(m) Holes (m)

2 x 100 2 x 18 5.3 9 1

Pipe No. Hole Fan Alarm

Length of 3mm Spacing Speed Level

(m) Holes (m)

2 x 100 2 x 18 5 9 1

Aspiratin

g

Smoke

Detector

6mm

End Hole

Pipe Lengths

(Includin

g

Riser)

Up to 100 m

Ceiling H e ig h t

2.5 m

Height From

Ground 1.5 m

Riser Height

1.0 m

25mm Pipe Diameter with 3mm Sampling Holes - 1 Channel with T-Piece

5 m

First Hole 5 m from Riser

6mm End Hole

Pipe No. Hole Fan Alarm

Length of 3mm Spacing Speed Level

(m) Holes (m)

1 x 2 2 x 9 10.5 9 1

x 100

Pipe No. Hole Fan Alarm

Length of 3mm Spacing Speed Level

(m) Holes (m)

2 x 2 2 x 2 5 9 1

x 50 x 6

Aspirating

Smoke

Detector

6mm

End Hole

Pipe Lengths

from bend

34 m

Ceil ing Height

2.5 m

Height From

Ground 1.5 m

Riser Height

1.0 m

25mm Pipe Diameter with 3mm Sampling Holes - 2 Channel with 2 T-Pieces

10 m

First Hole 19 m from Riser

6mm

End Hole

Top View

5 m

4 m from bend to first hole

Dista nce Between

Pipes 10 m

Distance Between

Pipes 10 m

Dista nce Between

Pipes 10 m

10 m

5 m

4 m from bend

to first hole

Pipe Lengths

from bend

34 m

Page 13

13

© System Sensor 2008 I56-2634-004ENPittway Tecnologica S.r.l, Via Caboto 19/3, 34147 Trieste, Italy

DEUTSCH

ENGLISH

APPENDICES

Detailed here is information to assist in the set-up of the air-sampling

system, including:

1. Basic Principals of Aspirating Systems

2. Guide to Available Pipe Parts

The pipe network is just as important as the detector itself in providing

a means of obtaining a reliable and continuous sample of air to be

monitored.

The pipework for air-sampling systems can vary greatly depending on

the particular application. The following are guidelines that can be

applied to any wide-bore systems. Please remember that these are

general guidelines only. For each specific installation the local

standards and codes of practice should be adhered to. Guidance on

the design of systems is given in BS 5839, BS 6266 and/or FIA Code of

Practice for Aspirating Detection Systems.

1. Basic Principals

Figure 1.3.1 Smoke Dilution

Figure 1.1 Pipe System Operation

1.1 Smoke T ests

IMPORTA NT

It is strongly recommended that, before designing the pipe-work

system, smoke tests be undertaken in order to show the

patterns of air movement within the areas to be protected. This is

particularly important in rooms with air-handling equipment. In

all cases the aim must be to place the sampling pipes at the

position the smoke is most likely to reach.

Smoke boxes or smoke matches can be used to establish air

movement within the protected area, from which the best place to

locate the pipes can be discovered, as well as where to place the

sampling holes in the pipe.

If air handling equipment is present in the environment, consideration

must be given to all the variable settings that are available (for

example, if it is switched on or off, or if an air conditioning unit has a

directional wave facility).

1.2 Response Times

This is the transport time taken from when a sample enters a pipe to

when the detector unit enters alarm mode.

Response times should be within reasonable limits. The simplest

method of achieving this is to keep pipe lengths to a minimum. This may

not always be possible but in the following example the benefits of

using more than one pipe in short lengths is demonstrated (this is being

used as a general example only, for any specific installation a proper

calculation will need to be made - This would include the length of the

piping, height of the room,the frequency and size of the sampling holes

etc).

In Figure 1.2.1, a room has a single sampling pipe that provides

detection for the whole room:

Aspirating Unit

containing detector

and fan

Fan draws air down

pipe system for

detector to sample

smoke plume rises and

enters pipe system through

samp ling poin t ho l e s

Figure 1.2.1 Single Sampling Pipe

In Figure 1.2.2, the same room has a two channel sensor, allowing two

sampling pipes:

Figure 1.2.2 Two Sampling Pipes

The system gives the same coverage as it would with one pipe, but the

response time is quicker. The principal shown here is also relevant

when considering the dilution rate. Please see the following section for

details on this.

1.3 Dilution

The response time example does not only show the benefit of shorter

pipes on response times. Dilution is also kept to a minimum by reducing

the length of the pipes. As the name suggests, dilution is the process

of lessening the concentration of smoke particles as the sample is

drawn towards the detector.

For example, if there is a sampling pipe measuring 50 metres and It

has sampling holes every 5 metres, giving 10 sampling holes including

the end cap. It can be assumed in this simplified case that the sampling

holes let in approximately the same amount of air as each other.

A smoke source of 2% obscuration/metre is introduced at the far end

of the pipe. No other smoke is entering any of the other sampling holes.

As the smoke passes each hole, it is added to with clean air. When the

sample reaches the detector it is now at 0.2% obscuration/metre or 1/

10th of its starting density. Therefore if the first alarm threshold is set at

0.2% obs/m, the smoke outside the hole must exceed 2% obs/m to

sound the alarm.

It is the case, therefore, that the longer the pipe and the greater the

number of sampling holes, the more susceptible the system will be to

dilution. It is wise to work on a worst case principle in these situations.

In actuality the calculation of dilution is not as straightforward as above

and more factors are involved. Each system will have different

characteristics meaning precise calculation is extremely complicated.

Issues that will affect the dilution rate include size and number of holes,

T-pieces and elbow joints in the pipe system, diameter of the pipe itself,

and outside elements such as air temperature, pressure and humidity etc.

Let us say that the response time for smoke that

Entered the very end of the pipe was 34 seconds

Smoke

Enters

Here

Smoke

Enters

Here

With two pipes feeding into a 2 channel detector,

the pipe length is approximately halved, and so is

the response time to 18 seconds

Page 14

14D200-41-00

Pittway Tecnologica S.r.l, Via Caboto 19/3, 34147 Trieste, Italy

As seen in the previous section on response times, shorter pipe runs

minimise dilution. In Table 1.3.1 there is a rough guide to varying dilution

rates for wide-bore systems - IMPORTANT: The different

characteristics of each installation must also be taken into account

when assessing the dilution rate. many factors can affect this, as

previously discussed.

Table 1.3.1 General Dilution Rates for Wide-Bore Systems

1.4 Pipe Construction and Sampling Holes

Single channel System Sensor aspirating detectors have a maximum

pipe length of 100 metres.

Dual channel aspirating detectors have a maximum pipe length of 100

metres for each channel. Wherever possible, the pipe lengths for each

channel need to be kept to broadly similar lengths (for example, if

channel 1 has a pipe length of 30 m, channel 2 should be approximately

the same length). Failure to do this can result in slow response times,

thereby negating some of the early warning ability of the system.

System Sensor recommends that ABS piping be used due to its

strength and heat resistant properties. The pipe sections should be

glued together using a suitable ABS glue to avoid separation or leaks.

If a section of pipe is likely to need to be disconnected for some reason

in the future, removable unions should be used instead.

Important: Never glue pipes into the aspirating detector unit itself.

Sampling holes should be 3mm in diameter. The end of the pipe should

be capped and have a hole of 6mm in diameter.

Important: Elbows and bends in the pipe system can affect the

flow of air/smoke through the pipes and should only be used

when necessary.

Capillary Sampling

Short lengths of small diameter flexible pipe may be spurred off from

the main wide-bore pipe. This pipe should have an internal diameter of

no less than 7mm and can be of lengths up to 2 metres. For this a

sampling point assembly should be used (an example is shown below).

Capillary tubes can be used to provide concealed sampling points. If

the sampling points need to be as unobtrusive as possible, the

capillary allows the point to be placed flush to the surface. These are

most commonly used when the main wide-bore pipe runs through a

ceiling void, with capillary sample pipes placed through the false

ceiling.

Note 1: It is recommended to avoid running lengths of pipe with

both standard sampling holes and capillary sampling points on

them as this can unbalance the airflow and slow the response

time from the capillary points.

Note 2: Though British Standard BS 5839-1 states that there

must be a minimum of 25mm between the ceiling and the

sampling point of a detector, because the aspirating system

actually draws air through the sampling points (holes in the

pipework in this case), it can be possible to mount the sampling

points flush with the ceiling providing this will not be

detrimental to the effectiveness of the system to detect fire (see

1.1 Smoke Tests).

1.5 The Design Process

When designing the actual sampling pipe network there are many

factors that need to be considered. The site must be carefully

surveyed and as much information as possible should be gathered.

1.5.1 Requirements

The first consideration is to precisely ascertain the requirements of the

installation. Once these have been decided, the type of situation can be

looked at.

1.5.2 Activities

The types of activities that take place within the space are very

important. A public area of a particular shape could well have different

system requirements to a warehouse of a similar shape.

Other information such as the expected hours of operation, whether

the area is manned or unmanned and whether any pollution or dirty air

is present should also be taken into account.

1.5.3 Physical Characteristics

Once the general installation type has been considered, the physical

characteristics of the space should be looked at.

· Is it a room, void, cabinet or enclosure?

· Are there any floor or ceiling voids and, if so, how are they

divided, are there any ducts, what are these used for and are

there any services already present?

· What are the exact measurements of the space?

· What materials have been used and are there any areas where

the network has to avoid?

· Are there any existing fire protection systems and where are

they situated?

1.5.4 Environmental Conditions

The environment within the space can have a very significant bearing

on which sampling method should be used to protect it. As already

mentioned, the smoke tests are vital in gathering this information. This

can tell you the patterns of air movement, the rate of circulation and

whether the airflow is static at any point. Other considerations include:

· If fresh air is introduced, at what rate and in what quantity?

· Is a reference detector necessary due to pollution?

· What is the temperature and relative humidity and are these

constant or variable?

· Are there any activities that may produce smoke, dust, steam

or flames and how often does this occur?

1.5.5 Risk Assessment

With any installation it is likely that some areas require more protection

than others. This could be because of expensive equipment or a

particularly vulnerable area such as a store for flammable materials.

These more susceptible areas must be considered along with any

structural hazards such as synthetic materials and foams or soft wood

partitioning.

1.5.6 Potential Sites

There are also factors to consider when deciding where to position the

detector unit itself. The main aim when positioning the unit is to tr y to

ensure a balanced system. This means that the pipes should be kept at

similar lengths. It is also important to try and keep response times and

dilution to a minimum.

The unit requires a power supply and access will be required for

maintenance. There may also be aesthetic reasons why a particular

position is not suitable.

1.5.7 Exhaust Pipe

The exhaust pipe on the bottom of the aspirating detector unit can have

piping added should it be required, for example if the air passing

through the detector needs to be returned to its source. Extra piping

can also be used to reduce the noise of the fan if needed.

Page 15

15

© System Sensor 2008 I56-2634-004ENPittway Tecnologica S.r.l, Via Caboto 19/3, 34147 Trieste, Italy

DEUTSCH

ENGLISH

2. Guide to Av ailable Pipe P arts

System Sensor offers the following pipe parts:

2.1 Metric 25mm Pipe Options

Model Number Product Description

02-0001-25 Large Bore Red Pipe 3m Length, 25mm

02-1001-25 Straight Union Large Bore 25mm

02-1002-25 90 deg. Bend Large Bore 25mm

02-1003-25 45 deg. Elbow Large Bore 25mm

02-1005-25 Removable Union Large Bore 25mm

02-1007-25 T-Piece 25mm

02-1006-25 End Cap for Large Bore 25mm

02-FLU2 Filter Unit 25mm With Filter Element

(for Harsh environment)

2.2 Common Accessories

There are a number of accessories that can be used:

Model Number Product Description

02-1008-15 Flush Capilar y Sampling Point

(T Piece & 1.5m Capillary Tube)

For use with false ceilings

02-1009-00 Sampling Point Label (Roll of 100)

02-1010-00 Open Pipe Clip (25mm)

02-1110-00 Closed Pipe Clip (25mm)

02-1011-00 ABS Pipe Adhesive (250ml tin)

25mm Wide

Bore Pipe

Filter Unit

Pipe

Ceiling

Page 16

16D200-41-00

Pittway Tecnologica S.r.l, Via Caboto 19/3, 34147 Trieste, Italy

3. Using Other Sensors with the A300

If the A300 units are to be used with sensors other than the

recommended 7251, please observe the following information:

3.1 Sensors Certified for use with the A300

The following sensors have been independently tested and certified to

CEA 4022 for use in the A300 unit. The table shows the limits which

should not be exceeded if the installation is to conform to this

requirement.

No.12345678910

Dist(m)99.5959085807570656055

Size(mm)3.43.43.43.43.433333

No.11121314151617181920

Dist(m)504540353025201510 5

Size(mm)2.52.52.52.52.522222

SINGLE PIPE VARIABLE HOLE CONFIGURATION

Sensor Model Sensitivity Level Sampling Hole Limits Max Pipe Length (m)

2251EM Standard (2200) 1 x 8mm End 50

2251EM High (1800) 2 x 5mm 50

ECO1003 N/A 2 x 5mm 50

7251 Alarm Level 3 13 x 3mm, 6mm End 100

7251 Alarm Level 1 18 x 3mm, 6mm End 100

7251 Alarm Level 1 20 x Variable Size 100

FSL-751E/

LZR-1M Alarm Level 1 18 x 3mm, 6mm End 100

FSL-751E/

LZR-1M Alarm Level 1 20 x Variable Size 1 00

4. UNUSUAL APPLICATIONS

In these different and variable situations, it is vital to perform smoke

tests to establish the air movements.

4.1 Freezer rooms

Freezer rooms often introduce extra difficulties into the design of a

system. The air temperatures at which the room operates must be

taken into account.

If the aspirating pipe network is inside the cold room the following points

should be noted:

1) The pipes should be suspended (or attached) further away than

usual from the ceiling or wall as these may contract and expand

with large changes in air temperature.

2) Sampling holes should be drilled on the

side of the pipes

to

minimise the risk of blockage owing to ice formation.

3) Vertical pipes running into the room from outside, and areas where

condensation could collect, must be avoided.

Figure 4.1: Typical Freezer Room Example

Heater

Element

Pipe Falls T o wards

Heater

Seal

Stand-Off

300mm Minimum

Holes Drilled in Side of Pipe

Aspirating

Detector

Insulate From W all

Air Return

Freezer Room

Water

Trap

Aspirating Detector and Associated Equipment

Located Outside Freezer Room

Seal

Temperature changes may cause expansion or contraction in the

aspirating pipe. ABS pipe has a linear coefficient of expansion of

around 10-4/°C and large temperature changes can have a significant

effect. These changes typically occur as the system is run to

operational temperature. So the air can easily vary from +18°C at

installation to -35°C in operation, representing a 53°C differential. This

drop applied to a 50m pipe run gives an expected end to end pipe

movement of 265mm. If the design of the system gives no allowance

for such variation in the pipe length, it is advisable to incorporate one or

more simple ‘U’ bends to act as an expansion/contraction point as

shown:

Page 17

17

© System Sensor 2008 I56-2634-004ENPittway Tecnologica S.r.l, Via Caboto 19/3, 34147 Trieste, Italy

DEUTSCH

ENGLISH

4.2: Cold Stores

Cold stores are similar to the freezer rooms with one major difference,

the temperature. The temper ature in a cold store is a lot less than a

freezer and is typically just at or above 0°C.

The pipes should be kept out of the immediate airflow from a chiller unit,

if used, as its air is often significantly colder than the room itself in order

to maintain the correct temperature.

In a cold room application it is not usually necessary to use a heater

element but only a water trap to remove condensation.

4.3: High buildings

Typical examples: Atria; Cathedrals

When designing a system to fit in a very large and high room such as

an atrium or high level warehouse, it is important to consider the

various possibilities. A simple atrium design is shown below, utilising

two pipes. The smoke cloud is shown as an example of how a

stratification layer prevents the pipes at the top of the building from

detecting smoke particles. The height at which the smoke forms a layer

varies depending on temperature and therefore a vertical sampling

pipe is used to cover this. There may be no stratification layer at all if the

air in the room is at a particular temperature, especially if smoke

ventilation is needed.

Figure 4.3: Typical Atrium Example

Sampling Pipes

Sampling Holes

Aspirating

Detector

Smoke Stratification Layer

Figure 4.4.2: High Roof Example 2

Pipes Running Parallel to the Roofline

Max.

10m

Max.

10m

Pipes Run the Length of the Building (Parallel to the Roofline)

Aspirating Detectors

Figure 4.4.1: High Roof Example 1

Pipes Running Across the Width of the Roofline

Aspirating

Detector

Maximum 10m Between

Pipes at the Roof

Pipes Run the Width of the Building (across the Roofline)

The second alternative shows the pipes running in parallel along the

roof. Again to comply with UK requirements the pipes should be a

maximum distance of 10m apart, sample holes in each pipe will be 10m

from each other and the pipe serving the apex should not be further

than 600mm from the top of the roof.

4.5: W arehouses

Warehouses can be considered to be similar to supermarkets except

the same problems that can occur with high buildings need to be taken

into account as well. Vertical sampling points may be needed and the

pipe lengths should be considered carefully to ensure reasonable

response times.

4.4: Supermarkets and Storage Areas

Supermarkets and storage areas require a high level of protection due

to the possible number of people using the space at certain times of the

day and/or due to the value of the goods present.

There are two ways of applying the pipe network. The exact structure

of the roof is likely to determine the better or most appropriate solution.

The pictures below assume a simple room layout.

In one alternative the pipes will follow the contour of the roof. To comply

with UK code of practice BS5839:1, pipes will be placed at a maximum

distance of 10m from each other and sampling holes will also be sited

at a maximum of 10m from each other, with the hole serving the apex

no more than 600mm away from the roof.

Loading...

Loading...